#Wool Processing

Explore tagged Tumblr posts

Text

I made a thing!

Last year I bought a pair of "used" carders. Fabulously discounted, even before they were marked down.

They were, unfortunately, not in a usable condition. Despite that, I still tried to use them as is.

The tines are broad, thick, and shorter than modern carders. The leather the tines are mounted to is dry and crumbles when you touch it. When you run your fingers across the tines, they are loose and jiggle more leather dust free.

They might have been fine as decorative pieces, but i have really been looking for a pair of hand carders, and I would love to own a functional pair.

So it went onto my shelf for ten months. Occasionally, I picked them up and would think about what I could do for these carders.

Then I started looking at blending boards and wondered if they sold the cloth by itself. And it is!

Terribly unhelpful product information, but i took a couple measurements and decided it would be big enough to cover both the carders. It was a bit of a risk as it did not say the TPI, but I decided that if it was not what I wanted for this project, I could put it on my shelf for a future (inevitable) project.

The cloth arrived, and I got a TPI count of 72, which is actually what I was hoping for. A good count for medium to fine wool, I believe.

So I removed the existing carding cloth and sanded down the wood of the handles. It very much needed the sanding.

After sanding, there was a lovely woodgrain visible on the carders. I decided that staining them would help protect the wood itself, but I did not want to cover up the grain.

I chose a white oak stain that I already have and stained them.

Once they dried, I cut the cloth to shape, put glue on both the face of the carder and the back of the cloth. Then I glued them together, let them dry, then used a staple gun to really attach the cloth to the carders.

I now have functional hand carders!

157 notes

·

View notes

Text

Been a couple days but I've been a busy bee!

The Shetland Cheviot fleece I ordered came in a couple days ago and I've been working on scouring it! It cleans up really well!! It's slow going but I'm having fun. Wool combs are on pause while I wash it, because I don't want it sitting unwashed for longer than it Has to, but we'll get there!

I got this fleece on eBay from the island farm shop up in Orkney. I don't know enough about fleeces to say much on it, to be honest, but it's been nice enough to work with and cleans up really well. I'm enjoying it even if it's hard work!

#perrin says#Penryth; baby's first fleece#hand spinning#wool processing#hand crafts#idk what tags people use for this but oh well! i hope you enjoy :3

57 notes

·

View notes

Text

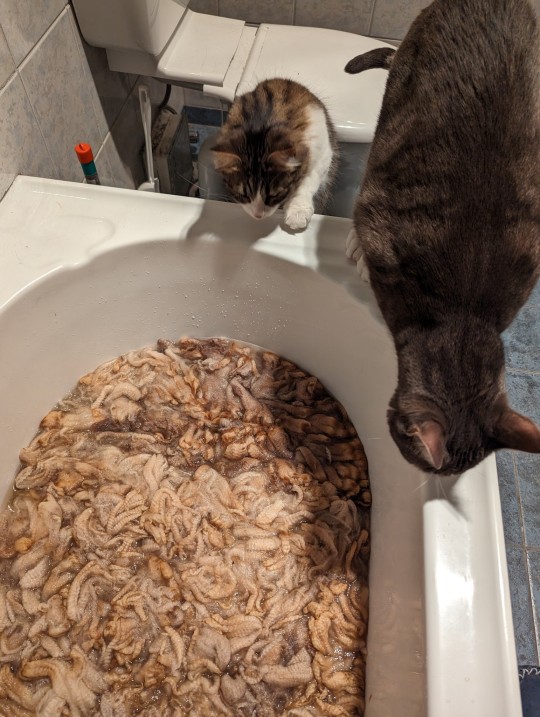

Why do cats love wool so much?

I was washing some fleece today (as you do) and one of my cats literally climbed into the storage bin with the wool. I wish I had pictures.

Then the whole time I was trying to pick locks he kept trying to run off with bits of fleece. I had to work in a little corner so he couldn't steal bits.

Because he eats it and that is not the kind of fiber he needs in his diet. Also because it's raw wool and it's disgusting. Also because I don't want him running off with my wool.

I did not get as much done as I'd wanted, but I did wash some and I have more ready to wash tomorrow.

