#die-cast automobile structural parts

Text

Typical case analysis of digital industry, real materials of die-casting!

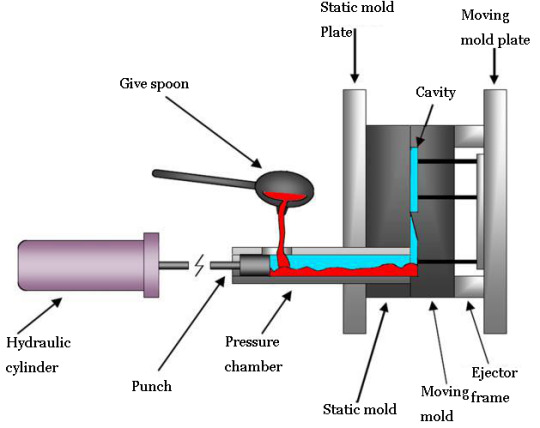

Die casting, also known as high pressure casting, is a near net shape technology that has been widely used in automotive, aerospace, and electronics industries in recent years. In die-casting process, molten metal (usually light alloy) fills cavity at high pressure and high speed under action of punch, and cools quickly to form final casting.Die-casting is generally divided into cold-chamber…

View On WordPress

#CAE analysis#cold-chamber die-casting#die casting technology#die-cast automobile structural parts#die-casting#die-casting company#die-casting enterprises#die-casting industry#die-casting machines#Die-casting mold#die-casting process#die-casting technology#high pressure casting#hot-chamber die-casting#Mold temperature

0 notes

Text

Driving Precision: Bharat Engineering's Role as a Premier Automotive Casting Manufacturer

Introduction:

In the automotive industry, precision and reliability are paramount. Every component, from the engine block to the smallest bracket, must meet exacting standards to ensure optimal performance, safety, and longevity of vehicles. As one of India's leading automotive casting manufacturers, Bharat Engineering plays a pivotal role in this ecosystem, delivering top-notch casting solutions that power the vehicles of today and tomorrow. Let's delve into how Bharat Engineering stands out as a premier provider of automotive castings, driving the wheels of innovation and excellence in the automotive sector.

The Significance of Automotive Castings:

Automotive castings form the backbone of vehicle manufacturing, encompassing a wide range of components such as engine blocks, cylinder heads, transmission housings, brake calipers, and suspension components. These castings are integral to the structural integrity, performance, and functionality of automobiles, contributing to their overall efficiency, safety, and aesthetics. With the automotive industry witnessing rapid technological advancements and evolving consumer preferences, the demand for high-quality castings has never been greater.

Bharat Engineering: Engineering Excellence in Automotive Castings:

With a rich heritage spanning decades, Bharat Engineering has emerged as a trusted name in the realm of automotive casting manufacturing. The company's commitment to innovation, quality, and customer satisfaction sets it apart in a competitive marketplace. Here's how Bharat Engineering is driving precision and reliability in automotive castings:

Advanced Casting Technologies: Bharat Engineering leverages cutting-edge casting technologies, including sand casting, die casting, and investment casting, to produce a diverse range of automotive components with exceptional precision and accuracy. Whether it's complex engine blocks or intricate suspension parts, the company's state-of-the-art facilities are equipped to meet the most demanding specifications of modern vehicle designs.

Metallurgical Expertise: The metallurgical composition of automotive castings is critical to their performance and durability. Bharat Engineering boasts a team of seasoned metallurgists and material scientists who possess deep expertise in selecting the right alloys and optimizing casting processes to ensure superior mechanical properties, corrosion resistance, and thermal stability in the finished components.

Customization and Prototyping: Recognizing that every automotive application is unique, Bharat Engineering offers custom casting solutions tailored to the specific requirements of its customers. From prototype development to full-scale production, the company collaborates closely with automotive OEMs and Tier-1 suppliers to deliver casting solutions that meet their exacting standards for performance, quality, and cost-effectiveness.

Quality Assurance: Quality is ingrained in every aspect of Bharat Engineering's operations. The company adheres to stringent quality control measures and testing protocols to validate the integrity and performance of its automotive castings. From dimensional accuracy and surface finish to mechanical properties and defect detection, Bharat Engineering ensures that every casting meets or exceeds industry standards and customer expectations.

Sustainability Initiatives: Bharat Engineering is committed to sustainable manufacturing practices that minimize environmental impact and promote resource efficiency. The company employs eco-friendly casting processes, recycles scrap materials, and invests in energy-efficient technologies to reduce its carbon footprint and contribute to a greener automotive industry.

Conclusion:

In an era of rapid technological evolution and shifting market dynamics, automotive manufacturers demand casting solutions that offer uncompromising quality, precision, and reliability. Bharat Engineering rises to this challenge, leveraging its engineering expertise, advanced technologies, and customer-centric approach to deliver casting solutions that drive automotive innovation and performance. As India's automotive industry continues to chart new frontiers, Bharat Engineering remains steadfast in its commitment to excellence, serving as a trusted partner in the journey towards a safer, more efficient, and sustainable mobility future.

0 notes

Text

Injection Mold Factory Processing Mold Application Field

Injection mold is an important process equipment for the production of various industrial products. With the rapid development of the plastics industry, the promotion and application of plastic products in aviation, aerospace, electronics, machinery, ships and automobiles and other industrial fields, the market requirements for molds are also getting higher and higher. Nowadays, the mold design method of traditional injection mold manufacturers is increasingly unable to meet people’s requirements. Compared with traditional mold design, computer-aided engineering techniques can increase productivity, ensure product quality, and reduce costs and labor. In terms of strength, Injection mold has a big advantage.

For mold parts with higher hardness, some injection mold manufacturers cannot be processed by mechanical processing methods, and they most use electric discharge machining. In addition, wire EDM can also be used for sharp corners, deep cavity parts and narrow grooves of mold cavities. CNC lathes are mainly used to process the standard parts of die rods, as well as the mold cavities or cores of rotary bodies, such as injection molds for bottles and POTS, and forging molds for shaft and disc parts. In the injection mold processing, the application of CNC drilling machine can also play a role in improving the processing accuracy and shortening the processing cycle.

