#cnc spring machine

Explore tagged Tumblr posts

Text

AutolinkCNC Technologies

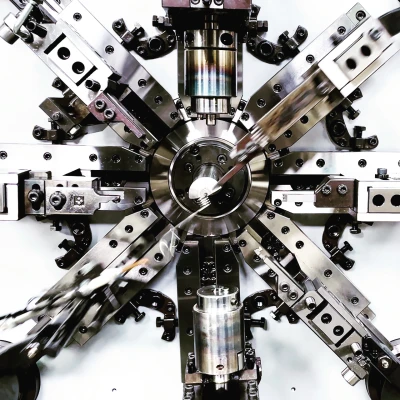

Autolink CNC Technology Co., Ltd. is a leading Supplier in China. We are specialized in supplying CNC spring coiling machines, CNC wire forming machines, and CNC wire bending machines.

We follow the main policy of new technology, quality assurance, and honest service. We are also specialized in providing customized wire bending machines to fulfill our customer requirements.

For more details,

Contact us @ +86 18948348793 Mail-id: [email protected]

#autolinkcnc#wire bending machine#steel wire bending machine#wire spring making machine#spring coiling machine#wire forming machine india#spring forming machine#cnc wire bender#cnc spring machine#spring manufacturing machine

0 notes

Text

The Efficiency of CNC Spring Coiling Machines in Modern Manufacturing

For manufacturers working with springs, precision, efficiency, and reliability are key. The CNC Spring Coiling Machine has become a critical tool in the production of high-quality springs with minimal manual intervention. By integrating advanced technology, CNC spring coiling machines bring a level of automation and precision to spring manufacturing that is difficult to achieve through traditional methods.

Precision and Consistency

One of the key advantages of using a CNC spring coiling machine is its ability to produce springs with high precision. These machines are designed to follow exact specifications, ensuring that each coil is consistent in size, shape, and tension. In industries where the quality and accuracy of springs are paramount—such as aerospace, automotive, and medical device manufacturing—having a CNC spring coiling machine can help ensure that every spring meets the required standards, reducing waste and minimizing defects.

Automation and Increased Production Speed

CNC spring coiling machines are equipped with advanced controls that allow for the automation of the coiling process. Once programmed, these machines can coil springs rapidly without the need for constant supervision. This automation not only improves the production speed but also reduces the potential for human error, allowing for continuous production without interruption. This is particularly beneficial in large-scale manufacturing environments where high-volume production is necessary.

Flexibility in Spring Design

CNC spring coiling machines offer flexibility in terms of the types of springs they can produce. Whether you need tension, compression, or torsion springs, CNC machines can handle a wide range of spring types and sizes. This adaptability makes them suitable for various industries, from consumer products to heavy industrial applications. The ability to easily adjust settings and parameters ensures that manufacturers can produce springs to meet specific requirements without the need for significant retooling.

Reduced Labor Costs and Increased Efficiency

The introduction of CNC technology in spring coiling has greatly reduced the need for manual labor. Traditional spring coiling often required skilled operators to manually adjust machines and supervise the coiling process. With CNC spring coiling machines, the process becomes automated, requiring less human intervention. This reduction in labor costs, combined with the faster production times, results in increased overall efficiency for manufacturers.

Reliability and Durability

CNC spring coiling machines are built to last. With their robust construction and advanced technology, these machines are designed to operate in demanding manufacturing environments. The machines require minimal maintenance and can run for extended periods without issue, making them a reliable tool for companies looking to streamline their production processes. With regular upkeep, these machines offer years of dependable service.

The Bottom Line

For manufacturers looking to improve the efficiency and quality of their spring production, investing in a CNC Spring Coiling Machine is a smart choice. By enhancing precision, increasing production speed, and reducing labor costs, these machines provide a comprehensive solution for modern spring manufacturing needs. The ability to produce high-quality springs with minimal intervention helps manufacturers stay competitive in an increasingly fast-paced market.

1 note

·

View note

Text

Perhaps so the universe has a way to make it up to us for everything else going on, there is currently an explosion in really neat laser-based tools. You can get a laser welder, or a laser CNC machine, or a laser engraver, or... a laser level. I swear I can almost afford that last one. They want like fifteen dollars for it at the Princess Auto. Sheesh. It's like they expect their core customer to be employed now.

Although lasers are probably centuries old, according to a drinking-machine summary of a wikipedia article I glanced at while trying to kill time in line at the parole office, it's only recently that humanity has figured out how to make them more affordable for the common, workaday asshole. What's the secret to this incredible advancement in inexpensive optical technology? Have a factory in China build them.

