#depolymerization

Explore tagged Tumblr posts

Text

Depolymerized Guar Gum by Chimique India

Discover the innovative Depolymerized Guar Gum from Chimique India, a versatile natural polymer derived from guar beans. This product offers enhanced solubility and improved viscosity, making it ideal for various applications in the food, pharmaceutical, and cosmetic industries. With its exceptional thickening and stabilizing properties, Depolymerized Guar Gum is designed to meet the demands of modern formulations while ensuring sustainability and performance.

1 note

·

View note

Text

I'm an H⁺ denier, in that I refuse to consider loose protons to be real hydrogen, so I personally believe it stands for 'pretend'.

Unsolved Chemistry Problems [Explained]

Transcript

[Hairbun stands behind a lectern on a podium with two Cueballs and Megan standing behind her. There is a "Grand Opening" sign hanging in the background along with some ornaments.]

Hairbun: Our lab will be working on chemistry's top unsolved problems: arbitrary enzyme design, protein folding, depolymerization, and, of course, the biggest one of all: Hairbun: Figuring out what the "p" in "pH" stands for.

470 notes

·

View notes

Text

Chemists discover common plastic pigment promotes depolymerization

It turns out that the black plastic lid atop your coffee cup has a superpower. And the Stache Lab at Princeton Chemistry, which uncovered it, is exploiting that property to recycle at least two major types of plastic. Their startling mechanism for promoting depolymerization relies on an additive that many plastics already contain: a pigment called carbon black that gives plastic its black color. Through a process called photothermal conversion, intense light is focused on plastic containing the pigment that jumpstarts the degradation. So far, researchers have shown that carbon black can depolymerize polystyrene and polyvinyl chloride (PVC), two of the least recycled plastics in the planet's waste stream. Through a process called photothermal conversion, intense light is focused on plastic containing the pigment that jumpstarts the degradation.

Read more.

#Materials Science#Science#Plastics#Pigments#Materials processing#Carbon#Photothermal#Recycling#Waste#Princeton University

25 notes

·

View notes

Text

A staggering 60 million tons of polyester are produced annually, for things like clothes, couches, and curtains. That polyester production takes a toll on the climate and environment, as only 15% of it gets recycled. The rest ends up in landfills or incinerated, which results in more carbon emissions. “The textile industry urgently requires a better solution to handle blended fabrics like polyester/cotton. Currently, there are very few practical methods capable of recycling both cotton and plastic—it’s typically an either-or scenario,” explains postdoctoral researcher Yang Yang of the Jiwoong Lee group at the University of Copenhagen’s chemistry department. “However, with our newly discovered technique, we can depolymerize polyester into its monomers while simultaneously recovering cotton on a scale of hundreds of grams, using an incredibly straightforward and environmentally friendly approach. This traceless catalytic methodology could be the game-changer.”

Continue Reading

193 notes

·

View notes

Text

Fwiw that guy is right about avoiding depolymerization and was probably only saying true shit people just hate it when you're correct.

2 notes

·

View notes

Text

Read Plastic Man No More, story about Eel going through what all plastic eventually does and depolymerize

it was ok

good art, touching moments for the character, but they wrote most of the league in a very cold, corporate manner

it also ended with plastic man becoming plastic hand which is really funny

2 notes

·

View notes

Text

Pseudomonas aeruginosa

Polyethylene plastic, found in products such as plastic bags, water bottles, and food packaging, takes 1,000 years to dissolve naturally.

The RPI team tackled the challenge of engineering this bacteria to convert the carbon atoms of polyethylene into a genetically encoded silk protein.

Polyethylene is particularly problematic, as it is commonly found in single-use applications. Resultingly, polyethylene is the most commonly produced plastic, representing 30% of all plastics production

Mechanical recycling is inefficient, typically yielding materials that have inferior mechanical properties compared to virgin plastics.

The development of a new strain of Pseudomonas bacteria capable of converting depolymerized polyethylene into high value bespoke recombinant protein products.

