#Industrial Processes

Text

Waste Heat Revolution at Industrial Heat Transfer Inc for Sustainable Energy

Explore the forefront of sustainable energy with Industrial Heat Transfer waste heat recovery units. Unleash the potential of your industrial processes by capturing and repurposing heat intelligently. Call now 608.452.3103.

0 notes

Text

Understanding the Landscape of China Compressor Industry

The advancing automotive as well as construction sectors in China have boosted the need for compressors in this nation, aiding these advancements. Moreover, compressors also play a key role across different sectors in this nation.

In this blog, we’ll be exploring the reasons for the increasing demand for compressors in China:

Increasing Industrialization

It is no secret that China’s extremely…

View On WordPress

#China Compressor Market#competitive environments#Construction#industrial processes#Manufacturing#Market dynamics#market trends#regulatory landscapes#strategic decisions#Technological advancements

0 notes

Text

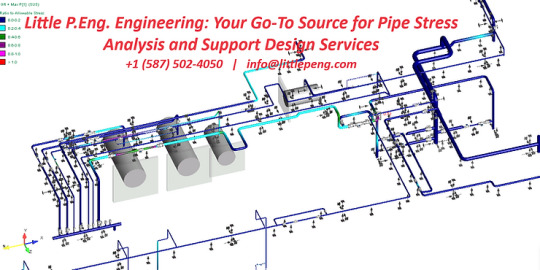

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

In the vast and complex world of engineering, precision and accuracy are paramount. Nowhere is this truer than in the field of piping systems, where even the smallest miscalculation or oversight can lead to catastrophic consequences. To ensure the safe and efficient operation of piping systems, the expertise of specialized engineers is required. This is where Little P.Eng. Engineering comes into play. With a reputation for excellence and a commitment to providing top-notch pipe stress analysis and support design services, Little P.Eng. Engineering stands as a trusted partner for industries that rely on flawless piping systems.

In this comprehensive guide, we will delve into the world of pipe stress analysis and support design services offered by Little P.Eng. Engineering. We will explore the importance of these services, their role in various industries, and how Little P.Eng. Engineering excels in delivering tailored solutions. Additionally, we will discuss the key factors that set Little P.Eng. Engineering apart from the competition and provide valuable insights into their commitment to safety, quality, and customer satisfaction.

Chapter 1: Understanding Pipe Stress Analysis

1.1 What is Pipe Stress Analysis?

Pipe stress analysis is a critical component of engineering that involves evaluating the forces and stresses acting on a piping system to ensure its structural integrity and safety. It plays a pivotal role in various industries, including petrochemical, oil and gas, power generation, and more. Pipe stress analysis helps engineers identify potential issues such as excessive strain, deformation, or failure that could compromise the functionality and safety of the system.

1.2 The Importance of Pipe Stress Analysis

The significance of pipe stress analysis cannot be overstated. Failing to perform adequate stress analysis can lead to a range of problems, including:

1.2.1 Safety Risks: Inadequate pipe stress analysis can result in ruptures, leaks, and catastrophic failures, endangering human lives and the environment.

1.2.2 Cost Overruns: Repairs and maintenance due to unforeseen issues can lead to substantial cost overruns in construction and operation projects.

1.2.3 Downtime: Unscheduled downtime can disrupt operations, leading to production losses and revenue reduction.

1.2.4 Legal and Regulatory Issues: Non-compliance with safety standards and regulations can result in legal and financial repercussions.

1.2.5 Reputation Damage: Incidents related to piping system failures can tarnish a company's reputation.

Chapter 2: The Role of Pipe Stress Analysis in Different Industries

2.1 Oil and Gas Industry

The oil and gas industry relies heavily on complex piping systems to transport hydrocarbons from extraction sites to refineries and end-users. Pipe stress analysis is crucial in this industry to prevent leaks, ruptures, and environmental disasters. Little P.Eng. Engineering provides specialized services tailored to the unique challenges of the oil and gas sector.

2.2 Petrochemical Industry

Petrochemical plants process raw materials into valuable chemical products. The precise and safe transport of chemicals through piping systems is essential. Pipe stress analysis ensures the structural integrity of these systems, mitigating the risk of chemical leaks and ensuring worker safety.

2.3 Power Generation

Power plants, whether they run on fossil fuels, nuclear energy, or renewable sources, require intricate piping networks to deliver steam, water, and gases to turbines and generators. Pipe stress analysis is vital to prevent system failures and maintain uninterrupted power generation.

