#custom pcb

Explore tagged Tumblr posts

Text

Viasion PCB: Your Trusted Partner for High-Quality Custom and Advanced PCBs

In today’s fast-paced electronics industry, choosing the right PCB manufacturer can make all the difference. Whether you're working on a new tech innovation or scaling an existing product, the quality, precision, and reliability of your printed circuit boards are critical. That’s where Viasion Technology Co., Ltd. steps in—a proven leader in the PCB industry with over 15 years of experience delivering excellence.

Viasion offers comprehensive PCB manufacturing and assembly services to clients across the globe, including the United States. From custom PCB boards to complex blind vias printed circuit boards, their products serve various industries including automotive, telecom, medical devices, and consumer electronics.

Why Choose Viasion for Your PCB Needs?

Viasion is more than just a custom PCB manufacturer. Their expertise spans across a wide range of advanced PCB types including blind via PCBs, ceramic PCBs, flexible PCBs, and copper based PCBs—all manufactured in ISO-certified facilities with stringent quality control.

Here’s a closer look at what makes Viasion a preferred partner:

1. Advanced Blind Via PCB Capabilities

For high-density interconnect (HDI) designs, blind vias PCBs are essential. These vias connect outer layers to inner layers without passing through the entire board, saving space and improving signal integrity. As a trusted blind vias PCB manufacturer, Viasion delivers precise, reliable blind via PCBs ideal for compact, high-speed devices.

Their expert team uses laser drilling and advanced lamination techniques to ensure accuracy and consistency in every board. Whether you're prototyping or in full-scale production, Viasion provides solutions that meet your specific requirements.

2. Durable and High-Performance Ceramic PCBs

When it comes to thermal conductivity, high-frequency performance, and durability, ceramic PCBs stand out. Ideal for aerospace, LED lighting, and automotive applications, these boards handle extreme environments where standard PCBs may fail.

As an experienced ceramic PCB manufacturer, Viasion offers a variety of ceramic substrates, including alumina and aluminum nitride, ensuring optimal performance even in the most demanding conditions. Their ceramic PCBs are designed to offer low thermal expansion, excellent insulation, and high mechanical strength.

3. Cost-Effective and Efficient Copper Based PCBs

Copper based PCBs are essential for high-power electronics due to their superior heat dissipation capabilities. These are commonly used in power converters, industrial control systems, and automotive components.

Viasion manufactures copper based PCBs with excellent reliability and durability. Their manufacturing process ensures a strong bond between copper and insulating layers, resulting in high-performance boards ready for tough applications.

4. Fully Customizable PCB Manufacturing

Need something tailored to your specific project? Viasion is a specialist custom PCB manufacturer, delivering bespoke PCB solutions that match your design and functional requirements. Whether it's a custom PCB board for a wearable device or a multi-layer board for an IoT product, their engineering team works closely with you to bring your design to life.

You’ll get DFM (Design for Manufacturing) support, fast prototyping, and competitive pricing—all while maintaining the highest quality standards.

5. Reliable Flexible PCB Manufacturing

For applications where space, weight, and flexibility are crucial, flexible PCBs are the go-to solution. Used in devices like smartphones, cameras, and medical instruments, flexible PCB boards allow for bendable, compact designs.

Viasion is a trusted flexible PCB manufacturer, producing single-sided, double-sided, and multi-layer flex PCBs. Their flex PCB capabilities include fine-line spacing, tight tolerances, and advanced materials like polyimide for high heat resistance.

Their flexible circuits are tested for bend cycles, ensuring longevity and reliability even under constant motion and mechanical stress.

Applications Across Every Industry

Viasion serves a wide array of industries:

Medical Devices: Miniaturized flexible PCBs and ceramic PCBs for diagnostic tools and implants

Automotive: High-temperature copper based PCBs and custom PCBs for control units

Consumer Electronics: High-density blind via PCBs and flexible PCBs for wearables and mobile devices

Telecommunications: Multi-layer custom PCBs and blind vias printed circuit boards for routers and servers

Industrial Equipment: Rugged ceramic PCBs and copper based PCBs for control systems

No matter your industry, Viasion brings the technical expertise and manufacturing excellence needed to make your project a success.

Why U.S. Customers Trust Viasion

Even though Viasion is based in Shenzhen, China, their services are perfectly aligned for U.S. businesses. With fast international shipping, English-speaking support staff, and a focus on total customer satisfaction, Viasion delivers a seamless experience for customers in the United States.