By increasing the investment in technology research and development, most production enterprises are optimizing the structural design of the mold system and the CAD/CAE/CAM of the forming part, making it more intelligent, improving the molding process of the forming part and the standardization level of the mold, and improving the accuracy and quality of the mold manufacturing.

Research and apply special materials with high performance and easy cutting for various types of mold parts can improve the performance of molds. In order to adapt to the diversification of the market and the trial production of new products, rapid prototyping technology is applied to the rapid manufacturing of forming molds, injection molds or die casting molds.

0 notes

Text

Crafting Quality and Precision: The Role of Forged Steel Automotive Parts Manufacturers

In the intricate world of automotive engineering, every component plays a vital role in ensuring the performance, safety, and reliability of vehicles. Among these components, forged steel automotive parts stand out as exemplars of strength, durability, and precision engineering. As the backbone of automotive manufacturing, forged steel parts manufacturers like AceForge have been instrumental in shaping the evolution of automobiles worldwide.

Forged steel automotive parts are crafted through a meticulous process that involves shaping metal using compressive force. This process enhances the inherent properties of steel, resulting in components that exhibit exceptional strength and resistance to fatigue, impact, and wear. From crankshafts and connecting rods to gears and suspension components, forged steel parts are found in critical areas throughout vehicles, contributing to their robustness and longevity.

One of the primary advantages of forged steel automotive parts lies in their superior material properties. Unlike cast or machined parts, forged steel components boast finer grain structures, which endow them with higher tensile and yield strengths. This makes them capable of withstanding extreme conditions encountered during vehicle operation, such as high temperatures, heavy loads, and intense vibrations.

Precision is another hallmark of forged steel automotive parts manufacturing. AceForge and similar companies leverage advanced technologies like computer numerical control (CNC) machining and die design to ensure that each component meets exacting specifications. This precision not only guarantees dimensional accuracy but also enhances the overall performance and efficiency of the parts, ultimately enhancing the performance of the vehicles they are installed in.

Moreover, forged steel parts offer significant weight savings compared to their cast counterparts, without compromising on strength or integrity. This reduction in weight contributes to fuel efficiency and helps automakers meet stringent emissions regulations without sacrificing vehicle performance or safety.

In addition to their mechanical advantages, forged steel automotive parts also offer environmental benefits. Steel is one of the most recyclable materials on the planet, with a high scrap value and minimal energy requirements for recycling. By choosing forged steel components, automakers can reduce their environmental footprint and contribute to a more sustainable automotive industry.

AceForge stands out among forged steel automotive parts manufacturers for its commitment to quality, innovation, and customer satisfaction. With state-of-the-art facilities and a team of skilled engineers and technicians, AceForge delivers precision-engineered components that meet the highest industry standards. Whether it's for mainstream vehicles, high-performance sports cars, or heavy-duty trucks, AceForge has the expertise and capabilities to produce forged steel parts tailored to specific requirements.

Looking ahead, the role of forged steel automotive parts manufacturers like AceForge is set to become even more crucial as the automotive industry continues to evolve. With the rise of electric vehicles, autonomous driving technologies, and lightweight materials, the demand for high-performance components that offer uncompromising strength and reliability will only grow.

In conclusion, forged steel automotive parts manufacturers play a pivotal role in shaping the vehicles we drive today and will drive in the future. Through their dedication to quality, precision, and innovation, companies like AceForge are driving advancements in automotive engineering and helping to build safer, more efficient, and more sustainable vehicles for generations to come.

0 notes

Text

More Information About Moulds For Automotive Structural Parts

moulds for automotive structural parts are tools used to manufacture automotive parts.

They can be used to produce a variety of automotive components, including but not limited to:

1. Doors, hoods, trunk lids, roofs, front and rear bumpers and other body parts.

2. Chassis components, such as wheels, brakes, suspension and steering systems, etc.

3. Seats, steering wheels, instrument panels, door trims and other interior parts.

4. Engine components, such as cylinder block, cylinder head, crankshaft and connecting rod, etc.

These molds are usually made of metals such as steel or aluminum, have a specific shape and size, and can be processed by injection molding, die casting, stamping, etc. to produce automotive parts.

0 notes

Text

Aluminum Die Casting: A New Dimension To The Modern Automotive Sector

Aluminum die casting has been reshaping the modern automotive industry. Today, aluminum die casting parts are used in every aspect of the assembly and production of automobiles. Right from engine components to structural components, manufacturers have diverse aluminum die casting solutions.

For more information on aluminum die casting parts and mass production of automotive parts, visit https://www.rockman.in

0 notes

Text

List of Key Industries for Investment Promotion in Yunnan Province (Green Aluminum Pa

December 02, 2022 10:29:23 Yunnan Provincial People's Government Network

Recently, the Yunnan Provincial People's Government issued guidance on further strengthening the work of attracting investment, among which the green aluminum part of the list of key industries for attracting investment is as follows:

1. The field of building structure (lightweight and high-strength building aluminum profiles and strips, building formwork profiles, production of structural aluminum profiles, system doors and windows, building formwork systems, building enclosure systems, all-aluminum bridges, all-aluminum houses, roads Light poles, bus station rain shelters, etc.)

2. Transportation field (lightweight car body profiles for automobiles, rail vehicles, etc., brazed composite plates and foils, commercial vehicle body plates and other plates and strips, aluminum alloy integral wheels, die castings and other castings production, bumpers, luggage racks , battery bracket and other auto parts modules, and all-aluminum body, etc.)

3. Packaging container field (aluminum sheet and foil used in the packaging field, tobacco packaging materials, easy-open lids, pharmaceutical packaging, household packaging, etc.)

4. Power electronics field (production of photovoltaic profiles, power wires, and pipes, production of extruded materials and strips for electronic product casings, production of aluminum foil products such as new energy power battery foils)

5. The field of durable consumer goods (production of aluminum profiles and strips for furniture, production of air-conditioning foil, etc.)

