#Titanium pipe sizes and specifications

Explore tagged Tumblr posts

Text

High-Quality Titanium Pipes in Mumbai: Reliable Solutions for Diverse Applications

Find premium titanium pipes in Mumbai for your industrial needs. Explore a wide range of high-quality titanium pipes that offer exceptional strength, corrosion resistance, and durability. Whether you require titanium pipes for chemical processing, aerospace applications, or any other industry, Mumbai provides reliable solutions to meet your specific requirements. Trust reputable suppliers in Mumbai who offer a diverse selection of titanium pipes, available in various sizes, grades, and specifications. Benefit from the exceptional properties of titanium, such as lightweight construction and excellent resistance to extreme temperatures and corrosive environments. Source your titanium pipes in Mumbai and ensure reliable and efficient performance for your critical applications.

#Titanium pipe#Titanium pipe Mumbai#Mumbai titanium pipe suppliers#Titanium pipe manufacturer in Mumbai#Corrosion-resistant titanium pipe#Industrial titanium pipe#Titanium pipe for aerospace applications#High-strength titanium pipe#Mumbai titanium pipe distributors#Titanium pipe supplier in India#Titanium pipe sizes and specifications#Titanium pipe price in Mumbai#Seamless titanium pipe#Welded titanium pipe#Custom titanium pipe solutions

1 note

·

View note

Text

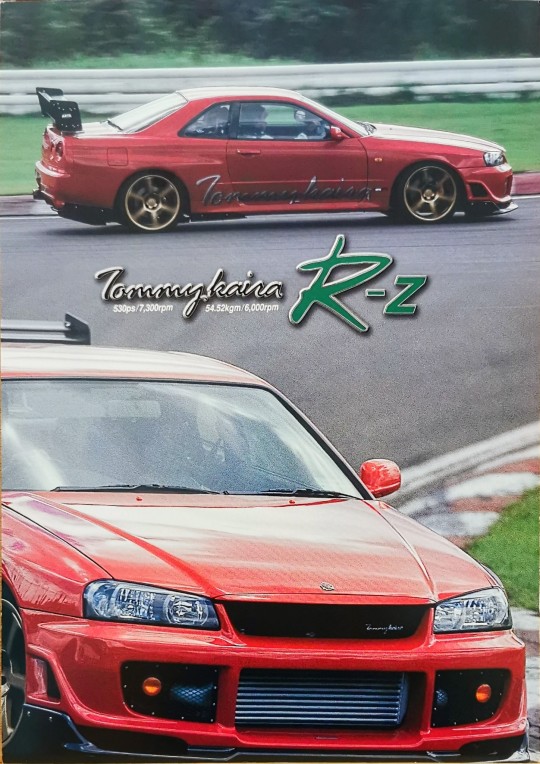

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

18 notes

·

View notes

Photo

New Post has been published on https://www.vividracing.com/blog/new-tomei-expreme-ti-full-titanium-exhaust-system-for-nissan-z-rz34/

New Tomei Expreme Ti Full Titanium Exhaust System for Nissan Z RZ34

Revving into the year 2022, the automotive world was abuzz with anticipation for the arrival of the new Nissan Z. And oh boy, did Nissan deliver! The Z34, equipped with a roaring 3.0L VR30DDTT Twin Turbo V6 and a thrilling 6-speed FS6R31 manual transmission, finally met the cravings of drivers left yearning for more in its predecessors, the Z34 and R35.

Enter Tomei, the legendary powerhouse in automotive tuning since its inception in 1968. Tomei’s legacy in motorsport and commitment to excellence has birthed the Expreme Ti Full Titanium Muffler Kits. Crafted with top-tier materials and engineered for supreme performance, these mufflers are the dream upgrade for enthusiasts seeking to unleash the true potential of this iconic sports car.

View Complete Tomei Catalog Here

For the Nissan Z enthusiasts craving the lightest exhaust system imaginable, Tomei introduces not one, but two, Expreme Ti exhaust systems! The Type-R single muffler kit and the Type-D dual muffler kit promise to take your Z’s performance and sound to the next level.

The Expreme Ti Full Titanium Mufflers for the Nissan Z are lightweight, strong, and highly durable. Tomei sources its own raw materials, which allows them to significantly improve quality while also keeping prices low. Using titanium maximizes weight reduction and durability while simultaneously providing that tantalizing racing note.

SILENCER CASE

This part is made from Titanium with the pipe size of Φ152 and 1mm thickness.

The oversized shell design optimizes exhaust gas flow which helps with power gains.

Then with the embossed Tomei logo and beautiful heat gradation colouring gives it the finishing touch that you’d expect.

PUNCHED MESH

Made entirely from Titanium of 1mm wall thickness and with the open slot ratio of 32.6%. With the combination of light weight Titanium material, the high flow design delivers a really nice racing exhaust sound.

GLASS WOOL

The long fiber wool threads were adopted for the silencer.

This type has proven to last longer than the traditional fiberglass materials even over a longer period of time with extensive high temperature exposure both at high and low pressures.

Flange

Flanges are cut from 8mm thick titanium, making them more resist to cracking and warping. In addition, the opening diameter is kept the same as stock to ensure a secure seal.

Type- R Single:

This new exhaust utilizes thin (1mm wall thickness) titanium piping with a single exit design. The midsection is connected with springs and clamps instead of flanges. With large 3.5 inch (89.1mm) piping, this exhaust offers significantly more flow than the OEM exhaust, which results in more power.

Compared to a Factory Nissan Z exhaust, the Tomei Expreme Ti is 29.7lbs lighter!

*32.3lbs lighter when paired with Tomei Full Titanium Y Shape Mid Pipe!)

1mm wall thickness thickness

Titanium construction

Light, strong, and durable

Single exit design

Sounds great!

More power!

Complete Kit: This kit includes all of the necessary components for a seamless installation, including the bolts and nuts. Bolt Smooth Paste is also included to help prevent the bolts from becoming seized under extreme heat.

Part Number: TB6090-NS21C

Product Name: FULL TITANIUM MUFFLER KIT EXPREME Ti 400Z RZ34 TYPE-R

MSRP: $1,290.00

Specification:

Material: Titanium

Main Pipe Diameter: 3.5in

Main Pipe Thickness: 1mm

Main Silencer Diameter: 6in

Main Silencer Thickness: 1mm

Sub Silencer Diameter: 4.7in

Sub Silencer Thickness: 1mm

Exit Diameter: 4.5in

Exit Thickness: 1mm

Fitment:

2023+ Nissan Z RZ34 VR30DDTT

Learn More and Purchase the New Tomei Type-R Full Muffler Kit Here.

Type-D Duel:

For those who wants to keep the duel exhaust system for your new Z, the Type-D style is what you need! This new exhaust utilizes thin (1mm wall thickness) titanium piping with a duel exit design. The midsection is connected with springs and clamps instead of flanges. With large 80.5mm piping, this exhaust offers significantly more flow than the OEM exhaust, which results in more power.

Compared to a Factory Nissan Z exhaust, the Tomei Expreme Ti is 17.4lbs lighter!

*20.0lbs lighter when paired with Tomei Full Titanium Y Shape Mid Pipe!)

1mm wall thickness

Titanium construction

Light, strong, and durable

Single exit design

Sounds great!

More power!

Complete Kit: This kit includes all of the necessary components for a seamless installation, including the bolts and nuts. Bolt Smooth Paste is also included to help prevent the bolts from becoming seized under extreme heat.

Part Number: TB6090-NS21D

Product Name: FULL TITANIUM MUFFLER KIT EXPREME Ti 400Z RZ34 TYPE-D

MSRP: $1,990.00

Specification:

Material: Titanium

Main Pipe Diameter: 3.2in

Main Pipe Thickness: 1mm

Main Silencer Diameter: 6in (x2)

Main Silencer Thickness: 1mm

Sub Silencer Diameter: 4.7in (x2)

Sub Silencer Thickness: 1mm

Exit Diameter: 4.5in (x2)

Exit Thickness: 1mm

Fitment:

2023+ Nissan Z RZ34 VR30DDTT

Learn More and Purchase the New Tomei Type-D Full Muffler Kit Here.

