#Standard Injection Molding Machine

Explore tagged Tumblr posts

Text

What Industries Is Injection Molding(Moulding) Applicable To?

Injection moulding is a common manufacturing process by injecting molten plastic material into a mould so that it can be formed into the desired product shape upon cooling.

Injection moulding process has the advantages of low cost, high production efficiency and stable product quality to make it widely used in various industries. In this vast injection moulding market, there are three industries are particularly eye-catching, which are extensively used for production and manufacturing due to their specific needs and product characteristics.

1.Household Appliance Manufacturing Industry

As an indispensable part of people's daily life, the market demand for household appliances is stable and continuously growing. The injection moulding process plays a pivotal role in the manufacturing of household appliances, from the outer shell to the internal components, injection moulding technology provides key support. Most of the exterior and structural components of home appliances, such as TV remote controls, refrigerators, TV sets, air-conditioning panels, and washing machine shells, are manufactured by injection molding process.

2.Automotive Components Industry & Transportation Sector

With the booming development of the automotive industry, the auto components and parts market has ushered in unprecedented development opportunities. Components and parts such as automotive dashboards, door interior panels, bumpers, and lamp housings as well as a wide range of pipework and connections are made through the injection moulding process. These parts require not only high precision and good mechanical properties, but also need to meet the strict appearance requirements, which injection moulding process is precisely by virtue of its unique advantages, in this field to occupy a place. In addition, with the rise of new energy vehicles, injection moulded parts play an important role in the manufacturing of key components such as battery packs and motor housings.

3.Medical Device Industry

With the increasing emphasis on health, the market demand for medical devices continues to grow. In medical device manufacturing, the injection moulding process is used to produce disposable medical devices such as syringes, infusion tubes and surgical instruments. These products require strict quality control and hygiene standards, and injection moulding process ensures product safety and effectiveness.

In addition, the injection moulding process is also widely used in the electrical and electronic industry, consumer electronics, packaging industry, toy manufacturing, construction materials, industrial parts, furniture and household furnishings and agriculture, among many others.

4.Electrical & Electronic Industry

In the manufacturing process of electronic products, many components such as housings, cases, sockets, connectors, cables, switches and holders for electronic circuit boards need to be manufactured by injection moulding process. Injection moulding process can achieve precise control of product appearance, size and structure, to meet the requirements of electronic products for appearance quality, functionality and reliability.

5.Consumer Electronics Industry

In the electronics industry, injection moulded parts are equally widely used. From mobile phone housings, computer components including keyboards and mice to remote controls and battery cases, the injection moulding process offers a wide variety of appearance and structure options for electronic products. These components not only need to have good mechanical properties and appearance, but also need to have excellent electrical insulation properties to ensure the stable operation of electronic products. Injection moulding technology occupies an important position in the manufacture of electronic products due to its advantages of high precision and low cost.

6.Construction Sector

In the construction field, injection moulded parts also have a wide range of applications, the drainage systems, door and window frames, pvc pipes, valves, wire troughs, insulation materials and other construction materials and accessories are mostly manufactured by injection moulding process. These components are not only high-strength and corrosion-resistant, but also weather-resistant and easy to install, meeting the construction industry's requirements for material performance and ease of use and improve construction efficiency and aesthetics. The application of injection moulding technology in the construction field not only improves the performance and quality of construction materials, but also promotes the sustainable development of the construction industry.

7.Packaging Industry

The packaging and container industry is also one of the key application areas for injection moulding processes. Plastic bottles, food boxes, cosmetic bottles, plastic bags and other packaging containers are mostly manufactured by injection moulding process to meet food safety and aesthetic requirements. These containers need to be well-sealed, drop-resistant, retain freshness and recyclable to ensure that the products are safe and environmentally friendly. Injection moulding processes can offer flexible design and manufacturing options to adapt to different packaging needs and provide strong support for the development of the packaging industry.

These areas above are just a few examples of the application areas of the injection moulding process. In the toy industry, injection moulded parts are used to manufacture a variety of plastic toys; In the textile and clothing industry, injection moulded parts are used to manufacture accessories such as zips and buttons; In the agricultural sector, injection moulded parts are used to manufacture agricultural tools and equipment such as sprayers and watering cans; Even in the aerospace sector, injection moulded parts are also used to manufacture parts for aircraft and spacecraft. It can be said that injection moulded parts have penetrated into almost every corner of our life.

In summary, injection moulded parts play an important role in several industries by virtue of their high precision, low cost and wide applicability. The application of injection moulding process in these areas not only improves production efficiency, but also meets the needs of product diversification and individualisation. With the continuous progress of science and technology and the continuous improvement of people's requirements on product quality, injection moulding technology will continue to be widely used and developed in various fields.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#injection molding#plastic injection molding#injection moulding machine#injection moulding#plastic injection#injection molded#injection molding parts#injection molded parts

2 notes

·

View notes

Text

Looking for the Best Tool & Die Steel Supplier in Hyderabad?

Look no further! Virat Special Steels Pvt. Limited is your go-to supplier for all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel.

Virat Special Steels Pvt. Limited stands out as one of the premier Tool & Die Steels Suppliers in Hyderabad. Let’s explore why they’re a top choice:

Wide Range of Materials: Virat Special Steels deals in various steel types, including:

Tool Steel: DB6 / DIN-1.2714 / AISI L6, essential for cutting, shaping, and forming tools.

Die Steel: DIN 2343, 2344 / AISI H11, H13, crucial for molds, dies, and precision components.

Plastic Mold Steel: DIN 2738, 2311 , AISI P 20, tailored for plastic injection molding.

High-Speed Steel: DIN 3243 , 3343 / AISI M2 , M35, ideal for high-speed machining.

Alloy Steel: Versatile and robust for diverse applications.

Value-Added Services: They go beyond supplying raw materials. Their services include: - Material Machining: Precision shaping and customization. - Cut Pieces: Ready-to-use segments for efficiency. - Tailor-Made Material: Customized to specific requirements.

Metallurgical Expertise: Virat Special Steels provides metallurgical advice to ensure optimal material selection and performance. Their team understands the nuances of steel properties and applications.

Quality Assurance: Quality is non-negotiable. They adhere to stringent standards. Ultrasonic inspection ensures material integrity.

State-of-the-Art Facilities: Their Gurugram and Ludhiana plants boast cutting-edge technology. Consistent quality and timely delivery are their hallmarks.

Strong Distribution Network: Virat Special Steels reaches across India, ensuring accessibility. Whether in Hyderabad or beyond, their steel is within reach.

For more information, visit Virat Special Steels. Trust in their expertise for all your steel needs! 🛠️🔥

Consultation: For further assistance, consult their #Gurugram office. Learn more https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-hyderabad/

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📨 [email protected] 📞 +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#Hyderabad#SteelSupplier#MetalTraders#db6 steel#h13toolsteels#h11steel#din 2714#din2344#din3343

2 notes

·

View notes

Text

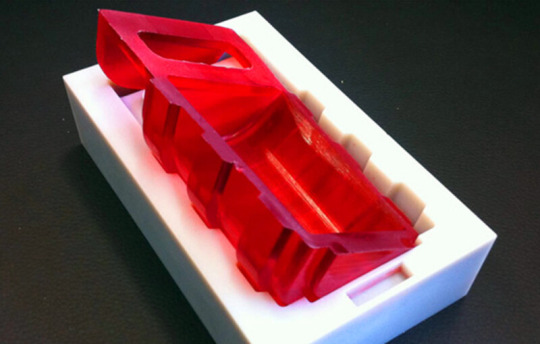

Learn About the Basics of Vacuum casting

Within the dynamic realm of production and prototyping, urethane casting is a unique technology that provides cost-effectiveness, accuracy, and diversity. Urethane casting has become the industry standard for a variety of applications, from complex prototypes to small-batch production runs, including consumer electronics, medical equipment, and the automotive and aerospace sectors.

