#Textile Manufacturing Innovation

Explore tagged Tumblr posts

Text

Pad Dyeing Machines Market Projected to Reach $1268.0 Million by 2035

The Pad Dyeing Machines market is set for significant growth, with industry revenue forecasted to increase from $516.9 million in 2024 to $1268.0 million by 2035, reflecting a Compound Annual Growth Rate (CAGR) of 8.5% over the forecast period. This growth is largely driven by rising demand from the textile and apparel industry, coupled with advancements in dyeing technologies and the adoption of sustainable dyeing practices.

Key Applications Driving Market Growth

Pad Dyeing Machines are essential in several industrial processes, particularly those requiring uniform color application and efficient production cycles. Core applications include:

Detailed Analysis - https://datastringconsulting.com/industry-analysis/pad-dyeing-machines-market-research-report

Textile Dyeing: Ensures high-speed, consistent dyeing across large fabric rolls with minimal chemical waste.

Industrial Garment Dyeing: Ideal for processing bulk garment lots with precise color control.

Printing Processes: Supports pre-treatment and post-treatment dyeing stages in textile printing operations.

Competitive Landscape and Industry Leaders

The market is characterized by intense competition and technological innovation. Major companies dominating the landscape include:

Benninger AG

CHTC Fong's International Co. Ltd

Alliance Machines Textiles

MCS Group Srl

Kuang Ta Hsing Industrial Co. Ltd

Sclavos by AIKI

Brazzoli S.p.A.

LAIP S.r.l.

Texfab Engineers India Pvt. Ltd.

Thies GmbH & Co KG

Tonello S.p.a.

These players are expanding globally, investing in R&D, and focusing on energy-efficient, low-liquor ratio machines to align with sustainability goals.

Market Drivers and Opportunities

Several key factors are contributing to the market’s robust outlook:

Growing Demand from the Apparel Industry: As fashion and fast-fashion sectors expand, the need for efficient dyeing systems is rising.

Sustainability Trends: The market is seeing growing interest in eco-friendly dyeing processes, including water-saving and chemical-reducing technologies.

Technological Innovations: Automated controls, AI-driven monitoring systems, and integration with IoT platforms are enhancing operational efficiency.

Expansion in Emerging Markets: Rapid industrialization in countries like Vietnam, Nigeria, and Qatar is creating new opportunities for manufacturers.

Regional Insights and Supply Chain Evolution

North America and Europe continue to lead the market due to advanced textile infrastructure and strong emphasis on sustainability. However, Asia-Pacific, especially China and India, is witnessing rapid growth due to increased manufacturing activity and government support for industrial modernization.

The supply chain is evolving, as manufacturers seek to reduce costs and improve efficiency. Companies are now focusing on:

Localizing component manufacturing

Forming strategic regional partnerships

Expanding assembly and service operations in emerging economies

Future Outlook

The Pad Dyeing Machines market is well-positioned for long-term growth, driven by:

Rising environmental awareness

Increasing adoption of automation

Demand for flexible and modular dyeing solutions

Strategic investments in technology innovation, regional expansion, and collaborations will shape the market trajectory through 2035.

About DataString Consulting

DataString Consulting is a global market research and business intelligence provider, offering end-to-end solutions for both B2B and B2C sectors. With over 30 years of combined industry expertise, DataString delivers:

Strategic consulting services

Tailored market opportunity assessments

Real-time tracking of high-growth industries in more than 15 sectors

Our goal is to equip businesses with actionable insights that support data-driven decision-making and long-term success.

#Pad Dyeing Machines Market#Textile Machinery Market#Industrial Dyeing Equipment#Textile Dyeing Technology#Sustainable Dyeing Solutions#Apparel Industry Equipment#Textile Manufacturing Innovation#Emerging Markets Textile Industry#Automation in Textile Industry#Dyeing Machinery Market Forecast#Energy Efficient Dyeing Machines#Textile Industry Trends 2024–2035#Smart Textile Equipment#Eco-Friendly Dyeing Technology#Global Textile Machinery Leaders

0 notes

Text

Innovation in Textiles: The Future of Clothing Exports in Bangladesh

#apparel supplier#Bangladesh#Clothing#clothing exporters Bangladesh#clothing manufacturers#Exports#Future#Innovation#Textiles

0 notes

Text

Top Synthetic Dyes Companies Driving Innovation & Sustainability in 2025

The global synthetic dyes market is undergoing a transformative shift. As the demand for sustainable, high-performance dyes surges across textiles, coatings, packaging, and plastics, industry leaders are stepping up with advanced technologies, eco-innovations, and bold strategic investments.

The synthetic dyes market is expected to grow at a CAGR of 5.0% to reach USD 9.05 billion by 2029

Here’s a deep dive into the top synthetic dye companies and how they’re shaping the future of colorants worldwide.

