#coolant system pressure test

Text

Water pump replacement was needed on an overheating Chevrolet Suburban.

The coolant reservoir was almost empty. After topping off the coolant, our technician performed a cooling system pressure test. He found that it was wet under the water pump and the pounds per square inch (psi) dropped by 5 in 10 minutes.

In addition to a new water pump, the Chevy Suburban received a new thermostat and a coolant fluid exchange.

Coolant fluid flushes help maintain cooling system parts and prevent a vehicle’s engine from overheating.

#coolant system pressure test#prince william county virginia#steve's auto repair and tire#overheating car#chevrolet suburban

0 notes

Text

OC Profile: Voss Mendelson

Long read and pictures.

Basic Info

Name: Voss Mendelson

Alias(es): R3d_F0X

Date of birth: February 26 2044

Zodiac sign: Pisces

Gender: Male

Place of Birth: Night City, Charter Hill

Sexuality: Bisexual

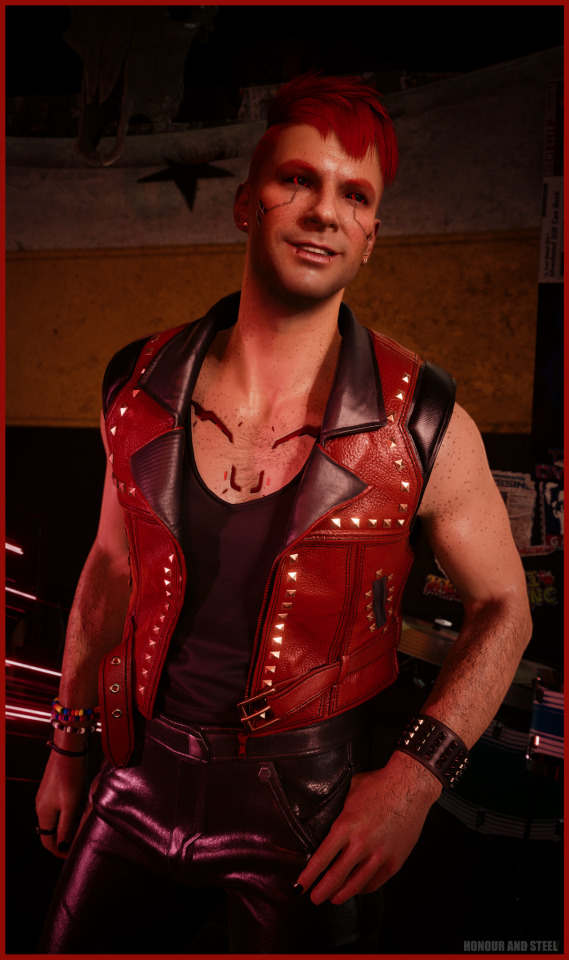

Voss in some of his preferred style

Appearance

Height: 5’ 7/170 cm

Build: Slim/athletic

Hair: Bright red (is a natural ginger)

Eyes: Natural green but now red and black

Cyberwear: Deep dive port, titanium spine with additional sockets to his internal cooling systems for coolant. Self-ICE, Mantis blades (although later replaced with regular arms), Arasaka Mk. 4 Cyberdeck, Lynx Paws, Kiroshi optical implants. Facial cybernetics linked to his cyberdeck allow him to activate pre-programmed actions with facial movements, other cybernetics to manage data flow and synchronise the link between him and his Cyberdeck.

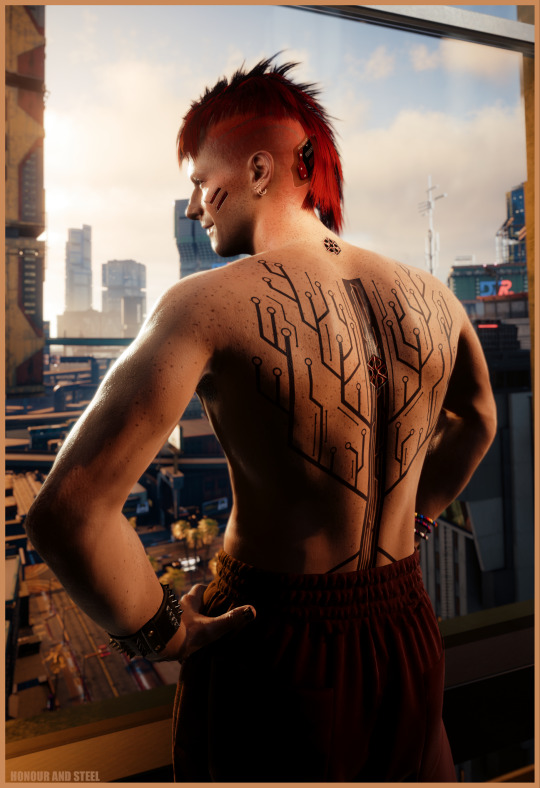

Voss' tattoo (mod by me) coolant port and skull socket mods by Anrui.

Background

Father: Frederick Mendelson (missing in action presumed deceased)

Mother: Hannah Mendelson (alive)

Languages: English, German (primary language)

Affiliations

Arasaka: former counterintelligence and Netrunner

Afterlife mercs: member

Aldecaldos: friend

Maelstrom: tolerated

Occupation: Mercenary

Role: Netrunner, infiltrator, thief

Weapons: Mantis blades, Nue, Archangel (later especially after giving up his Mantis blades.)

Personality type: INFJ-T The Advocate is one of the most conscientious, principled, and idealistic personality types. Advocates, filled with lofty goals and ambitions, are far from idle dreamers. But it’s all too easy for them to feel weighed down by internal pressures when their reality doesn’t match their great aspirations.

German Dad, NUSA Mum. Both his parents were Arasaka employees. His Dad was presumed dead when Voss was 16, while on corporate espionage operations but a body was never recovered. His mother was also an Arasaka employee, specialising in weapons development. He is an only child and speaks English and German. So handy for the mess that he was clearing up with the leak in Frankfurt before Jenkins’ hit attempt on Abernathy.

He sometimes found the life his family had limiting and restrictive; his parents were strict. They pushed him hard at school, and Voss did his best to achieve. His Dad taught hom how to run the Net from an early age, trained him in his own test environments before they ventured online together. Voss hasn’t looked back since. He’s very close to his Dad’s side of the family.

Voss was never destined to follow his Dad directly as his parents had hoped; Voss tends to stand out a bit too much for the job and never wanted to be the “grey man" his Dad tried to mould him into. His Dad was actually more relaxed of the two; he was much more kind and affectionate towards Voss, and they had a good relationship. His mother however was more detached and didn’t like her husband encouraging Voss to find a balance of achieving and becoming his own person. Frederick was still proud of his son whereas Hannah treated Voss as more of the joint experiment she originally planned. Frederick realised trying to force Voss into something he clearly wasn’t was going to do more harm than good and did his best to nurture him.

After his father vanished, his mother didn’t deal with it well. She resented Voss as he was very much his father’s son. He looks similar to Frederick and he continued to speak both languages.

Voss in his Arasaka career years

Hannah estranged and disowned Voss when he went to university; Voss was out as bi before Frederick vanished. Frederick accepted his orientation but when Hannah discovered Voss was in a relationship with another male student while at university, she threw him out. Jackie and his Mum took Voss in, as Valerian, a friend (and an OC belonging to a friend) of Voss’ from Pacifica, wasn’t able to help him out.

Voss ended up joining Arasaka after successfully graduating but in counterintelligence with an emphasis on Netrunning. He enjoyed the work and met Jessica Kikuchi, a PR liaison representative for Arasaka who often worked with his department in managing publicity when some operations were in public view or had a public aspect to them. They were together for five years until she was summoned to a role in Japan at short notice. Jenkins refused Voss’ transfer request.

Voss and Jessica

Trying to find friends and his place in Night City frequently brought Voss into conflict with his parents, or more exactly his Mum hated it but his Dad was relaxed. Staying out late, not telling them the whole story of where he'd been and who he was with were common reasons. Voss has known Jackie since he was quite young and in many ways Jackie was just as important an influence on the young Voss as his Dad. Jackie helped Voss become a bit more confident.

Voss and Kerry Eurodyne

Voss suffered from scoliosis. His Dad had been setting aside money for Voss to use when he was fully grown to have surgery and give him cybernetics he would need. Part of this was a titanium spine to resolve the scoliosis as well as add in additional ports for his Netrunning. Voss hates the scar on his spine as it follows the path his organic spine went and he had it obscured by his tattoo. He has others which he also doesn’t like, particularly one on his left brow. He can be self-concious about his body as it can tend to softness, particularly around his middle. Doesn’t help that others thought he wasn’t masculine enough because of how he is physically and emotionally.

