#automation and control solutions

Explore tagged Tumblr posts

Text

Streamlining Innovation: Unveiling the Engineering Process with our ERP Module

Call us for free Demo : +91-9825056355 www.sterpsoftware.com

#sterp#sterperp#Sterpsoftware#Erpsoftwaresolutions#Marketing#Erpsoftware#Technology#Erpsystem#Clouderp#Erpsolutions#Erpsoftwareforengineering#Softwaredevelopment#Industry#Communication#Control#Productive#Manufacturers#Automation#Solutions#Experience#Accounting#Engineeringerp#Businessprocess#Managementsoftware#Businessandmanagement#Businessanalytics#Businessanalyst#Business#Engineering#Engineeringservices

4 notes

·

View notes

Text

Smart Home Solutions at Palm Beach Audio Visions

At Palm Beach Audio Visions (PBAV), we are passionate about delivering exceptional audio visual, home automation, lighting, and technology integration solutions for residential and commercial projects. From the initial concept to the final system deployment, we are dedicated to ensuring that projects are completed on time and within budget while exceeding industry standards for quality. Our team of experienced professionals brings a wealth of expertise in the high-end market and a strong focus on building lasting relationships with our clients. Feel free to visit us!

#Lutron Homeworks Dealer Whole House Smart Lighting Consultant#Design#Installation#Manager Solutions#Smart Home Network Setup Wifi Installation#Smart Home Security Camera Installation#Lutron Smart Window Electric Shades#Outdoor Entertainment System Design Installation Solution with Pool Patio Surround Sound Speakers#Outdoor Patio TV speaker Solution with Surround Sound#Universal Remote Control Smart Touch Screen Solution Programming Installation in Frenchman's Creek Palm Beach Gardens#Samsung QLED#Sony OLED#LG OLED Smart TV Dealer Installation Service#Home Theater System Consultant#Design and Installation Services#Sonos Dealer and Speaker Installation#Surround Sound Setup with In-ceiling Invisible Speakers#Whole House Multi Room Home Audio Installation Services#Smart Home Technology Consultant#Whole Home Automation Expert Installation Company#Control4 Smart Home Dealer - Installer

3 notes

·

View notes

Text

Innovate and Excel: Unlocking the Potential of ERPNext Manufacturing with Sigzen.

Welcome to ERPNext Manufacturing, where innovation meets excellence in real-time. As an ERPNext expert, I’m excited to guide you through how this solution transforms manufacturing operations. In today’s fast-paced market, businesses need to streamline processes and deliver quality products efficiently. ERPNext Manufacturing offers a comprehensive solution to integrate all aspects of manufacturing…

View On WordPress

#Agile Manufacturing#Automation Solutions#Digital Transformation#ERPNext#Lean Manufacturing#Manufacturing#ProcessOptimization#Quality Control#Technology Integration

3 notes

·

View notes

Text

Unlock the Power of Employee Automation Control Training

At BIN95, we understand the importance of equipping your team with the skills they need to excel in today's fast-paced world. That's why we offer an unbeatable deal - half off of our comprehensive training program and unlimited user and installation licenses.

Imagine the possibilities when every member of your organization (company or School) has access to cutting-edge training materials and resources. Our program covers everything from basic concepts to advanced techniques, ensuring that your team is well-equipped to handle any automation challenge that comes their way.

But time is running out! Don't let this opportunity slip through your fingers. Visit https://bin95.com/educational-site-licenses/ for more details and secure your purchase order today.

Invest in the future of your business or institution with Automation Control Training. Together, let's unlock a world of endless possibilities!

#automation control software#automation training#plc training#training solutions#tech school#STEM education#corporate training#community colleges#vocational training#plc#Motor Controls#hmi#vfd

2 notes

·

View notes

Text

Exploring the Smart Home Revolution with SwitchBot: The Smart Fan Advantage

The Smart Home Industry is rapidly evolving, and one brand making waves is SwitchBot. Known for its innovative solutions, SwitchBot is at the forefront of creating a more connected and convenient living environment.