Top Synthetic Dyes Manufacturers

The synthetic dyes market is dominated by several major players—known for their innovation, sustainability, and expansive portfolios. Here are the standout companies shaping the industry:

1. BASF SE

Germany-based BASF leads the field with high-performance and eco-friendly synthetic dyes. With a strategic €70 million investment in bio-based Natupal® TS colorants, they’re committed to renewable feedstocks and strong collaborations—like with Nestlé for plant-based meat color solutions

2. Huntsman Corporation

A major US player offering a wide range of dyes for textiles, plastics, coatings, and cosmetics. Huntsman champions sustainability, with innovations like Eriopon® E3-Save reducing water and energy use during application

3. Clariant AG

Swiss-based Clariant integrates circular economy principles with technologies like Reaxol®, which recycles textile dye wastewater and cuts effluent by 90%. Their global partnerships, such as with ITC in India, showcase their capability

4. Archroma

Known for sustainable and high-performance dyes, Archroma offers eco-conscious ranges like EarthColors and innovations like metal-free acid dyes. Their comprehensive portfolio includes AVITERA SE, Diresul, and LUMAPLAST

5. DyStar Group

A global leader in textile dyes and chemicals, DyStar focuses on vertical integration and cost-effective production. Their Eco-Advanced Black and EcoFast Pure technologies improve dyeing efficiency and sustainability

6. DIC Corporation / Sun Chemical

Japan’s DIC—with its Sun Chemical subsidiary—leads in industrial and packaging dyes, offering UV- and heat-resistant pigments for coatings and printing

7. Kiri Industries Ltd.

An Indian powerhouse, Kiri focuses on cost-effective reactive dyes and is expanding capacity with a new Gujarat plant. Their Axill Series targets international markets with price-competitive solutions

8. Atul Ltd.

Another Indian leader with a broad product portfolio, Atul serves over 4,000 customers globally with specialty dyes and chemicals, emphasizing both diversity and customization

9. Zhejiang Longsheng (DyStar), Sumitomo Chemical, Lanxess AG, Heubach Colorants & Aarti Industries

These firms are essential players with offerings across textiles, coatings, plastics, and food; many are scaling up with eco-innovations and regulatory compliance in mind

Download PDF Brochure :

Industry Trends & Competitive Strategies

Sustainable Chemistry: Emphasis on low-VOC, bio-based dye systems like BASF’s Natupal® and Archroma’s EarthColors.

Circular Solutions: Clariant and DyStar focus on wastewater recycling and resource-efficiency technologies.

M&A & Partnerships: Huntsman’s acquisition of Gabriel Performance and Archroma’s alliances bolster portfolios and technology reach.

Digital & High-Performance Dyes: Oil- and UV-resistant pigments for industrial coatings and automotive OEMs are gaining traction.

Regional Market Insights

Asia-Pacific dominates with >70% market share, driven by China, India, Bangladesh, and Vietnam’s textile sectors

North America focuses on high-performance, specialty dyes in automotive, packaging, and construction.

Europe demands advanced technical and eco-friendly dyes in automotive, coatings, and packaging industries.

Why These Companies Lead

Robust R&D: Leaders like BASF, Huntsman, and Clariant invest heavily in sustainable, high-performance innovations.

Global Reach: Strong manufacturing and distribution networks across Asia, Europe, and North America.

Regulatory Agility: Strength in global compliance—from REACH to OEKO-TEX and ZDHC.

Diversified Portfolios: Serving multiple sectors—textiles, plastics, coatings, packaging, and specialty industries.

To maintain a competitive edge, companies must continue:

Pushing green chemistry and sustainability-focused product lines.

Scaling production of low-environmental-impact dyes.

Digitalizing operations for custom, high-performance dye formulation.

Partnering strategically to enter new verticals and regions.

Get Sample Report Now : The global synthetic dyes industry is no longer just about color—it's about sustainability, innovation, and resilience. As top players invest in cleaner technologies and smarter strategies, the future of synthetic dyes is vibrant in more ways than one.

#synthetic dyes manufacturers#top dye companies 2025#textile dyes market#eco-friendly dyes#BASF dyes#Archroma EarthColors#DyStar sustainability#reactive dyes India#bio-based colorants#textile chemical leaders#dye industry trends#pigment market leaders#dyeing innovation#global dyes market#sustainable dyeing solutions

0 notes

Text

ShinWon Corporation’s Strategic Expansion in Central America

In a global apparel industry marked by rising demand for fast delivery, innovation, and sustainability, ShinWon Corporation a South Korean textile and apparel giant is making bold moves to stay ahead. The company’s strategic expansion in Central America is more than just geographic growth; it reflects a commitment to a new era of activewear manufacturing driven by technology, speed, and eco-consciousness.

ShinWon Corporation’s Global Vision

ShinWon Corporation, founded in 1973, has become a prominent name in the international apparel production industry. Known for its vertically integrated systems from textile processing to finished garments ShinWon has long catered to global retail brands with a focus on quality and delivery efficiency. The company’s expansion into Central America aligns with its nearshoring strategy, aiming to serve the U.S. market more swiftly and cost-effectively.

Why Central America?