He’s great at netrunning, prefers to sneak and use stealth to deal with many things. He can talk his way into and out of things, a useful skill learned with Jackie and for survival in the Arasaka world.

Being freed from Arasaka allowed Voss to have the freedom he had craved but there are still all the tricks and plays he knows from the game which he likes to use to his advantage and as a way to get back in a small way at all that happened to him. He hasn’t forgotten what he was, and yet he fully embraced the change his removal from the corporation presented.

Voss in his characteristic Netrunning suit

He can be a bit of a people pleaser, mostly just because he didn’t have much opportunity for making friends growing up, and the pressure on him to succeed academically strengthened those traits. He can have difficulty in saying no to some things but has learned from past mistakes. Voss is charming, easy to talk to and sensitive to those closest to him. Voss has a soft heart if you get past the sarcasm and layers of old Corpo armour he hasn’t quite got rid of. The better he knows somebody or feels comfortable around them, the better they see who he is, so if you see him at his weirdest, most crazy and lively then you’re close to him.

L to R; Jackie, Voss and V(Vesper)

His upbringing taught him determination, resilience and how to thrive under pressure but at times when things get too much it manifests in feeling overwhelmed, anxiety and occasionally depression if left unchecked. It is exacerbated by his autism too. He tends to withdraw and isolate when he gets that way but his close friends can be relied upon to help when he’s headed that way. He is an overthinker which is useful for his work but has it’s downsides and can feed his anxiety. Voss is prone to migraines which are usually caused by stress or if a Netrunning gig has been particularly taxing.

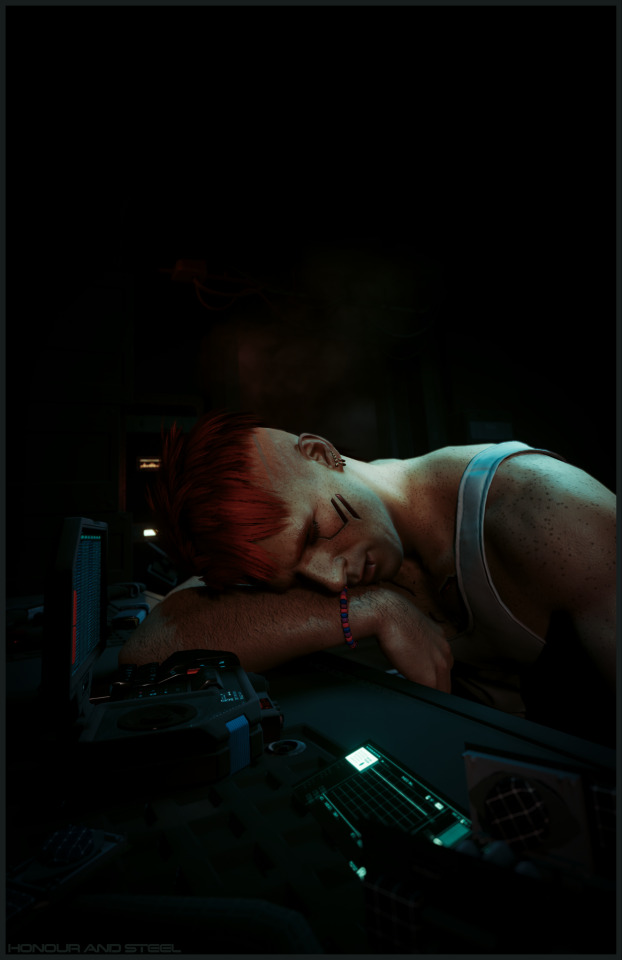

Hyperfocus can have it's downsides!

Voss is autistic. He’s managed in corporate life by what his Dad taught him and has masked a lot. He found that his intelligence, his capabilities and manner could be used to compensate. He can tend to info dump and talk in an excitable manner, something Vesper picks up on very early on. More information is in another post to come.

He’s perceptive so he picks things up, as he’s casually going around the city. People watching is one of his favourite things to do. That said he can handle himself in a physical fight when he has to; Mantis blades and being quick on his feet makes him a surprising and challenging opponent.

Voss is friends with Jackie, V(esper), Lightning, Valerian. He meets Kerry thanks to V and over time they get into a relationship, eventually they formalise their relationship. Voss is also friendly with Panam, Judy, Carmelo, Rogue.

#cyberpunk 2077#virtual photography#cyberpunk#oc: voss mendelson#cp2077#oc profile#R3d_F0X#Netrunner

26 notes

·

View notes

Text

RV Maintenance Tips for Traveling Through Crawfordville, Georgia

Traveling through Georgia, especially near areas like Crawfordville, offers picturesque views, tranquil surroundings, and the ultimate escape into nature. As you journey, it’s crucial to ensure your RV is in tip-top shape. Whether you’re staying at Sunrise River RV Park or passing through RV parks near Augusta, GA, maintaining your RV is vital to ensure a smooth and enjoyable trip. Below are some essential RV maintenance tips to keep in mind as you explore this beautiful region.

1. Regular Tire Inspections

One of the most critical aspects of RV maintenance is tire care. Before heading to any RV park near Augusta, GA, check your tires for proper inflation, wear, and tear. The varied terrain in Georgia, from highways to forest trails, can strain your tires. Ensure they are inflated to the manufacturer's recommended pressure. Also, inspect the treads for any signs of excessive wear, and replace tires if necessary. A blowout on the road can be dangerous and inconvenient, so this simple check can save you a lot of trouble.

2. Check and Maintain Brakes

Given the hilly landscapes around Crawfordville, ensuring your brakes are in excellent condition is essential. Regularly check the brake pads, rotors, and fluid levels. If you notice any squeaking, grinding, or decreased braking efficiency, get them serviced immediately. The peace of mind knowing your brakes are functioning correctly will make your travel through Georgia’s scenic routes much safer.

3. Inspect Roof Seals and Vents

Georgia’s climate can be unpredictable, with sudden rain showers even in sunny conditions. To avoid leaks and water damage, inspect the seals around your RV's roof, windows, and vents. Look for any cracks or deteriorated seals, and reapply sealant if necessary. This small step can prevent costly repairs later, especially if you're planning to stay at Sunrise River RV Park, where the natural surroundings are best enjoyed dry and leak-free!

4. Keep the Electrical System in Check

Your RV’s electrical system is its lifeline, powering everything from the refrigerator to the air conditioning. Before you park at any RV park near Augusta, GA, inspect your batteries, wires, and connections. Make sure your batteries are fully charged and in good condition. Test your generator to ensure it’s functioning properly, especially if you plan to camp in more remote areas like Crawfordville. Keeping a multimeter handy can help you diagnose any electrical issues that may arise on the road.

5. Monitor Your Water System

Georgia’s humidity and temperatures can lead to unique challenges for your RV’s water system. Regularly check your freshwater, gray, and black water tanks for leaks or signs of wear. Ensure that the hoses are in good condition and securely connected. If you plan on staying at Sunrise River RV Park, you’ll appreciate having a fully functional water system for showers and kitchen use. Additionally, consider investing in a water pressure regulator to prevent high-pressure water at certain campsites from damaging your RV’s plumbing.

6. Keep Your HVAC System Clean

The summer heat in Georgia can be intense, making your RV’s HVAC system essential for comfort. Clean the filters regularly and ensure that the air conditioning unit is functioning properly. If you're visiting Crawfordville during the warmer months, you’ll want to stay cool and comfortable after a day of exploring. Routine maintenance of your HVAC system will keep you and your family comfortable throughout your journey.

7. Stock Up on Essential Supplies

Crawfordville offers natural beauty and serenity, but it’s also essential to be prepared for any situation. Ensure you have a well-stocked toolkit that includes wrenches, screwdrivers, pliers, and any other tools specific to your RV model. Carry spare fuses, bulbs, and essential fluids like oil, coolant, and windshield washer fluid. Being prepared will ensure that minor issues don’t escalate into significant problems, allowing you to enjoy your stay at any RV park near Augusta, GA, or beyond.

8. Plan for Waste Disposal

Responsible waste management is vital for the environment and the longevity of your RV’s sanitation system. Before arriving at Sunrise River RV Park, familiarize yourself with the park's waste disposal facilities. Ensure that your black and gray water tanks are emptied and clean. Carry appropriate chemicals to treat your tanks, reducing odors and buildup. Keeping your waste management system in top shape ensures a pleasant experience for you and your fellow campers.

