#addition:

Explore tagged Tumblr posts

Text

Engineers 3D print the electromagnets at the heart of many electronics - Technology Org

New Post has been published on https://thedigitalinsider.com/engineers-3d-print-the-electromagnets-at-the-heart-of-many-electronics-technology-org/

Engineers 3D print the electromagnets at the heart of many electronics - Technology Org

Imagine building an entire dialysis machine using nothing more than a 3D printer.

Caption:MIT researchers modified a multi-material 3D printer so it could produce three-dimensional solenoids in one step by layering ultrathin coils of three different materials. It prints a U.S. quarter-sized solenoid as a spiral by layering material around the soft magnetic core, with thicker conductive layers separated by thin insulating layers. Illustration by the researchers

This could not only reduce costs and eliminate manufacturing waste, but also since this machine could be produced outside a factory, people with limited resources or those who live in remote areas may be able to access this medical device more easily.

While multiple hurdles must be overcome to develop electronic devices that are entirely 3D printed, a team at MIT has taken an important step in this direction by demonstrating fully 3D-printed, three-dimensional solenoids.

Solenoids, electromagnets formed by a coil of wire wrapped around a magnetic core, are a fundamental building block of many electronics, from dialysis machines and respirators to washing machines and dishwashers.

The researchers modified a multimaterial 3D printer so it could print compact, magnetic-cored solenoids in one step. This eliminates defects that might be introduced during post-assembly processes.

This customized printer, which could utilize higher-performing materials than typical commercial printers, enabled the researchers to produce solenoids that could withstand twice as much electric current and generate a magnetic field that was three times larger than other 3D-printed devices.

In addition to making electronics cheaper on Earth, this printing hardware could be particularly useful in space exploration. For example, instead of shipping replacement electronic parts to a base on Mars, which could take years and cost millions of dollars, one could send a signal containing files for the 3D printer, says Luis Fernando Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories (MTL).

“There is no reason to make capable hardware in only a few centers of manufacturing when the need is global. Instead of trying to ship hardware all over the world, can we empower people in distant places to make it themselves? Additive manufacturing can play a tremendous role in terms of democratizing these technologies,” adds Velásquez-García, the senior author of a new paper on the 3D printed solenoids that appears in the journal Virtual and Physical Prototyping.

He is joined on the paper by lead author Jorge Cañada, an electrical engineering and computer science graduate student; and Hyeonseok Kim, a mechanical engineering graduate student.

Additive advantages

A solenoid generates a magnetic field when an electrical current is passed through it. When someone rings a doorbell, for instance, electric current flows through a solenoid, which generates a magnetic field that moves an iron rod so it strikes a chime.

Integrating solenoids onto electrical circuits manufactured in a clean room poses significant challenges, as they have very different form factors and are made using incompatible processes that require post assembly. Consequently, researchers have investigated making solenoids utilizing many of the same processes that make semiconductor chips. But these techniques limit the size and shape of solenoids, which hampers performance.

With additive manufacturing, one can produce devices that are practically any size and shape. However, this presents its own challenges, since making a solenoid involves coiling thin layers made from multiple materials that may not all be compatible with one machine.

To overcome these challenges, the researchers needed to modify a commercial extrusion 3D printer.

Extrusion printing fabricates objects one layer at a time by squirting material through a nozzle. Typically, a printer uses one type of material feedstock, often spools of filament.

“Some people in the field look down on them because they are simple and don’t have a lot of bells and whistles, but extrusion is one of very few methods that allows you to do multimaterial, monolithic printing,” says Velásquez-García.

This is key, since the solenoids are produced by precisely layering three different materials — a dielectric material that serves as an insulator, a conductive material that forms the electric coil, and a soft magnetic material that makes up the core.

The team selected a printer with four nozzles — one dedicated to each material to prevent cross-contamination. They needed four extruders because they tried two soft magnetic materials, one based on a biodegradable thermoplastic and the other based on nylon.

Printing with pellets

They retrofitted the printer so one nozzle could extrude pellets, rather than filament. The soft magnetic nylon, which is made from a pliable polymer studded with metallic microparticles, is virtually impossible to produce as a filament. Yet this nylon material offers far better performance than filament-based alternatives.

