#chamfering machine

Explore tagged Tumblr posts

Text

Mastering Tile Edges: The Role of Chamfering Machines in Modern Tiling

Chamfering is the technique of beveling the edges of tiles to remove sharpness and create a more refined look. This is particularly important in areas where tiles meet at corners or edges, as it enhances both the safety and aesthetic appeal of the tiled surface.

Importance of Tile Chamfering Machines

1. Precision

Tile chamfering machines are designed to deliver consistent and accurate bevels, ensuring uniformity across all tiles.

2. Efficiency

These machines streamline the chamfering process, significantly reducing the time and labor required compared to manual methods.

3. Versatility

Capable of handling various tile materials, including ceramic, porcelain, and natural stone, tile chamfering machines are suitable for a wide range of applications.

Types of Tile Chamfering Machines

1. Manual Chamfering Tools

Ideal for small-scale projects or on-site adjustments, manual chamfering tools are portable and cost-effective.

2. Electric Chamfering Machines

These machines offer higher efficiency and are suitable for medium to large-scale projects, providing faster processing times.Basair Electro Mechanical Co., LTD

3. Automatic Chamfering Systems

Designed for industrial-scale operations, automatic systems offer high-speed processing with minimal manual intervention, ensuring maximum productivity.

Applications of Tile Chamfering Machines

Residential and Commercial Tiling Projects Enhancing the finish of tiled surfaces in homes, offices, and commercial spaces.

Tile Manufacturing Used in production lines to pre-chamfer tiles before packaging and distribution.

Custom Tile Designs Facilitating intricate designs and patterns by allowing precise edge modifications.

Maintenance and Safety Tips

Regular Cleaning Keep the machine clean to prevent debris buildup, which can affect performance.

Routine Inspections Check for wear and tear on components to ensure the machine operates efficiently.

Proper Training Ensure operators are well-trained to handle the machine safely and effectively.

Use Protective Gear Operators should wear appropriate safety equipment, such as gloves and eye protection, during operation.

Conclusion

Tile chamfering machines play a crucial role in achieving high-quality, safe, and aesthetically pleasing tiled surfaces. By understanding their functions, types, and maintenance requirements, professionals can make informed decisions to enhance their tiling projects.

0 notes

Text

#spmequipment#pipe stand#pipe support roller#motorized pipe rotator#pipe chamfering machine#wedge bending mandrel#pipe bending die shoe

0 notes

Text

0 notes

Text

0 notes

Text

Tube Chamfering Machine in punjab

A tube chamfering machine is a specialized industrial tool used for precision beveling or chamfering the edges of cylindrical tubes or pipes. This machine is designed to create a smooth, angled surface at the end of a tube, which is useful for various applications such as welding, assembly, or ensuring a proper fit with other components

0 notes

Text

This is the wheel that you've been waiting for! When Dodge launched the incredible 1025HP Demon 170, they offered an option to equip the vehicle with the most technologically-advanced road wheels ever sold by any automotive manufacturer: The Lacks Carbon Fiber Drag Pack. This same 18x8/17x11 setup is now available with our new Lacks Carbon Dodge Drag Pack Series, including the original revolutionary carbon fiber barrels from Lacks Enterprises combined with precision-machined 6061-T6 forged aluminum centers from Forgeline. The Lacks Carbon Fiber Dodge Drag Pack Series has debuted with two new wheel models ready to order, the LCF200 and the LCF205. The LCF200 combines its carbon fiber barrel with a unique precision-machined forged aluminum center consisting of five muscular spokes with strong chamfered machining details, while the LCF205 is a lightweight racing-inspired ten spoke design with an open-lug hub center and aggressive I-beam machining. Both wheels are available in 18x8.0 front and 17x11.0 rear drag pack fitments for the Dodge Demon 170 and the wide body Hellcat. And they are equipped with a special version of the lightweight Lacks carbon fiber barrels that are 40% lighter than an aluminum equivalent and are treated with a high-friction anti-slip coating applied to the rear barrels to eliminate tire slip between the wheel and tire for maximum launch velocity. The Lacks carbon fiber barrel preserves its standard satin-gloss natural carbon weave finish, while the LCF200 and LCF205 forged aluminum centers are available in the full array of customizable finish options. Learn more about the LCF200, LCF205, and the Lacks Carbon Fiber Dodge Drag Pack Series at: https://www.forgeline.com/lacks-carbon-dodge-drag-pack-series/c1956

