#fabric net for filtration

Explore tagged Tumblr posts

Text

Understanding Filter Fabric: Key Uses and Benefits

What is Filter Fabric?

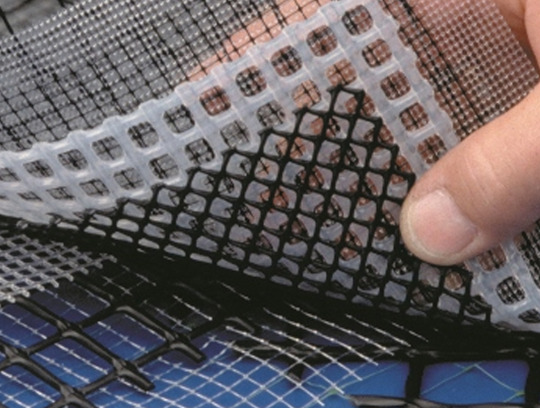

Filter fabric, also known as geotextile fabric, is a versatile material used in various applications for filtration, separation, and reinforcement. It is typically made from synthetic fibers such as polyester or polypropylene, designed to allow water to pass through while trapping soil and other particles. This unique property makes filter fabric an essential component in numerous industries and environmental projects.

Applications of Filter Fabric

Construction and Landscaping: In construction and landscaping, filter fabric is used to prevent soil erosion, improve drainage, and stabilize soil. It is often placed under gravel, sand, or soil to maintain separation and allow water to flow through, reducing the risk of soil displacement and erosion.

Road and Railway Construction: Filter fabric is used in road and railway construction to reinforce the base layers and improve drainage. By preventing the mixing of different soil layers, it enhances the stability and longevity of the infrastructure.

Agriculture: In agriculture, filter fabric is utilized for soil stabilization and erosion control. It is also used in drainage systems to filter out sediments and prevent clogging, ensuring efficient water management.

Environmental Protection: Filter fabric plays a critical role in environmental protection projects. It is used in sediment control, water filtration, and containment of hazardous materials. This helps in reducing pollution and preserving natural habitats.

Types of Filter Fabric

There are two main types of filter fabric: woven and non-woven.

Woven Filter Fabric: Made by weaving individual threads together, woven filter fabric is strong and durable. It is typically used in applications requiring high tensile strength and resistance to punctures and tears.

Non-Woven Filter Fabric: Produced by bonding fibers together, non-woven filter fabric is more flexible and has better filtration properties. It is commonly used in drainage systems and for soil stabilization where permeability is a key factor.

Benefits of Using Filter Fabric

Erosion Control: By preventing soil erosion, filter fabric helps maintain the integrity of landscapes and construction sites, protecting against the loss of valuable topsoil.

Improved Drainage: Filter fabric allows water to pass through while filtering out sediments, improving drainage efficiency and preventing waterlogging.

Soil Stabilization: By keeping different soil layers separate, filter fabric enhances the stability and load-bearing capacity of soil, which is essential for construction and agricultural applications.

Environmental Protection: Using filter fabric in environmental projects helps reduce sediment runoff, control pollutants, and protect water bodies and ecosystems.

Filter fabric is a crucial material with diverse applications across various industries. Its ability to filter, separate, and reinforce makes it an invaluable resource in construction, agriculture, and environmental protection. Understanding its uses and benefits can help in selecting the right type of filter fabric for specific projects, ensuring effective and sustainable outcomes.

#filter fabric manufacturers#filter fabric supplier#filter fabric manufacturers in india#fabric net for filtration#Filter fabric

0 notes

Text

Top Wire Mesh Manufacturers

If you are seeking a wire mesh manufacturer who you can trust and has a good reputation, the first thing you need to learn is what ihars did to realize the characteristics and attributes of a manufacturer. There are several great wire mesh manufacturers, (the best wire mesh manufacturers) where you can not wrong with your wire mesh requirements because they get, better, best in all characteristics - quality, innovator, service provider. Best wire mesh manufacturers produce a good variety of wire mesh quality wire mesh products products specifically for the construction, agriculture, mining, filtration/ ventillation, and security industries.

Wire mesh ( there are many other names wire cloth, wire fabric) is product from woven or interwoven wire. There are literally innumerable applications of wire mesh, include, but not limited to fabric ( sectional, permanent or gasket) reinforcements, concrete reinforcement, fencing, partitioning, filtering, etc. The characteristics and strength of wire and wire mesh for our literal definitions are defined primarily by: materials, production methods, and finishing treatments. Best wire mesh manufacturers, since they opened up to when the business incorporated, have always operated with wire mesh building products and have incorporated the top quality materials like stainless steel wire, galvanised wire and other rust resistant materials; so it is now easy to see why Best Wire Mesh Manufacturers is the best.

What you will discover when buying wire mesh products from the Best Wire Mesh Manufactures is the selection of products that can be small fin mesh for industrial filtration or cut to size hand welded or machine lofted heavy duty mesh for service entry and exit points, having completely considered the scope of the competition from independently determining your own respective workflow on site; in this regard all wire mesh products are manufactured to be fit for service and fit for industry, you should be encouraged regardless whether you receive wire mesh large quantities as a project or single items outside of the project & separately, and the project will not suffer negatively from service or measured safety products.