Gratitude Casting of Urethane

The first step in the procedure is to create a master pattern, which is usually done via fast prototyping techniques like CNC machining or 3D printing. The silicone molds that are made from this master pattern are used to pour polyurethane resin into. The resin mimics the fine features of the master design once it has dried, producing pieces that are excellent and ready for manufacturing.

Flexibility throughout Sectors

The adaptability of urethane casting across sectors is one of its most noteworthy benefits. Urethane casting may be used for a variety of purposes, including the production of end-use components and prototypes for new product development. For instance, urethane casting makes it possible to quickly iterate ideas for dashboard panels, interior trim, and lighting fixtures in the car industry. Similar to this, urethane casting makes it easier and faster to produce unique medical device housings, surgical instruments, and prosthetic components in the medical profession. Vacuum casting also offers flexibility.

Benefits Compared to Conventional Approaches

When compared to conventional production techniques like CNC machining and injection molding, urethane casting has several significant benefits. The most important factor is cost-effectiveness. Because urethane casting requires less tooling up front, it's a great option for low-volume production runs if standard tooling costs are too high. Urethane casting also has a short turnaround time, which enables companies to quickly develop and refine ideas without having to wait for long lead periods.

Additionally, the design freedom provided by urethane casting makes it feasible to produce intricate surface details, undercuts, and complicated geometries that would be difficult or impossible to accomplish with alternative manufacturing processes. This versatility also applies to the choice of material, since a variety of polyurethane resins are available to satisfy certain performance needs, including those related to hardness, flexibility, and chemical resistance. You can Explore vacuum casting also.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Urethane Casting#Explore vacuum casting#Custom Vacuum Casting Services

2 notes

·

View notes

Text

Streamline Your ERP Plastic Manufacturing: The Otibro Techni Advantage

The plastic manufacturing industry is a dynamic landscape, constantly evolving with new materials, technologies, and customer demands. From injection molding to extrusion and blow molding, managing complex processes, intricate bills of material, and volatile raw material prices can be a Herculean task. Without a robust system, companies often grapple with inefficiencies, costly errors, and missed opportunities.

This is where a purpose-built ERP system becomes an absolute game-changer. And when it comes to tailoring ERP solutions specifically for the plastic industry, Otibro Techni stands out as a leading partner, understanding the nuanced challenges and delivering transformative results.

The Mold of Manual Management: Why Traditional Methods Fall Short

Many plastic manufacturers still rely on a patchwork of spreadsheets, isolated software, and manual processes. This often leads to:

Inaccurate Inventory: Difficulty tracking raw materials, work-in-progress, and finished goods leads to stockouts, overstocking, and wasted capital.

Production Bottlenecks: Inefficient scheduling, lack of real-time visibility into machine availability, and poor capacity planning cripple output.

Quality Control Challenges: Manual quality checks are prone to error, making it hard to maintain consistent product standards and ensure traceability.

Cost Overruns: Poor visibility into production costs, regrind management, and material consumption can erode profit margins.

Compliance Headaches: Meeting stringent industry regulations and maintaining audit trails becomes a daunting task.

Slow Decision-Making: Lack of centralized, real-time data means managers are often making decisions based on outdated information.

Forging a Future with ERP: The Otibro Techni Advantage

An ERP system designed for plastic manufacturing acts as a central nervous system, integrating every aspect of your operations into a single, cohesive platform. Here's how it transforms your business:

1. Precision Production Planning & Scheduling:

ERP systems enable precise scheduling of machines, molds, and labor. They account for multi-cavity tooling, family molds, and complex production sequences, ensuring optimal utilization of resources and minimizing downtime. This leads to significantly improved on-time delivery.

2. Intelligent Inventory Management:

Track raw materials (resins, additives, colorants), work-in-progress, and finished goods in real-time. Features like batch tracking, lot tracking, and FIFO/FEFO ensure optimal stock levels, reduce waste, and manage shelf-life-sensitive materials.

3. Robust Quality Control & Traceability:

From incoming raw material inspection to in-process checks and final product testing, ERP ensures consistent quality. It provides end-to-end traceability, allowing you to track every component from supplier to the finished product, crucial for compliance and swift issue resolution.

4. Optimized Cost Management:

Gain granular insights into your production costs, including raw materials, labor, machine usage, and overheads. Manage regrind effectively, identify cost-saving opportunities, and ensure accurate job costing and profitability analysis.

5. Streamlined Supply Chain & Procurement:

Automate purchase orders, manage supplier relationships, and gain real-time visibility into inbound shipments. This strengthens supplier collaboration and ensures timely availability of critical materials.

6. Real-time Reporting & Analytics:

Access comprehensive dashboards and generate real-time reports on key performance indicators (KPIs) like OEE (Overall Equipment Effectiveness), production output, waste percentages, and financial performance. This empowers informed decision-making.

Otibro Techni specializes in implementing ERP solutions that are not just generic software, but deeply tailored to the unique workflows of plastic manufacturing, whether you're dealing with intricate injection molded components, continuous extruded profiles, or large blow molded containers. Their expertise ensures that the system aligns perfectly with your specific operational needs, from managing multi-level BOMs to handling tooling controls.

Your Future is Molded by Smart Choices

In the competitive world of plastic manufacturing, embracing digital transformation through a specialized ERP system is no longer an option, but a necessity. It’s about more than just efficiency; it’s about agility, resilience, and sustained growth. By partnering with experts like Otibro Techni, you can streamline your operations, minimize waste, elevate product quality, and ultimately, enhance your profitability.

Ready to unlock the full potential of your plastic manufacturing business? Connect with Otibro Techni today for a personalized demo of their industry-specific ERP solution and discover how you can achieve operational excellence.

0 notes

Text

Marck Industries: Trusted Manufacturer of Premium Elevator Spare Parts

Why Reliable Spare Parts Matter in Elevator Systems

Elevators are essential in modern buildings—transporting people and goods swiftly and safely. Downtime due to broken or worn-out parts isn’t just inconvenient—it can impact safety, building efficiency, and tenant satisfaction. That’s why having a dependable source of high-quality spare parts is vital.

What Sets Marck Industries Apart

1. Decades of Expertise

With years of experience in manufacturing elevator components, Marck Industries understands the stringent requirements of vertical transportation—ensuring every part is engineered for precision, durability, and compliance with international safety standards.

2. Comprehensive Product Portfolio

From mechanical to electrical systems, we supply a full range of elevator parts, including:

Controller boards & PCBs

Inverter and VFD units

Proximity switches & sensors

Door lock and safety gear

Brake assemblies & drums

Buffers, rollers, and pulleys

Cabin fixtures: buttons, display panels, handrails

3. Precision Manufacturing

Utilizing CNC machining, injection molding, and automated PCB assembly, each component is produced to exact tolerances—ensuring fit and function with OEM performance or better. Strict quality checks, including EN 81, ASME A17.1, and ISO audits, guarantee consistency.

4. Certified Quality & Safety

Marck operates with certifications to:

ISO 9001 Quality Management

CE marking and compliance

Adherence to EN (Europe) and ASME (North America) elevator safety codes

These credentials ensure safe, global-grade parts.

5. Custom Solutions & Adaptability

Recognizing that every elevator system is unique, Marck Industries excels in custom engineering—from tailored connectors and cables to complete PCB re-engineering—while maintaining cost and lead-time efficiency.

Benefits of Partnering with Marck Industries

Advantage

Impact

High Uptime & Quick Delivery

Minimize downtime with rapid part replacement and fast shipping

Competitive Pricing

Optimized production lowers costs without compromising quality

Global Support Infrastructure

Sales and technical teams available round-the-clock across regions

Extended Product Warranty

Confidence via long-term warranty and support packages

Serving Diverse Market Segments

Residential Buildings: Reliable replacements for passenger-lift maintenance.

Commercial Complexes: Durable components suited for high-traffic usage.