FULL TITANIUM Y SHAPE MID PIPE:

Compared to a Factory Nissan Z Mid Pipe, the Tomei Titanium Y Pipe is 2.7lbs lighter!

Part Number: TB6110-NS21A

Product Name: FULL TITANIUM Y PIPE KIT EXPREME TI Q50/Q60/400Z

MSRP: $890.00

Specification:

Material: Titanium

Main Pipe Diameter: 2.5-2.76in

Main Pipe Wall Thickness: 1mm

Flange Thickness: 8mm

Fitment:

Nissan VR30DDTT / VQ37VHR 400Z RZ34 / Q50 / Q60

Learn More and Purchase the New Tomei Full Titanium Y Shape Mid Pipe Here.

If you have questions, please contact us. You can reach us by phone at 1-480-966-3040 or via email at [email protected].

#2023 Nissan Z exhaust#400z#exhaust#Light weight#Nissan 400Z#Nissan Z#rz34#tomei#Tomei Exhaust#twin turbo#V6#vr30#VR30DDTT

2 notes

·

View notes

Text

Why Standard Titanium Co Leads in Premium Titanium Tube and Sheet Solutions

In today’s fast-evolving industrial world, quality materials are essential for ensuring strength, precision, and longevity. For industries ranging from aerospace and marine to medical and chemical processing, Titanium Tube and Titanium Sheet products are fundamental components. At the forefront of this demand is Standard Titanium Co, a trusted supplier known for its superior-grade titanium materials and world-class service.

The Power of Titanium: Why It Matters

Titanium is known for its incredible strength-to-weight ratio, corrosion resistance, and biocompatibility. Unlike steel or aluminum, it performs exceptionally in extreme environments — whether under the ocean, inside the human body, or in high-altitude aerospace structures.

Key advantages of titanium include:

Exceptional strength and low density

High resistance to corrosion from seawater and chemicals

Long life cycle with minimal maintenance

Excellent heat and pressure tolerance

This makes titanium a go-to material for manufacturers and engineers worldwide.

Titanium Tube: Lightweight Strength in Motion

The Titanium Tube is a crucial component in high-performance applications. It is commonly used in:

Aircraft hydraulic systems

Heat exchangers

Exhaust and intake pipes

Medical devices and implants

At Standard Titanium Co, each tube is manufactured to strict quality standards, ensuring dimensional accuracy, consistent wall thickness, and a smooth surface finish. Whether you require seamless, welded, or customized titanium tubing, we deliver with unmatched precision.

Our tubes are available in grades such as Grade 2 (commercially pure titanium) and Grade 5 (Ti-6Al-4V alloy), which are ideal for both structural and pressure-bearing uses.

Titanium Sheet: Versatile and Resilient

The Titanium Sheet is another popular product that combines flexibility with incredible strength. Used in everything from architectural facades to medical instruments, these sheets are corrosion-resistant and easy to fabricate.

Common applications of Titanium Sheet include:

Cladding and roofing

Marine hulls and offshore platforms

Surgical tools and implants

Industrial equipment and heat shields

Standard Titanium Co offers sheets in a variety of thicknesses, grades, and surface finishes. Each sheet undergoes rigorous inspection to ensure consistency, flatness, and defect-free quality. Whether for large-scale projects or precision manufacturing, our titanium sheets are engineered for excellence.

Industry Applications We Serve

Standard Titanium Co supplies to a broad range of sectors:

Aerospace & Aviation: Aircraft structures, fuel systems, fasteners

Medical & Dental: Implants, instruments, prosthetics

Marine & Offshore: Ship parts, drilling components

Chemical Processing: Heat exchangers, reactors, pipelines

Automotive & Motorsport: Exhaust systems, engine parts

By partnering with us, clients receive materials that meet international standards (ASTM, ASME, ISO), ensuring compatibility with advanced production systems worldwide.

Why Choose Standard Titanium Co?

What sets us apart is not just the quality of our Titanium Tube and Titanium Sheet, but the service that supports it. We provide:

Custom sizing and cutting

Fast delivery across global markets

Technical consultation and support

Strict adherence to international quality standards

Our team of metallurgists and engineers work closely with clients to understand their specific material needs — delivering not just titanium, but solutions.

Conclusion

For businesses and industries that can’t compromise on material performance, Standard Titanium Co offers the ultimate combination of quality, reliability, and expertise. Whether you need a robust Titanium Tube for extreme environments or a high-precision Titanium Sheet for your next engineering breakthrough, we’re here to deliver.

Get in touch with Standard Titanium Co today and discover why we’re the first choice for high-performance titanium materials worldwide.

1 note

·

View note

Text

Guide on Bolts: Manufacturing Process, Grades, Specifications, and Materials

Designed to securely join two or more components, bolts offer high tensile strength, durability, and reliability under varying loads and environmental conditions. Unlike simple nails or screws, bolts typically work in combination with nuts and washers, providing a strong clamping force that maintains structural integrity even under vibration, stress, and extreme temperatures.

From massive infrastructure projects like bridges and skyscrapers to critical machinery in aerospace, automotive, marine, oil & gas, and manufacturing industries, bolts ensure safety and performance across countless applications. They are available in a wide range of sizes, materials, grades, and specifications to meet the unique requirements of each industry. Understanding the different types of bolts, their manufacturing process, material grades, and specifications is crucial for selecting the right fastener for any application.

Bolt Manufacturing Process: Step-by-Step Overview

The bolt manufacturing process involves multiple stages, ensuring high-quality fasteners for diverse applications:

Raw Material Selection: The process begins by selecting raw materials like carbon steel, stainless steel, alloy steel, brass, titanium, Inconel, and Monel based on application needs.

Cutting: The raw material is cut into precise lengths (blanks) which are then processed into bolts.

Heading: Undergoes cold or hot forging to form the bolt head.

Thread Rolling: Threads are formed through thread rolling, enhancing the bolt's strength and precision without removing material.

Heat Treatment: Bolts are heat-treated to achieve desired mechanical properties like tensile strength, hardness, and durability.

Surface Treatment: Coatings such as zinc plating, galvanization, black oxide, or anodizing are applied for corrosion resistance.

Inspection and Testing: Each bolt undergoes strict quality checks for dimensional accuracy, strength, and surface finish.

Packaging and Dispatch: Bolts are packaged and shipped to clients worldwide.

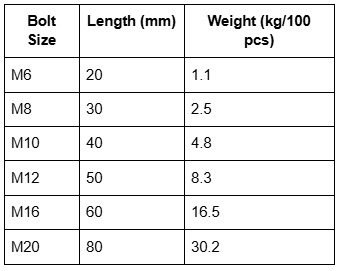

Bolt Weight Chart: Quick Reference

A bolt weight chart helps determine the weight based on dimensions and material type, crucial for logistics and structural calculations.

Note: Weight varies depending on material density.

High-Temperature Bolt Materials: Top Choices

For high-temperature applications, selecting the correct bolt material is crucial to ensure both safety and optimal performance.

Inconel Alloys (600, 625, 718): Superior strength and oxidation resistance.

Hastelloy: Outstanding corrosion and high-temperature resistance.

Stainless Steel (310, 321, 347): Designed to withstand high-temperature oxidation and minimize creep deformation.

Nickel Alloys: Deliver exceptional stability against thermal expansion and corrosion across a wide temperature range.

Titanium Alloys: Lightweight with excellent strength and heat resistance.

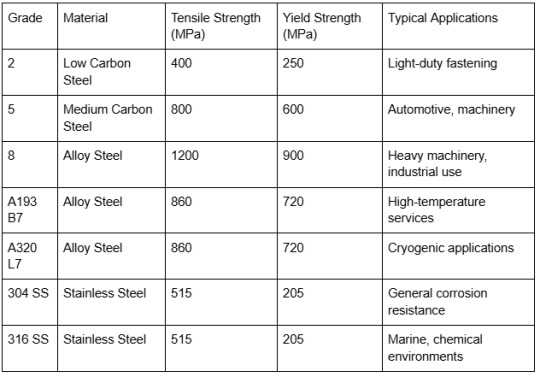

Bolt Grades: Classification and Applications

Understanding bolt grades is crucial for ensuring structural integrity and achieving optimal performance in various applications:

Grade 5: Produced from medium carbon steel and subjected to heat treatment, widely used in automotive, machinery, and equipment manufacturing due to its improved strength and durability.