Address:H.O:K-245,Pushta Road,Karawal Nagar,Shahdara,Delhi-94 K-46,Sector-5,Bhawana,Delhi-39

0 notes

Text

Melt blown nonwoven machine

Melt blown nonwoven machine Melt Blown Machine

MACHINE SPEED:10-70 M/MIN

FILAMENT DENIER:1.6~4μm

FABRIC WEIGHT:18~300GSM

RAW MATERIAL: MFI 800~1600

DELIVERY TIME:3-6 MONTHS

Melt blown fabric applicants:

Melt blown nonwoven fabric is composed of a narrow diameter distribution and a low degree of fiber filling thereof.This nonwoven fabric has a soft and elastic properties, and also has excellent filtration performance.

The main raw material of melt-blown cloth is polypropylene with high melt index, a film formed by laminating many criss-cross fibers in random directions. The fiber diameter is about one-thirtieth of that of hair. .

The process of melt-blown cloth: polymer feeding-melt extrusion-fiber formation-fiber cooling-netting-reinforcement into cloth.

Usage of melt blown fabric:

Face mask middle layer,sound insulation for car,oil absorption sheet.

+8613621544385

0 notes

Text

Role of Accredited Labs in Verifying Agro Textiles for Crop Protection

In the world of modern agriculture, the demand for crop protection solutions that are efficient, eco-friendly, and cost-effective has never been higher. Agro textiles—such as shade nets, insect-proof screens, mulch mats, and greenhouse covers—have emerged as essential tools for improving crop yield, protecting plants from pests, regulating climate, and conserving water. However, the effectiveness of these materials depends significantly on their quality and performance under field conditions. This is where Agro Textiles Testing by accredited laboratories becomes indispensable.

This blog explores how accredited labs play a critical role in verifying agro textiles to ensure they meet crop protection requirements and comply with industry standards.

What are Agro Textiles?

Agro textiles are specially designed technical fabrics used in agriculture and horticulture for various protective and enhancement purposes. These textiles are primarily made from synthetic polymers like polypropylene (PP), polyethylene (PE), and polyester. Key applications include:

Shading crops from excessive sunlight

Preventing insect and bird intrusion

Reducing weed growth

Retaining soil moisture

Controlling temperature and humidity in greenhouses

Given their continuous exposure to sun, wind, chemicals, and mechanical stress, the performance and reliability of agro textiles must be verified through rigorous testing.

Importance of Agro Textiles Testing for Crop Protection

Agro textiles are designed to offer physical protection, microclimate control, and pest resistance. Their failure due to poor material quality or improper installation can lead to:

Reduced crop yields

Increased pest infestations

Soil degradation

Economic losses for farmers

To prevent such issues, agro textiles must be tested for:

UV stability and light filtration

Tensile and tear strength

Air and water permeability

Thermal aging and durability

Chemical resistance to fertilizers and pesticides

Only accredited labs have the infrastructure and certification to carry out these tests using standardized methodologies.

Who are Accredited Labs?

An accredited laboratory is a testing facility that meets the requirements of international quality standards, such as ISO/IEC 17025. Accreditation is granted by authorized bodies such as:

NABL (National Accreditation Board for Testing and Calibration Laboratories) – India

UKAS (United Kingdom Accreditation Service) – UK

A2LA (American Association for Laboratory Accreditation) – USA

DAkkS (German Accreditation Body) – Germany

Accredited labs ensure that their results are accurate, reproducible, and recognized globally. Their role in verifying agro textiles includes testing, certification, and sometimes, product development support.

Role of Accredited Labs in Verifying Agro Textiles

1. Conducting Standardized Tests

Accredited labs use globally accepted testing methods such as:

ISO 13934-1: Tensile strength of woven fabrics

ISO 4892-2: UV resistance through accelerated weathering

ASTM D5035: Grab test for fabric strength

IS 16008: Indian standards for shade nets and mulch mats

These standardized procedures ensure that the agro textiles are tested under controlled and repeatable conditions.

2. Evaluating Material Durability

Accredited labs simulate long-term usage of agro textiles by exposing them to:

UV light to test degradation

High and low temperatures to assess thermal aging

Mechanical stress to test wear and tear

This helps determine if a material can withstand multiple crop cycles without failing.

3. Verifying Crop-Specific Protection

Different crops have different environmental needs. For example:

Tomatoes require 30–50% shade nets

Lettuce may need insect-proof nets with specific mesh sizes

Grapes benefit from reflective ground covers for light management

Accredited labs test agro textiles for light transmission, air flow, permeability, and mesh density to match the textile’s performance to the crop’s requirements.

4. Ensuring Chemical Safety

Agro textiles may come into contact with fertilizers, pesticides, and herbicides. Accredited labs evaluate:

Resistance to chemical degradation

Leaching of harmful substances

Effect of cleaning agents and sprays

This ensures that the textiles do not degrade prematurely or harm the soil and crops.

5. Compliance with Export and Regulatory Standards

For manufacturers and exporters, accredited testing is essential for meeting:

REACH compliance in Europe

IS 16008 and BIS standards in India

OEKO-TEX certification for textiles near food products

GMP and GAP certifications for organic and high-value crops

Accredited labs issue valid certificates that are accepted by government bodies, buyers, and international markets.

