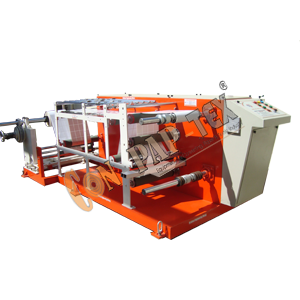

#Winding Rewinding Slitting Machine

Text

A paper tube cutting machine is a versatile and essential machine used in the paper industry. It is designed to cut large rolls of paper into smaller, more manageable rolls of desired width and length. This machine is crucial in various sectors, including printing, packaging, and converting industries.

Unwinding: The process begins with loading a large roll of paper onto the unwinding shaft. The machine then unwinds the paper roll at a controlled speed.

Slitting: The unwound paper is then passed through sharp blades or rotary knives that slit the paper into smaller widths. The number of blades can be adjusted based on the number of rolls required.

Rewinding: The slit paper is then rewound onto separate cores to form smaller rolls. The tension and speed of rewinding can be controlled to ensure the rolls are wound tightly and evenly.

Cutting: Some machines also have an integrated cutting mechanism that cuts the rewound rolls to the desired length.

Quality Control: Many Paper Slitter Rewinders come with built-in inspection systems that check for defects or irregularities in the paper.

The Paper Slitter Rewinder is known for its high efficiency, precision, and speed. It can handle a wide range of paper types and thicknesses, making it a versatile choice for businesses. With its robust construction and advanced features, this paper core machine ensures smooth and consistent operation, enhancing productivity and reducing waste. Whether you’re a small print shop or a large paper mill, a Paper Slitter Rewinder can be a valuable addition to your production line.

Paper Slitter Rewinder: Enhancing Efficiency in Manufacturing

The Paper Slitter Rewinder is a game-changer in the manufacturing industry, significantly enhancing efficiency and productivity. This machine is designed to transform large rolls of paper into smaller ones, tailored to specific requirements. Here’s how it contributes to manufacturing efficiency:

High-Speed Operation: paper tube winder machine operate at high speeds, capable of processing large volumes of paper in a short time. This speed significantly reduces production time, enabling businesses to meet high demand quickly.

Precision Cutting: With adjustable blades, the machine ensures precise and consistent cuts every time. This precision eliminates waste from inaccurate cuts, saving materials and costs.

Automation: Many models come with automated features, reducing the need for manual intervention. This automation not only saves labor costs but also minimizes human error, ensuring consistent quality.

Quality Control: With built-in inspection systems, the machine can detect and rectify defects or irregularities in the paper. This feature ensures that only high-quality paper rolls reach the end of the production line.

Space Efficiency: Despite its robust capabilities, the Paper Slitter Rewinder has a compact design that saves valuable floor space in manufacturing facilities.

By investing in a Paper Slitter Rewinder, businesses can significantly enhance their manufacturing efficiency. This core pipe-making machine not only speeds up the production process but also ensures the consistent quality of the final product, leading to increased customer satisfaction and profitability.

Paper Slitter Rewinders for Every Industry Need

Paper slitter rewinders play a pivotal role across diverse industries, addressing unique needs with precision and efficiency:

Printing Industry: In printing, these machines facilitate the production of custom-sized paper rolls, optimizing printing processes and reducing waste.

Packaging Sector: The packaging industry benefits from the adaptability of paper slitter rewinders, ensuring the creation of tailored rolls for various packaging applications, enhancing efficiency and minimizing material costs.

Converting Industries: Paper converting relies on these machines to transform large paper rolls into smaller, usable rolls with specific dimensions, meeting the requirements of different product lines.

Flexibility in Width and Length: The versatility of paper slitter rewinders allows for the customization of roll width and length, catering to the unique specifications of each industry and product.

Enhanced Productivity: With precise cutting and rewinding capabilities, these machines contribute to increased productivity, reducing downtime and enhancing overall operational efficiency in multiple sectors.

0 notes

Text

Top Benefits Of An Air Shaft In Manufacturing

The manufacturing industry-centric air shaft is employed for fitting into the core that wounds a variety of materials, including paper, cards, and plastic films. It readily expands on fitting into a core, leading to flawless operation during the manufacturing cycle.

Plenty of industrial converting machines employ the product. A slitting machine, widely known as a slitter rewinder has an air shaft in its core. It is basically designed to cut or slit large rolls of different types of material into smaller rollers. How does its engineering work? In this regard, you can connect with a reputed air shaft manufacturer.