Grade 8: Constructed from alloy steel and heat-treated, designed for heavy-duty industrial and high-stress environments.

ASTM A193 B7: An alloy steel grade engineered for high-temperature service, ideal for use in pressure vessels and piping systems.

ASTM A320 L7: Alloy steel designed for low-temperature services.

Stainless Steel Grades (304, 316, 410, 17-4PH): Superior corrosion resistance for marine and chemical industries.

Bolt Specifications: Industry Standards

Bolt specifications detail the size, material type, mechanical properties, and protective coatings needed for specific applications. Leading international standards include:

ASTM Standards: A193, A307, A325, A490.

ISO Standards: ISO 898-1.

DIN Standards: DIN 931, DIN 933.

SAE Standards: SAE J429.

Specifications generally cover:

Bolt dimensions (diameter, length, thread pitch)

Material and grade

Mechanical properties (tensile strength, yield strength, hardness)

Coating and surface finish

Bolt Grades Chart: Complete Data Table

Bolt Material Grades: Selection Criteria

Selecting the correct bolt material grade ensures performance, safety, and longevity. Consider:

Environmental factors (corrosion, temperature)

Load-bearing requirements (tensile/yield strength)

Compliance with industry standards

Cost-effectiveness

Common Bolt Material Grades:

Carbon Steel: Cost-effective for general applications.

Stainless Steel (304, 316, 410): Provides outstanding corrosion resistance, with 316 offering enhanced performance in chloride-rich environments.

Alloy Steel: Superior strength and durability.

Exotic Alloys (Inconel, Hastelloy, Monel): For extreme environments and specialty industries.

Bolts Manufacturing Industry Overview

The global bolts manufacturing industry serves numerous sectors, including construction, automotive, oil & gas, aerospace, and infrastructure development. Key growth drivers include:

Rising demand for high-performance, corrosion-resistant fasteners.

Technological advancements in CNC machining, forging, and additive manufacturing.

Expanding infrastructure projects in emerging economies.

Strict adherence to ISO, ASTM, and ASME standards ensures consistent quality, safety, and compatibility across applications.

Leading manufacturers invest significantly in R&D to develop innovative, high-strength, corrosion-resistant, and lightweight bolt solutions.

Conclusion

Bolts are indispensable fasteners that come in a variety of grades, materials, and specifications. Understanding the bolt manufacturing process, bolt weight chart, high-temperature bolt materials, bolt grades, bolt specifications, and bolt material grades ensures that engineers and procurement managers make informed choices for maximum safety, performance, and cost efficiency. The bolts manufacturing industry continues to evolve with technological advancements, offering cutting-edge solutions for every industrial need.

FAQs

Q1. What are the most commonly used bolt materials?

A1. Due to their combination of affordability, strength, and durability, carbon steel and stainless steel are the most widely used materials for bolt manufacturing.

Q2. Which materials are ideal for high-temperature bolts?

A2. Inconel, Hastelloy, certain stainless steel grades (310, 321), and titanium alloys are best suited for high-temperature environments.

Q3. What does bolt grade signify?

A3. Bolt grade indicates the mechanical characteristics like tensile strength, yield strength, and hardness, helping to select the right fastener for specific applications.

Q4. How can I calculate bolt weight?

A4. Bolt weight is calculated based on its dimensions and material density. Bolt weight charts provide quick reference values.

Q5. Why is heat treatment crucial in bolt manufacturing?

A5. Heat treatment enhances bolt strength, hardness, and durability, making them suitable for demanding industrial applications.

#Bolts#Fasteners#BoltManufacturing#BoltGrades#BoltSpecifications#BoltMaterials#HighTemperatureBolts#IndustrialFasteners#EngineeringFasteners#Ananka#Anankafasteners#Linkedin#manufacturer#supplier

0 notes

Text

Gobal Flat Type Ni-Mo-B Alloy Market Sector Analysis: Technology Trends and Future Outlook 2024–2032

Gobal Flat Type Ni-Mo-B Alloy Market continues to show promising growth, with its valuation reaching US$ 220 million in 2024. According to comprehensive market analysis, the sector is projected to expand at a CAGR of 6.3%, ultimately reaching approximately US$ 360 million by 2032. This steady progression is driven by increasing industrial applications requiring high-performance corrosion-resistant materials, particularly in energy, chemical processing, and aerospace sectors.

Flat Type Ni-Mo-B Alloys are critical components in environments demanding exceptional resistance to harsh chemicals and extreme temperatures. Their superior mechanical properties and durability make them indispensable for manufacturers prioritizing equipment longevity and operational safety. As global industries emphasize sustainability, the demand for these high-performance alloys continues to accelerate.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/293013/global-flat-type-ni-mo-b-alloy-market-2025-2032-147

Market Overview & Regional Analysis

North America currently leads the Flat Type Ni-Mo-B Alloy market due to its robust aerospace and defense sectors, coupled with significant investments in chemical processing infrastructure. The region accounts for over 35% of global consumption, driven by stringent industry standards and technological advancements in alloy development.

Asia-Pacific is witnessing the fastest growth, fueled by expanding industrial bases in China, India, and Southeast Asia. Europe maintains steady demand from its established chemical and petrochemical industries, while emerging markets in the Middle East show increasing adoption for oil and gas applications.

Key Market Drivers and Opportunities

The market growth is primarily driven by escalating demand from the chemical processing industry, which accounts for nearly 45% of total consumption. These specialized alloys offer unparalleled resistance to hydrochloric and sulfuric acids, making them vital for reactors, heat exchangers, and piping systems. The energy sector follows closely with 30% market share, utilizing these materials in offshore platforms and refinery components.

Significant opportunities exist in next-generation applications, including hydrogen production infrastructure and nuclear power components. The development of customized alloy formulations for specific industrial applications presents another promising avenue for manufacturers to differentiate their offerings.

Challenges & Restraints

The market faces challenges including high raw material costs and complex manufacturing processes, which contribute to premium pricing. Volatility in nickel prices significantly impacts production costs, while strict environmental regulations on mining and processing pose additional constraints. Competition from alternative materials like titanium alloys in certain applications creates price pressure, though Ni-Mo-B alloys maintain superiority in most corrosive environments. Market Segmentation by Type

Sheet Type

Plate Type

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/293013/global-flat-type-ni-mo-b-alloy-market-2025-2032-147 Market Segmentation by Application

Chemical Processing Equipment

Aerospace Components

Oil & Gas Equipment

Power Generation

Medical Devices

Others

Market Segmentation and Key Players

SMC

ThyssenKrupp VDM

Carpenter

Imphy Alloys

Allegheny

Hitachi Metals

Haynes International

VDM Metals

Nippon Yakin

ATI Metals

DEW

JLC Electromet

Carpenter Technology

Precision Castparts

AMG Superalloys UK

Report Scope

This comprehensive report provides complete analysis of the global Flat Type Ni-Mo-B Alloy market across key regions from 2024 to 2032. It delivers authoritative insights including:

Market size and growth forecasts

Detailed breakdown by product type and application

Competitive landscape and vendor strategies

The study encompasses thorough profiles of major industry participants, featuring:

Business operations and product portfolios

Production capabilities and market positioning

Financial performance and growth strategies

Our research methodology included extensive primary interviews with industry executives and analysis of proprietary data sources to ensure accuracy and reliability. While identifying current market trends, the report also examines emerging opportunities and potential disruptors in the alloy industry.

Get Full Report Here: https://www.24chemicalresearch.com/reports/293013/global-flat-type-ni-mo-b-alloy-market-2025-2032-147

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearc

0 notes

Text

Why Titanium Tubes and Sheets from Standard Titanium Co Are an Industry Game-Changer

In industries where strength, corrosion resistance, and lightweight materials are critical, titanium has emerged as a premium choice. Whether you're working in aerospace, marine engineering, medical devices, or chemical processing, titanium tube and titanium sheet products offer unparalleled benefits. At Standard Titanium Co, we specialize in supplying top-tier titanium materials that meet the highest standards of quality, reliability, and performance.