4 notes

·

View notes

Note

Happy STS! So, while recently thinking about the words depolymerize, neodymium, ammonium persulfate, and other chemistry-related terminology for no reason, I found myself wondering: How do you go about your chemistry-related research for GSNBTR, and how do you decide which compounds, etc. to name-drop for the scientific elements of your story?

Happy STS, Kate!

Hmmm ... what a funny question to ask, being that I'm an English and creative writing major with absolutely no knowledge of any of those concepts. 😅

The truth is, a layperson can sound fairly authoritative (at least to other laypeople) using a combination of knowledge gleaned from AP science courses, years of having read widely but not particularly deeply, and, of course, Google. 😅

It really does help if you do have some baseline knowledge, although you don't need much. For instance, I'd heard of the concept of neodymium magnets, although not what they were actually called, so I googled "strong magnets used in scientific research" and they came up instantly.

Same thing with depolymerization, basically. And then as I was reading about that, it emphasized the importance of catalysts, of which ammonium persulfate is a common one -- essentially chosen at random, though I tried to go for something plausible. Reading about that, in turn, led me to the process of electrolysis, which is the common way it's synthesized in the lab. In that way, one concept can lead you to another.

The key, for me, is to go lightly on trying to explain concepts I myself don't fully understand, or I'll end up sounding ridiculous. If you're fairly sure you understand something, chances are your readers will, too. And have faith that your scientific wunderkind of an MC can handle everything else 😁

And of course, all of this is predicated on the assumption that nobody reading my work is an actual research chemist, because if they are, they're sure to hunt me down and hurl a beaker of sulfuric acid in my face (yes, I googled that, too). 😂

(For anyone confused by this delightfully tongue-and-cheek answer and question, the words Kate mentioned all appear in Ch. 31 of GSNBTR, posted yesterday. )

4 notes

·

View notes

Text

[post reads]

Society/Culture

Most 'sex education' past the basics relies on linux user logic (it doesn't work in practice)

So I was at a furry convention a couple months ago and I was at a panel where a guy was explaining how he fit insanely huge dildos up his ass. To be fair, the guy was a bit drunk explaining it but the panel just didn't convince me. He tried to convince the audience how asshole stretching is a myth, how the inside of the anus will over time reshape itself to accommodate extremely large dragon dildos, how you absolutely need to use certain kinds of lubricants or the dildo will be entirely ruined by depolymerization, how you need to be constantly paying attention to what you're doing or you fuck things up (like how his surgeon once shaped the inside of his ass back to normal, which fucked up years of training his anus to accommodate the dildos) etc etc etc … It really struck me how much of it seemed exactly like the kinds of rationalizations a linux user might come up with. You need to constantly be doing everything perfectly and any fuck up is because you weren't informed enough, therefore it's entirely your fault. There's also the exact same extremely opinionated takes on every topic - literally when someone tries to convince me to use something like GNOME or Wayland on Linux, I think back to how hard that panelist was trying to push buying dildos from Etsy businesses instead of Bad Dragon. I think in any community that encourages black and white thinking, whatever information is provided will inevitably only help those who obsess over minutae while providing a bad experience for anyone else … which in my controversial opinion describes kink spaces pretty accurately.

i love reddit so fucking much

56K notes

·

View notes

Text

Microcrystalline Cellulose: The Versatile Ingredient Revolutionizing Industries

Microcrystalline cellulose (MCC) has emerged as a game-changer in various industries, thanks to its unique properties and versatile applications. This naturally derived ingredient has become an essential component in pharmaceuticals, food products, cosmetics, and more. Let's dive into the world of microcrystalline cellulose and explore its significance. Microcrystalline Cellulose is a purified, partially depolymerized cellulose derived from high-quality wood pulp or cotton linters. The manufacturing process involves treating the raw material with acid to remove amorphous regions, leaving behind crystalline cellulose particles. The resulting MCC is a white, odorless, and tasteless powder with exceptional properties. Get more insights on, Microcrystalline Cellulose

#Coherent Market Insights#Pharmaceutical Excipients#Tablet Binder#Food Additives#Industrial Cellulose

0 notes

Text

The Rise of Polypropylene: Future-Proofing Plastics Across Industries

Polypropylene (PP) is one of the most widely used thermoplastics in the world. Valued for its durability, lightweight nature, chemical resistance, and recyclability, polypropylene plays a critical role in industries ranging from automotive and packaging to healthcare and electronics.