As a result of all this trans-national becheapening, the local "maker space" has acquired for themselves a thousand-watt laser welder. Any moron off the street can use it to stitch two pieces of metal together in a way that would make professional welders poop with envy. Which is perfect, if you're a moron off the street and your $89 Princess Auto "Li'l Don't Look Directly At The Spark Junior Welder's Kit" doesn't quite have the zoot to put those spring perches on a rusty, oily Ford 8.8 you got out of that big F150 crash on the side of the highway last winter.

Like you would expect, it (the welder, not the axle) cost about as much as a good used car used to cost, before used cars cost $20,000. Still, that's peanuts if you have several hundred members who are willing to pay to use it to make Star Wars pirate memorabilia and combat robots. I, however, am not willing to pay. In fact, I have to be forced to spend money on just about anything. So I decided to see if I could just walk in there, use the laser welder to do my daily welding, and then bounce without opening my wallet.

Friends: it worked great. After a couple minutes of pushing buttons and adjusting various screens that I wouldn't bothered to have read fully even if they weren't written in Chinese, I was able to fart on a pair of narrowed spring perches that were ideal for my Viscount.

Now, you might think it's suspicious that I was able to roll a 175-pound chunk of cast iron through the middle of a warehouse full of nerds without anyone asking me for my ID, but it's all thanks to another fancy new consumer of inexpensive lasers: the smoke alarm on the ceiling. I set that sucker off with a brick to the "test" button, before walking right in the front door while dressed as a firefighter. Sometimes, rock beats laser.

110 notes

·

View notes

Text

people learning about the taiwan cnc series spring making machines. beautiful world.

27 notes

·

View notes

Text

Why Apple Watch Bands Command a Premium Price?

Apple recently released the Rainbow Sport Band for the Apple Watch on their official website. Priced at $54, it is compatible with the Apple Watch Series 3 and newer models. Along with the band, Apple has also launched matching Rainbow Celebration watch faces and wallpapers for both the Apple Watch and iPhone. To access these new features, users need to upgrade their devices to watchOS 9.5 and iOS 16.5.

Many people question why Apple’s original watch bands, such as this one, come with a higher price tag, especially when third-party options offer similar styles at much lower prices. The Stainless Steel Milanese Loop, for example, is priced at $110 on Apple's website, further prompting the question: Why are Apple Watch bands so expensive?

The answer lies in both the brand value and engineering precision that Apple incorporates into each watch band. It’s not just about the Apple name—there’s a level of craftsmanship that goes into every detail. For example, the component formed by three seemingly simple buttons on the Apple Watch band is referred to as the X206 spring structure. This structure ensures that when the band slides into the groove of the watch, the buckle aligns perfectly. As it slides into place, the spring mechanism engages, pushing the band securely into position.

A former Apple engineer revealed that achieving this level of precision required a significant investment. Apple purchased hundreds of Swiss CNC machines worth $2 million each to ensure that the band’s fit could be engineered with a margin of error of just 5 microns. That kind of precision isn’t something you’ll find in third-party alternatives.

Additionally, many Apple Watch bands are redesigned and refined by Apple’s in-house design team. For example, before finalizing the design for the Link Bracelet, Jony Ive and his team spent almost a year perfecting the structural elements. Even the Milanese Loop, which might look like a simple woven stainless steel band, goes through a laser sealing and polishing process that enhances its texture and durability.

Though this level of detail and precision increases the cost of production, Apple engineers see it as a necessary investment. One engineer expressed that while these efforts might go unnoticed by some, they represent a level of artistry and craftsmanship that sets Apple Watch bands apart from their competitors.

In the end, you’re not just paying for the materials or design—you’re paying for the meticulous engineering, innovative design, and the seamless integration of technology and fashion that only Apple can deliver.

Recommended Websites: https://bandletic.com/

4 notes

·

View notes

Text

Global top 13 companies accounted for 66% of Total Frozen Spring Roll market(qyresearch, 2021)

The table below details the Discrete Manufacturing ERP revenue and market share of major players, from 2016 to 2021. The data for 2021 is an estimate, based on the historical figures and the data we interviewed this year.

Major players in the market are identified through secondary research and their market revenues are determined through primary and secondary research. Secondary research includes the research of the annual financial reports of the top companies; while primary research includes extensive interviews of key opinion leaders and industry experts such as experienced front-line staffs, directors, CEOs and marketing executives. The percentage splits, market shares, growth rates and breakdowns of the product markets are determined through secondary sources and verified through the primary sources.