An air shaft is also recognized by many other names in the industry circles, including air expandable shaft and air expanding shaft.

Salient Features of the Air Shaft

A premium quality air shaft displays the following salient features during application:

Competent to adjust to different speed variations

Proficient to adjust to different core widths

Demonstrates high speed, when repositioning of the product doesn’t happen

Efficient gripping

Efficient core centering

Manages uneven cores

For detailed information, collaborate with a prominent air shaft manufacturer in Ahmedabad.

Manufacturing Industries Drawing Benefits from the Air Shaft

Manufacturing industries galore are drawing benefits from mechanical product, including:

Packaging

Steel

Paper

As far as dimension of the air shaft is concerned, it is available in different dimensions. In case, you are searching for a custom-designed air shaft, you can collaborate with a reputed air shaft manufacturer.

Applications

An airshaft is a mechanical device designed for handling winding reels in the processing of web-fed materials.

0 notes

Link

#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder Machine

0 notes

Link

#Slitting Machine#Winding Rewinding#Slitting Machine With One Stage Slitting#Winding Rewinding Slitting Machine#Winding Rewinding Slitting Machine With One Stage Slitting

1 note

·

View note

Link

We are Manufacturer of Winding Rewinding Slitting Machine with Two Stage Slitting. Winder Machine manufacturer, Winding Rewinder Machine, heavy duty winding rewinding with slitting system manufacturer. Doctoring Rewinding, Doctoring Rewinding Table Top, Table Top Doctoring Rewinding,High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Winding Rewinding, Winding Rewinder Machine, Winder Rewinder Machine, Slitting Rewinding System, Doctoring Rewinder Machine, Doctor rewinder Machine.

#Winding Rewinding Slitting Machine#Winding Rewinding#Winding Rewinding Machine#Winding Rewinder Machine#Winding Rewinder#Winder Rewinder Machine#Slitting Rewinding System#Slitting Rewinding#Doctoring Rewinder Machine#Doctoring Rewinder#Doctor Rewinder Machine#Doctor Rewinder

0 notes

Link

Krishna Engineering Works Manufacturers, exports & supplies Table Top Doctoring Rewinding. Our Table Top Doctoring Rewinding Machine is used for all types of Laminates like, Foil, Paper, LDPE, HDPE, PVC, etc. Our Table Top Doctoring Rewinding Machine is manufactured with us most precision which ensure zero maintenance up to 10 years. We have been manufacturing various types of Doctoring Rewinding Machine for different industries and for different applications per client’s requirement. For more information contact our sales team: [email protected]

#Doctoring Rewinding Machine#Standard Doctoring Rewinding Machine#Table Top Doctoring Rewinding#High Speed Doctoring Rewinding#Heavy Duty Doctoring Rewinding#Doctoring Rewinding With Slitting System#Doctoring Slitting Rewinding#Doctoring Rewinding Winding Unwinding#Doctoring Rewinding Winding Rewinding For Batch Printing#Doctoring Winding Rewinding With Inkjet Printer#Industrial Inkjet Printer with Winder Rewinder Machine#Inspection Doctoring Rewinding Machine

4 notes

·

View notes

Link

Krishna Engineering Works is a leading manufacturer, exporter and supplier of Rewinding Machine, Roll-to-Roll Processing Machines for a variety of processes such as Rewinding Machine, Slitting, Docking Rewinding, Winding Rewinding, Rewinding Unwinding, Jumbo Roll to Small Roll Folding, etc. Different types of Winding Rewinding Machine with high quality and heavy duty equipment. Winding rewinding machine with 25 different types per client's application and industry specific requirements. Also a manufacturer of doctoring rewinding machine, Rotogravure printing machine.

#Winding Rewinding Machine for Inkjet Printer#Winding Rewinding Machine#Film Winder Rewinder Machine#Rewinder for Inkjet Printer#Industrial Inkjet Printer with Winder Rewinder Machine#Heavy Duty Doctoring Rewinding Machine#Doctoring Rewinding Machines#Doctoring Machine#Doctoring Re-Reeling Machine#Doctoring Inspection Machine with Slitting System

6 notes

·

View notes

Link

Krishna Engineering Works have been biggest successfully manufacturing & supplying all types of Jumbo Roll Slitting Rewinding Machine. Our Jumbo Roll Slitting Rewinding Machine required for its confirmed slitting and rewinding remuneration qualities with support International Standard. It is available in adjustable model to suit your requirement. Manufacturer of Jumbo Roll Slitting Rewinding Machine of all types of material like Plastic, Paper, Flexible Packaging, PVC, Aluminum Foil, Stretch Film, LDPE Film, BOPP Film, BOPP Tape, etc.