Industrial Facilities: Heavy-duty parts designed for freight and goods lifts.

OEM Collaborations: Contract manufacturing aligned with global elevator brands.

Quality Control & Testing Procedures

Each batch undergoes:

Incoming Material Inspection (IQC)

In-Process Monitoring (IPC)

Performance Testing: Load, endurance, vibration, and electrical tests

Final Audits & Certification

Partnering with Marck: How It Works

Initial Consultation Understand your system specs, OEM models, and usage patterns.

Quotation & Sample Approval We provide detailed proposals and offer test samples for validation.

Order & Production Ranging from small spare lots to mass production, with regular updates.

Technical & After-Sales Support Including troubleshooting, field assistance, and prompt RMA processes.

Ongoing Relationship We offer lifecycle support—even for legacy elevators requiring obsolete part replacements.

Elevate Your Operations with Marck Industries

Your elevator fleet deserves nothing less than reliable, certified parts that stand the test of time. Choose Marck Industries for precision, safety, and peace of mind—backed by technical excellence and global service reach.

Ready to discuss your parts needs? Contact our sales team or request a quote through the Marck Industries website today.

0 notes

Text

China Die Casting Manufacturer | High Quality At Lower Cost

China Die Casting Manufacturer are globally diagnosed for turning in exceptional, precision-engineered metal components at competitive costs. With many years of revel in, today's facilities, and a skilled staff, these manufacturers serve a wide variety of industries, which includes automobile, electronics, aerospace, medical, and patron goods.

China Die Casting is a manufacturing system where molten steel—usually aluminum, zinc, or magnesium—is injected into a metal mold underneath high strain. This results in complicated, dimensionally accurate components with high-quality floor finishes. Chinese die casting agencies offer high-pressure die casting (HPDC) and low-stress die casting (LPDC) based on the software’s needs.

Key Benefits of China Die Casting Manufacturers

Cost-Effective Production- Chinese manufacturers can produce large volumes of die-cast components at a decreased price because of reduced labor and operational prices. This makes them a perfect preference for agencies seeking to lessen production expenses without compromising on great.

Advanced Manufacturing Technology- Leading die casting factories in China use contemporary systems, together with CNC machining facilities, robot casting lines, X-ray trying out systems, and automatic satisfactory control. These talents help make regular high-quality and tight tolerances.

Full-Service Capabilities- Most producers provide end-to-end services which includes product design, tooling and mold fabrication, prototyping, die casting, machining, surface treatment, and meeting. This incorporated technique simplifies the supply chain and hastens production.

Global Standards and Certifications- Many Biandiecast meet global certifications which include ISO 9001, IATF 16949, and RoHS. This ensures compliance with worldwide pleasant and safety requirements, mainly for automobile and electronic elements.

Applications of Die Casting from China

China Die Casting components are extensively utilized in:

Automotive elements – housings, engine blocks, gear covers

Electronics – enclosures, brackets, warmness sinks

Industrial machinery – additives requiring strength and precision

Consumer merchandise – handles, fittings, decorative elements

Conclusion

China Die Casting Manufacturer offers a really perfect combination of excellence, efficiency, and affordability. With the potential to handle high-quantity orders, offer engineering assistance, and deliver components globally, these producers are a preferred choice for businesses looking for dependable and scalable metal component production. Whether you are growing a new product or scaling production, China’s die casting enterprise relies on answers to satisfy your wishes.

#China Die Casting Manufacturer#China Die Casting#Die Casting#die casting parts#die castings#service#top die casting#china die casting factory#china die cast

0 notes

Text

Top 10 Cleaning Robot Manufacturers in China

Cleaning Robots refer to autonomous devices specifically engineered to maintain floor surfaces through automated vacuuming and

mopping functions. These intelligent machines utilize cutting-edge technologies including LIDAR navigation, AI-powered path planning,

and smart suction systems to deliver thorough, hands-free cleaning. The core purpose of these robots is to provide a safer, more convenient,

and time-efficient solution for home and commercial cleaning, particularly in large spaces or hard-to-reach areas. China has emerged as

the global manufacturing center for robotic cleaning technology, housing numerous specialized manufacturers recognized for their innovative

designs, superior quality, and continuous technological advancements.

In this definitive industry guide, we will examine the top 10 floor cleaning robot manufacturers in China. You'll gain detailed insights into each

company's background, technological capabilities, product advantages, market positioning, and ideal use cases - all from the perspective of

an industry insider with over a decade of manufacturing experience. Whether you're a wholesaler, private label brand, or commercial buyer,

this guide will help you identify the perfect manufacturing partner for your specific business needs.

Brand

Strengths

Best For

1: LINCINCO

Premier OEM/ODM Specialist

OEM partners, tailored solutions

2: Ecovacs Robotics

Technology Leader

High-end residences and families of technology enthusiasts

3: Roborock

Premium Performance

Hard floor cleaning and quality-oriented users

4: Xiaomi Mijia

Value Leader

Entry-level market, young user group

5: Dreame Technology

Dreame Technology

Demand for technology-innovative products

6: ILIFE Robotics

Specialized Cleaning Solutions Expert

Special floor cleaning requirements

7: Kyvol

Smart Home Integration Leader

Smart home integration scenarios

8: Lefant

Compact Design Specialist

An apartment with low furniture

9: Proscenic

Commercial Cleaning Solutions

The field of commercial cleaning

10: Coredy

Balanced Value Provider

Basic cleaning of rental housing

1. LINCINCO - Premier OEM/ODM Specialist

Headquarters: Dongguan, Guangdong Established: 2018

Factory Area: 50,000㎡

Employee: 635 ( include 65 professionals)

135 sets of molding injection, molding machine 80-1400T.

Production lines: 11 finished product assembly lines, 4.5 finished product lines

Production Capacity:4 million units per year

Product Standard:

GB 4343.1-2009;GB 4706.1-2005;

GB 4706.7-2004;GB 17625.1-2012 Export Markets: 85% of production (North America, Europe, Asia)

Technical Specifications:

Navigation: LIDAR 4.0 + AI Visual (dual system)

Corner Cleaning:Mechanical arm extension,clean the corners

Suction Power: 5000Pa-10000Pa (adjustable)

Battery: 5200mAh lithium (120min runtime)

Noise Level: ≤65dB

Key Advantages:

Deep Customization: 15+ customizable points including:

Housing colors/materials

Voice prompt languages (supports 12 languages)

App interface branding

Cleaning mode presets

Rapid Prototyping: New samples ready in 7-10 days

Quality Assurance: 7 inspection points with <0.5% defect rate

Certifications: CE, FCC, RoHS, ERP, KC, PSE

Market Positioning:

SegmentPrice RangeMOQLead Time

Entry-level

$120-$180

500

25 days

Mid-range

$180-$280

300

30 days

Premium

$280-$400

200

35 days

Recent Development: Launched new AI-powered navigation system in Q1 2024, reducing cleaning time by 25% through optimized path algorithms.

Recommended For: Private label brands, wholesalers needing custom solutions, buyers targeting specific regional markets.

