#automatic block making machine

Explore tagged Tumblr posts

Text

Revolutionizing Construction with Automatic Block Making Machines

In the ever-evolving world of construction, staying ahead of the curve is crucial for success. The introduction of automatic block making machine has revolutionized the industry, offering efficiency, precision, and quality that was once unimaginable. Concrete Block Making Machines have become the go-to choose for construction companies looking to streamline their operations. In this blog article, we will discuss the myriad benefits and advantages of these machines, shedding light on the innovations they bring to the industry. Additionally, we will explore the leading hollow brick machine supplier, a key player in this domain.

1. The Rise of Automatic Block Making Machines:

The construction industry has witnessed a significant shift toward automation, and the rise of automatic block making machines is a testament to this trend. These machines operate on advanced technology, allowing for the production of high-quality concrete blocks and hollow bricks on a large scale. The precise and efficient nature of these machines reduces waste, enhances productivity, and ensures cost-effectiveness.

2. Unleashing Efficiency and Productivity:

Gone are the days of painstakingly hand-making concrete blocks; automatic block making machines have amplified efficiency like never before. With their ability to produce a vast quantity of blocks in a short amount of time, construction companies can now meet project deadlines effectively. The automated processes of these machines ensure consistent quality, precision, and even density, leaving no room for errors. This ensures that construction projects progress smoothly, ultimately leading to improved productivity and customer satisfaction.

3. Enhanced Quality and Versatility:

The automatic block making machine have raised the bar with their ability to produce high-quality concrete blocks. These machines employ advanced molding techniques, resulting in sturdy and durable blocks. Moreover, they can be tailored to produce blocks of various shapes, sizes, and textures, allowing construction companies to cater to diverse architectural designs. From industrial buildings to residential homes, the versatile nature of these machines contributes to their popularity among construction professionals.

4. Meet the Hollow Brick Machine Supplier: [Supplier Name]:

When it comes to automatic block making machines, [Supplier Name] emerges as a trusted hollow brick machine supplier in the industry. With a strong commitment to quality and innovation, they offer a wide range of automatic block making machines equipped with the latest technological advancements. Their expertise lies in providing state-of-the-art machines that cater to the specific requirements of construction projects, enabling seamless operations and achieving superior results. Their unmatched customer service and technical support make them the go-to supplier for construction companies seeking excellence.

Conclusion:

Automatic block making machine have transformed the construction industry, offering efficiency, productivity, and precision that surpass traditional methods. Their ability to produce top-quality concrete blocks and hollow bricks in a fraction of the time has revolutionized the way construction projects are undertaken. With the leading hollow brick machine supplier, [Supplier Name], paving the way with cutting-edge technology, companies can embrace the future of construction confidently. As the demand for innovation in construction grows, these automatic block making machines will continue to be the backbone of the industry, driving progress and success.

0 notes

Text

The automatic block making machine is a highly efficient and reliable solution for producing high-quality blocks. With its advanced automation features, this machine can effortlessly manufacture blocks of various sizes and shapes.

Visit us: https://block-machinery.com/product-category/automatic-block-machine/

0 notes

Text

Building a Sustainable Future: The Rise of Fully Automatic Fly Ash Brick Machines in India

India's construction sector is booming, and with it, the demand for efficient, sustainable building materials. In this landscape, fully automatic fly ash brick machines are emerging as a game-changer, revolutionizing brick manufacturing across the nation. These advanced machines not only offer high productivity but also contribute significantly to environmental conservation by utilizing industrial waste.

What are Fully Automatic Fly Ash Brick Machines?

At its core, a fully automatic fly ash brick machine is an industrial marvel designed to produce high-quality bricks from fly ash – a byproduct of coal combustion in thermal power plants – mixed with other raw materials like sand, lime, gypsum, and cement. The "fully automatic" aspect signifies that the entire production process, from raw material feeding and mixing to pressing, molding, and often even stacking, is automated, requiring minimal human intervention.

These machines leverage sophisticated technologies such as:

Hydraulic Pressure Systems: Ensuring uniform compression and high-density bricks with excellent strength.

Vibro-Compaction Technology: Combining vibration with pressure to eliminate air bubbles and achieve superior compaction and dimensional accuracy.

PLC (Programmable Logic Controller) Control: For precise management of the entire operation, enabling consistent quality, adjustable pressure settings, and real-time monitoring.

Automated Raw Material Feeding and Batching Systems: Ensuring precise proportions of materials for optimal brick composition.

Mould Flexibility: Allowing for the production of various brick types, including solid, hollow, paving blocks, and interlocking bricks, using interchangeable molds.

Auto-Stacker Systems: In advanced models, bricks are automatically stacked post-production, reducing manual labor and improving efficiency.

The Unmatched Advantages in the Indian Context

The adoption of fully automatic fly ash brick making machines in India offers a multitude of benefits, both economic and environmental:

High Production Capacity: These machines are designed for large-scale output, with some models capable of producing 1500-2500 bricks per hour, or even up to 30,000 bricks per day. This high volume helps meet the escalating demand in the rapidly growing Indian construction market.

Consistent Quality and Durability: Automation eliminates human error, leading to uniformly shaped, high-strength bricks with low water absorption and excellent thermal insulation. This translates to better structural integrity and longer-lasting buildings.

Environmental Sustainability: By utilizing fly ash, a significant industrial waste product, these machines contribute to:

Waste Utilization: Reducing the burden on landfills and promoting a circular economy.

Reduced Carbon Footprint: Less reliance on traditional clay bricks, which often involve topsoil excavation and energy-intensive firing processes.

Lower Water Usage: Fly ash brick production typically requires less water compared to conventional clay bricks.

Compliance with Regulations: The Indian government, through notifications from the Ministry of Environment & Forests (MoEF&CC), has mandated the utilization of fly ash in construction activities within a certain radius of thermal power plants, further driving the demand for these machines.

Cost-Effectiveness and Quick ROI: While the initial investment might seem substantial (prices for fully automatic plants can range from INR 10.5 Lakh to over INR 2 crore, depending on capacity and features), the long-term cost savings are significant. Reduced labor requirements, minimal maintenance, and high production output lead to a faster return on investment (ROI).

Reduced Labor Dependency and Enhanced Safety: Automation minimizes the need for manual labor, addressing concerns about labor availability and reducing occupational hazards associated with traditional brick-making.

Versatility: The ability to produce various types of bricks and blocks caters to diverse construction needs and market segments, from residential and commercial buildings to infrastructure projects and landscaping.

Energy Efficiency: Modern machines are optimized for lower power consumption, contributing to reduced operational costs.

Leading Manufacturers and Market Trends in India

India boasts a strong ecosystem of manufacturers specializing in fully automatic fly ash brick machines. Companies like Narsinh Industries, Endeavour Intelligent Equipments Private Limited, HVB Exports, Revomac Industries, Laxmi Engineering Works, and Kailash Engineering are prominent players, offering a wide range of machines with varying capacities and features. Many manufacturers are based in industrial hubs like Ahmedabad, Morbi, Mehsana, and Coimbatore.

The market trend is clearly towards more advanced, energy-efficient, and highly automated solutions. Manufacturers are focusing on:

Integrating IoT and remote monitoring capabilities for enhanced control and diagnostics.

Developing machines with even higher pressing capacities for denser bricks.

Offering customized solutions to meet specific client requirements.

Ensuring robust build quality for long operational life and minimal wear and tear.

Investing in a Sustainable Future

For entrepreneurs and construction companies in India looking to scale up their operations while embracing sustainable practices, investing in a fully automatic fly ash brick machine is a strategic decision. These machines not only promise high productivity and superior product quality but also align with the nation's growing emphasis on green building and responsible waste management. As India continues its infrastructure development, the demand for eco-friendly and high-performance building materials like fly ash bricks, produced efficiently by these advanced machines, is set to soar.

