#Engineering solutions

Explore tagged Tumblr posts

Text

#job#jobs#jobsearch#best jobs#job interview#career#lucknow#jobs from home#artificial intelligence#placement engineering colleges in bangalore#engineering college#engineering student#engineering services#engineering solutions#engineering projects#computer science#education#course#technology#research scientist#online jobs#fresher jobs#jobseekers#remote jobs#employment#part time jobs#job search#careers#interview tips#interview with the vampire

2 notes

·

View notes

Text

Engineering Jobs in Lucknow https://grplindia.com/btech-jobs/ Apply Now At www.grplindia.com Call & WhatsApp 8188998866, 8188998899 #job #jobs #engineering #hiring #hiringnow

#inside job#job interview#job search#jobs#jobsearch#employment#jobseekers#online jobs#work#engineering services#engineering company#engineering projects#engineering college#engineering solutions#engineering jobs#civil engineering#mechanical pencil#mechanical engineering#engineering#hiring and recruiting#hiring services#hiring near me#hiring solutions#hiring process#recruiting#recruitment#human resources#hire

2 notes

·

View notes

Text

Exploring Engineering Solutions That Technology Has Brought Into The Construction Industry!

The construction industry has witnessed remarkable transformation over the past few decades, largely due to advancements in technology and engineering solutions. https://www.tumblr.com/ramsetnz/785414066042814464/exploring-engineering-solutions-that-technology?source=share

0 notes

Text

Fabrication Workshop and Its Importance: The Foundation of Contemporary Industry

A fabrication workshop is essential to contemporary manufacturing since they serve as the location where raw materials are converted into completed parts, equipment, and buildings. The engineering plans' conceptual concepts are meticulously and expertly realised in these workshops.

The engineering solutions are essential to industrial production, whether it is for the mining, automotive, aerospace, construction, or energy industries. They help smaller companies and bespoke builders that depend on accurate, long-lasting, and useful components in addition to major manufacturers.

Improving Personalisation and Creativity

Because fabricators collaborate directly with designers and clients to accomplish particular objectives, this flexibility stimulates innovation and problem-solving. Fabrication workshops act as innovation hubs in fields like research and development and renewable energy, where specialised solutions are frequently needed. Fabrication workshops assist ensure that what is constructed not only performs as intended but also endures the test of time and environmental conditions thanks to their professional-grade tools and quality control procedures.

Boosting Regional Economies and Industries

Additionally, fabrication workshops are essential to the growth of regional businesses and economies. For skilled professionals like welders, machinists, fabricators, and technicians, they generate job prospects. Workshops are frequently a component of small-to-medium-sized businesses that support the local economy.

Additionally, they provide prompt service, fast turnaround times, and the flexibility to adjust to shifting demands to promote local industry. The longevity and dependability of complete equipment or buildings can be influenced by the quality of the fabrication.

Developing Workforce Expertise and Skills

A fabrication workshop serves as a learning environment in addition to being a place of production. The practical aspect of the task encourages discipline, accuracy, and problem-solving skills.

Employees acquire the skills necessary to handle sophisticated machinery, understand blueprints, and adhere to stringent safety regulations. The development of a trained workforce that can support sophisticated industry, technological innovation, and national infrastructure projects depends on this training.

Source

0 notes

Text

Sputtering Systems in Industrial R&D: How Xytel India Engineers Precision for the Future

Meeting the Demands of Modern Materials Science

In today’s advanced manufacturing landscape, the need for precise, reliable, and scalable thin film deposition systems is more critical than ever. Whether for semiconductors, optics, or high-performance coatings, sputtering systems have emerged as an indispensable tool for R&D facilities and pilot-scale plants.

At the heart of this technology is the physical vapor deposition (PVD) process — a technique that relies on controlled plasma environments to deposit ultra-thin layers of metal or dielectric materials onto a target substrate. But designing a sputtering system that meets stringent research demands while offering flexibility, scalability, and engineering robustness is no small feat.