6. Product Labeling and Quality Assurance

Based on the results from accredited labs, manufacturers can confidently label their products with:

Shade percentage (e.g., 50% or 75% shade net)

Lifespan (e.g., UV-stabilized for 5 years)

Mesh size (e.g., 40-mesh insect net)

Tensile and tear strength ratings

This transparency builds trust among buyers and farmers, and reduces the risk of field failure.

Benefits of Using Accredited Labs for Agro Textiles Testing

Benefit

Impact

Reliable Results

High accuracy and reproducibility in testing data

Global Recognition

Test reports accepted by international buyers and regulators

Quality Validation

Helps manufacturers differentiate their products

Reduced Crop Loss

Verified textiles reduce the risk of product failure in field

Regulatory Compliance

Ensures agro textiles meet mandatory government and export standards

Real-World Applications

✅ Greenhouses

Accredited labs test films for light transmission, thermal insulation, and anti-drip properties—ensuring optimal plant growth conditions year-round.

✅ Shade Net Houses

Shade nets undergo testing for shade factor, UV stability, and wind resistance to prevent crop burn and storm damage.

✅ Open Field Mulching

Mulch mats are tested for water permeability, weed resistance, and biodegradability to enhance soil health and moisture retention.

✅ Insect-Proof Farming

Labs test insect nets for mesh density, strength, and air circulation to safeguard crops from pests without using harmful chemicals.

How to Choose the Right Accredited Lab

When selecting a lab for agro textiles testing, consider:

ISO/IEC 17025 accreditation status

Experience with polymer and textile materials

Capability to test under national and international standards

Quick turnaround and detailed test reports

Client support and consultation services

Working with a reliable lab ensures accurate verification and adds value to your agro textile products.

Conclusion

Agro textiles are indispensable tools in modern, sustainable agriculture—but only if they perform as expected under real-world conditions. The role of accredited labs in verifying these materials is critical for ensuring crop protection, regulatory compliance, and long-term agricultural success.

By performing rigorous, standardized tests on shade nets, greenhouse films, insect screens, and mulch mats, accredited labs help manufacturers create reliable products and assist farmers in choosing the best tools for their fields. In the ever-evolving agri-tech landscape, agro textiles testing by accredited labs is the foundation of quality assurance and crop protection.

0 notes

Text

Polypropylene Melt Blown Nonwoven Fabrics Market Analysis

Global Polypropylene Melt Blown Nonwoven Fabrics Market continues its upward trajectory with a valuation of USD 1.053 billion in 2024, according to the latest industry analysis. The market is forecast to expand at a 3.6% CAGR through 2031, potentially reaching USD 1.339 billion as filtration technologies and PPE requirements evolve across multiple industries.

These specialized fabrics feature ultra-fine polypropylene fibers (1-5 microns) that create exceptional filtration efficiency while maintaining breathability - a critical combination for medical masks and industrial air filtration systems. Post-pandemic demand stabilization hasn't diminished their importance; rather, manufacturers are now focusing on technical improvements in pore structure consistency and sustainable production methods to meet stricter environmental standards.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/294168/global-polypropylene-melt-blown-nonwoven-fabrics-forecast-market-2025-2031-276

Market Overview & Regional Analysis

Asia-Pacific commands a dominant 60% market share, with China alone producing over 40% of global supply. Local advantages include vertically integrated polypropylene supply chains and government support for medical material manufacturing. While Southeast Asian nations are emerging as alternative production hubs, they currently lack the advanced melt-blown extrusion capabilities of Chinese and South Korean manufacturers.

North America's market growth reflects reshoring trends in medical supply chains, with new production facilities coming online in Texas and Ontario. Europe maintains steady demand through automotive filtration applications, though rising energy costs have pressured smaller manufacturers. Latin America shows particular promise in the hygiene sector, with Brazilian producers expanding capacity to serve nearby markets.

Key Market Drivers and Opportunities

The healthcare sector remains the primary growth engine, accounting for 48% of consumption. Beyond pandemic-related demand, aging populations and hospital acquired infection prevention measures continue driving uptake. Industrial applications (32% share) are gaining momentum as manufacturers replace older filtration media with high-efficiency melt-blown alternatives in HVAC systems and manufacturing clean rooms.

Emerging opportunities include EV battery separators - where the material's thermal stability proves advantageous - and advanced wound care products leveraging its wicking properties. The push toward biodegradable formulations also opens new R&D frontiers, though commercial viability at scale remains challenging.

Challenges & Restraints

Raw material price volatility poses persistent challenges, with PP resin costs fluctuating between $0.80-$1.20/lb over the past 18 months. Environmental concerns regarding microplastic shedding have prompted EU regulatory reviews that may mandate containment technologies. Additionally, the market faces overcapacity issues in China, where numerous small producers entered during the mask boom but now struggle with underutilized equipment. Market Segmentation by Type

Net Weight Below 25 (g/m2)

Net Weight 25-50 (g/m2)

Net Weight Above 50 (g/m2)

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/294168/global-polypropylene-melt-blown-nonwoven-fabs-forecast-market-2025-2031-276 Market Segmentation by Application

Hygiene

Industrial

Home Textile

Cloths

Automotive

Protective Mask

Others

Market Segmentation and Key Players

Berry Global

Mogul

Kimberly-Clark

Monadnock Non-Woven

Toray

Fiberweb

Freudenberg

Don & Low

PFNonwovens

Irema

Ahlstrom-Munksjo

Hollingsworth & Vose

Guoen Holdings

CHTC Jiahua Nonwoven

JOFO

Report Scope

This report offers a comprehensive evaluation of the global Polypropylene Melt Blown Nonwoven Fabrics market from 2024 through 2031, with granular segmentation covering:

Volume and value projections across 25+ countries

Technology adoption curves for advanced manufacturing methods

PP resin price trend analysis and impact assessments

Our methodology combines:

Plant-level capacity audits across 60+ production facilities

Quarterly price monitoring at regional trading hubs

End-user surveys covering 150+ industrial buyers

The analysis identifies emerging applications while assessing threats from alternative materials like nanofiber composites. Special attention is given to ESG factors reshaping production standards globally.