With rising demand for sustainable materials, cost-effective production, and high-performance polymers, the polypropylene market is witnessing rapid growth across both developed and emerging economies.

Market Overview

The global polypropylene market is expanding steadily due to increasing consumption in rigid and flexible packaging, automotive components, and medical applications. Its versatility, low density, and easy processability make it a preferred material for injection molding, blow molding, and extrusion processes.

Asia-Pacific leads global production and demand, particularly China and India, while North America and Europe are innovating with bio-based polypropylene and high-performance grades.

Key Market Drivers

Growing demand in packaging for food, consumer goods, and e-commerce

Automotive sector focus on lightweight, fuel-efficient vehicles

Rapid industrialization and urbanization in emerging economies

Rising adoption in healthcare and hygiene products

Development of recyclable and bio-based polypropylene grades

Applications Across Industries

1. Packaging

Used in rigid containers, flexible films, caps, and closures due to its toughness, moisture resistance, and affordability.

2. Automotive

PP is widely used in bumpers, interior trim, dashboards, and battery cases—reducing vehicle weight and improving fuel efficiency.

3. Healthcare

Medical-grade PP is used in syringes, pill containers, surgical instruments, and non-woven fabrics in masks and gowns.

4. Textiles & Non-Wovens

Employed in carpets, thermal wear, and geotextiles due to its softness, stretchability, and low absorbency.

5. Consumer Products

From storage bins and housewares to toys and electronics casings, PP is everywhere in daily life.

Benefits of Polypropylene

High Chemical Resistance – Suitable for aggressive substances

Lightweight & Durable – Reduces material use and cost

Excellent Fatigue Resistance – Ideal for hinge-based products

Cost-Effective – Affordable alternative to engineering plastics

Recyclable – Increasing demand for circular economy applications

Key Market Players

Major companies are focusing on capacity expansion, R&D in bio-based PP, and collaborations for sustainable production. Key players include:

LyondellBasell Industries

SABIC

ExxonMobil Chemical

Reliance Industries Limited

Borealis AG

Braskem S.A.

INEOS Group

TotalEnergies

China National Petroleum Corporation (CNPC)

Formosa Plastics Corporation

Future Outlook & Trends

Bio-based chemical innovations

High-performance PP for EVs and aerospace

Advanced recycling and chemical depolymerization tech

Growth in non-woven applications post-COVID

Increased demand from 3D printing and medical devices

Conclusion

The Polypropylene Market continues to be an essential pillar in global manufacturing and sustainability. With innovation driving recyclable, lightweight, and high-performance applications, PP remains a go-to material for industries seeking cost-effective yet responsible solutions.

As demand grows in sectors like packaging, automotive, and healthcare, polypropylene’s future is as versatile as the material itself—balancing performance, price, and planet.