According to the new market research report “Global Discrete Manufacturing ERP Market Report 2023-2029”, published by QYResearch, the global Discrete Manufacturing ERP market size is projected to reach USD 9.78 billion by 2029, at a CAGR of 10.6% during the forecast period.

Figure. Global Frozen Spring Roll Market Size (US$ Mn), 2018-2029

Figure. Global Frozen Spring Roll Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Discrete Manufacturing ERP include Visibility, Global Shop Solutions, SYSPRO, ECi Software Solutions, abas Software AG, IFS AB, QAD Inc, Infor, abas Software AG, ECi Software Solutions, etc. In 2021, the global top five players had a share approximately 66.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

2 notes

·

View notes

Text

Goddamn everyone in this bandom is so fuckin talented, especially at music

Like, y'all playing the new song already hot damn y'all are amazing people you know that?

... And I'm just sitting here, banging my head on my desk for getting into YET ANOTHER dumbass project that I've decided to make harder on myself because that is What I Do Best.

But, uh, if I manage to get it to work... A Ghost themed music box. The kind that you wind up and it plays a little song. Initial idea was for it to play Life Eternal, but I might try and see about Pro Memoria or maybe the outtro bit of Respite On The Spitalfields. Instead of the little pop-up ballerina, a figurine of red suit Copia from the Rats music video.

This is assuming I'm able to make the metal comb, which is the bit with the metal teeth that make the actual sounds. I'm attempting to see if I can make one out of a sheet of bronze, since it supposedly has a nice sound to it, if I can work harden it and keep it flat, and get the cuts right... And then tune it... Spring temper steel would be the best option, but I'm not sure where to get a thin sheet of it nor how to cut it. Might be a job for pestering one of my teachers at school to see if they'll let me play with a cnc machine, if that'll do fine enough cuts. I dunno, I'm stuff fucking with the idea.

But yeah, that's one of the things I'm working on...

#I like to make things harder than they should be#Yes I can just buy the whole mechanism but I wanna make it myself#To prove that I can#Because I'm a dumb

3 notes

·

View notes

Text

AI and IoT Fuel Smart Active Isolation Systems

The Vibration Isolators Market was valued at approximately $2.6 billion in 2022 and is forecast to reach $4.1 billion by 2030, growing at a CAGR of 6.3%. This growth is supported by increasing demand from industrial, aerospace, and semiconductor applications. North America holds about 28% of the market share, followed closely by Asia-Pacific, the fastest-growing region.

To Get Free Sample Report: https://www.datamintelligence.com/download-sample/vibration-isolators-market

Key Market Drivers

1. Elastomeric Isolators Lead Adoption With a 40% share of the market in 2023, elastomeric isolators are widely used in automotive, HVAC, and heavy machinery. Their cost-effectiveness, vibration attenuation, and durability make them the dominant type across multiple industries.

2. Pneumatic and Compact Isolators Expand Use Cases Pneumatic isolators, particularly air-spring-based systems, are preferred in precision engineering sectors such as semiconductors, optics, and medical equipment. Compact pneumatic systems are gaining favor due to adjustable performance and low maintenance.

3. Active and Smart Isolation Technologies on the Rise Active vibration control systems, incorporating sensors and real-time feedback loops, are driving advanced use cases in the semiconductor, biotech, and defense sectors. Integration of AI and IoT technologies is enhancing responsiveness and remote monitoring capabilities.

4. Aerospace & Defense Fuel High CAGR The aerospace sector is expected to grow at a CAGR of 7.8% through 2030 due to stringent vibration control requirements in aircraft, drones, and satellite systems. Vibration isolators are essential to ensure structural safety and performance reliability.

5. Semiconductor Industry Drives Demand The semiconductor sector alone accounts for over 40% of isolation demand. Cleanroom environments, lithography, and fabrication processes require ultra-low vibration, making high-precision isolators indispensable in chip manufacturing.

6. Sustainability and Innovation Drive Market Evolution The trend toward sustainable products is leading to the adoption of recyclable elastomers, natural rubber, and 3D-printed isolators. Companies are innovating to produce compact, lighter, and more environmentally responsible isolation systems.

Application Insights

Construction and Architecture: Base isolators are increasingly used in earthquake-prone zones. Seismic base isolation and vibration dampers are widely applied in smart city infrastructure and high-rise buildings.

Industrial Machinery: Vibration isolators are crucial for extending equipment life and ensuring production consistency in CNC machines, compressors, and conveyor systems.

Medical Devices: MRI, CT, and surgical robots benefit from ultra-low vibration environments made possible by smart isolators.

Consumer Electronics: Compact vibration pads are being embedded in wearable and handheld devices for protection and enhanced user experience.

