#engineering solutions

Text

#job#jobs#jobsearch#best jobs#job interview#career#lucknow#jobs from home#artificial intelligence#placement engineering colleges in bangalore#engineering college#engineering student#engineering services#engineering solutions#engineering projects#computer science#education#course#technology#research scientist#online jobs#fresher jobs#jobseekers#remote jobs#employment#part time jobs#job search#careers#interview tips#interview with the vampire

2 notes

·

View notes

Text

Engineering Jobs in Lucknow https://grplindia.com/btech-jobs/

Apply Now At www.grplindia.com

Call & WhatsApp 8188998866, 8188998899

#job #jobs #engineering #hiring #hiringnow

#inside job#job interview#job search#jobs#jobsearch#employment#jobseekers#online jobs#work#engineering services#engineering company#engineering projects#engineering college#engineering solutions#engineering jobs#civil engineering#mechanical pencil#mechanical engineering#engineering#hiring and recruiting#hiring services#hiring near me#hiring solutions#hiring process#recruiting#recruitment#human resources#hire

2 notes

·

View notes

Text

Material Surface Protection Different Methodologies and Underlying Concepts

It is a well-known fact, any material surface which has to be protected from outside dangers such as corrosion, deformation due to weather, losing its lustre, weakening, rusting and so on must necessarily treated with suitable protective agents. The protection may be of external application and or other methods that bring about the desired outcome. This process is however used in a wide range of technological applications which include cutting tools, optical devices, surgical equipment and microelectronics. However this functionality of forming a protective layer on the material surface depends on the physical attributes of the material used to coat and the material to be coated as well. In certain methods of surface coating large quantities of ionized particles which form the film are generated, which in turn is regulated taking into consideration the residual stress, hardness and the refractive index of both the material and the coating material to form the required thickness of the film.

In this technique there are two key methods, chemically modifying the surface by suitable approaches, or deposition of thin films of materials. Although both the methods a relatively simple, the first method because of its complexity in assessing the surface properties gets quite limited to certain areas. The second method offers more flexibility due to its simple and straight way. Whatever may be the method, a keen observation, in depth study about the characteristics of both materials, the force of adhesion and other critical properties must necessarily be evaluated to arrive at a proper output. With more and more advancements and research in this field it has been proved that bio based polymers have been very good substrates and can give out extremely good results, due to its flexibility especially in the nanotechnology industry. Being a bio degradable polymer, these materials prove to be excellent supporters of green life and green environment protection. This apart it is also found to be a promising material because of its mechanical properties and versatility. As the coating has to be thin, lightweight and flexible and since these materials have good properties like stretch, changing to required shapes, they are found to be the most appropriate materials for this method.

Along with this, these materials have been known to possess a special property of UV protection, elasticity and dust resistance which makes it a preferred agent for coating. Organizations like WWG Engineering have been carrying out surface engineering technology, in a very efficient and meticulous way with emphasis on customer requirement. WWG Engineering has been working towards more advancements and technical innovations in this sector so that a perfect and suitable solution can be delivered to the client. The company has also been rendering first class engineering services like equipment servicing, re-manufacturing, petrochemicals, power generation, offshore, machine refurbishment service, marine and refinery sectors.

#Industrial Machinery Maintenance#Machine Refurbishment Service#Mechanical Engineering Services#Engineering Service Company#Engineering Service Provider#Engineering Solutions

0 notes

Text

#remote jobs#employment#mba#mbastudent#placement engineering colleges in bangalore#internship#jobseekers#fresher jobs#online jobs#hr solutions#engineering college#engineering student#engineering services#engineering projects#engineering solutions#computer science#education#research scientist#course#technology#best jobs#jobs#jobs from home#jobsearch#job search#part time jobs#careers#job interview#career company#career advice

1 note

·

View note

Text

Engineering Solutions

Seeking innovative engineering solutions? Our expert team provides tailored solutions for diverse engineering challenges. Contact us for more information. For #Engineering #Solutions, click: https://ramset.co.nz/

0 notes

Text

Philippines Urged to Step Up Earthquake Preparedness After Taiwan Quake

Scan the QR code to get this post on the go.