9. Check Your Propane System

Propane is essential for cooking, heating, and refrigeration in many RVs. Before embarking on your journey through Georgia, inspect your propane tanks and lines for leaks. Make sure your tanks are securely mounted and that your regulator is functioning correctly. It’s also wise to keep a carbon monoxide detector in your RV for safety. Regularly inspecting your propane system will allow you to enjoy meals and hot showers without worry during your stay.

10. Protect Against Pests

Crawfordville, with its lush landscapes and natural beauty, can also be a haven for insects and small animals. To protect your RV from unwanted guests, seal any gaps or cracks where pests might enter. Regularly clean your RV’s interior, removing food crumbs and trash that could attract pests. If you’re staying at Sunrise River RV Park, you’ll want to focus on the natural beauty of the area, not on dealing with ants or mice inside your RV!

11. Keep Your RV Clean

Traveling through Georgia can expose your RV to dust, dirt, and debris. Regularly wash your RV to maintain its appearance and protect its exterior from damage. Pay special attention to the undercarriage, especially after traveling on dirt roads or through muddy areas. Cleaning your RV not only keeps it looking good but also helps prevent rust and corrosion, ensuring it stays in excellent condition for years to come.

12. Stay Informed About Local Road Conditions

As you travel through Georgia, staying informed about local road conditions can help you avoid unexpected delays or hazards. Check weather forecasts and road reports, especially during the rainy season, when roads can become slick or flooded. Knowing the conditions ahead of time allows you to plan your route and adjust your driving to ensure a safe journey to Sunrise River RV Park or any other destination in the area.

Conclusion

Maintaining your RV is essential to ensure a safe, comfortable, and enjoyable journey through Crawfordville and the surrounding areas of Georgia. Whether you’re heading to Sunrise River RV Park or exploring RV parks near Augusta, GA, following these maintenance tips will keep your RV in top condition, allowing you to focus on the adventure ahead.

From regular tire checks to ensuring your water and electrical systems are functioning properly, taking the time to maintain your RV will enhance your travel experience. By being proactive with your maintenance routine, you can enjoy the natural beauty and serene landscapes of Crawfordville, Georgia, without worry. Safe travels!

2 notes

·

View notes

Text

How to Do a Load Bank Test on a Generator?|EMAX Load Bank

Load bank testing is a crucial aspect of generator maintenance. It ensures optimal performance, identifies potential issues, and safeguards against unexpected failures. By simulating real-world conditions, you can verify your generator's capacity to deliver consistent power when needed most. In this blog post, we'll guide you through the process of conducting a load bank test on your generator.

Understanding Load Bank Testing

A load bank is essentially a resistive load that simulates various electrical loads. By connecting it to your generator, you can assess its performance under different load conditions. This testing helps identify issues such as voltage regulation problems, engine performance, and overall system efficiency.

Preparing for the Test

Before commencing the test, ensure the following:

Safety First: Adhere to all safety guidelines, including wearing appropriate personal protective equipment (PPE).

Qualified Personnel: The test should be conducted by trained professionals familiar with generator operation and load bank usage.

Proper Equipment: Ensure you have the right load bank capacity to match your generator's output. Other necessary equipment includes voltage and current meters, temperature gauges, and a reliable power source.

Generator Condition: Verify that your generator is in good operating condition with adequate fuel and coolant levels.

Test Environment: Choose a well-ventilated area for the test to prevent overheating.

Steps Involved in Load Bank Testing

Connect the Load Bank: Carefully connect the load bank to the generator's output terminals, following the manufacturer's instructions.

Start the Generator: Start the generator and allow it to reach operating temperature.

Apply Load Gradually: Begin by applying a light load to the generator and gradually increase it to the desired level. Monitor the generator's performance throughout the process.

Monitor Parameters: Continuously monitor key parameters such as voltage, current, frequency, and engine temperature. Record these readings for analysis.

Check for Overloads: If the generator shows signs of overload, such as excessive voltage drop or overheating, reduce the load immediately.

Maintain Load for Specified Duration: Keep the load applied for the recommended duration to assess the generator's sustained performance.

Cool Down: After the test, gradually reduce the load and allow the generator to cool down before shutting it down completely.

Analyzing Test Results

Once the test is complete, analyze the collected data to evaluate the generator's performance. Look for any deviations from the manufacturer's specifications or unexpected trends. Common parameters to assess include:

Voltage Regulation: Check if the voltage remains within acceptable limits under varying load conditions.

Current and Power Factor: Verify that the generator delivers the required current and maintains a suitable power factor.

Frequency Stability: Ensure the generator maintains a stable frequency.

Engine Performance: Assess engine parameters like RPM, oil pressure, and coolant temperature.

Exhaust Emissions: Monitor exhaust emissions for any signs of abnormal combustion.

Benefits of Load Bank Testing

Regular load bank testing offers several advantages:

Early Detection of Issues: Identifies potential problems before they lead to costly breakdowns.

Performance Verification: Confirms the generator's ability to meet power demands.

Extended Equipment Life: Proper maintenance through load testing prolongs the generator's lifespan.

Compliance with Regulations: Demonstrates adherence to safety and performance standards.

Improved Efficiency: Optimizes generator performance for fuel efficiency.

Conclusion

Load bank testing is an indispensable tool for ensuring the reliability and efficiency of your generator. By following these guidelines and conducting regular tests, you can maximize the performance of your equipment and minimize the risk of unexpected failures.

2 notes

·

View notes

Text

From Engine to Electronics: Proper Diagnostic Techniques for Resolving Maserati Problems

Maserati, the epitome of Italian luxury and performance, is renowned for its stylish design and high-performance capabilities. However, like any high-end vehicle, Maserati can encounter a range of issues, from engine troubles to electronic malfunctions. Proper diagnostics is crucial in maintaining the health and performance of these sophisticated machines. This article will guide you through the common problems Maserati face and the proper diagnostic techniques to resolve them.

Common Maserati Problems

1. Engine Issues

Maserati engines are marvels of engineering, but they can develop problems over time. Common engine issues include:

Misfires and Rough Idling: This can be caused by faulty spark plugs, ignition coils, or fuel injectors.

Overheating: Often due to a malfunctioning cooling system, such as a failed water pump or a clogged radiator.

Oil Leaks: These can originate from various seals and gaskets, leading to low oil levels and potential engine damage.

2. Transmission Problems

Maserati transmissions are designed for performance but can experience:

Slipping Gears: This could indicate worn-out clutch plates or issues with the transmission fluid.

Delayed Shifts: Often due to problems with the transmission control module or low fluid levels.

3. Electrical and Electronic Failures

Modern Maseratis are equipped with advanced electronics that can sometimes fail, including:

Dashboard Warning Lights: These can indicate issues ranging from simple sensor failures to serious engine problems.

Infotainment System Glitches: Problems with the touch screen, navigation, or audio system are not uncommon.

Diagnostic Techniques

1. OBD-II Scanner

The On-Board Diagnostics II (OBD-II) scanner is an essential tool for diagnosing Maserati problems. It can read error codes from the car's computer, providing insight into various issues.

How to Use: Connect the OBD-II scanner to the port located under the dashboard. Turn on the ignition and follow the scanner’s instructions to retrieve the error codes.

Interpreting Codes: Each code corresponds to a specific problem. For example, P0300 indicates a random/multiple cylinder misfire, while P0128 points to a coolant thermostat issue.

2. Visual Inspection

A thorough visual inspection can reveal obvious issues such as leaks, damaged components, or worn-out parts.

Engine Bay: Check for oil leaks, loose connections, and the condition of belts and hoses.

Undercarriage: Inspect for fluid leaks and damage to the exhaust system.

Electrical Connections: Look for corroded or loose battery terminals and wiring issues.

3. Multimeter Testing

A multimeter is useful for diagnosing electrical issues in a Maserati.

Battery Voltage: Measure the voltage across the battery terminals. A healthy battery should read around 12.6 volts when the car is off and around 14 volts when running.

Sensor Checks: Test various sensors, such as the oxygen sensor or mass airflow sensor, to ensure they are functioning correctly.

4. Compression Test

A compression test helps diagnose internal engine problems such as worn piston rings or valves.

Procedure: Remove the spark plugs and insert a compression gauge into each cylinder. Crank the engine and note the pressure readings. Low or uneven readings indicate internal engine issues.

5. Professional Diagnostic Tools

Maserati dealerships and specialized repair shops use advanced diagnostic tools that can access proprietary systems and provide more detailed information.

SD2/SD3 Diagnostic Systems: These are specialized tools used by Maserati technicians to diagnose and program vehicle systems accurately.

Diagnostic Software: Tools like Xentry or PIWIS can interface with Maserati's electronic systems for comprehensive diagnostics.

Addressing Common Issues

1. Engine Repairs

Misfires and Rough Idling: Replace faulty spark plugs, ignition coils, or fuel injectors. Regular maintenance and using high-quality fuel can prevent these issues.