#forgeline#forgelinewheels#forgedwheels#customwheels#carbonforged#carbonfiber#LCF200#ForgelineLCF200#LCF205#ForgelineLCF205#notjustanotherprettywheel#doyourhomework#madeinUSA#🇺🇸#carenthusiast#carbonfiberwheels#LacksCarbon#wheelwednesday

3 notes

·

View notes

Text

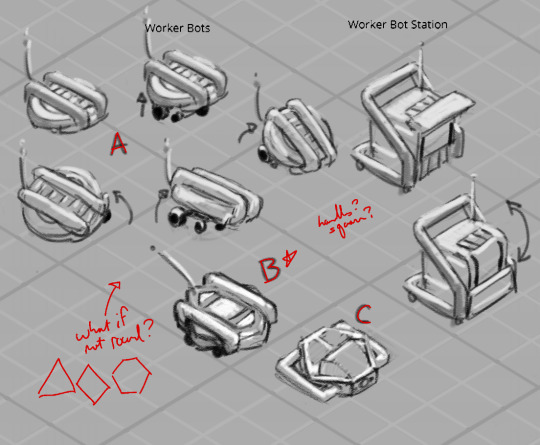

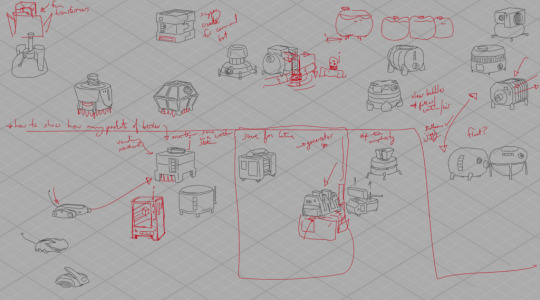

Astronomics Game Art : Designing Mining Equipment! Pt 2

Brainstorming and feedback loops One of the first steps of designing is always brainstorming -- sometimes this starts before research, sometimes I research first, and often I go back and forth, letting brainstorming push me to the limits of my current knowledge and then taking to the internet to open up new territory. For the equipment for Astronomics (demo on steam right now!), while the design team had a few key assets they were looking for, they were also still brainstorming and so we were all kind of discovering what the equipment part of the game could be as a whole.

For me, that brainstorming usually looks like a LOT of very rough drawings. I usually have my research sketches open nearby for reference, and I try and draw small enough that i can see all my brainstorming and seek out possibility spaces between ideas. Above is my first VERY rough brainstorming page, and on it you can see art from two passes - the softer, lighter drawings are the open-ended thinking; the darker clear lines are the second pass, where I start filtering, choosing which pieces to take to the rest of the team to start conversations with.

You can see how we would collect feedback above - i would write notes and do additional drawing on top of the submitted artwork as we went through things in screenshared video meetings, and then have these with me as I iterated further. One thing you might notice is that these are all drawn with straight lines -- Astronomics is a low-poly 3D style game, and it was fun to think about simplifying the shapes right from the beginning. While I didn't do all my drawing like this, it was a fast and quick way to get clean linework that had some connection to the style of the game long before we really knew anything about said style! Speaking of style... Next up, we had to make some big decisions. Astronomics has a lot of equipment with a big range of functions and scales and the most important thing was making sure it all read like equipment from the same manufacturer - that being CubeCorp, as you'll see in the demo. I narrowed it down to three possibilities:

I went in three directions -- "Star Wars" style, all panel lines and chamfered edges and a sense of overall complexity; "Safety" style, with safety bars and frames around everything, focusing otherwise on simple, chunky shapes; and "Modern" style, exploring simple silhouettes with hidden complexity. (none of these are official names for known styles, eg, the star wars style didn't actual aim for matching the style in those films particularly -- these names were more mnemonic devices to help me quickly sum up what I was thinking in a punchy way, and help my coworkers refer to the styles more easily in conversation while we discussed an debated direction together.) In the end, what we chose was mostly Safety-styled, but elements from both other directions made their way in too!