Adtech Metallurgical Materials Co.,Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of adtech :

porous ceramic filter, cff filter. ceramic foundry filter . porous ceramic plate . ceramic filter plate . deep bed filter. deep bed filter aluminium.

ceramic foam filter . metal foam filter. alumina foam. metal filtration.

degassing aluminum,rotary degassing, inline degasser .online degasser . nitrogen degassing . degassing equipment . rotary degassing . rotary degasser,. aluminium degassing machine. rotary degassing aluminum .degassing machine. degassing unit .

boron nitride coating ,deslagging , granular flux,bn coating,tundish powder, refining flux, aluminum casting Flux.casting flux .aluminum degassing flux . refining agent . deslagging agent . cover flux for aluminium, cover flux, flux for aluminum casting . boron nitride paint . covering agent .

launder system . electric launder system .

tundish nozzle, tap out cone, tap out cone, caster tip , tap cone, etc.

To learn more, please follow website: https://www.alalloycasting.com/

Contact: [email protected]

#Aluminum#AluminumFiltration#AluminumDegassing#AluminumIngot#AluminumFactory#AluminumProcessing#porousceramicfilter#degassingunit

0 notes

Video

youtube

What is automotive lightweighting

What is automotive lightweighting

The lightweight of the car is to reduce the curb weight of the car as much as possible on the premise of ensuring the strength and safety performance of the car, thereby improving the power of the car, reducing fuel consumption and reducing exhaust pollution. Experiments have shown that if the quality of the car is reduced by half, the fuel consumption will also be reduced by nearly half. Due to the needs of environmental protection and energy saving, the lightweight of automobiles has become the trend of automobile development in the world.

Experiments have shown that if the weight of the vehicle is reduced by 10%, the fuel efficiency can be increased by 6%-8%; the fuel consumption per 100 kilometers can be reduced by 0.3-0.6 liters for every 100 kg of vehicle curb weight; the fuel consumption can be reduced by 0.7 liters when the vehicle weight is reduced by 1% %. At present, due to the needs of environmental protection and energy saving, the lightweight of automobiles has become the trend of automobile development in the world.

main method

① The mainstream specifications of automobiles are continuously optimized. On the premise of retaining the main parameters of the specifications, the structural strength of the whole vehicle is improved and the consumption of consumables is reduced;

② Lightweight materials are used. Such as aluminum, magnesium, ceramics, plastics, glass fiber or carbon fiber composite materials;

③ Use computer for structural design. Such as the use of finite element analysis, local strengthening design, etc.;

④ Adopt the load-bearing body to reduce the thickness of the body sheet.

Among them, the current major automotive lightweight measures are mainly the use of lightweight materials.

Both theoretical analysis and experimental results show that lightweighting is an effective way to improve vehicle fuel economy. In order to meet the requirements of lightweight automobiles, some new materials came into being and expanded the scope of application. The rapid growth of the application of non-ferrous alloys in automobiles is a major trend in the development of automobile materials, especially aluminum alloys.

(1) Cast aluminum alloy

The automotive industry is the main market for aluminum castings. For example, in Japan, 76% of aluminum castings and 77% of aluminum die castings are automotive castings. Aluminum alloy castings are mainly used in engine cylinder blocks, cylinder heads, pistons, intake manifolds, rocker arms, engine mount brackets, air compressor connecting rods, transmission housings, clutch housings, wheels, brake parts, handles and Cover shell parts, etc.

(2) Deformed aluminum alloy

Deformed aluminum alloys refer to aluminum alloy sheets, extruded profiles and forged materials, which are mainly used in automobile body panels, body frames, engine radiators, air conditioner condensers, evaporators, wheels, decorative parts and suspension system parts, etc. .

(3) Aluminum matrix composite materials

Aluminum matrix composites have low density, high specific strength and specific modulus, and good thermal fatigue resistance, but their application in automobiles is restricted by price and production quality control, and has not yet formed a large scale. At present, the test or use of aluminum matrix composites on parts such as connecting rods, pistons, cylinder bores, brake discs, brake calipers and drive shaft tubes has shown excellent performance

One-piece die casting is a revolution in the production process of automobiles. The integrated die-casting process adopted by Tesla Model Y can be regarded as the beginning of the integration of auto parts, and the application parts are mainly on the rear floor of the car. The original more than 70 parts were integrated into 1-2 parts, so that the number of molds and presses was greatly reduced, and the production efficiency was also rapidly improved, which also brought about a significant reduction in costs. It is estimated that the aluminum consumption of the integrated die-casting process is about 100kg. The promotion of this process will greatly increase the penetration rate of aluminum in automobiles. However, although the one-piece body brings convenience to manufacturing, the follow-up maintenance has also become a problem. It is hoped that in the near future, with the development of science and technology, this problem can also be solved.

Fenan Aluminum also produces some lightweight products for automobiles, such as Aluminium auto pedal; anti-collision beam; Aluminium Battery Enclosures; Aluminium battery base,etc.If you have any need,be free to contact us.

Thanks for reading today's sharing

#aluminiummanufacturing #aluminiumprofilesupplier #fenanaluminum #foenaluminum#automotivelightweighting#lightweighting

https://www.foenalu.com/

0 notes

Text

Precision Forging Manufacturers & Exporters | Syndicate Industry

Syndicate Industry specializes in manufacturing Forged and Machined Components in Stainless Steel, Alloy Steel, Carbon Steel, Copper Alloys and Aluminum Alloys. Syndicate Industry is ISO 9001:2008, PED 97/23/EC, Annex 1, clause 4.3 & AD 2000 Merkblatt W0 approved. We can manufacture Forged Components as per our client’s designs and Products & Pipe Fittings as per various International Standards with a range of 0-100kg. we provide unit/units 5000 Unit/Units per Day

Syndicate Industry is a new company formed in 2008. Syndicate Industry acquired 18 acres of land in 2008 and in just a span of 16 months has reached the commercial production stage. Syndicate Industry is located at delhi. The strategic location of this industrial town has the likes of General Motors within 5kms distance from Syndicate Industry . We produce parts that combine the necessary structural integrity, with increased fatigue resistance, plus high quality and on-time tooling capabilities. The product and process quality that APP is known for is supported by Statistical Process Control of critical operations and a company-wide focus on Total Quality Management.