The move into Central America particularly regions such as El Salvador and Guatemala offers ShinWon several strategic advantages:

Proximity to the U.S. Market: Shorter transit times help meet fast fashion cycles and urgent restocks.

Cost-Efficient Labor: Competitive labor costs compared to Asia, with rising productivity levels.

Favorable Trade Agreements: The CAFTA-DR agreement allows duty-free exports to the U.S., benefiting both ShinWon and its retail partners.

Regional Expertise: Central America has a growing base of skilled workers and infrastructure for textile and apparel production.

By building state-of-the-art factories and integrating local supply chains, ShinWon Corporation is poised to reduce lead times dramatically while ensuring high production capacity.

Introducing SWIMS: Smart Manufacturing System

One of the most innovative aspects of ShinWon’s expansion is the deployment of its proprietary Manufacturing Execution System, called SWIMS (ShinWon Integrated Management System). This system digitally connects every stage of production from inventory tracking and quality assurance to real-time performance data.

Through SWIMS, ShinWon Corporation ensures that every order meets stringent global standards while optimizing timelines and reducing material waste. This smart manufacturing model is increasingly crucial in 2025 as retailers demand agility, transparency, and accountability from suppliers.

Growth in Activewear Demand

The rise of health-conscious lifestyles and remote work culture has fueled a surge in activewear manufacturing. Consumers are now looking for garments that offer comfort, durability, and sustainability. ShinWon’s facilities are equipped to meet this demand by producing:

Performance fabrics

Eco-friendly activewear

Stretchable and breathable materials

Seamless garment solutions for sports and lifestyle brands

By focusing on high-demand categories like yoga wear, running gear, and athleisure, ShinWon Corporation is positioning itself as a go-to supplier for the activewear segment.

Commitment to Sustainability

In addition to advanced technology, ShinWon Corporation is integrating sustainability into its Central American operations. The company uses water-saving dyeing techniques, solar-powered facilities, and recycled materials to reduce its carbon footprint. Sustainable garment production is no longer a luxury it’s a necessity, and ShinWon is leading this change.

Their ESG (Environmental, Social, and Governance) approach includes:

Ethical labor practices

Wastewater management systems

Responsible sourcing of raw materials

Energy-efficient production lines

Impact on Global Supply Chains

ShinWon’s move signifies a growing trend in the textile Industry and garment manufacturing industry nearshoring to improve logistics and reduce dependence on Asia-only supply chains. With geopolitical risks, port delays, and increasing freight costs, having a production base closer to North American markets makes strategic and financial sense.

This shift not only strengthens ShinWon’s role as a global manufacturer but also helps American and European brands diversify their sourcing networks.

Conclusion

ShinWon Corporation’s expansion in Central America is a decisive step toward the future of global apparel sourcing. By combining nearshoring benefits, smart factory systems like SWIMS, and eco-conscious operations, the company is setting a benchmark for modern apparel production. As the demand for faster, greener, and smarter solutions grows, ShinWon Corporation is not just keeping up it’s leading the way.

0 notes

Text

#innovative-roller#rubber-roller#rubber-roller-manufacturers#pu-rubber-roller-manufacturers#industrial-rollers-manufacturers#hard-chrome-plated-roller#aluminum-roller-manufacturer#silicone-rubber-roller-manufacturer#steel-roller-manufacturers#steel-industry-roller-manufacturer#textile-industry-roller-manufacturer

0 notes

Text

𝐔𝐧𝐥𝐨𝐜𝐤 𝐭𝐡𝐞 𝐒𝐞𝐜𝐫𝐞𝐭𝐬 𝐁𝐞𝐡𝐢𝐧𝐝 𝐋𝐮𝐱𝐮𝐫𝐢𝐨𝐮𝐬 𝐅𝐚𝐛𝐫𝐢𝐜𝐬: 𝐃𝐢𝐯𝐞 𝐢𝐧𝐭𝐨 𝐅𝐚𝐛𝐫𝐢𝐜 𝐅𝐢𝐧𝐢𝐬𝐡𝐢𝐧𝐠 𝐓𝐞𝐜𝐡𝐧𝐢𝐪𝐮𝐞𝐬

Discover how fabric finishing transforms raw textiles into luxurious materials. Explore essential techniques like scouring, bleaching, and mercerizing that enhance texture, appearance, and performance. Learn about mechanical processes such as calendering and raising, and chemical treatments that impart wrinkle resistance and water repellency. This comprehensive guide offers insights into the art and science behind the fabrics we use daily, making it indispensable for textile enthusiasts and professionals alike.