Key benefits for U.S. clients include:

No minimum order quantity

Quick turnaround and prototyping

Full turnkey PCB assembly service

Competitive pricing without compromising quality

UL and ISO certified production processes

Get Started Today

Whether you need a custom PCB board, ceramic PCB, or a complex blind vias PCB, Viasion is equipped to deliver top-tier solutions tailored to your unique specifications. Their dedication to quality, innovation, and customer support makes them the go-to custom PCB manufacturer for companies across the USA and beyond.

👉 Visit www.viasionpcb.com to request a quote or reach out to their team at [email protected] for personalized support.

0 notes

Text

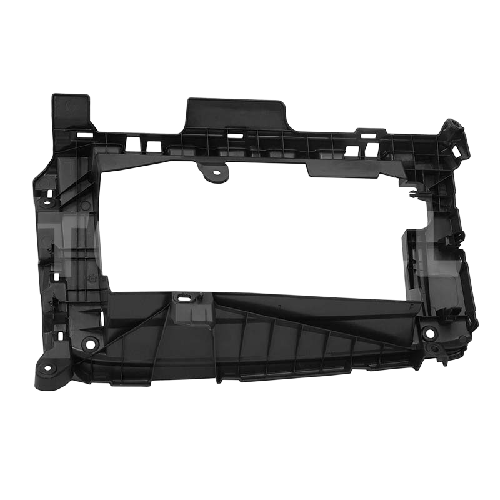

Custom PCB and ABS Plastic Molds: Revolutionizing Manufacturing with Topwell Moulding

In the world of manufacturing, customization, precision, and quality are essential. Topwell Moulding stands at the forefront, offering advanced solutions in Custom PCB design and ABS Plastic Mold manufacturing, driving success across diverse industries. Here, we explore how Topwell Moulding meets unique production demands and why they’re the go-to choice for companies requiring custom circuit boards and durable plastic molds.

1. The Power of Custom PCBs

Printed Circuit Boards (PCBs) are fundamental components in electronics, acting as the backbone for transmitting electrical signals across various devices. However, a one-size-fits-all approach doesn’t suit industries with unique or complex requirements. Custom PCBs from Topwell Moulding are tailored to each client’s specifications, ensuring enhanced performance and adaptability for various applications.

Advantages of Custom PCBs:

Precise Specifications: Custom PCBs allow for specific configurations, from material types and sizes to layer counts and component layouts, making them suitable for specialized electronics.

Enhanced Reliability: Topwell's precision engineering ensures that each PCB meets the highest standards, reducing potential failures and extending product lifespan.

Optimized Performance: With tailored designs, devices operate efficiently with improved signal integrity and reduced electrical noise, ideal for critical sectors like medical devices, telecommunications, and automotive systems.

Topwell Moulding leverages cutting-edge technology and expert engineering to deliver PCBs that support innovation and performance, tailored to meet each client’s functional and technical requirements.

2. ABS Plastic Molds: The Foundation of Durable and Versatile Parts

ABS (Acrylonitrile Butadiene Styrene) plastic is one of the most widely used materials in mold manufacturing. Known for its durability, resistance to impact, and ease of molding, ABS is ideal for creating complex parts with precision. Topwell Moulding specializes in designing and producing custom ABS plastic molds that are reliable, versatile, and meet the demands of high-quality production.

Key Benefits of ABS Plastic Molds:

High Durability: ABS molds withstand rigorous use, making them suitable for products requiring strength, like automotive parts, appliances, and toys.

Custom Design Flexibility: ABS can be molded into complex shapes with intricate details, allowing for customized designs tailored to unique project requirements.

Cost-Effective Production: ABS plastic is affordable and, combined with Topwell’s efficient manufacturing, provides high-quality results without excessive costs.

Topwell Moulding’s expertise in ABS plastic molds ensures consistent, top-quality parts that meet each client’s unique specifications, helping businesses achieve durability and efficiency in their products.

3. Topwell Moulding: The Ideal Mold Manufacturer

As a leader in both custom PCB and ABS plastic mold manufacturing, Topwell Moulding excels by combining expertise, technology, and a commitment to quality. Their services extend across various industries, providing solutions that range from prototype development to mass production.

Why Choose Topwell Moulding?

Advanced Manufacturing Facilities: Equipped with the latest technology, Topwell ensures precision and quality in every product, whether it’s a custom PCB or an ABS plastic mold.

Experienced Engineering Team: The team of specialists at Topwell works closely with clients to understand their needs, provide guidance, and deliver products that align with specific requirements.