Regional Analysis

North America leads the market with a 28% share, driven by aerospace R&D, smart manufacturing, and industrial automation investments. The U.S. is a key contributor due to its advanced defense and semiconductor industries.

Asia-Pacific is the fastest-growing region with a projected CAGR of 8.5%, led by China, Japan, and South Korea. Rapid industrialization, growing electronics manufacturing, and seismic construction practices are propelling demand.

Europe holds about 22% of the global share, with major contributions from Germany, France, and the UK. The region benefits from well-established automotive and aviation sectors.

Rest of World regions including Latin America, the Middle East, and Africa are gradually adopting isolator systems, particularly in infrastructure and transport.

Challenges

High Initial Investment: Advanced isolation systems often involve high capital costs, especially for active or smart isolators.

Technical Integration Complexity: Retrofitting vibration control in legacy infrastructure or older machinery can be complex and cost-intensive.

Material Pricing Fluctuations: Volatile raw material prices, especially for metals and polymers, may affect supply chain stability.

Limited Awareness in Developing Markets: Small-scale industries may be unaware of the long-term benefits of vibration isolators, hindering adoption.

Industry Trends

IoT and Predictive Maintenance: Embedded sensors allow users to monitor isolation performance in real-time, reducing downtime and predicting maintenance needs.

3D Printing for Customization: Manufacturers are using additive manufacturing to produce tailored isolator components at lower costs and faster turnaround.

Miniaturization and Modularity: Demand for compact and modular isolators is rising across medical, electronics, and drone applications.

Eco-Friendly Materials: Biodegradable rubbers and recyclable polymers are gaining traction as ESG concerns influence purchasing decisions.

Get the Full Report: https://www.datamintelligence.com/buy-now-page?report=vibration-isolators-market

Competitive Landscape

Key players in the global vibration isolators market include:

LORD Corporation

Parker Hannifin

Trelleborg AB

Hutchinson

Getzner Werkstoffe

VibraSystems Inc.

Kinetics Noise Control

Fabreeka International

Isolation Technology Inc.

Newport Corporation

Conclusion

The vibration isolators market is witnessing a transformation driven by smart technologies, sustainability, and demand from critical sectors. Elastomeric products continue to dominate, but active and pneumatic systems are gaining share with their adaptability and high precision. As industries move toward more connected and resilient infrastructures, smart vibration isolators are expected to become standard across both industrial and commercial applications.

0 notes

Text

QC11Y CNC Hydraulic Guillotine Shearing Machine

The frame and tool rest are constructed from steel structural components, with the upper tool rest being tempered to eliminate internal stress, resulting in enhanced rigidity and improved organizational stability. Under the action of the oil cylinder, the tool holder moves along the guide rail to achieve shearing motion. A ball screw drives the rear stopper, while motor-driven adjustment enables precise positioning and ensures fast and smooth operation of the stopper distance. The material-pressing mechanism consists of a set of material-pressing oil cylinders that overcome spring tension through pressure oil during operation. After completion of shearing, reset is achieved using spring tension. To facilitate cutting wider sheet materials, a front supporting frame is provided with one featuring a scale and side positioning stop.

0 notes

Text

0 notes

Text

RC car Button Head Grade 5 Titanium Screws - Length Options

All of our titanium screws are made from Grade 5 titanium, rolled threads and CNC machined heads. Using Grade 5 allows us to offer a far superior grade screw as compared to Grade 2 titanium.

0 notes

Text

The Technological Development of Mattress Making Machines

The technology of mattress making machines has evolved rapidly in recent years. This evolution has been driven by the need to improve the quality, comfort, and durability of mattresses, as well as to increase production efficiency. One of the significant technological advancements is the use of computer – controlled systems in mattress making machines. For instance, in foam cutting, computer – numerical – control (CNC) machines can be programmed to cut foam with extreme precision. This allows for the creation of complex shapes and contours that can better adapt to the human body’s curves, providing enhanced comfort. In the production of springs, automated spring – making machines now use advanced sensors and controls to ensure the correct tension and shape of each spring. This results in a more stable and long – lasting spring system. Another notable development is the integration of smart manufacturing technologies. Mattress making machines can now be connected to a central control system, enabling real – time monitoring and adjustment of the production process. Manufacturers can collect data on machine performance, production output, and quality metrics, which helps in optimizing the production line and reducing downtime. With these technological advancements, mattress making machines are set to revolutionize the bedding industry, offering consumers more comfortable and high – quality mattresses at a faster pace and lower cost.