Regards, Fashion Articles by Waves Fashion Institute

#fabric#fabric processing#textile#textile industry#fabric care#textile innovation#textile technology#textile manufacturing#fabric finishing#fashion#fashion design#textile science#fabric science#dyeing#printing#painting#cleaning

0 notes

Text

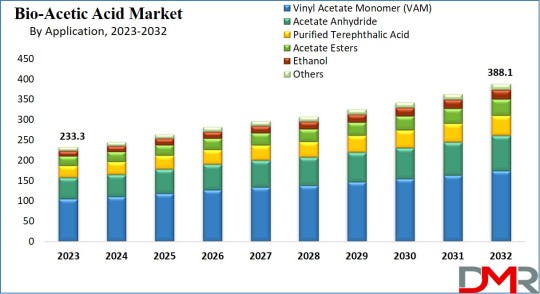

Global Bio-Acetic Acid Market Analysis: Trends, Innovations, and 2024 Forecast Study

The Global Bio-Acetic Acid Market is witnessing significant growth, driven by the increasing demand for sustainable and environmentally friendly alternatives to traditional petrochemical-based products. Valued at USD 233.3 million in 2023, this market is anticipated to grow at a compound annual growth rate (CAGR) of 5.8% during the forecast period from 2023 to 2032. Bio-acetic acid, produced from renewable feedstocks such as biomass and agricultural waste, is gaining popularity as a green substitute for petrochemical-derived acetic acid, particularly in industries such as automotive, textiles, plastics, and paints and coatings.

Understanding Bio-Acetic Acid: A Sustainable Alternative

Acetic acid is a crucial industrial chemical used in a variety of applications, including food processing, textiles, and pharmaceuticals. Traditionally, it has been derived from petrochemical sources, raising concerns about sustainability and environmental impact. Bio-acetic acid, however, is produced through the fermentation of renewable materials, offering a more eco-friendly alternative to conventional acetic acid production.

The global shift towards sustainability is a key driver for the growth of bio-acetic acid. As industries increasingly seek to reduce their carbon footprints and adopt renewable sources, bio-acetic acid is becoming a preferred choice for replacing petroleum-based chemicals. This bio-based acetic acid is not only environmentally friendly but also provides high-quality performance for various applications, making it an attractive option for numerous sectors.

Request For a PDF Sample@ https://dimensionmarketresearch.com/report/bio-acetic-acid-market/request-sample/

Key Growth Drivers in the Bio-Acetic Acid Market

Demand for Sustainable Chemicals

The growing awareness of environmental issues and the need to transition away from fossil-based resources are major factors propelling the demand for bio-acetic acid. Industries across the globe are prioritizing sustainability and adopting greener alternatives to reduce their environmental impact. Bio-acetic acid fits this demand perfectly by offering a renewable and biodegradable option for a wide range of applications.

As sustainability becomes a key focus for consumers and businesses alike, bio-acetic acid provides a solution that aligns with these growing environmental concerns. The global push for a more circular economy, where materials are reused, recycled, or replaced by renewable alternatives, is another contributing factor to the rise of bio-acetic acid.

Technological Advancements in Production

Advancements in biotechnology and fermentation processes have played a significant role in making bio-acetic acid production more efficient and cost-effective. Improved production technologies have reduced the cost gap between bio-acetic acid and petrochemical-based acetic acid, making the former a more viable option for industries looking for sustainable alternatives. Furthermore, the ability to use diverse feedstocks, including agricultural residues and biomass, has increased the feasibility of bio-acetic acid on a commercial scale.

These technological innovations not only help lower production costs but also enhance the scalability of bio-acetic acid production, ensuring a steady supply of this eco-friendly chemical for a growing market.

Rising Consumer Demand for Eco-Friendly Products

As consumers become more eco-conscious, the demand for products made from sustainable materials is growing. In industries such as textiles, paints and coatings, and plastics, there is a clear shift towards bio-based chemicals as part of efforts to reduce environmental impact. Bio-acetic acid, with its renewable origin, is seen as a solution that meets these demands, offering an environmentally friendly option for various applications.

Industries are under increasing pressure from both consumers and regulators to adopt sustainable practices, and bio-acetic acid is increasingly recognized as an essential component of this transformation.

Talk to our Expert@ https://dimensionmarketresearch.com/enquiry/bio-acetic-acid-market/

Applications of Bio-Acetic Acid

Bio-acetic acid is a versatile chemical with numerous applications across various industries. Some of the most significant sectors utilizing bio-acetic acid include:

Automotive Industry

The automotive sector is a major consumer of acetic acid, particularly in the production of paints, coatings, and plastics used in vehicle manufacturing. As demand for environmentally friendly vehicle production grows, bio-acetic acid is becoming an attractive alternative to traditional petrochemical-based chemicals. The Asia Pacific region, home to leading automotive manufacturers such as Toyota, Nissan, and Hyundai, is expected to drive the demand for bio-acetic acid in this sector.

Textiles and Fabrics

In the textile industry, acetic acid is used in dyeing and finishing processes. Bio-acetic acid is increasingly being adopted in this sector as part of the shift toward more sustainable textile production. The use of bio-acetic acid ensures that the textiles produced are both high-quality and environmentally friendly, appealing to the growing consumer demand for sustainable fashion.

Food and Beverage Industry

Bio-acetic acid is also used as a food preservative and flavoring agent, especially in the production of vinegar. As the food and beverage industry moves towards more natural and sustainable ingredients, bio-acetic acid is gaining recognition as a renewable solution that meets consumer demands for eco-friendly products.