And here was my first sheet ft a pass on the drill, pump and vaccuum, containers for solids, liquids and gasses, a worker bot, a worker bot home, and a robust scanner machine. A few things we were thinking about: we wanted there to be a sense of a unit of size that everything fit into - CubeCorp, remember? - and so even our most complicated equipment needed to pack down into that cube. That meant that we were going to be animating equipment essentially unfolding, so I tried even at this stage to think about what that could mean for the drill and pump and vaccuum, and you can see packed and unpacked states up there for each design. They also were likely to be carried around by our little darling worker bots -- so everybody needed feet the bots could squeeze between to get underneath. Speaking of, they probably went through the most designs of everything, and what's in the demo does not appear in these pages at all, haha, but here, a few more passes:

In fact, you might not be able to find any of these exact designs in the demo -- that's just the nature of concept art in games! What the game needed then and what it needed later -- as the game design itself was developed -- well, it changed, as it often can! I think it can be easy from the outside to assume that everything anyone thought of was eventually brought to life, but that rarely ever happens. Concept art is a process, and so even if these designs didn't make it into the game, they were an important step along the path towards designs that did, and they taught us a lot about what we did and didn't want Astronomics to look like! Read the full article

8 notes

·

View notes

Text

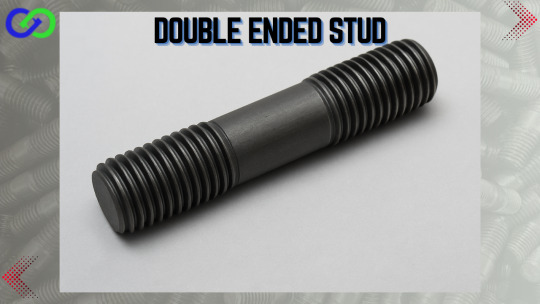

Double Ended Stud: Complete Guide

Ananka Fasteners offers premium-quality Double Ended Studs, engineered for maximum performance and durability. Designed to meet the highest industrial standards, our double ended studs deliver superior fastening solutions across industries that demand strength, precision, and corrosion resistance.

With advanced manufacturing facilities and a deep understanding of industrial fastening solutions, we deliver top-quality double ended studs tailored to meet diverse engineering applications.

What is a Double Ended Stud?

A Double Ended Stud is a type of fastener that features threads on both ends, separated by an unthreaded shank or a body in the middle. These studs are designed to be screwed into a tapped hole at one end while the other end accommodates a nut to fasten components together securely. Unlike standard bolts, double ended studs offer higher strength, precise alignment, and improved load distribution.

Key Features of Double Ended Studs

Threaded on both ends with consistent or varied thread types/sizes

Chamfered ends for easy assembly

Available in metric and imperial sizes

Custom lengths and threads as per client specifications

High tensile strength and excellent mechanical stability

Corrosion-resistant materials available for harsh environments

Applications of Double Ended Studs

Double ended studs are widely used in:

Automotive (engine assemblies, exhaust systems)

Oil & Gas (flanges, high-pressure fittings)

Petrochemical and Chemical Industries

Power Plants (turbines, boilers)

Construction and Heavy Machinery

Marine and Offshore Installations

Types of Double Ended Studs We Manufacture

We offer a wide variety of double ended studs to meet industrial requirements:

Fully Threaded Studs

Tap-End Studs (one short thread for screwing into a tapped hole, one long for a nut)

Reduced Shank Studs

Continuous Threaded Studs

Studs with Chamfered Ends

Material Grades

We manufacture double ended studs in various grades and alloys:

Stainless Steel:

SS 304, 304L, 316, 316L, 310, 321, 347

Alloy Steel:

ASTM A193 Grade B7, B7M, B8, B8M, B16

High-Temperature Alloys:

Inconel 600, 625, 718

Hastelloy C22, C276

Monel 400, K500

Nickel 200/201

Titanium Grade 2 / Grade 5

Duplex & Super Duplex:

UNS S31803, S32205, S32750, S32760

Others:

Brass, Copper, Silicon Bronze, Carbon Steel, Aluminium Bronze

Standard Specifications

Our double ended studs conform to the following standards:

ASTM / ASME: A193, A320, A307

DIN / ISO / BS / JIS Standards

Custom specifications as per client drawings

Surface Coating & Finishes

To improve performance and corrosion resistance, we offer various coatings:

Zinc Plated (Clear/Yellow/Black)

Hot Dip Galvanized (HDG)

PTFE Coated (Blue, Green, Red)

Xylan, Teflon, and Fluoropolymer Coating

Black Oxide, Dacromet, Geomet

Why Choose Ananka Fasteners?