#Paper Slitting Machine#Jumbo Roll Slitting Rewinding Machine#Roll Rewinding Machine#Roll Winding Machine#Jumbo Roll Slitter Rewinder#Roll Slitter Rewinder#Roll Slitting Machine for Sale#Rewinding Machine#Slitter Rewinder#Slitting Rewinding Machine#Slitting Machine#Slitter Rewinder Machine#Slitting Machine Price#Heavy Duty Slitter

1 note

·

View note

Link

KEW ENGG MFG PVT LTD Trim Rewinder includes many features for high reliability of trim winding. Trim Rewinder is used for any winding and unwinding application that reduces material waste to guide the web and achieves high productivity with minimal manpower. Trim Rewinder Machine are highly appreciated by our customers and are widely used in a number of demanding applications in the converting industry.

#Trim Rewinder Machine#Trim Rewinder#Trim Winder#Trim Winder Machine#Trim Winder For Slitting Machine#Slitter Trim Winding Machine#High Speed Trim Winder Machine#High Speed Auto Trim Rewinder#Trim Film Rewinder#Semi-Automatic Trim Winder

1 note

·

View note

Link

Heavy Duty and Light Duty Metallized Polyester Film Slitter Rewinder Machine We are award winning company of Slitting Machine Manufacturer, Exporter. Different types of films like, Chemical Metallized Polyester Film, Metallized Polyester Film Slitter Rewinder Machine, Metalized Polyester Film, Synthetic Metallized Polyester Film, and Corona Metalized Polyester Film. All our slitter Rewinder machines designed with heavy duty and high quality equipment for different types of applications in various applications. Our machine is an ultimate Slitter and Rewinder Machine for its accurate slitting and rewinding qualities. It ensures perfect slitting of rolls with consistent, flawless results and constant line speed. It is available in adaptable model to suit your requirement. Our Slitter Rewinder Machine is available in Rewinder, Duplex surface slitter and Rewinder and Canti lever differential slitter and Rewinder. Our Slitting Rewinding Machine is renowned for its accurate slitting at a higher speed and vibration less working.

#Film Slitter Rewinder Machine#Slitting Machine#Slitter Rewinder Machine#Slitting Rewinding Machine#Slitter Rewinder#Slitter Machine#Slitters#Metallized Polyester Film Slitter#Slitter#BOPP Film#Paper Slitter Machine#Roll Slitting Rewinding Machines#Fabric Slitter Rewinder Machines#Winder Rewinder#Winding Rewinding Machine#Rewinder Unwinder Machine#Film Slitter Rewinder Machine Manufacturer#Film Slitter Machine Supplier

1 note

·

View note

Link

Web Guiding System Manufacturer, Rewinding Unwinding is a process to rewind - unwind your material available in roll form like, flexible packaging, film, paper, foil, etc. Rewinding Unwinding is a repetitive process with high accuracy to wind or rewind your material in roll form. Unwinding or Rewinding Machine designed and suitable for all types of machines like Roto Gravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Extruder Machine, Textile Machine, Tyre Machine, etc. Web Guiding System Manufacturer, Rewinding Unwinding, Web Guiding System, Slitting Rewinding Machine, Doctoring Salvage Rewinder, Salvage Rewinders, Slitter Rewinder Machine , Winding Rewinding, Web Guiding Salvage Rewinding, Web Guiding System Manufacturer

#Web Guiding System Manufacturer#Rewinding Unwinding#Web Guiding System#Slitting Rewinding Machine#Doctoring Salvage Rewinder#Salvage Rewinders#Slitter Rewinder Machine#Winding Rewinding#Web Guiding Salvage Rewinding

1 note

·

View note

Link

Doctoring Rewinding Machine manufacturer India, Reversible Rewinding Machine, Doctoring Slitting Machine, Heavy-duty Doctoring Rewinding Machine. Doctoring Rewinding Machines Manufacturer to make doctoring process for your flexible Packaging Roll with high quality equipment. Doctoring Rewinding Machines like, Standard Doctoring Rewinding Machine, Table Top Doctoring Rewinding, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Doctoring Rewinding with Slitting System, Doctoring Slitting Rewinding, Doctoring Rewinding Winding Unwinding.