Plastics and Polymers

In the production of plastics, bio-acetic acid is used to synthesize key chemicals such as terephthalic acid, which is a building block for polyethylene terephthalate (PET) plastics. As the demand for biodegradable and sustainable plastics rises, bio-acetic acid is becoming an essential raw material in the production of eco-friendly polymers and plastics.

Paints and Coatings

Bio-acetic acid is widely used in the paints and coatings industry as a solvent. With the increasing demand for environmentally responsible products, many paint and coating manufacturers are turning to bio-acetic acid to replace traditional solvents derived from petrochemical sources. This trend is expected to contribute to the overall growth of the Global Bio-Acetic Acid Market.

Regional Insights: Asia Pacific Leads the Market

In 2023, the Asia Pacific region holds a dominant share of 48.6% in the global bio-acetic acid market. This region's leadership can be attributed to its strong industrial base, particularly in sectors such as automotive, textiles, plastics, and paints and coatings. Several key factors contribute to the growth of the bio-acetic acid market in Asia Pacific:

Growing Automotive Industry

Asia Pacific is home to some of the largest automotive manufacturers, including Toyota, Hyundai, and Nissan. The region's expanding automotive sector is a major driver of demand for bio-acetic acid, particularly in the production of eco-friendly vehicle components such as paints and coatings.

Expanding Consumer Market

The rising disposable income and expanding middle class in Asia Pacific have led to increased consumer demand for sustainable products. This shift in consumer preferences is driving the adoption of bio-acetic acid in industries such as textiles, plastics, and paints, further fueling the growth of the market in the region.

Strong Manufacturing Base

Asia Pacific's strong manufacturing capabilities and the presence of leading players in industries such as textiles, automotive, and paints are expected to continue driving demand for bio-acetic acid. As the region's manufacturing sector increasingly embraces sustainability, the use of bio-acetic acid is expected to grow across various industrial applications.

Conclusion

The Global Bio-Acetic Acid Market is poised for robust growth, driven by the increasing demand for sustainable and renewable chemicals. As industries continue to prioritize eco-friendly alternatives, bio-acetic acid is emerging as a key solution in sectors ranging from automotive to textiles and food processing. Asia Pacific, with its strong industrial base and growing consumer demand for sustainable products, is expected to maintain its leadership in the market.

While challenges such as production costs and feedstock availability remain, advancements in production technologies and increasing consumer preference for sustainable products are expected to fuel the market’s expansion. Bio-acetic acid represents a critical step towards a greener, more sustainable future, offering a renewable and environmentally friendly alternative to traditional petrochemical-based chemicals.

#Bio-Acetic Acid#Sustainability#Green Chemistry#Renewable Chemicals#Eco-Friendly#Chemical Manufacturing#Bio-Based Products#Bio-Economy#Asia Pacific#Chemical Industry#Automotive Sector#Textiles#Plastics#Paints and Coatings#Industrial Innovation#Renewable Energy#Green Tech

0 notes

Text

Future-Ready; RSWM’s plans for a sustainable and automated future !!

RSWM Limited, the flagship company of LNJ Bhilwara Group is a name synonymous with excellence in the textile industry. One of India’s largest manufacturers and exporters of synthetic and blended spun yarns, the company has also carved a niche for itself with its knitted fabrics.

Explore our media coverage and discover how we’re making headlines. Click below to read more!

0 notes

Text

#PPMultifilamentYarn#IndustrialMaterials#Manufacturing#FormosaSynthetics#Textiles#Automotive#GeoTextiles#CostEffective#Durability#Versatility#MaintenanceTips#IndustrialApplications#Performance#Reliability#Polypropylene#Craftsmanship#Innovation#Sustainability#IndustrialEngineering#QualityAssurance#BusinessSolutions

0 notes

Text

Synthetic Leather Market | A Comprehensive Analysis of the Global Landscape

The global synthetic leather market is anticipated to reach USD 66.24 billion by 2030 and is projected to grow at a CAGR of 7.87% from 2024 to 2030, according to a new report by Grand View Research, Inc. Growing awareness among consumers regarding animal exploitation, aided by programs run by organizations such as PETA, has played a major role in increasing the demand for leather alternatives. The growing supply-demand gap in the natural leather industry is also a major factor responsible for manufacturers opting for synthetic or artificial leather. Furthermore, natural leather is obtained from animals, which has resulted in animal killings. There have been various guidelines and laws established by various countries to protect animal rights. Animal rights laws have become a major hurdle for natural leather manufacturers in several countries.