2.4 Pharmaceutical and Food Industries

In industries where product purity and safety are paramount, such as pharmaceuticals and food production, pipe stress analysis ensures the integrity of sanitary piping systems. Little P.Eng. Engineering's expertise extends to designing hygienic piping solutions that meet the strictest standards.

2.5 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in commercial and industrial buildings rely on complex piping networks. Proper stress analysis ensures the efficient functioning of HVAC systems, contributing to comfort and energy efficiency.

Chapter 3: Little P.Eng. Engineering's Pipe Stress Analysis Services

3.1 Expertise and Experience

Little P.Eng. Engineering boasts a team of highly skilled and experienced engineers with a deep understanding of the complexities involved in pipe stress analysis. Their expertise spans various industries, ensuring that clients receive tailored solutions that align with their specific needs and challenges.

3.2 Advanced Technology and Software

Staying at the forefront of technological advancements is crucial in the engineering field. Little P.Eng. Engineering utilizes state-of-the-art software and tools for pipe stress analysis, enabling precise simulations and evaluations. This ensures the accuracy and reliability of their services.

3.3 Customized Solutions

One of the key strengths of Little P.Eng. Engineering is their ability to provide customized solutions. They understand that each project is unique and may have distinct requirements. By tailoring their services to individual client needs, they ensure optimal results and client satisfaction.

3.4 Compliance with Industry Standards

Compliance with industry standards and regulations is non-negotiable in the world of engineering. Little P.Eng. Engineering ensures that all their pipe stress analysis services meet or exceed relevant industry standards, codes, and safety guidelines.

Chapter 4: Pipe Support Design Services

4.1 What is Pipe Support Design?

Pipe support design is an integral part of piping system engineering. It involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibration, and stress. Proper support design ensures the longevity and stability of piping systems.

4.2 Importance of Pipe Support Design

Inadequate or improperly designed supports can lead to several problems, including:

4.2.1 Excessive Stress: Unsupported piping can experience undue stress, leading to damage and failure.

4.2.2 Vibrations: Vibrations can affect the performance of piping systems and nearby equipment.

4.2.3 Misalignment: Improper alignment can cause leaks and inefficiencies.

4.2.4 Premature Wear: Unsupported piping can wear out faster, leading to maintenance and replacement costs.

4.3 Little P.Eng. Engineering's Pipe Support Design Services

Little P.Eng. Engineering offers comprehensive pipe support design services to ensure that piping systems are adequately supported and stable. Their services include:

4.3.1 Structural Analysis: Evaluating the structural integrity of supports and ensuring they meet safety and code requirements.

4.3.2 Custom Designs: Tailoring support solutions to the unique needs of each project.

4.3.3 Material Selection: Recommending suitable materials for support components, considering factors like corrosion resistance and load-bearing capacity.

4.3.4 Installation Guidance: Providing guidance and recommendations for the proper installation of supports.

Chapter 5: What Sets Little P.Eng. Engineering Apart

5.1 Commitment to Safety

Safety is Little P.Eng. Engineering's top priority. Their pipe stress analysis and support design services are driven by a commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

5.2 Quality Assurance

Quality is woven into the fabric of Little P.Eng. Engineering's services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

5.3 Timely and Efficient Service

Time is often of the essence in engineering projects. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality.

5.4 Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process.

5.5 Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members.

Chapter 6: Case Studies and Success Stories

6.1 Case Study 1: Oil Refinery Piping

A major oil refinery faced ongoing issues with leaks and failures in its piping system, resulting in costly downtime and environmental concerns. Little P.Eng. Engineering conducted a comprehensive pipe stress analysis and identified critical stress points. They then designed and implemented reinforced supports and provided guidance on material selection. The result was a significant reduction in incidents, ensuring safe and uninterrupted operations.

6.2 Case Study 2: Pharmaceutical Facility

A pharmaceutical company needed to upgrade its piping system to comply with stringent FDA regulations. Little P.Eng. Engineering provided customized pipe stress analysis and support design services to ensure compliance with hygienic standards. The project was completed successfully, allowing the company to maintain product integrity and regulatory compliance.

6.3 Case Study 3: Power Plant Efficiency

A power plant was experiencing inefficiencies in its piping system, resulting in reduced energy output. Little P.Eng. Engineering conducted a detailed pipe stress analysis and identified areas of improvement. They designed and implemented optimized supports, resulting in increased energy efficiency and cost savings.