Reflecting on recent seismic activity and the devastating potential of earthquakes, Ariel Nepomuceno, the administrator of the Office of Civil Defense (OCD), has emphasized the paramount importance of bolstering engineering solutions and ensuring compliance with building codes. This imperative comes in anticipation of seismic events, particularly the…

View On WordPress

#Building code compliance#Building code enforcement#Disaster mitigation#Earthquake Disaster Preparedness#Engineering solutions#Infrastructure Resilience#National Building Code#Natural disasters#Office of Civil Defense#Seismic Activity#Seismic risks#Taiwan earthquake#the big one#west valley fault

0 notes

Text

Advanced Industrial Engineering Solutions for Resource Extraction

Industrial engineering is a field that focuses on optimizing complex systems and processes within industries to improve efficiency and productivity. Professionals in this field analyze and design systems that integrate people, machines, materials, energy, and information to create streamlined operations. From manufacturing plants to service industries, industrial engineers play a crucial role in identifying bottlenecks, reducing waste, and enhancing overall performance. With their expertise in optimization and problem-solving, industrial engineers drive innovation.

#water resources engineering#flood mapping#industrial engineering consultants#engineering solutions#accounting#dam design solutions#mining site

0 notes

Text

TGP India - Trusted Engineering Solutions Provider

Explore TGP India for comprehensive engineering solutions, including fabrication, erection, and maintenance services. With a focus on quality and efficiency, we deliver reliable results for diverse industrial needs.

0 notes

Text

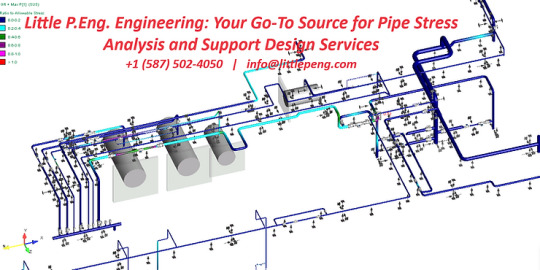

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

In the vast and complex world of engineering, precision and accuracy are paramount. Nowhere is this truer than in the field of piping systems, where even the smallest miscalculation or oversight can lead to catastrophic consequences. To ensure the safe and efficient operation of piping systems, the expertise of specialized engineers is required. This is where Little P.Eng. Engineering comes into play. With a reputation for excellence and a commitment to providing top-notch pipe stress analysis and support design services, Little P.Eng. Engineering stands as a trusted partner for industries that rely on flawless piping systems.

In this comprehensive guide, we will delve into the world of pipe stress analysis and support design services offered by Little P.Eng. Engineering. We will explore the importance of these services, their role in various industries, and how Little P.Eng. Engineering excels in delivering tailored solutions. Additionally, we will discuss the key factors that set Little P.Eng. Engineering apart from the competition and provide valuable insights into their commitment to safety, quality, and customer satisfaction.

Chapter 1: Understanding Pipe Stress Analysis

1.1 What is Pipe Stress Analysis?

Pipe stress analysis is a critical component of engineering that involves evaluating the forces and stresses acting on a piping system to ensure its structural integrity and safety. It plays a pivotal role in various industries, including petrochemical, oil and gas, power generation, and more. Pipe stress analysis helps engineers identify potential issues such as excessive strain, deformation, or failure that could compromise the functionality and safety of the system.

1.2 The Importance of Pipe Stress Analysis

The significance of pipe stress analysis cannot be overstated. Failing to perform adequate stress analysis can lead to a range of problems, including:

1.2.1 Safety Risks: Inadequate pipe stress analysis can result in ruptures, leaks, and catastrophic failures, endangering human lives and the environment.

1.2.2 Cost Overruns: Repairs and maintenance due to unforeseen issues can lead to substantial cost overruns in construction and operation projects.

1.2.3 Downtime: Unscheduled downtime can disrupt operations, leading to production losses and revenue reduction.

1.2.4 Legal and Regulatory Issues: Non-compliance with safety standards and regulations can result in legal and financial repercussions.

1.2.5 Reputation Damage: Incidents related to piping system failures can tarnish a company's reputation.

Chapter 2: The Role of Pipe Stress Analysis in Different Industries

2.1 Oil and Gas Industry

The oil and gas industry relies heavily on complex piping systems to transport hydrocarbons from extraction sites to refineries and end-users. Pipe stress analysis is crucial in this industry to prevent leaks, ruptures, and environmental disasters. Little P.Eng. Engineering provides specialized services tailored to the unique challenges of the oil and gas sector.

2.2 Petrochemical Industry

Petrochemical plants process raw materials into valuable chemical products. The precise and safe transport of chemicals through piping systems is essential. Pipe stress analysis ensures the structural integrity of these systems, mitigating the risk of chemical leaks and ensuring worker safety.

2.3 Power Generation

Power plants, whether they run on fossil fuels, nuclear energy, or renewable sources, require intricate piping networks to deliver steam, water, and gases to turbines and generators. Pipe stress analysis is vital to prevent system failures and maintain uninterrupted power generation.