Overheating: Ensure the cooling system is functioning correctly by checking the water pump, radiator, and thermostat. Flushing the coolant system periodically is also recommended.

Oil Leaks: Identify the source of the leak and replace the necessary seals or gaskets. Regularly check oil levels and change the oil according to the manufacturer's recommendations.

2. Transmission Solutions

Slipping Gears: Inspect and replace worn clutch plates and ensure the transmission fluid is at the correct level. Consider a fluid change if necessary.

Delayed Shifts: Diagnose and repair issues with the transmission control module or solenoids. Regular transmission servicing can prevent many of these problems.

3. Electrical Fixes

Dashboard Warning Lights: Use an OBD-II scanner to identify and address the underlying issue. Reset the warning lights after repairs are completed.

Infotainment System Glitches: Perform software updates and check for any loose connections or faulty components. In some cases, a complete system reset may be required.

Conclusion

Proper diagnostics are essential for maintaining the performance and reliability of your Maserati. By using the right tools and techniques, you can identify and resolve issues promptly, ensuring your luxury car continues to deliver the driving experience it was designed for. Regular maintenance and timely repairs are key to keeping your Maserati in top condition, from the engine to the sophisticated electronics.

#maserati car#maserati car diagnosis#maserati service center#maserati car maintenance#maserati car mechanic

2 notes

·

View notes

Text

Accident Investigation Report

(I originally posted this on Reddit.)

This is a translation of the original incident report from the Space Travel Safety Commission of the United Syndicate. Units, star names, and nomenclature have been localised. For a direct translation, see Addendum 1.

The Orolda was a hyperspace-capable passenger liner 205 metres from nose to bell with a cylindrical cross-section. The main body was 10 metres in diameter, with a gravity ring in the fore section with a diameter of 80 metres. She had a crew of 26, and carried 80 passengers. On October 18th, 12 A.C. at 0632 (Vienna time), she departed a station at 40 Eridani without incident. Her intended final destination was Delta Pavonis.

When traveling through the Gliese 1061 system, Junior Engineer Lurin, who had been kept on duty for nineteen hours due to his junior status, was ordered to refill the radiator coolant because of an earlier leak. The proper procedure was to open the valve separating the primary and auxiliary coolant reservoirs, and then actuate a series of valves to push coolant out of the backup reservoir and into the primary reservoir. Junior Engineer Lurin actuated the wrong set of valves, pushing coolant out of the primary reservoir and into the backup reservoir.

A sensor existed to monitor the pressure level of the primary reservoir, but the alarms were disabled when fluids were being transferred to avoid alarms triggering during nominal and routine activities.

As the coolant drained, the remaining coolant in the system increased in temperature. This caused damage to the cooling pipes and radiators. Roughly three minutes after the coolant began draining, a partially melted pipe began leaking superheated coolant inside the Orolda's fission reactor. The coolant pressure dropped sharply, and without coolant the reactor rapidly overheated. Three minutes and forty-one seconds after the coolant began draining, a rapid increase in temperature caused the reactor to automatically SCRAM. This prompted the ship to move to Alert Status Two. The computer roused Captain Uliz.

The SCRAM was not successfully completed. Why it failed is unknown, but the reactor's automatic SCRAM had not been tested in several years. Twenty seconds after the attempt, radiation detectors indicated an ongoing meltdown. This prompted Alert Status One, waking all crew and sending them to emergency stations. Due to the radiation hazard, the aft engineering spaces were evacuated, which included Junior Engineer Lurin, who did not close the valve as he left (and was not aware that he had done anything wrong).

Two minutes later, radiation detectors indicated that the core had collapsed and penetrated the interior reactor wall. The temperature was increasing rapidly, and the cooling system was operating well below its typical efficiency. Radiation sensors in the fore section indicated that radiation was still within acceptable levels, so Captain Uliz did not order a retreat to the radiation storm shelter, for fear this would hamper repair efforts and panic the passengers.

All crew were accounted for in the shielded fore section. Of the five in the aft section at the time of the incident, all were exposed to radiation exceeding the allowable yearly dose, one suffered light radiation sickness, and two suffered acute radiation sickness: Engineer Iraz was only two metres away from the reactor and began vomiting almost immediately. Chief Engineer Aralt, who was watching him from twelve metres away, carried him to safety but was exposed to a much larger dose in the process. Both were immediately placed in medical cryostasis and are currently undergoing nanotherapy; they are expected to recover.

Once all crew were accounted for, Captain Uliz instructed Engineer Yrenzl (The highest-ranking engineer with Chief Engineer Aralt in medical cryostasis) to send a drone to examine the reactor. Although the video signal was degraded by radiation, the drone 's cameras revealed that the outer casing was melting.

Upon confirmation of the reactor being effectively unrecoverable, First Officer Intri deployed the automated hyperspace distress buoy, as there were no United Syndicate ships in the system. It would reach the next system in thirty-eight days.

Twenty minutes after the meltdown, radiator efficiency had fallen to 60%, and damage alarms were continuing. Captain Uliz ordered a visual inspection of the radiators. Instead of their usual cherry-red, they were not glowing at all, indicating a complete system failure. Captain Uliz was unresponsive and emotional for several minutes, so First Officer Intri ordered a full diagnostic on the heat management systems.

Twenty-three minutes after the meltdown, with the diagnostic still ongoing, the Orolda received a message from the Sixteen Kilotons, a Terran mining ship 25 metres from nose to bell and 15 metres in diameter at the widest point, with a crew of six. She was eleven light-minutes away (and moving away from the Orolda quickly) and the only other vessel in the system: "We see radiation from your reactor consistent with an uncontrolled meltdown. We are now moving towards you at half a gee. How many souls are on board? Are there any other issues?"

Because of the tense relationship between Earth and the United Syndicate, the crew of the Orolda assumed that the Sixteen Kilotons was a pirate or privateer taking advantage of their situation. They grimly discussed whether to resist until Engineer Yrenzl announced that the diagnostics were completed. All of the coolant was gone from the system, and high heat had melted the valves in their current position. The figure of 60% was inflated, since the pipes themselves were acting as heatsinks. The radiators were effectively turned off, but more heat than ususal was coming from the reactor. The cabin temperature would begin increasing in 6 hours, and become incompatible with life in 8.

On hearing this, Captain Uliz, previously silent, ordered the crew to cooperate fully with the humans, and stated that he would accept all responsibility for the capture of the ship. "They are likely to hold us for ransom", he said, "but they are unlikely to kill us. The same is not true for the heat."

First Officer Intri responded to the Sixteen Kilotons as follows: "Our reactor has melted down and our radiators are shot. We have 8 hours before we all bake. We have 106 souls on board. We will cooperate fully and follow all instructions."

Fifty seconds after this message was received, the Sixteen Kilotons jettisoned her load of ice. Lightened, her acceleration increased to six gees. She thereby arrived at the Orolda in five hours, thirty minutes.

An hour before the Sixteen Kilotons arrived, the crew of the Orolda, following instructions from the Sixteen Kilotons, brought all passengers into the radiation storm shelter, sealed every hatch and bulkhead, and depressurized the mid-section. Once all this was confirmed to be done, the crew of the Sixteen Kilotons used their mining laser to cut the Orolda in half at the thinnest point of her midsection. Although the two ships' docking systems were not compatible, the crew of the Sixteen Kilotons was able to attach the ports to form an airtight seal using three hundred and fifty metres of fibre-reinforced plastic adhesive strips.

Once this connection was established, three crew-members from the Sixteen Kilotons entered with a large cooling device connected by flexible tubes to their ship's cooling system. Captain Uliz presented the ship's rifle to the Terran captain, and offered surrender. The translator records the Terran Captain's reply as "What the hell are you talking about?".

Once the cooling systems were established, the Sixteen Kilotons' reactor and radiators, which because of her duties were more powerful than the Orolda's own, were able to keep the crew at a comfortable temperature until the United Syndicate patrol ship Arteyna arrived and began ferrying passengers and crew to safety.

Recommendations

The common practice on merchant ships of severely overworking new crewmembers as a rite of passage must be curtailed.

It is advised that it be regulated that two crewmembers be present whenever liquids are being manually transferred within a ship.

Regulation should be enacted to require regular testing of a reactor's SCRAM functions, including in suboptimal conditions.

The feasibility of equipping all ships with military-style reactor jettison systems should be examined.

The uniquely human concept of a "Mayday" or "Distress call" in maritime, aviation, and orbital culture should be examined in detail.

Duct tape should be made mandatory on all ships.