Precision Engineering with CNC machining and threading Wide Range of Materials and grades available Custom Manufacturing to meet specific application needs Strict Quality Control in accordance with ISO standards Timely Delivery with export-ready packaging Global Supply Network across the USA, Europe, Middle East, Africa & Asia

Industries We Serve

Oil & Gas

Aerospace

Automotive

Marine

Petrochemical

Power Generation

Construction & Infrastructure

Double Ended Studs Exporter – Global Reach

Ananka Fasteners exports premium quality double ended studs to several countries including:

USA, UK, Germany, France, and Italy

UAE, Saudi Arabia, Oman, Qatar

South Africa, Nigeria, Kenya

Australia, Singapore, Malaysia

Brazil, Mexico, and Canada

Contact Us

Looking for a reliable Double Ended Stud supplier?Contact Ananka Fasteners today for competitive pricing, technical consultation, and bulk orders.

Frequently Asked Questions (FAQs)

Q1. What is the difference between a double ended stud and a threaded rod?A double ended stud has threads on both ends with an unthreaded middle portion, while a threaded rod is fully threaded along its entire length.

Q2. Can double ended studs be customized?Yes, we offer custom sizes, thread types, and coatings based on your requirements.

Q3. Which coating is best for marine applications?PTFE or Xylan-coated stainless steel studs are ideal for corrosion resistance in marine environments.

Q4. Do you provide test certificates?Yes, we provide MTC, NABL-approved lab reports, and third-party inspection reports on request.

#DoubleEndedStuds#StudBolts#IndustrialFasteners#FastenerSolutions#EngineeringFasteners#PrecisionFasteners#MechanicalFasteners#ThreadedStuds#BoltingSolutions#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#Tumblr#tumblr blog#bolt#stud bolt#articles

0 notes

Text

#spmequipment#pipe stand#pipe support roller#motorized pipe rotator#pipe chamfering machine#wedge bending mandrel

0 notes

Text

1 note

·

View note

Text

Tube Sheet Drilling: Precision Engineering for Heat Exchanger Efficiency

Introduction to Tube Sheet Drilling

Tube sheet drilling is a highly specialized machining process used to create accurate and aligned holes in tube sheets—critical components in heat exchangers, boilers, pressure vessels, and condenser systems. These precision-drilled holes allow for the insertion and secure mounting of heat exchange tubes, ensuring optimal thermal transfer efficiency and mechanical stability.

With increasing demands in petrochemical, oil & gas, power generation, and chemical industries, high-precision tube sheet drilling has become more essential than ever for leak-proof, high-pressure, and high-temperature applications.

What is a Tube Sheet?

A tube sheet is a thick metal plate, typically made from carbon steel, stainless steel, copper alloys, or nickel-based alloys, that holds tubes in position within a heat exchanger or similar device. These plates are drilled with hundreds or even thousands of holes, each of which must be precisely located and dimensioned to ensure proper tube alignment and flow dynamics.

Tube sheets may be:

Flat or flanged

Cladded or solid

Fixed or floating

The integrity of tube sheet drilling directly influences the operational efficiency and lifespan of the entire equipment.

Key Features of Tube Sheet Drilling

1. Ultra-Precision Hole Placement

Hole pitch accuracy within ±0.02 mm

Accurate alignment for seamless tube-to-sheet welding or expansion

Support for complex configurations like square, triangular, or staggered pitch patterns

2. Custom Hole Diameters

Hole diameters typically range from 10 mm to 50 mm

Precision tools for countersinking, reaming, and chamfering as per design requirements

3. CNC and Multi-Spindle Drilling Options

CNC drilling offers repeatability, speed, and automation

Multi-spindle heads reduce cycle time by drilling multiple holes simultaneously

Option to program tool paths, feed rates, and depths

4. Compatibility with Multiple Materials

High-speed steel and carbide-tipped drill bits for superior performance

Capability to drill cladded tube sheets (e.g., stainless steel + carbon steel)

Coolant-fed tools and optimized cutting conditions to handle exotic alloys

Applications of Tube Sheet Drilling

1. Heat Exchangers

Critical for U-tube heat exchangers, shell & tube designs, and double-pipe configurations

Precise drilling ensures efficient thermal conductivity and mechanical locking

2. Boilers and Pressure Vessels

Supports high-pressure operations

Helps in achieving zero-leakage expansion joints

3. Oil Refineries and Chemical Plants

Used in corrosive environments where precision and metallurgy are key

Hole alignment ensures uninterrupted flow of process fluids

4. Power Generation and Nuclear Plants

Used in superheaters, economizers, and condenser systems

Requires radiographic inspection compliance for nuclear-grade tube sheets

Tube Sheet Drilling Process: Step-by-Step

1. Design and Layout Preparation

3D CAD models or 2D technical drawings created for hole mapping

Pitch, margin, and hole count are finalized

2. Material Preparation

Tube sheets undergo annealing, cleaning, and marking

Plate thickness checked (often ranges from 20 mm to 200 mm)

