#Web Aligner for Liner Rewinder Machine

Explore tagged Tumblr posts

Link

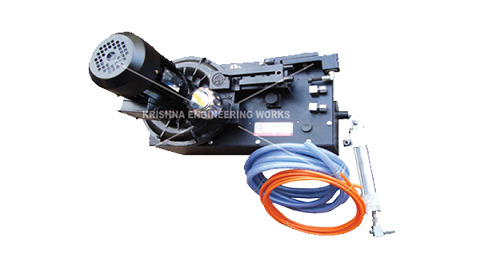

Krishna Engineering Works leading manufacturer of Web Guiding System for Liner Rewinder Machine. Web Guiding System for Liner Rewinder Machine, Web Guiding Systems are used to automatically guide all type of all type of flexible material of any width, under any load, at any seed. Web Guiding Systems which serves various application for all type of flexible printing, packaging & converting machineries. Web Guiding System for Liner Rewinder Machine available with Edge Guiding, aligner, Tracking Roller Assembly etc.

#Web Guiding System#Rewinding Machine with Web Guiding System#Web Aligner System Manufacturer#Unwinding Machine with Web Guiding System#Web Aligner for Liner Rewinder Machine#Web Aligner for Sheet Metal Industry#Web Aligner System#Web Guiding System for Liner Rewinder Machine

5 notes

·

View notes

Link

Web Aligner for Liner Rewinder Machine manufacturer. Web Aligner for Liner Rewinder Machine, Web Guiding Systems are used to automatically guide all type of all type of flexible material of any width, under any load, at any seed. Web Guiding Systems which serves various application for all type of flexible printing, packaging & converting machineries. Also Manufacturer of Web Guiding Systems available with Edge Guiding, aligner, Tracking Roller Assembly etc..

#Web Aligner for Liner Rewinder Machine#Aligner Unit#Web Guiding System#Web Guide System#Web Guide Systems#Web Guide#Web Guides#Web Guiding Unit#Web Guiding Units#Web Guide Unit#Web Guide Units

1 note

·

View note

Link

Web Master ”CONPAPTEX” Cord-aligner is centralizing device specially meant for Tyre Cord Aligner like Liner Re-Winder, Calendars, Dipping Plant, Let-off and Wind-up Stations. Web Master the unit consists of two numbers jointed axle bowed Rolls light duty or heavy duty as per application/fabric tension. Both side fabric edges are sensed sensor and take correction as required by jointed axle bow roll which works independently both sides by the sensing given by each side sensor.

#Tyre Cord Aligner#Tire Cord Machines#Liner Rewinder#Web Tyre Cord Aligner#Webmaster Machine Manufacturer#Technical Textile Machinery

1 note

·

View note

Link

We are a well-known Manufacturer Web Guide System, Power Brake is widely used to experience and understand the web psychology and behaviour. Our products are manufactured and designed using high quality material and cutting-edge technology for the better development of our products. Briefly, the coupling comprises of two concentric parts, the body or input part containing the field coil within it, separated by small annular gap, an inner rotor, or output part. The annular gap contains a ferromagnetic powder, which is activated when the coil is energized. The resultant flux which is generated , passes through the powder , causing it to align with the flux path , and there by creates a driving bond between input and output part , the strength of which is solely determined by value of D.C. current applied to the field coil.

#Power Brake#Web Aligner Unit#Web Guide System#Pneumatic Brake#Unwinding Machine with Web Guiding System#Rewinding Machine with Web Guide System#Hydro Pneumo Web Aligner System#Rubber Roller Manufacturer#Liner rewinding Machine#Slitter Rewinder Machine#Power Brake Supplier#Power Brake Manufacturer

0 notes

Link

We Are Manufacturers & Suppliers of Technical Textile Products. Fabric – Re – Rolling, winding, unwinding Machine with heavy duty equipment, Tyre Cord Machinery Exporter India. Heavy duty machinery manufacturer for tire Industry, all type of tyre cord, tire cord machines with high quality. Tyre-Cord and Technical Textiles Machinery, Liner Rewinder, Linear Drying, Inspection Machine, Tyre Cord Dipping Plant, Calendering Plant, Web Aligner.