Using the conductive material also posed challenges, since it would start melting and jam the nozzle. The researchers found that adding ventilation to cool the material prevented this. They also built a new spool holder for the conductive filament that was closer to the nozzle, reducing friction that could damage the thin strands.

Even with the team’s modifications, the customized hardware cost about $4,000, so this technique could be employed by others at a lower cost than other approaches, adds Velásquez-García.

The modified hardware prints a U.S. quarter-sized solenoid as a spiral by layering material around the soft magnetic core, with thicker conductive layers separated by thin insulating layers.

Precisely controlling the process is of paramount importance because each material prints at a different temperature. Depositing one on top of another at the wrong time might cause the materials to smear.

Because their machine could print with a more effective soft magnetic material, the solenoids achieved higher performance than other 3D-printed devices.

The printing method enabled them to build a three-dimensional device comprising eight layers, with coils of conductive and insulating material stacked around the core like a spiral staircase. Multiple layers increase the number of coils in the solenoid, which improves the amplification of the magnetic field.

Due to the added precision of the modified printer, they could make solenoids that were about 33 percent smaller than other 3D-printed versions. More coils in a smaller area also boosts amplification.

In the end, their solenoids could produce a magnetic field that was about three times larger than what other 3D-printed devices can achieve.

“We were not the first people to be able to make inductors that are 3D-printed, but we were the first ones to make them three-dimensional, and that greatly amplifies the kinds of values you can generate. And that translates into being able to satisfy a wider range of applications,” he says.

For instance, while these solenoids can’t generate as much magnetic field as those made with traditional fabrication techniques, they could be used as power convertors in small sensors or actuators in soft robots.

Moving forward, the researchers are looking to continue enhancing their performance.

For one, they could try using alternate materials that might have better properties. They are also exploring additional modifications that could more precisely control the temperature at which each material is deposited, reducing defects.

Written by Adam Zewe

Source: Massachusetts Institute of Technology

You can offer your link to a page which is relevant to the topic of this post.

#000#3d#3D printers#additive manufacturing#applications#biodegradable#Building#chips#computer#Computer Science#contamination#devices#direction#earth#electromagnets#electronic#electronic devices#Electronics#employed#engineering#engineers#Fabrication#form#Forms#friction#Fundamental#Global#Hardware#heart#illustration

0 notes

Photo

PORTO ROCHA

1K notes

·

View notes

Photo

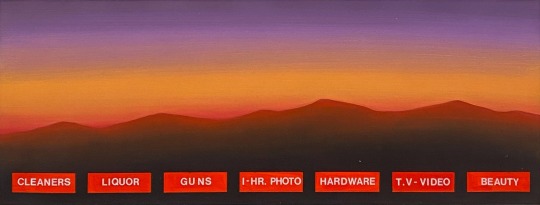

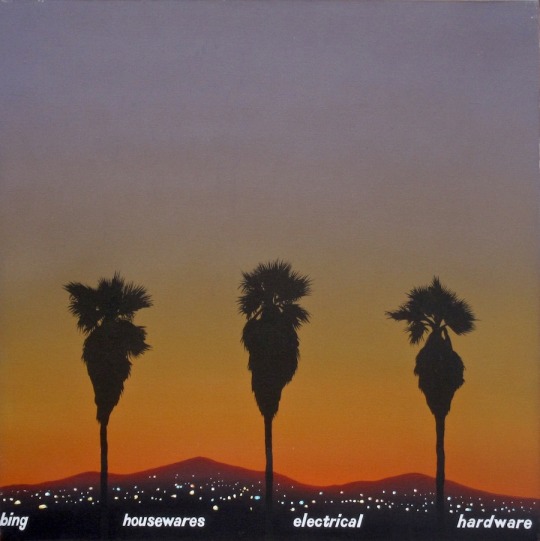

(vía Another America 50 by Phillip Toledano)