2. Ecovacs Robotics - Technology Leader

Headquarters: Suzhou, Jiangsu Annual Output: 3 million+ units R&D Investment: 8.7% of revenue

Flagship Model: DEEBOT X2 Omni

Navigation: AIVI 3.0 (AI Visual Interpretation)

Suction: 8000Pa (industry-leading)

Features: Auto-empty, auto-mop wash, voice control

Battery: 6400mAh (200min runtime)

Market Reach:

Sold in 60+ countries

1,200+ retail partners worldwide

37% market share in North America (2023)

Strengths: Best-in-class navigation technology, complete product ecosystem Weaknesses: Higher price point, limited customization options Recommended For: Tech-focused buyers, premium market segments

3. Roborock - Premium Performance

Production Base: Beijing Employees: 2,800+ (35% in R&D)

Technology Highlights:

ReactiveAI 2.0: Recognizes 42 object types

Sonic Mopping: 3,000 vibrations/minute

Dock Features: Hot water washing, 3-hour drying

2024 Models Comparison:

ModelSuctionBatteryPriceSpecial Feature

S8 Pro Ultra

5100Pa

5200mAh

$1,599

VibraRise 2.0

Q Revo

5500Pa

5000mAh

$899

Dual Spinning Mops

Dyad Pro

N/A

60min

$499

Wet/Dry Combo

Recent Achievement: Roborock S8 Pro Ultra won 2024 CES Innovation Award Recommended For: High-end residential market, tech enthusiasts

4. Xiaomi Mijia - Value Leader

Parent Company: Xiaomi Ecosystem Manufacturing Partners: 3 contract factories

Product Strategy:

Price Range: $200-$500

Refresh Cycle: 18 months

Smart Home Integration: Mi Home ecosystem

Market Performance:

#1 budget brand in Asia (32% market share)

15 million units sold globally (2023)

4.8/5 average customer rating

Recommended For: Price-sensitive markets, first-time buyers

5. Dreame Technology - Innovation Powerhouse

Owned By: Xiaomi (minority stake) Patents Held: 1,200+

Breakthrough Technologies:

Auto-Empty Station: 60-day capacity

Dual-Rotary Mopping: 180RPM

Cross-Brand Compatibility: Works with 3rd party apps

2024 Expansion:

New D10 series for European market

Partnership with Bosch for motor technology

$200 million R&D center under construction

Recommended For: Innovative retailers, smart home integrators

Comparison Table: Top 5 Manufacturers

ManufacturerStrengthPrice RangeMOQLead TimeBest For

LINCINCO

Customization

$120-$400

200

25-35d

OEM/Private Label

Ecovacs

Technology

$400-$1,500

1,000

45d

Premium Retail

Roborock

Performance

$500-$1,600

800

50d

High-End Market

Xiaomi

Value

$200-$500

5,000

20d

Mass Market

Dreame

Innovation

$300-$800

1,500

30d

Tech Retailers

6. ILIFE Robotics - Specialized Cleaning Solutions Expert

Headquarters: Shenzhen, Guangdong Established: 2007 Annual Production: 2.4 million units

Technical Specifications:

Navigation System: Gyroscopic navigation with anti-drop sensors

Suction Power: 1000-2000Pa (adjustable)

Specialized Models:

V3s Pro: Pet hair specialist with tangle-free rubber brush

A4s: Hard floor expert with triple cleaning system

W400: Wet/dry hybrid for complete floor care

Manufacturing Capabilities:

FacilityAreaProduction LinesDaily Output

Shenzhen

45,000㎡

8

8,000 units

Dongguan

30,000㎡

5

5,000 units

Market Performance:

85% export ratio (North America 60%, Europe 25%)

35% YOY growth in pet specialty models

4.3/5 average Amazon rating across products

Recommended For: Retailers targeting pet owners, hard surface cleaning specialists

7. Kyvol - Smart Home Integration Leader

Headquarters: Nanjing, Jiangsu R&D Team: 150+ engineers Patents Held: 87 (including 12 invention patents)

Smart Connectivity Features:

App Control: Kyvol Home App (iOS/Android)

Voice Control: Amazon Alexa, Google Assistant

Smart Scheduling: AI-powered cleaning planning

Matter Protocol: Full compatibility with smart home ecosystems

Product Line Overview:

SeriesKey FeaturePrice RangeTarget Market

E30

Basic Smart

$199-$249

Entry-level

E31

Matter Support

$279-$329

Smart Homes

P50

AI Camera

$399-$449

Premium

Quality Certifications:

CE, FCC, RoHS

ISO 9001:2015 certified

Google Home official partner

Recommended For: Smart home retailers, tech-focused distributors

8. Lefant - Compact Design Specialist

Factory Location: Zhongshan, Guangdong Production Area: 28,000㎡ Workforce: 800+ employees

Design Innovations:

Ultra-Low Profile: 2.85" height (industry thinnest)

Modular Design: Quick-change components

Quiet Operation: As low as 52dB (library-quiet)

Product Comparison:

ModelHeightNoiseSuctionBattery

M210

2.85"

52dB

2000Pa

2600mAh

M280

3.15"

55dB

2500Pa

3000mAh

M350

3.50"

58dB

3000Pa

3200mAh

Market Position:

#1 in compact robots (32% market share)

90% customer satisfaction rate

18-month product lifecycle

Recommended For: Apartment dwellers, urban retailers, pet owners

9. Proscenic - Commercial Cleaning Solutions

Parent Company: Proscenic Technology Group Established: 1996 Global Offices: 5 countries

Commercial Product Line:

UV Sterilization Series:

Hospital-grade disinfection

99.9% germ elimination rate

50,000 sq.ft daily coverage

Large-Area Series:

6000mAh battery (8h runtime)

5000Pa suction

Fleet management software

Window Cleaning Series:

25kg suction force

IP65 waterproof

200m cable length

Certifications:

ISO 13485 (Medical Devices)

EN 60601-1 (Medical Electrical Equipment)

UL Commercial Grade

Recommended For: Hotel chains, hospital suppliers, facility managers

10. Coredy - Balanced Value Provider

Manufacturing Base: Ningbo, Zhejiang Export Experience: 12 years Main Markets: Europe (60%), North America (30%)

Value Proposition:

Price-Performance Ratio: 30% below major brands

Reliability: <2% return rate

Simplicity: One-button operation

Product Matrix:

SeriesSuctionBatteryNavigationPrice

R300

2000Pa

2600mAh

Random

$199

R500

2500Pa

3000mAh

Gyro

$249

R700

3000Pa

3200mAh

LDS

$299

Production Capacity:

3 fully automated production lines

40,000 units/month capacity

15-day standard lead time

Recommended For: Value-focused retailers, secondary product lines

Detailed Comparison: 6-10 Manufacturers

CriteriaILIFEKyvolLefantProscenicCoredy

Specialization

Pet/Hard Floors

Smart Home

Compact

Commercial

Value

Price Range

$199-$399

$199-$449

$179-$349

$499-$2,999

$199-$299

MOQ

500

300

400

100

500

Lead Time

30d

25d

28d

45d

20d

Customization

Limited

UI Only

Colors

Full OEM

None

Best For

Specialty Retail

Tech Stores

Urban

B2B

Mass Market

How to Choose Your Ideal Manufacturer?

Selection Matrix:

NeedBudgetRecommended Choice

Custom OEM/ODM

Medium

LINCINCO

Cutting-Edge Tech

High

Ecovacs

Premium Performance

High

Roborock

Mass Market Value

Low

Xiaomi

Innovative Features

Medium

Dreame

Pet Hair Solutions

Medium

ILIFE

Smart Home Focus

Medium

Kyvol

Compact Design

Low-Med

Lefant

Commercial Grade

High

Proscenic

Balanced Value

Medium

Coredy

Why LINCINCO Stands Out for Business Buyers?

While all these manufacturers have strengths, LINCINCO offers unique advantages for B2B buyers:

True Customization: Unlike brands focused on their own products, we adapt to your specifications

Flexible MOQs: Starting from 200 units vs. typical 1,000+ minimums

Faster Time-to-Market: 30-day average production cycle vs. industry-standard 45-60 days

Direct Factory Pricing: No brand premium markup

Quality Assurance: Our defect rate is 80% lower than industry average

Recent Client Success: Helped a European retailer launch their private label line with 15 customized models in just 4 months.

Conclusion

China's cleaning robot manufacturers offer unparalleled variety from budget to premium segments. For private label and customized

solutions, LINCINCO provides the ideal combination of quality, flexibility and value. Meanwhile, brands like Ecovacs and Roborock lead

in consumer-facing technology. Your optimal choice depends on target market, technical requirements and business model.