Synthetic Leather Market Report Highlights

The automotive application segment is anticipated to grow at a CAGR of 8.9% over the forecast period. Synthetic leather is used in several automotive applications such as upholstery, dashboards, headliners, seat belts, airbags, and floor & trunk carpets. It is employed in passenger vehicles, light & commercial vehicles, heavy trucks, and buses & coaches as it is lighter than real leather. Its high elasticity enables passenger comfort in addition to providing resistance against hot & cold temperatures and spillage. The product also increases the durability of automotive interiors and reduces maintenance requirements

The PU synthetic leather segment held the largest market share of 60.8% in 2023. PU leather has good elasticity, resistance to solvents, high tensile strength, and skin abrasion resistance. These properties have been a major help in increasing its market penetration in the automotive, footwear, and furnishing sectors

Asia Pacific dominated the synthetic leather market. China is the largest market for synthetic leather in Asia Pacific. It is also among the major consumers of leather in primary application segments such as automotive, furnishing, and clothing. Automotive and footwear industry, which are vital application segments for synthetic leather, are witnessing a rapid growth in the country. China mainly imports synthetic leather from India, Korea, and Italy

In December 2021, Dow, a U.S.-based company, announced the launch of LUXSENSE, a silicone synthetic leather. It is the world's first high-end silicone synthetic leather material designed to meet specifications in furniture, wearable devices, fashion, transportation seating and interiors, and consumer electronics, offering unique features

For More Details or Sample Copy please visit link @: Synthetic Leather Market Report

Manufacturing activities of natural leather, especially tanning, lead to pollution of the nearby surroundings. This is another major reason leading to the shift in preference toward synthetic leather. Stringent environmental laws and government regulations have been influential in promoting the demand for synthetic leather.

India is among the world’s top five producers of leather. However, the Central government of India has banned the slaughter of cows for meat and leather, which has adversely affected the leather industry in the country. Most of India’s leather and meat industry comprises unorganized players, owing to which a reduction in the annual production from these industries is not feasible to estimate. The market situation has widened the demand-supply gap of genuine leather, which is expected to supplement the India PU market’s growth over the forecast period.

#synthetic leather#faux leather#vegan leather#artificial leather#polyurethane leather#market analysis#textile industry#sustainability#fashion#consumer goods#manufacturing#material science#environmentally friendly#global market#luxury goods#leather alternatives#innovation#trends#market research

1 note

·

View note

Text

Winch Dyeing Machines Market to Reach $1175.7 Million by 2035

The global market for Winch Dyeing Machines is projected to grow significantly, reaching an estimated value of $1175.7 million by 2035, up from $536.1 million in 2024. This marks an average annual growth rate of 7.4% between 2024 and 2035.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/winch-dyeing-machines-market-research-report

Winch Dyeing Machines play a vital role in various applications, including textile dyeing, fabric coloring, industrial cleaning, and the production of technical textiles. Market expansion will be driven by developments in machine technology, sustainability-focused dyeing methods, and increasing demand for high-quality textiles.

Competitive Landscape and Market Leadership

The Winch Dyeing Machines industry is highly competitive, with major players striving for market share and innovation leadership. Key companies include:

Benninger AG

Braunschweigische Maschinenbauanstalt AG

Fongs Industries Co Ltd

Jiangsu Hailong

Tong Geng Enterprise Co. Ltd

Alliance Machines Textiles

CHTC Fong's International Co. Ltd

MCS Group

Brazzoli S.p.A

Sclavos SA

Tecnorama Srl

Navis Global

Technological innovation and eco-efficient solutions are driving competition, as companies look to stay ahead in meeting sustainability standards and quality expectations.

Key Growth Drivers and Opportunities

Several factors are fueling market expansion:

Technological Advancements: Innovations in textile processing and dyeing techniques are making machines more efficient and eco-friendly.

Rising Demand for Premium Textiles: Quality-conscious consumers are pushing for advanced dyeing methods.

Strategic Collaborations: Partnerships among manufacturers, suppliers, and technology providers are opening new revenue streams.

Untapped Markets: High-growth potential in regions such as China, India, Germany, U.S., and the UK provides new investment avenues.

Regional Outlook and Supply Chain Evolution

Asia-Pacific and North America are currently the most dynamic regions in the Winch Dyeing Machines market. While installation and operational costs remain a challenge, the supply chain is evolving with new sourcing strategies and manufacturing hubs.

Emerging markets such as Vietnam, Bangladesh, and Indonesia are witnessing increased activity as companies seek revenue diversification and Total Addressable Market (TAM) expansion. The regional shift is expected to reshape supply chains across raw material sourcing, component manufacturing, and end-user distribution.

About DataString Consulting

DataString Consulting is a comprehensive market research and business intelligence firm catering to both B2C and B2B sectors. With over 30 years of combined industry experience, the company delivers tailored market insights and strategic consulting solutions.

Specializing in opportunity assessment, growth strategy, and competitive analysis, DataString Consulting supports clients in navigating high-growth industries across global markets. Their customized research methodology and sector expertise ensure actionable insights for strategic business decisions.