6 notes

·

View notes

Text

1.Tell me how you’d check that the brakes are working before starting a journey.

Brakes should not feel spongy or slack. Brakes should be tested as you set off. Vehicle should not pull to one side.

2. Tell me where you’d find the information for the recommended tyre pressures for this car and how tyre pressures should be checked.

Manufacturer’s guide, use a reliable pressure gauge, check and adjust pressures when tyres are cold, don’t forget spare tyre, remember to refit valve caps.

3. Tell me how you make sure your head restraint is correctly adjusted so it provides the best protection in the event of a crash.

The head restraint should be adjusted so the rigid part of the head restraint is at least as high as the eye or top of the ears, and as close to the back of the head as is comfortable. Note: Some restraints might not be adjustable.

4. Tell me how you’d check the tyres to ensure that they have sufficient tread depth and that their general condition is safe to use on the road.

No cuts and bulges, 1.6mm of tread depth across the central three-quarters of the breadth of the tyre, and around the entire outer circumference of the tyre.

5. Tell me how you’d check that the headlights and tail lights are working. You don’t need to exit the vehicle.

Explain you’d operate the switch (turn on ignition if necessary), then walk round vehicle (as this is a ‘tell me’ question, you don’t need to physically check the lights).

6. Tell me how you’d know if there was a problem with your anti-lock braking system.

Warning light should illuminate if there is a fault with the anti-lock braking system.

7. Tell me how you’d check the direction indicators are working. You don’t need to exit the vehicle.

Explain you’d operate the switch(turn on Hazards) (turn on ignition if necessary), and then walk round vehicle (as this is a ‘tell me’ question, you don’t need to physically check the lights).

8. Tell me how you’d check the brake lights are working on this car.

Explain you’d operate the brake pedal, make use of reflections in windows or doors, or ask someone to help.

9. Tell me how you’d check the power-assisted steering is working before starting a journey.

If the steering becomes heavy, the system may not be working properly. Before starting a journey, 2 simple checks can be made.

Gentle pressure on the steering wheel, maintained while the engine is started, should result in a slight but noticeable movement as the system begins to operate. Alternatively turning the steering wheel just after moving off will give an immediate indication that the power assistance is functioning.

10. Tell me how you’d switch on the rear fog light(s) and explain when you’d use it/them. You don’t need to exit the vehicle.

Operate switch (turn on dipped headlights and ignition if necessary). Check warning light is on. Explain use.

11. Tell me how you switch your headlight from dipped to main beam and explain how you’d know the main beam is on.

Operate switch (with ignition or engine on if necessary), check with main beam warning light.

12. Open the bonnet and tell me how you’d check that the engine has sufficient oil.

Identify dipstick/oil level indicator, describe check of oil level against the minimum and maximum markers.

13. Open the bonnet and tell me how you’d check that the engine has sufficient engine coolant.

Identify high and low level markings on header tank where fitted or radiator filler cap, and describe how to top up to correct level.

14. Open the bonnet and tell me how you’d check that you have a safe level of hydraulic brake fluid.

Identify reservoir, check level against high and low markings.

12 notes

·

View notes

Text

I don't know who else had this problem, but I never learned anything about Chernobyl other than "Russian reactor exploded". Thing is, I like learning about things, so I have fixed this issue. Problem is, this is going to be a rather lengthy post, the events are actually very complicated...

So, firstly, it's important to have a slight knowledge on how an RBMK reactor works. It's similar to how the usual "Western" reactor works, but is different in a few key areas.

The power is generated by running water through a series of tubes with decaying uranium isotopes, which is such an exothermic reaction that it heats the water to VERY significant temperatures. This results in a lot of boiling water, which is then funneled to a separate chamber where the steam generated by the reaction is sent to turbines to generate the power where it is then cooled off and sent to that same chamber from before, where it joins the water that didn't become steam and is pumped back into the tubes.

That steam is cooled by going into a chamber that has pipes with different water brought in from an outside source that lowers the temperature. The coolant being a separate system of water will be important, and is one of the differences from western reactors.

In the event of a loss of power, the water pumps would stop working, and thus the entire thing would start to have some issues. Specifically, overheating in the core, which is pretty bad. There were backup generators, but they took up to a minute to actually build up to the level they needed to be at. However, this was accounted for, and the pumps had specific weights that would keep water flowing through inertia long enough for the generators to get them back online.

HOWEVER if a coolant leak happened during these events, then this method wouldn't work. Instead, another emergency coolant system would pump water into the core, replenishing the leaking coolant. The steam turbines should theoretically generate enough power to run that pump as they slowed down due to the loss of pressure.

OK, back to Chernobyl, which as you can probably guess, is an RBMK reactor.

A test was planned to see if the turbines would actually be able to run the emergency pumps as they wound down. This would be achieved by running half the turbines on external power, then basically shutting the reactor down to see what happened with the other turbines. Due to some issues and delays, things got a bit scrambled and messy. This resulted in the steam supply being polluted with a byproduct, and reactor output did a sudden drop instead of the gradual decrease that was planned. This was resolved, but was not a great start.

Due to complicated reactor stuff, a number of control rods (which control the rate of the reaction and were being interfered with by the byproduct) were removed, which got the reactor to the power levels needed for the test, but it was getting very unstable.

An unstable RBMK reactor has issues when the places where water are supposed to be are suddenly filled with steam. Keep this in mind.

The test officially began, and the steam was shut off to the turbines. The reduction in power to the pumps decreased water flow, which meant that steam pockets could start forming in the tubes, which would actually increase reactivity.

For some reason that can only be speculated, an emergency shutdown of the reactor was initiated, which involves putting in all control rods. This was a catastrophic mistake.

For just a few seconds, when the water was displaced and covered more of the fuel rods, power output spiked. Dramatically. This, combined with the extra steam in the system, was enough for the coolant system to just fail and the core overheated, which started an unstoppable chain of events. In essence, there was a massive buildup of steam in the system with nowhere to go, which steam doesn't like, so it decided to break something.

There was a large explosion of steam, blowing off the top of the reactor like a manhole. This resulted in the fuel cells and coolant water being exposed to each other, resulting in a flash steaming event, which caused a second, even stronger explosion, which pretty much shredded the reactor, and ended the chain reaction. The result of the disaster was all of the carefully shielded radiation being released into the surrounding area, including the nearby town of Pripyat, which was not even alerted to the issue until roughly 10 hours had passed, when the town was evacuated.

Interestingly enough, this reactor was Chernobyl-4, one of a series of 6 total reactors, though 5 and 6 never competed construction. Chernobyl reactors 1-3 survived the explosion, and ran for over a decade afterwards, only getting shut down between 1996 and 2000. Chernobyl-4 is the only RBMK reactor that was destroyed, and there are still 9 RBMK reactors still in use today.

Anyways. If you were looking for a short version of events, Chernobyl was the perfect storm of events that resulted in the reactor coolant system exploding into steam. It was not quite the fiery mushroom cloud explosion that I always thought it was, just a really large and angry puff of steam.

2 notes

·

View notes

Text

Figuring out how to land humans on the moon was a challenge, but the six Apollo crews who achieved this aim encountered another perplexing problem once they arrived: moon dust. The tiny, electrostatically charged particles made of crushed lunar rock clung to every surface, from spacesuits to electronics, and even infiltrated the astronauts’ lungs. Crews tried using a brush or their hands to sweep the sharp, abrasive dust off their spacesuits, but neither method proved very effective.

Now, as NASA once again prepares to send humans to the moon with the Artemis program, researchers at Washington State University say they’ve come up with a promising solution to the dust issue. In laboratory experiments, they effectively removed dust from surfaces using pressurized liquid nitrogen, according to a new paper published in February in the journal Acta Astronautica.

To see whether liquid nitrogen—typically used as coolant—might be up to the task of removing moon dust, the scientists created miniature, replica spacesuits and placed them on Barbie dolls. Then, they coated the suits with volcanic ash from Mount St. Helens and other substances meant to imitate lunar dust. After placing the dolls in a vacuum chamber, they used a sprayer full of pressurized liquid nitrogen to blast away the particles.

In 233 total tests on 26 simulated spacesuits, the pressurized liquid nitrogen removed more than 98 percent of the moon dust substitute. Perhaps even more exciting is that the technique caused little damage to the spacesuits. This is important because “traditional spacesuit cleaning methods, such as brushing and vacuuming, have limited effectiveness and introduce suit fabric abrasion,” the researchers write in the paper.

The mechanism at play is known as the Leidenfrost Effect, in which a liquid droplet hovers over a very hot surface, rather than making contact with it. This happens, for example, when a chef pours cold water into a very hot pan—rather than coating the bottom, the water beads up and skitters across the surface. The researchers say the same thing occurred when they sprayed cold liquid nitrogen onto the warmer spacesuits: The nitrogen encapsulated the dust particles in droplets, then floated away.