0 notes

Text

A Comprehensive Guide to Heating Element Manufacturers in India and the Role of Cartridge Heaters with Thermocouples

In the rapidly evolving industrial landscape, the demand for efficient, reliable, and high-performance heating solutions is on the rise. Whether it’s for the plastic processing industry, packaging, food production, or pharmaceutical manufacturing, heating elements play a critical role in various applications. Among the most essential components in this field are cartridge heaters, especially when integrated with thermocouples. India has emerged as a significant hub for quality heating element manufacturing, offering a wide array of solutions for diverse industries. In this blog, we’ll explore the importance of heating element manufacturers in India and delve into the functionality and advantages of a cartridge heater with thermocouple.

The Rise of Heating Element Manufacturers in India

India has witnessed remarkable growth in the industrial heating sector over the past decade. Thanks to increasing industrialization, technological advancements, and the need for energy-efficient processes, there’s been a surge in demand for advanced heating solutions. Heating element manufacturers in India have responded to this need with innovation, customization, and quality manufacturing practices.

These manufacturers specialize in designing and producing a variety of heating components such as tubular heaters, immersion heaters, band heaters, ceramic heaters, and most notably, cartridge heaters. What sets Indian manufacturers apart is their ability to deliver high-quality products at competitive prices, making them a preferred choice for both domestic and international clients.

Moreover, many heating element manufacturers in India follow strict quality standards like ISO certifications and adhere to international safety protocols, ensuring durability and performance across various sectors.

Understanding Cartridge Heaters: Compact Yet Powerful

A cartridge heater is a cylindrical-shaped heating element that can be inserted into holes in metal blocks or plates to provide localized and precise heat. These heaters are commonly used in mold heating, plastic injection molding, hot stamping, and packaging machines due to their compact size and high watt density.

What enhances the performance of these heaters further is the addition of a thermocouple — a sensor that measures temperature and allows real-time temperature control. When integrated, a cartridge heater with thermocouple becomes an intelligent heating solution capable of delivering accurate and consistent thermal energy.

Benefits of Using Cartridge Heaters with Thermocouples

Accurate Temperature Monitoring: The integration of a thermocouple allows precise temperature monitoring, making it easier to maintain process consistency. This is particularly useful in applications that require strict thermal regulation, such as medical equipment manufacturing or plastic molding.

Improved Energy Efficiency: With real-time temperature feedback, cartridge heaters consume only the amount of power necessary to maintain the desired temperature. This reduces energy waste and lowers operational costs.

Extended Equipment Life: Overheating can significantly reduce the lifespan of machinery. By using a cartridge heater with thermocouple, manufacturers can avoid overheating, ensuring equipment longevity and reducing downtime.

Versatility and Customization: These heaters are available in various sizes, wattages, and configurations. Leading heating element manufacturers in India offer custom solutions to match the specific requirements of the customer, including custom sheath materials and lead wire designs.

Compact Design for Tight Spaces: Their small size makes them perfect for applications where space is limited but high heating performance is required.

Leading Applications of Cartridge Heaters with Thermocouples

Plastic Injection Molding: Used for maintaining temperature inside the mold to ensure the quality of plastic products.

Packaging Industry: For sealing machines and heat-cutting equipment where temperature control is crucial.

Food Processing: To ensure hygiene and safety in food production processes by maintaining consistent heat.

Medical Equipment Manufacturing: For sterilizers and diagnostic instruments that need precise heating.

Die-Casting Machines: To maintain the temperature of metal molds, ensuring accurate shaping of metal parts.

Why Choose Indian Manufacturers?

The Indian manufacturing industry has matured over the years, offering products that meet global standards. Choosing heating element manufacturers in India brings numerous advantages:

Cost-Effective Solutions: Indian suppliers offer competitive pricing without compromising on quality.

Global Reach: Many Indian manufacturers export their products worldwide, providing international-grade heating solutions to clients in Europe, North America, Southeast Asia, and the Middle East.

Technical Expertise: Indian manufacturers invest in R&D, offering innovative products like cartridge heaters with thermocouple, which are designed to meet the specific needs of different industries.

After-Sales Support: With robust customer service and technical assistance, Indian companies ensure smooth operations for their clients even post-purchase.

Final Thoughts

In today’s fast-paced industrial world, heating elements are more than just components; they are the backbone of precision, safety, and efficiency in many production environments. Cartridge heaters with thermocouples represent a fusion of simplicity and smart control, making them a vital part of modern heating technology.

As demand continues to grow, heating element manufacturers in India are well-positioned to lead the global market with their innovative designs, customer-centric approach, and adherence to high manufacturing standards. Whether you’re a small business looking for reliable heating solutions or a large enterprise in need of customized, scalable options, Indian manufacturers have the tools, technology, and talent to deliver.

Need quality heating solutions? Consider partnering with a reputed heating element manufacturer in India to enhance your industrial heating operations with products like cartridge heaters with thermocouples that offer precision, performance, and peace of mind.

0 notes

Text

Hygienic Thermoformed Trays for Food Packaging by INPAK

Key Benefits of Hygienic Thermoformed Food Trays

One of the major advantages of using thermoformed plastic trays in food packaging is hygiene. Since these trays are produced in a controlled manufacturing environment, they meet strict sanitary requirements, reducing the risk of contamination. Plastic trays used for food applications are designed to be sealed immediately after filling, maintaining product integrity from the production line to the consumer’s hands. The result is a packaging format that ensures consumer safety and compliance with health regulations.

Another benefit lies in the cost-effectiveness of thermoformed trays. The thermoforming machine production process consumes less raw material compared to injection molding or other packaging methods. This efficiency translates into reduced material waste and lower production costs. Moreover, since thermoformed packaging is lighter, it reduces transportation expenses and carbon emissions, contributing to a more sustainable supply chain. For businesses, these factors make thermoformed trays for food packaging both an economically and environmentally smart choice.

Lastly, customization and brand presentation are enhanced with thermoformed trays. The ability to mold trays into virtually any shape allows businesses to develop unique packaging styles that reflect their brand identity. This is especially beneficial in competitive markets like ready-to-eat meals and premium grocery items, where product visibility and appeal directly impact consumer buying decisions. With high-clarity materials and printable surfaces, plastic food trays can also be easily integrated with labeling, tamper-evident seals, or even embedded RFID technology.

How Are Thermoformed Trays Manufactured?

The production of thermoformed trays starts with a plastic roll or sheet made of materials like PET, PP, or PLA. The sheet is fed into a thermoforming machine, where it passes through a heating station. Once the sheet reaches its forming temperature, it moves into a mold station where vacuum and/or pressure are applied to shape the material into the desired tray form. This step is crucial for ensuring the consistency and quality of the thermoformed plastic trays.

After forming, the trays move to the trimming section, where excess material is cut away, and the final shape of the plastic trays is defined. The cutting process is extremely precise, enabling tight tolerances for sealed packaging. Some advanced thermoforming machines include features like servo-driven trim stations and robotic stacking systems, which improve efficiency and reduce labor needs. Food packaging machines integrated with automated conveyors and inspection systems further streamline the production line.

Quality control is a critical phase in the production of thermoformed trays for food packaging. Manufacturers conduct visual inspections, dimensional checks, and hygiene validations to ensure each batch meets regulatory and client specifications. With INPAK’s modern thermoforming machine manufacturing capabilities, clients are assured of consistent performance, precision, and reliability in tray production. The result is high-quality thermoformed packaging that meets global food safety standards and customer expectations.

Industries and Applications of Thermoformed Food Packaging

The food industry is the primary user of thermoformed trays, especially in sectors that require sanitary and secure packaging. Ready meals, fresh produce, meats, seafood, dairy, and bakery items all benefit from thermoformed food packaging. These plastic food trays allow producers to offer single-serve, multi-compartment, or family-size packaging that ensures freshness and visual appeal. The ability to apply modified atmosphere or vacuum sealing also extends shelf life for perishable items.