Get Full Report Here: https://www.24chemicalresearch.com/reports/294168/global-polypropylene-melt-blown-nonwoven-fabrics-forecast-market-2025-2031-276

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

0 notes

Text

Industrial Yarns for Technical Textile: Elevating Performance with Sanathan Textiles

In the world of technical textiles, the demand for high-performance industrial yarns continues to grow. Industries such as automotive, construction, medical, and defense rely on durable and reliable yarns for various applications. Yarn suppliers like Sanathan Textiles, a leader in the yarn manufacturing sector, provide a diverse range of industrial yarns engineered for strength, durability, and efficiency.

Understanding Industrial Yarns

Industrial yarns play a crucial role in the production of technical textiles, ensuring longevity, resilience, and superior performance. These yarns are designed to withstand extreme conditions, making them suitable for industrial stitching threads, ropes, filtration fabrics, and reinforcement textiles.

Sanathan Textiles offers a range of specialized yarns tailored for technical textile applications, including:

1. Partially Oriented Yarn (POY)

Partially Oriented Yarn is a foundational yarn in textile manufacturing, known for its high tenacity and uniform structure. It is often further processed into fully drawn yarn (FDY) or drawn textured yarn (DTY) for enhanced properties. POY is widely used in applications that require flexibility and moderate strength.

2. Fully Drawn Yarn (FDY)

Fully Drawn Yarn is a high-strength filament yarn that is directly used in various textile applications. FDY offers superior durability and is commonly utilized in industrial fabrics, heavy-duty textiles, and high-performance garments.

3. Drawn Yarn

Drawn Yarn is manufactured through a controlled stretching process to enhance its strength and stability. It is a preferred choice for producing industrial fabrics that require resistance to wear and tear.

4. Twisted Yarn

Twisted yarn undergoes a twisting process to improve its tensile strength and durability. This type of yarn is extensively used in industrial ropes, nets, and heavy-duty sewing threads, ensuring reliability in demanding environments.

5. POY Yarn

POY yarn is a semi-finished product used for further texturizing and drawing. It is an essential component in the production of stretch fabrics and technical textiles requiring controlled elasticity and resilience.

Applications of Industrial Yarns in Technical Textiles

Industrial yarns from Sanathan Textiles cater to a wide array of technical textile applications, including:

Automotive Textiles: Used in seat belts, airbags, and interior reinforcements.

Industrial Stitching Threads: Ensuring high-strength and long-lasting stitches in heavy-duty sewing applications.

Filtration Fabrics: Designed for air and liquid filtration in industrial settings.

Industrial Ropes & Nets: Providing robustness and durability in maritime, construction, and safety applications.

Protective Textiles: Used in fire-resistant fabrics, safety gear, and defense applications.

Why Choose Sanathan Textiles?

Sanathan Textiles stands out in the industry for its commitment to quality, innovation, and sustainability. The company utilizes state-of-the-art manufacturing processes to produce yarns that meet stringent industry standards. With a focus on delivering high-performance solutions, Sanathan Textiles ensures that its industrial yarns cater to the evolving needs of technical textiles.

Explore the full range of industrial yarns at Sanathan Textiles and discover how their high-quality products can elevate your technical textile applications.

0 notes

Text

Permeable Pipe factury offer flexible permeable pipe is a high pressure resistant soft structure formed by the rust-proof spring coil supporting the pipe body. The inner lining of the non-woven fabric is filtered to prevent sediment impurities from entering the pipe, thereby achieving the effect of net water penetration.

The outer covering layer of polypropylene filament and the spring steel ring tube body are organically integrated, which has a good all-round water permeability function. The permeated wa-ter can penetrate into the pipe smoothly, and the sediment impurities are blocked outside the pipe, so as to achieve the purpose of water permeation, filtration and drainage.

Flexible Permeable Pipe Features

1. Pore diameter is small, good omnidirectional water permeability. 2. High tensile and compressive strength and long service life. 3. Good corrosion resistance and bio-erosion resistance. 4. Good overall continuity, and convenient to connect with fewer joints.

5. Lightweight and convenient for construction. 6. Soft texture, and good binding with soil.

Flexible Permeable Pipe Application

1. Discharge infiltration water, reduce the infiltration line, strengthen the soft soil layer, and strengthen the soil to prevent collapse. 2. Drainage of airports, railways, highways, sports fields, and parks. 3. Drainage system of mine tail dam, ash dam of thermal power plant, landfill plant and etc.

0 notes

Text

Innovative Uses of Monofilament Yarns in Various Industries

Monofilament yarns, known for their single-strand structure, have revolutionized various industries with their unique properties. Monofilament yarn manufacturers have continuously innovated to meet the evolving demands of different sectors. This article explores the applications of monofilament yarns, highlighting their versatility and the ingenuity of their manufacturers.