One of their standout products is the Smart Fan. This device not only provides a refreshing breeze but also integrates seamlessly with your smart home ecosystem. Imagine controlling your fan from your smartphone or setting it to operate on a schedule that fits your lifestyle.

SwitchBot’s Smart Fan is designed to enhance comfort while being energy-efficient. With its sleek design and user-friendly app, it's never been easier to enjoy a cool breeze on a hot day. Plus, it can be connected to voice assistants, making it a perfect addition to your smart home setup.

Embrace the future of home automation with SwitchBot and experience how their Smart Fan can transform your living space into a more enjoyable and efficient environment!

#smartphone control#connected living#home automation#voice assistants#Smart Fan#comfortable living#innovative solutions

0 notes

Text

The Ultimate Guide to the PetSafe Cat Litter Box: Unveiling the ScoopFree Crystal Smart in 2025

For cat owners, the daily task of scooping the litter box can be a tedious and unpleasant chore. Messy, time-consuming, and often odor-laden, it’s a job few enjoy. Enter the PetSafe cat litter box, specifically the ScoopFree Crystal Smart Self-Cleaning Cat Litter Box, a revolutionary device designed to simplify litter maintenance and enhance your home’s hygiene. This PetSafe cat litter box…

#automated litter box#cat care#cat health monitoring#cat litter box#cat litter management#cat litter solutions#crystal litter#litter box maintenance#multi-cat litter box#Odor control litter box#pet hygiene#pet technology#PetSafe app#PetSafe cat litter box#PetSafe ScoopFree#ScoopFree Crystal Smart#self-cleaning litter box#smart litter box#smart pet devices#Wi-Fi litter box

0 notes

Text

The Man B&W 3157167-5.1 Master Control Unit is a high-performance industrial control board designed for efficient automation and reliable operation. It features multiple digital and analog input/output connections, programmable functions, and advanced diagnostic capabilities. Ideal for marine and industrial systems, this control unit ensures smooth and safe machine operations. Its modular design allows easy integration into existing setups, while robust components support long-term durability. The unit supports serial communication and network connectivity, making it suitable for complex automation tasks. Choose the Man B&W 3157167-5.1 Master Control Unit from Auto2mation for trusted performance in demanding environments.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Man B&W#Master Control Unit#Control unit

0 notes

Text

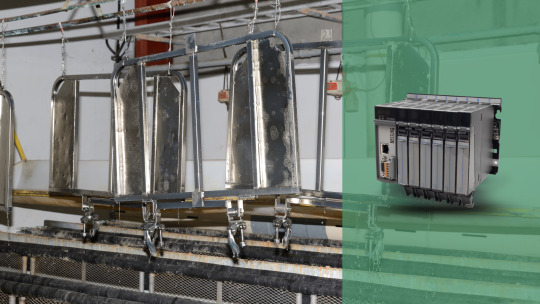

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

When to Redesign SAP Roles: During ECC or Post-Migration to S/4HANA or Rise with SAP

Migrating to SAP S/4HANA or adopting RISE/GROW with SAP is a strategic milestone for organizations aiming to modernize their ERP landscape. However, one critical consideration often overlooked during these transitions is the redesign of SAP roles. The timing of this redesign can significantly influence the success of the migration and the overall efficiency. Should you redesign roles during the ECC phase or wait until after the migration to S/4HANA? This blog explores the key factors driving this decision and introduces the S.M.A.R.T framework—a modern approach to SAP role redesign that ensures compliance, efficiency, and business alignment.

Understanding the Need for Role Redesign

SAP roles are pivotal in defining user access, ensuring compliance, and maintaining operational efficiency. Over time, roles in ECC systems often become bloated with unused authorizations or misaligned with current business needs. This can lead to:

Compliance Risks: Excessive authorizations increase the risk of segregation of duties (SoD) violations.

Migration Complications: Legacy roles with redundancies can complicate the migration process to S/4HANA.

Operational Costs: Since the licensing model is based on assignment and not by usage in S/4HANA and RISE, you may need to procure more licenses than required.

A role redesign ensures clean, streamlined, and compliant access structures, setting the stage for a smooth transition and efficient system post-migration.

ls.ECC vs. S/4HANA: When to Redesign Roles?