#automatic bricks making machine manufacturer#automatic paver block machine manufacturer#fly ash block making machine#paver block manufacturing machine#semi-automatic block making machine#vibrating paver block machine

0 notes

Text

Hollow Solid Block Making Machine – Trusted Solutions by Ultra Tile Machine

In the construction industry, the demand for reliable and cost-effective building materials has never been higher. With infrastructure projects on the rise, both hollow and solid blocks are rapidly replacing traditional bricks due to their structural advantages, durability, and cost efficiency. At the core of producing these essential materials lies the Hollow Solid Block Making Machine, a critical asset for modern builders and manufacturers.

When it comes to choosing a dependable manufacturer, Ultra Tile Machine stands tall as an industry leader. With years of expertise and a reputation for quality and innovation, Ultra Tile Machine is your go-to partner for high-performance block making solutions.

What Is a Hollow Solid Block Making Machine?

A Hollow Solid Block Making Machine is a versatile industrial machine used to manufacture both hollow and solid concrete blocks. These machines compact a mixture of cement, sand, and aggregates into pre-defined molds using hydraulic or mechanical pressure. The result is uniformly shaped, high-strength blocks suitable for various construction needs.

Hollow blocks are lighter and used for non-load bearing walls, while solid blocks are denser and used in load-bearing structures. A machine that can produce both types offers manufacturers maximum flexibility and better ROI.

Why Hollow and Solid Blocks Are Gaining Popularity

Construction professionals are shifting towards hollow and solid concrete blocks due to their numerous advantages over traditional bricks. Some of these include:

Better thermal insulation

Faster construction speed

High load-bearing capacity

Reduced dead load on structure

Eco-friendly materials

Lower water absorption

Uniform shape and size

This shift has directly increased the demand for machines that can produce these blocks efficiently.

Types of Hollow Solid Block Making Machines

Depending on the scale and automation needs of your business, Ultra Tile Machine offers a range of machines such as:

Manual Block Making Machines

Semi-Automatic Machines

Fully Automatic Machines

Hydraulic Press Block Machines

Vibration Cum Compression Machines

Each type caters to a different production requirement, ensuring that businesses of all sizes can find the right fit.

Advantages of Investing in a Hollow Solid Block Making Machine

High Productivity

These machines are designed to produce hundreds or even thousands of blocks in a single shift, drastically improving output.

Versatility

Manufacturers can produce a wide range of block types, including hollow blocks, solid blocks, interlocking blocks, and more using different molds.

Cost Efficiency

Modern machines reduce labor dependency and minimize raw material waste, increasing overall profitability.

Better Quality Control

Precision engineering ensures consistency in size, strength, and shape, which is vital for large-scale construction projects.

Environmentally Friendly

These machines support the use of fly ash, slag, and other industrial waste, contributing to sustainable construction practices.

Why Choose Ultra Tile Machine as Your Manufacturer?

Industry Experience

Ultra Tile Machine has built a legacy of trust and excellence in the block making machinery sector. With decades of experience, the company understands the pulse of the construction industry and delivers solutions tailored to real-world challenges.

Advanced Technology

All machines by Ultra Tile Machine are designed using the latest technology to ensure high output and consistent performance. Key features include:

High-pressure hydraulic systems

Heavy-duty steel construction

Advanced vibration technology

Precision molds

User-friendly controls

Long service life

These features enable operators to run production smoothly with minimal downtime.

Wide Product Range

Ultra Tile Machine offers a full suite of machinery for every scale of operation:

Manual Machines: Ideal for startups and small-scale units

Semi-Automatic Models: A perfect mix of manual and automatic features

Fully Automatic Machines: Best suited for large-scale continuous production

Hydraulic Block Machines: Ensures greater compression and block durability

Whether you’re a beginner or a seasoned industrialist, there's a machine that suits your business needs.

Customization Options

Ultra Tile Machine provides full flexibility in customizing:

Block size and mold design

Output capacity

Power source (electric or diesel)

Machine frame and configuration

Color and branding

Custom machines ensure that your production line aligns perfectly with market demand and your brand identity.

Quality Assurance

Ultra Tile Machine places strong emphasis on quality at every stage of manufacturing. Every machine undergoes rigorous quality checks to ensure:

Flawless operation

Durability and reliability

Resistance to wear and tear

Energy efficiency

Customers receive machines that perform consistently for years with low maintenance requirements.

Competitive Pricing

Despite offering premium features, Ultra Tile Machine maintains highly competitive prices. Their goal is to make quality machinery accessible to everyone, from small business owners to industrial giants. Transparent pricing, zero hidden costs, and a strong return on investment make them a clear choice.

Strong After-Sales Support

What truly sets Ultra Tile Machine apart is their dedication to customer satisfaction beyond the sale. They offer:

Installation and commissioning support

Operational training for staff

Routine maintenance and inspection services

Readily available spare parts

Prompt technical assistance

This helps ensure that your production stays uninterrupted and efficient.

Nationwide and Global Reach

Ultra Tile Machine serves clients across India and exports machinery to several countries. Their machines are built with global standards in mind and come with all necessary documentation, training materials, and remote support for overseas clients.

Positive Customer Testimonials

“Ultra Tile Machine gave us a powerful machine that revolutionized our block manufacturing process. Their service team was quick, professional, and helpful.” – Arjun, Hyderabad

“We use their hydraulic solid block machine, and the output is simply unmatched. Highly recommended!” – Neha, Pune

Feedback like this showcases the strong reputation Ultra Tile Machine enjoys in the industry.

How to Choose the Right Machine for Your Needs?

Before you invest in a Hollow Solid Block Making Machine, consider the following:

Production Volume: Assess how many blocks you need to produce per day

Automation Level: Go with automatic models for higher speed and lower labor costs

Block Types: Choose a model compatible with the kinds of blocks you plan to manufacture

Available Space: Some machines require more floor space for installation and raw material handling

Budget: Ultra Tile Machine offers machines in a variety of price brackets to fit your investment range

Applications of Hollow and Solid Blocks

Hollow and solid blocks produced by these machines are used in:

Residential and commercial buildings

Roadside pavements

Compound walls and fences

Industrial structures

Warehouses and godowns

Load-bearing and non-load-bearing walls

Their strength, cost-efficiency, and long lifespan make them a preferred material in construction across the globe.

Focus on Sustainability

Ultra Tile Machine is committed to promoting eco-conscious practices. Their machines support:

The use of fly ash, slag, and other industrial byproducts

Reduced water usage in block curing

Low energy consumption

Long-term recyclability of produced blocks

This not only aligns with green building standards but also appeals to environmentally responsible contractors and builders.

Conclusion

In the ever-evolving world of construction, the need for reliable, durable, and high-quality blocks is more important than ever. Investing in a Hollow Solid Block Making Machine is a strategic move that can transform your business by increasing efficiency, reducing production costs, and meeting the growing demand for sustainable construction materials.

Ultra Tile Machine, as a trusted manufacturer, offers unmatched expertise, top-tier machinery, and unwavering customer support. Whether you’re starting a new venture or expanding an existing one, Ultra Tile Machine provides everything you need to succeed in the block manufacturing industry.

#Paver Block Making Machine Manufacturer#Hollow Solid Block Making Machine#Fly Ash Brick Making Machine#Concrete Block and Brick Making Machine#Chemical Hardener Manufacturers#Interlocking Paver Block Making Machine#Automatic Brick Making Machine Manufacturer

0 notes

Text

Small Business? Get an Automatic Fly Ash Brick Making Machine

The rising market need for sustainable building materials alongside their durability creates business opportunities to start profitable small brick manufacturing operations. You will obtain the most significant return on investment through an automatic fly ash brick making machine. Modern industrial machinery helps enterprises attain maximum efficiency while cutting down expenses for small business operators who seek growth opportunities..

An Automatic Fly Ash Brick Making Machine carries multiple essential characteristics which support its functionality.

Complete automation eliminates human involvement which results in improved operational speed.

High production capacity: Produces thousands of bricks per shift.

Precision and uniformity: Ensures accurate brick dimensions and strength.

Energy-efficient design: Lowers electricity consumption and operational costs.

Robust construction: Long-lasting performance with minimal wear and tear.

How an Automatic Fly Ash Brick Making Machine Benefits Small Businesses

Faster Return on Investment (ROI)

The high production rate along with reduced labor costs combined with maintenance expenses enables small businesses to swiftly return their investment so they can start making profits quickly.