Quality Assurance: Every product undergoes rigorous testing and quality control measures, ensuring it meets international standards and exceeds client expectations.

Scalability: Whether you need a small prototype run or large-scale production, Topwell has the capacity to meet diverse volume demands while maintaining quality.

Applications of Custom PCBs and ABS Plastic Molds

From consumer electronics and medical devices to automotive and industrial applications, the versatility of custom PCBs and ABS plastic molds is vast. With Topwell Moulding, clients can expect solutions that fit seamlessly into any production line and elevate the quality of the final product.

Partnering with Topwell Moulding

With years of experience and a commitment to innovation, Topwell Moulding is the preferred partner for companies looking to elevate their manufacturing capabilities. Custom PCBs and ABS plastic molds from Topwell are not just components; they’re integral parts of products that define quality and functionality.

To explore Topwell Moulding’s capabilities and see how they can meet your manufacturing needs, visit topwellmoulding.com.

0 notes

Text

youtube

You should watch this just for Phyllis. I'd love to know what she was making, and what she thought of the internet!

1 note

·

View note

Text

okay idea

like does this make sense

idk my brain was bored even tho i wanted to keep drawing my sonadow fankids this weekend but i don’t think that’s gonna happen

ok but fr tho my mindset changes from “pure fluff sonadow so cute soft” to “i need to make a doohickey right now” like phases of the moon it’s fucking crazy and i don’t like it actually

#my stuff#idk i wouldn’t call this art lol#idea#eureka !#does anyone have an old pair of switch joycons they wanna give me?#it literally doesn’t matter if there’s crusty bugs on it i just need them for the hardware lol#if not i will soldier on through ebay#okay ebay isn’t actually that bad it’s just that i’ve customized multiple switch controllers before just with the simple shells#but when i order a used pair of joycons that claims to be nintendo legit#it turns out it’s not bc the PCB isn’t even the right shape for the inner shell basket thingy dawg#idk the words rn i’m tired oops#oh uh#3d modeling ??#engineering student#how about that i think that tag fits here

673 notes

·

View notes

Text

isn't it fucked how the ability to prototype hardware projects is region-locked

#deerbleats#there are no hackerspaces in my country so I can't get affordable non-industrial 3D printing/CNCing to make my own tools#and bc of ridiculous shipping times/costs just getting the right resistors for a shitty project's LEDs would take weeks of planning/waiting#meanwhile mfs in the global north will next-day-shipping order solder masks made out of custom PCBs and call it a 'budget friendly hack'#like if I were to order literally anything from PCBWay I'd have to pay over 50USD just for shipping#and if I get the wrong parts or if I break something it's fucktons of money in shipping + even more time waiting for shit yet again

7 notes

·

View notes

Video

youtube

FPC flexible circuit board production process #fpc #circuitboard #pcb #technology #factory #customer #icgoodfind

2 notes

·

View notes

Text

The Rise Of Flexible And Foldable Pcbs In Consumer Electronics

The technological transition occurring inside electronic devices matches the fast pace of changing devices themselves in modern times. The evolution of consumer electronics receives transformative power through the development of flexible , foldable custom PCB board. Flexible circuit boards break traditional electronic design rules when they are produced for sleek modern electronics that become easily integrated into everyday use. Flexible PCBs serve as the core elements that allow smartphones to open and close while wearable fitness trackers match the human wrist shape.

1. The Evolution from Rigid to Flexible

Device designs were constrained to boxy shapes by the inflexible, flat nature of traditional PCBs. The requirement for electronics to fit into increasingly small and unusually shaped goods marked the beginning of the road toward flexibility. In order to allow circuits to bend without breaking connections, engineers created materials and manufacturing processes. It took years of development into conductive materials that could sustain repetitive flexing without losing their electrical integrity for this evolution to occur.

2. Space-Saving Advantages in Modern Devices

Electronic gadgets' use of space has been transformed by the capacity to fold and bend circuitry. Every millimeter matters in the cutthroat world of consumer electronics. Flexible PCBs can be curved to fit asymmetrical spaces that would otherwise go unused, folded into small configurations, or stacked in three dimensions. Manufacturers may either reduce the overall size of devices or fit more functions into the same footprint thanks to this space efficiency. Modern smartphones, for instance, can have more cameras, bigger batteries, and more features while still having thin profiles because flexible circuit designs save space.