Aspect

Redesign During ECC

Redesign Post-Migration to S/4HANA

Compliance

Proactively addresses SoD conflicts and access risks.

Allows compliance alignment with new functionalities post-migration.

Migration Complexity

Simplifies migration with clean and optimized roles.

Reduces redundant effort, focusing only on relevant roles in the new system

Alignment with New Features

May require rework later to incorporate S/4HANA-specific functionalities.

Ensures roles are tailored to new modules, Fiori apps, and processes.

Timeline and Resources

Increases project timelines due to pre-migration workload.

Defers redesign efforts, potentially affecting initial system efficiency.

Business Process Analysis

Limited to existing ECC processes, with potential misalignment after migration.

Better aligned with current and optimized business processes in S/4HANA.

Redesigning SAP Roles with RISE with SAP

If you are moving to RISE with SAP, it is advisable to conduct a complete role redesign during the ECC phase. Once the migration is complete, perform a retrofit to align roles with the cloud-specific requirements introduced by RISE. This approach addresses the unique security, integration, and scalability considerations of a cloud-oriented transformation. You might have many questions at this juncture – What is the best approach? Which tools must be considered? Are there any accelerators that can be used? Can we use stock ready/ready to deploy role structures?

Challenges with Stock Ready Rulesets

Many system integrators offer pre-packaged or stock-ready rulesets as part of their role redesign services. While these rulesets might appear to save time and effort, they often come with significant challenges, making them unsuitable for many businesses. Here’s why the stock-ready approach is not recommended:

Lack of Customization: Stock-ready rulesets are designed to be generic and may not align with the specific needs of your industry or business processes. This can result in inadequate or excessive authorizations.

Compliance Risks: These pre-packaged rulesets may not fully address industry-specific compliance requirements, leaving gaps that could lead to audit findings or regulatory penalties.

Misalignment with Business Processes: Every organization has unique workflows and processes. Stock-ready rulesets may not account for these nuances, leading to inefficiencies and user frustrations.

Post-Implementation Challenges: Organizations often need to spend additional time and resources customizing these rulesets post-implementation, negating the perceived benefits of a quick deployment.

Instead of relying on stock-ready rulesets, organizations should invest in a tailored role redesign approach. This ensures that roles are aligned with specific business processes, compliance requirements, and future scalability needs, delivering long-term value and efficiency. This is where S.M.A.R.T approach/framework can be a life saver.

The S.M.A.R.T Role Redesign Framework

At ToggleNow, we leverage the S.M.A.R.T framework for SAP role redesign. This approach ensures that roles are:

Simplified: Designed to reduce complexity while maintaining operational effectiveness.

Mitigated for Risks: Focused on eliminating SoD conflicts and maintaining regulatory compliance.

Aligned with Business Tasks: Task-based roles ensure that access permissions directly support specific workflows.

Responsive to Change: Built to adapt seamlessly to future business or technical changes.

Transparent and Optimized: Designed with a focus on license optimization to eliminate unnecessary expenditures.

This framework delivers roles that are not only secure but also cost-effective and easy to manage

ToggleNow Advantage

ToggleNow brings a unique value proposition to SAP role redesign initiatives, ensuring a seamless and efficient process tailored to your business needs. Here’s why we stand out:

Customized Solutions: Unlike stock-ready rulesets, ToggleNow develops tailored role designs aligned with your specific business processes, compliance requirements, and industry standards.

Deep Expertise: With extensive experience in SAP role redesign, ToggleNow combines technical proficiency with a deep understanding of regulatory compliance and security best practices.

Innovative Tools:ToggleNow leverages proprietary tools such as Verity, Optimus and accelerators such as xPedite to streamline role redesign, risk analysis, and validation, ensuring faster project delivery.

Focus on Scalability:Our approach ensures that the roles we design are not only compliant and efficient but also scalable, adapting to your future business growth.

Proven Track Record:Trusted by leading organizations, ToggleNow has successfully delivered role redesign projects across diverse industries, enabling smoother migrations and enhanced system performance.

By partnering with ToggleNow, organizations can confidently navigate their SAP transitions, optimizing roles to drive operational excellence and long-term success.