Competitive Edge in the Market

Superior brick quality combined with efficient production gives businesses a competitive advantage in the construction market which enables them to gain reliable supplier status and draw in more customers.

Scalable Business Growth

Businesses can smoothly achieve increased production through higher demand by expanding their operation with one automatic machine for sustained long-term growth.

Compliance with Industry Standards

The bricks created by automatic machinery fulfill industry requirements which help small businesses obtain needed authorizations to perform major building works.

#Automatic Fly Ash Brick Making Machine#fly ash brick making machine#brick making machine#paver block making machine#hydraulic brick making machine#brickmakingmachine#fly ash brick making machine in gujarat#brick making machine in india#brickmachine#fly ash brick plant#block making machine

0 notes

Text

Top Brick and Paver Machine Manufacturers in Morbi: Revolutionizing Construction with Advanced Technology

In the bustling hub of Morbi, Gujarat, a revolution in construction technology is taking place. Companies like Lomango Machinery are at the forefront, providing state-of-the-art machines that are transforming the way we build. From brick machines to paver block machines, Lomango Machinery stands out as a leading manufacturer, offering a range of products that cater to various construction needs. In this blog, we'll delve into the details of their offerings, highlighting the key features and benefits of each.

Bricks Machine Manufacturer in Morbi

Lomango Machinery is a prominent bricks machine manufacturer in Morbi. Their machines are designed to produce high-quality bricks that meet industry standards. The advanced technology used in these machines ensures efficient production processes, reducing manual labor and increasing output.

Key Features:

High Efficiency: The machines are designed for high output, ensuring a steady supply of bricks for large construction projects.

Durability: Made from robust materials, these machines are built to last, providing long-term value for money.

User-Friendly: The intuitive design makes them easy to operate, even for those with minimal technical expertise.

Brick Machine Manufacturer in Gujarat

As a brick machine manufacturer in Gujarat, Lomango Machinery caters to a wide market, supplying machines to various regions across the state. Their reputation for quality and reliability has made them a preferred choice among builders and contractors.

Advantages:

Local Support: Being based in Gujarat, they offer excellent customer support and after-sales service to their clients.

Cost-Effective: Their machines are competitively priced, offering excellent value for money.

Fly Ash Brick Making Machine Manufacturer

The fly ash brick making machines from Lomango Machinery are a game-changer in the industry. These machines utilize fly ash, a by-product of coal combustion, making them an eco-friendly option for brick production.

Key Benefits:

Environmental Impact: Using fly ash reduces the need for clay, preserving natural resources and reducing environmental degradation.

Strength and Durability: Fly ash bricks are known for their superior strength and durability compared to traditional clay bricks.

Automatic Fly Ash Brick Making Machine

For those seeking to automate their brick production, Lomango Machinery offers automatic fly ash brick making machines. These machines streamline the production process, reducing the need for manual intervention and increasing efficiency.

Features:

Automation: Fully automated systems ensure consistent quality and high production rates.

Precision: Advanced technology ensures precise brick dimensions and uniformity.

Fly Ash Brick Making Machine Fully Automatic

The fully automatic fly ash brick making machines from Lomango Machinery represent the pinnacle of modern brick manufacturing technology. These machines are designed for large-scale production, making them ideal for big construction projects.

Advantages:

Labor Savings: Automation reduces the need for manual labor, cutting down on labor costs.

Consistency: Ensures consistent quality and uniformity in every batch of bricks produced.

Fly Ash Brick Making Machine Supplier

As a trusted fly ash brick making machine supplier, Lomango Machinery ensures that their clients receive top-quality machines that meet their specific needs. Their commitment to customer satisfaction sets them apart in the industry.

Services:

Customization: They offer customized solutions to meet the unique requirements of their clients.

After-Sales Support: Comprehensive after-sales support ensures that any issues are promptly addressed.

Paver Block Machine Manufacturer in Morbi

In addition to brick machines, Lomango Machinery is also a leading paver block machine manufacturer in Morbi. Their machines are designed to produce high-quality paver blocks that are widely used in landscaping and paving projects.

Features:

Versatility: Capable of producing various shapes and sizes of paver blocks.

Durability: Built to withstand the rigors of continuous use, ensuring long-term reliability.

Paver Making Machine for Sale

Lomango Machinery offers a range of paver making machines for sale, catering to different budgetary and production requirements. Their machines are known for their efficiency and reliability.

Benefits:

Cost-Effective: Competitive pricing makes their machines accessible to a wide range of customers.

High Output: Designed for high production rates, ensuring timely completion of projects.

Paver Block Making Machine Manufacturers

As leading paver block making machine manufacturers, Lomango Machinery's products are trusted by contractors and builders across the region. Their machines are designed to deliver high performance and reliability.

Advantages:

Innovative Technology: Incorporating the latest technology to ensure superior performance.

Customer Satisfaction: A strong focus on customer satisfaction ensures long-term relationships with their clients.

Automatic Paver Block Making Machine

For those looking to streamline their paver block production, Lomango Machinery offers automatic paver block making machines. These machines automate the production process, reducing manual labor and increasing efficiency.

Features:

Automation: Fully automated systems ensure high efficiency and consistent quality.

Ease of Use: Designed for easy operation and maintenance.

In conclusion, Lomango Machinery stands out as a leader in the construction machinery industry. Their range of brick and paver block machines is designed to meet the diverse needs of their clients, offering advanced technology, reliability, and excellent value for money. Whether you're looking for a bricks machine manufacturer in Morbi or a paver block machine manufacturer, Lomango Machinery has you covered. Visit their website at Lomango Machinery to learn more about their products and services.

#Bricks Machine Manufacturer Morbi#brick machine manufacturer in gujarat#fly ash brick making machine manufacturer#automatic fly ash brick making machine#fly ash brick making machine fully automatic#fly ash brick making machine supplier#paver block machine manufacturer morbi#paver making machine for sale#paver block making machine manufacturers#automatic paver block making machine

0 notes

Text

Listen to your elders

So last week I posted abut the importance of downloading your fic. And then three days later AO3 went down for 24 hours. No one was more weirded out by this than I was. But while y’all were acting like the library at Alexandria was on fire I was reading my download fic and editing chapter eight of Buck, Rogers, and the 21st Century. And also thinking about what I could do to be helpful when the crisis was actually over.

So first off, I’m going to repeat that if you’re going to bookmark a fic, you really need to also download the fic and back it up in a safe place. I just do it automatically now and it’s a good habit to get into.

But let’s talk about some other scenarios. Last October I lost power for over a week after hurricane Ian. Apart from not having internet or A/C I did find plenty to do, I collect books so I had plenty to read, but maybe, unlike me, your favorite comfort reads aren’t sitting on a bookshelf. So let’s do something about that, shall we?

In olden times many long years ago around 1995 we printed off a lot of fic. It was mostly SOP to print a fic you planned to reread and stick it in a three ring binder. And that’s totally valid today too, but you can also make a very nice paperback with a minimum amount of skill and materials.