2.4 Pharmaceutical and Food Industries

In industries where product purity and safety are paramount, such as pharmaceuticals and food production, pipe stress analysis ensures the integrity of sanitary piping systems. Little P.Eng. Engineering's expertise extends to designing hygienic piping solutions that meet the strictest standards.

2.5 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in commercial and industrial buildings rely on complex piping networks. Proper stress analysis ensures the efficient functioning of HVAC systems, contributing to comfort and energy efficiency.

Chapter 3: Little P.Eng. Engineering's Pipe Stress Analysis Services

3.1 Expertise and Experience

Little P.Eng. Engineering boasts a team of highly skilled and experienced engineers with a deep understanding of the complexities involved in pipe stress analysis. Their expertise spans various industries, ensuring that clients receive tailored solutions that align with their specific needs and challenges.

3.2 Advanced Technology and Software

Staying at the forefront of technological advancements is crucial in the engineering field. Little P.Eng. Engineering utilizes state-of-the-art software and tools for pipe stress analysis, enabling precise simulations and evaluations. This ensures the accuracy and reliability of their services.

3.3 Customized Solutions

One of the key strengths of Little P.Eng. Engineering is their ability to provide customized solutions. They understand that each project is unique and may have distinct requirements. By tailoring their services to individual client needs, they ensure optimal results and client satisfaction.

3.4 Compliance with Industry Standards

Compliance with industry standards and regulations is non-negotiable in the world of engineering. Little P.Eng. Engineering ensures that all their pipe stress analysis services meet or exceed relevant industry standards, codes, and safety guidelines.

Chapter 4: Pipe Support Design Services

4.1 What is Pipe Support Design?

Pipe support design is an integral part of piping system engineering. It involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibration, and stress. Proper support design ensures the longevity and stability of piping systems.

4.2 Importance of Pipe Support Design

Inadequate or improperly designed supports can lead to several problems, including:

4.2.1 Excessive Stress: Unsupported piping can experience undue stress, leading to damage and failure.

4.2.2 Vibrations: Vibrations can affect the performance of piping systems and nearby equipment.

4.2.3 Misalignment: Improper alignment can cause leaks and inefficiencies.

4.2.4 Premature Wear: Unsupported piping can wear out faster, leading to maintenance and replacement costs.

4.3 Little P.Eng. Engineering's Pipe Support Design Services

Little P.Eng. Engineering offers comprehensive pipe support design services to ensure that piping systems are adequately supported and stable. Their services include:

4.3.1 Structural Analysis: Evaluating the structural integrity of supports and ensuring they meet safety and code requirements.

4.3.2 Custom Designs: Tailoring support solutions to the unique needs of each project.

4.3.3 Material Selection: Recommending suitable materials for support components, considering factors like corrosion resistance and load-bearing capacity.

4.3.4 Installation Guidance: Providing guidance and recommendations for the proper installation of supports.

Chapter 5: What Sets Little P.Eng. Engineering Apart

5.1 Commitment to Safety

Safety is Little P.Eng. Engineering's top priority. Their pipe stress analysis and support design services are driven by a commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

5.2 Quality Assurance

Quality is woven into the fabric of Little P.Eng. Engineering's services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

5.3 Timely and Efficient Service

Time is often of the essence in engineering projects. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality.

5.4 Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process.

5.5 Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members.

Chapter 6: Case Studies and Success Stories

6.1 Case Study 1: Oil Refinery Piping

A major oil refinery faced ongoing issues with leaks and failures in its piping system, resulting in costly downtime and environmental concerns. Little P.Eng. Engineering conducted a comprehensive pipe stress analysis and identified critical stress points. They then designed and implemented reinforced supports and provided guidance on material selection. The result was a significant reduction in incidents, ensuring safe and uninterrupted operations.

6.2 Case Study 2: Pharmaceutical Facility

A pharmaceutical company needed to upgrade its piping system to comply with stringent FDA regulations. Little P.Eng. Engineering provided customized pipe stress analysis and support design services to ensure compliance with hygienic standards. The project was completed successfully, allowing the company to maintain product integrity and regulatory compliance.

6.3 Case Study 3: Power Plant Efficiency

A power plant was experiencing inefficiencies in its piping system, resulting in reduced energy output. Little P.Eng. Engineering conducted a detailed pipe stress analysis and identified areas of improvement. They designed and implemented optimized supports, resulting in increased energy efficiency and cost savings.