12 notes

·

View notes

Text

Got bored and messed around, found out natural henna powder when made into a thin soupy consistency is AMAZING at dying/staining wool!! I assumed it would do *something* because it dyes skin and hair so well, but I didn't expect such a vibrant color so quickly! I don't know how well it'll last or anything since I'm just getting into fiber arts/textile arts, but like look at this color😍 This is JUST raw (washed) wool dipped into the 'liquid' for all of maybe 10 minutes and rinsed, no mordant or anything of the sort. Needless to say I think the experiment is a success lmao

#spinning#spinning wheel#wool#dyeing#dye#henna as dye#dyed wool#hand dyed wool#hand spinning#fiber arts#textile arts#textile work#sca#henna#raw wool#wool processing#dyeing wool#drop spindle#spinning wool#yarn#hand dyed yarn#dying yarn#yarn making#crochet#knitting

10 notes

·

View notes

Text

I thought, that I should probably look at how much weight the fleece lost, after cleaning. And also give a soft of report about the amount of water and energy used, and his clean it got.

Under the cut, because looooooong

Roughly 100g raw fleece, cleaned with unicorn power scour made 75,29g of fiber

Very clean, zero amount of oil or lanolin can be feeled, smells like wool and a but like the power scour. Doesn't feel felted. The ends are a tad yellow

Recourses: Used 2 liters if the hottest available tabwater (47°C), 3,8g of unicorn power scour and roughly 8 liter of hot water to rinse (around 38°C-40°C).

Work: let it soak and rinse it out. Very easy, not much Equipment or brain power needed

Roughly 100g raw fleece, cleaned with homemade chestnut detergent made 77,50g of fiber

Still dirt left, we'll see how it cleans out while combing and caring, there seems to be a minimal amount of lanolin left, but it's so little I am not Shure. Ends are almost brown. Also smells kind of bad

Recourses: 5 chestnuts peeled and cut, simmered with 300ml for 15 minutes, 2l of my hottest tab water, around 8 liters for rinsing.

Work: collecting, Peeling and cutten the chestnuts, then soaking and rinsing the wool.

Roughly 100g raw fleece, cleaned with potash made 79,95g of fiber

Very clean, no traces of oil or lanolin. Smells like clean wool, ends very compacted still, also the most felted from all the projects (not badly felted though)

Recourses: 60g potash (had to order it online, not even the alternative apothecary had it), 3 liter of cold water to rinse it beforehand, 2 liter of hot water to simmer it, something to simmer the wool in and 6 liter to rinse

Work: the most workintens process, aquire the potash, rinse the wool, simmer it (but not to hot, so you need something to monitor the temperature) rinse it again... but you can reuse the potash water lots. So good if you want to clean lots of wool, but I think it's also the one where you can make the most mistakes...

Roughly 50g raw fleece, cleaned with dish soap made 39,67g of fiber

No lanolin left, smells clean, not too yellow, but some dirt was left. Not felted

Recourses: around a table spoon of dish soap, 2 liter of hot tabwater, 4 liter of tabwater to rinse

Work: soak and rinse very easy

Roughly 50g raw fleece, cleaned with wool fiber detergent made 38,85g of fiber

Very clean, almost now yellowijg, smells like wool and hint of the detergent we use, not felted

Recourses: 60ml (one serving?) Of wool laundry detergent, 2 liter of hot tab water and 6 liter to rinse

Work: soak and rinse again

Now to the most Interesting method imo!

The suint fermentation

Roughly 50g raw fleece, cleaned with fermentating it in destilled water made 40,31g of fiber

Very clean, despite some lanolin left, the whitest of them all, not felted very soft, smells the most like wool (it's a bit dirty because I dropped it on the balcony floor)

Recourses: well I bouth a black bucket with a lid So I can do it without smell attacking my neighbors, 2 liter of destilled water (or rain water, but I can't really collect that) 4 liter to rinse (same temperature as the suint bath

Work: fill the bucket with water and wool. Then wait, rinse and let it dry in the sun (so it goes faster) I didn't mind the smell to much. You mostly smell it when you open the bucket and while rinsing, after that it vanished very fast. Needed the least amount of energy.