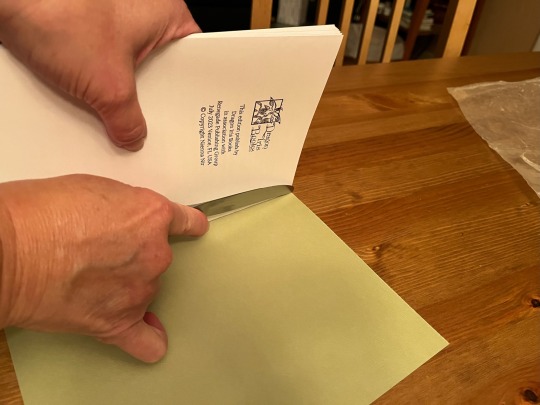

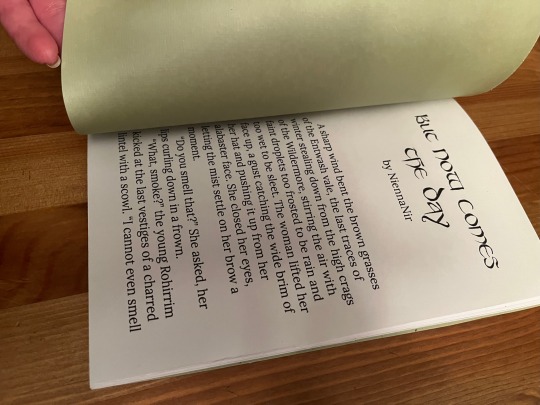

Let’s start with the download; Go to Ao3 and select your fic, we’ll be working with one of mine. This method works best with one shots, long fic tends to need a more complicated approach. Get yourself an HTML download

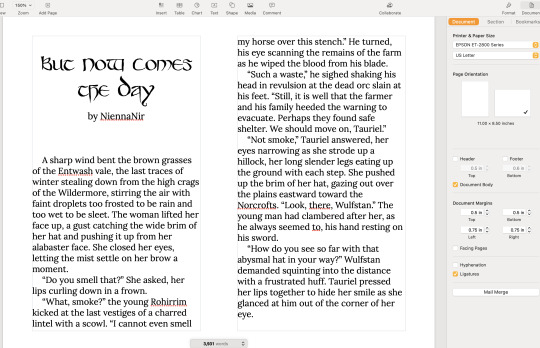

Open up the HTML download and select all then copy paste into any word processor. Set the page to landscape and two columns, then change the font to something you find easy to read, this is your book, no judgement. This is all you have to do for layout but I like to play a little bit. I move all the meta, summary, notes to the end and pick out a fun font for the title:

No time like the present to do a quick proofread. Congratulations, you’ve just created your first typeset. On to the fun part.

Now you’re going to need some materials: 8.5x11in paper ruler one sheet of 12x12 medium card stock (60-80lb) scissors pencil pen or fine tip marker sheet of wax paper white glue two binder clips 2 heavy books or 1 brick butter knife

You’ll also need a printer, if you’re in the US there is almost a 100% chance your local library has a printer you can use if you don’t have your own. None of these materials are expensive and you can literally use cheap copy paper and Elmers glue.

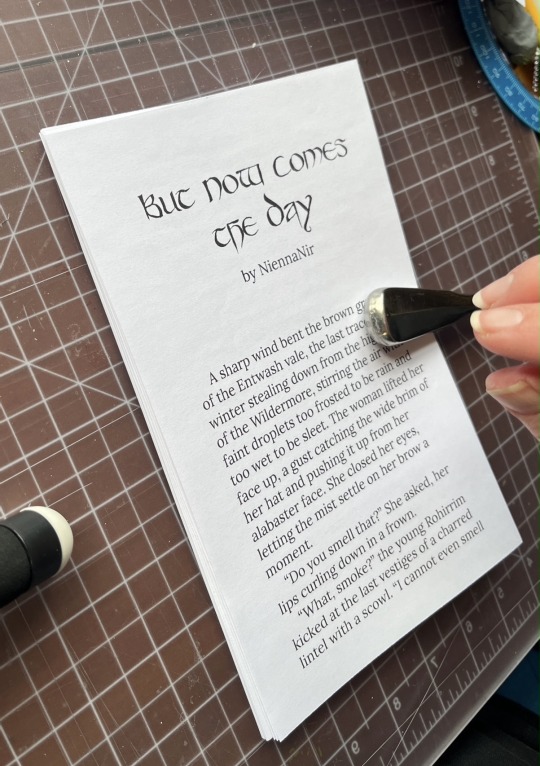

Print your text block, one page per side. Fold the first page in half so that the blank side is inside and the printed side out:

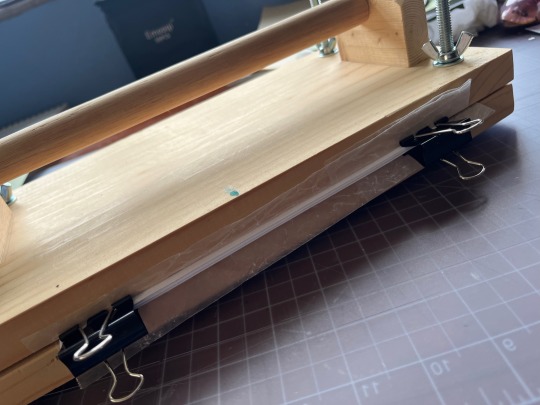

use the butter knife to crease the edge. Repeat on all the sheets. When you’ve finished, stack them up with the raw edge on the left and the folded edge on the right. I used standard copy paper, because you’re only printing on one side there’s no bleed to worry about. Take the text block and line everything up. Use the binder clips to hold the raw edge in place.

Wrap the text block in the wax paper so that the raw edge and binder clips are facing out. I’m going to use my home built book press but you don’t need one, a brick or a couple of books or anything else heavy will work fine.

Once the text block is anchored down, take off he binder clips and get out the glue.

You can use a brush but you don’t need one, smear some glue on that raw edge.

Go make a margarita, watch The Mandalorian, call your mother. Don’t come back for at least an hour

In an hour smear some more glue on there and shift your brick forward so that the whole book is covered. This keeps the paper from warping. While glue part 2 is drying we’ll do the cover. Get out your 12x12 cardstock

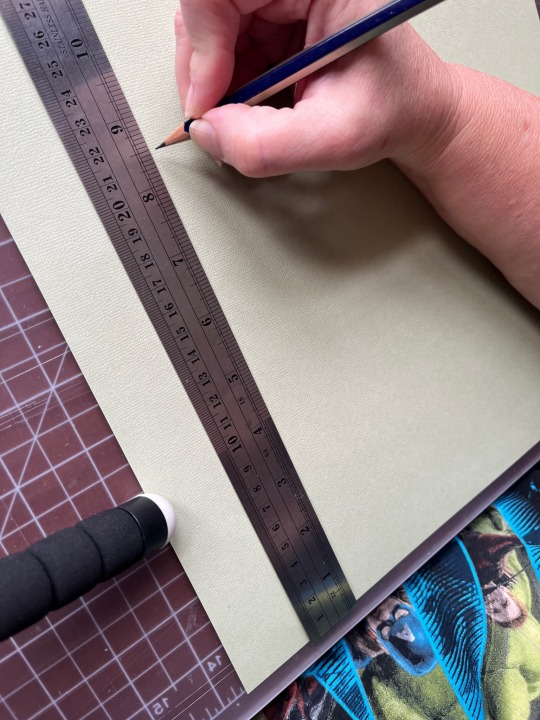

Mark the cardstock off at 8.5 inches and cut it. Measure in 5.5 inches from the left and put in a score line with the butter knife (the back edge not the sharp edge)

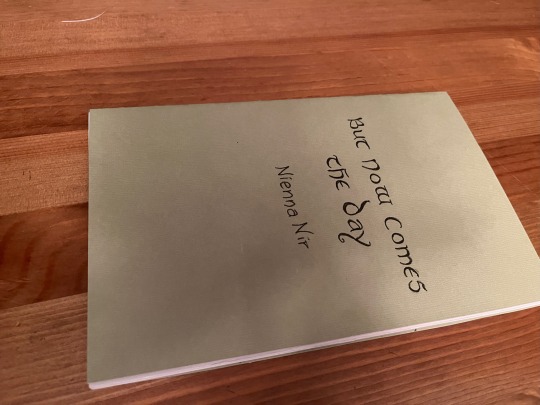

Carefully fold the score line, this is your front cover. You have some options for the cover title, you can use a cutting machine like a cricut if you have one, you can print out a title on the computer and use carbon paper to transfer the text to the cardstock. I was in a mood so I just freehanded that beoch. Pencil first then in pen.

Take your text block out from under your brick. Line it up against the score mark and mark the second score on the other side of the spine

Fold the score and glue the textblock into the cover at the spine. Once the glue dries up mark the back cover with the pencil and then trim the back cover to fit with your scissors.

Voila:

I’m going to put this baby on the shelf next to the Silmarillion.

The whole process, not counting drying time, took less than an hour.

If you want to make a book of a longer fic, I recommend Renegade Publishing, they have a ton of resources for fan-binders.