Syndicate Industry is your destination. You may have travel many roads but then, all roads lead to delhi. And well, Syndicate Industry is that. Your delhi ! We, at specialize in manufacturing and exporting a variety of steel components, as per client's requirement. The products ranges of conveyor belt manufacturers, die casting parts, precision forging manufacturers, Drill Bit, air compressor supplier, drill holder tool belt, bucket elevators manufacturers, vertical conveyor, horizontal conveyor, cnc turned components, ferrous and non ferrous metals, conveyor chain manufacturers, cylindrical roller bearing, The list doesn't end here. There is more, such as fabrication services, welding service, repairing services, glazing services, galvanizing services, sheet metal bending services. We manufacture the above mentioned products for various industries like Electronic & Electrical, Sanitary ware Applications, PPRC Fittings, Wood Working Tools, Automobile Industry, etc.

We pride ourselves in finding the right products to suit the customer requirement. Along with product we also provide best-possible service and training, The price negotiation is based on the principle of satisfying our clients to the fullest.

Manufacturer of a Wide Range of steel and iron Products, Specialist In conveyor belt manufacturers, die casting parts, precision forging manufacturers, Drill Bit, air compressor supplier, drill holder tool belt, bucket elevators manufacturers, vertical conveyor, horizontal conveyor, cnc turned components, ferrous and non ferrous metals, conveyor chain manufacturers, cylindrical roller bearing, fabrication services, welding service, repairing services, glazing services, galvanizing services, sheet metal bending services.

WE are india's largest iron and steel industry for manufacturing and supplying and providing unlimited iron and steel product, and we also provide many service like fabrication services, welding service, repairing services, glazing services, galvanizing services, sheet metal bending services. so vist http://www.syndicateindustry.co.in/ . make a great deal!!!

1 note

·

View note

Photo

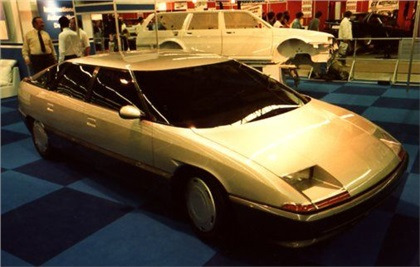

That Time Forgot: IAD Alien (and related concepts)

I gotta admit. For the longest time, I thought that this car, with its supremely space-age design, was not real. But after a bit of a search and some other things... I found it was. I believe some people might share this sentiment. Today, I’m going to talk about the history behind the IAD Alien, along with, as a bonus, all of the other things IAD made over the years.

IAD, or International Automotive Design, was a British design company founded in 1976 by husband and wife Yvonne and John Shute. The company originally designed bodies for trains (my other interest), but eventually branched out to designing bodies for automobiles. Increasing demand eventually caused IAD to branch out to encompassing various different facets of the industry, from design and sculpting models to small-scale production. In the 1980s, IAD was one of the biggest automotive design firms in the world, competing against such giants like Bertone, Italdesign and of course, Pininfarina, and also had multiple facilities around the world.

Touted as “Britain’s Largest Styling Company”, IAD meant business. To prove that they were a force in the industry, they designed a number of concept cars throughout the 1980s to early 1990s, and we’ll be talking about them here. I will not be counting cars that were designed by IAD, but manufactured by another company.

The first of the concept cars they designed was known as the TRX.

The TRX was a radical restyling of the Triumph TR7, designed by Martin Longmore. The TRX attempted to make the car have a completely different appearance, but keeping the fundamental structure of the car as close as possible to the TR7. General Electric Plastics helped to fund the project. It was displayed at the 1980 Birmingham Motor Show.

Their next project was the Arrival, displayed at the 1985 Frankfurt Motor Show. The car attempted to demonstrate IAD’s expertise with computer-aided design, showing a proposal for a five-door sedan designed entirely with a computer.

The next car IAD would design would turn out to be arguably their most famous design yet, helped by the fact that a Hot Wheels model was produced replicating the car: the Alien.

The IAD Alien was designed by Longmore and Marcus Hotblack, and was their proposal for a futuristic mid-engined supercar. Featuring a canopy door which tilted forward for unhindered entrance and egress, the Alien showcased a number of interesting solutions for the general public. The car was first introduced at the 1986 Turin Motor Show.

The car itself featured a highly sophisticated interior with a starship-like steering wheel and heads-up display for the dashboard. The interior was also well-protected, with an integrated roll cage in the car. Quite possibly the most interesting part of the car was its modularity; owners of the car could switch out engines on the fly for easy upgrading, maintenance or to change to something else the driver suited. A bit over the top, yes, but that’s what the ‘80s were like.

Unfortunately, the car was non-functional, and Longmore and Hotblack would move on to their next project.

The Impact was their next project, also designed by Longmore and Hotblack. Built on a Ford Sierra chassis and powered by a 2.8L Cologne V6, the Impact aimed to be one of the most barrier-free SUVs possible, with folding steps when any of the doors opened. A split tailgate and underfloor storage allowed the Impact to store more than a usual SUV could. It was branded as a Sports/Utility Car by a brochure, and featured an in-car navigation system. The car was showcased at the 1987 Frankfurt Motor Show.

To add to their SUV portfolio, IAD did up the Interstate. Designed by Tony Pettman, the usual Ford Cologne V6 was fitted underneath a soundproof cover, allowing for some of the quietest rides. It too, like the Impact, was introduced at the 1987 Frankfurt Motor Show.

Following up the Impact was the Hunter, a rugged off-road vehicle equipped with navigational systems and a telephone. Appearing very similarly to the Impact, the Hunter was also fitted with the same Ford Cologne V6 and featured weatherproof seats made out of foam. It was showcased at the 1988 Turin Motor Show, and was designed by Longmore, Hotblack and Dave Ancona.

After the Hunter came the Royale, designed by Bill Barranco and Jose Diaz de la Vega. The Royale was built around a highly modified Subaru XT-6, with the wheelbase stretched. Meant for business executives, the Royale had a rotary keypad and controls for the CD player and satnav systems available to both rear passengers. The headlights and taillights were engineered by Phillips (yes, that Phillips), and featured a massive LED screen in the rear of the car integrated with the taillamps engineered to give various pieces of road safety information. It, like the Hunter, was also shown off at the 1988 Turin Auto Show.