3. Enabling New Form Factors and Designs

The rise of whole new device categories is arguably the most obvious effect of flexible PCBs. Without circuitry that can repeatedly bend at the hinge without degrading, foldable cell phones that open into tablet-sized screens would not be feasible. Circuit boards that can take on non-flat designs are also necessary for electronic fabrics, wraparound displays, and curved-screen televisions. Because the electronics may now adapt to the ideal product shape, product designers are no longer compelled to construct devices around inflexible rectangular boards. This paradigm change promotes industrial design innovation by enabling businesses to investigate organic shapes that are more conducive to human interaction.

4. Enhanced Durability and Reliability

Contrary to popular belief, flexible PCBs frequently perform better in durability testing than their rigid counterparts. When exposed to physical shock or vibration, traditional rigid boards might crack, leading to connection failures and irreversible damage. Flexible circuits, on the other hand, can withstand shocks by gradually deforming and then reverting to their initial state. They are perfect for portable gadgets that are subjected to drops or bumps on a regular basis because of their natural shock resistance. Furthermore, because flexible PCBs may be produced as a single continuous circuit, numerous solder joints that serve as failure spots in traditional designs are eliminated, resulting in fewer interconnection points overall.

5. The Role in Wearable Technology Growth

The wearable technology industry has expanded during the past years to make smartwatches and fitness trackers together with health monitors commonplace consumer items. The evolution of flexible printed circuit boards that could conform to human body contours would have limited the growth in this field. Devices used for prolonged wear require flexible features which rigid electronics technology cannot reproduce. The flexible nature of these circuits allows devices to match human body movements and maintain stable contact with the skin for accurate biometric monitoring and prevent any unwanted pressure on the skin. Flexible PCB technology enables wearable devices to stay discreet in daily life because their low weight reduces overall device mass.

6. Manufacturing Challenges and Innovations

Manufacturing processes experienced crucial developments due to the specific difficulties in producing flexible PCBs. Certain raw materials with particular manufacturing methods must be utilized to produce bendable conductive components. Manufacturers use modern printing technologies to establish new methods of tracing conductive tracks on flexible surfaces instead of using traditional etching methods. Traditional fiberglass boards resist heat damage better than flexible materials therefore maintaining proper assembly temperature remains essential. The production of flexible circuits has produced both specialized tools and procedures because of these technical obstacles. Flex PCB engineering technology that was previously reserved for high-end products because of manufacturing costs now reaches reasonable prices for consumer electronics through ongoing advancements and market scalability factors thus driving manufacturers to replace rigid circuitry.

7. Environmental and Sustainability Benefits

Compared to conventional rigid boards, flexible PCBs have a number of environmental benefits. Their decreased volume and weight result in less material being used, and their compact size frequently enables more effective shipping and smaller product packaging. Further lowering the amount of material needed, flexible circuits usually need fewer layers to accomplish the same functionality as multilayer rigid boards. The total amount of electronic waste produced is also reduced by doing away with large connectors. Compared to conventional rigid boards made of fiberglass, certain flexible PCB materials are also easier to recycle.

8. Future Prospects and Emerging Applications

The evolution of flexible and foldable PCB technology shows no signs of slowing. Current research focuses on stretchy electronics that can expand and contract while maintaining functionality, imagine devices that can be stretched to twice their size without damage. Other innovations include biodegradable flexible circuits for temporary electronic applications and self-healing conductors that can repair minor damages autonomously. These advancements will enable entirely new product categories, from rollable displays that unfurl from compact tubes to smart clothing with seamlessly integrated electronics. Medical applications are particularly promising, with flexible electronics enabling conformable sensors for continuous health monitoring and even implantable devices that match the contours of internal organs.

Conclusion

A significant change in the philosophy of electronic design may be seen in the emergence of flexible and foldable PCBs. With vlsi physical design manufacturers can produce gadgets that better meet human requirements through increased durability, greater ergonomics, and creative form factors by escaping the constraints of inflexible circuits. Flexible circuit technology will continue to grow in consumer electronics, opening up product categories we haven't yet thought of, despite ongoing difficulties with production scalability and cost reduction.

0 notes

Text

#Mobile App Development#Parts#Supply and Sourcing Strategy#Manufacturing Support#custom PCB design services#end-to-end product development

0 notes

Text

alpha 28-key keyboard + wrk choc keycaps - ig: @smallsplitkeyboard (2022)

0 notes

Text

Unlocking Innovation in Electronics: The Power of Specialized PCBs

In the world of modern electronics, printed circuit boards (PCBs) serve as the essential foundation of nearly every device, from consumer gadgets to advanced industrial systems. As technology continues to evolve, the demand for highly specialized PCBs such as blind via PCBs, ceramic PCBs, flex PCBs, copper based PCBs, and custom PCB boards has surged dramatically. These innovations not only provide enhanced performance but also meet the increasing complexity of today’s electronic applications.