Chapter 7: Conclusion

In conclusion, Little P.Eng. Engineering stands as a premier provider of pipe stress analysis and support design services, catering to various industries where the integrity and safety of piping systems are of utmost importance. Their commitment to safety, quality, client satisfaction, and continuous improvement sets them apart as a trusted partner in the world of engineering.

Whether you operate in the oil and gas, petrochemical, power generation, pharmaceutical, or HVAC sector, Little P.Eng. Engineering has the expertise and experience to deliver customized solutions that meet your unique needs. By prioritizing safety, adhering to industry standards, and consistently providing timely and efficient services, Little P.Eng. Engineering has earned its reputation as a leader in the field of pipe stress analysis and support design.

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Pipe Stress Analysis

Little P.Eng. Engineering

Finite Element Analysis

Structural Integrity

Engineering Expertise

Thermal Expansion

Support Design Services

Oil and Gas

ASME Codes

Industry Standards

Power Generation

Stress Evaluation

Piping Systems

Safety and Compliance

Engineering Solutions

Precision Analysis

Industrial Processes

Petrochemical

Seismic Analysis

Customized Solutions

Pressure Analysis

Pipe Support Design

Safety Regulations

Reliability Assurance

Complex Piping Systems

Chemical Industry

Pharmaceutical Industry

Vibrations Analysis

Stress Distribution

Pipe Failure Prevention

Pipe Stress Analysis Services

Engineering Services

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Pipe Stress Analysis#Little P.Eng. Engineering#Finite Element Analysis#Structural Integrity#Engineering Expertise#Thermal Expansion#Support Design Services#Oil and Gas#ASME Codes#Industry Standards#Power Generation#Stress Evaluation#Piping Systems#Safety and Compliance#Engineering Solutions#Precision Analysis#Industrial Processes#Petrochemical#Seismic Analysis#Customized Solutions#Pressure Analysis#Pipe Support Design#Safety Regulations#Reliability Assurance#Complex Piping Systems#Chemical Industry#Pharmaceutical Industry#Vibrations Analysis#Stress Distribution

0 notes

Text

What are the main parts of chiller?

WHAT IS A CHILLER & HOW DOES IT WORK? | INDUSTRIAL CHILLER.

Chillers consist of four essential components; an evaporator, a compressor, a condenser, and an expansion unit. In addition, every chiller system contains a refrigerant.

A chiller is a vital component in air conditioning and industrial cooling systems, consisting of several key parts that work together to remove heat from a space or process. The main parts of a chiller include the compressor, evaporator, condenser, and expansion valve.

Compressor: This is the heart of the chiller, responsible for compressing the refrigerant gas. It raises the pressure and temperature of the refrigerant, preparing it for the cooling process.

Evaporator: The evaporator absorbs heat from the surrounding environment or a process fluid, causing the refrigerant to evaporate and turn into a low-pressure, low-temperature gas. This chilled gas is then sent to the compressor to restart the cycle.

Condenser: The condenser releases the heat absorbed by the refrigerant in the evaporator. It transforms the high-pressure, high-temperature gas into a high-pressure liquid by dissipating the heat into the air or another cooling medium.

Expansion Valve: This valve regulates the flow of the refrigerant, reducing its pressure and temperature before it enters the evaporator. This process allows the refrigerant to absorb heat efficiently in the evaporator.

These components work in a continuous cycle, facilitating the transfer of heat and maintaining the desired temperature in various applications, from commercial buildings to industrial processes.

#What are the main parts of chiller#chiller#Chillers#compressor chillers systems#compressor to restart#condenser cooling process#evaporator#expansion valv ehigh-temperature#industrial cooling systems#industrial processes#low-temperature#garefrigerant gas#Reynold india#Water Chillers

0 notes

Text

Innovation in Heat Generation: The Role of Coal Fired Boilers

Coal-fired boilers have been a mainstay of heat generation for centuries, but innovation in the field is transforming them into even more dependable and sustainable sources of heat. From state-of-the-art combustion techniques to environmentally conscious designs, coal-fired boilers are meeting the needs of industries while also reducing their environmental impact. we explore the synergy between tradition and innovation in the world of coal-fired boilers. We delve into some of the most transformative innovations that have elevated these boilers to new heights, and showcase how they are helping industries to achieve their sustainability goals. For more information contact us at https://www.thermodyneboilers.com/coal-fired-boiler-manufacturer-in-india/