This is where Xytel India steps in — offering custom-built sputtering systems engineered for excellence in industrial research and development environments.

What Is Sputtering and Why Does It Matter

Sputtering is a physical vapor deposition method where atoms are ejected from a solid target material due to bombardment by energetic plasma ions. These atoms then condense onto a substrate, forming a thin, uniform film. It’s a process favored for its:

High film adhesion and density

Uniform thickness control

Scalability for multiple material types

Clean deposition environment

This makes sputtering especially valuable in industries like:

Semiconductors: Thin layers of conductive or insulating materials

Optical coatings: Anti-reflective or scratch-resistant films

Surface engineering: Protective or functional coatings for tools and components

Energy research: Solar cell material deposition

Aerospace and defense: Precision coatings for sensitive equipment

Common Challenges in Sputtering System Design

Despite its advantages, sputtering systems come with complex engineering challenges:

Maintaining stable vacuum conditions

Achieving uniform film thickness over various substrate sizes

Managing plasma power inputs (DC, RF, or pulsed)

Incorporating in-situ diagnostics for real-time monitoring

Handling temperature-sensitive substrates

Offering flexibility for multi-material or multi-layer deposition

For manufacturers and researchers alike, a one-size-fits-all approach simply doesn’t work, and that’s why Xytel India’s custom engineering is essential.

Xytel India’s Approach: Engineering Custom Sputtering Systems That Work

At Xytel India, we understand that pilot-scale sputtering systems must be flexible, precise, and robust. Every system we design is tailored to your specific research needs — whether you’re evaluating new materials, scaling up processes, or running continuous tests for product development.

Key Features of Xytel India’s Sputtering Systems:

Precision Vacuum Control

High-integrity vacuum chambers to ensure minimal contamination and consistent deposition quality.

Advanced Plasma Source Integration

Systems are built to support DC, RF, or pulsed plasma power supplies, depending on the application.

Stable plasma environments for repeatable thin film characteristics.

Custom Substrate Handling Mechanisms

Fixed, rotary, or planetary substrate holders for optimal uniformity.

Substrate temperature control for sensitive deposition requirements.

Multi-Material and Layer Support

Multi-target configurations enabling sequential or co-sputtering for layered film structures.

In-Situ Monitoring and Diagnostics

Real-time sensors and monitoring tools to fine-tune deposition parameters.

Integrated control systems to adjust film thickness and rate dynamically.

Material Versatility

Designed to handle a wide range of metals, oxides, nitrides, and dielectrics — suitable for research in evolving materials.

Built for Pilot Plants and Industrial R&D

Unlike commercial off-the-shelf units, Xytel India’s sputtering systems are built to serve pilot plants, material science labs, and industrial R&D environments. Our systems are engineered for:

Rapid prototyping and experimentation

Process parameter optimization

Scalability assessment before mass production

Integration with existing plant control systems

Whether you are a materials scientist pushing the boundary of nanotechnology or an engineering head at a manufacturing plant preparing for product transition, our systems give you the data, flexibility, and confidence needed to scale successfully.

Designed for Your Industry

Xytel India’s systems are currently suited to — and customizable for — the following sectors:

Semiconductor R&D

Energy technology (photovoltaics, fuel cells)

Aerospace and defense coatings

Medical device surface engineering

Optoelectronics and display technology

Our solutions are especially valuable for institutions and industries looking to bridge the gap between benchtop discovery and production-level validation.

Why Choose Xytel India?

For over 40 years, Xytel has been known for designing and fabricating high-performance pilot plants and process systems. Our sputtering systems embody the same spirit: engineered with precision, built for flexibility, and designed to serve the most demanding research environments.

When you work with Xytel India, you gain:

End-to-end collaboration from concept to commissioning

Custom mechanical and electrical design

Integration with your existing automation or control infrastructure

Long-term support and optimization services

Conclusion: Let’s Engineer the Future of Thin Film Deposition

Sputtering systems are foundational to modern innovation, but to unlock their full potential, you need systems that reflect the specific needs of your research or industrial application.