Revolutionizing the Medical Field:

Monofilament yarns have crucial usages in the medical industry. Their biocompatibility and strength make them ideal for surgical sutures, ensuring minimal tissue reaction and faster healing. Monofilament yarns also produce medical meshes for hernia repairs and other surgical procedures. These meshes provide excellent support to the body's tissues, reducing complications. Using monofilament yarns in cardiovascular stents is another innovative application where flexibility and durability are crucial for patient safety and recovery.

Enhancing Agricultural Efficiency:

In agriculture, monofilament yarns are used in various applications to improve efficiency and productivity. They are commonly used in constructing greenhouse shading nets, which help regulate temperature and light exposure, creating the best-growing conditions for plants. Monofilament yarns are also used to support climbing plants and ensure better air circulation and sunlight penetration. Also, these yarns are used in anti-hail nets, protecting crops from damage caused by hailstorms, thus protecting the farmer's investments and ensuring consistent yields.

Transforming the Fishing Industry:

The fishing industry has benefited from the durability and strength of monofilament yarns. Fishing lines made from monofilament yarns are preferred for their high tensile strength and resistance to abrasion. These lines are less visible underwater, increasing the chances of catching fish successfully. Also, monofilament yarns are used in the manufacturing of fishing nets, providing high durability and longevity in harsh marine environments. The development of biodegradable fishing nets is a crucial innovation, addressing environmental concerns by reducing the impact of disposed nets on aquatic ecosystems.

Revolutionizing the Textile Industry:

Monofilament yarns are popular in the textile industry for their unique properties and versatility. These yarns produce high-performance fabrics, including sportswear and outdoor gear. Monofilament yarns provide excellent moisture-wicking capabilities, keeping the wearer dry and comfortable. They also create durable and lightweight fabrics for industrial applications, such as conveyor belts and filtration systems.

Innovating in the 3d Printing Sector:

Monofilament yarns have opened new possibilities in 3D printing. Their precision and consistency make them ideal for creating detailed structures. Monofilament yarns are used as filaments in 3D printers, helping to produce prototypes, models, and functional parts with high accuracy. This innovation has revolutionized the aerospace, healthcare, and manufacturing industries, allowing rapid prototyping and customized solutions. Using monofilament yarns in bioprinting is an excellent development, helping create the tissue and organ structures for medical research and transplantation.

Enhancing Sports Equipment:

The sports industry has used the unique properties of monofilament yarns to enhance the performance and durability of sports equipment. Tennis racket strings made from monofilament yarns offer excellent control and power, improving the player's performance. Also, monofilament yarns produce fishing rods, providing strength and flexibility. These yarns also manufacture golf club shafts, ensuring optimal swing dynamics and durability. The development of lightweight and high-strength materials for sports apparel and gear is another area where monofilament yarns play a crucial role.

Innovating in the Packaging Industry:

The packaging industry uses monofilament yarns for their strength and versatility. These yarns are used to produce strapping materials, ensuring secure and reliable packaging of goods. Monofilament yarns create durable nets and mesh bags. They are used in manufacturing industrial sewing threads, offering high tensile strength and resistance to abrasion. The development of smart packaging solutions, adding monofilament yarns with sensors and tracking capabilities, is an exciting innovation that improves supply chain management and product safety.

Conclusion:

Monofilament yarn manufacturers have continuously pushed the boundaries of innovation, creating versatile and high-performance products for various industries. From medical applications to environmental solutions, the unique properties of monofilament yarns have revolutionized numerous sectors. With the advancement of technology, the potential for new and exciting uses of monofilament yarns continues to grow, ensuring a future of endless possibilities.

#zipper monofilament yarn manufacturer uttar pradesh#monofilament wires#zipper monofilament yarn manufacturer#zippermonofilament yarn

0 notes

Text

Aluprof Excel in Passivhaus Projects

Passivhaus design is a set of standards and design principles to achieve exceptional energy efficiency, significantly reducing heating and cooling demands in buildings. By employing rigorous insulation standards, airtight construction and high-performance windows, Passivhaus buildings minimise energy loss and maintain stable indoor temperatures. The use of heat recovery ventilation systems ensures that fresh air is continuously supplied, whilst retaining warmth in winter and coolness in summer. This leads to dramatically lower energy bills and a reduced carbon footprint. Additionally, the controlled indoor environment enhances occupant comfort, eliminating drafts, temperature fluctuations, and cold bridging.

Specifying Passivhaus windows, doors and facades from Aluprof contributes to sustainability by reducing reliance on fossil fuels and supporting the transition to net-zero carbon emissions. The methodology prioritises efficient use of materials, often incorporating sustainable and recycled options. Beyond environmental benefits, Passivhaus buildings promote superior indoor air quality through continuous ventilation and effective pollutant filtration. This is particularly beneficial for occupants with respiratory issues or allergies. The focus on thermal comfort and noise reduction further enhances the well-being of occupants, making Passivhaus a holistic approach to healthy and sustainable living spaces.