This relatively gentle method can be used 75 times without causing damage to the suit, writes Space.com’s Elizabeth Howell. A brush, for comparison, damages a spacesuit with just one use.

Though the initial findings are promising, they represent only a first step toward implementing the technique on future lunar landings. For one, the researchers tested the liquid nitrogen on Earth, which has much stronger gravity than the moon. Astronauts would also face logistical challenges bringing pressured liquid nitrogen aboard a spacecraft.

Even so, NASA is eager to come up with a solution to the moon dust problem and wants to collaborate with partners that might be able to help. In 2019, the space agency launched the Lunar Surface Innovation Initiative to develop new technologies that could support astronauts and vehicles that land on the moon—and dust is one of its key areas of focus. Staff working on the initiative are considering “active and passive mitigation technologies for different exploration systems, like rovers, power systems, spacesuits and other surface hardware exposed to dust,” according to NASA.

NASA engineers have been testing some ideas, including slippery coatings to prevent dust from sticking to surfaces in the first place and electrostatic devices to repel particles. They’re also considering using waves of ultrasonic energy to remove dust. In the end, they may need to use all of these techniques—and then some—to protect the materials astronauts bring to space and finally vanquish their pesky lunar dust foe.

“There’s not going to be one solution,” said Sharon Miller, who is leading NASA’s dust-mitigation efforts, to Wired’s Eric Niiler in 2021. “For every material that you need to have up there, we’ll have to do something different.”

2 notes

·

View notes

Text

Understanding Vehicle Maintenance: A Seasonal Checklist for Vancouver Drivers

Keeping your vehicle in top shape is essential for safe driving and extending its lifespan. Living in mechanic Vancouver, with its unique climate and road conditions, requires specific maintenance attention throughout the year. This blog post will guide you through a seasonal checklist to help you maintain your vehicle effectively, ensuring you’re always ready for the roads.

Spring Maintenance Checklist

As winter ends and spring blooms, it’s time to shake off the cold and prepare your vehicle for warmer months.

1. Tire Check

Tread Depth: Inspect your tires for adequate tread. Use the penny test—insert a penny into the tread with Lincoln’s head down. If you can see all of his head, it’s time for new tires.

Air Pressure: Cold temperatures can lower tire pressure. Check and inflate your tires to the recommended levels.

2. Battery Inspection

Clean any corrosion from the battery terminals.

Check the battery's charge; if it’s over three years old, consider getting it tested.

3. Fluid Levels

Engine Oil: Check your oil level and change it if it’s dirty or below the recommended level.

Coolant: Ensure your coolant is filled to the proper level to prevent overheating as temperatures rise.

4. Wiper Blades

Inspect your wipers for wear and replace them if they leave streaks or miss spots.

5. Brakes

Listen for unusual noises and check the brake pads for wear. It’s a good time to have them inspected by a professional if you notice any issues.

Summer Maintenance Checklist

Summer in Vancouver can be beautiful but also hot and humid. It’s vital to keep your vehicle ready for the heat.

1. Air Conditioning

Test your AC system to ensure it’s cooling properly. If it’s weak or not working, have it serviced.

2. Tire Care

Keep an eye on tire pressure, as heat can increase it. Don’t forget to rotate your tires every 5,000 to 7,000 kilometers to ensure even wear.

3. Coolant System

Double-check your coolant levels and hoses for leaks. Make sure your radiator is clean and functioning well.

4. Windshield Washer Fluid

Fill up your windshield washer fluid to ensure clear visibility during those summer road trips.

5. Interior Cleaning

Give your car a good clean to remove any clutter. Consider using sunshades to protect your interior from UV damage.

Fall Maintenance Checklist

As the leaves change and rain returns, it’s important to prepare your vehicle for wet and slippery roads.

1. Tires for Rain

Check the tread depth again. Consider switching to all-season or winter tires if you anticipate heavy rain or early snow.

2. Brake System

Have your brakes inspected, especially if you’ve driven a lot over the summer. Wet conditions can affect stopping distances.

3. Fluid Levels

Top off all fluids, especially windshield washer fluid, as you may need it more often in the rain.

4. Battery Check

Inspect your battery again as colder temperatures can decrease battery performance.

5. Lights and Signals

Ensure all lights (headlights, brake lights, turn signals) are functioning correctly for better visibility in rain and fog.

Winter Maintenance Checklist

Mechanic Vancouver winters can be mild but often come with rain and occasional snow. Proper preparation is key to navigating the season safely.

1. Winter Tires

If you haven’t already, switch to winter tires. They provide better traction on slippery roads.

2. Fluids

Use antifreeze in your coolant system to prevent freezing. Ensure your windshield washer fluid is rated for low temperatures.

3. Battery and Electrical System

Cold weather can sap battery power. Get your battery tested to ensure it can handle winter temperatures.

4. Emergency Kit

Prepare an emergency kit with blankets, water, snacks, a flashlight, and a first-aid kit in case of emergencies.

5. Regular Checks

Check your vehicle regularly for any signs of wear or problems, especially before long trips.

General Maintenance Tips

In addition to seasonal checks, here are some ongoing maintenance tips to keep your vehicle in top condition year-round.

1. Regular Oil Changes

Change your oil every 5,000 to 8,000 kilometers or according to your vehicle’s manual.

2. Scheduled Maintenance

Follow your vehicle's manufacturer maintenance schedule. This often includes important inspections and part replacements.

3. Keep it Clean

Regularly wash your vehicle, especially in winter when road salt can cause rust. Waxing can also protect the paint.

4. Monitor Your Driving

Pay attention to how your vehicle handles. Any strange noises, vibrations, or warning lights should prompt a visit to a mechanic.

Conclusion

Understanding vehicle maintenance is essential for every Vancouver driver. Following this seasonal checklist will help you keep your car safe, efficient, and ready for any weather. Remember, a little attention goes a long way in ensuring your vehicle serves you well for years to come. Happy driving!

Let's Connect!

Name: wrenchpatrol

Telephone: (888) 779-8651

Local call: (604) 757-1297

0 notes

Text

Essential Tools for Cummins Engines: A Guide to Cummins Service Tools

Working with Cummins engines requires a deep understanding of their design and functionality, as well as access to the right tools to keep them running smoothly. Tools for Cummins engines are designed specifically to meet the demands of these robust and reliable diesel powerplants. In this comprehensive guide, we'll explore the range of Cummins Service Tools and Diesel Engine Tools necessary for maintaining and servicing Cummins engines, ensuring that they continue to deliver optimal performance.

The Importance of Specialized Tools for Cummins Engines

Cummins engines are known for their durability and performance, making them a popular choice across various industries, from trucking to marine applications. However, their complexity also means that they require specialized tools for proper maintenance and repair. Generic tools may not provide the precise fit or functionality needed, which can lead to improper servicing and potential engine damage. Cummins Service Tools are engineered to meet the specific requirements of these engines, enabling technicians to perform maintenance tasks with accuracy and confidence.

Why Invest in Tools for Cummins?

When it comes to servicing Cummins engines, using the right tools is critical. Here's why investing in specialized Tools for Cummins is essential:

Precision Engineering for Accurate Servicing

Cummins engines are built to tight tolerances, and maintaining these engines requires tools that can match that level of precision. Cummins Service Tools are designed with exact specifications, ensuring that each tool fits perfectly and functions as intended. This precision is crucial for tasks such as torquing bolts to the correct specification, aligning components properly, and ensuring that all parts are installed correctly.

Durability and Reliability

Diesel Engine Tools designed for Cummins engines are built to withstand the rigors of heavy-duty maintenance. These tools are made from high-quality materials that resist wear and tear, ensuring they remain reliable over time. Whether you're working in a shop or out in the field, you can trust these tools to perform consistently, reducing the risk of tool failure during critical tasks.

Key Tools for Cummins Engine Maintenance

Servicing a Cummins engine requires a variety of specialized tools, each designed for specific tasks. Below are some of the essential Tools for Cummins engines that every technician should have.

Fuel System Tools

The fuel system in a Cummins engine is a critical component that requires careful maintenance. Cummins Service Tools for the fuel system include fuel injector pullers, fuel line disconnect tools, and pressure testing kits. These tools allow technicians to safely remove and install injectors, disconnect fuel lines without damaging them, and test the fuel system for proper pressure and flow.