79 notes

·

View notes

Photo

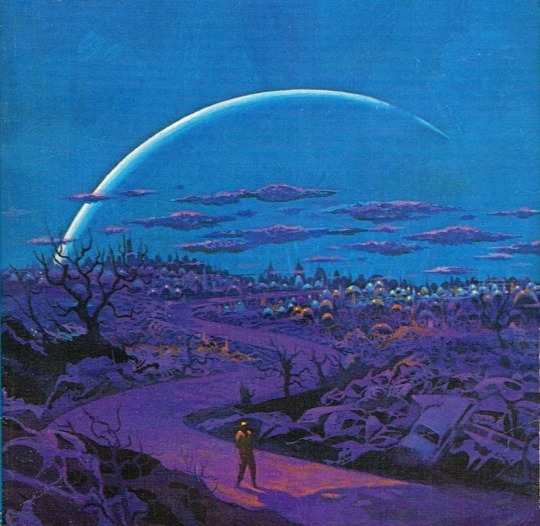

One of my favorites by Paul Lehr, used as a 1971 cover to "Earth Abides," by George R. Stewart. It's also in my upcoming art book!

1K notes

·

View notes

Quote

もともとは10年ほど前にTumblrにすごくハマっていて。いろんな人をフォローしたらかっこいい写真や色が洪水のように出てきて、もう自分で絵を描かなくて良いじゃん、ってなったんです。それで何年も画像を集めていって、そこで集まった色のイメージやモチーフ、レンズの距離感など画面構成を抽象化して、いまの感覚にアウトプットしています。画像の持つ情報量というものが作品の影響になっていますね。

映画『きみの色』山田尚子監督×はくいきしろい対談。嫉妬し合うふたりが語る、色と光の表現|Tokyo Art Beat

155 notes

·

View notes

Photo

No one wants to be here and no one wants to leave, Dave Smith (because)

111 notes

·

View notes

Text

don’t call me whiny baby if you didn’t care about my whiny baby feelings already, which you didn’t care about!!! shocker!!!

53 notes

·

View notes

Text

Boosting rocket reliability at the material level - Technology Org

New Post has been published on https://thedigitalinsider.com/boosting-rocket-reliability-at-the-material-level-technology-org/

Boosting rocket reliability at the material level - Technology Org

The success of the SpaceX Falcon 9 reusable launch vehicle has been one of the most remarkable technological achievements of the last decade. Powered by SpaceX’s Merlin engine, the Falcon 9 booster can be reused over 10 times, with minimal maintenance between flights.

“The new class of reusable launch vehicles is likely to transform the space industry by lowering launch costs and improving space accessibility,” says Professor Zack Cordero. Image credit: David Sella/MIT Corporate Relations

Now there is a new generation of reusable rocket engines and vehicles that promise much larger payloads and greater reuse. Unlike Falcon 9, the 390-foot-tall SpaceX Starship, powered by its new Raptor engines, can land both the booster and the second stage for reuse, thereby further reducing launch costs. Blue Origin has its own next-generation BE-4 engine that will power its 320-foot New Glenn launch vehicle.

“The new class of reusable launch vehicles is likely to transform the space industry by lowering launch costs and improving space accessibility,” says Zack Cordero, the Esther and Harold E. Edgerton Career Development Assistant Professor of Aeronautics and Astronautics at MIT. “This will enable applications such as mega constellations for space-based internet and space-based sensing for things like persistent, real-time CO2 emissions monitoring.”

Yet, launch failures such as the April 2023 explosion of SpaceX’s Starship prototype suggest that the new designs still have significant reliability issues. In the Starship explosion, about six of the 33 Raptor engines on the boost stage appear to have malfunctioned. In June, Blue Origin’s BE-4 engine exploded during acceptance testing, suggesting the engine suffers from similar challenges.

“People assume that Starship is going to succeed, but that isn’t necessarily true,” says Cordero. “There is a real, underappreciated risk that these new heavy lift launch vehicles will continue to fail unless there are fundamental advances in materials technology.”

The Cordero Lab, based in the MIT Aerospace Materials and Structures Laboratory, has accepted this challenge with a variety of projects that aim to solve the reliability problem at the materials level. Working with partners including NASA, which plans to use Starship for its crewed Artemis missions to the moon, Cordero is leveraging expertise in additive manufacturing (AM), processing science, materials engineering, and structural design. The goal is to reduce the maintenance costs and extend the lifespan for reusable rockets while decreasing the chance of catastrophic failure.