In this article, we’ll explore the key types of advanced PCBs, including the benefits of working with a reliable blind vias PCB manufacturer, the importance of custom PCB manufacturers, and how these different PCB types are shaping the future of electronic product design.

What Are Blind Via PCBs?

One of the most significant advancements in PCB design is the blind via PCB. Vias are the holes that connect different layers of a multi-layer PCB. In blind vias printed circuit boards, these holes connect an outer layer to one or more inner layers without penetrating the entire board. This feature allows for a more compact and efficient layout, especially in high-density interconnect (HDI) applications.

By incorporating blind vias, engineers can increase component density without sacrificing board size or performance. This makes blind via PCBs ideal for applications such as smartphones, medical devices, and compact industrial electronics where space is at a premium.

A reputable blind vias PCB manufacturer uses laser drilling or advanced mechanical drilling to achieve precise and clean vias, ensuring optimal performance and reliability. These manufacturers often provide design support to ensure that the via placement aligns with the functional needs of the product while maintaining cost efficiency.

Ceramic PCBs: High Thermal Conductivity for Harsh Environments

Another innovative PCB solution is the ceramic PCB, which is particularly suited for high-power or high-frequency applications. These boards are made using ceramic substrates like aluminum oxide (Al2O3) or aluminum nitride (AlN), which offer excellent thermal conductivity and mechanical stability.

Ceramic PCBs are widely used in LED lighting, automotive electronics, and aerospace systems, where conventional PCBs might fail due to heat or mechanical stress. Their ability to operate in extreme conditions while maintaining electrical performance sets them apart from traditional boards.

Choosing a knowledgeable ceramic PCB manufacturer is crucial. Such manufacturers specialize in using thick film or direct bond copper (DBC) technology to create boards that can handle high temperatures and thermal cycling without degradation. Their manufacturing processes are tailored to ensure the structural integrity and thermal performance required by demanding industries.

Copper Based PCBs: Power and Durability Combined

Copper based PCBs are designed for applications where heat dissipation and current carrying capacity are critical. These boards use a thick copper layer—typically 1 oz to 10 oz per square foot—making them ideal for power supplies, automotive systems, and industrial control equipment.

The thick copper not only supports high current loads but also aids in effective heat dissipation, which extends the lifespan of both the board and its components. In power electronics, copper based PCBs are often the go-to choice due to their durability and performance.

Whether it’s single-layer or multi-layer copper boards, selecting a manufacturer with experience in copper based PCB production ensures precision in etching and lamination processes, which are crucial for maintaining electrical efficiency.

Flex PCBs: The Future of Flexible Electronics

As electronic devices become more compact and ergonomic, flex PCBs (flexible printed circuit boards) are gaining popularity. These boards are made from flexible substrates like polyimide, which allow them to bend and twist without breaking.

Flex PCBs are used in wearable technology, medical devices, and compact consumer electronics. Their unique design makes it possible to connect electronic components in tight or irregular spaces, something rigid PCBs cannot accommodate.

Unlike traditional boards, flex PCBs require special expertise in both design and manufacturing. A skilled flex circuit manufacturer will take into account factors like bending radius, dynamic flexing requirements, and signal integrity to deliver a board that performs reliably under mechanical stress.

The Importance of Custom PCB Boards

While standardized PCBs serve many applications, unique projects often require custom PCB boards designed to meet specific electrical, mechanical, or thermal requirements. A custom PCB could involve specific layout constraints, unusual form factors, or integration with other technologies like sensors or embedded antennas.

Working with an experienced custom PCB manufacturer provides access to tailored design, prototyping, and production services. Whether it’s a custom PCB board for a wearable fitness tracker or a complex multi-layer design for a satellite module, the ability to customize every aspect of the board’s structure is a key advantage in competitive industries.

Customization also enables designers to optimize the board for size, performance, and cost—something that off-the-shelf PCBs cannot provide. A good custom PCB manufacturer will work closely with engineers to understand application needs and deliver a solution that meets both technical and budgetary goals.