#Coal Fired Boilers#Heat Generation#Sustainability#Energy Efficiency#Environmental Impact#Industrial Processes#Boiler Innovations

0 notes

Text

Chemical plants produce large quantities of basic chemicals used in everyday consumer goods, industrial processes and research laboratories.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#chemical plant#chemicals#consumer goods#industrial processes#research laboratory#manufacturing

0 notes

Text

It seems like traditionally milling is done by starting with a rectangular prism stock block, then removing everything you don’t want, often like 80+% of the material. I’m wondering about the viability of using some low-resolution process like sand-casting, or maybe in a more modern twist, crappy low-res metallic 3D printing, to create a form that’s almost like the final form (but strictly larger), then milling to finish. An extra step, but it would save a lot on material, milling time, and tool wear. Is that ever done? Does anyone find it worthwhile?

1 note

·

View note

Text

Me: Hey film studios can I have some light in these scenes?

Film studios:

Me: Hey can I have some subtitles?

Film studios:

Me: Hey can I have some actual sound?

Film studios:

[id in alt text]

32K notes

·

View notes

Text

Oil Mist Detector for Marine Safety | Auto2mation

Stay safe with Auto2mation's marine automation oil mist detector. Protect your marine engines from oil mist with our high-quality and reliable detector.

0 notes

Text

I think 90% of my gripes with how modern anime looks comes down to flat color design/palettes.

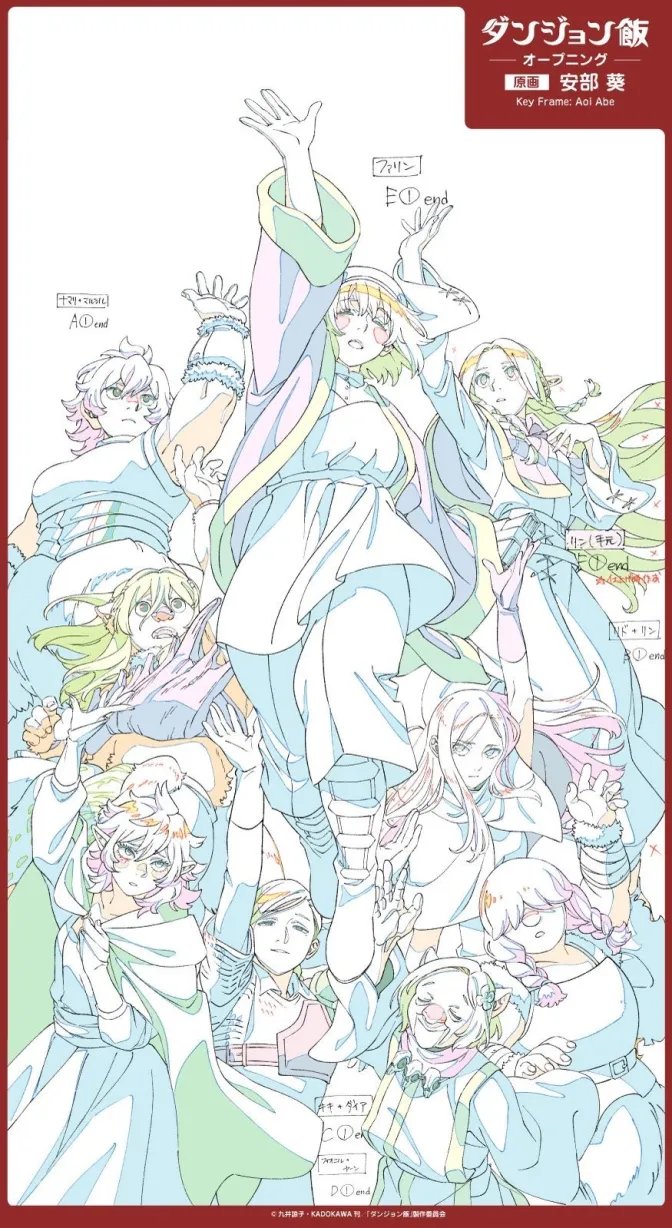

Non-cohesive, washed-out color palettes can destroy lineart quality. I see this all the time when comparing an anime's lineart/layout to its colored/post-processed final product and it's heartbreaking. Compare this pre-color vs. final frame from Dungeon Meshi's OP.