Cooling System Tools

Maintaining the cooling system in a Cummins engine is essential for preventing overheating and ensuring that the engine operates within the correct temperature range. Diesel Engine Tools for the cooling system include radiator pressure testers, thermostat removal tools, and coolant flow testers. These tools help diagnose and repair cooling system issues efficiently, ensuring that the engine remains cool under all operating conditions.

Crankshaft and Camshaft Tools

The crankshaft and camshaft are vital components of a Cummins engine, and servicing these parts requires specialized tools. Tools for Cummins engines in this category include crankshaft seal installers, camshaft alignment tools, and timing tools. These tools ensure that the crankshaft and camshaft are properly aligned and sealed, which is crucial for engine performance and longevity.

Diagnostic Tools for Cummins Engines

In addition to mechanical tools, diagnostics play a vital role in maintaining Cummins engines. Identifying issues early can prevent costly repairs and downtime. Cummins provides a range of diagnostic tools that are essential for keeping these engines in top condition.

Electronic Diagnostic Tools

Electronic diagnostics are critical for modern Cummins engines, which rely on complex electronic control systems. Cummins Service Tools include diagnostic scanners and software that interface with the engine's onboard computer systems. These tools can read fault codes, monitor engine parameters, and run tests to identify issues quickly and accurately.

Mechanical Diagnostic Tools

Mechanical diagnostic tools, such as compression testers and cylinder leakage testers, are also essential for assessing the physical condition of the engine. These Diesel Engine Tools help technicians determine whether the engine's internal components are functioning correctly, providing valuable insights into the engine's health.

The Benefits of Using Genuine Cummins Service Tools

While there may be cheaper aftermarket options available, using genuine Tools for Cummins offers several key advantages that make them the best choice for professionals.

Guaranteed Compatibility and Fit

Genuine Cummins tools are designed specifically for Cummins engines, ensuring that they fit perfectly and function as intended. This compatibility eliminates the guesswork and potential issues that can arise from using generic tools, which may not provide the precise fit needed for certain tasks.

Manufacturer Support and Warranty

When you invest in genuine Cummins Service Tools, you benefit from the support of the manufacturer. This includes access to technical support, warranties on tools, and the assurance that you're using tools designed to meet Cummins' exacting standards. This support can be invaluable when dealing with complex engine issues or when new tools are needed for the latest engine models.

Long-Term Reliability and Cost Savings

Although genuine Cummins tools may have a higher upfront cost, they offer long-term reliability that can lead to cost savings over time. Their durability means fewer tool replacements, and their precision reduces the likelihood of mistakes that can lead to costly engine repairs.

Conclusion: Essential Tools for Optimal Cummins Engine Maintenance

Maintaining and servicing Cummins engines requires more than just basic mechanical knowledge; it requires the right tools for the job. Cummins Service Tools and Diesel Engine Tools are essential for ensuring that these powerful engines continue to perform at their best. Whether you're performing routine maintenance or tackling a complex repair, having the correct Tools for Cummins ensures that the job is done right, every time.

By investing in genuine Cummins tools, technicians can trust that they are equipped to handle any challenge, ensuring the long-term performance and reliability of the engines they service.

0 notes

Text

Panel Mounted Gauges and Test Plugs for Pressure Gauges

Understanding Panel Mounted Gauges and Test Plugs for Pressure Gauges

Panel mounted gauges and test plugs for pressure gauges are essential components in various industrial and mechanical systems. They are crucial for monitoring and maintaining the integrity of pressurized systems, ensuring safety, and optimizing operational efficiency. In this blog, we will explore what these components are, their applications, and the benefits they offer in different industries.

What is a Panel Mounted Gauge?

A panel mounted gauge is a type of Panel mounted gauge that is designed to be installed on a control panel or a dashboard. Unlike conventional gauges that are directly attached to pipes or tanks, panel mounted gauges provide a centralized location for monitoring pressure. This is particularly useful in systems where operators need to keep an eye on multiple pressure points from a single location.

Applications of Panel Mounted Gauges:

Industrial Equipment Monitoring: In manufacturing and processing plants, panel mounted gauges are used to monitor the pressure of various fluids and gases. This helps in maintaining process consistency and safety.

Automotive and Marine Industries: These gauges are also used in vehicles and boats to monitor engine oil pressure, coolant levels, and other vital parameters from the dashboard.

HVAC Systems: Heating, ventilation, and air conditioning systems use panel mounted gauges to monitor and control the pressure of refrigerants and other gases.

Advantages of Panel Mounted Gauges:

Centralized Monitoring: Operators can easily monitor multiple pressure points without having to physically check each gauge, which is especially useful in large systems.

Improved Safety: By centralizing the monitoring, operators can quickly detect and respond to any pressure anomalies, reducing the risk of accidents.

Space Efficiency: These gauges are designed to fit compactly on control panels, saving space while providing essential information.

What is a Test Plug for Pressure Gauges?

A test plug, also known as a test point or pressure test plug, is a small device that allows for the safe and easy measurement of system pressure without the need for permanently installed gauges at every test point. It consists of a valve and a protective cap, and it can be used to temporarily connect a pressure gauge to the system for testing purposes.

Applications of Test Plugs for Pressure Gauges:

Periodic Maintenance and Testing: Test plugs are commonly used during routine maintenance to check the pressure in various parts of a system without interrupting its operation.

Troubleshooting: When a pressure anomaly is detected, a test plug can be used to measure pressure at specific points to diagnose the issue.

Calibration: Test plugs enable easy access for calibrating pressure gauges, ensuring that they provide accurate readings.

Advantages of Test Plugs for Pressure Gauges:

Non-Intrusive Testing: Test plugs allow pressure measurements to be taken without disrupting the system, making the process safer and more efficient.

Versatility: They can be installed in various parts of the system, providing flexibility for monitoring and testing.

Cost-Effective: By using test plugs, there is no need to install permanent gauges at every point, reducing equipment costs and complexity.

Conclusion

Both panel mounted gauges and test plugs for pressure gauges play a vital role in maintaining the functionality and safety of pressurized systems. Panel mounted gauges provide a centralized monitoring solution, allowing operators to keep track of critical pressure levels from a single location. Meanwhile, test plugs offer a convenient and non-intrusive way to measure and verify pressure at specific points, supporting effective maintenance and troubleshooting.

Incorporating these components into your system design can significantly enhance operational efficiency, safety, and reliability. Whether you are in manufacturing, automotive, HVAC, or any other industry that relies on precise pressure control, understanding and utilizing these tools effectively can make a substantial difference in your operations.

0 notes

Text

Wheel Loader Maintenance: Your Complete Guide to Ensuring Peak Performance

Wheel loaders are vital machines in industries such as construction, mining, agriculture, and material handling. Proper maintenance is the key to keeping these machines running efficiently and reliably. Here’s a complete guide to maintaining your wheel loader for optimal performance and longevity.

Daily Pre-Shift Inspection

A quick but thorough inspection before each shift can prevent costly repairs and downtime. Check the following:

Fluid Levels: Ensure proper levels of engine oil, hydraulic fluid, coolant, and transmission fluid.

Tires: Inspect for correct pressure, tread condition, and any signs of punctures or damage.

Lights and Signals: Test all lights, indicators, and warning signals for functionality.

Attachments: Confirm that the bucket, forks, or other attachments are securely attached and undamaged.

Brakes: Test both service and parking brakes to ensure they respond properly.

Leaks: Look for any fluid leaks, which may indicate a more serious issue.

Belts and Hoses: Check for wear, cracks, or damage, and replace as needed.

Safety Features: Ensure mirrors, backup alarms, and horns are functioning properly.

Engine Maintenance

The engine is the heart of the wheel loader, so proper care is essential:

Oil Changes: Stick to the manufacturer’s recommended intervals for oil and filter changes.

Air Filters: Regularly clean or replace air filters to prevent debris from entering the engine.

Fuel System: Check fuel lines and filters for blockages or leaks.

Cooling System: Keep coolant levels at the proper level and make sure the radiator is clean.

Exhaust System: Inspect the exhaust for any leaks or damage that could impact performance.

Hydraulic System Maintenance

Maintaining the hydraulic system is critical for smooth operation of the loader's arms and attachments:

Fluid Levels: Regularly check hydraulic fluid levels and top up as necessary.

Filters: Change hydraulic filters based on the manufacturer's guidelines.

Hoses and Lines: Look for cracks, wear, or leaks and replace damaged parts immediately.

Cylinders: Inspect for leaks and ensure smooth operation.

Pumps and Valves: Regularly check for proper function, addressing any issues promptly.

Transmission and Drivetrain

These components are essential for smooth power transfer and reliable operation:

Transmission Fluid: Keep an eye on fluid levels and replace them at regular intervals.

Drive Axles and Joints: Inspect for wear, damage, or unusual operation.