Beyond retail food packaging, thermoformed trays are widely used in food service and catering. Hotels, airlines, hospitals, and restaurants use thermoformed plastic trays for efficient portion control and hygienic serving. Because of their lightweight and disposable nature, these trays reduce dishwashing needs and help maintain hygiene in high-volume environments. Their customizable design also allows for embossed branding or compartmentalized meal kits tailored for specific uses.

Outside the food sector, thermoformed packaging has applications in pharmaceutical, electronics, and industrial parts packaging. However, thermoformed trays for food packaging remain the most widespread due to evolving consumer demands and strict food safety regulations. As consumers become more health-conscious and sustainability-minded, businesses are increasingly relying on advanced food packaging machines to produce trays that are not only functional and safe but also eco-friendly and visually appealing.

Types of Thermoforming Machines Used in Tray Production

To meet various production needs, manufacturers use different types of thermoforming machines. These machines vary in complexity, size, and automation levels, depending on the application. Roll-fed thermoforming machines are common in high-speed operations, ideal for mass-producing thermoformed trays for food and retail packaging. These systems offer automatic feeding, forming, trimming, and stacking, optimizing every step of the production cycle.

Shuttle or platen-type thermoforming machines are typically used for lower-volume or specialty production. While they operate slower than roll-fed systems, they offer more flexibility in tray design and material types. These machines are often used by businesses developing customized thermoformed plastic trays for niche markets or promotional packaging. With servo-driven motors and programmable controls, even these compact machines can deliver precise and repeatable performance.

Hybrid thermoforming machines, which integrate features of both vacuum and pressure forming, offer versatility in tray production. These machines support multiple material types and can handle complex tray geometries. They are ideal for businesses producing plastic food trays that require deep draws, high clarity, or intricate details. At INPAK, a full range of such machines is available, including models like TSR-800 and TS-1000, engineered specifically for thermoforming tray production at scale.

Thermoforming Machines for Thermoformed Tray Manufacturers

For businesses entering or scaling in the thermoformed trays for food packaging sector, choosing the right machinery is critical. A high-performance thermoforming machine must offer speed, accuracy, hygiene compliance, and minimal maintenance. Manufacturers require machines that integrate easily into existing production lines and adapt to varying tray designs and material specifications. INPAK’s lineup of food packaging machines offers all these advantages and more.

The INPAK TSR-800, for example, is a versatile thermoforming machine that enables fast changeovers and modular configurations. It’s designed for the production of both standard and custom thermoformed plastic trays. Features such as remote access, automated lubrication, and servo-plug assist ensure high uptime and uniform material distribution. These technical enhancements are crucial for maintaining product consistency and reducing operational costs in tray manufacturing.

Investing in the right thermoforming machine manufacturing partner like INPAK means gaining access to engineering support, spare parts, training, and after-sales service. It also ensures that businesses can comply with international food safety and packaging regulations. As global demand for hygienic and sustainable thermoformed packaging grows, manufacturers equipped with INPAK machinery can scale operations efficiently while meeting consumer and retailer expectations.

INPAK’s Role in Supplying Advanced Thermoforming Equipment

As one of the leading thermoforming machine manufacturers, INPAK is committed to innovation, quality, and customer satisfaction. With decades of experience, the company offers advanced solutions for businesses producing thermoformed trays for food packaging. INPAK machines are designed with user-friendly interfaces, remote diagnostics, and customizable features that meet the specific needs of the food packaging sector. This makes INPAK a preferred thermoforming machine supplier for companies around the world.

INPAK’s engineering team continuously develops new technologies to improve productivity and reduce energy consumption. By offering machines that can handle diverse materials like PET, PP, and biodegradable PLA, INPAK supports sustainable packaging goals. The ability to adjust heater configurations, control chain tension, and automate stacking also means that clients benefit from high-speed production and minimal downtime. These features are essential for staying competitive in today’s demanding food packaging machines market.

What sets INPAK apart as a thermoforming machine supplier is its dedication to full-cycle support—from consultation and custom design to installation and training. Whether you’re a startup or an established thermoformed tray manufacturer, INPAK offers scalable, reliable, and efficient equipment to suit every production need. With a strong global presence and customer-first approach, INPAK continues to shape the future of thermoforming machine production for food-grade applications.

#inpak#thermoforming machines#manufacturer thermoforming machines#supplier thermoforming machines#manufacturing thermoforming machines

0 notes

Text

Plastic Injection Molding Parts | Designed To Your Specs

Plastic Injection Molding Parts are important additives used at some point of industries together with car, medical, electronics, consumer gadgets, and packaging. This manufacturing machine allows the mass production of plastic components with excessive precision, repeatability, and rate-effectiveness.

What is Plastic Injection Molding?

Plastic injection molding is a system in which molten plastic is injected into a mildew hollow region beneath immoderate stress. The plastic cools and solidifies, taking the form of the mold. Once cooled, the mold opens and the issue is ejected. This cycle may be repeated suddenly, making it perfect for high-amount manufacturing.

Characteristics of Injection Molded Parts

Plastic Injection Molding Parts Suppliers in China are stated for their durability, complexity, and tight tolerances. They can variety from easy family gadgets like bottle caps to complex elements like medical tool housings or vehicle connectors.

Key characteristics include:

High precision: Molds are designed with intense accuracy, regularly indoors with a tolerance of ±0.001 inch.

Repeatability: Every element produced in a mould is kind of identical, making sure product consistency.

Surface surrender: Injection molding can obtain clean or textured finishes straight away from the mildew.

Material versatility: An excellent type of thermoplastics may be used, which include ABS, polycarbonate, nylon, polypropylene, and extra.

Common Applications

Plastic Injection Molding Parts Manufacturer in China are discovered in nearly every area:

Automotive: Dashboards, moderate housings, clips, and handles.

Medical: Syringe our bodies, housings for diagnostic devices, and surgical device additives.

Consumer electronics: Casings for phones, a protracted manner of controls, and keyboards.

Packaging: Lids, containers, and closures.

Each software wishes special popular common performance tendencies, which includes UV resistance, flame retardancy, or effect electricity, which may be finished through material preference and mould layout.

Design Considerations

To create first-rate molded elements, several elements should be taken into consideration for the duration of the design phase:

Wall thickness: Uniform wall thickness ensures right filling and minimizes warping.

Draft angles: Slight angles on vertical partitions help with element ejection.

Ribs and managers: Used for structural assist or attachment points.

Undercuts: Require component-movements or collapsible cores, developing mould complexity.

Using laptop-aided layout (CAD) and simulation software program software allows in optimizing the issue format for manufacturability.

Advantages of Plastic Injection Molding Parts

Efficiency in excessive volumes: Once the mildew is made, factors may be produced fast and at low price in step with unit.

Material standard performance: Excess plastic can frequently be recycled and reused.

Strength and consistency: Engineered plastics can shape the power of metals in a few programs.

Automation: Injection molding techniques are pretty automated, reducing hard paintings expenses and mistakes.

Conclusion

Plastic Injection Molding Parts in China play a vital function in modern-day manufacturing. Their versatility, precision, and fee-effectiveness lead them to best for mass manufacturing in the course of numerous industries. With non-prevent advances in materials and mildew generation, the functionality for innovation in plastic component format and feature continues to develop.

#Plastic Injection Molding Parts#Plastic Injection Molding Parts in China#Plastic Injection Molding Parts Supplier#Plastic Injection Molding Part

0 notes

Text

Advantages and Uses of Melt Flow Index Tester

Source of Info: https://www.perfectgroupindia.co.in/blog/advantages-and-uses-of-melt-flow-index-tester

Introduction

In the plastics industry a Melt Flow Index Tester is a helpful tool to analyze how easily melted plastic flows under specific conditions, helping manufacturers in processing. This user-friendly tool offers useful details that can help reduce waste, deliver accurate data faster, and improve the quality of plastic products. It is important for quality checks and manufacturing methods or laboratories. This equipment is useful for a variety of uses, including understanding material behavior and guaranteeing following industry standards. Perfect Group India is a reputable company that sells accurate and reliable models of this testing equipment.