So much sharpness and detail and weight gets washed out and flattened by 'meh' color design. I LOVE the flow and thickness and shadows in the fabrics on the left. The white against pastel really brings it out. Check out all the detail in their hair, the highlights in Rin's, the different hues to denote hair color, the blue tint in the clothes' shadows, and how all of that just gets... lost. It works, but it's not particularly good and does a disservice to the line-artist.

I'm using Dungeon Meshi as an example not because it's bad, I'm just especially disappointed because this is Studio Trigger we're talking about. The character animation is fantastic, but the color design is usually much more exciting. We're not seeing Trigger at their full potential, so I'm focusing on them.

Here's a very quick and messy color correct. Not meant to be taken seriously, just to provide comparison to see why colors can feel "washed out." Top is edit, bottom is original.

You can really see how desaturated and "white fluorescent lighting" the original color palettes are.

[Remember: the easiest way to make your colors more lively is to choose a warm or cool tint. From there, you can play around with bringing out complementary colors for a cohesive palette (I warmed Marcille's skintone and hair but made sure to bring out her deep blue clothes). Avoid using too many blend mode layers; hand-picking colors will really help you build your innate color sense and find a color style. Try using saturated colors in unexpected places! If you're coloring a night scene, try using deep blues or greens or magentas. You see these deep colors used all the time in older anime because they couldn't rely on a lightness scale to make colors darker, they had to use darker paints with specific hues. Don't overthink it, simpler is better!]

#not art#dungeon meshi#rant#i'm someone who can get obsessive over colors in my own art#will stare at the screen adjusting hues/saturation for hours#luckily i've gotten faster at color picking#but yeah modern anime's color design is saddening to me. the general trend leans towards white/grey desaturated palettes#simply because they're easier to pick digitally#this is not the colorists fault mind you. the anime industry's problems are also labor problems. artists are severely underpaid#and overworked. colorists literally aren't paid enough to do their best#there isn't a “creative drought” in the anime industry. this trend is widespread across studios purely BECAUSE it's not up to individuals#until work conditions improve anime will unfortunately continue to miss its fullest potential visually#don't even GET ME STARTED ON THE USE OF POST-PROCESSING FILTERS AND LIGHTING IN ANIME THOUGH#SOMEONE HOLD ME BACK. I HATE LENS FLARES I HATE GRADIENT SHADING I HATE CHROMATIC ABBERATION AND BLUR

2K notes

·

View notes

Text

The Buzz on the Wax Market: Applications and Demand

Wax, a multipurpose and time-tested material, has played an important role in many sectors and working throughout history. Presently, the wax industry continues to thrive, propelled by many applications and a rising demand for its unique features.

The wax market revenue is estimated at USD 10.6 billion in 2023, and it will advance at a CAGR of 4.9% between 2024 and 2030, to reach USD 14.7…

View On WordPress

#cosmetic industry#global industry#industrial processes#Key players#market trends#Packaging#sustainability trends#wax applications#wax market

0 notes

Text

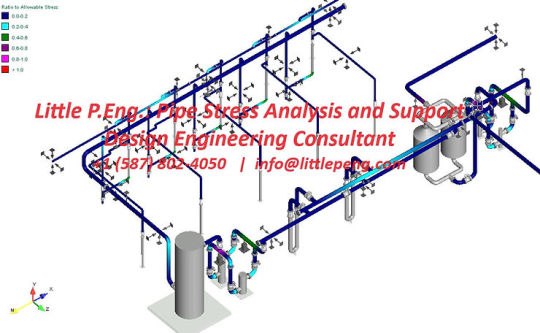

Little P.Eng.: Pipe Stress Analysis and Support Design Engineering Consultant

In the world of engineering, precision and safety are paramount, especially when it comes to piping systems. Any miscalculation or oversight can have severe consequences, ranging from safety hazards to costly downtime. This is where Little P.Eng. Engineering steps in as a trusted partner, providing expert pipe stress analysis and support design services to ensure the structural integrity and efficiency of piping systems across various industries.

With a reputation for excellence and a commitment to delivering tailored solutions, Little P.Eng. Engineering has established itself as a go-to engineering consultant for those seeking to optimize their piping systems.

Expertise in Pipe Stress Analysis

At the core of Little P.Eng.'s services is their expertise in pipe stress analysis. This crucial engineering discipline involves assessing the forces, stresses, and displacements acting on piping systems to ensure they operate safely and efficiently. Whether it's static stress analysis, dynamic stress analysis, thermal analysis, or seismic analysis, Little P.Eng. Engineering has a team of highly skilled engineers who are well-versed in these complex assessments.