With decades of experience and a commitment to innovation, Standard Titanium Co delivers titanium solutions engineered to perform in the most demanding environments.

Why Titanium?

Titanium is known for its exceptional combination of strength, low density, and corrosion resistance. It is approximately 45% lighter than steel yet maintains excellent tensile strength, making it ideal for applications where performance and weight reduction are critical.

Key advantages of titanium include:

High strength-to-weight ratio

Exceptional resistance to corrosion, especially from seawater and chemicals

Biocompatibility for medical and dental applications

High temperature resistance

Long service life with minimal maintenance

Applications of Titanium Tubes

A titanium tube is a cylindrical product made from titanium, designed for high-stress and high-corrosion environments. At Standard Titanium Co, we manufacture and supply a wide range of seamless and welded titanium tubes that cater to industries such as:

1. Aerospace and Aviation

Titanium tubes are frequently used in hydraulic systems, fuel lines, and structural components. Their lightweight yet strong characteristics make them ideal for reducing the overall mass of aircraft while maintaining structural integrity.

2. Chemical Processing

In plants where pipes are exposed to corrosive fluids, titanium tubes provide excellent longevity and safety. They resist acids and chlorine-based solutions better than most metals, reducing downtime and replacement costs.

3. Medical Applications

Titanium is biocompatible, making it safe for internal use in medical devices and implants. Tubes are often used for surgical instruments, orthopedic rods, and dental frames.

4. Marine Engineering

Titanium’s resistance to saltwater corrosion makes titanium tube an excellent choice for marine condensers, heat exchangers, and offshore oil rigs.

Versatility of Titanium Sheets

A titanium sheet is a flat, thin piece of titanium alloy that offers superior strength and flexibility. These sheets are widely used in:

1. Architectural and Structural Components

Modern architecture increasingly incorporates titanium sheets for facades, cladding, and decorative panels due to their sleek look and resistance to weathering.

2. Automotive and Motorsport

Titanium sheets are used in high-performance vehicle components such as exhaust systems, engine parts, and protective shielding.

3. Electronics and Energy

Due to their thermal conductivity and corrosion resistance, titanium sheets are valuable in battery production, heat exchangers, and electronic shielding.

4. Medical Equipment

In surgical trays, orthopedic devices, and prosthetics, titanium sheet offers hygiene, safety, and long-term durability.

Standard Titanium Co: Your Trusted Supplier

When it comes to sourcing titanium tube and titanium sheet materials, quality is non-negotiable. At Standard Titanium Co, we focus on delivering products that meet or exceed global industry standards.

Custom Sizes & Grades

We supply titanium products in multiple grades, including Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V) to match specific project requirements. Custom thicknesses, lengths, and finishes are available upon request.

Precision Manufacturing

Our advanced facilities ensure tight tolerances and consistent quality. Whether you're ordering seamless tubes or rolled sheets, you can count on flawless fabrication and timely delivery.

Global Shipping & Compliance

We serve clients around the world and ensure all our titanium products comply with ASTM, AMS, and other international standards. We also handle customs documentation and logistics to make the process seamless for you.

Choosing Between Titanium Tube and Sheet

While both materials offer durability and corrosion resistance, their applications differ:

Our technical team can guide you in selecting the right product for your needs, ensuring that every project gets the right titanium solution.

Sustainability and Longevity

One of titanium’s most overlooked benefits is its environmental sustainability. Its long service life reduces the need for replacements, while its corrosion resistance minimizes leaks, failures, and hazardous waste—making it an ideal material for green engineering and design.

Final Thoughts

If you’re seeking high-performance materials that deliver strength, versatility, and reliability, look no further than Standard Titanium Co. Our extensive inventory of titanium tube and titanium sheet products is backed by years of expertise, global reach, and a relentless commitment to quality.

Whether you’re working on a high-stakes engineering project, a medical innovation, or an architectural masterpiece, Standard Titanium Co is your go-to source for titanium excellence.

0 notes

Text

Knockout Punches for Stainless Steel: What You Need to Know

When working with stainless steel, precision and efficiency are key, especially when it comes to creating clean, accurate holes. Knockout punches are an essential tool for electricians, metal fabricators, and construction professionals who need to cut through tough materials like stainless steel. However, not all knockout punches are suitable for this demanding task. In this guide, we’ll explore the best knockout punches for stainless steel, how to use them effectively, and key factors to consider when making your selection.

Why Use Knockout Punches for Stainless Steel?

Stainless steel is valued for its exceptional strength, resistance to corrosion, and long-lasting durability. While these properties make it a great material for electrical enclosures, panels, and structural components, they also make it difficult to cut through. Traditional drilling methods can be time-consuming, create rough edges, and wear out drill bits quickly.

Knockout punches offer a better solution by:

Creating clean, burr-free holes with minimal effort

Reducing material stress and distortion

Offering faster hole-making compared to drilling

Extending tool life when used correctly

Choosing the Right Knockout Punch for Stainless Steel

Not all knockout punches are designed to handle the hardness of stainless steel. Here’s what you should look for:

1. Material and Coating

Knockout punches specifically designed for stainless steel are usually made from hardened tool steel or high-speed steel (HSS) with coatings such as titanium nitride (TiN) to improve durability and reduce friction.

2. Hydraulic vs. Manual Knockout Punches

Manual knockout punches work well for mild steel and softer materials, but stainless steel requires hydraulic knockout punches for increased power and efficiency.

Hydraulic knockout punches use a pump to apply consistent force, making it easier to punch through stainless steel without excessive strain.

3. Size and Compatibility

Ensure that the knockout punch set you choose includes dies and cutters designed for stainless steel and supports the hole sizes you need for electrical conduit or pipe fittings.

How to Use a Knockout Punch on Stainless Steel

Follow these steps for best results when using a knockout punch on stainless steel:

Step 1: Mark and Drill the Pilot Hole

Use a center punch to mark the hole’s center.

Drill a pilot hole slightly larger than the knockout punch draw stud.

Step 2: Assemble the Knockout Punch

Insert the draw stud through the hole.

Attach the die and cutter to each side, ensuring they are aligned correctly.

Step 3: Apply Force

If using a manual punch, turn the wrench to tighten the draw stud until the hole is cut.

For hydraulic punches, engage the pump to apply consistent pressure.

Step 4: Remove the Slug and Inspect

Once the hole is cut, remove the punch and inspect for burrs.

Use a deburring tool if necessary for a smooth finish.

Pro Tips for Success

Use lubrication (cutting oil) to reduce friction and extend tool life.

Choose the right tonnage for hydraulic punches stainless steel requires more force than mild steel.

Inspect and maintain your knockout punch set to prevent dull cutting edges.

Conclusion

Knockout punches are a game-changer for working with stainless steel, providing clean and precise holes with minimal effort. By selecting the right tools, using proper techniques, and maintaining your equipment, you can achieve professional results while maximizing efficiency.

0 notes

Text

Shell and Tube Heat Exchanger: Design, Applications, and Advantages

Introduction to Shell and Tube Heat Exchanger

The shell and tube heat exchanger is one of the most widely used types of heat exchangers in industrial applications. Its robust design, efficiency, and versatility make it suitable for various processes, including power generation, chemical processing, and HVAC systems. This article explores the working principle, components, applications, and benefits of shell and tube heat exchangers.

How a Shell and Tube Heat Exchanger Works

A shell and tube heat exchanger operates by transferring heat between two fluids—one flowing inside the tubes (tube-side fluid) and the other outside the tubes but within the shell (shell-side fluid). The heat transfer occurs through the tube walls, allowing efficient thermal exchange without direct mixing of the fluids.

Key Components of a Shell and Tube Heat Exchanger

Shell – The outer vessel that houses the tube bundle and shell-side fluid.

Tubes – Small-diameter pipes through which the tube-side fluid flows.

Tube Sheets – Plates that hold the tubes in place and separate the shell and tube sides.

Baffles – Plates that direct shell-side fluid flow to enhance heat transfer.

Inlet and Outlet Nozzles – Entry and exit points for both fluids.