Why Melt Flow Index Tester is Important?

A Melt Flow Index Tester is a type of laboratory instrument that measures the speed at which the thermoplastic polymer will melt and flow under pressure. Using a specified weight, the melted plastic is pushed through a small die after being heated to a specified temperature.The amount of material that flows out in ten minutes is measured giving us the MFI value.

This test helps industries to identify whether a plastic is suitable for processes like extrusion, blow molding or injection by analyzing the quality of the material.

Advantages of Using a Melt Flow Index Tester

1. Simple and Fast Testing Process

One of the major advantages is its simple use. The equipment gives results within minutes allowing faster decision making in quality control departments.

2. Cost Effective Quality Check

By detecting material problems early in the manufacturing process, reducing waste, and avoiding defective batches a Melt Flow Index Tester can help save costs.

3. Improved Process Control

Knowing the exact MFI value helps manufacturers adjust machine settings such as temperature, speed and pressure to optimize the process and guarantee smooth production.

4. Helps in Material Selection

Different polymers have different flow rates. MFI testing helps in selecting the right level of polymer based on user needs which is important for guarantee product performance.

5. Consistency in Production

With regular MFI testing manufacturers can maintain batch to batch consistency which is important for customer satisfaction and durable brand value.

6. Compliance with Standards

Most industries follow ASTM or ISO standards which require MFI testing for quality assurance. Using a reliable tester helps companies meet these global standards.

7. User-Friendly Design

Modern testers come with digital displays, programmable timers and automatic cutting, making them easy to work, even for technicians with little training.

8. Minimized Human Error

Advanced features like automatic sample cutting and real time digital readouts reduce the chances of manual error during testing.

9. Supports Multiple Materials

Whether it’s polyethylene, polypropylene, polystyrene or ABS the Melt Flow Index Tester is suitable for a wide variety of thermoplastics.

10. Data Storage and Reporting

Many new models come with USB or computer connectivity allowing users to store and print test reports for documentation and audits.

Industrial Uses of Melt Flow Index Tester

Plastic Manufacturing Plants

MFI testers are widely used in factories that produce plastic films, containers, sheets and molded items. They help manufacturers analyze the flow properties of polymers before manufacturing begins.

Injection Molding

In molding use it is important to know how quickly and smoothly a material melts. A suitable MFI value guarantees the polymer fills the mold perfectly without defects.

Quality Control Laboratories

Laboratories use this equipment to monitor material quality during incoming analysis and final product testing. This step is important to guarantee reliable performance and safety of plastic items.

Material Research and Development

R&D departments use Melt Flow Index Tester to develop new plastic formulations and blends. It allows them to experiment and analyze how different additives or fillers affect flow behavior.

Automobile and Aerospace

These industries require highly accurate plastic products. Before materials are used in manufacturing MFI testing makes sure that they fulfill all required mechanical and flow requirements.

Packaging Industry

For producing bottles, pouches, containers and films, packaging manufacturers choose on MFI values to make sure materials can be processed easily and form strong, lightweight products.

Medical and Pharma Applications

Plastics used in syringes, medical devices and drug containers must meet high flow and quality guidelines. Maintaining those standards requires MFI testing.

Why Every Plastic Manufacturer Needs It

The modern market requires plastic products that are high performing, reasonably priced and free of defects. Warping, surface problems or structural failure can result from small modifications in the behavior of the material. Making wise choices and identifying these problems early are made simple with the help of the Melt Flow Index Tester.

In order to guarantee consistency this tool also makes it possible to compare batches or suppliers quickly. Testing flow rate provides a clear picture of how the material will behave in manufacturing no matter whether it's a new supplier or a new grade of polymer.

Choosing the Right Tester for Your Business

When selecting a Melt Flow Index Tester it's important to look for features like:

• Digital temperature controls

• Automatic sample cutting

• Easy to read displays

• Strong build quality

• Compliance with ASTM D1238 and ISO 1133 standards

Conclusion

The Melt Flow Index Tester helps industries in selecting the best materials for manufacturing and is important in understanding how plastic materials behave when melted. This testing device provides simple but useful data to improve the performance, quality and design of products. It is widely used in research centers, manufactures and labs. It offers many advantages from helping with mold design to monitoring plastic flow rates. It makes quality control simpler and is trusted by many industries. Perfect Group India offers instruments which allow improved decision making and consistent product results across various plastic uses for reliable and productive testing solutions.

0 notes

Text

Top PET Preform Manufacturers India Leaders in Packaging Innovation

India has emerged as a global powerhouse in PET preform manufacturing, with top manufacturers leading the way in packaging innovation and sustainability. These industry leaders are known for their cutting-edge technology, precision engineering, and commitment to quality, catering to diverse sectors such as beverages, pharmaceuticals, cosmetics, and household products. By offering customized, eco-friendly, and cost-effective solutions, India’s PET preform manufacturers are setting new benchmarks in the global packaging industry. This blog explores the top PET preform manufacturers in India, highlighting their capabilities, production standards, and contributions to transforming the future of packaging with efficiency, reliability, and environmental responsibility at the core.

India’s PET Preform Industry A Rapidly Growing Sector

The pet preform manufacturers india industry in India has seen remarkable growth over the last decade, fueled by rising demand in beverage, pharma, and FMCG sectors. Indian manufacturers have scaled their operations using world-class machinery, automation, and R&D to deliver preforms that meet international standards. This growth is not only driven by domestic needs but also by increasing exports to Asia, Africa, and the Middle East. The Indian government’s support for manufacturing and sustainability further enhances the sector’s competitiveness. With a focus on innovation, Indian PET preform producers are now seen as reliable global partners for premium-quality packaging solutions.

Technology-Driven Manufacturing for Precision and Consistency

Top PET preform manufacturers in India leverage state-of-the-art injection molding machines, robotics, and advanced quality control systems to ensure consistency in weight, clarity, and dimensional accuracy. Automation plays a significant role in reducing human error and enhancing productivity. These technological investments allow for faster turnaround times and flexible production lines capable of handling custom specifications. From high-speed manufacturing units to integrated software monitoring, India’s leading manufacturers are setting a new standard for precision. This technical edge not only ensures product reliability but also improves efficiency across supply chains, benefiting both domestic clients and international buyers.

Customization Capabilities to Serve Diverse Industries

One of the defining strengths of Indian PET preform manufacturers is their ability to offer tailor-made solutions. Whether it’s neck size, weight variation, or specific color and resin requirements, manufacturers provide complete customization to meet client specifications. This versatility caters to a wide range of applications, including water, carbonated beverages, edible oils, cosmetics, and pharmaceuticals. The flexibility to create preforms suitable for unique bottle shapes or specialized storage conditions gives Indian manufacturers a competitive advantage. This adaptability ensures that businesses can maintain brand consistency, improve product protection, and respond swiftly to changing market trends.

Strict Quality Control and Global Certifications

India’s top PET preform manufacturers adhere to rigorous quality control standards and hold international certifications such as ISO 9001, FSSC 22000, and GMP. These manufacturers conduct in-depth testing at every stage of production—from raw material assessment to final product inspection. Parameters such as color uniformity, acetaldehyde content, and dimensional precision are meticulously checked to ensure flawless output. With dedicated in-house laboratories and real-time monitoring systems, Indian producers guarantee high-quality and safe packaging materials. Their commitment to quality has earned them long-standing trust among global brands, especially those in the food and pharmaceutical sectors where compliance is non-negotiable.