Their next car was the rather interesting-looking (and potentially rather unsightly) Venus. Introduced at the 1989 Tokyo Motor Show, the Venus was designed by Michael Ani and touted as a futuristic supercar with both performance and a distinctive appearance. The design aimed to form a blend between the technical and aesthetic aspects of the car. A functioning model of the car was eventually built on a Lotus Elise chassis.

Their next project was simply titled the Mini MPV. Powered by a Ford Escort’s CVH 1.9L engine, the Mini MPV could seat six people in three rows. It debuted at the 1990 Turin Motor Show and may have been trialed at Los Angeles International Airport at the time.

Okay, I’m breaking the “outsourced production” rule, but technically this thing was designed by IAD but never produced, so it sort of qualifies. This is the IAD Magia (or Lancia Magia), designed by Ani and Brian Osborn. Featuring the 2.0L FIAT Twin-Cam inline-4 from a Lancia Delta Integrale, the Magia featured a “svelte body” on top of a Lancia Dedra platform, and was touted as “a car to capture the imagination of all the devotees of sporting coupes”. The car was shown off at the 1992 Turin Auto Show, where it was extremely well received, although serial production never materialized.

Reeling from the effects of the European Union’s automobile industry’s worst recession, IAD went into receivership and was acquired by Mayflower Group in 1993. John Shute would die two years later on 13 January 1995, aged 54. Despite his death, IAD would go on to design one more concept on their own.

That design was the EuroTaxi. This was a taxi designed to be the cheapest and most efficient taxi to operate by miles. The EuroTaxi attempted to extend service intervals through the use of both an internal combustion engine and an onboard battery pack, and as a result, decrease downtime. The car was showcased at the 1995 Frankfurt Motor Show, but of course, no orders were placed. The EuroTaxi would turn out to be IAD’s last design.

With the money running dry due to said recession, Britain’s Leading Styling Company were forced to release their chokehold on the car design industry and vanished. The company’s design facilities were bought over by Daewoo Motors, and IAD faded into obscurity, never to be heard from again, while Pinifarina, Bertone and Italdesign are still around today, designing cars.

Okay, now that we’ve gotten the history of IAD out of the way, let’s talk about what you came for: the Hot Wheels version of the IAD Alien.

The Alien was designed by Larry Wood and first introduced in the 1989 Speed Fleet series in the above color, somewhat replicating that of the real Alien; however, this color is quite rare and was quickly replaced by the far more common red version. The casting never received any mention of IAD on it; for all its releases it was simply titled “Alien”.

The Alien features a plastic wraparound body rivited to the base, with metal fender flares and a plastic canopy. This canopy can theoretically be removed, but I’m not going to attempt to do so; instead, I’ll show a picture of one with the canopy removed.

The casting has a metal base, which makes this casting quite heavy. It actually has some decent details on the undercarriage.

The base features few markings apart from the logo and copyright information. I can honestly see people not being able to identify this car, but this was at a time where little other information other than copyright and the Hot Wheels logo was placed on the base; this lasted from about the mid-’80s to the mid-to-late-’90s, at which point it was presumably mandated to put the name of the casting on the base unless it couldn’t fit.

The Alien enjoyed the privilege of being released quite often when it was in the lineup, but ultimately this casting was doomed in 1999 for one reason, and one reason only: the Final Run Series.

The Final Run Series started in 1999 and acted as what I would consider a very glorified funeral for a casting; Hot Wheels would give these cars special tires and paint, in exchange for vowing to never produce them again by cutting their toolings in half. The Alien was unfortunately one of the castings to fall victim to the Final Run Series, and although it might not have been one of the more popular castings to retire that year, it was still retired regardless. As the first batch of cars to be Final Run, having been introduced in the 1999 series, the Alien will never be seen again in the Hot Wheels lineup unless a new tool and die is created for it, which I believe is highly unlikely. The Final Run Series itself has been on hiatus since 2006. In total, the Alien had fifteen releases.

Always on the receiving end of very loud decals due to its plastic sides and large fenders, the Alien will be dearly missed (by me, at least) in the Hot Wheels lineup, and I wouldn’t mind seeing a modern recreation of the Alien return to the Hot Wheels lineup as a premium piece.

I hope this post has given you a better idea on the history of this futuristic British supercar concept, and the history of its small Hot Wheels counterpart. As usual, I’d write something like this any day.

- Grunty

3 notes

·

View notes

Text

Design key points and technical summary of automobile headlight reflector injection molds.

Car headlight reflector (also known as reflector) is a part of car headlight lighting system that has a reflection function to avoid direct light. It is located inside lens and decorative frame, is assembled with lens. Reflector can be seen from outside of car light through lens. Plastic parts are exterior parts with aluminum-plated surfaces. They are high-gloss electroplated parts with…

View On WordPress

#automobile headlight reflector injection molds#automobile headlight reflector molds#automobile mold design#automotive molds#automotive plastic parts#BMC material injection molding process#core-pulling mechanism#design of automotive molds#Design of demoulding system#die-casting molding process#gating system design#injection mold#injection molding process#mold design#mold processing#Mold structure analysis#Mold working process#molded parts#molded plastic part#molding#plastic parts#Structural analysis of plastic parts#temperature control system design#thermoplastic injection mold#thermoplastic plastic molding#thermosetting injection molding#thermosetting plastic injection molding

0 notes

Text

Driving Precision: Bharat Engineering's Role as a Premier Automotive Casting Manufacturer

Introduction:

In the automotive industry, precision and reliability are paramount. Every component, from the engine block to the smallest bracket, must meet exacting standards to ensure optimal performance, safety, and longevity of vehicles. As one of India's leading automotive casting manufacturers, Bharat Engineering plays a pivotal role in this ecosystem, delivering top-notch casting solutions that power the vehicles of today and tomorrow. Let's delve into how Bharat Engineering stands out as a premier provider of automotive castings, driving the wheels of innovation and excellence in the automotive sector.

The Significance of Automotive Castings:

Automotive castings form the backbone of vehicle manufacturing, encompassing a wide range of components such as engine blocks, cylinder heads, transmission housings, brake calipers, and suspension components. These castings are integral to the structural integrity, performance, and functionality of automobiles, contributing to their overall efficiency, safety, and aesthetics. With the automotive industry witnessing rapid technological advancements and evolving consumer preferences, the demand for high-quality castings has never been greater.