3. CNC Drilling Operation

CNC-controlled drill head moves in X-Y coordinates

Drilling depth, diameter, and tolerance pre-set for each hole

Coolant system active to prevent heat build-up and tool wear

4. Finishing

Chamfering or reaming if needed

Deburring for smooth hole edges

Non-destructive testing (NDT) to check hole accuracy and spacing

Advanced Technologies in Tube Sheet Drilling

1. Deep Hole Drilling Machines

Capable of handling thick tube sheets over 150 mm

Specialized gun drilling or BTA (Boring & Trepanning Association) methods used

2. Laser Drilling (For Special Alloys)

Non-contact, heat-concentrated drilling

Used where traditional tooling may not work (e.g., titanium, Inconel)

3. Robotic Drilling Systems

Fully automated arms integrated with CAD/CAM

Ideal for custom tube sheets or small production batches

Quality Control and Inspection

1. Dimensional Inspection

Coordinate Measuring Machines (CMM) used for verifying hole positions

Ensures compliance with ASME, TEMA, and ISO standards

2. Surface Integrity Checks

Inspection for burrs, cracks, or work hardening

Use of penetrant testing (PT) and ultrasonic testing (UT)

3. Fit-Up Verification

Tube insertion test to validate hole alignment and tightness

Simulates real working conditions under thermal and hydraulic stress

Choosing the Right Tube Sheet Drilling Partner

When selecting a supplier for tube sheet drilling, consider the following:

Experience in large-diameter tube sheets

Capability for high-volume or prototype jobs

Access to modern CNC drilling machines

Compliance with international QA/QC standards

In-house NDT and post-drilling inspection systems

Conclusion

Tube sheet drilling is more than just a machining task—it is an engineering-critical operation that demands micron-level accuracy, repeatability, and material adaptability. As industries continue to evolve towards energy efficiency and system reliability, precision-drilled tube sheets form the backbone of high-performance heat exchange systems. Investing in advanced tube sheet drilling solutions means investing in long-term operational safety, energy conservation, and system longevity.

1 note

·

View note

Text

0 notes

Text

0 notes

Text

0 notes

Text

When Dodge launched the incredible 1025HP Demon 170, they offered an option to equip the vehicle with the most technologically-advanced road wheels ever sold by any automotive manufacturer: The Lacks Carbon Fiber Drag Pack. This same 18x8/17x11 setup is now available here with the LCF200, including the revolutionary Lacks carbon fiber barrels and precision-machined 6061-T6 forged aluminum centers from Forgeline. The LCF200 combines its carbon fiber barrel with a unique precision-machined forged 6061-T6 aluminum center featuring five muscular spokes with strong chamfered machining details to yield a wheel with absolutely impressive performance metrics: very low static mass, very low rotational inertia, minimal deflection, and excellent fatigue strength. The LCF200’s super-lightweight carbon fiber barrel creates an attractive and visually distinctive rim that is 40% lighter than its aluminum equivalent, delivering a significant weight reduction to the wheel's outer perimeter, where it has the greatest reduction in unwanted inertia and yields real-world improvements to acceleration, braking, cornering traction, ride quality, NVH (noise, vibration, & harshness), driver/passenger comfort, and fuel economy. The rear wheels are further treated with a high-friction anti-slip coating applied to the Lacks carbon fiber barrels to eliminate tire slip between the wheel and tire for maximum launch velocity. The LCF200 is available in 18x8 front and 17x11 rear fitments specifically engineered for the Dodge Demon 170 and widebody Hellcat. And like any Forgeline wheel, the LCF200’s forged aluminum center is available in the full array of customizable finish options. Learn more about the LCF200 (including sizes and pricing) at: https://www.forgeline.com/lcf200/p409

#forgeline#forgelinewheels#forgedwheels#customwheels#LCF200#ForgelineLCF200#CarbonFiber#notjustanotherprettywheel#doyourhomework#madeinUSA#SEMA#SEMAShow#SEMA2024#carenthusiast#wheelsofinstagram#Dodge#Demon170#Hellcat#DragRacing

2 notes

·

View notes