Eco-Friendly Practices and Sustainable Production

Sustainability is becoming a core priority for PET preform manufacturers in India. Many top companies are adopting green practices such as energy-efficient machinery, waste recycling systems, and the use of recycled PET materials. Lightweighting initiatives help reduce plastic usage without compromising performance. These sustainable innovations not only lower environmental impact but also reduce production costs for clients. Additionally, manufacturers focus on eco-friendly packaging designs that support recycling and reduce landfill waste. By integrating environmental responsibility into their operations, India’s PET preform leaders are playing a vital role in shaping the future of sustainable packaging worldwide.

Cost-Effectiveness and Competitive Advantage

One of the key reasons global buyers are turning to India for PET preform solutions is cost-effectiveness. Indian manufacturers offer high-quality preforms at competitive prices, thanks to efficient production systems, affordable labor, and access to raw materials. Bulk manufacturing capabilities and strategic supply chain management further drive down operational costs. Despite lower pricing, these companies maintain strict quality standards and fast turnaround times, making them highly attractive for both small-scale and large-scale packaging needs. This value-for-money proposition allows Indian PET preform suppliers to compete successfully in both domestic and international markets without compromising on excellence.

Export Excellence and Global Market Reach

India’s leading PET preform manufacturers have significantly expanded their international footprint, supplying to over 50 countries across the globe. Backed by strong logistics networks, adherence to international regulations, and superior product quality, they serve clients in Europe, the Middle East, Africa, and Southeast Asia. Export-driven growth is also supported by government incentives and trade agreements that encourage Indian companies to explore new markets. By participating in global packaging expos and forging strategic partnerships, these manufacturers continuously boost their brand visibility. Their global presence affirms India’s rising status as a trusted, innovative, and scalable PET preform production hub.

Conclusion

The top PET preform manufacturers in India are redefining the standards of packaging through innovation, quality, and sustainability. With state-of-the-art technology, strict quality control, and a customer-centric approach, these industry leaders cater to a wide range of sectors both locally and globally. Their ability to offer customized, cost-effective, and eco-friendly solutions positions India as a key player in the global packaging market. As demand for reliable and sustainable packaging continues to grow, India’s PET preform manufacturers stand ready to meet future challenges and opportunities, delivering excellence at every stage of the production and supply chain.

0 notes

Text

Premium Quality PET Masterbatch by Shubh Labh International in Narela, Delhi 110040

Introduction to PET Masterbatch Manufacturing Excellence

At Shubh Labh International, we take immense pride in being one of the leading manufacturers and suppliers of PET masterbatch in India, headquartered in the thriving industrial hub of Narela, Delhi 110040. With an unwavering commitment to quality, innovation, and customer satisfaction, we provide cutting-edge PET colour and additive masterbatches tailored to meet the evolving demands of the plastic packaging and manufacturing industries.

What is PET Masterbatch and Why It Matters

PET (Polyethylene Terephthalate) masterbatch is a concentrated mixture of pigments and additives encapsulated during a heat process into a carrier resin, which is then cooled and cut into granules. It is widely used to enhance the properties and aesthetics of PET-based plastic products such as bottles, containers, films, and preforms.

At Shubh Labh International, our PET masterbatches are designed to ensure:

Consistent and vibrant color dispersion

Enhanced mechanical properties

UV resistance and improved durability

Food-grade safety compliance

Processability across various PET applications

Why Choose Shubh Labh International?

1. State-of-the-Art Infrastructure

Operating from our modern facility in Narela, Delhi, we use the latest twin-screw extrusion machines, advanced laboratory testing equipment, and automated quality control systems. This ensures that every batch we produce adheres to international quality standards, including ROHS, FDA, and REACH compliance.

2. Decades of Expertise

With over two decades of experience, Shubh Labh International has built a strong reputation for consistency, trust, and performance in the PET masterbatch industry. Our technical team comprises experienced polymer engineers, chemists, and R&D experts, who continuously innovate to develop superior and sustainable products.

3. Custom Color Matching

Our lab offers custom color matching services using precision colorimeters and spectrophotometers, allowing us to deliver tailor-made masterbatches that perfectly align with your brand and product needs. Whether you need opaque, transparent, metallic, fluorescent, or pearlescent effects, we can formulate it with accuracy.

4. Fast Turnaround & Nationwide Delivery

From small trial orders to bulk industrial consignments, we offer swift order processing and timely pan-India delivery with our optimized logistics network. Our strategic location in Narela Industrial Area enables easy access to major transportation routes.

Our PET Masterbatch Product Range

1. Color Masterbatches for PET

We manufacture a wide range of PET color masterbatches, including:

Blue, green, amber, and violet for beverage bottles

White and black masterbatches with excellent opacity and dispersion

Custom corporate colors for packaging and branding All of our colors are developed with high thermal stability and UV resistance, ensuring lasting quality even under harsh conditions.

2. Additive Masterbatches for PET

Our specialty additive masterbatches include:

UV Stabilizers — Protection against sunlight degradation

Anti-Static Agents — For dust-free packaging

Slip and Anti-Block Additives — For smooth surface and easy processing

Antioxidants — To protect polymer chains during processing

Barrier Additives — To improve shelf life of food and beverages

3. PET Preform Masterbatch Solutions

PET preforms require precise color control and thermal properties, and our masterbatches are engineered specifically for injection molding processes. We ensure no impact on IV (Intrinsic Viscosity) and provide easy dispersibility, leading to better preform transparency and finish.

Industries We Serve

Our PET masterbatches are widely used in:

Beverage and Water Bottling

Pharmaceutical Packaging

Cosmetic and Personal Care Containers

Household and Industrial Products

Flexible and Rigid Packaging

Textile Spinning Applications

With customers ranging from large MNCs to SMEs, we offer flexible packaging solutions to cater to diverse industry requirements.

Sustainability at Core

Shubh Labh International is deeply committed to eco-friendly and sustainable manufacturing practices. We have implemented:

Energy-efficient processes

Zero liquid discharge systems

Recyclable and biodegradable carrier resins

Lead-free and non-toxic formulations We continually innovate to support a circular economy by developing recyclable and bio-based masterbatch solutions.

Quality Assurance You Can Trust

Every batch of PET masterbatch undergoes rigorous quality checks, including:

MFI (Melt Flow Index) testing

Color consistency and dispersion analysis

Thermal stability and migration resistance

Moisture content measurement This ensures optimum compatibility with PET resin grades and flawless performance during processing and in the end-use application.

Client-Centric Approach

At Shubh Labh International, we believe that customer success is our success. Our technical support team provides:

Application guidance

Product selection consultations

On-site support if needed

24/7 assistance for urgent requirements We treat every client project with utmost priority, delivering not just products but complete solutions.

How to Get in Touch

We welcome you to visit our Narela, Delhi facility, explore our production capabilities, and discuss your masterbatch requirements. Whether you’re launching a new packaging product or scaling up your production, we have the expertise and infrastructure to support your vision.

📍 Shubh Labh International B-70, DSIDC Industrial Complex, Narela Industrial Area, Delhi — 110040, India 📞 Phone: +91–9310136358 📧 Email: [email protected] 🌐 Website: www.shubhlabhinternational.com

1 note

·

View note

Text

Customized Molding Machine Manufacturer in Ahmedabad, India

Top Customized Molding Machine Manufacturer in Ahmedabad, and High-quality Customized Injection Molding Press Machine Supplier across India by Inspire Engineers

Customized machines are specially designed and engineered to meet the specific requirements of industries that need specialized equipment for their production processes. These machines are tailored to perform precise operations that cannot be efficiently carried out by standard machines. The key advantage of customized machines is their flexibility in design, which allows for a high degree of customization in terms of functionality, capacity, and configuration. The design and construction of customized machines involve detailed consultation between the manufacturer and the client to understand the production needs, operational environment, and material specifications.

🔧 Customized Machines for Precision & Performance

📱 +91 90338 42504 📧 [email protected] 🌐https://inspireengineers.in/products/customized-press/customized-machine/

0 notes

Text

Engineering the Edge: What Separates Good from Great in Modern Factories