Xytel India offers more than just equipment — we offer engineering solutions that adapt to your goals and accelerate your progress.

Ready to design your next sputtering system?

Let’s start a conversation about your pilot-scale or R&D sputtering needs. Our engineers are ready to work with you, from the drawing board to deployment.

👉 Contact Xytel India Today

0 notes

Text

they solved the Trolley Problem for real

153K notes

·

View notes

Text

Top Scaffolding Material Manufacturer Company In North East India

Leading the Way in Construction Support

Scaffolding is needed throughout all construction activities to render everything safe and define a structure in which work is carried out. In North East India, Nezone would claim to be the top scaffolding material manufacturer company, trusted by contractors, builders, and engineers from the vicinity.

Quality That Speaks for Itself

Nezone manufactures a full-range scaffolding showroom, including steel pipes, tubes, and complete scaffolding systems. Each product is made from quality raw material and subjected to strict quality controls at every stage of production. Their products are designed for durability and strength, and by national and international safety requirements.

Customized Scaffolding Solutions The major strength of Nezone is in its ability to provide custom scaffolding solutions depending on project needs. Whether it is small housing developments or major industrial or infrastructure projects, Nezone is geared to provide exactly what its customers need.

Carbon-friendly Manufacturing Techniques Ne-zone implements the latest technology in its manufacturing units to ensure it satisfies the highest industrial standards in respect of efficiency and cost. The company also nurtures the idea of sustainable manufacturing, thus using eco-friendly practices to reduce waste along with green construction.

Stronghold in the North East From Assam, Meghalaya, Manipur, Nagaland and beyond, Nezone's products enter public and private sector construction works alike, making significant contributions towards the sustainable regional development.

To Conclude Primarily known for scaffolding materials that are safe, durable, and high-performing, Nezone is the top scaffolding material manufacturer company in North East India.

#Assamconstruction#Scaffoldingmanufacturer#Nezonescaffolding#Infrastructuredevelopment#Engineering Solutions

0 notes

Text

𝗘𝘅𝗽𝗮𝗻𝗱 𝗬𝗼𝘂𝗿 𝗘𝗻𝗴𝗶𝗻𝗲𝗲𝗿𝗶𝗻𝗴 𝗪𝗼𝗿𝗸𝗳𝗼𝗿𝗰𝗲 𝘄𝗶𝘁𝗵 𝗧𝗼𝗽 𝗜𝗻𝗱𝗶𝗮𝗻 𝗧𝗮𝗹𝗲𝗻𝘁

Are you facing challenges in finding skilled engineers for your projects in Germany? Awilli Group is here to help!

At Awilli Group, we bridge the talent gap by connecting top-tier Indian engineers with leading companies in Germany and across Europe. Whether you need mechanical, civil, electrical, software, or automotive engineers, we deliver highly qualified professionals to match your project needs.

𝗪𝗵𝘆 𝗖𝗵𝗼𝗼𝘀𝗲 𝗔𝘄𝗶𝗹𝗹𝗶 𝗚𝗿𝗼𝘂𝗽?

1️⃣ We have access to India’s best engineering talent - 1.5M+ engineers graduate annually, offering a vast, skilled workforce.

2️⃣ We offer efficient & cost-effective hiring – Our streamlined recruitment process saves you time and resources.

3️⃣ We provide end-to-end recruitment solutions – From sourcing and screening to visa assistance and onboarding, we handle everything!

4️⃣ We have diverse Industry Expertise – With years of proven experience, we serve semiconductors, pharmaceuticals, automotive, manufacturing, renewable energy, and more.

Build a world-class engineering team with top Indian talent! Partner with Awilli Group for seamless, cost-effective recruitment solutions. Contact us now and we will connects you with India’s skilled engineering professionals to power your European projects!