Roughly 50g raw fleece, cleaned with fermentating it in hard tab water made 40,66g of fiber

A bit more lanolin that the destilled water. Not Shure if that is due to the harder water or that the weather got colder and I had to stop. Very soft to the touch. A bit more yellow in the tips than the destilled water and smells like wool but in an unpleasant way (not really bad, but also nothing I want to shove my nose into)

Recourses: same as destilled water but ran water

Work: also same as destilled water

All in all, I loved the fermentation the most, also I heard that you can store the bath over a year, so you can make it in time warm season and just store it for the next?? Very cool. Feels raw in the same way that spinning the locks without combing or carding. 10/10 also very recourses friendly, doesn't take lots of energy (body, brain and electric) and the least amount of work (the most work I had with it was setting up my very safe totally not dangerous way of drying it)

My least favorite was the potash, it's lots of extra steps like: getting everything out of storage to simmer it, get some potash (that you'll need lots of) let it simmer for 8 minutes, let it rest for 8 and then rinse! If you have a dedicated space for it, it could be very easy, but I don't have that space 😬

Unicorn power scour is also good. Got it very clean, was very easy and no unpleasant smells, also very fast.

80 notes

·

View notes

Text

Learning Process no. 1.2: Extracting lanolin from sheep wool

I'm trying to different processes for extracting lanolin

Cold prewash: I've washed it 4 times while it has soaked for a few hours about 5.

"The wool grease is continuously removed during this washing process by centrifugal separators, which concentrate it into a wax-like substance melting at approximately 38°C" - Sengupta, Amit; Behera (2014). "Comprehensive view on chemistry, manufacturing & applications of lanolin extracted from wool pretreatment,also used in vitamins" (PDF). American Journal of Engineering Research (AJER).

That means the cold wash may still have the lanolin oil

I possibly have to investigate how to do some centrifugal separation?

Boiled: I would prefer not to use this method as i understand from my research that the wool will not be useable after having it boiled. "Wool felt melts between 105 and 110F" - p. 50. the Big Book of Handspinning by Alden Amos

The water needs to boil for a few hours.

I'm reading from different sources especially this thread on permies.com

https://permies.com/t/65837/extract-lanolin-wool#2624426

And watched different videos on YouTube:

Extracting Lanolin from Sheep's Wool, Edwardian Farm

https://www.youtube.com/watch?v=d2pEIsyWD-Y

Lanolin extraction from Sheep's wool DIY : My learning Process, homemade from scratch

https://www.youtube.com/watch?v=xoH3Cv5AS4A&t=635s

If you have some knowledge to share, please do! It will be much appreciated

#Learning Process#Lanolin Extraction#Sheep Wool#Cold Prewash#Centrifugal Separation#Wool Processing#DIY Skincare#Natural Fibers#Sustainable Living#Wool Crafts#Handmade Textiles#Crafting Journey#Lanolin Research#Textile Science#Wool Grease#Lanolin DIY#Permaculture#Fiber Arts#Natural Oils#YouTube Resources#Wool Care#KnittersOfTumblr

7 notes

·

View notes

Text

Hot take but TERFs and Zionists and shit shouldn’t be welcomed. Anywhere. I don’t care if “this is a bird group, we need to keep it welcoming and free of politics!!” Get the fuck out of here.

#ornithology#aviculture#birdwatching#beekeeping#apiary#sheep#wool processing#crafts#needlework#all communities Im in

4 notes

·

View notes

Text

Batts up top, roving below, and rolags in the bottom. Batts are the fastest, rolags are the longest, and each has different outcomes.

8 notes

·

View notes

Text

Any people with sheep in the central florida area willing to sell wool to me?

I'm willing to clean and process it myself - I want to try making my own wool batting for quilts. But I can't have the damn cute things in my back yard ( not enough space, HOA would also say no).

If you also know cheaper ways to get 100% wool for quilt batting let me know too ( that stuff is expensive); but yeah I'm happy to throw money at local people who can give wool.

Is there like a network or forum I can join of sheep farmers willing to sell wool? Come on guys, we gotta keep the sheep people in business!!!

#sheep#sheep farmers#wool#quilting#wool batting#local trade groups#florida farming#farming groups#florida#tell me your sheep wool secrets#local buy sell trade#support local farmers#quilting to sheep farmer pipeline#wool processing

5 notes

·

View notes

Text

i keep forgetting to post things, but look! last batch of wool that needed washed is drying now.

15 notes

·

View notes

Text

Just got a pair of wool combs to help me process this bit of Gotland fleece, and holy fuck I love them. Wasn't happy working with how the hand carders on this one, and just picking by hand was still giving me a lot of uneven slubby-ness, but the combs are great for fluffing and straightening the fibers so they draft out without much fuss. With any luck I'll spin through the last of this one tonight. Then tomorrow I can wash either the Gestrike or the Värmland wool.