Static stress analysis, for example, is employed to evaluate the stresses in stationary piping systems, ensuring they can withstand the pressures and loads they are subjected to during normal operation. Dynamic stress analysis, on the other hand, deals with transient conditions such as startup, shutdown, and water hammer, which can place additional stress on the system.

Ensuring Compliance with Standards

One of the hallmarks of Little P.Eng.'s services is their unwavering commitment to compliance with industry standards and codes. Piping systems must adhere to strict safety and regulatory guidelines, and Little P.Eng. Engineering ensures that all their analyses and designs meet or exceed these standards. Whether it's ASME, ANSI, API, ASTM, or local building codes, clients can trust that their projects are in full compliance.

Customized Solutions for Unique Needs

No two piping systems are identical, and Little P.Eng. Engineering understands this well. They excel in providing customized solutions that align with the specific needs and challenges of each project. Whether it's an oil refinery, a pharmaceutical facility, or a power plant, Little P.Eng.'s team tailors their services to ensure optimal results.

Support Design Expertise

In addition to pipe stress analysis, Little P.Eng. Engineering offers support design services that play a critical role in the stability and longevity of piping systems. Proper support design involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibrations, and stress.

Little P.Eng. Engineering's support design services encompass a range of aspects, including pipe support design, structural analysis, material selection, and installation guidance. These services are crucial in preventing issues like excessive stress, vibrations, misalignment, and premature wear in piping systems.

Commitment to Safety and Quality

Safety is Little P.Eng.'s top priority. Their pipe stress analysis and support design services are driven by a deep commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

Quality assurance is woven into the fabric of Little P.Eng.'s services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process. This approach fosters trust and transparency, key elements in successful engineering projects.

Timely and Efficient Service

In the world of engineering, time is often of the essence. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality. This ensures that clients can rely on them to meet their project deadlines and objectives.

Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members. This dedication to staying at the forefront of technological advancements allows them to provide cutting-edge solutions to their clients.

Little P.Eng.: Pipe Stress Analysis and Support Design Engineering Consultant

A Pipe Stress Analysis and Support Design engineering consultant offers a range of services to ensure the structural integrity, safety, and efficiency of piping systems in various industries. These services may include:

1. Pipe Stress Analysis:

Static Stress Analysis: Evaluating stresses, forces, and displacements in stationary piping systems.

Dynamic Stress Analysis: Assessing the effects of transient conditions, such as startup, shutdown, and water hammer.

Thermal Stress Analysis: Analyzing the impact of temperature variations on piping materials and components.

Seismic Analysis: Evaluating the response of piping systems to seismic forces and designing for earthquake resistance.

Fatigue Analysis: Predicting the fatigue life of components subjected to cyclic loading.

2. Support Design Services:

Pipe Support Design: Designing supports, hangers, and restraints to prevent excessive movement and stress in piping systems.

Structural Analysis: Evaluating the structural integrity of support structures and ensuring compliance with safety codes.

Material Selection: Recommending suitable materials for support components based on factors like load-bearing capacity and corrosion resistance.

Installation Guidance: Providing recommendations and specifications for the proper installation of supports.

3. Compliance with Standards and Codes:

Ensuring that all designs and analyses meet relevant industry standards, codes, and regulations, such as ASME, ANSI, API, ASTM, and local building codes.

Assisting clients in obtaining necessary permits and approvals for piping system installations or modifications.

4. Customized Solutions:

Tailoring pipe stress analysis and support design services to the specific needs and requirements of each project.

Developing unique solutions for complex or challenging piping system configurations.

5. Failure Analysis and Troubleshooting:

Investigating and diagnosing issues related to piping system failures, leaks, or performance problems.

Recommending corrective actions and retrofits to address identified problems.

6. Hygienic Piping Design (in industries like pharmaceuticals and food production):

Designing piping systems that comply with stringent sanitary and hygiene standards to prevent contamination.

Implementing design solutions that minimize dead legs, reduce the risk of bacterial growth, and facilitate cleaning and sterilization.

7. Stress Testing and Simulation:

Conducting computer simulations and modeling to predict stress and strain behavior under different operating conditions.

Performing load testing to validate the performance of pipe supports and restraints.

8. Energy Efficiency Optimization:

Identifying opportunities to improve energy efficiency by optimizing piping system configurations and insulation.