Reusable rocket research is just one of several Cordero Lab projects to address emerging aerospace applications. Cordero is also developing technologies for in-space manufacturing of larger space structures such as solar cells, solar sails, and reflectors, enabled by the greater payloads of heavy-lift reusable rockets. Cordero’s novel manufacturing technique uses plastic deformation to fold metallic feedstock into net-shaped reticulated structures. These structures can then precisely contour a reflector surface using embedded electrostatic actuators.

Bigger reusable rockets = bigger reliability challenges

Unlike traditional, expendable rockets, reusable launch vehicles must integrate components and design elements that allow the vehicles to automatically maneuver for a soft landing. They also require greater thermal protection to withstand extreme aerothermal heating during reentry.

“Propulsion devices need to be designed differently for reusable rockets,” says Cordero. “With reusable liquid propellant rocket engines, you must ensure safe operation over multiple flight cycles and ease off on performance to reduce stress.”

Larger, more powerful reusable rockets make these design additions even more challenging. “SpaceX’s Raptor and Blue Origin’s BE4 engines operate on different power cycles compared to the Merlin engine,” says Cordero. “The new staged combustion power cycles are more amenable to reusability because they lower turbine inlet temperatures to extend the life of turbine hardware. Yet, the new power cycles pose a greater risk of catastrophic failure. Oxygen compatibility and metal fires represent critical challenges.”

Cordero is attempting to strengthen the components that limit the life of a reusable rocket engine, starting with the turbopump that pressurizes the liquid propellant. Other vulnerable components include the thrust chamber in which propellants are burned to create a hot gas, as well as the nozzle through which the gas is exhausted.

Extended wear on turbopumps, chambers, and nozzles does not always end in a catastrophic explosion. Yet, they add to the maintenance and repair costs that are factored into overall launch payload costs.

“There is a wide spectrum of failure behaviors,” says Cordero. “Thrust chambers can start to crack but continue to function. Yet, turbopumps can have more serious issues. There could be a blisk [a type of rotor disc] failure or in the case of oxygen-rich turbopumps, a rub between the rotor and casing. The new engines are also vulnerable to particle impact ignition in which FOD [foreign objects and debris] are accelerated into a surface, igniting the hardware. In a turbopump, these ignition modes can lead to a metal fire and a catastrophic, single-point failure mode that results in the vehicle exploding.”

The growing role of AM in reusable rockets

Additive manufacturing is now widely used in the space industry, including printing parts for launch vehicles with laser power bed fusion printers. “Space is probably the heaviest user of metal AM and is basically dictating technological developments,” says Cordero.

AM is frequently used to print metal propulsion devices such as the small pumps used in gas generator engines. However, it is only selectively used in larger boost stage engines and their turbopumps.

“There is a debate over whether metal 3D printing of large structures is economical,” says Cordero. Yet, improved quality control and qualification protocols have enabled greater use in large, mission critical-flight devices. The next step is developing novel materials that improve reliability.

“We are developing material advances that should enable greater use of AM for larger turbopumps,” says Cordero. “Our technology enables novel designs with improved thermal efficiency or resilience against high temperatures or rapid thermal transients.”

One critical challenge for full-flow staged combustion (Raptor) and oxygen-rich stage combustion (BE-4) engines is the problem of oxidizer compatibility. “In the turbine and downstream hardware, you often see high-temperature, high-pressure oxygen gas, which can drive metal fires and rapid energetic failure modes,” says Cordero.

One solution is to design a pump with larger clearances in the rotating hardware. Yet because this approach degrades performance, Cordero has chosen another path: using metal AM to create more intrinsically oxygen-compatible materials. “Building oxygen-rich turbopumps with metal AM makes it easier to integrate exotic materials that are more compatible with high-pressure, high-temperature oxygen environments,” says Cordero.

Cordero Lab is pursuing this approach with two projects. The first is developing oxygen-compatible ceramic coatings that protect against particle impact ignition. The second is creating ignition-resistant AM materials that can be printed into complex net shapes to avoid friction ignition.

Toughening up coatings with metallic ductile phases

In the coating project, stationary and rotating components in oxygen-rich turbopumps are coated with an inner ceramic coating that prevents heat transfer to the substrate and protects the metal from high pressure oxygen. “The advantage of coatings is that you can apply them to almost any kind of hardware whether printed, cast, or forged,” says Cordero.