From left to right- loaded comb not yet combed through, comb with wool already combed and ready to spin, trusty drop spindle, two singles waiting for a third for plying, small hank of chain-plied yarn ready for a soak to set the twist.

24 notes

·

View notes

Text

Turned some gotland locks into rollags

18 notes

·

View notes

Text

Jet Dyeing Machines Market Set to Hit $1569.3 Million by 2035

The Jet Dyeing Machines market is projected to experience substantial growth, with industry revenue estimated to rise from $596.0 million in 2024 to $1569.3 million by 2035. This growth represents a Compound Annual Growth Rate (CAGR) of 9.2% from 2024 to 2035. As industries across the globe adopt advanced technologies and prioritize sustainability, the demand for Jet Dyeing Machines is expected to surge, driven by key applications such as textile dyeing, wool processing, plastic coloring, and leather treatment.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/jet-dyeing-machines-market-research-report

Key Applications Driving Market Growth

Jet Dyeing Machines are critical in a wide range of applications where precision and efficiency are necessary. The major sectors relying on these machines include:

Textile Dyeing: Essential for the mass production of textiles, ensuring uniform and high-quality dyeing for fabrics used in various industries, including fashion and home textiles.

Wool Processing: Used to achieve optimal dyeing for wool fibers, which are sensitive to heat and require gentle treatment.

Plastic Coloring: Important in the plastic industry for achieving consistent and uniform coloring of plastic materials.

Leather Treatment: Plays a vital role in achieving consistent dyeing results for leather products, which are used in fashion, furniture, and automotive industries.

Industry Leadership and Competitive Landscape

The Jet Dyeing Machines market is characterized by fierce competition, with several leading players such as Thies GmbH & Co. KG, Fong's Industries Company Limited, Sclavos TVE ESCE, Brazzoli S.p.A., CHTC Fong's International Co. Ltd., Jeanologia S.L., and others dominating the market. These companies are actively innovating and expanding their operations to meet growing demand across multiple industrial sectors.

Technological advancements in jet dyeing machines, coupled with the rise of sustainable manufacturing processes, are expected to significantly drive the market's expansion. Efficiency improvements, reduced water consumption, and enhanced dye quality are key areas where innovation is helping to capture more market share.

Growth Opportunities in Emerging Markets

The Jet Dyeing Machines market presents substantial growth opportunities in emerging markets, where rapid industrialization, urbanization, and increasing environmental concerns are driving demand for more efficient and sustainable dyeing solutions. Key countries such as China, India, Germany, U.S., and Italy continue to lead the market, while emerging markets like Vietnam, Ethiopia, and Bangladesh represent significant revenue opportunities for manufacturers.

Regional Shifts and Evolving Supply Chains

North America and Europe are the two primary regions driving the demand for Jet Dyeing Machines. These regions benefit from high industrialization levels and technological advancements in manufacturing processes. However, the market dynamics are shifting as manufacturers look to streamline their supply chains and cater to the growing demand in emerging markets. Challenges such as high equipment costs, regulatory hurdles, and environmental concerns are also pushing the market to evolve.

Emerging markets such as Vietnam, Ethiopia, and Bangladesh are expected to present strong opportunities for revenue diversification and Total Addressable Market (TAM) expansion as local industries adopt more advanced technologies to meet the increasing demand for high-quality and eco-friendly dyeing processes.

Future Outlook

The Jet Dyeing Machines market is set to undergo significant growth over the next decade, driven by technological advancements, sustainability trends, and expanding industrial automation. The adoption of green dyeing technologies and improvements in dyeing efficiency will continue to play a critical role in shaping the future of the market. With the strategic expansion into emerging markets and a focus on technological innovation, the Jet Dyeing Machines market will likely witness substantial transformation, presenting new opportunities for both established players and new entrants.

About DataString Consulting

DataString Consulting is a global leader in market research and business intelligence, offering comprehensive solutions for both B2B and B2C markets. With more than 30 years of combined experience in market research and strategy advisory, DataString Consulting provides tailored services designed to meet the specific needs of businesses across various industries.

Through its unique approach to market research and insights, DataString helps clients navigate emerging market trends, optimize strategies, and unlock new opportunities in an ever-evolving marketplace.