22K notes

·

View notes

Text

Brick vs Block: Which Construction Material Is Right for You?

Introduction

Choosing the right construction material is a crucial decision for builders and contractors. Concrete bricks and blocks are two popular choices, each with its own set of advantages and applications.

In this blog, we will compare these two construction materials to help builders make informed decisions that align with their project requirements. Additionally, we'll explore the importance of selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers.

Concrete Bricks:

Concrete bricks are widely used in construction due to their versatility and aesthetic appeal. Here are some key benefits and applications of concrete bricks:

1. Aesthetics: Concrete bricks come in a variety of colors and textures, making them an excellent choice for projects that prioritize aesthetics. They can be used to create visually appealing facades, accent walls, and even decorative elements within a structure.

2. Precision: Concrete bricks are manufactured to precise dimensions, ensuring uniformity and ease of installation. This precision makes them ideal for intricate brickwork patterns and designs.

3. Durability: Concrete bricks are known for their strength and durability, making them suitable for load-bearing applications. They can withstand harsh weather conditions, which is essential for structures exposed to the elements.

4. Thermal Insulation: Concrete bricks offer good thermal insulation properties, helping to regulate indoor temperature and reduce energy consumption. This makes them a popular choice for residential construction.

5. Soundproofing: Due to their density, concrete bricks also provide effective soundproofing, which is valuable in reducing noise transfer between rooms or from the outside.

Applications of Concrete Bricks:

Residential homes

Commercial buildings

Retaining walls

Fireplaces

Garden walls

Decorative features

Concrete Blocks:

Concrete blocks, often referred to as cinder blocks or concrete masonry units (CMUs), have their own unique advantages and applications:

1. Structural Strength: Concrete blocks are favored for their structural strength and load-bearing capacity. They are commonly used in the construction of foundations, retaining walls, and other structural elements.

2. Cost-Efficiency: Concrete blocks are generally more cost-effective than bricks. Their larger size means fewer blocks are needed to cover a given area, reducing material and labor costs.

3. Speed of Construction: Due to their size, concrete blocks can be laid quickly, speeding up the construction process. This efficiency is particularly beneficial for large-scale projects.

4. Fire Resistance: Concrete blocks offer excellent fire resistance, which is a critical factor in building safety. They can withstand high temperatures and provide valuable fire protection.

5. Minimal Maintenance: Concrete blocks require minimal maintenance over the years, making them a low-maintenance option for long-lasting structures.

Applications of Concrete Blocks:

Foundations

Basement walls

Retaining walls

Commercial buildings

Industrial facilities

Warehouses

Selecting Reliable Concrete Brick and Block Making Machine Manufacturers

In addition to choosing the right construction material, it's essential to consider the machinery and equipment used in the manufacturing process. High-quality concrete bricks and blocks depend on the reliability of the production equipment. Here's why selecting trustworthy Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is crucial

1. Product Quality: Reliable manufacturers produce machines that meet industry standards, ensuring the consistent production of top-quality bricks and blocks.

2. Efficiency: Modern brick and block making machines offer improved efficiency and output. Investing in machinery from reputable manufacturers can lead to increased productivity and reduced production costs.

3. Support and Service: Established manufacturers often provide comprehensive support and maintenance services for their equipment, minimizing downtime and optimizing machine performance.

4. Innovation: Leading manufacturers invest in research and development, resulting in innovative features and technologies that can enhance the quality and efficiency of brick and block production.

5. Compliance: Ensure that the machinery you purchase complies with safety and environmental regulations in your region.

Conclusion

Both materials have their strengths and applications. Concrete bricks offer versatility and aesthetics, while concrete blocks provide structural strength and cost-efficiency. The choice between these two construction materials depends on your project's specific needs.

Additionally, selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is essential to ensure the consistent production of high-quality building materials. By carefully considering both the construction material and the machinery used in production, builders and contractors can make informed decisions that lead to successful and durable construction projects. Whether it's the material or the machinery, quality, and reliability are key to building a solid foundation for any construction venture.

Benny Enterprises is the best option for your best brick-making machine and block-making machine manufacturers we are also well known for being the best Fly ash brick making machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more.

Contact us for further…

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Text

With Hydraform's Soil Diesel Brick Machine and build a sustainable future. It produces environmentally friendly bricks by harnessing the power of cement, dirt, and fuel. Reduce environmental impact while producing bricks that are effective, robust, and adaptable. With Hydraform's Soil Diesel Brick Machine, embrace sustainability, make a positive impact on the environment, and create the foundation for a brighter future. Visit us for more details.

#brick making machine#block making machine#hollow brick machine suppliers#interlocking brick making machine#hollow blocks machine for sale#automatic brick making machine#gmt pallet#concrete block machine price#paving brick making machine#manual block making machine#manual block making machine for sale#automatic block machine#automatic brick making machine price#Mobile Block Making Machine#Diesel Brick Machine