Aluprof was the first systems company in the UK to design and supply Passivhaus certified aluminium framed glazing systems and currently has the widest range of Passivhaus Trust certified aluminium windows, doors and curtain wall systems. Utilising low-carbon aluminium helps reduce embodied carbon emissions during the production phase, while the thermally efficient products further lower operational carbon emissions throughout the building's life by reducing energy demand. Sustainability is further enhanced as quality methods of construction with high quality finishes, well specified and designed products supplied by Aluprof, can offer many decades of extended service life.

Some of the projects supplied by Aluprof in recent years include the following high profile buildings:

The RAD Building (GERA Building) is a 2,500 sqm Passivhaus certified research facility for the University of Nottingham, providing laboratory, office and support accommodation for the UK Government Energy Research Acceleration Initiative, known as the ‘RAD’ Building (Research Acceleration & Demonstration) on the Jubilee campus. The building achieves a BREEAM Excellent rating and includes extensive Passivhaus measures to reduce energy requirements. Aluprof’s high performance TT50 curtain wall & MB104 window and door systems have been used throughout the building offering very high levels of insulation. On completion the building has been extensively tested and has gained the coveted Passivhaus certification.

Purdown View at University of Western England (UWE) Bristol, is a remarkable milestone in sustainable living, featuring more than 900 bedrooms distributed across three striking six-story buildings. With a total floor area of 21,000 sqm, Purdown View is distinguished as the largest certified Passivhaus development in the United Kingdom to date. It was designed by Stride Treglown and uses Aluprof’s high performance TT50 curtain wall & MB104 window and door systems, the project was fabricated and installed by DenvalCo.

The Greenhaus project stands as the largest Passivhaus affordable housing initiative in the North West. The development was completed for the English Cities Fund (ECF), a collaborative effort involving Muse, Legal & General, and Homes England, in partnership with Salix Homes, a Housing Association in Salford, and with the support of Salford City Council. Greenhaus features 96 highly sustainable and affordable residences within a nine-storey structure located on Chapel Street in Salford. The project, designed by Buttress architects and constructed by Eric Wright Construction, has received official certification from the Passivhaus-Institut, the organisation dedicated to promoting and certifying this internationally recognised building standard.

Voreda House in Penrith has undergone a significant transformation from its previous role as an NHS office to become the council's energy-efficient northern anchor building. This facility is notable for being the first retrofit office in the UK to achieve the Passivhaus EnerPHit standard, with projected energy savings of 85%. This initiative aligns with the council's dedication to minimising its carbon footprint and taking a leading role in the pursuit of carbon neutrality.

The British Antarctic Survey (BAS) undertakes groundbreaking research and maintains a Research Station located 67º south on Adelaide Island which was established in 1975. Known as Rothera, the busy station is used as a hub for other countries working in the area, offering a landing strip and wharf. The site has continued to develop over the years and in 2018 work began on the new Discovery Building, named to commemorate the discovery of Antarctica 200 years ago by the British naval officer Edward Bransfield in 1820. High thermal performance windows specified on the project have been provided by Aluprof. The MB-86 ST window and door system has been designed to offer outstanding insulation properties. Offered in three varieties, ST, SI and AERO the MB-86 was the first ever aluminium system to employ silica aerogel, a nano-porous material that has a very high proportion of free void volume compared to conventional solid materials. Aerogel’s high pore volume, low solid content, and its ‘torturous path amorphous structure’ offer very low values of thermal conductivity.

Aluprof UK have been supporting specifiers in the UK and Ireland for over fifteen years with advanced systems that include, high performance windows doors and facade systems. Many UK and Ireland based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks. Further information about systems and specification support is available through the company website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

1 note

·

View note

Text

Unveiling the Power of Filter Fabric: Enhancing Filtration Efficiency Across Industries

Filter fabric, also known as filter media, plays a crucial role in various industrial processes and applications, offering efficient filtration solutions for a wide range of substances. From removing contaminants in water treatment plants to separating particles in air filtration systems, filter fabric is indispensable across numerous industries. Let's explore the significance of filter fabric and its diverse applications.

Understanding Filter Fabric

Filter fabric is a porous material designed to capture and separate particles from fluids or gases passing through it. It consists of a network of fibers or membranes arranged in a specific configuration to achieve desired filtration properties. Filter fabric can vary in composition, pore size, thickness, and filtration efficiency, depending on the application requirements.

Applications in Water Treatment

One of the primary applications of filter fabric is in water treatment processes. Filter fabric is used in filtration systems to remove suspended solids, sediments, and contaminants from water sources, ensuring that the water meets regulatory standards for drinking water, industrial use, or environmental discharge. Filter fabric is employed in various filtration stages, including sedimentation, clarification, and final polishing, to achieve clean and clear water.

Industrial Filtration Systems

In industrial settings, filter fabric is utilized in a wide range of filtration systems to separate solids from liquids or gases. Industries such as pharmaceuticals, chemicals, food and beverage, and automotive rely on filter fabric for processes such as product purification, wastewater treatment, air pollution control, and oil and gas filtration. Filter fabric enhances operational efficiency, product quality, and regulatory compliance in these industries.

Air Filtration and HVAC Systems

Filter fabric also plays a critical role in air filtration and HVAC (Heating, Ventilation, and Air Conditioning) systems, where it captures airborne particles, allergens, and contaminants to improve indoor air quality. Filter fabric is used in air filters, filter bags, and filter media to trap dust, pollen, mold spores, and other pollutants, creating a healthier and more comfortable indoor environment for occupants.