Choosing the Right PCB Manufacturer

With so many specialized PCB types available, it’s essential to partner with a manufacturer that offers comprehensive capabilities. Whether you’re sourcing a blind vias PCB manufacturer, a ceramic PCB manufacturer, or a supplier of flex PCB and copper based PCB solutions, the ideal partner will offer:

Advanced manufacturing technologies

In-house engineering support

Quick turnaround and low minimum order quantities

Certifications such as ISO and UL

Quality assurance testing at every stage

Partnering with a one-stop manufacturer that offers everything from custom PCB design to assembly and testing ensures a smoother production process and a higher-quality final product.

Conclusion

The electronics industry continues to push boundaries, demanding more compact, efficient, and robust solutions. From blind via PCBs that enhance space utilization, to ceramic PCBs built for harsh environments, and flex PCBs that enable groundbreaking product designs, the world of PCB manufacturing is more dynamic than ever.

Whether you're designing a next-generation wearable, an industrial automation controller, or a high-power automotive system, choosing the right type of PCB—and the right manufacturer—is crucial. Work with a proven custom PCB manufacturer that understands your needs, offers flexible solutions, and delivers on time and within budget.

By leveraging specialized boards such as blind vias printed circuit boards, ceramic PCBs, and copper based PCBs, you’re not just building a device—you’re building a competitive advantage.

0 notes

Text

Factors to Consider When Selecting A Low-Cost PCB Manufacturer

Choosing the right low-cost PCB manufacturer can be challenging, especially with many available options. To help you make an informed decision, we've outlined five key factors to consider when selecting a low-cost PCB manufacturer.

#custom pcb manufacturing#pcb fabrication#pcb manufacturer in india#prototype pcb manufacturing#pcb manufacturer#two layer pcb stencil#pcbcircuit#best pcb stencil maker in hyderabad#pcb manufacturer in delhi#pcb manufacturer in maharashtra

0 notes

Text

Top PCB Manufacturer in India

PCBcircuit is a leading PCB manufacturer in India, offering high-quality printed circuit boards tailored to diverse industries. With advanced technology, precision engineering, and reliable customer support, we ensure efficient and cost-effective PCB solutions to power your innovations. Trust PCBcircuit for quality and excellence in PCB manufacturing.

#flex pcb manufacturer#prototype pcb manufacturing#pcb manufacturer#custom pcb manufacturing#low-cost pcb manufacturer#pcb fabrication#quick turn pcb fabrication#high-quality pcb manufacturing#multilayer pcb manufacturer

0 notes

Text

Essential Tools and Techniques in Prototype PCB Manufacturing

Prototype PCB manufacturing by PCB Circuit is a specialized process focused on quickly and efficiently bringing electronic designs from concept to functional boards. Whether testing new circuit designs or refining existing ones, PCB Circuit ensures precise fabrication, quality control, and quick turnaround times to help clients accelerate their product development cycles.

#PCB manufacturer#PCB fabrication In india#custom PCB manufacturing in india#prototype PCB manufacturing#low-cost PCB manufacturer#high-quality PCB manufacturing#quick turn PCB fabrication#flex PCB manufacturer#multilayer PCB manufacturer#Best pcb manufacturer#Top 10 pcb manufacturer#Pcb manufacturer near me#Pcb manufacturer in Maharashtra#Pcb manufacturer in haryana#Pcb manufacturer in delhi#Pcb manufacturer in india#Pcb manufacturer in Bombay#Pcb manufacturer in jaipur

0 notes

Text

Printed Circuit Board (PCB) design is a meticulous art that requires precise attention to detail. Central to this process is PCB routing, the sophisticated method of connecting electrical components, defining the pathways for signal propagation within the circuit. This critical phase not only determines the efficiency of signal transmission but also holds the key to signal integrity, which is essential for optimal circuit performance. In this article, we’ll explore PCB routing in depth, highlighting its significance, best practices, guidelines, rules, recommendations, and strategies to ensure you achieve superior signal integrity in your designs.

0 notes

Text

SMD PCB Board Assembly in Hyderabad - Pcbcircuit

SMD is also known as Surface Mount Device. It is an electronic device. SMT (Surface Mount Technology) is the technique that is necessary for the production of SMDs on a large scale. Being a well-established organization, we are offering SMD PCB Board Assembly in Hyderabad . We have team of experts for procurement of high-quality low-cost electronic components while rendering this PCB manufacturing service.

#Pcbcircuit#PCB Manufacture#low-cost PCB manufacturer#PCB fabrication#custom PCB manufacturing#Pcb manufacturer in india#Pcb stencil#Two layer pcb stencil

0 notes