0 notes

Text

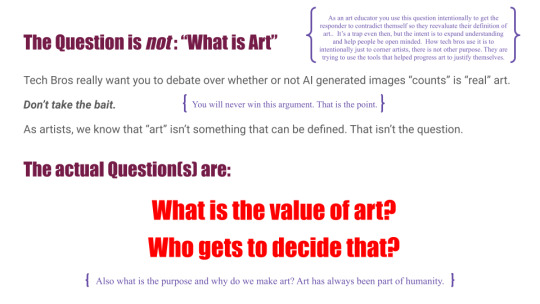

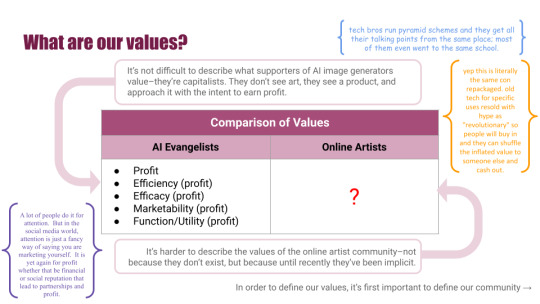

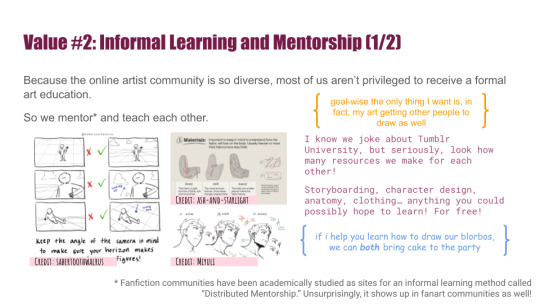

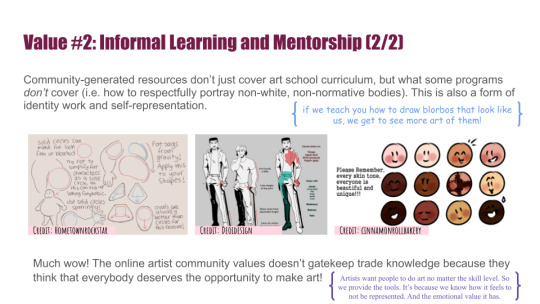

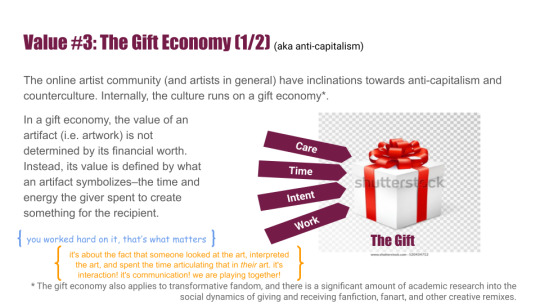

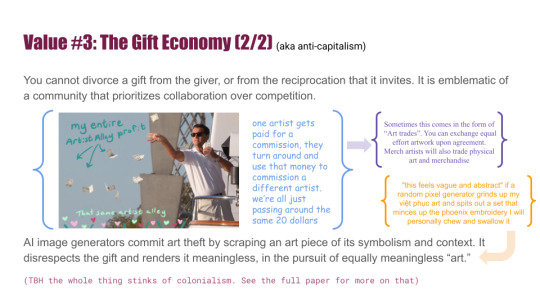

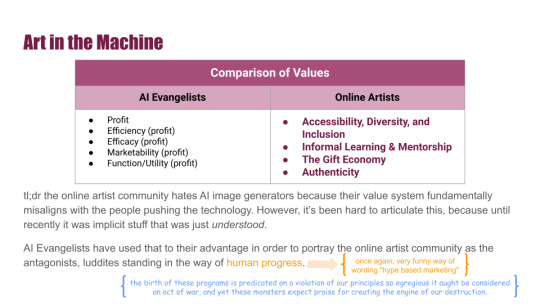

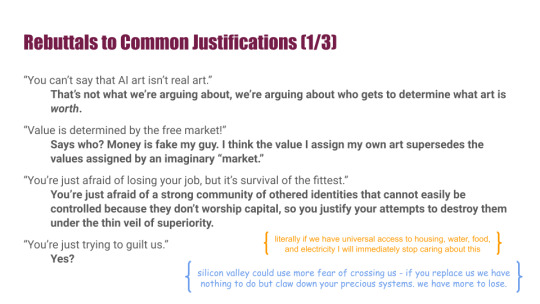

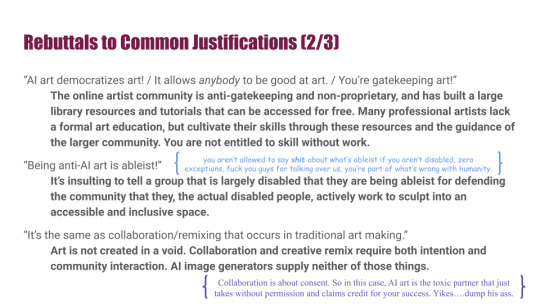

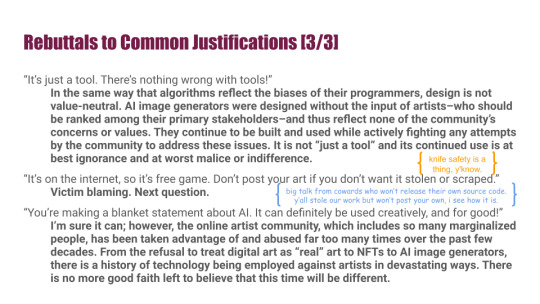

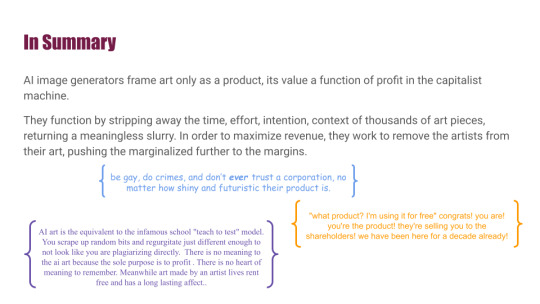

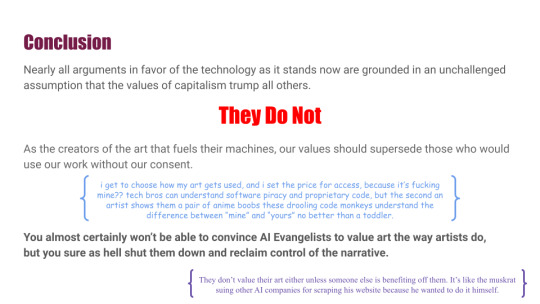

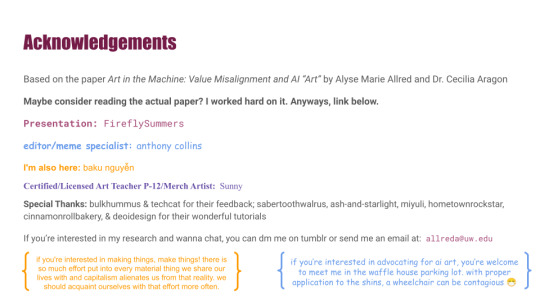

FireflySummers’ Guide to Arguing Against the Use of AI Image Generators

(AKA I hate AI image generators so fucking much that I published a whole ass academic article on it)

Read the Paper: Art in the Machine: Value Misalignment and AI "Art"

Citation: Allred, A.M., Aragon, C. (2023). Art in the Machine: Value Misalignment and AI “Art”. In: Luo, Y. (eds) Cooperative Design, Visualization, and Engineering. CDVE 2023. Lecture Notes in Computer Science, vol 14166. Springer, Cham. https://doi.org/10.1007/978-3-031-43815-8_4

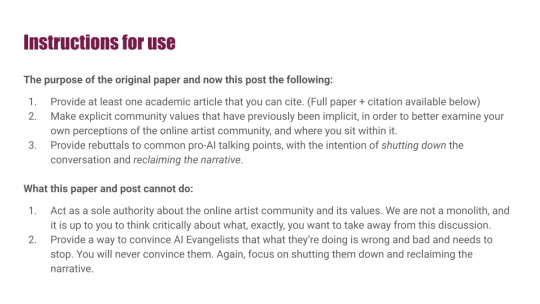

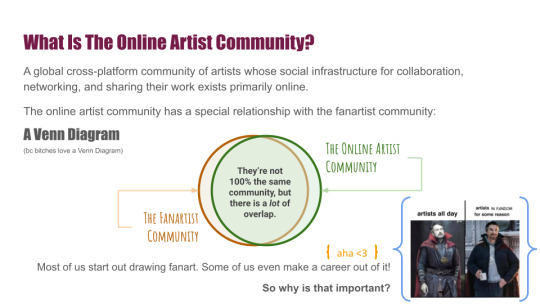

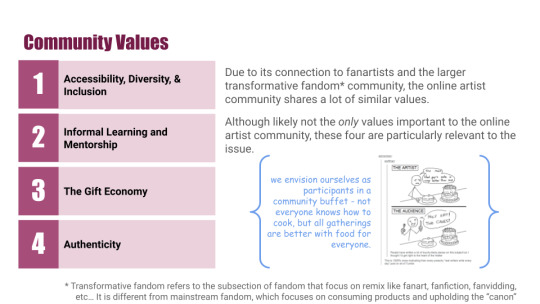

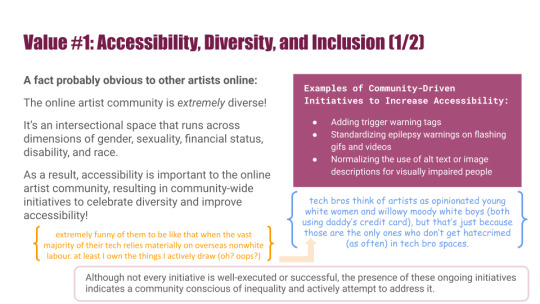

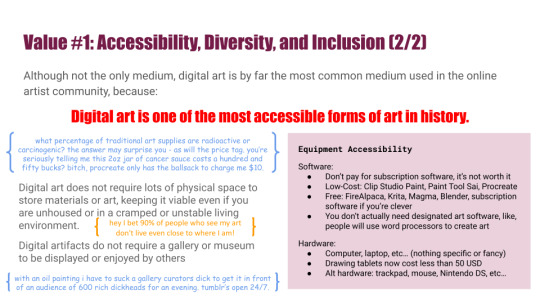

The purpose of the original paper and now this post is the following:

Provide at least one academic article that you can cite. (Full paper + citation available below)

Make explicit community values that have previously been implicit, in order to better examine your own perceptions of the online artist community, and where you sit within it.

Provide rebuttals to common pro-AI talking points, with the intention of shutting down the conversation and reclaiming the narrative.

What this paper and post cannot do:

Act as a sole authority about the online artist community and its values. We are not a monolith, and it is up to you to think critically about what, exactly, you want to take away from this discussion.

Provide a way to convince AI Evangelists that what they’re doing is wrong and bad and needs to stop. You will never convince them. Again, focus on shutting them down and reclaiming the narrative.