Chapter 7: Conclusion

In conclusion, Little P.Eng. Engineering stands as a premier provider of pipe stress analysis and support design services, catering to various industries where the integrity and safety of piping systems are of utmost importance. Their commitment to safety, quality, client satisfaction, and continuous improvement sets them apart as a trusted partner in the world of engineering.

Whether you operate in the oil and gas, petrochemical, power generation, pharmaceutical, or HVAC sector, Little P.Eng. Engineering has the expertise and experience to deliver customized solutions that meet your unique needs. By prioritizing safety, adhering to industry standards, and consistently providing timely and efficient services, Little P.Eng. Engineering has earned its reputation as a leader in the field of pipe stress analysis and support design.

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Pipe Stress Analysis

Little P.Eng. Engineering

Finite Element Analysis

Structural Integrity

Engineering Expertise

Thermal Expansion

Support Design Services

Oil and Gas

ASME Codes

Industry Standards

Power Generation

Stress Evaluation

Piping Systems

Safety and Compliance

Engineering Solutions

Precision Analysis

Industrial Processes

Petrochemical

Seismic Analysis

Customized Solutions

Pressure Analysis

Pipe Support Design

Safety Regulations

Reliability Assurance

Complex Piping Systems

Chemical Industry

Pharmaceutical Industry

Vibrations Analysis

Stress Distribution

Pipe Failure Prevention

Pipe Stress Analysis Services

Engineering Services

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Pipe Stress Analysis#Little P.Eng. Engineering#Finite Element Analysis#Structural Integrity#Engineering Expertise#Thermal Expansion#Support Design Services#Oil and Gas#ASME Codes#Industry Standards#Power Generation#Stress Evaluation#Piping Systems#Safety and Compliance#Engineering Solutions#Precision Analysis#Industrial Processes#Petrochemical#Seismic Analysis#Customized Solutions#Pressure Analysis#Pipe Support Design#Safety Regulations#Reliability Assurance#Complex Piping Systems#Chemical Industry#Pharmaceutical Industry#Vibrations Analysis#Stress Distribution

0 notes

Text

0 notes

Text

⚡ Vorson Engineering Services: Your Trusted Partner in Comprehensive Electrical Solutions ⚙️

Empower your projects with Vorson Engineering Services! 🏢 Our dedicated electrical engineering team ensures reliable and top-notch solutions for all your electricity-related needs. From powering buildings to installing cutting-edge security systems like access control, CCTV, and fire alarm systems, we've got you covered!

🔌 Services We Offer:

Building Power Solutions

Electricity Distribution

Low-Current System Installation

Access Control and Parking Management

Video Surveillance and CCTV

Video Conferencing Solutions

Fire Alarm Systems

At Vorson, we prioritize excellence, delivering tailored services to meet your unique requirements effectively. Trust us for unparalleled expertise in the world of electrical engineering. ⚡✨

#VorsonEngineering#ElectricalServices#InnovationInEngineering#hvac services#engineering company#engineering solutions

0 notes

Text

America Lubricants Market: Charting the Course of Eco-Friendly Lubricants in the Booming Industry

The America lubricants market is expected to reach USD 45.8 billion by 2030, registering a CAGR of 3.0% during the forecast period, as per the new report by Grand View Research, Inc. The growth is attributed to the increase in demand for the automotive and industrial segments within the region. The lubricants market in America is expected to increase significantly, during the forecast period. The region's fast growth in the automotive and industrial end-use categories will bolster the enlargement. The major application markets, which account for more than 90.0% of the market share, are automotive and industrial manufacturing. The need for industrial applications is likely to be the largest contributor, owing to rising disposable incomes and strong employment figures. As a result of the changing pollution standards and the introduction of electric vehicles, the growth within the automobile industry is expected to be restrained. Top producers in the industry at present cater to the high-margin application sectors of aerospace and marine.

The development of better infrastructure and public transportation networks in emerging economies such as Argentina and Brazil has resulted in improving economic situations. Apart from that, people in the U.S. are increasingly choosing personal vehicles. This is likely to drive demand for the high-performance oil used in automobiles within the region during the forecast period.

Companies are strategically divesting assets and investing in upstream facilities, making the industry extremely competitive. Premium lubricants are projected to be the main driver of industry growth in the future. Companies are also seeking strategic alliances and collaborations, in order to enhance their brand image and invest in new product development.