📩 Request a quote to [email protected] / [email protected]

🌐 Visit our website for more details: www.awilli-ag.ch

#EngineeringTalent #HiringEngineers #IndianEngineers #GermanyJobs #CivilEngineering #ElectricalEngineering #SoftwareEngineers #TalentAcquisition #AwilliGroup

#Mechanical Engineering#Engineering Talent#Hiring Engineers#Europe Recruitment#Skilled Workforce#Global Workforce#Engineering Solutions

0 notes

Text

Capstone was founded with the purpose of equipping the global Construction, Oil & Gas, and Infrastructure industries with premier engineering capabilities. We are sensitive to the business challenges of these sectors, driven by economic upheavals, high competition, and resource constraint. Our solution is to assist companies in realizing their core functions while we solve their problems creatively and through cutting-edge technology. With a strong foundation in engineering excellence and a commitment to delivering world-class services, Capstone is the trusted partner that organizations rely on for seamless project execution and sustainable growth.

1 note

·

View note

Text

Enhance your projects with expert BIM services, MEP coordination, and structural engineering solutions from SmartCADD. Get precise As-Built Drawings, clash detection, and efficient 3D modeling for seamless project execution.

#BIM services#MEP coordination#structural engineering#As-Built Drawings#clash detection#3D modeling#SmartCADD#construction technology#engineering solutions#building information modeling

0 notes

Text

Crafted for precision, strength, and durability. 💙 Our Blue Tempered Spring Steel Strips are designed to meet the toughest demands while maintaining flexibility and resilience. Perfect for springs, saw blades, and beyond. 🌟 Experience the unmatched performance of premium heat-treated steel.

#BlueSpring Steel#Tempered Steel#Steel strips#Spring Steel#Industrial Materials#Saw Blade Steel#Metal Craft#Heat Treated Steel#Engineering Solutions#Durable Materials

0 notes

Text

Metal Machining & Cylindrical Grinding: Precision at Its Finest

Metal machining and cylindrical grinding are essential processes in modern engineering, enabling the manufacturing of components with unparalleled precision and durability. These processes play a pivotal role in various industries, such as aerospace, automotive, power generation, and heavy machinery. From crafting new parts to repairing damaged ones, machining and grinding ensure components meet the most stringent requirements for size, finish, and functionality. At WWG Engineering, the Machining Workshop is the hub where these crucial operations take place, powered by state-of-the-art equipment and skilled professionals.

The Machining Workshop at WWG Engineering

The Machining Workshop at WWG Engineering was established with very specific objectives:

To manufacture new components and fabricate parts through machining and grinding.

To perform pre-machining and undercutting, preparing surfaces for Surface Engineering processes in both repair and new manufacturing.

To provide final machine turning, facing, and grinding finishing for Thermal Spray Coated, Cold Spray Coated, or Welded surfaces.

This well-equipped workshop allows WWG Engineering to offer comprehensive surface and cylindrical grinding capabilities. These capabilities enable the company to grind various materials on both external and internal faces, ensuring polished and finished components that meet the highest tolerances and form integrity. Whether it is for new manufacturing or repairing existing parts, the workshop stands as a center of precision and excellence in the field of metalworking.

Precision Metal Machining

Metal machining involves removing material from a work piece to achieve the desired shape, size, and finish. The process utilizes a wide range of tools, including lathes, milling machines, and horizontal boring machines, each selected based on the specific requirements of the job. At WWG Engineering, machining operations range from simple tasks such as threading to the creation of complex shapes like tapers and spheres.

One of the major strengths of WWG Engineering lies in its versatility. Whether a client needs small or large components, the workshop is equipped to handle it. The lathe machines in the workshop can accommodate work pieces from short to 10 meters long, offering flexibility for various machining needs. With its expertise in machining, WWG Engineering ensures that every project, from small parts to larger industrial components, is completed with precision and efficiency.