Differentials: Change the oil in the differentials as recommended, and check for leaks.

Electrical System Maintenance

A reliable electrical system is key to maintaining productivity:

Battery: Check for corrosion and ensure solid connections.

Wiring: Look for signs of wear or damage, and make sure all connections are secure.

Alternator and Starter: Test for proper functionality, addressing any issues immediately.

Tire Maintenance

Proper tire care ensures stability and optimal performance:

Tire Pressure: Monitor and adjust tire pressure according to the manufacturer's specifications.

Tire Rotation: Rotate tires regularly to ensure even wear.

Tire Replacement: Replace any tires that are excessively worn or damaged to avoid failure.

Brake System Maintenance

The brake system is crucial for safety on the job site:

Brake Fluid: Regularly check brake fluid levels and top up as necessary.

Brake Pads and Shoes: Inspect for wear and replace them as needed.

Brake Lines: Check for leaks, cracks, or wear in the brake lines and repair immediately.

Operator's Cabin

A well-maintained cabin promotes both safety and comfort:

Seats and Seatbelts: Ensure the seat is properly adjusted and seatbelts are functioning.

Controls and Gauges: Test all controls and gauges to ensure accurate readings.

Climate Control: Ensure the heating and air conditioning systems are working effectively.

Frame and Chassis

Routine inspection of the frame and chassis prevents structural issues:

Frame Inspection: Look for rust, cracks, or other signs of wear or damage.

Chassis Lubrication: Lubricate pivot points and joints regularly to prevent wear.

Regular Cleaning

Keeping your loader clean prevents long-term issues and preserves its appearance:

Exterior: Regularly clean the machine to remove dirt, mud, and debris that can cause rust or corrosion.

Engine Bay: Clear debris from the engine bay to maintain cooling and overall performance.

Radiators and Cooling Fins: Keep radiators and cooling fins clean to ensure proper heat dissipation.

Conclusion

Regular, thorough maintenance is the cornerstone of keeping your wheel loader in excellent working order. By following this guide, you can extend the lifespan of your equipment, reduce downtime, and maintain peak performance on every job. Invest in preventative care today for long-term reliability and efficiency. Readmore...

0 notes

Text

A Comprehensive Guide to Skoda Servicing: Keeping Your Car in Top Shape

Skoda vehicles are known for their reliability, efficiency, and robust engineering. However, like all cars, regular servicing is essential to ensure your Skoda performs at its best, providing a smooth, safe, and fuel-efficient driving experience. Whether you drive a city-friendly Fabia, a versatile Octavia, or a dynamic Kodiaq, proper maintenance will extend your car's life and enhance its performance.

Why Regular Skoda Servicing Is Important

Regular Skoda car servicing is not just about maintaining your car’s warranty; it’s about safeguarding your investment and ensuring the car remains safe and efficient. Skoda cars, with their advanced engineering, require periodic checks to ensure that all systems are running optimally. Servicing addresses minor issues before they become costly repairs, ensures compliance with safety standards, and helps to maintain a higher resale value.

Types of Skoda Servicing

Skoda car servicing generally comes in two types: Interim Service and Full Service. Here's a breakdown of what each includes:

1. Interim Skoda Service

An interim service is designed for high-mileage drivers or those who want their car checked more frequently. Typically, it is recommended every 6 months or 6,000 miles. It includes:

Oil and filter change

Checking lights, tyres, exhaust, and brakes

Inspection of fluid levels (e.g., coolant, brake fluid)

Visual inspection of key components for any wear and tear

This service ensures your Skoda runs smoothly between full services, addressing immediate issues that can affect performance.

2. Full Skoda Service

A full service is more comprehensive and is usually recommended once a year or every 12,000 miles. It includes everything covered in an interim service, along with:

Replacement of air and pollen filters

Detailed inspection of the engine and transmission

Testing battery condition and charging system

Checking suspension, steering, and wheel alignment

Inspection and replacement of spark plugs if needed (for petrol engines)

A full service ensures your Skoda remains in top condition, providing peace of mind when it comes to long-term reliability.

Key Components Checked During a Skoda Service

During a Skoda service, various components are thoroughly inspected to ensure they are functioning properly. Some of the most important elements include:

Engine oil and filter: Regular oil changes ensure smooth engine operation and prevent wear.

Brake system: Brake pads, discs, and fluid are checked for wear to ensure optimal braking performance.

Tyres: The condition, tread depth, and pressure of all tyres are inspected to promote safe driving.

Battery and electrical system: Ensuring the battery is charging correctly and the vehicle’s electrical systems are functioning properly.

Suspension: A check of the suspension components to maintain ride comfort and handling.

Skoda Digital Service Records

In the digital age, Skoda offers a Digital Service Record for every new car. This system replaces the traditional paper service booklet, providing a comprehensive digital log of all maintenance and repairs carried out on your vehicle. The benefits of a digital service record include:

Easy access to the complete service history of your Skoda.

Increased transparency, with a trusted record of all service work.

Added resale value, as buyers can verify the car’s service history.

Benefits of Skoda Dealer Servicing

Opting to service your car at an authorized Skoda service center has several advantages:

Certified Technicians: Skoda-trained professionals who understand the ins and outs of your vehicle.

Genuine Parts: Use of genuine Skoda parts ensures your car remains true to its original build quality.

Warranties: If your car is under warranty, servicing at a Skoda dealer ensures that your warranty remains intact.

Software Updates: Skoda dealerships have access to the latest software updates, improving the performance and efficiency of your vehicle.

When Should You Service Your Skoda?

The ideal servicing schedule depends on your driving habits, but a general guideline is:

Interim Service: Every 6 months or 6,000 miles

Full Service: Every 12 months or 12,000 miles

Check your Skoda's manual or consult with a Skoda service advisor for the specific service intervals based on your model and driving conditions.

How to Book a Skoda Service

Booking a service for your Skoda is straightforward. Many authorized dealers offer an online booking system, where you can select your preferred service type, date, and time. Additionally, some Skoda service centers provide collection and delivery options, or even a courtesy car, ensuring that servicing your vehicle doesn’t disrupt your day.

Skoda Service Plans

Skoda also offers service plans that allow you to spread the cost of servicing across manageable monthly payments. These plans often include the following benefits:

Fixed prices for the duration of the plan, protecting against inflation.

Easy budgeting with low monthly payments.

Peace of mind knowing your servicing needs are covered.

Conclusion

Regular servicing is vital for maintaining the performance, safety, and longevity of your Skoda. By staying on top of service intervals and choosing an authorized Skoda service center, you ensure your car is in expert hands, using genuine parts and receiving the care it needs. With a variety of service plans and options, Skoda makes it easier than ever to maintain your vehicle without breaking the bank.

0 notes

Text

Essential RV Travel Checklist: What You Need Before Hitting The Road?

Before you hit the road, it's an RV travel checklist that both you and your RV are ready for the adventure. Start by inspecting your vehicle to make sure all systems are functioning properly. This includes checking the engine, brakes, tires, and fluids such as oil, coolant, and brake fluid. Make sure your RV's lights, signals, and wipers are working as well. Additionally, review the condition of your RV’s batteries, and test the generator, ensuring they are fully operational. Equally important is ensuring your RV’s living essentials, such as the water system, propane, and electrical hookups, are in good condition.

Complete RV Travel Checklist For A Hassle-Free Adventure

A hassle-free RV trip begins with thorough planning and ensuring you’ve packed all necessary items for both comfort and safety. For a smooth adventure, ensure you’ve packed essentials such as clothing for varying weather RV travel checklist, sleeping bags for colder nights, and sunscreen for those sunny days. Stock up on toiletries like soap, toothbrushes, toothpaste, and first-aid items such as bandages, antiseptic creams, and any prescription medications. Don’t forget insect repellent and sunscreen, which will be invaluable when enjoying outdoor activities. Be sure to bring entertainment options for downtime, like books, board games, or portable speakers.

The Ultimate RV Travel Checklist: Be Fully Prepared For Your Next Trip

Being fully prepared for your RV trip means covering all your bases, from the basic to the unexpected. Begin with your RV's toolkit, which should include essential items like wrenches, screwdrivers, duct tape, and a tire pressure gauge. Spare fuses, extra light bulbs, and jumper cables are also good to have on hand. RV travel checklist of breakdowns, a roadside assistance membership can be a lifesaver, so make sure you have those details accessible. Another critical area is food preparation. A portable grill or stove, pots, pans, and cooking utensils are must-haves. Make sure you have sufficient propane or charcoal, as well as kitchen essentials like spices, oils, and condiments. Equally important is water storage.

RV Travel Checklist: Must-Have Items For A Smooth Journey