#Doctoring Rewinding Machine#Doctoring Rewinding Machine Manufacturer#Winding Rewinding#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Doctoring Slitting Rewinding#Doctor Rewinder Machine#Doctor Rewinder Machine Manufacturer#Doctor Rewinder#High Speed Doctoring Rewinding#Heavy Duty Doctoring Rewinding

3 notes

·

View notes

Link

We have been manufacturing various types of Doctoring Rewinding Machine for separate industries and for different request per client’s requirement. Custom and proper Application for Doctoring Rewinding Machine, 28 separate type of Doctoring Rewinding Machine Manufacturer, exporter, supplier. Doctoring Rewinding Machine with Slitting System like, Standard Doctoring Rewinding Machine, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Doctoring Rewinding with Slitting System, Table Top Doctoring Rewinding etc.

#Doctoring Rewinding Machine#Doctoring Machine#Doctoring Rewinding Machine with Slitting System#Doctoring Rewinding Machine Manufacturers#Inspection Machine#Doctoring Rewinding Machine Price#Heavy Duty Doctoring Rewinding Machine#Film Winder Rewinder Machine#Winding Rewinding Machine#Slitting Rewinding Machines

7 notes

·

View notes

Link

We CON-PAP-TEX are been successfully Manufacturing, Exporting & Supplying all types of Heavy Duty Doctoring Rewinding Machine and Winding Rewinding Machine for Inkjet Printer & Batch Printing, Slitter Rewinder Machine at best price. Doctoring Rewinding Machine industrialist to make doctoring process for your flexible Packaging Roll with high-quality equipment. It is actually designed and built for the heavy-duty procedure of doctoring rewinding.

#Doctoring Rewinding Machine#Doctoring Machine#Heavy Duty Doctoring Rewinding Machine#Inspection Rewinding Machine#Rewinding Machine#Rewinding Machine Price#Automatic Rewinding Machine#Heavy Duty Winding Rewinding Machine#Doctoring Inspection Machine with Slitting System#Winding Rewinding Machine#Doctoring Rewinding#Winder Rewinder#Slitter Winder

1 note

·

View note

Link

Krishna Engineering Works we have been manufacturing, exporting, and supplier of all types of Doctor Re Reeling Machine, Doctoring Rewinding Machine, Inspection Rewinding Manufacturer, Winding Rewinding Machine. We have designed and built for accuracy for doctoring use with air brake with reel diameter, Edge Guide with actuator for the Unwind reel, Air shafts for Doctoring Re Reeling Machine units. It is used to salvage badly rewound coils produced on the Slitting and Rewinding Machine.

#Doctoring Re Reeling Machine#Doctoring Slitting Machine#Winding Unwinding Machine#Unwinding & Rewinding Machine#Inspection Doctoring Rewinding Machine#Doctoring Rewinding Machine#Fabric Winding Machine#Inspection Rewinding#Automatic Reeling Machine Price#Textile Reeling Machine#Industrial Slitting#Winding Rewinding Machine#Film Winder Rewinder Machine#Doctoring Inspection Machine

5 notes

·

View notes

Link

KEW ENGG. & MFG. PVT. LTD. have been manufacturing, exporting and supplying various types of Winding Rewinding Machine. Different types of Winding Rewinding Machine with high quality and heavy duty equipment. Winding Rewinding Machines Like, Film Winding Rewinding For Batch Coding, Winding Rewinding For Batch Printing, Winding Rewinding With Inkjet Printer and with Multihead Inkjet Printer, Winding Rewinding With Thermal Transfer Overprinter, Doctoring Film Strip Winding Rewinding, Winding Rewinding With and Without Slitting System, Coil Winding etc.

#Film Winding Rewinding Machine For Batch Coding#Rewinding Machine#Film Winding Rewinding For Batch Coding#Winding Rewinding For Batch Printing#Winding Rewinding With Inkjet Printer#Winding Rewinding With Thermal Transfer Overprinter#Doctoring Film Strip Winding Rewinding#Winding Rewinding With and Without Slitting System#Doctoring Rewinding Machines#Heavy Duty Doctoring Rewinding Machine#Film Winding Rewinding Machine#Doctoring Rewinding Machine#Winding Unwinding Machine#Roll to Roll Rewinding Machine#Automatic Roll Rewinder Machine#Inspection Winding Rewinding Machine

1 note

·

View note