Final Disclaimer: I'm a very fallible researcher who is still very much learning how to do academia. I cannot speak for the entirety of the online artist community or fanartist community. We all have different lived experiences. I have done my best to include diverse voices; however if you have concerns or critiques, I am open to hearing them.

If you show up to debate in favor of AI image generators, you will be automatically blocked.

Credits:

Editors, Meme Experts, and Annotators: @starbeans-bags, @b4kuch1n, @cecilioque.

Tutorial Examples: @sabertoothwalrus, @ash-and-starlight, @miyuliart, @hometownrockstar, @deoidesign, @cinnamonrollbakery

If you have read this far, thank you very much. I hope that you have found a constructive lens for approaching the war with AI image generators, as well as a new tool for shutting down debate and reclaiming the narrative.

#anti ai#fuck ai#fuck ai everything#fuck ai bros#anti ai art#ai is theft#ai is a plague#fandom#fandom research#fanart#my academics#that's a new tag for me#long post

3K notes

·

View notes

Text

Automatic Block Making Machine

If you are looking for the best automatic block making machine in China, you could observe the general recommendations mentioned earlier to find a dependable supplier. Specifically, while attempting to find a hole block making machine, take into account the subsequent elements.

0 notes

Text

Automatic Block Making Machine

Are you looking for Automatic Block Making Machine? We offers high-quality automatic block making machines that are efficient and reliable. Find more about their advanced features and how they can enhance your block production process. For more details call us at +86 18953953978

0 notes

Text

Investing in the Future of Construction: Choosing the Right Block Making Machine

The construction industry is constantly evolving, with a growing emphasis on efficiency, sustainability, and cost-effectiveness. For businesses looking to capitalize on the demand for high-quality construction materials, investing in the right block making machine is a crucial decision. Whether you're aiming to produce durable paver blocks, eco-friendly fly ash blocks, or require a balance of automation and manual control with a semi-automatic machine, understanding your options is key to success.

We offer a comprehensive range of block making machines designed to meet diverse production needs and scales. Let's delve into the benefits and considerations for each type:

The Power and Precision of Paver Block Manufacturing Machines

Paver blocks are a popular choice for landscaping, walkways, driveways, and industrial areas due to their strength, aesthetic appeal, and ease of installation. A high-quality paver block manufacturing machine is essential for producing these blocks efficiently and consistently.

Key Advantages of Investing in a Paver Block Manufacturing Machine:

High Production Capacity: Modern machines can produce a significant number of paver blocks per cycle, increasing your output and profitability.

Consistent Quality: Automated or semi-automated processes ensure uniform size, shape, and density, leading to durable and aesthetically pleasing pavers.

Versatility: Many machines can produce various paver block designs and sizes by simply changing the mold.

Reduced Labor Costs: Automation reduces the reliance on manual labor, leading to lower operational expenses.

Meeting Market Demand: The demand for well-crafted paver blocks remains strong, making this a lucrative investment.

When choosing a paver block manufacturing machine, consider factors like production capacity, automation level, mold design options, power consumption, and the manufacturer's reputation for reliability and after-sales service.

Sustainable Solutions with Fly Ash Block Making Machines

In today's environmentally conscious world, fly ash blocks are gaining significant traction as a sustainable alternative to traditional clay bricks. Fly ash, a byproduct of coal-fired power plants, can be effectively utilized in block manufacturing, reducing waste and offering excellent construction properties. A dedicated Fly ash block making machine is designed to handle the specific requirements of producing these eco-friendly blocks.

Benefits of Utilizing a Fly Ash Block Making Machine:

Environmental Friendliness: Utilizing fly ash helps in waste management and reduces the environmental impact of construction.

Cost-Effectiveness: Fly ash is often a more economical raw material compared to clay.

Excellent Strength and Durability: Fly ash blocks can offer comparable or even superior strength and durability compared to traditional bricks.

Improved Thermal Insulation: Fly ash blocks often exhibit better thermal insulation properties, contributing to energy savings in buildings.

Government Incentives: Many regions offer incentives for using sustainable building materials like fly ash blocks.

Selecting the right Fly ash block making machine involves considering the mixing capabilities for fly ash, the required pressure for compaction, curing methods, and the machine's overall efficiency in handling this specific raw material.

Finding the Balance: Semi-Automatic Block Making Machines

For businesses seeking a balance between automation and manual control, a Semi-automatic block making machine offers a cost-effective and flexible solution. These machines typically automate key processes like mixing, feeding, and pressing, while still requiring some manual intervention for tasks like mold handling and block stacking.

Advantages of Opting for a Semi-Automatic Block Making Machine:

Lower Initial Investment: Compared to fully automatic machines, semi-automatic options generally have a lower upfront cost.

Flexibility and Adaptability: Semi-automatic machines can be more adaptable to smaller production runs and varied product types.

Reduced Complexity: The simpler design often translates to easier operation and maintenance.

Gradual Scalability: Businesses can start with a semi-automatic machine and gradually upgrade to more automated systems as their production needs grow.

Suitable for Diverse Block Types: Many Semi-automatic block making machines can be configured to produce various types of blocks, including paver blocks and fly ash blocks, with appropriate mold changes.

When choosing a Semi-automatic block making machine, consider the level of automation in different stages of the production process, the ease of mold changing, the required labor for operation, and the machine's overall build quality and reliability.

Your Partner in Block Manufacturing: Karmayog India

Our machines are built with quality components, ensuring durability and reliable performance. We also provide comprehensive support, including installation, training, and after-sales service, to ensure your success in the block manufacturing industry.

Visit our website today at https://karmyogindia.com/ to explore our range of block making machines and contact our expert team for personalized guidance and solutions. Invest in your future with the right technology and become a key player in the growing construction materials market.

#paver block manufacturing machine#Vibrating paver block machine#Fly ash block making machine#Semi-automatic block making machine#automatic paver block machine manufacturer#Automatic Bricks Making Machine Manufacturer

0 notes

Text

Best Paver Block and Brick Making Solutions from Ultra Tiles Machine

When it comes to producing high-quality paver blocks, bricks, and other concrete products, having the right equipment is crucial. Ultra Tiles Machine has established itself as a leading name in the industry, providing top-notch machinery for all your block and brick-making needs. With a wide range of machines designed to meet the demands of various construction projects, we cater to businesses that require efficiency, reliability, and precision in their manufacturing processes.

In this blog, we’ll explore the different types of machines offered by Ultra Tiles Machine, including Paver Block Making Machine, Hollow Solid Block Making Machine, Fly Ash Brick Making Machine, Concrete Block and Brick Making Machine, Chemical Hardener Manufacturers, Interlocking Paver Block Making Machine, and Automatic Brick Making Machine Manufacturer.

Paver Block Making Machine

A Paver Block Making Machine is essential for creating durable, aesthetically pleasing paving stones used in roads, driveways, walkways, and other outdoor spaces. At Ultra Tiles Machine, we offer advanced paver block machines that produce high-quality interlocking paver blocks in various shapes and sizes.

Our machines are designed to cater to both small and large-scale production needs, ensuring consistent output with minimal labor.

These machines are designed for optimal performance, ensuring that each paver block produced has the desired strength, texture, and finish.

Whether you need blocks for residential, commercial, or industrial projects, our Paver Block Making Machine will meet your specific requirements, ensuring efficiency, precision, and cost-effectiveness.

The Hollow Solid Block Making Machine offered by Ultra Tiles Machine is designed for producing high-strength blocks that are both cost-effective and versatile. Hollow blocks are widely used in the construction of walls, foundations, and other structures, offering excellent insulation and soundproofing properties. Our machine can produce both hollow and solid blocks, depending on your project’s requirements.

The machine is engineered with precision and advanced technology, ensuring that the blocks produced are uniform in size and shape. This ensures a smooth construction process, reducing material wastage and improving overall building quality. Additionally, our Hollow Solid Block Making Machine is designed to be durable, ensuring a long service life with minimal maintenance.

Fly Ash Brick Making Machine

Ultra Tiles Machine is a prominent Fly Ash Brick Making Machine manufacturer, offering state-of-the-art machines that are environmentally friendly and economically viable. Fly ash bricks are an eco-conscious alternative to traditional clay bricks, made from industrial waste products like fly ash, cement, and sand. These bricks are stronger, lighter, and more durable than conventional bricks, making them an ideal choice for modern construction projects.