Recommending modifications to reduce heat loss or improve heat transfer.

9. Retrofit and Upgrade Design:

Developing plans and designs for the retrofit or upgrade of existing piping systems to meet current safety and performance standards.

Incorporating advanced technologies and materials for improved reliability and efficiency.

10. Documentation and Reporting:

Generating comprehensive reports, including stress analysis reports, design drawings, specifications, and installation instructions.

Maintaining accurate records of all analyses, designs, and project documentation.

11. Consulting and Expert Witness Services:

Providing expert consulting services for legal matters, including expert witness testimony in cases involving piping system failures or disputes.

12. Project Management and Coordination:

Overseeing and coordinating the implementation of recommended design changes or support installations to ensure proper execution.

Pipe Stress Analysis and Support Design engineering consultants play a crucial role in ensuring the safe and efficient operation of piping systems across various industries, and their services are vital for preventing failures, reducing downtime, and maintaining regulatory compliance.

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Little P.Eng.

ASME standards

Engineering expertise

Thermal expansion

Structural integrity

Regulatory compliance

Pipe stress analysis

Documentation

Industrial processes

Engineering consultant

Advanced software

Pressure changes

API standards

Maintenance costs

Optimization

ISO standards

Seismic events

Oil and gas industry

Custom support systems

Inspection readiness

Load-bearing capacities

Compliance standards

Piping systems

Power generation

Fluid dynamics

Petrochemical industry

Support design engineering

Troubleshooting

Temperature fluctuations

Safety analysis

Pipe Stress Analysis Services

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng.#ASME standards#Engineering expertise#Thermal expansion#Structural integrity#Regulatory compliance#Pipe stress analysis#Documentation#Industrial processes#Engineering consultant#Advanced software#Pressure changes#API standards#Maintenance costs#Optimization#ISO standards#Seismic events#Oil and gas industry#Custom support systems#Inspection readiness#Load-bearing capacities#Compliance standards#Piping systems#Power generation#Fluid dynamics#Petrochemical industry#Support design engineering#Troubleshooting#Temperature fluctuations

0 notes

Text

An innovation that propelled Britain to become the world’s leading iron exporter during the Industrial Revolution was appropriated from an 18th-century Jamaican foundry, historical records suggest.

The Cort process, which allowed wrought iron to be mass-produced from scrap iron for the first time, has long been attributed to the British financier turned ironmaster Henry Cort. It helped launch Britain as an economic superpower and transformed the face of the country with “iron palaces”, including Crystal Palace, Kew Gardens’ Temperate House and the arches at St Pancras train station.

Now, an analysis of correspondence, shipping records and contemporary newspaper reports reveals the innovation was first developed by 76 black Jamaican metallurgists at an ironworks near Morant Bay, Jamaica. Many of these metalworkers were enslaved people trafficked from west and central Africa, which had thriving iron-working industries at the time.

Dr Jenny Bulstrode, a lecturer in history of science and technology at University College London (UCL) and author of the paper, said: “This innovation kicks off Britain as a major iron producer and … was one of the most important innovations in the making of the modern world.”

The technique was patented by Cort in the 1780s and he is widely credited as the inventor, with the Times lauding him as “father of the iron trade” after his death. The latest research presents a different narrative, suggesting Cort shipped his machinery – and the fully fledged innovation – to Portsmouth from a Jamaican foundry that was forcibly shut down.

[...]

The paper, published in the journal History and Technology, traces how Cort learned of the Jamaican ironworks from a visiting cousin, a West Indies ship’s master who regularly transported “prizes” – vessels, cargo and equipment seized through military action – from Jamaica to England. Just months later, the British government placed Jamaica under military law and ordered the ironworks to be destroyed, claiming it could be used by rebels to convert scrap metal into weapons to overthrow colonial rule.

“The story here is Britain closing down, through military force, competition,” said Bulstrode.

The machinery was acquired by Cort and shipped to Portsmouth, where he patented the innovation. Five years later, Cort was discovered to have embezzled vast sums from navy wages and the patents were confiscated and made public, allowing widespread adoption in British ironworks.

Bulstrode hopes to challenge existing narratives of innovation. “If you ask people about the model of an innovator, they think of Elon Musk or some old white guy in a lab coat,” she said. “They don’t think of black people, enslaved, in Jamaica in the 18th century.”