Bharat Engineering: Engineering Excellence in Automotive Castings:

With a rich heritage spanning decades, Bharat Engineering has emerged as a trusted name in the realm of automotive casting manufacturing. The company's commitment to innovation, quality, and customer satisfaction sets it apart in a competitive marketplace. Here's how Bharat Engineering is driving precision and reliability in automotive castings:

Advanced Casting Technologies: Bharat Engineering leverages cutting-edge casting technologies, including sand casting, die casting, and investment casting, to produce a diverse range of automotive components with exceptional precision and accuracy. Whether it's complex engine blocks or intricate suspension parts, the company's state-of-the-art facilities are equipped to meet the most demanding specifications of modern vehicle designs.

Metallurgical Expertise: The metallurgical composition of automotive castings is critical to their performance and durability. Bharat Engineering boasts a team of seasoned metallurgists and material scientists who possess deep expertise in selecting the right alloys and optimizing casting processes to ensure superior mechanical properties, corrosion resistance, and thermal stability in the finished components.

Customization and Prototyping: Recognizing that every automotive application is unique, Bharat Engineering offers custom casting solutions tailored to the specific requirements of its customers. From prototype development to full-scale production, the company collaborates closely with automotive OEMs and Tier-1 suppliers to deliver casting solutions that meet their exacting standards for performance, quality, and cost-effectiveness.

Quality Assurance: Quality is ingrained in every aspect of Bharat Engineering's operations. The company adheres to stringent quality control measures and testing protocols to validate the integrity and performance of its automotive castings. From dimensional accuracy and surface finish to mechanical properties and defect detection, Bharat Engineering ensures that every casting meets or exceeds industry standards and customer expectations.

Sustainability Initiatives: Bharat Engineering is committed to sustainable manufacturing practices that minimize environmental impact and promote resource efficiency. The company employs eco-friendly casting processes, recycles scrap materials, and invests in energy-efficient technologies to reduce its carbon footprint and contribute to a greener automotive industry.

Conclusion:

In an era of rapid technological evolution and shifting market dynamics, automotive manufacturers demand casting solutions that offer uncompromising quality, precision, and reliability. Bharat Engineering rises to this challenge, leveraging its engineering expertise, advanced technologies, and customer-centric approach to deliver casting solutions that drive automotive innovation and performance. As India's automotive industry continues to chart new frontiers, Bharat Engineering remains steadfast in its commitment to excellence, serving as a trusted partner in the journey towards a safer, more efficient, and sustainable mobility future.

0 notes

Text

Have air tightness requirements

It is estimated that the amount of magnesium used in auto parts worldwide will increase by more than 15% annually from 1996 to 2008. Figure 2 shows the magnesium alloy gearbox casing and magnesium alloy steering wheel prepared in China. For these reasons, the price of oxygenated die castings is 10% to 15% more expensive than ordinary die castings., Shenzhen Foxconn Company, Shenzhen The magnesium alloy notebook computer cases and mobile phone cases developed by Jiafeng Metal Products Factory and Dongguan Baoyuan Technology Magnesium Alloy Factory and Qingdao Jingu Magnesium Co. Statistics of magnesium alloy die casting production in 2001. Oxygen-filled die-casting Oxygen-filled die-casting is to fill oxygen into the cavity before the die-casting cavity is filled with liquid metal. Among them, the growth rate in North America is 30%, and that in Europe is more than 60%. The microstructure of ordinary die-casting parts has a considerable number of iron-containing needle-like structures, which reduces the plasticity. However, the use of oxygen-filled die-casting reduces casting waste, improves performance, and saves machining costs.

Therefore, the American company Dow Chemical has developed a semi-solid thixoforming process and equipment for magnesium alloys. Compared with aluminum wheels, the weight of magnesium wheels is reduced by 15%. Therefore, under the requirements of thin wall, light and thin, impact resistance, electromagnetic shielding, heat dissipation and environmental protection, magnesium alloy has become the best choice for manufacturers. Magnesium alloy die-casting parts of the car transmission body of Shanghai Qiantong Auto Accessories Co.. It is necessary to change the method of replacing magnesium castings with aluminum castings after introducing new models to improve the production level of China's own magnesium alloys. Therefore, oxygen-filled die casting is particularly suitable for die castings that require heat treatment to improve mechanical properties, have air tightness requirements, are used at higher temperatures, or require welding combinations. We must take action, make full use of China's rich magnesium resources and huge magnesium production capacity, do a good job in developing magnesium alloy key technologies for the development of magnesium alloy applications, and welcome the arrival of the climax of magnesium alloy applications. Manufacturers use magnesium alloy parts in automobiles not only to reduce weight, but also to continuously improve the price-performance ratio of automobiles to strengthen their Competitive advantage in the increasingly fiercely competitive automobile market.

For example, in the past few years, China has conducted a lot of research on the process of semi-solid coagulation, and has achieved some research results, but the development of this process as china copper elbow a practical process for products has not been reported. Opportunities and Challenges Facing Domestic Die Casting Enterprises With the improvement of people's living standards, the automobile and information industry have developed rapidly. Vacuum die-casting Vacuum die-casting eliminates or significantly reduces the porosity and dissolved gas in the die-casting parts by pumping the gas in the cavity during the die-casting process, and improves the mechanical properties and surface quality of the die-casting parts. Foreign magnesium alloy die-casting technology and its application Using traditional die-casting technology to die-cast magnesium alloy, like other alloys, there is a problem that the gas in the cavity and the gas generated by the die-casting paint cannot be smoothly discharged. Thixotropic injection molding technology is a technology that melts a low-melting alloy and injects raw materials into a metal mold at high speed and high pressure for molding, and has now entered the practical stage. The elongation of castings has been increased from 8% to 16%. Development status of domestic magnesium alloy die casting In recent years, the average annual growth rate of domestic magnesium alloy die casting production has reached 18%. These gases are either dissolved in the magnesium alloy under high pressure, or form many high-pressure micropores dispersed in the die-casting. The grains of oxygen-filled die-castings are very fine, which has good tensile strength and fatigue performance.