#Jet Dyeing Machines#Textile Machinery#Textile Dyeing#Industrial Dyeing Equipment#Dyeing Technology#Textile Manufacturing#Sustainable Dyeing#Wool Processing#Plastic Coloring#Leather Dyeing#Industrial Automation#Eco-Friendly Dyeing Solutions#Fabric Dyeing Machines#Textile Industry Trends#Dyeing Machine Market Forecast#Emerging Markets#Market Research#DataString Consulting#Industrial Equipment Market#Global Textile Market

0 notes

Text

Today I started the experiment!

Filled up a black bucket with 2l of distilled water and 50g of raw fleece! Now we wait for the warmth and microbes to do the rest!

And

100g washed with power scour from unicorn fiber

I used 3.8ml of power scour on 2 liters of water 47°C for 100g raw fleece, and needed to rinse 4 times with 2 liters of water roughly 38 to 40°C each time.

Geels, looks and smells already very clean. Vegeta let matter will be carded and combed out later

(left raw fleece and left from the washed fleece)

87 notes

·

View notes

Text

hello friends and strangers! i have been washing wool

i've been half-heartedly spindle-spinning for a few years now and the way i frequent stores that sell secondhand craft things means i've just kind of Acquired a variety raw fleece. also (very exciting) i bought a lovely little third-hand ashford traditional spinning wheel off the internet a few weeks ago and the person who sold it to me gave me a couple giant trash bags of unprocessed fiber with it ("... are you sure you want this?" like the wool under all that hay isn't soft and finely crimped).

unwashed wool is really gross. i'm a city kid and most of my nature ventures as a youth were into desert, not farm. i feel that i wouldn't mind cleaning the poop quite so much if i knew the animal and it wasn't, y'know, mystery anonymous poop. alas. most of the wool i have was at least little bit cleaned and skirted before it came to me but one of the big trash bags i got with the spinning wheel was full of not only anonymous poop but also anonymous plant burrs and anonymous insect eggs and anonymous live moths which i fear have infected my entire apartment and i WILL be investing in mothballs as soon as i next get to the hardware store.

my process for washing has been thus:

wash one: fill my big dye pot with a few inches of the hottest water from the tap and a few swirls of dish soap. stuff my singular mesh bag (ostensibly for washing lingerie but i bought it from a bin of various 50c drawstring pouches so i kind of doubt any one has ever put anything frilly in it) with a reasonable amount of wool, press it into the water, let sit 15+ minutes.

wash two: repeat with less dish soap

wash three because after wash two invariably the water was still running the kind of brown i would rather forget and actively decided not to document: repeat with less dish soap

wash four: with a healthy glug of white vinegar

roll and press into a towel to remove excess water. (the instructions always say to use "an old towel" for these kinds of things like everyone has a surplus of linen hanging around. towels even from the thrift store cost upwards of $8 each these days, you know. all my towels get regular use! although i do have one dedicated for craft things.)

drape over a partially disassembled cardboard box on the counter near the window for a few days to dry.

repeat until the whole fleece is clean.

(the hanger is for drying my finishing handspun skeins. and YES that navajo-churro wool looks horrifyingly like human hair. i felt like a serial killer caring for my trophies while cleaning it in the worst possible way.)

i've been putting this off for a while so i had the big trash bag, two lamb fleeces, and a few other bits to wash. it took about a week to get through all of it (even though i'm unemployed and have a lot of time on my hands). there's something uniquely exhausting about having to get up every 15 minutes to run the tap and wait for the water to get hot, again.

my two lamb fleeces: navajo-churro still looking like human hair on the left and a border leicester mix on the right.

i've mostly been referencing Maggie Casey's Start Spinning and Judith MacKenzie McCuin's The Intentional Spinner for my learning, by the by. they're just what i have / what looked good at the library, so i can't attest to these books being better than any others but they've been serving me fine.

do i really know what i'm doing? no. but i don't mind spinning poorly. people have been spinning poorly for as long as spinning has existed. and, i'm having fun. although i am very glad to be done with this step (for now) and looking forward to being able to use my dye pot for dyeing all of my clothes black again, as is its intended purpose.

#long post#p.s. i plan to be posting more stuff like this here in future#ah i know some people don't like looking at the piles of wool so if that's you please block:#raw wool#wool processing#p.s. i don't mind getting advice from more experienced fiber-ists. consider advice not unsolicited although i reserve the right to ignore#textiles

1 note

·

View note

Text

My new flicker is very bitey. I am getting better at the floof though.

10 notes

·

View notes