For More Details or Sample Copy please visit link @: America Lubricants Market Report

America Lubricants Market Report Highlights

Automotive segment accounted for 56.0% of revenue share in 2021. The growth is attributed to the increase in demand for passenger vehicles, commercial vehicles, and scooters. Growth in the consumption of personal vehicles is driving demand for the lubricant oil, used for maintaining vehicle

Industrial segment is anticipated to grow at a CAGR of 3.1% from 2022 to 2030 in terms of revenue as there is a rising need for industrial vehicles owing to the infrastructural development, which in turn will drive demand for the product in the region

Motorcycle vehicle type dominated the industry with USD 6.8 billion in 2021. The demand is anticipated to grow with an increase in consumption of the latest type of motorcycle by the young population of the region

Aerospace segment is anticipated to witness a CAGR of 3.8% during the forecast period. The growth is anticipated due to the increase in the use of oil in aircraft. Aerospace lubricants are used to ensure reliability and provide long-lasting lubrication

Companies have integrated throughout the value chain, to gain the competitive advantage

#Lubricants Industry#Industrial Lubricants#Automotive Lubrication#America Lubricants Market#Grease and Oil#Lubrication Technologies#Sustainable Lubricants#Lubricants Innovation#Eco-Friendly Lubrication#Oil and Gas Industry#Lubricants Analysis#Engineering Solutions#Fluid Technology

0 notes

Text

TEST BANK introduction to chemical engineering thermodynamics 7th edition

TEST BANK introduction to chemical engineering thermodynamics 7th edition

use promo code EXAM07

#chemical industry#chemical peels#chemical#engineering student#engineering solutions#engineering college#thermodynamics

0 notes

Text

Synthetic Polymers And Their Significance in Surface Engineering

Surface engineering is a comprehensive, facilitating activity that calls for meticulous expertise. Comprising of surface modification techniques and processes, producing diverse as well as combined material surface properties to address the challenging requirements, surface coating or surface engineering is practically employed in various industrial sectors and individual clients.

The processes are carried out by applying a protective film of materials or its alloys in order to safeguard the outer surface of a material from getting spoilt by external hazards like rusting, corrosion and other weathering actions that may prove to be disastrous to the material itself. These techniques are mainly based on coating of synthetic polymers, which are nothing but industrially produced elements containing large, interconnected molecules that make a strong but yet flexible, films on the material surfaces. Similarly materials like pigments also constitute surface coatings, which are used in case of materials which require the retaining of colour, glossy finish, opacity, and so on. To enable the easy application of these pigments or colours, a suitable solvent or solvents or carrier liquids, are incorporated into it in order to facilitate a paintable or applicable liquid medium, thereby providing a host of properties and advantages.

Chemically these polymer-based coatings that are applied on the material surface are considered to be a mixture of composite materials mainly consisting of a pigment or coloured particles which are disseminated in a solution of a suitable polymer. Owing to its chemically active property of resistance and flexibility, which supplements its adhering to the substrate, polymers provide and excellent coating over the materials surface.

Since these polymer based coatings have certain speciality qualities like, durability, glossy nature, and resistance against weathering actions, they make a very good surface coating which is reliable and long lasting. Surface coating is also carried out y one more popular and reliable method, that is powder coating. In this method, the material surface is coated with a shower of pigmented or coloured polymer particles, which are then bonded on to the surface by heating, which thereby forms a continuous thin film which acts as a protective sheet or layer on the material surface. Although reactions may take place throughout the heat induced melting of particles and adhering or fusing, the major aspect of film is the formation of the protective coating.

WWG Engineering Pte Ltd located in Singapore has been an integrated one-Stop engineering solutions and services. Blended with a distinctive and specialized technology, and an equally knowledgeable engineering backing, WWG Engineering is undoubtedly a pioneer in the area of engineering equipment and component machine refurbishment services and repairing.

To Learn About More Details On Engineering Service Company Please Come And Visit Our Website..!

#Surface Engineering Technology#Engineering Service Company#Engineering Solutions#Engineering Service Provider#Mechanical Engineering Services#Machine Refurbishment Services

0 notes

Text

Construction-Speed-in-Precast-Solutions

precast solutions is crucial in achieving this delicate balance between rapid economic expansion and robust infrastructure, positioning India as a precast industry leader.

#Precast road solutions#Precast bridge components#fuji precast#precast construction industry in india#engineering solutions#Precast construction industry in India#Precast manufacturing#precast supplier#precast solutions#precast project management#precast construction materials

0 notes

Text

Engineering Solutions

Engineering problems? Our expert Engineering Solutions provide innovative answers. We're here to solve building challenges! For #EngineeringSolutions, click: https://ramset.co.nz/

0 notes