The Art of Cylindrical Grinding

Cylindrical grinding is a specialized form of grinding used to shape the exterior or interior of a workpiece, ensuring that it meets exact dimensional specifications. WWG Engineering offers both small and large cylindrical grinding machines, enabling the handling of a wide variety of work piece sizes. Whether grinding small shafts or large crankshafts, the team is experienced in producing highly polished, finished components to the tightest tolerances.

The process involves rotating the work piece around a central axis while it is ground with an abrasive wheel. This ensures even material removal and a smooth surface finish. Cylindrical grinding is commonly used to achieve fine tolerances, often in conjunction with other machining processes such as turning and milling. WWG Engineering excels in this field, offering grinding services that guarantee dimensional accuracy, surface finish, and form integrity.

Surface Engineering and Finishing

Metal surfaces often undergo additional treatments after machining or grinding to improve their durability, resistance to wear, or appearance. At WWG Engineering, surface engineering involves processes such as thermal spray coating, cold spray coating, and welding. After these treatments, the surfaces often require final finishing, which includes machine turning, facing, and cylindrical grinding.

The final finishing process is critical to ensuring that coated surfaces meet the exact specifications required for their intended applications. For instance, thermal spray-coated parts often need to be ground and polished to achieve a smooth, durable finish. WWG Engineering’s expertise in combining machining and grinding with advanced surface engineering technologies allows them to deliver high-quality, long-lasting components that meet the most demanding industry standards.

Comprehensive Machine Capability

WWG Engineering's workshop is equipped with a comprehensive range of machines, enabling it to undertake a variety of precision machining services. The available equipment includes:

Small, medium, and large lathe machines, capable of handling short to 10-meter-long work pieces.

Small and large cylindrical grinding machines, for external and internal grinding of different-sized components.

Small and large crankshaft grinding machines, for precision grinding of crankshafts.

Milling machines and other specialized tools for creating complex shapes and machining precise components.

Horizontal boring machines, used for machining large parts that require deep holes or large-diameter bores.

Polishing machines, used to achieve high-quality surface finishes after machining and grinding.

This extensive range of equipment allows WWG Engineering to provide efficient, effective solutions for various machining and grinding challenges. Whether it is manufacturing new components or repairing worn-out parts, the workshop’s capability ensures that all work is done to exacting standards, ensuring client satisfaction.

Expertise and Experience

WWG Engineering’s reputation in the field of metal machining and cylindrical grinding stems from its experience, expertise, and commitment to delivering high-quality results. The company has built a strong team of skilled machinists and engineers who work together to ensure that every project is completed with precision. From initial design to final finishing, the team’s attention to detail and focus on quality ensures that components meet the highest standards.

With advanced technologies and a deep understanding of machining and grinding processes, WWG Engineering continues to be a trusted partner for industries that require precision-engineered components. Whether you need simple machining tasks or complex grinding services, WWG Engineering is equipped to provide solutions tailored to your exact needs.

Conclusion

Metal machining and cylindrical grinding are critical processes that ensure the precision, functionality, and longevity of industrial components. At WWG Engineering, the Machining Workshop stands as a testament to the company’s commitment to delivering high-quality, reliable machining and grinding services. With a comprehensive range of machines and equipment, as well as a team of skilled professionals, WWG Engineering continues to push the boundaries of precision engineering, delivering solutions that meet the most demanding industry standards.

#Surface Engineering Technology#Engineering Service Company#Engineering Service Provider#Engineering Solutions#Cylindrical Grinding Machine#Metal Machining Services in Singapore

0 notes

Text

Boost Your Projects with Premium Brass Tube Fittings!

Looking for reliable and durable connections for your piping systems? Look no further! Our Brass Tube Fittings are designed to deliver exceptional performance across various industries.