0 notes

Text

Molded Foams Market Size, Key Players & Opportunities Forecast

Molded Foams Market Overview The global Molded Foams Market is witnessing robust growth, valued at approximately USD 12.5 billion in 2024, with expectations to reach USD 18.9 billion by 2030, growing at a CAGR of 7.1% during the forecast period. Molded foams, including expanded polystyrene (EPS), expanded polypropylene (EPP), and polyurethane (PU) foams, are extensively used in packaging, automotive, consumer goods, and construction industries due to their lightweight, energy absorption, thermal insulation, and cushioning properties. Rising demand from the automotive and packaging sectors, coupled with growing environmental awareness, is propelling the adoption of molded foam solutions. Industry advancements in sustainable and bio-based molded foam formulations are also contributing to market expansion, aligning with circular economy goals. Molded Foams Market Dynamics Key market drivers include increasing demand for protective packaging in e-commerce, growing use of lightweight materials in automotive manufacturing to improve fuel efficiency, and the rising need for thermal insulation in the construction industry. Additionally, advancements in foam molding technologies and automation are enhancing production capabilities and efficiency. However, the market faces restraints such as fluctuating raw material prices, particularly crude oil derivatives, and environmental concerns over non-biodegradable foams. Regulatory pressure on non-recyclable plastics is pushing companies to explore alternative eco-friendly materials. Opportunities lie in the development of biodegradable molded foams and expanding applications in healthcare and electronics sectors. Sustainability is becoming a strategic focus, prompting investments in green manufacturing practices and recyclable product lines. Download Full PDF Sample Copy of Molded Foams Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=153007&utm_source=PR-News&utm_medium=361 Molded Foams Market Trends and Innovations The market is being reshaped by emerging technologies such as 3D mold printing, advanced polymer blending, and low-VOC (volatile organic compound) foam solutions. Innovations like biodegradable EPS alternatives, starch-based foams, and flexible foam composites are gaining traction. Companies are collaborating across the value chain to accelerate R&D efforts in sustainable foam solutions. Strategic partnerships and joint ventures between foam manufacturers and automotive OEMs, packaging companies, and construction material suppliers are creating new product offerings tailored to evolving industry requirements. The increasing use of closed-cell foams in cold chain logistics, medical equipment packaging, and electric vehicle components is expanding the market footprint. Molded Foams Market Challenges and Solutions The market is challenged by supply chain disruptions in raw material sourcing, geopolitical uncertainties, and increasing transportation costs. Volatile prices of isocyanates and styrene derivatives have put pressure on profit margins. Additionally, growing regulatory scrutiny over chemical foaming agents and landfill concerns around plastic waste are creating compliance hurdles. Solutions include investing in localized raw material sourcing, adopting circular economy practices, and transitioning toward bio-based feedstocks. Regulatory support for biodegradable materials and the development of advanced recycling technologies such as chemical depolymerization can further mitigate these challenges. Molded Foams Market Future Outlook Over the next decade, the molded foams market is expected to experience sustained growth driven by rising environmental consciousness, expanding end-use applications, and material innovation. Key factors influencing this growth trajectory include increasing adoption of green building codes, rapid growth in electric vehicle production requiring lightweight components, and consumer preference for recyclable and biodegradable packaging.

Market players that invest in R&D, sustainability, and supply chain optimization are poised to gain competitive advantages. With a continued focus on eco-friendly foam alternatives and intelligent manufacturing, the molded foams market is set to evolve into a more sustainable and diversified industry. Key Players in the Molded Foams Market Molded Foams Market are renowned for their innovative approach, blending advanced technology with traditional expertise. Major players focus on high-quality production standards, often emphasizing sustainability and energy efficiency. These companies dominate both domestic and international markets through continuous product development, strategic partnerships, and cutting-edge research. Leading manufacturers prioritize consumer demands and evolving trends, ensuring compliance with regulatory standards. Their competitive edge is often maintained through robust R&D investments and a strong focus on exporting premium products globally. Sonoco Products Company Sealed Air Corporation Pregis Corporation ACH Foam Technologies Rogers Foam Corporation Plymouth Foam Foam Fabricators Tucson Container Corporation Plastifoam Company Wisconsin Foam Products. Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount?rid=153007&utm_source=PR-News&utm_medium=361 Molded Foams Market Segments Analysis and Regional Economic Significance The Molded Foams Market is segmented based on key parameters such as product type, application, end-user, and geography. Product segmentation highlights diverse offerings catering to specific industry needs, while application-based segmentation emphasizes varied usage across sectors. End-user segmentation identifies target industries driving demand, including healthcare, manufacturing, and consumer goods. These segments collectively offer valuable insights into market dynamics, enabling businesses to tailor strategies, enhance market positioning, and capitalize on emerging opportunities. The Molded Foams Market showcases significant regional diversity, with key markets spread across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Each region contributes uniquely, driven by factors such as technological advancements, resource availability, regulatory frameworks, and consumer demand. Molded Foams Market, By Type • Expanded Polystyrene Foam• Expanded Polyethylene Foam• Expanded Polypropylene Foam• Polyurethane Foam• Others Molded Foams Market, By Application • Automotive• Auto Components• Consumer Goods• Others Molded Foams Market By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/molded-foams-market/ About Us: Verified Market Research Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information-enriched research studies. We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and critical revenue decisions. Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research methodology, expertise, and years of collective experience to produce informative and accurate research. Contact us: Mr. Edwyne Fernandes US: +1 (650)-781-4080 US Toll-Free: +1 (800)-782-1768 Website: https://www.verifiedmarketresearch.com/ Top Trending Reports https://www.verifiedmarketresearch.com/ko/product/packaged-terminal-air-conditioners-ptac-market/ https://www.verifiedmarketresearch.com/ko/product/green-insurance-market/ https://www.verifiedmarketresearch.com/ko/product/conveyor-lubrication-market/ https://www.verifiedmarketresearch.com/ko/product/green-screen-production-kit-market/