1 note

·

View note

Text

Qualified Aluminium Die Casting Mold Manufacturer

Specialized Aluminium Die Casting Mold Producer: Trying to find the highest die casting mold producer throughout Chinese suppliers? Were a major die casting mold brewer with The far east, we have been specialized in making and also fabricating the high good quality die casting mold.Die casting will be a flexible method regarding developing constructed material areas simply by requiring melted material less than questionable into reusable precious metal molds.Aluminum Die Casting is associated to the development of items including house windows, cladding, drape walling, prefabricated architectural structures, retailer partitions, and fittings.

Likewise, light weight aluminum die casting bags are utilised in aerospace experditions and also aeroplanes everywhere over the world.The aerospace sector wishes to generate a a lot more lustrous and more substantial quality item on lower costs for these air-frame elements since aircraft increase bigger coupled with human population rates.

Most people guarantee any life-long mold good quality for the mildew most people made.In circumstance there exists every mold challenge, for just a move to help oversea, we're going to offer tech support team or perhaps replacement service in case needed.Should there's any serious issue that can not be settled by way of in this way, i will give reimburse or compensation.

However, for the output mold , we're going to provide life-long mend, routine maintenance, or maybe restore with regard to free.So our own customers will probably not have trouble once they obtain die casting mold out of us.In most all cases, organizations that contain a desire for a gentle steady stream with very precise parts will probably choose metal die casting.

The most expense with lightweight aluminum die casting is the manufacture of the die itself.But after we currently have built the actual die , developing several long-lasting, difficult elements in the short amount of time is actually comparatively simple and easy low-cost when compared to fine sand or even long term mold processes.The growing emission laws by means of the costa rica government regulatory specialists, coupled with purchaser require for the greater fuel-efficient auto can be acquiring essential intended for aluminium casting.

An illustration of greater surgical procedures to get that is a incorporates the replacing of metal in addition to steel pieces automobile having light in weight high-quality aluminium as a way to enhance the energy resource efficiency.The Light weight aluminum die throw solution is great for digital connectors as well as housings die to the superb electric powered efficiency in addition to safeguarding components, even in high-temperature environments. What exactly do you think you're anticipating? Get hold of us all on the web page to understand more details on your die casting tooling products.

1 note

·

View note

Text

Metal Forging: All About Different Forging Methods And Their Uses | Pahladrai Forgings

Forging is a manufacturing process in which the metal is pounded, pressed or squeezed under heavy pressure into high powered strength parts known as Forging. The process is typically performed by preheating the metal into its desired temperature before it is given the shape. But it is crucial to remember that this process is entirely different from that of Casting Process, as the metal used is never poured or melted, which is being done in the casting process.

Why Use Forgings And Where Are They Used?

Forging process creates stronger parts than those, which are manufactured by any other metal process. This is the reason Forging process is more preferred as reliability and human safety are utmost important. You will rarely find forgings in daily day to day life as they are the component inside parts of assembled items such as automobiles, airplanes, ships, oil drilling equipment, engines, tractors, missiles, all other kinds of capital equipment to name a few.

Who Purchase These Forgings?

These customized parts vary in various shape, size and finesse - from the wrench and hammer in your toolbox to accommodate tolerance precision parts in the Boeing 747 and NASA space shuttle. In fact, a 747 Boeing contains nearly 18,000 forgings. Some of the purchasers and consumer markets include national defence, aerospace, agriculture, automotive, mining, construction, material handling and general industrial equipment.

What Metals Are Forged?

Any metallic substance can be forged. However, the common metals which are used are alloy and stainless steels, carbon, brass, copper, aluminium, titanium, hard tool steels, and high-temperature alloys containing cobalt, molybdenum or nickel. Each of these metals has its own distinct weight or strength characteristics which provide maximum utilization if best applied to any specific parts by the customer.

How Are Forgings Produced?

Gear Forging, or copper Forging , or be it forged steel rings, are all done by customized shaping of the metal by deformation that includes a myriad of techniques and equipment. The key to understanding forging designs, one needs to know the forging characteristics and operations of how the metal flow and what each produces. Forging is one process which takes into the metal's natural flow of grain into its advantage to confirm the unique contours of each part.

Hammer and Press Forging

The forging copper and other metals are carved into shape either by a press or a hammer. Forging done by the hammer is conducted out by repetitive blows. But the hammer forging and its productivity all depend on the techniques and skill of the operator. With the rise of technology and the arrival of automated hammers, it has resulted in the lesser time taken, enhanced flexibility and lesser worker dependency. During the process of the press, the stock is hit usually once in each blow.

The Open Forging or Hammer process

Open die forging is nothing but a modern day extension of the hammer and press process that a metal smith practised in anvil the pre-industrial period.

In the open die forging process, the workpieceis not entirely held in the die to give the desired shape. Usually, the open die forging technique is connectedwith large parts such as metal shafts, sleeves and disks. Most of the open die forging products is built on flat forging dies. Sometimes the round swaging dies and V-shaped dies are utilised in along with the flat dies.

Methods implemented on open die presses include:

· Outstretch and reduce the cross-section of the ingot or billet and expand it

· Upset forging to decrease the length of the ingot or billet where only one side of the metal requires forging

· Upset, outstretch, and piercing processes coupled with forging over a mandrel for unevenly shaped forged steel rings

As the open die forging includes hammered or pressed workpiece, it is frequently manipulated within the dies till it gets its final forged shapes. Because the process depends more on the workers' skill, this process is ambiguous and substantial workpiece stock quantities are preserved to provide forging abnormalities.

The forged parts of the workpieceare roughly shaped and finished to final dimensions. But with the increasing demand and use of the open die forging method and all other forging processes of this type are being automated.

On the other hand, the features of roll-forged elements are very satisfying. In most cases, roll-forged components have no flash, and the metal grain structure is convenient and constant in all parts. The forged steel rings and rolls offer a certain amount of descaling, making the product exterior smooth and free of scale pockets.

Impression Die Forging

In the impression die forging process, two dies are taken together and the workpiece goes through plastic deformation until its developed sides reach the side walls of the die.

During the process of impression die forging, some material starts to slip outside the die impression, forming some flashes.

Once the flashes cool down, they form intensified resistance to deformation. These cooled flashes build pressure inside the bulk of the workpiece and help material flowing into the vacant impressions.