847 notes

·

View notes

Text

Sustainable and Reliable Commercial steam boiler

Thermodyne is a leading manufacturer of commercial steam boilers. Our boilers are known for their high performance, efficiency, and reliability. We offer a wide range of boilers to meet the needs of a variety of applications, including industrial processes, power generation, and building heating. Our boilers are engineered to maximize energy efficiency, which can help you reduce your operational costs and environmental impact. We also incorporate eco-friendly features to limit emissions and resource consumption. For more information contact us at https://www.thermodyneboilers.com/

#Commercial steam boilers#Reliability#Energy efficiency#Sustainability#Heating solutions#Industrial processes

0 notes

Text

open ai made a little post about how they chose their chatbot voices and two things stood out to me:

a) I am genuinely pleased and surprised that the voices come from specific real people that they hired and paid, rather than being built off of all of the data open ai has scraped. the voice for siri did one job for one company 20 years ago and now she is literally everywhere without ever being compensated by apple or even acknowledged as the voice. there's simply no way she was paid enough in that original job. whereas, open ai says "each actor receives compensation above top-of-market rates, and this will continue for as long as their voices are used in our products." this could mean literally anything (what market rate are we going above? does continue mean they get residuals or get paid for doing more sessions?) but, christ, at least the actors are doing it with full knowledge of what their voices are being used for and can decide for themselves if the compensation is enough

b) the post talks about working with "award-winning casting directors" to get the voices. first of all, yay for paying casting directors! we love to see it. but they also say the CDs received over 400 submissions in a week and they state that like a big number and it's just...not at all. and look, without knowing the intricacies of the casting process, it's hard to know what approach the CDs took - it's very possible they were selective from the jump and 400 is a lot from the pool they were tapping. 400 would be a lot if you were going to the agencies directly and asking for names, but there's just no way in hell open ai went after big stars for this. so it would've been a pool of unknowns. in which case, 400 is laughably small. even if you're not using the big casting sites like actorsaccess, I've worked on projects with CDs and their own internal systems where we've gotten over 100 submissions for a single role. I've posted roles on casting sites and received literally thousands of submissions in just a few days

look, I have a very limited perspective on this - I am not a casting director (imo, one of the most important and undervalued jobs in hollywood) and I, in fact, hate the process of casting with a passion. but 400 just seemed like such a tiny pool to pull from and, idk, it heartens me! it's heartening to think that there's very little interest from actors and agents to be doing this kind of stuff. and absolutely no shade to the actors who did--I want actors to get their bag however they want as long as it's, like, safe sane and consensual, you know? but there's something encouraging about thinking that open ai hired some big casting agency to get their foot into the voice acting door and people didn't come running

#ai#entertainment industry#lauren takes too long to say things#I am not anti-AI#mostly because I can tell when I've lost a war and need to figure out how to live with my new overlords lol#but also bc chat has genuinely been helpful for writing research!#(more in the sense that it helps me narrow down what I need to do real research on)#(bc the information it gives is often wrong)#but I am of COURSE concerned about how it's going to affect my industry#and if you've been following me for a while you probably saw my sag posting last summer during the strike#and given the contract sag got around AI#actors disinterest is THEE cudgel with which we will beat this stuff down#so the fact that the most popular AI company in the world had 400 people to choose from#is nice to my ears!!!!#(assuming of course that I'm correct about their process)#plus I'm just so RELIEVED that they actually hired people to do this#that's all that really matters - consent#if you're an actor and you give your voice to an AI company that will use it forever#as long as you KNOW that#and you have someone looking over a contract for you#more power to you!

55 notes

·

View notes

Text

My growth as an artist was heavily stifled by the dogmatism in the online art community I was subjected to as a teen (aka by rhetoric implying or straight up saying art has to be made a certain way to be valuable, which discouraged me from experimenting and developing for my own methods, customising my artistic process felt illegal) and i will forever be mad about it

Anyways if any young artist follows me : the only good art advice is get weird about it and fuck around a lot. Also be honest

#sam speaks#art advice#lol#this isn’t discrediting advice that’s like pls learn the basics and here’s how to get better at anatomy#this is pointed towards those artists that act like lineart is a given in tutorials#thankfully I’ve seen more and more ppl divorce from the lineart industrial complex#also *insert rant about the internet and mainstream culture’s bias towards smooth art#and how it reveals society’s desire to forget the artist#atsv and itsv ? breeze of fresh air BECAUSE it is innovative artistic processes#and places the human feels of strokes at the center

354 notes

·

View notes