🔑 Key Features: ✅ Corrosion-resistant for extended service life ✅ Leak-proof and secure connections ✅ Easy to install and maintain ✅ Suitable for high-pressure and high-temperature applications

🏗️ Perfect for use in: ✔️ Oil & gas ✔️ Chemical processing ✔️ Plumbing systems ✔️ Automotive and more!

Upgrade your fittings for a smooth, efficient, and reliable system! Explore our range today at avlok.com.

0 notes

Text

Understanding Aerodynamic Performance: A Study on Passenger Cars

The field of aerodynamics plays a critical role in the automotive industry, as it directly impacts a vehicle’s fuel efficiency, speed, stability, and overall performance. At Graphler Technology Solutions, we recently conducted an aerodynamic simulation of a passenger car to assess and optimize its aerodynamic performance. Here’s an overview of the key elements of this study and its outcomes.

1.Objective of the Study

The primary goal of this aerodynamic analysis was to evaluate the aerodynamic torsor, which includes both drag and lift forces acting on the car. Additionally, the study focused on the flow features around the vehicle, including the wake and bodywork. These analyses are essential for improving vehicle design by minimizing drag, enhancing stability, and increasing fuel efficiency.

2.Methodology: Wind Tunnel Simulation

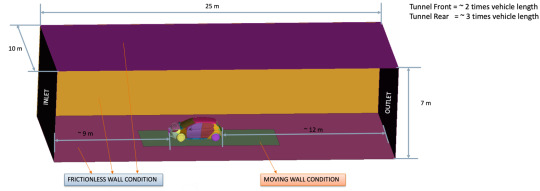

The study utilized a wind tunnel simulation setup, with specific boundary conditions replicating real-world scenarios. The tunnel design ensured that the aerodynamic features of the vehicle could be accurately observed:

Tunnel Front: ~2 times the vehicle length.

Tunnel Rear: ~3 times the vehicle length.

The boundary conditions included an inlet velocity, pressure outlet, frictionless walls, and a moving belt to simulate ground movement. Additionally, tires, rims, brakes, and air intake were modeled with realistic conditions such as angular velocities and mass flow.

Vehicle Parameters

The vehicle dimensions used in the study were as follows:

Length (X-axis): 4009.67 mm

Width (Y-axis): 1996.85 mm

Height (Z-axis): 1443.07 mm

These dimensions were crucial in determining the drag and lift forces experienced by the vehicle during the analysis.

3.Key Deliverables

The outputs of the study offered valuable insights into the vehicle’s aerodynamic performance:

Aerodynamic Torsor:

Global and Discretized Data: The analysis provided both global and specific measurements for the drag and lift forces on various parts of the vehicle.

Bodywork Analysis:

Parts Contribution to Drag and Lift: A detailed breakdown of the aerodynamic forces contributed by different regions of the vehicle, such as the superstructure, wheels, under the hood, and floor, helped pinpoint areas for potential improvements.

Flow Analysis:

Pressure Coefficient (CP) Distribution: This analysis was performed along the vehicle’s body to map pressure variations, which influence drag and lift.

Wake Analysis: The wake region, critical for vehicle stability, was analyzed using tomography. Velocity, pressure, and pathlines in the wake were studied to better understand airflow patterns behind the vehicle.

4.Practical Applications

Understanding how drag and lift forces impact a vehicle allows for more efficient design choices. For instance, reducing drag enhances fuel efficiency, while controlling lift improves vehicle stability at high speeds. Our comprehensive aerodynamic analysis provides the necessary data to make informed design adjustments, whether for mass production cars or specialized racing vehicles.

Conclusion

Through this simulation, Graphler Technology Solutions continues to demonstrate its commitment to providing innovative engineering solutions. By analyzing and refining aerodynamic performance.

Graphler Technology, one of the best Product Design Companies and CFD consulting services providers. We also specialize in stress analysis services, structural analysis services, and structural design services. For more information on night purging and how you can incorporate it into your next project, please feel free to contact us today.

0 notes

Text

0 notes