Closed die forging, another type of impression die forging, is performed within a narrow cavity that restricts excess material from flashing out. This process is not dependant on the flash formation. Thus this is the most popular type of impression die forging.

The forging dies become more influential than the workers' skill in case of impression die forging methods. Impression forging program usually shapes materials and finish the piece with the preform, pierce, or cut method.

Precision Forging

Precision Forging means close-tolerance or close to final type forging. This forging technique is not a special technology but an advancement of the existing forging methods to a point where the forged part can be fitted with little or without any subsequent machining.

These advancements include not only the forging method but also preheating, descaling, lubricating, and temperature control works. But the application of Precision Forging method depends on the relevant financial condition of the business. Due to expensive tooling and development costs, precision forging is usually limited within the exceptionally high-quality apparatus.

Steel Ring Rolling

Ring rolling has grown from an art to a stringently managed engineering method. Faultless forged steel rings and other metal rings are constructed on a wide range of equipment.

Ring rolling gives a product a consistent, smooth exterior with peripheral grain orientation. These rings generally have diverging strength and elasticity, and often are less costly to manufacture than closed die forgings.

In whole, the ring rolling process gives uniform grain flow, ease of production, and adaptability in material, volume, size and geometry.

Cutting-edge ring rolling apparatus can roll different shapes in both inner and outer breadth of the forged ring, allowing them for unique weight reductions,and reduced material and machining expense.

Extrusion

In the Extrusion method, the forging workpiece is put in a container and pressed till it reaches the flow-stress level. The workpiece then thoroughly fills the container, and further pressure causes it to move through the cracks, and create the extruded metal piece.

There are different variants of the extrusion process, and many of them are patented. In all states, the degree of heating, the competence of scale elimination or restriction, and the effectiveness of lubrication are matters of obvious concern. The variety of shapes produced through hot extrusion is various. Dimensional precision, surface property, and productivity are high, and a higher range of deformation can be accomplished in a single procedure than in any other metal forging technique.

Extrusion can be Direct as well as Reverse, depending on the direction of motion between the ram and the extruded product. An extruded product can be both hollow and solid. Tube extrusion is ideal of forwarding extrusion of hollow shapes, and reverse extrusion is best for mass manufacturing of containers.

Piercing

Piercing method is closely connected to reverse extrusion process. However, it is recognised by the higher flow of the punch that is related to the velocity of the workpiece material.

Secondary Processes

Along with the primary forging methods, secondary methods are also employed often.

Deformation -The deformation method is such a secondary forging process where divergent compression is applied. The width of the drawing ring may be reasonably smaller than the external width of the pre-forged crust to manage or reduce wall density and raise the height of the shell in a drawing or ironing procedure.

Bending - Even after the completion of copper forging, forged gear, or any other metal forging process, bending can be performed. Furthermore, bending can be applied at any stage of the forging process.It is nearly impossible to build complicated shapes in only one die impression. Thus performing forging stock by bending or rolling the forged metal, or by following a fundamental die may be more profitable.

Preform Forging - The preform design in metal forging performs an essential role in advancing the forging product characteristic, such as defect-free quality and proper metal movement. Preforming also helps in improved productivity, extended die life, and reduced worker expenses. Copper Forging, steel forging or any other metal forging in single die impression is usually effective for much smaller parts.

Special Techniques

After deformation of metal, the forged parts often undergo added metalworking. In case of open die forging the flash is removed. The punched holes may be required, and polished surface finish, as well as closer dimensional accuracy, may be needed. To meet the requirements, additional forging techniques are implemented.

Trimming - Flash is trimmed before the forged metal is ready to use. Seldom, mainly with crack-sensitive alloy metals, trimming is done by grinding, sawing, milling, or flame cutting.

Coining - It is typically the sizing works with stress applied to sharp surfaces to increase tolerance, smoothen surface, and reduce draft. Coining is usually performed on exteriors parallel to the parting line, while ironing is meant to be forced by a cup-shaped element through a ring to measure on the outward diameter. Minor metal flow is included in either direction and flash is not grown

Swaging- This is related to the open die forging method how the stock is drawn out within the flat, narrow dies. However, instead of stock, the hammer is wheeled to deliver increased blows to give the forged metal the desired finishing. Swaging can be paused at any stage in the length of stock and is usually used for pointing tube and bar ends and for manufacturing advanced columns and shafts of decreasing width.

Different Types of Forging

There are three major types of forging – Cold Forging, Warm Forging and Hot Forging.

Cold Forging

Cold forging involves either closed die forging or the impression die forging with lubrication and circular dies at or near room temperature. Cold forging usually processes carbon and standard alloy steels like forged steel rings. These cold forged workpieces are generally proportional and rarely exceed 25 lb. The main benefit of cold forging is the material savings due to its exact shapes that need little or no finishing. Fully enclosed impressions and extrusion metal flow allow draftless, close-tolerance elements. Thus, production rates are very high with outstanding die life. While cold forging usually enhances the mechanical qualities, the change is not useful in commonoperations and economic advantages are principal interest here.

Warm Forging

Warm forging has plenty of economic benefits that mark its rising use as a production technique. In the warm forging, the temperature range of forging steel runs above room temperature to below the recrystallization temperature. However, the temperature ranging between 1,000 and 1,330°F is most preferred for the highest commercial potential for warm forging. Compared to cold forging, warm forging has the potential benefits of minimised tooling charges, decreased press loads, improved steel ductility, removal of the need to tempering preceding forging, and desirable forged properties that lead to eliminating further heat treatment.

Hot Forging

In Hot forging method recrystallization occurs concurrently with deformation, thus circumventing strain crystallisation. For this to occur, high workpiece temperature, resembling the metal's recrystallization temperature, must be achieved during the entire process. The kind of hot forging is isothermal forging, where materials and dies are heated to equal temperature. In nearly all instances, isothermal forging is carried on super-alloys in a vacuum or extremely repressed atmosphere to stop oxidation.

Get in touch with us

Name- Pahladrai Steel Forging Works

Email- [email protected]

Phone No- +91 9792114433

Website- http://www.pahladforgings.com

Adderss- 83/141 Juhi Kanpur - 208014

1 note

·

View note

Link

0 notes