#Textile Machinery#Dyeing Technology#Winch Dyeing Machines#Textile Equipment Market#Fabric Dyeing Solutions#Market Research Tags:#Market Forecast 2035#Industry Analysis#Market Growth Trends#B2B Market Insights#Textile Industry Outlook#Business & Strategy Tags:#Strategic Partnerships#Emerging Markets#Industrial Automation#Sustainable Manufacturing#Global Supply Chain#Geographical Tags:#Asia-Pacific Market#North America Market#Textile Market China#Textile Industry India#Europe Textile Equipment#Company/Competitor Tags:#Benninger AG#Fongs Industries#Brazzoli S.p.A#Jiangsu Hailong#CHTC Fong's#Technology & Innovation Tags:

0 notes

Text

Flameproofing Futures: Navigating the Fire-Resistant Fabrics Market Landscape

The global fire-resistant fabrics market is witnessing growth and is projected to reach USD 5.9 billion by 2030. This growth can be credited to the increase in the demand for such materials from the chemical, oil & gas, and construction sectors. Credited to the severe guidelines for workplace safety in advanced countries. On the basis of type, the industry is divided into treated and inherent…

View On WordPress

#automotive interiors#Competitive Landscape#Fire Hazards Prevention#Fire-Resistant Fabrics Market#Flame-Resistant Materials#Home Furnishings#Industrial Safety#Investors#manufacturers#market analysis#Market Segments#opportunities#Protective Clothing#Regional Influences#Safety Industry#Textile Innovation

0 notes

Text

Dress for Success: Sustainable Fashion Tips for the Modern Workforce with Sri Shakthi Tex

In today’s dynamic and eco-conscious world, dressing for the office isn’t just about looking professional — it’s also about making ethical and sustainable choices. Sri Shakthi Tex, a leading manufacturer of quality textiles in Erode, offers a stunning range of natural fabrics that are perfect for creating chic and comfortable workwear ensembles.

So, ditch the bland, synthetic suits and embrace the power of conscious fashion! Here are some sustainable style tips to help you achieve a polished and professional look while feeling confident and comfortable all day long:

1. Embrace the Versatility of Natural Fabrics:

Sri Shakthi Tex offers a treasure trove of breathable and eco-friendly fabrics like organic cotton, linen, and rayon. These natural fibers not only drape beautifully but also keep you cool and comfortable throughout the workday.

2. Play with Prints and Patterns:

Subtle prints and textures can add visual interest to your outfit without compromising professionalism. Sri Shakthi Tex boasts a collection of exquisite prints inspired by nature and Indian heritage, perfect for making a statement without going overboard.

3. Invest in Classic Staples:

Build your workwear wardrobe with versatile pieces that can be easily mixed and matched. A crisp white shirt, a well-fitted blazer, and tailored trousers from Sri Shakthi Tex can be adapted to create countless professional looks.

4. Accessorize Wisely:

The right accessories can elevate your outfit and add a touch of personality. Opt for simple yet elegant jewelry, a statement scarf, or a sleek leather bag for a polished finish.

5. Comfort is Key:

Remember, you’ll be sitting and moving around throughout the day, so prioritizing comfort is essential. Choose pieces that allow for freedom of movement without compromising on style. Sri Shakthi Tex’s natural fabrics are naturally soft and breathable, ensuring you stay comfortable all day long.

6. Embrace the Ethical Choice:

By choosing sustainable fabrics from Sri Shakthi Tex, you’re not just making a statement about your personal style, you’re also contributing to a healthier planet and fairer working conditions for textile workers. Sri Shakthi Tex is committed to ethical production practices and sustainable sourcing, making them the perfect choice for the conscious consumer.

Conclusion:

Dressing for success in the modern workplace doesn’t have to be boring or unsustainable. With Sri Shakthi Tex’s quality textiles in erode and these styling tips, you can create a professional and polished look that reflects your commitment to both style and sustainability. So step into the office feeling confident and empowered, knowing that you’re making a positive impact on the planet one outfit at a time.

#Textile Manufacturing#Fabric Production#Textile Industry#Quality Fabrics#Yarn Manufacturing#Weaving Services#Knitting Solutions#Fabric Export#Sustainable Textiles#Textile Innovation#Textile Products#Yarn Suppliers#Dyeing and Finishing#Textile Processing#Apparel Fabrics

0 notes

Text

"South African entrepreneur Phumla Makhoba is on a mission to solve the “global south housing crisis.” And she’s doing it by using clothing waste.

Her invention, Texiboard, is a material that combines fibers found in textile waste with lime cement to create a durable, affordable, and circular building material.

The result is a textured, white square, almost tile-like, that is created with recycled materials — not emission-generating wood or concrete.

“It can be used to make furniture, flooring, walls, or even your entire home,” Makhoba said in a video for social media account We Got Earth.

The first iterations of the Texiboard included colorful cotton threads that were compressed together, with multiple attempts to remove cracks and seams and perfect the ratios of size, shape, and material mass.

With her design firm, Studio People, Makhoba has been working since 2022 to perfect the TexiBoard.

Makhoba has since created a solid panel, with shredded textile fiber and natural lime cement fully cured. Finally, it can be formed into a full sheet of building material.

Once realized, the Texiboard will confront the estimated 92 million tons of clothing waste generated around the globe each year. But it will also provide safe and stable housing that Makhoba says only 20% of South Africans can afford.