Conclusion

The decision to redesign SAP roles during ECC or post-migration to S/4HANA or RISE with SAP depends on your organization’s priorities, resources, and timeline. Redesigning during ECC can simplify the migration process, while post-migration redesign allows alignment with new functionalities. For RISE with SAP, role redesign becomes even more critical to address cloud-specific requirements.

Moreover, organizations should avoid the pitfalls of stock-ready rulesets and opt for a customized approach that aligns with their unique requirements. By investing in a well-planned redesign, organizations can unlock the full potential of SAP S/4HANA or RISE with SAP, driving operational excellence and business growth.

Read more: https://togglenow.com/blog/redesign-sap-roles-ecc-or-s-4hana/

#SAP Risk Management#SAP access risk analysis tool#SAP GRC access control solution#SAP segregation of duties automation#SoD risk analysis for SAP

0 notes

Text

Modern Commercial Lighting for Technology MNC | Ideeaz Automation

Discover how Ideeaz Automation transformed the workspace of a leading Technology MNC with cutting-edge commercial lighting solutions. Explore this smart lighting project designed for productivity, sustainability, and modern aesthetics.

#Commercial Lighting#Smart Lighting#Technology Office Lighting#Lighting Automation#IoT Lighting Solutions#Workspace Lighting Design#Sustainable Lighting#Ideeaz Automation Projects#Modern Office Lighting#Technology MNC Lighting#ideeaz automation#smart house lighting#smart home#lighting control systems#energy-efficient lighting#efficiency

0 notes

Text

Exploring the Exciting World of Smart Home Automation with SwitchBot!

The Smart Home Industry is rapidly evolving, and one of the standout brands making waves is SwitchBot. Known for its innovative solutions, SwitchBot is revolutionizing the way we interact with our living spaces. One of their most impressive products is the automation blinds control, which allows users to effortlessly manage their window coverings with just a tap or a voice command.

Imagine waking up in the morning to the soft glow of sunlight filtering through your automated blinds, all thanks to SwitchBot's technology. With their user-friendly app, you can schedule your blinds to open or close at specific times, enhancing both convenience and energy efficiency in your home. Plus, the sleek design of SwitchBot products complements any decor, making them a stylish addition to your smart home setup.

Whether you want to create a cozy atmosphere for movie nights or ensure your home stays cool during the hot summer months, SwitchBot's automation blinds control offers a practical solution. Embrace the future of home automation and enjoy the comfort and convenience that SwitchBot brings to your life!

0 notes

Text

Smart Parking Solution for Property Owners & Managers: Boost Revenue & Optimize Operations

Managing parking areas is not only about allocating space, it’s also+about maximizing returns, improving tenant satisfaction, and simplifying operations. With smart technology transforming every aspect of real estate, a smart parking solution for property owners and managers has become a critical investment.

In this article, we explore how modern parking systems like LotPilot are empowering property managers to solve long-standing parking challenges, increase revenue, and create seamless experiences for residents and visitors alike.

Why Property Owners Need Smart Parking Solutions

Property owners and managers face multiple challenges in handling parking facilities:

Inefficient space utilization

Manual tracking and enforcement

Unauthorized or overstaying vehicles

Revenue leakage in paid parking zones

Poor tenant or visitor experience

Traditional methods like paper tickets or manual monitoring fall short in today’s fast-paced environments. This is where a smart parking solution designed specifically for property management steps in offering data-driven control and automation.

Key Benefits of a Parking Solution for Property Owners & Managers

1. Maximized Space Utilization

Smart parking platforms like LotPilot use real-time data and occupancy sensors to help managers allocate and monitor parking spaces effectively. This ensures that no space goes underused, especially in high-demand residential, commercial, or mixed-use properties.

2. Automated Access & Entry Control

Smart access systems integrated with License Plate Recognition (LPR) or QR-based entry eliminate the need for manual gates or physical passes. This reduces operational costs and enhances security.

For example, with LotPilot, property managers can issue digital permits, restrict entry to unauthorized vehicles, and monitor every vehicle entering or exiting the premises.