0 notes

Text

Elevate Your Off-Road Ride with the 2.5 Coilover

When it comes to dominating rugged trails and navigating uneven locked offroader rain, every component of your suspension system matters. That’s where Locked Offroad steps in with their premium 2.5 Coilover, built for performance, durability, and control. Whether you're hitting high-speed desert runs or crawling over rocky passes, these coilovers deliver uncompromising results. As one of the most sought-after offroad coilovers on the market, they are engineered to meet the demands of serious off-roaders who need suspension components they can trust.

Product Information

The 2.5 Coilover from Locked Off Road is built for those who require high-performance suspension without compromise. Designed with a 2.5” diameter shock body, these coilovers offer increased oil capacity, superior cooling, and improved damping control. The result? A smoother, more controlled ride across all types of off-road terrain. Each 2.5 Coilover is precision-crafted in the USA using aircraft-grade aluminum and robust internal components that exceed OEM specifications. The shocks are fully rebuildable and revalving, allowing for long-term performance tuning and maintenance. This means you're not just buying a shock — you're investing in a long-term solution for high-performance off-road driving.

Why Choose the 2.5 Coilover?

There are countless suspension upgrades on the market, but few deliver the balance of performance and durability found in the 2.5 Coilover. This coilover is built to tackle extreme terrain, endure high-impact off-roading, and maintain comfort and handling on the road.

Here’s why off-road enthusiasts prefer this product:

Custom Valving – Every 2.5 Coilover is valved specifically for your application, vehicle weight, and intended use.

Rebuildable Design – Extend the life of your coilovers with a rebuildable design that allows full internal servicing.

Precision Machining – The coilovers are built with top-tier CNC machined parts, ensuring fit, finish, and function are all of the highest standards.

Anodized Finish – Long-lasting corrosion resistance and an aggressive appearance.

Whether you’re building a trail crawler or a high-speed desert racer, the 2.5 Coilover provides the versatility and toughness your vehicle needs.

What You Get with Your 2.5 Coilover Purchase

When you order the 2.5 Coilover, you receive:

(1) 2.5" Coilover Shock (Sold Individually)

Custom-tuned valving to match your vehicle

High-quality mounting hardware

Pre-installed reservoir hoses (if applicable)

Premium finish with sleek, professional branding

Please note: Coil springs are sold separately, allowing you to choose the spring rate that best matches your setup and needs.

Who Should Choose the 2.5 Coilover?

The 2.5 Coilover is engineered for off-road drivers who refuse to compromise. Whether you're a weekend warrior exploring fire roads or a competitive off-road racer tackling the Baja 1000, these coilovers are for you. They are ideal for:

DIY overland builders

Off-road racing enthusiasts

4x4 truck and SUV owners

Fabricators creating custom suspension setups

Adventure seekers upgrading their rigs for harsh terrain

This is not a casual upgrade; it's a performance essential for serious off-roaders who push their vehicles beyond stock capabilities.

Key Features and Benefits

Here’s a breakdown of what sets the 2.5 Coilover apart from other off road coilovers on the market:

1. Massive 2.5" Shock Body

The larger diameter body allows for increased oil capacity, reducing shock fade during prolonged use and keeping your suspension consistent even in the harshest environments.

2. Custom Valving

Each shock is tailored to your specific needs, whether you’re rock crawling, dune bashing, or daily driving. This ensures optimal performance for your unique driving style.

3. Adjustable Ride Height

Fine-tune your lift height to accommodate larger tires, additional accessories, or personal preference, giving you both performance and flexibility.

4. Floating Piston Reservoir (Optional)

Remote or piggyback reservoirs increase fluid volume and cooling, allowing for better performance during high-speed or long-duration runs.

5. Rebuildable and Serviceable

These coilovers are built to last. All components are fully serviceable, so you can replace seals, revalving, or refresh them over time rather than buying replacements.

6. Premium Construction

Made with aircraft-grade aluminum and featuring anodized finishes, the 2.5 Coilover offers strength, reliability, and corrosion resistance in extreme environments.

Who Benefits from This Product?

The 2.5 Coilover offers massive benefits for a wide range of off-roaders and outdoor professionals:

Off-Road Enthusiasts: From sand dunes to rocky trails, the coilovers give better handling, less body roll, and a smoother ride — all while taking the abuse that comes with extreme terrain.

Overlanders: Loaded rigs carrying rooftop tents, gear, and fuel can maintain balance and comfort thanks to these performance-tuned coilovers.

Fabricators and Custom Builders: Those creating long-travel or linked suspension setups will find the 2.5 Coilover adaptable and durable for various vehicle platforms.

Competitive Racers: If speed, responsiveness, and durability are non-negotiables, these coilovers deliver with confidence under high-impact, high-speed conditions.