2 notes

·

View notes

Link

Non-Woven Fabric Slitting Rewinding Machine Manufacturer, We engaged in Manufacturing various types of Slitter Rewinder Machine, Web Aligner. Non-Woven Fabric is slitted into different size of small Rolls in our Non-Woven Fabric Slitter Rewinder Machine, Textile Cloth and Fabric Slitter Rewinder Machine, Nylon Dipping Fabric Slitter Rewinder Machine, Geogrid Fabric Slitting Rewinding Machine, Liner Fabric Rewinding Machine, Polypropylene Liner Fabric Slitter Rewinder Machine. Our Non-Woven Fabric Slitting Rewinding Machine is able to process all types of Non-Woven Fabric of any thickness.

#Non-Woven Fabric Slitting Rewinding Machine#Fabric Slitting Rewinding Machine#Slitting Rewinding Machine#Slitting Rewinding Machines#Slitting Rewinding Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machines#Slitter Rewinder Machine Manufacturer#Slitting Rewinding#Slitter Rewinder#Geogrid Fabric Slitting Rewinding Machine#Liner Fabric Rewinding Machine#Polypropylene Liner Fabric Slitter Rewinder Machine

0 notes

Text

How are Plastic Bags Made? - XL Plastics

LPlastic bags enjoy their widespread popularity as they are exceptionally versatile and durable in terms of use. Plastic, otherwise known as poly bags, are extremely convenient and can be used to store food, carry goods and products, and can be Plastic Bag Machines re-used as trash liners or to collect waste, etc. They are especially popular because they are easy Bottom Seal Bag Making Machines to store and can be folded to fit any storage space, making them easily accessible when required. Once the extrusion process is completed, the product is sent to the conversion department for further processing. After the plastic is unwrapped, it is sliced with a heated knife that seals the sides while Side Seal Bag Making Machines the plastic sheet into the desired shape or size. Then, special characteristics are added for the completed product. This includes dies that are used to cutout the handles, T-Shirt Bag Making Machine wheels for production of gussets and various other features are added, those include the logo printing, and addition of seals are taken care of in this step to obtain the finished bag.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand.

Due to its varied number of uses as well as its durable nature, these poly bags can be re-used multiple times. The type of material used to produce these poly bags also allow for Center Seal Pouch Making Machine easy customization in terms of shape, style, size etc., making them the preferred material for everyday storage needs in various industries.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand.

The Extrusion Process :

The first step of the plastic bag making process is known as the extrusion process, where an extruder is used to heat polythene plastic resin pellets to a temperature of about 500 degree Fahrenheit. Once the pellets melt, a screw inside the extrusion machine pushes the molten plastic through the machine and into a die that controls the thickness of the product. The side seal bag making machine delivers Three Side Seal Pouch Making Machine up to 300 strokes / minute and is suitable for LDPE / HDPE / PP / BOPP films. There are a various attachments available for this machine to make a variety of bags like handle punch, pre sealer, bottom gusset, inside / outside lip former , lateral sealer, perforation, tape applicator for courier bags, web aligner etc.After which, the molten plastic is supplied with air to create a bubble, to initiate the cooling process. The air is then pinched PVC Label cutting machine out and the bubble is flattened to cut the film in the required size which is later wrapped on a spindle.

The Conversion Process :

Once the extrusion process is completed, the product is sent to the conversion department for PVC Shrink Label Sleeving further processing. After the plastic is unwrapped, it is sliced with a heated knife that seals the sides while cutting the plastic sheet into the desired shape or size. Then, special characteristics are added for the completed product. This includes dies that are used to cutout the handles, wheels for Plastic Bag Machines production of gussets and various other features are added, those include the logo printing, and addition of seals are taken care of in this step to obtain the finished bag.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and printing machinery. It seamlessly blends professional acumen Bottom Seal Bag Making Machines with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand.

Since the process is so simple and highly standardized, thousands of bags can be produced within Combined Pouch Making Machine short periods of time, at cost effective rates. The equipment used to produce these bags are also widely available and can be distinguished based on the type of plastic bag it produces. You can pick from a large variety of plastic processing equipment such as Bottom Seal Bag Machine, Side Seal Bag Machine, Soft Loop and Patch Handle Bag Machine, the T-Shirt Bag Making Machine, along with various other Special Purpose Bag Making Machines to name a few.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand.