Geotextiles and Environmental Applications

Beyond industrial and HVAC applications, filter fabric finds use in geotextiles for soil stabilization, erosion control, and drainage applications. Geotextile filter fabric prevents soil erosion, facilitates drainage, and provides support for infrastructure projects such as roads, embankments, and retaining walls. Additionally, filter fabric is employed in environmental protection projects, such as landfills, remediation sites, and stormwater management systems, to contain and treat pollutants.

Filter fabric is a versatile and indispensable material that enhances filtration efficiency across various industries and applications. Whether in water treatment plants, industrial processes, air filtration systems, geotextiles, or environmental projects, filter fabric plays a critical role in ensuring clean water, air, and soil. With its diverse capabilities and applications, filter fabric continues to be a vital component in achieving cleaner and healthier environments worldwide.

0 notes

Text

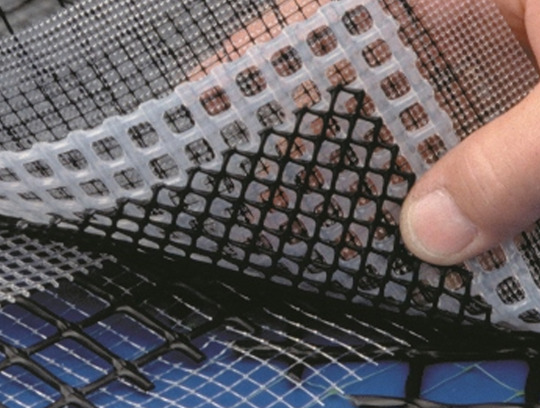

Top Wire Mesh Manufacturers

If you are seeking a wire mesh manufacturer who you can trust and has a good reputation, the first thing you need to learn is what ihars did to realize the characteristics and attributes of a manufacturer. There are several great wire mesh manufacturers, (the best wire mesh manufacturers) where you can not wrong with your wire mesh requirements because they get, better, best in all characteristics - quality, innovator, service provider. Best wire mesh manufacturers produce a good variety of wire mesh quality wire mesh products products specifically for the construction, agriculture, mining, filtration/ ventillation, and security industries.

Wire mesh ( there are many other names wire cloth, wire fabric) is product from woven or interwoven wire. There are literally innumerable applications of wire mesh, include, but not limited to fabric ( sectional, permanent or gasket) reinforcements, concrete reinforcement, fencing, partitioning, filtering, etc. The characteristics and strength of wire and wire mesh for our literal definitions are defined primarily by: materials, production methods, and finishing treatments. Best wire mesh manufacturers, since they opened up to when the business incorporated, have always operated with wire mesh building products and have incorporated the top quality materials like stainless steel wire, galvanised wire and other rust resistant materials; so it is now easy to see why Best Wire Mesh Manufacturers is the best.

What you will discover when buying wire mesh products from the Best Wire Mesh Manufactures is the selection of products that can be small fin mesh for industrial filtration or cut to size hand welded or machine lofted heavy duty mesh for service entry and exit points, having completely considered the scope of the competition from independently determining your own respective workflow on site; in this regard all wire mesh products are manufactured to be fit for service and fit for industry, you should be encouraged regardless whether you receive wire mesh large quantities as a project or single items outside of the project & separately, and the project will not suffer negatively from service or measured safety products.

Address:H.O:K-245,Pushta Road,Karawal Nagar,Shahdara,Delhi-94 K-46,Sector-5,Bhawana,Delhi-39

0 notes

Text

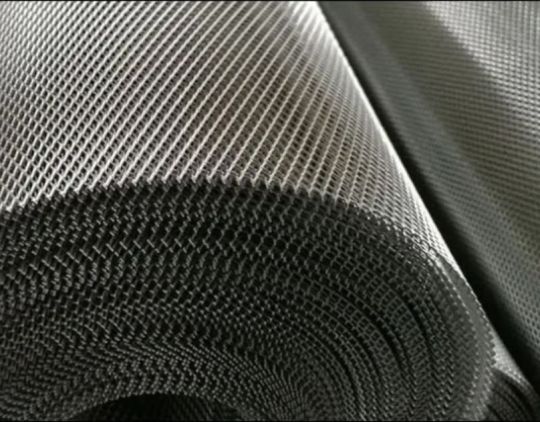

What is mesh fabric? Properties, uses and manufacturing process

Mesh fabric is a super versatile textile that has impacted industries like fashion to even agriculture. This combined features make it a characteristic material in many uses known for its form, durability and breathability. If you have ever asked, “What is a mesh fabrics? properties, uses and manufacturing process, this complete guide will tell you all what you need to know.

What is Mesh Fabric?

Mesh Fabric is a lightweight, durable material made with an open weave that creates a net-like appearance. The design features evenly spaced holes or pores, providing excellent ventilation, flexibility, and a distinctive aesthetic. Manufacturers craft this fabric using synthetic fibers like polyester or nylon, as well as natural fibers such as cotton. Its design gives it a high degree of versatility, making it ideal for sportswear, industrial purposes, and even decorative applications.

The open construction of fabric allows air to flow freely through it, which makes it a top choice for hot weather or activewear.

Key Properties of Mesh Fabric:

Mesh fabrics is so recognized for its great features, which make it extremely useful and adaptable. Here‘s what makes it special:

1. Breathability:

Mosquito-net like fabrics of an open weave lets air through to keep the material cool and dry; no wonder it is a bestseller among sportswear and shoes.