The design ensures maximum surface area for heat exchange while maintaining structural integrity under high pressures and temperatures.

Types of Shell and Tube Heat Exchangers

Several configurations exist based on flow arrangement and construction:

1. Fixed Tube Sheet Exchanger

Tubes are permanently attached to the tube sheets.

Simple and cost-effective but less suitable for thermal expansion.

2. Floating Head Exchanger

One tube sheet is fixed, while the other can move ("float").

Accommodates thermal expansion, making it ideal for high-temperature applications.

3. U-Tube Exchanger

Tubes are bent in a U-shape, allowing free expansion.

Reduces stress but can be harder to clean.

4. Kettle Reboiler

A specialized shell and tube heat exchanger used for vaporizing liquids.

Common in distillation processes.

Each type serves specific operational needs, ensuring flexibility across industries.

Applications of Shell and Tube Heat Exchangers

Due to their durability and efficiency, shell and tube heat exchangers are used in:

1. Oil Refineries and Petrochemical Plants

Cooling hydrocarbons and condensing vapors.

2. Power Plants

Acting as condensers in steam turbines.

3. HVAC Systems

Regulating temperatures in large-scale heating and cooling systems.

4. Food and Beverage Industry

Pasteurization and sterilization processes.

5. Marine Applications

Cooling engine systems and other machinery.

Their adaptability to high-pressure and high-temperature conditions makes them indispensable in heavy industries.

Advantages of Shell and Tube Heat Exchangers

1. High Efficiency

Large surface area and turbulent flow (enhanced by baffles) improve heat transfer.

2. Durability

Constructed from materials like stainless steel, titanium, or copper alloys for corrosion resistance.

3. Easy Maintenance

Modular design allows for cleaning and tube replacement without dismantling the entire unit.

4. Scalability

Can be designed for small or large capacities by adjusting tube numbers and shell size.

5. Pressure and Temperature Resistance

Suitable for extreme operating conditions, unlike plate heat exchangers.

These benefits explain why shell and tube heat exchangers remain a preferred choice in demanding environments.

Design Considerations for Shell and Tube Heat Exchangers

To optimize performance, engineers must consider:

1. Fluid Properties

Viscosity, thermal conductivity, and fouling tendencies affect material selection.

2. Flow Arrangement

Counter-flow (most efficient), parallel flow, or cross-flow configurations.

3. Thermal Expansion

Differential expansion between shell and tubes must be managed to avoid damage.

4. Fouling Resistance

Proper material selection and periodic cleaning prevent buildup.

5. Cost vs. Performance

Balancing initial investment with long-term efficiency and maintenance costs.

A well-designed shell and tube heat exchanger ensures longevity and operational efficiency.

Conclusion

The shell and tube heat exchanger remains a cornerstone of thermal management in industrial systems. Its versatility, efficiency, and robustness make it indispensable across multiple sectors. By understanding its design, types, and applications, engineers can select the best configuration for their specific needs.

Whether in power plants, refineries, or HVAC systems, the shell and tube heat exchanger continues to play a vital role in energy transfer and process optimization.

This article provides a comprehensive overview of shell and tube heat exchangers, covering their functionality, variations, uses, and benefits. If you have further questions or need assistance in selecting the right heat exchanger, consulting a thermal engineering expert is recommended.

1 note

·

View note

Text

Stainless Steel 321 Flanges Suppliers

Introduction:-

Stainless Steel 321 flanges are widely used in high-temperature and corrosion-resistant applications due to their excellent mechanical properties and oxidation resistance. Manufactured from ASTM A182 F321 stainless steel, these flanges contain titanium, which stabilizes the alloy and prevents carbide precipitation, making them ideal for applications requiring resistance to intergranular corrosion.

Stainless Steel 321 flanges are essential components in industrial piping systems, known for their excellent high-temperature strength, oxidation resistance, and corrosion resistance. These flanges are manufactured using ASTM A182 F321 stainless steel, a titanium-stabilized alloy that prevents carbide precipitation and enhances intergranular corrosion resistance, making them ideal for applications in extreme environments.

Product Overview:-

We are a leading manufacturer of stainless steel flanges in various qualities, scales, shapes and standards. We specialize in manufacturing 321 stainless steel flanges with a yield strength of 320 ksi and a tensile strength of over 75 ksi. The nominal inside diameter size of our flanges ranges from 1/2 inch to 48 inches. Additionally, our company manufactures his 321 stainless steel blind flanges. This is used to close the flow at the end of the pipe, making cleaning and maintenance easier.

We manufacture slip-on flanges from 321 stainless steel that are used in low pressure environments where the risk of leakage is minimized. We offer a selection of affordable ASTM A182 F321 flanges that can be customized to meet your specific requirements. We also offer affordable and high quality material, No. 1.4541 Orifice Flange, and other flanges, which can be delivered to your doorstep.

Specifications:-

Stainless Steel 321 FlangesTechnique Use In Forging

Forged, Heat treated,& machined Flanges Top 4 TypesScrewed / Forged/ Threaded / PlateMostly Use TypesLap Joint, Threaded, Weld Neck, Blind, Slip-On, Socket-WeldIndustries UseWaterworks & Municipal Pipe Systems Nuclear Power And The Power Plants Industry Food Processing & Manufacturing High TemperatureAbove 400°C (750°F) And Above 200°C (400°F) For 150LBLow TemperatureAbove -29 °C (−20°F)JIS Standards5K To 63KManufacturing Flange FaceLap-Joint Face, Large Tongue & Groove And Small Tongue Groove, RTJ, FF, Raised Face, Large Male-Female And Small Male-FemaleSize1/2 Inch To 48 InchWe Manufacturer This MaterialsCarbon Steel, Inconel, Hastelloy, Copper Nickel, Stainless Steel, Cast Iron, Duplex Steel & Super Duplex Steel, Wrought Iron, Alloy Steel, Mild Steel.Thickness SizeNormal Pipe Size ≤ 18Bore DiameterNPS ≤ 10RPF India Manufacturer Below StandardsUNI, EN-1092, ANSI/ASME B16.5, B16.47 Series A & B, BS1560-3.1, API7S-15, ASME B16.48, AWWA C207, IS 2062, EN1092, API7S-43, MSS S44, ISO70051, ASME B16.36, DIN, API, ISO, API605, BS4504Pressure Ratings150 To 2500

Benefits:-

Our 321 SS weld neck flange can withstand hazardous conditions such as high temperatures and large pressure fluctuations. We also manufacture large diameter stainless steel 321 flanges, which are metal rings used to connect valves, pipes, and other equipment to pipelines. Here, you can get different types of flanges all from one source. Our UNS S32100 socket weld flanges are made from Alloy 321, a titanium-stabilized true stainless steel with excellent resistance to intergranular corrosion.

Conclusions:-

Manufacturers employ advanced forging, machining, and heat treatment techniques to ensure precision, durability, and compliance with international standards such as ASME B16.5, ANSI, and DIN. SS 321 flanges are widely used in industries like petrochemicals, aerospace, power generation, and marine applications, where reliable performance under high temperatures and aggressive conditions is crucial. Leading manufacturers focus on quality assurance through rigorous testing methods, including ultrasonic testing, hydrostatic testing, and PMI (Positive Material Identification), to deliver high-performance flanges for critical industrial applications>

Email Id:[email protected]

Contact Number:-88797-09191

0 notes

Text

Black Titanium Stainless Steel Perforated Sheet

Introducing the Black Titanium Stainless Steel Perforated Sheet from SD-steel, a premium choice for architects, designers, and engineers seeking both aesthetic appeal and durability. This innovative product combines the strength and corrosion resistance of stainless steel with the striking visual impact of black titanium coating, making it an ideal solution for a variety of applications.

Product Description

The Black Titanium Stainless Steel Perforated Sheet is designed to offer a sleek, modern look while maintaining the robustness required for industrial and architectural uses. The perforations are precisely engineered to provide optimal airflow and light transmission, making it suitable for both functional and decorative purposes.