The material improves on current ceramic coatings used in conventional gas turbine designs. “Conventional aero coatings tend to delaminate and break apart under the rapid thermal transients that are typical in rockets,” says Cordero. “In an aero engine, the engine starts up in over a minute, then idles a few minutes before taking off. By contrast, a rocket engine goes to full throttle in a split second. The rapid change from very low to very high temperatures generates incredible stresses that cause conventional coatings to pop off.”

To solve this problem Cordero is using toughened ceramic coatings with embedded metallic ductile phases that suppress delamination via crack bridging. “If cracks develop in the ceramic coating, they are bridged and held in place by metallic inclusions that help it to withstand the thermal transients,” says Cordero.

The Cordero Lab has successfully tested the coatings with typical thermal transients seen in rockets. “Now we are exploring how to apply them to real-world flight hardware and optimize their composition and design for higher turbine inlet temperatures,” says Cordero.

The researchers are collaborating with NASA to investigate the particle impact ignition resistance of the coatings using different thicknesses, particle sizes, and operating conditions. “Our research into fundamental principles of ductile phase toughened environmental barrier coatings should allow us to develop new coatings with chemistries and properties specifically tuned to different applications,” says Cordero. One potential application is to “cover acreage aero-surfaces on hypersonic vehicles.”

Printing friction-resistant alloys

Cordero Lab’s research into ignition-resistant alloys is a collaboration with Aerospace Corp., a nonprofit federally funded R&D center. The lab is investigating the mechanisms that drive frictional ignition, another ignition mode that can lead to metal fires.

Frictional ignition, which “is like striking a match when the match is traveling at 300 meters per second,” is often caused by a rub between the rotor and casing, says Cordero. To reduce the risk, Cordero is designing new printable superalloy materials that incorporate oxide nanoparticles for dispersion-strengthening. Dubbed TGT100, the material “can be printed into complex net shapes and offers best-in-class frictional ignition resistance.”

The burn-resistant material will first be used to print casing and stationary hardware. Cordero has launched a startup called Top Grain Technologies that will commercialize the material, as well as the ceramic coatings.

Cordero has recently begun to investigate how turbopumps could be redesigned using his new materials to achieve extremely long lifespans. “Our goal is to build a turbopump that can endure hundreds of hot cycles before replacing or repairing components,” says Cordero.

Solving the reliability issues of reusable rockets will require expertise in cross-disciplinary subjects that are not typically paired. Toward this end, Cordero recently worked with the MIT Department of Aeronautics and Astronautics and the Industrial Liaison Program to launch a new one-week crash course in AM for aerospace engineers.

Cordero has also organized a yearly workshop with collaborators from Aerospace Corp. and Lehigh University that explores materials challenges in reusable rocket engines. “We are bringing together experts from academia, industry, and government to discuss the key technical challenges,” says Cordero.

Beyond education, more collaboration is needed between academics and companies like SpaceX and Blue Origin, says Cordero. “The academics have more time to explore these more fundamental challenges,” he says. “The vision is to bring reliability and reusability of reusable rocket engines up to the standards of aero engines, which would transform the industry.”

Written by Eric Brown

Source: Massachusetts Institute of Technology

You can offer your link to a page which is relevant to the topic of this post.

#2023#3d#3D printing#Accessibility#additive manufacturing#aeronautics#aerospace#amp#applications#approach#Astronomy news#barrier#Blue#Building#career#career development#Cells#challenge#CO2#coatings#Collaboration#Companies#Composition#course#crash#debris#Design#development#Developments#devices

0 notes

Photo

PORTO ROCHA

773 notes

·

View notes

Photo

Beautiful photo of the Princess of Wales departing Westminster Abbey after attending the Commonwealth Day Service. --

#catherine elizabeth#princess catherine#princess of wales#princess catherine of wales#catherine the princess of wales#william arthur philip louis#prince william#prince of wales#prince william of wales#william the prince of wales#prince and princess of wales#william and catherine#kensington palace#british royal family

84 notes

·

View notes

Text

GENERAL MEMES: Vampire/Immortal Themed 🩸🦇🌹

↳ Please feel free to tweak them.

Themes: violence, death, blood, murder, depression/negative thoughts

SYMBOLS: ↳ Use “↪”to reverse the characters where applicable!