Fleet and Expedition Operators: For companies or teams building expedition-ready vehicles, reliability is crucial. These shocks provide a dependable upgrade that minimizes downtime and maximizes capability.

What to Expect with Your 2.5 Coilover

Each order includes the following:

2.5 Coilover Shock

Custom valving and nitrogen charge

High-grade mounting hardware

Optional remote reservoir setup

Instructions for proper installation and maintenance

Note: Springs are sold separately, providing flexibility for vehicle-specific tuning.

Why Choose This Company?

When you're investing in high-performance off-road gear, the brand behind the product matters. Locked Off Road is known in the off-roading community for producing American-made, race-proven suspension components that hold up in real-world abuse. Their shocks are used in everything from weekend trail rigs to competitive racing vehicles.

What sets them apart?

Made in the USA – Precision-built using quality American materials.

Customer Support – Dedicated support to guide you through product selection, installation, and maintenance.

Performance First – Every product is designed with functionality, endurance, and real-world application in mind.

Industry Reputation – Trusted by racers, overlanders, and pro builders across North America.

If you’re looking for coilovers that are built to perform and built to last, you can trust the engineering behind these high-quality shocks.

Take Control of Every Trail

Ready to transform your off-road experience? Don’t settle for average suspension. Order your 2.5 Coilover today and experience the difference real performance makes. Whether you're customizing your weekend adventure rig or upgrading your race truck, these coilovers provide the foundation for better handling, more control, and greater confidence on every trail.

Closing Statement

In the world of off road coilovers, the 2.5 Coilover stands as a proven performer. Engineered for demanding terrain and extreme use, these coilovers combine technical precision with rugged durability. Whether you're climbing boulders or carving through the desert, they give you the control and comfort you need. Trust Locked Off Road to deliver high-performance suspension components that elevate your driving experience — on-road and off.

0 notes

Text

Hastelloy C22 Fasteners Manufacturer, Supplier & Exporter in India

Overview

Ananka Group is a leading manufacturer, supplier, and exporter of Hastelloy C22 Fasteners in India and globally. Designed to withstand the most aggressive environments, Hastelloy C22 fasteners offer excellent resistance to corrosion, stress, and oxidizing or reducing chemicals. We manufacture our fasteners in compliance with international standards such as ASTM, ASME, DIN, and ISO, guaranteeing exceptional quality and reliable performance across all applications.

What is Hastelloy C22?

Hastelloy C22, or Alloy C22, is a nickel-chromium-molybdenum-tungsten alloy that possesses high corrosion resistance in a broad spectrum of severe environments. It offers superior performance in oxidizing, reducing, and mixed acid environments, far exceeding that of standard stainless steels and many other corrosion-resistant alloys.

Types of Hastelloy C22 Fasteners We Offer

Hastelloy C22 Bolts

Hex Bolts

Heavy Hex Bolts

U-Bolts

Eye Bolts

J-Bolts

Socket Head Bolts

Hastelloy C22 Nuts

Hex Nuts

Heavy Hex Nuts

Nylock Nuts

Flange Nuts

Dome Nuts

Coupling Nuts

Hastelloy C22 Screws

Machine Screws

Socket Head Cap Screws

Self-Tapping Screws

Countersunk Screws

Hastelloy C22 Washers

Flat Washers

Spring Washers

Lock Washers

Fender Washers

Hastelloy C22 Threaded Rods

Fully Threaded Rods

Stud Bolts

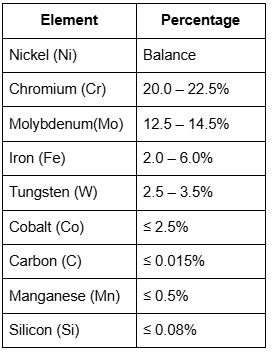

Chemical Composition of Hastelloy C22

Mechanical Properties

Key Features of Hastelloy C22 Fasteners

Reliable performance in both oxidizing and reducing conditions.

Suitable for wet chlorine gas, nitric acid, acetic acid, formic acid, and seawater

Superior thermal stability and mechanical strength

Weldable and formable for complex assemblies

Applications of Hastelloy C22 Fasteners

Chemical Processing Industries

Pulp and Paper Manufacturing

Waste Treatment Plants

Pharmaceutical & Biotech Equipment

Marine and Offshore Engineering

Pollution Control Systems

Nuclear Power Systems

Why Choose Ananka Group for Hastelloy C22 Fasteners?

State-of-the-Art Manufacturing – Precision CNC machining and rigorous quality control.

Worldwide Delivery Network – Catering to clients throughout the USA, Europe, the Middle East, and Asia.