This Multi-purpose pouch Machine converts a lay flat sheet of Laminated film of PET-PE, BOPP-PE into three side sealed pouches as well as Center seal , Lap seal pouches with various attachments. It’s a high-speed pouch machine with a maximum speed of 160 cycles / min.

Touch screen PVC Label cutting machine control for all functions Edge guiding system on unwinder for accurate folding Auto tension control system with load cell and particle brake on Unwind and Rewind Maximum web width of machine is 580 mm before Side Seal Bag Making Machines folding Air shafts on unwind and rewind Pneumatically operated Glue Dispenser unit

All you need to do is Center Seal Pouch Making Machine identify your bag making requirements and needs to select the right equipment.Over the years, we have successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go out PVC Shrink Label Sleeving of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors.

#Plastic Bag Machines#Bottom Seal Bag Making Machines#Side Seal Bag Making Machines#T-Shirt Bag Making Machine#Center Seal Pouch Making Machine

0 notes

Link

The Web Guiding System or Web Aligner system cannot work stand-alone without the help of supplied equipment’s or supporting Equipment. KEW Manufactures all types of Equipment that can be supplied along with Web Guiding System like Unwind Trolley, Rewind Trolley, Combined Unwinder Rewinder Trolley, Tracking Roller Assembly, etc.

#Aligner Unit#Web Guiding System#Web Guide Unit#Web Aligner for Liner Rewinder Machine#Web Guide#Tracking Roller#Hydro-Pneumo Web Aligner

0 notes

Link

KEW ENGG. & MFG. PVT. LTD. is one of the leading Manufacturers, Exporters, and Suppliers of Tyre - Cord & Technical Textiles Machinery, Textile Processing, Paper Industries, Plastic Packaging & Converting related machinery and equipment from India. High quality and Heavy Duty equipment for different types of Industry, application, and per client's requirements. We provide a whole range of products & machinery for all the industries that can be used from the inception of raw material to the end product/output for the customer. Liner Rewinder Machine with heavy duty and high quality equipment. Completely fabricated from Heavy Duty Chanel Angle structure of Rewinder Stand and Let-Off Stand Complete with pneumatic break and Safety Chucks. Fabric Re Rolling Machine is used for any winding & unwinding application for guiding the web to reduce the wastages of the material & to get high production output with minimum man power. Each Rollers designed for high quality and accurate thickness per requirement. Rubber sheet thickness determined by final roll gap. Rubber Roller for Tire Cord Machinery and Textile machinery spare parts. High quality and heavy duty Web Aligner for different types of machine and applications per client’s requirement. We have been manufacturing, exporting and supplying Web Aligner for with 0.5 hp and 1.0 hp for different machines per various industries like, flexible packaging, paper processing, tyre cord machinery etc.

https://youtu.be/u_nGlFcLaPA

#Flexible Packaging Machinery#Tyre Cord Machinery#Technical Textiles Machinery#Textile Processing Machinery#Paper Industries Machinery#Flexible Packaging & Converting Machinery and Equipment#Tyre cord manufacturer#Tyre Cord#Tire Cord Machinery price#Rewinder Machine#Slitter Rewinder Machine

0 notes

Link

Tyrecord Textile Machinery Manufacturer India, Liner Rewinder Machine with heavy-duty processing equipment, Tire Cord Machine for Tyre Industry. All type of Tyrecord Textile Machinery, Technical Textile Machine, Tyre Cord Machine with heavy duty process parts. International Standard of quality equipment. Tyrecord Textile Machinery for Tire Cord, Tyre Cord Industry. Liner Rewinder Machine, Cooling And Heating Drums, Hydro Pneumo Web Aligner System, Automatic Festoon Accumulator, Equipments For Calendering Plant.

#Tyrecord Textile Machinery#Tyrecord Textile Machinerys#Textile Machinery#Tire Cord Machine#Tire Cord Machines#Textile Machinerys#Tyre Cord Machinery#Tyre Cord Machinerys#Technical Textile Machinery#Technical Textile#Technical Textiles

0 notes