🦇 - To catch my muse transforming into a bat 🌞 - To warn my muse about/see my muse in the sunlight. 🩸 - To witness my muse drinking blood from a bag. 🐇 - To witness To catch my muse drinking blood from an animal. 🧔🏽 - To witness To catch my muse drinking blood from a human. 🦌 - For our muses hunt together for the first time. 🏃🏿♀️ - To see my muse using super speed. 🏋🏼♂️ - To see my muse using their super strength. 🧛🏻♂️ - To confront my muse about being a vampire. 🌕 - For my muse to lament missing the sun. ⏰ - For my muse to tell yours about a story from their long, immortal life. 🤛🏽 - To offer my muse your wrist to drink from. 👩🏿 - For my muse to reminisce about a long lost love. 👩🏽🤝👩🏽 - For your muse to look exactly like my muse's lost love. 👄 - For my muse to bite yours. 👀 - For my muse to glamour/compel yours. �� - To try and sneakily feed my muse garlic to test if they're a vampire. 🔗 - To try and apprehend my muse with silver chains. 🔪 - To try and attack my muse with a wooden stake. 👤 - To notice that my muse doesn't have a reflection. 🌹 - For my muse to turn yours into a vampire. 🌚 - For my muse and yours to spend time together during the night. 🧛🏼♀️ - For my muse to tell yours about their maker/sire.

SENTENCES:

"I've been alive for a long time [ name ], I can handle myself." "I'm over a thousand years old, you can't stop me!" "Lots of windows in this place, not exactly the greatest place for a vampire." "Do you really drink human blood? Don't you feel guilty?" "Vampires are predators, [ name ] hunting is just part of our nature, you can't change that." "You just killed that person! You're a monster!" "Tomorrow at dawn, you'll meet the sun [ name ]." "Can you make me like you?" "Do you really want to live forever?" "You say you want to live forever, [ name ], but forever is a long time, longer than you can imagine." "What was it like to live through [ historic event / time period ]?" "Did people really dress like that when you were young?" "What were you like when you were human?" "We’re vampires, [ name ], we have no soul to save, and I don’t care." "How many people have you killed? You can tell me, I can handle it." "Did you meet [ historic figure ]?" "Everyone dies in the end, what does it matter if I... speed it along." "Every time we feed that person is someone's mother, brother, sister, husband. You better start getting used to that if you want to survive this life." "[ she is / he is / they are ] the strongest vampire anyone has heard of, no one knows how to stop them, and if you try you're going to get yourselves killed." "Vampire hunters are everywhere in this city, you need to watch your back." "Humans will never understand the bond a vampire has with [ his / her / their ] maker, it's a bond like no other." "Here, have this ring, it will protect you from the sunlight." "I get you're an immortal creature of the night and all that, but do you have to be such a downer about it?" "In my [ centuries / decades / millennia ] of living, do you really think no one has tried to kill me before?" "Vampires aren't weakened by garlic, that's a myth." "I used to be a lot worse than I was now, [ name ], I've had time to mellow, to become used to what I am. I'm ashamed of the monster I was." "The worst part of living forever is watching everyone you love die, while you stay frozen, still, constant." "I've lived so long I don't feel anything any more." "Are there more people like you? How many?" "Life has never been fair, [ name ], why would start being fair now you're immortal?" "You want to be young forever? Knock yourself out, I just hope you understand what you're giving up." "You never told me who turned you into a vampire. Who were they? Why did they do it?" "I could spend an eternity with you and never get bored." "Do you really sleep in coffins?" "There are worse things for a vampire than death, of that I can assure you [ name ]." "You need to feed, it's been days. You can drink from me, I can tell you're hungry." "The process of becoming a vampire is risky, [ name ], you could die, and I don't know if I could forgive myself for killing you." "I'm a vampire, I can hold a grudge for a long time, so believe me when I say I will never forgive this. Never." "You were human once! How can you have no empathy?" "You don't have to kill to be a vampire, but what would be the fun in that." "You can spend your first years of immortality doing whatever you want to whoever you want, but when you come back to your senses, it'll hit you harder than anything you've felt before." "One day, [ name ], everything you've done is going to catch up to you, and you're never going to forgive yourself." "Stop kidding yourself, [ name ], you're a vampire, a killer, a predator. You might as well embrace it now because you can't keep this up forever." "You can't [ compel / glamour ] me, I have something to protect me." "When you've lived as long as me, there's not much more in life you can do." "You want me to turn you? You don't know what you're asking me to do." "You really have to stop hissing like that, it's getting on my nerves." "I'm going to drive this stake through your heart, [ name ], and I'm going to enjoy it."