Standards Compliance – ASTM B574, B564, B575, ASME, DIN, ISO, and more.

Custom Solutions – We manufacture as per client's drawings and specifications.

Bulk Stock Availability – Fast turnaround time with ready-to-ship inventory.

Available Standards & Grades

ASTM B574 / B564 / B575 / B622 / B619

ASME SB-574 / SB-564 / SB-575

ISO, DIN, EN, BS Standards on request

Packaging & Export

Our Hastelloy C22 fasteners are securely packed in:

Wooden crates

Bubble wraps

Waterproof packaging

Custom labeling for bulk orders

Exported to over 30 countries, including the USA, UK, Germany, UAE, Saudi Arabia, Australia, and Singapore.

FAQs

Q1. What are Hastelloy C22 fasteners used for?They are utilized in extremely corrosive environments such as chemical processing, marine, and nuclear industries.

Q2. Are Hastelloy C22 fasteners resistant to seawater?Yes, they offer excellent resistance to saltwater corrosion and pitting.

Q3. What makes Hastelloy C22 better than other alloys?It offers superior corrosion resistance in both oxidizing and reducing environments, making it versatile for complex applications.

Q4. Do you offer custom fastener manufacturing?Yes, we offer made-to-order solutions per drawings or sample requirements.

#Hastelloy#Hastelloyc22#B2B#b2bbusiness#Marketing#Manufacturing#Fasteners#Engineering#Grade#Material#Blog#Articles#Export#GlobalBusiness#Networking#Innovation#MadeInIndia#GlobalSupplyChain#BusinessGrowth#anankafasteners#ananka#manufacturer#supplier#tumblr#blog tumblr

0 notes

Note

What is your favorite industrial machine?

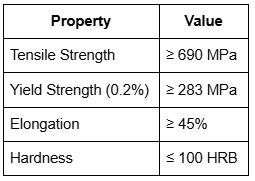

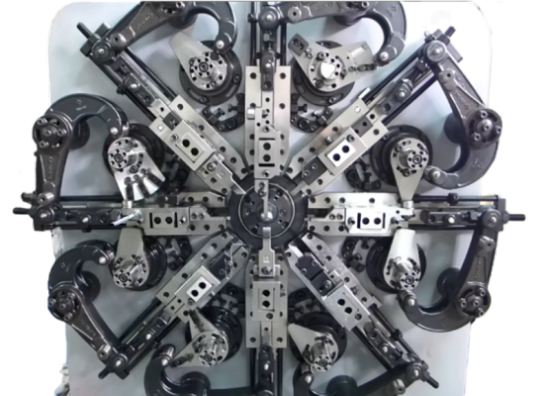

the taiwan simco spring former (cnc series) is seriously unparalleled to me. fuckin look at it

21 notes

·

View notes

Text

Top-Rated Leaf Spring Manufacturing Machinery

In the realm of heavy-duty vehicles and automotive suspension systems, leaf springs continue to play a critical role. Their durability, load-bearing capacity, and performance make them essential components in trucks, trailers, and commercial vehicles. But behind every high-quality leaf spring lies a backbone of precision machinery. This article explores the top-rated Leaf spring machines machinery, key features, leading brands, and the transformative impact these machines have on modern production lines.

What is Leaf Spring Manufacturing Machinery?

Leaf spring manufacturing machinery refers to a specialized set of equipment used to produce leaf springs for automotive suspension systems. These machines carry out essential processes such as cutting, punching, cambering, hardening, tempering, surface treatment, and assembly. High-end machines can produce uniform, strong, and reliable leaf springs, essential for vehicle safety and performance.

With the rising demand for commercial vehicles globally, the need for efficient, automated, and top-rated leaf spring machinery has surged. Manufacturers are now investing in advanced technology to ensure their products meet global quality standards while optimizing production time and cost.

Essential Types of Leaf Spring Manufacturing Machines

To understand what makes a machine “top-rated Best leaf spring machines,” it’s important to know the common machinery used in the leaf spring manufacturing process:

Shearing Machines: For cutting steel plates or strips into precise lengths for leaf production.

Punching Machines: Used for creating bolt holes or eyelets in the leaf pieces.

Cambering Machines: Critical for imparting the correct arc or camber to the spring leaf.

Heat Treatment Furnaces: These provide the necessary hardening and tempering to ensure leaf springs meet durability standards.

Shot Peening Machines: Used to improve fatigue resistance by creating a compressive stress layer on the surface.

Assembly Machines: These automate the stacking and clamping of leaves to form the final leaf spring product.

Each piece of machinery contributes to the overall strength and quality of the final product, and automation has dramatically improved efficiency and consistency.