“Growing up, I saw two worlds: one with polished buildings, and one built from scrap,” she said in a video. “I always wondered, why do some people get homes that last and others get homes that leak?”

Now, the Texiboard design is available as an open-source resource, and Makhoba and her team host in-person workshops for locals living in shacks to learn how to build their own supportive and sustainable housing.

“Just having a roof isn’t enough,” Makhoba said. “A real home should protect you from the weather, work for your daily life, and not fall apart in five years.”

Her approach includes a full theory of change. Right now, Studio People is in the input process, building partnerships and funding to scale their operation. From there, they hope to develop a fully sustainable supply chain to manufacture and sell Texiboards and help build affordable housing for people in need.

Once that dream is realized, Makhoba outlines the tangible output of this work: Economically inclusive waste management, circular building materials, green jobs, and a sustainable housing and manufacturing market.

“Informal settlements can be transformed when we all work together,” she shares on the Studio People website. “Texiboard is the seed of innovation that will create updated trade jobs in the innovative building industry.”

Although the Texiboard is still being completely perfected, the goal is to provide a weather-proof, cost-effective, and circular way to house people by democratizing the act of building.

“Our goal is to create an egalitarian and sustainable urban environment, helping shack dwellers and youth out of poverty,” Studio People shared on LinkedIn.

“We empower the underdog, including people and businesses, to co-create solutions in our fight against the housing crisis, unsustainable building materials, and unemployment — one board at a time.”"

-via GoodGoodGood, May 28, 2025

#south africa#africa#entrepreneur#black excellence#black women#textiles#textile waste#clothing#clothing industry#housing#sustainability#circular economy#architecture#sustainable architecture#good news#hope

1K notes

·

View notes

Text

#innovative-roller#rubber-roller#rubber-roller-manufacturers#pu-rubber-roller-manufacturers#industrial-rollers-manufacturers#hard-chrome-plated-roller#aluminum-roller-manufacturer#silicone-rubber-roller-manufacturer#steel-roller-manufacturers#steel-industry-roller-manufacturer#textile-industry-roller-manufacturer

0 notes

Text

Embracing the Versatility of Synthetic Fibers: A Modern Wardrobe Essential

In the world of fashion, there is a continuous need for novelty and adaptability. When it comes to fulfilling such needs, synthetic fibers have always come up with something new. Whether it is for their robustness, cost, or ecological nature, such fibers have become a primary in our modern wardrobes.

Synthetic Fibers Provide Durability and Longevity

One of the key substantial benefits of synthetic fibers is their extraordinary toughness. Not like natural fibers, like silk or cotton, synthetics such as nylon and polyester are made to endure unremarkable wear and tear. This toughness makes them ideal for casual wear, as they can stay in their shape and resist wrinkles even after several washes. Synthetic fibers are popular for their withstanding to fading, stretching, and fading making them the best for making long-lasting cloths that can bear the demands of our fast-paced lifestyles.

Synthetic Fibers are Affordable and Accessible

Another factor synthetic fibers have gotten huge acceptance is their cost-efficient nature. Compared to their natural complements, synthetic fabrics are usually more pocket-friendly, creating them available to an extensive variety of customers.

This convenience permits people to experiment with diverse styles and trends without being short on money. Moreover, synthetic fibers can copy the luxurious feel and look of natural materials at a segment of the price, providing a reasonable substitute for those who appreciate the aesthetics of high-end fashion.

Synthetic Fibers are More Eco-Friendly

As sustainability becomes a progressively vital concern in the fashion industry, synthetic fibers have made substantial steps in decreasing their ecological impact. Via technological improvements, ecological synthetic fibers, like recycled polyester, have developed. Such fibers are credited from post-customer plastic waste, like rejected bottles, decreasing the dependability on virgin materials and lessening plastic contamination. Moreover, synthetic fibers need lesser resources, like water and land, during making compared to natural fibers, creating them a more sustainable option.

Adaptability and Performance

Synthetic fibers provide supreme versatility, permitting makers to create clothes for several reasons. Their innate properties, such as quick-drying and moisture-wicking abilities, make them perfect for sportswear and activewear. Furthermore, the suppleness of synthetic fibers permits the making of stretchy fabrics, offering ease and liberty of movement.

Synthetic fibers have certainly renovated the fashion sector, providing a variety of advantages that fulfill our modern requirements. From their toughness and affordability to their ecological nature and versatility, such fibers have become a vital part of our wardrobes. As we navigate a world that continually demands flexibility, synthetic fibers offer us ease, style, and a supportable fashion solution. Embracing the wonders of synthetics guarantees that we can uniform casually with confidence while aiding a more sustainable future.

#Synthetic Fibers market#textile manufacturing#market trends#global market outlook#sustainable fibers#market dynamics#research and development#innovative applications#market growth factors#performance textiles#regulatory landscape#quality assurance#apparel industry#environmental sustainability#technical textiles

0 notes