#ask meme#symbol meme#roleplay sentence meme#sentence starter meme#rp sentence prompts#vampire ask meme#ask box#ask memes#vampires#tw : blood#tw: violence#tw: death#tw: depression#tw: vampires#tw: murder

172 notes

·

View notes

Quote

よく「発明は1人でできる。製品化には10人かかる。量産化には100人かかる」とも言われますが、実際に、私はネオジム磁石を1人で発明しました。製品化、量産化については住友特殊金属の仲間たちと一緒に、短期間のうちに成功させました。82年に発明し、83年から生産が始まったのですから、非常に早いです。そしてネオジム磁石は、ハードディスクのVCM(ボイスコイルモーター)の部品などの電子機器を主な用途として大歓迎を受け、生産量も年々倍増して、2000年には世界で1万トンを超えました。

世界最強「ネオジム磁石はこうして見つけた」(佐川眞人 氏 / インターメタリックス株式会社 代表取締役社長) | Science Portal - 科学技術の最新情報サイト「サイエンスポータル」

81 notes

·

View notes

Photo

The Delian League, Part 2: From Eurymedon to the Thirty Years Peace (465/4-445/4 BCE)

This text is part of an article series on the Delian League.

The second phase of the Delian League's operations begins with the Hellenic victory over Mede forces at Eurymedon and ends with the Thirty Years Peace between Athens and Sparta (roughly 465/4 – 445/4 BCE).The Greek triumph at Eurymedon resulted in a cessation of hostilities against the Persians, which lasted almost six years. Whether or not this peace or truce followed from some formal treaty negotiated by Cimon, son of Miltiades, remains unknown.

Nevertheless, the Greek success at Eurymedon proved so decisive, the damage inflicted on Persia so great, and the wealth confiscated so considerable that an increasing number of League members soon began to wonder if the alliance still remained necessary. The Persians, however, had not altogether withdrawn from the Aegean. They still had, for example, a sizeable presence in both Cyprus and Doriscus. They also set about to build a great number of new triremes.

REDUCTION OF THASOS & THE BATTLE OF DRABESCUS

A quarrel soon erupted between the Athenians and Thasians over several trading ports and a wealth-producing mine (465 BCE). Competing economic interests compelled the rich and powerful Thasos to revolt from the Delian League. The Thasians resisted for almost three years. When the polis finally capitulated, the Athenians forced Thasos to surrender its naval fleet and the mine, dismantle defensive walls, pay retributions, and converted the future League contributions to monetary payments: 30 talents annum. Some League members became disaffected with the Athenian reduction of Thasos. Several poleis observed the Athenians had now developed a penchant for using "compulsion." They started to see Athens acting with both "arrogance and violence." On expeditions, furthermore, the other members felt they "no longer served as equals" (Thuc. 1.99.2).

The Athenians, meanwhile, attempted to establish a colony on the Strymon river to secure timber from Macedon, which shared its borders with the west bank. The location also proved a critical strategic point from which to protect the Hellespont. The Thracians, however, repelled the League forces at Drabescus. The Athenians soon realized the threats from both Thrace and Macedon made permanent settlements in the region difficult as they were essentially continental powers, and the League fleet could not reach them easily. Designs for the region, however, would not change, and the Athenians would return there again.

The Delian League had by this time demonstrated an inherent conflict from its beginnings: on the one hand, it engaged in heroic struggles against the Mede and extended its influence, reaping enormous benefits (especially for its poorer members). On the other hand, it also suppressed its members and soon demanded obedience from them.

The League engaged from the outset in a form of soft imperialism, collecting and commanding voluntary naval contributions and tribute while Athens used those resources and led all expeditions, enforcing continued membership but also showing little or no interest to interfere with the internal mechanisms of any member polis (unless it openly rebelled).

Continue reading...

35 notes

·

View notes