Material & Specifications

| Material | Thickness (mm) | Width (mm) | Length (mm) | Perforation Pattern |

|--------------|--------------------|----------------|----------------|-------------------------|

| Stainless Steel 304 | 1.2 - 3.0 | 1000 - 1500 | 2000 - 6000 | Square, Round, Hexagonal |

Dimensions & Patterns

Our perforated sheets come in a range of standard sizes and can be customized to meet specific project requirements. Common patterns include square, round, and hexagonal holes, each offering unique benefits depending on the application. The black titanium coating not only enhances the sheet's appearance but also provides additional protection against environmental factors, ensuring longevity and minimal maintenance.

Usage Scenarios

This versatile material finds extensive use in:

Facade Cladding: Enhances building exteriors with a distinctive finish.

Interior Design: Ideal for partitions, screens, and decorative panels.

Furniture: Perfect for creating stylish yet durable furniture pieces.

Ventilation Systems: Provides efficient ventilation while adding a touch of elegance.

Furniture: Suitable for tables, chairs, and other furniture designs.

Decorative Panels: Adds a contemporary touch to interior and exterior design projects.

Furniture: Ideal for creating unique furniture pieces that combine functionality with style.

Ventilation Systems: Ensures effective air circulation without compromising on aesthetics.

Architectural Elements: Used in walls, ceilings, and flooring solutions.

Furniture: Offers a modern aesthetic for tables, chairs, and other custom furniture designs.

Lighting Fixtures: Enhances lighting fixtures with its elegant appearance.

Ceiling Panels: Adds a sophisticated look to ceiling installations.

Exterior Applications: Suitable for cladding, signage, and artistic installations.

Company Strengths

SD-steel boasts over two decades of experience in the steel industry, backed by state-of-the-art manufacturing facilities and rigorous quality control processes.

FAQs

Q: What are the advantages of using Black Titanium Stainless Steel?

A: The combination of stainless steel ensures durability and resistance to corrosion, while the black titanium coating adds a luxurious finish.

Contact Us

For more information or to place an order, please contact us at +65 83016969.

加飞机@yuantou2048

Stainless Steel Perforated Sheet

Stainless Steel Pipe

0 notes

Text

Precision Pipe Fittings Manufacturer in Jaduguda

Ped-Lock Valves & Fittings is a leading manufacturer of precision pipe fittings in India, offering a diverse range of products designed for instrumentation, process, and fluid control applications. Their fittings are available in various configurations, end connections, and sizes to ensure leak-free performance in process systems. Standard materials include brass and 316 stainless steel, with options for Monel, Hastelloy C276, Inconel, Incoloy, Duplex, Super Duplex, and Titanium upon request.

While Ped-Lock Valves & Fittings is based in Ahmedabad, Gujarat, they serve clients across multiple states, including Andhra Pradesh, Assam, Bihar, Chhattisgarh, Delhi, Goa, Haryana, Himachal Pradesh, Jammu & Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Odisha, Punjab, Rajasthan, Tamil Nadu, Telangana, Uttar Pradesh, Uttarakhand, and West Bengal.

For clients in Jaduguda, Jharkhand, Ped-Lock Valves & Fittings can be contacted directly to discuss product availability, specifications, and delivery options. Their commitment to quality and customer satisfaction makes them a reliable choice for precision pipe fittings in the region.

Contact Information:

Address: Shed-8 B.N Estate, Nr Kathwada G.I.D.C. Road, Sardar Patel Ring Rd, Nikol, Ahmedabad, Gujarat-382415

Phone: +91-99256 06950

Email: [email protected]

For more details, visit their official website: https://pedlockvalve.com/precision-pipe-fittings.php

0 notes

Text

Fin Tube: A Key Innovation by Timex Metals for Efficient Heat Transfer

In today's fast-paced industrial world, enhancing the efficiency of heat transfer equipment is critical. One such innovation that plays a pivotal role in improving thermal performance across various industries is the Fin Tube. Timex Metals, a trusted name in the metal industry, has emerged as a leading Fin Tube Manufacturer in India, providing top-quality solutions that meet both domestic and international standards.

What is a Fin Tube?

A Fin Tube is a type of heat exchanger tube with fins attached to its outer surface. These fins significantly increase the surface area of the tube, allowing more efficient heat transfer between fluids. Fin tubes are widely used in industries like power plants, chemical processing, air conditioning, refrigeration, and petrochemical industries.

The main advantage of using fin tubes lies in their ability to improve heat dissipation, reduce energy consumption, and enhance the overall performance of heat exchangers. As a result, they have become indispensable components in a range of heating and cooling systems.

Why Timex Metals?

When it comes to choosing a reliable Fin Tube Supplier, Timex Metals stands out due to its commitment to quality, innovation, and customer satisfaction. As a renowned FinTube Manufacturer, the company uses advanced manufacturing techniques and state-of-the-art machinery to produce fin tubes that meet the highest international standards.

Here are a few reasons why industries choose Timex Metals:

High-Quality Materials: Timex Metals uses only premium-grade materials for manufacturing fin tubes. This ensures superior durability, corrosion resistance, and efficient thermal conductivity.

Customization Options: Every industry has unique needs. Timex Metals offers custom solutions in terms of size, material, fin type, and tube design to suit specific application requirements.

Global Reach: As a prominent Fin Tube Manufacturer in India, Timex Metals exports its products to clients around the world, maintaining a strong reputation in both domestic and international markets.

Applications of Fin Tubes

Fin tubes are versatile and serve a wide range of applications:

Heat Exchangers: Used extensively in both air-cooled and water-cooled heat exchangers.

Boilers: Improve heat recovery and efficiency in boiler systems.

HVAC Systems: Provide effective heat transfer in heating and cooling applications.

Power Plants: Crucial in condensers and other thermal systems.

Timex Metals’ fin tubes ensure optimal heat exchange performance, reduce operational costs, and extend equipment life, making them a top choice among engineers and system designers.

Expanding Capabilities: Titanium Pipe Manufacturing

Timex Metals not only excels in fin tubes but has also gained recognition as a premier Titanium Pipe Manufacturer in India. Titanium pipes are known for their excellent strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. These properties make them ideal for applications in aerospace, marine, and chemical processing industries.

By offering both fin tubes and titanium pipes, Timex Metals showcases its diverse capabilities in the metal manufacturing space, reinforcing its status as an industry leader.

The Future of Heat Transfer Solutions

With rising energy costs and growing environmental concerns, the need for efficient and sustainable heat transfer solutions is more pressing than ever. As a dedicated Fin Tube Supplier, Timex Metals continues to invest in research and development to deliver innovative products that align with global energy efficiency goals.

Their expert team, modern infrastructure, and unwavering focus on quality position Timex Metals as a dependable partner for industries seeking advanced thermal solutions.

Conclusion

In the evolving world of industrial manufacturing, Timex Metals has carved a niche for itself as a trusted FinTube Manufacturer and Titanium Pipe Supplier in India. Whether you're looking for high-performance fin tubes for your HVAC systems or durable titanium pipes for a critical application, Timex Metals offers solutions that ensure performance, reliability, and long-term value.

0 notes

Text

The Ultimate Dab Rig Guide: Everything You Need to Know

Hey there, cannabis enthusiasts! If you're looking to dive into the world of dabbing or just want to upgrade your current setup, you've come to the right place. This comprehensive guide will take you through everything you need to know about dab rigs. From the basics to advanced tips, we've got you covered. So, let's get started!

What is a Dab Rig?

A dab rig is a specialized water pipe designed specifically for vaporizing cannabis concentrates like wax, shatter, or resin. Unlike traditional bongs, which are used for smoking dried cannabis flower, dab rigs work by heating a small amount of concentrate on a nail or banger. This process vaporizes the concentrate, producing a smooth and potent hit.

Key Components of a Dab Rig

Rig Body: This is the main part of the dab rig, which holds the water. The water helps to cool and filter the vapor, making the hit smoother and easier on the lungs.

Nail or Banger: This is where the concentrate is placed and heated. Nails can be made from various materials like titanium, quartz, or ceramic. Each material has its own benefits in terms of heat retention and flavor.

Dome (Optional): Some dab rigs come with a dome that fits over the nail to capture the vapor. While not always necessary, domes can help to concentrate the vapor for a more efficient hit.

Torch or E-Nail: A torch is used to heat the nail to the right temperature. Alternatively, an e-nail can be used for more precise temperature control.