Features of Top-Rated Leaf Spring Manufacturing Machinery

Top-rated machinery is not just about functionality—it’s about precision, durability, automation, safety, and low maintenance costs. Here are some must-have features:

1. CNC Control Systems

Computer Numerical Control (CNC) allows for precise adjustments and repeatability in cutting, punching, and cambering. This technology ensures exact specifications are met in every cycle, minimizing errors and waste.

2. High-Speed Operation

Top-rated machines offer high-speed operation while maintaining tight tolerances. This improves productivity and reduces manufacturing time without compromising quality.

3. Integrated Safety Mechanisms

Modern machines include advanced safety systems such as automatic shutoffs, emergency stop buttons, and protective covers, ensuring operator safety.

4. Energy Efficiency

Energy-efficient machines help reduce operational costs and environmental impact. This is particularly important for large-scale manufacturing plants.

5. Remote Monitoring and Diagnostics

Smart manufacturing machinery is now equipped with IoT-enabled features that allow remote diagnostics, predictive maintenance, and real-time monitoring of performance.

Leading Manufacturers of Leaf Spring Machinery

Here’s a look at some of the top global brands known for manufacturing world-class leaf spring production equipment:

1. Schuler Group (Germany)

Renowned for its advanced press systems and automation solutions, Schuler’s cambering and forming machines are used by leading OEMs worldwide.

2. Enomoto (Japan)

Specializing in forging and heat treatment, Enomoto’s spring manufacturing machinery is known for precision and durability, especially in the Japanese automotive market.

3. SMS Group (Germany)

SMS Group manufactures a wide range of metal forming machinery, including advanced spring steel processing lines and hardening furnaces.

4. Patson Machines Pvt. Ltd. (India)

This Indian manufacturer offers a comprehensive range of spring end grinding and cambering machines at competitive prices, making them ideal for emerging markets.

5. Benteler Machinery (Germany)

Known for high-speed automation and integrated systems, Benteler provides machinery for spring forming, hardening, and tempering.

Benefits of Using Top-Rated Machinery

✅ Consistent Quality

Top-rated machinery ensures that each spring meets exact specifications in terms of thickness, camber, and hardness, crucial for vehicle safety.

✅ Increased Production Speed

Advanced machines reduce processing times significantly, enabling manufacturers to meet tight deadlines and large-volume orders.

✅ Lower Labor Costs

Automation minimizes manual labor requirements, reducing costs and improving workplace safety.

✅ Reduced Downtime

Machines from reliable manufacturers have longer maintenance cycles and offer predictive maintenance features, minimizing downtime.

✅ Customization Flexibility

Top-tier machines allow for rapid changes in production specs, which is essential for meeting varied customer requirements.

Cost Considerations

While top-rated leaf spring manufacturing machinery may come with a higher initial investment, the long-term benefits far outweigh the cost. Improved durability, reduced maintenance, and higher throughput can lead to significant savings over time.

It's also worth noting that many leading manufacturers offer modular systems. These can be upgraded as needed, allowing smaller manufacturers to scale production without replacing entire lines.

Key Factors to Consider Before Buying

Production Capacity – Match machinery with your expected output levels.

Space Requirements – Some systems require large floor space; plan accordingly.

After-Sales Support – Choose vendors with global support and quick spare part availability.

Automation Level – Decide how much automation your plant needs.

Budget and ROI – Consider lifecycle cost and potential return on investment.

Future Trends in Leaf Spring Manufacturing

🔹 Smart Factories

With Industry 4.0, factories are becoming more data-driven. Expect machines with sensors, AI-powered analytics, and predictive maintenance to dominate the market.

🔹 Eco-Friendly Production

New leaf spring machinery designs focus on reducing energy consumption and using recyclable materials.

🔹 Hybrid Materials

As automotive manufacturers seek to reduce weight, machines capable of handling hybrid or composite spring materials are in demand.

Conclusion

The use of top-rated leaf spring manufacturing machinery is revolutionizing the automotive and commercial vehicle sectors. Precision, durability, speed, and automation define today’s high-performance equipment. Whether you're a large-scale OEM or a mid-sized manufacturer, investing in modern machinery is crucial to staying competitive in a fast-evolving market.

If you’re planning to upgrade your production line, consider machines with advanced features such as CNC control, real-time monitoring, and energy efficiency. Reliable brands like Schuler, Enomoto, and Patson offer comprehensive solutions tailored to a variety of production needs.

With the right equipment in place, manufacturers can ensure consistent product quality, reduce costs, and boost operational efficiency for years to come.

0 notes