https://www.verifiedmarketresearch.com/ko/product/iot-for-cold-chain-monitoring-market/

0 notes

Text

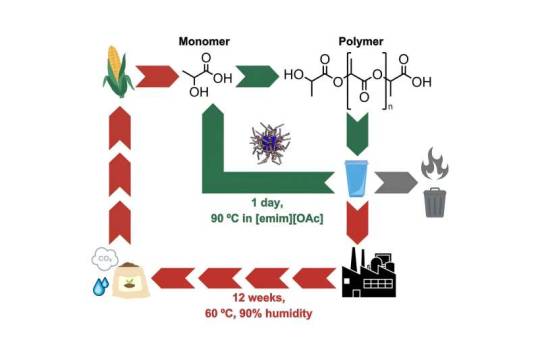

An enzyme used in laundry detergent can recycle single-use plastics within 24 hours

Scientists at King's College London have developed an innovative solution for recycling single-use bioplastics commonly used in disposable items such as coffee cups and food containers. The novel method of chemical recycling, published in Cell Reports Physical Science, uses enzymes typically found in biological laundry detergents to "depolymerize"—or break down—landfill-bound bioplastics. Rapidly converting the items into soluble fragments within just 24 hours, the process achieves full degradation of the bioplastic polylactic acid (PLA). The approach is 84 times faster than the 12-week-long industrial composting process used for recycling bioplastic materials. This discovery offers a widespread recycling solution for single-use PLA plastics, as the team of chemists at King's found that in a further 24 hours at a temperature of 90°C, the bioplastics break down into their chemical building blocks. Once converted into monomers—single molecules—the materials can be turned into equally high-quality plastic for multiple reuse.

Read more.

#Materials Science#Science#Enzymes#Plastics#Polymers#Recycling#King's College London#Bioplastics#Biomaterials#Polylactic acid

55 notes

·

View notes

Text

Plastic Waste to Oil Market Growth Driven by Waste Management Demand

The plastic waste to oil market focuses on converting end-of-life plastics into valuable hydrocarbon fuels and chemicals through processes such as pyrolysis, catalytic depolymerization, and gasification. These technologies transform mixed polymer waste streams into pyrolysis oil, synthetic crude, and specialty chemicals, providing an eco-friendly alternative to landfill disposal and incineration. Key advantages include reduced greenhouse gas emissions, decreased reliance on virgin fossil resources, and improved circular economy performance.

Get More Insights on Plastic Waste to Oil Market https://www.patreon.com/posts/plastic-waste-to-131289866

#PlasticWasteToOilMarket#PyrolysisTechnology#CircularEconomySolutions#SyntheticCrudeOil#CoherentMarketInsights

0 notes

Text

Anyone can speak authoritatively on if Carbios is the real deal and how it compares to competitors? Polyethylene terephthalate (PET) plastic degradation opening up in France

Should I be reading this paper out of IIT or is there a simpler direction to get a read on the industry?

Would be interested to see American based competitors to emerge. Especially if we can safely do it in the mid west and parts of the south. Would be a cool job

0 notes