Types of Dab Rigs

Traditional Glass Dab Rigs

These are the most common type of dab rigs. They are made from high-quality glass, which is durable, easy to clean, and preserves the flavor of your concentrates. Traditional glass dab rigs come in a variety of designs, from simple and sleek to intricate and artistic.

Mini Dab Rigs

Mini dab rigs are perfect for those who want a portable option. They are smaller in size but still deliver a powerful hit. These rigs are great for on-the-go use and are easy to carry around.

Electric Dab Rigs (E-Rigs)

Electric dab rigs, or e-rigs, are a modern alternative to traditional dab rigs. They use a battery-powered heating element instead of a torch, providing precise temperature control. This makes them ideal for beginners and those who want a more consistent experience.

Recycler Dab Rigs

Recycler dab rigs are designed to cycle the vapor through the rig multiple times before it reaches the mouthpiece. This process enhances the flavor and smoothness of the hit. Recycler rigs are perfect for connoisseurs who want the best possible experience.

Silicone Dab Rigs

Silicone dab rigs are known for their durability and flexibility. They are virtually indestructible and easy to clean. Silicone rigs are also lightweight and portable, making them a great choice for those who want a rugged and reliable option.

How to Use a Dab Rig

Using a dab rig is a straightforward process, but it does require some practice to get it right. Here are the basic steps:

Prepare Your Rig: Fill the water chamber to the appropriate level. The water should be enough to filter the vapor without causing it to splash back into the mouthpiece.

Heat the Nail: Use a torch or e-nail to heat the nail to the desired temperature. For a smoother hit, aim for a lower temperature around 300°F to 400°F.

Apply the Concentrate: Using a dab tool, place a small amount of concentrate onto the heated nail. Be careful not to use too much, as this can lead to a harsh hit.

Inhale the Vapor: Slowly inhale the vapor through the mouthpiece. Take your time to fully enjoy the flavors and effects.

Dabbing Techniques and Tips

Low-Temperature Dabbing

Low-temperature dabbing involves heating the nail to a lower temperature, typically between 300°F and 400°F. This method preserves the terpenes and cannabinoids in the concentrate, resulting in a smoother and more flavorful hit.

Cold Start Dabbing

Cold start dabbing involves placing the concentrate onto a cold nail and then heating it. This technique allows for a more controlled and flavorful hit, as it prevents the concentrate from burning.

Using a Carb Cap

A carb cap is a small device that fits over the nail to control the airflow. By limiting the airflow, a carb cap can enhance the flavor and smoothness of the hit. It also helps to conserve the concentrate, making it last longer.

Terp Pearls

Terp pearls are small glass or ceramic beads that can be placed inside the banger. They help to distribute the concentrate more evenly across the heated surface, ensuring consistent vaporization and enhancing the flavor.

Maintaining Your Dab Rig

Proper maintenance is essential for the longevity and performance of your dab rig. Here are some tips to keep your rig in top condition:

Clean Regularly

Use isopropyl alcohol and salt to clean your rig and nail. This will remove any residual reclaim and bacteria, ensuring a cleaner and more flavorful hit. Regular cleaning also helps to prevent the buildup of residue, which can affect the performance of your rig.

Change Water Frequently

Fresh water is crucial for a smooth and filtered hit. Change the water in your rig after each session or at least once a week. Stale water can harbor bacteria and affect the taste of your hits.

Inspect for Damage

Regularly inspect your rig for any cracks or damage. Glass rigs, in particular, can be prone to breakage if not handled carefully. Any damage can compromise the functionality and safety of your rig, so it's important to replace it if necessary.

Choosing the Right Dab Rig

Choosing the right dab rig depends on your personal preferences and needs. Here are some factors to consider:

Material

Glass: Glass dab rigs are durable, easy to clean, and preserve the flavor of your concentrates. They come in a variety of designs and sizes.

Silicone: Silicone dab rigs are virtually indestructible and easy to clean. They are lightweight and portable, making them a great choice for on-the-go use.

Ceramic: Ceramic dab rigs offer a gentle and consistent heat, making them ideal for low-temperature dabbing. They are also easy to clean and maintain.

Size

Standard: Standard-sized dab rigs are perfect for home use. They offer a comfortable and spacious experience, making them ideal for longer sessions.

Mini: Mini dab rigs are compact and portable. They are perfect for those who want a discreet and convenient option for on-the-go use.

Features

Quartz Bangers: Quartz bangers are known for their excellent heat retention and flavor preservation. They are a popular choice among dabbing enthusiasts.

Recyclers: Recycler dab rigs enhance the flavor and smoothness of the hit by cycling the vapor through the rig multiple times. They are perfect for connoisseurs who want the best possible experience.

E-Nails: E-nails offer precise temperature control, making them ideal for those who want a consistent and reliable experience. They eliminate the need for a torch, making them beginner-friendly.

Safety Considerations

Safety should always be a priority when using a dab rig. Here are some important tips to keep in mind:

Proper Heating

Ensure that the nail is heated to the correct temperature. Overheating can result in harsh hits and potential damage to the rig. For a smoother and more flavorful experience, aim for a lower temperature around 300°F to 400°F.

Ventilation

Use your dab rig in a well-ventilated area to avoid inhaling any residual fumes or smoke. Proper ventilation ensures a safer and more enjoyable experience.

Storage

Store your dab rig and concentrates in a secure location, away from children and pets. This helps to prevent accidents and ensures that your rig remains in good condition.

Cleanliness

Regularly clean your rig and dab tools to prevent the buildup of reclaim and bacteria. A clean rig ensures a safer and more flavorful experience. Use isopropyl alcohol and salt to clean your rig, and change the water frequently to keep it fresh.

Conclusion

Dab rigs offer a unique and enjoyable way to experience cannabis concentrates. Whether you're a beginner or an experienced dabber, there's a dab rig out there that's perfect for you. By understanding the basics, exploring different types, and following proper maintenance and safety guidelines, you can enhance your dabbing experience and enjoy all the benefits that concentrates have to offer. So, go ahead and find the perfect dab rig to suit your needs and preferences. Happy dabbing!

0 notes

Text

Nut Bolt Supplier for DIY & Professional Use

Nuts and bolts are essential components in construction, manufacturing, home improvement, and various industrial applications. Whether you're a DIY enthusiast working on household projects or a professional contractor managing large-scale operations, the quality of nuts and bolts significantly impacts the durability and safety of your work.

A reliable nut bolt supplier ensures that you get high-quality, corrosion-resistant, and precisely engineered fasteners for your needs. From small DIY home projects to large construction sites, choosing the right supplier guarantees efficiency, strength, and cost-effectiveness.

In this article, we will explore the importance of quality nuts and bolts, types of fasteners available, applications in various industries, and how to choose the best supplier for both DIY and professional use.

Importance of Quality Nuts and Bolts

Nuts and bolts serve as the backbone of mechanical assemblies, joining materials securely and ensuring structural integrity. Using substandard or low-quality fasteners can lead to mechanical failures, safety hazards, and increased maintenance costs.

Key Benefits of High-Quality Nuts and Bolts

✅ Durability – Made from strong materials like stainless steel, carbon steel, and brass, ensuring long-lasting performance. ✅ Corrosion Resistance – Coatings like galvanized, zinc-plated, and black oxide protect against rust. ✅ Precision Engineering – Ensures accurate fits, reducing the risk of loosening or failure. ✅ Versatility – Available in various sizes, thread types, and head shapes to suit different applications. ✅ Cost-Effective – Long-lasting fasteners reduce the need for replacements, lowering maintenance expenses.

Types of Nuts and Bolts Available

A good nut bolt supplier stocks a diverse range of fasteners to meet the requirements of both DIY users and professional contractors. Here are some of the most commonly used nuts and bolts:

1. Common Types of Bolts

🔹 Hex Bolts – Used in construction, machinery, and automotive industries. 🔹 Carriage Bolts – Ideal for wooden structures, fences, and furniture. 🔹 Anchor Bolts – Used in concrete structures for secure mounting. 🔹 Flange Bolts – Provide extra stability with a built-in washer. 🔹 Eye Bolts – Designed for lifting and load-bearing applications. 🔹 U-Bolts – Used for attaching pipes and tubing to surfaces.