3. Simplified Visitor Management

Managing guest parking can be chaotic. A smart system enables residents to pre-book visitor slots, and digital passes can be sent to guests for seamless entry. This reduces confusion at entry points and improves tenant satisfaction.

4. Revenue Optimization

For paid or mixed-use parking lots, LotPilot allows full automation of payment processing. Whether it’s pay-per-use, monthly subscriptions, or dynamic pricing during peak hours, the platform can manage it all.

Integrated reports give property owners full visibility into parking revenues, helping identify trends and maximize profitability.

5. Enhanced Security and Monitoring

With integrated surveillance, entry logs, and advanced analytics, LotPilot improves overall property security. Managers can get instant alerts for rule violations, overstays, or suspicious activity, maintain order and safety in shared spaces.

Customizable Solutions for Different Property Types

LotPilot isn’t a one-size-fits-all solution. It offers flexibility to adapt to various property settings.

Residential complexes: Allocate dedicated slots, manage visitors, and provide app-based access to residents.

Commercial properties: Enable tiered pricing, tenant management, and real-time space availability updates.

Mixed-use properties: Seamlessly manage both short-term and long-term parking needs, all in one platform.

Whether you're running a gated community, a shopping center, or a corporate office, LotPilot's scalable architecture can be tailored to your specific needs.

Real-time Insights and Reporting

One of the most powerful features of modern parking systems is data. LotPilot provides actionable insights into:

Peak usage times

Average duration of stays

Revenue per slot

Compliance metrics

This helps property owners make informed decisions—like when to expand capacity, increase rates, or change operational hours.

Cloud-based Control Anytime, Anywhere

Cloud technology ensures that you don’t need to be physically present to manage your property’s parking operations. Through LotPilot’s cloud dashboard, you can monitor, assign, and control access to your parking areas remotely—24/7.

Sustainable & Future-ready

Smart parking also contributes to sustainability goals. Efficient traffic flow, reduced idle time, and minimized emissions create a better environment for everyone. With the number of electric vehicles(EVs) on the road rising, platforms like LotPilot are already integrating EV charging station management—future-proofing the property.

Final Thoughts

A reliable parking solution for property owners and managers isn’t just a convenience, but a strategic advantage. By streamlining operations, increasing security, and unlocking new revenue streams, solutions like LotPilot help transform parking from a cost center to a profit generator.

Whether you're a developer planning a new project or a property manager looking to modernize your facility, investing in a smart parking platform is the way forward.

Explore LotPilot today and see how it can simplify parking management while enhancing tenant and visitor satisfaction.

#Smart parking solution#Parking management system#Property parking solutions#LotPilot parking platform#Smart parking for property owners#Parking automation system#Parking solutions for real estate#Parking access control system

0 notes

Text

Get Organized: ERPNext Distribution by Sigzen Makes It Easy

In today’s fast-paced Running a business can be tough, especially when things get messy. But what if there was a way to make it all simpler. That’s where ERPNext Distribution comes in. This awesome tool helps you manage your stuff like inventory, deliveries, and ordering without any hassle. It’s like having a helper for your business tasks. With ERPNext Distribution, you can say goodbye to…

View On WordPress

#Business Automation#ERP Integration#ERP Software Solutions#Inventory Management System#Procurement Management#Resource Planning#Stock Control#Workflow Optimization

3 notes

·

View notes

Text

🚨 Why 4–20 mA? What makes it the gold standard in industrial automation?

📄 [PDF link Attached]

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#Solution#linkdin#linkdinpost#industrial applications#industrial automation#industrial equipment#industrial control

1 note

·

View note

Text

Smart Parking Management Software | Parkomax Streamline your parking operations with Parkomax's advanced parking management software. Real-time monitoring, automated access, and seamless reporting in one platform.

#Parking Management Software#Smart Parking System#Automated Parking Software#Parking Control System#Parking Lot Management Software#Cloud-based Parking Software#Parking Garage Management System#Parking Access Control#Parking Operations Software#Digital Parking Solutions#Parkomax parking software#IoT-enabled parking system#Parking analytics and reporting tool#Multi-location parking management solution#Parking ticketing and billing automation

0 notes