Our Fly Ash Brick Making Machine uses innovative technology to ensure the production of high-quality fly ash bricks with consistent strength and size. This machine is perfect for businesses looking to reduce their environmental footprint while maintaining high standards of construction. With high automation and low energy consumption, it helps reduce production costs and enhances overall operational efficiency.

Concrete Block and Brick Making Machine

Our machines are designed to create blocks and bricks in various sizes, including standard, interlocking, and custom designs. The flexibility of our Concrete Block and Brick Making Machine ensures that it can cater to the specific needs of different construction projects. Whether you're building residential complexes, commercial buildings, or infrastructure projects, our machines deliver the perfect solution.

Chemical Hardener Manufacturers

In the production of paver blocks, bricks, and other concrete products, it’s essential to ensure high strength and durability. This is where the role of chemical hardeners comes into play. Ultra Tiles Machine is a trusted Chemical Hardener Manufacturer, offering top-quality hardening agents that improve the overall strength and resistance of concrete products.

Chemical hardeners are used to enhance the surface hardness of concrete products, providing them with greater resistance to wear, moisture, and weathering. By using the right chemical hardeners in your production process, you can ensure the longevity and durability of your paver blocks, bricks, and other concrete products.

Interlocking Paver Block Making Machine

At Ultra Tiles Machine, we ensure that the Interlocking Paver Block Making Machine we offer delivers precision and consistency in every block produced. With advanced technology and efficient production processes, these machines provide excellent results in a variety of sizes and designs to suit different project needs.

As an Automatic Brick Making Machine Manufacturer, Ultra Tiles Machine offers machines that automate the process of brick production, resulting in reduced labor costs and increased efficiency. Our Automatic Brick Making Machines are designed to produce high-quality bricks with minimal manual intervention. These machines are ideal for businesses that need to produce large volumes of bricks quickly while maintaining high standards of quality.

Our automatic machines are equipped with advanced features such as automated brick molding, high-pressure forming, and easy-to-use control systems. This ensures that each brick produced meets the highest quality standards while reducing the need for manual labor and increasing overall productivity.

Why Choose an Ultra Tiles Machine?

At Ultra Tiles Machine, we are committed to providing our customers with the best machinery solutions for their block and brick-making needs. Here’s why you should choose us:

Advanced Technology: We use the latest technology to manufacture machines that deliver high-quality products with minimal labor.

Customization: We offer customized solutions tailored to your specific production needs, ensuring that you get the perfect machine for your requirements.

Durability and Reliability: Our machines are built to last, with high-quality materials and precision engineering ensuring long service life.

Eco-friendly Solutions: We are committed to providing eco-friendly machinery, including Fly Ash Brick Making Machines that help reduce your carbon footprint.

Customer Support: We offer excellent customer support, ensuring that you have the assistance you need at every step of the way.

Conclusion

Whether you're looking for a Paver Block Making Machine, Hollow Solid Block Making Machine, Fly Ash Brick Making Machine, Concrete Block and Brick Making Machine, Chemical Hardener Manufacturers, Interlocking Paver Block Making Machine, or Automatic Brick Making Machine Manufacturer, Ultra Tiles Machine is the trusted partner for all your block and brick-making needs.

With our high-quality machines, advanced technology, and exceptional customer service, we guarantee that your production process will be efficient, cost-effective, and reliable.

Contact Ultra Tiles Machine today to learn more about our products and how we can help you take your construction business to the next level.

#Paver Block Making Machine Manufacturer#Hollow Solid Block Making Machine#Fly Ash Brick Making Machine#Concrete Block and Brick Making Machine#Chemical Hardener Manufacturers#Interlocking Paver Block Making Machine#Automatic Brick Making Machine Manufacturer

0 notes

Text

Top Model in automatic fly ash brick making machine in India

In this growing field and profession, the use of technology has become crucial. Specifically, the Automatic Fly Ash Brick Making Machine in India has proved to be an innovative solution to the brick making industry by revolutionizing the whole process of making bricks. These machines provide not only capacity and product quality but are vital tools for any contemporary manufacturer of bricks.

Automated manufacturing of bricks is important to increase productivity and improve the quality of bricks being produced. An automatic fly ash brick making machine in India can increase the production rate many folds in comparison to the manual production line while also decreasing the overall cost of labor. These machines work without much variation, meaning that human factors like tiredness do not affect the quality of the bricks produced.

Key Features to Look

The productivity of a fly ash brick making machine defines the number of bricks that it is capable of churning within a given period of time. This is important in regard to large orders, as the ability to produce a large quantity of products in a short amount of time is quite valuable. Look for the machines which can produce large numbers of bricks within a short time to enable you meet the market demand.

One of the most important factors that may determine the level of efficiency of a brick making machine and the ease of its operation is the degree of its automation. It requires little human interjection while providing quality control for the bricks as well as cutting cost on labor. Choose machines that incorporate the key aspects of automation such as the feeding, mixing, molding, and ejection systems.

Energy efficiency is the key to minimizing cost and ensuring that the best practices are followed at all times. An automatic fly ash brick making machine with low energy intake supports high production without wasting much energy. Look for machines made with efficiency features to reduce the cost of your electricity bill and the effects on the environment.

It is of great importance for a user to be able to operate, control or even maintain the fly ash brick making machine easily. Choose machines with clear physical controls, documented procedures, and easily accessible service parts. Maintenance is important in order to avoid failures and to work in the best conditions, so, select a model that will guarantee easy maintenance processes.

Brick machinery is the top name in brick making machine industry. Brick machinery offers various types of Automatic fly ash brick making machine in India with advanced technology. Brick machinery has range of product with advanced automation features that gives you satisfied output and high production. Here we are presenting you some of our best machines.

Top Models of Automatic Fly Ash Brick Making Machine in India

FAM-1440 Automatic Fly Ash Brick Making Machine

The FAM-1440 Automatic Fly Ash Brick Making Machine is one of the most efficient models which is quite popular among users due to its high performance and maximum longevity. This machine is technically designed to lower operational complexities and require very little maintenance. That makes it perfect for medium to large manufacturing operations; the FAM-1440 is capable of producing up to 1920 bricks per hour. According to users, the FAM-1440 is easy to use and dependable.

FAM-1080 Automatic Fly Ash Brick Making Machine

The FAM-1080 is another top model from Brick Machinery that is specifically designed to be versatile and highly efficient in its operations. It involves high levels of automation and control in an effort to produce high standard dimensioned bricks with minimal deviations. The FAM-1080 can produce up to 1440 bricks per hour, making it best choice to use in small to medium industries. The FAM-1080 has been positively received by customers who have complimented it as being well built and reliable.

FAM-2520 Automatic Fly Ash Brick Making Machine

FAM-2520 is the model with the highest technical level and automation rate among all of them and is considered to be the most successful and perspective one. This machine is intended for high-production mode and is amazing in its functionality and quality of the produced bricks. The FAM-2520 has a production capacity of up to 3360 bricks per hour and is suitable for large scale operations. The FAM-2520 has been praised highly in terms of its high production output and performance.

Each of the machines has special features aimed at improving your production of bricks making them worthy of consideration.We would like to invite you to also check out some of the most popular models and determine whether they will fit your need. For further details, please visit or get in touch with us at Brick Machinery to know how we may meet your needs.

#fly ash brick making machine#brick making machine#brickmakingmachine#automatic fly ash brick making machine in India#fly ash brick plant manufacturers#fly ash brick making machine in gujarat#fly ash brick plant#block making machine#brick making machine in india#brick making machine manufacturer#brickmachine

0 notes

Text

#Bricks Machine Manufacturer Morbi#brick machine manufacturer in gujarat#bricks machine manufacturer rajkot#fly ash brick making machine manufacturer#automatic fly ash brick making machine#fly ash brick making machine fully automatic#fly ash brick making machine supplier#paver block machine manufacturer morbi#paver making machine for sale#paver block making machine manufacturers#automatic paver block making machine

1 note

·

View note