2. Common Types of Nuts

🔹 Hex Nuts – The most commonly used nut, compatible with standard bolts. 🔹 Lock Nuts – Designed to prevent loosening due to vibration. 🔹 Wing Nuts – Easy to tighten by hand, used in quick-assembly projects. 🔹 Flange Nuts – Distribute pressure more evenly to prevent damage. 🔹 Cap Nuts – Provide a smooth, finished look while protecting from exposure. 🔹 T-Nuts – Used for woodworking and metal fabrication.

3. Specialty Nuts and Bolts

Some projects require custom or high-performance fasteners to meet industry-specific demands. Suppliers also offer:

🔹 High-Tensile Bolts – Used in structural and load-bearing applications. 🔹 Brass Nuts and Bolts – Known for corrosion resistance and aesthetic appeal. 🔹 Titanium Fasteners – Lightweight yet strong, ideal for aerospace and automotive industries. 🔹 Aluminum Fasteners – Used for applications requiring a lightweight solution.

Applications of Nuts and Bolts in DIY & Professional Use

1. DIY Home Projects

Homeowners, hobbyists, and DIY enthusiasts rely on nuts and bolts for various repair and improvement projects. Some common applications include:

✅ Furniture Assembly – Securely fastening wooden or metal components. ✅ Appliance Repairs – Fixing washing machines, refrigerators, and other home equipment. ✅ Home Decor & Fixtures – Hanging shelves, light fixtures, and wall-mounted equipment. ✅ Automobile Maintenance – Attaching accessories, replacing car parts, and general repairs.

2. Construction & Infrastructure

Nuts and bolts play a crucial role in the construction industry, ensuring the stability and durability of structures.

✅ Steel Structures – High-tensile bolts secure beams, columns, and framework. ✅ Bridges & Highways – Corrosion-resistant bolts ensure long-term safety. ✅ Commercial Buildings – Used in doors, windows, and foundation fixings. ✅ Railways & Airports – Heavy-duty bolts provide structural strength.

3. Industrial & Manufacturing Use

Factories and manufacturing units require reliable fasteners for machinery, production lines, and heavy equipment.

✅ Machinery Assembly – Fasteners hold together industrial machines. ✅ Automotive Production – Used in engine components, chassis, and vehicle frames. ✅ Electronics & Appliances – Small screws and bolts secure electronic devices. ✅ Heavy Equipment & Mining – High-strength bolts withstand extreme pressure.

4. Agriculture & Irrigation

Farmers and agricultural engineers use nuts and bolts for assembling farming equipment, greenhouses, and irrigation systems.

✅ Tractor & Equipment Repairs – Essential for maintaining farming tools. ✅ Irrigation Systems – Fasteners ensure stable water pipes and pumps. ✅ Greenhouse & Shed Construction – Secure structures against environmental factors.

How to Choose the Best Nut Bolt Supplier?

Finding a reliable nut bolt supplier is crucial for ensuring quality, affordability, and efficiency. Here are some factors to consider:

1. Product Quality & Certification

Ensure the supplier provides ISO-certified, ISI-marked, and ASTM-standard fasteners. This guarantees durability and compliance with industry standards.

2. Variety & Customization Options

A good supplier should offer a wide range of fasteners in different sizes, materials, and finishes. If needed, they should provide custom nut and bolt manufacturing.

3. Pricing & Bulk Discounts

Compare pricing from multiple suppliers and check if they offer wholesale rates, bulk order discounts, and flexible payment options.

4. Delivery & Availability

Fast and reliable delivery is essential, especially for professional contractors with tight project deadlines. Look for suppliers with efficient logistics and large inventory stock.

5. Customer Support & Technical Assistance

A reputable supplier should provide guidance on selecting the right fasteners and after-sales support for returns or replacements.

Top Nut Bolt Suppliers for DIY & Professional Use

Here are some leading nut bolt suppliers known for their quality, reliability, and affordability:

🔹 Unbrako – Offers high-strength industrial fasteners. 🔹 LPS (Lakshmi Precision Screws) – Known for precision-engineered fasteners. 🔹 TVS Fasteners – Supplies automotive, construction, and industrial bolts. 🔹 Hindustan Fasteners – Trusted for corrosion-resistant and heavy-duty fasteners. 🔹 Local Wholesalers & Distributors – Available in major cities like Delhi, Mumbai, Chennai, and Bangalore.

Conclusion

Choosing the right nut bolt supplier ensures that your DIY projects, construction work, and industrial applications are completed with strong, durable, and high-quality fasteners. Whether you're a home improvement enthusiast, an engineer, or a contractor, sourcing from a trusted supplier guarantees reliability, safety, and cost-efficiency.

When purchasing nuts and bolts, always consider product quality, variety, pricing, and supplier reputation to make the best decision for your needs.

#NutBoltSupplier#Fasteners#DIYProjects#ConstructionMaterials#IndustrialHardware#HighTensileBolts#ReliableSupplier#QualityFasteners#StrongConnections

1 note

·

View note

Text

Why Standard Titanium Co Leads in Titanium Tube and Sheet Solutions for Global Industries

In high-performance industries where strength, weight, and corrosion resistance matter most, titanium stands as a material of choice. From aerospace to medical, marine to chemical processing, titanium products are the backbone of innovation and reliability. Among the many suppliers around the globe, Standard Titanium Co has emerged as a leading force in delivering premium-grade titanium tubes and titanium sheets to meet the rigorous demands of today’s global industries.

In this blog, we’ll explore what makes Standard Titanium Co a preferred partner for titanium solutions, the unique benefits of titanium tube and sheets, and how these products are being used across sectors that require nothing short of excellence.

The Rise of Titanium in Modern Industry

Titanium is prized for its exceptional properties: it is lightweight yet extremely strong, corrosion-resistant, biocompatible, and able to withstand extreme temperatures. These qualities make it an indispensable material in sectors where ordinary metals like steel or aluminum might fail.

However, not all titanium is created equal—and choosing the right manufacturer is key to ensuring quality, consistency, and performance. This is where Standard Titanium Co sets itself apart.

About Standard Titanium Co

Standard Titanium Co is a globally recognized manufacturer and supplier of titanium and titanium alloy products. With a strong focus on engineering precision, quality assurance, and customer satisfaction, the company supplies a wide range of titanium forms, with a core focus on:

Titanium Tubes: Welded and seamless options in grades like Gr1, Gr2, Gr5, and more.

Titanium Sheets: Thin and thick sheet materials used in aerospace, medical, and industrial applications.

By combining state-of-the-art production technology with strict international standards (ASTM, ASME, AMS, etc.), Standard Titanium Co consistently delivers products that meet the toughest industrial requirements.

Titanium Tube: Lightweight Strength in Every Application

Titanium tubes are essential components in heat exchangers, condensers, exhaust systems, and chemical processing pipelines. They are particularly valued for their ability to:

Resist corrosion in seawater and chemical environments

Deliver high strength-to-weight ratios

Operate reliably at both sub-zero and elevated temperatures

Withstand high internal and external pressures

Common Applications of Titanium Tubes:

Aerospace: Hydraulic and pneumatic systems

Marine: Desalination plants and offshore structures

Medical: Surgical implants and hospital equipment

Chemical processing: Acid-resistant piping and heat exchangers

Standard Titanium Co offers seamless and welded titanium tubes in a variety of sizes and grades to suit specific project needs, with custom fabrication and precise tolerances available upon request.

Titanium Sheet: High-Performance Flat Material for Complex Fabrications

Titanium sheet are used when flat material is needed for fabrication, shielding, and structural components. They offer excellent workability, corrosion resistance, and fatigue strength.

Key Features of Titanium Sheets:

Excellent formability for stamping, folding, or laser cutting

High biocompatibility (perfect for medical and dental applications)

Resistance to chloride environments (ideal for marine use)

Superior performance in high-temperature aerospace conditions

Applications of Titanium Sheet:

Aircraft skin panels and components

Medical implants and prosthetics

Architectural cladding

Power generation turbine components

Industrial gaskets and washers