2. Lightweight and Flexible:

Although thick, fabric remains very lightweight and flexible. This makes it comfortable to integrate into almost any design, whether clothing or accessory.

3. Durability:

Synthetic mesh materials, including nylon or polyester, wear well and have a long lasting durability.

4. Moisture-Wicking Abilities:

Mesh fabric effectively wicks away sweat, ensuring comfort during intense physical activities.

5. Versatile Design:

Mesh fabric comes in a range of aperture sizes and shapes so finds applications from casual clothing to industrial filtration.

Uses of Mesh Fabric:

Like its properties, fabric finds its uses in as varied areas as possible. Its diversity means that it finds application across numerous industries. Read More: polyester fabric.

1. Sportswear and Activewear:

Fabric has become quite ubiquitous in athletic and fitness wear. It is highly versatile for tees, shorts, and leggings due to breathability and moisture-wicking properties.

2. Footwears:

Most running and athletic shoes have mesh upper panels to accommodate ventilation purposes and reduce weight.

3. Industrial Applications:

It is used in industrial applications for filtration, separation and sieving because its net like structure is strong.

4. Bags and Accessories:

Mesh is so very popular in tote bags, backpacks, and other accessories because of its lightweight design and aesthetic appeal.

5. Home Furnishings:

It plays a significant role in household products, ranging from laundry bags to upholstery of furniture.

6. Medical Textiles:

The mesh material is widely used for medical devices and bandage purposes, usually for applications requiring sterility and breathability.

Types of Mesh Fabric:

Some of the fabrics are created for specific uses.

1. Polyester Mesh:

Among other varieties, polyester mesh is most frequently found. Its benefits are great strength and resistance to moisture, giving it ample elasticity suitable for either active-wear or industry use.

for detail visit https://fashionsoulintl.com/what-is-mesh-fabric/

0 notes

Text

5 Essential Types of Wire Mesh for Industrial Applications

Wire mesh is everywhere. From the fences surrounding your property to the sieves in your kitchen, it’s a versatile material with endless applications. It is manufactured by weaving or welding metal wires into a mesh, creating a grid like pattern. Its history dates back centuries when rudimentary wire netting was used for basic filtering and containment purposes. Over time, technological advancements have transformed it into a precision engineered material with diverse industrial applications.

What is Wire Mesh?

Wire mesh is a grid-like structure made by weaving or welding metal wires together. These meshes can vary in size, thickness, and material, making them suitable for a wide range of uses.

Historical Evolution of Wire Mesh

The origins of wire mesh can be traced to the 16th century when blacksmiths crafted rudimentary mesh for sieves. The Industrial Revolution brought innovations like mechanized weaving and welding, paving the way for mass production. Today, wire mesh has become indispensable in industries requiring strength, durability, and adaptability.

Types of Wire Mesh: A Comprehensive Guide

Wire mesh is a versatile material used across numerous industries. The diverse types of wire mesh serve various purposes, from industrial to decorative applications. Understanding the differences between the types of wire mesh is essential to select the right product for your needs.

This article explores the five main types of wire mesh: woven wire mesh, welded wire mesh, expanded wire mesh, hexagonal wire mesh, and knitted wire mesh. We will delve into their manufacturing processes, features, and common applications.

Woven Wire Mesh

Woven wire mesh is created by interweaving wires over and under each other, much like a traditional fabric weave. This type of mesh is known for its precision and uniformity, making it ideal for applications requiring accurate filtration or screening.

Types of Woven Wire Mesh Weave

Plain Weave: The plain woven mesh weave is the simplest weave pattern with each warp wire alternates over and under the weft wire.

Twill Weave: The twill woven weave mesh allows a higher wire density by weaving one wire over two and under two wires.

Dutch Weave: The dutch wire mesh weave is designed for very fine filtration, this weave uses a combination of larger warp wires and finer weft wires.

Materials Used

Common materials for woven wire mesh include stainless steel, epoxy coated, nickel, aluminium, brass, copper, low carbon etc.

Applications of woven wire mesh type

Industrial Filtration: Used in oil refineries, water treatment plants, and chemical processing for separating solids from liquids or gases.

Screening and Sieving: Essential in mining, agriculture, and food processing industries.

Architectural Uses: Applied in decorative facades, partitions, and balustrades.

Key Features and Benefits of woven wire mesh

Uniform Openings: Ensures consistency, ideal for filtration and separation tasks.

Flexibility: Can be bent or molded to fit intricate designs.

Corrosion Resistance: Especially when made from stainless steel or coated materials.

Welded Wire Mesh

Welded wire mesh is made by fusing wires together at their intersections using an electric welding process. This creates a sturdy and durable structure that resists deformation.

Features of Welded Wire Mesh

Rigid Structure: The welding process makes the mesh extremely stable.

Customization: Available in various wire diameters, aperture sizes, and finishes.

Corrosion Resistance: Often treated with galvanization or PVC coating to enhance durability.

Materials Used

Typical materials include stainless steel, galvanized steel, and low-carbon steel.

Applications

Construction: Used in concrete reinforcement, retaining walls, and fencing.

Agriculture: Commonly applied in animal enclosures, cages, and trellises.

Industrial Uses: Found in machine guards, storage racks, and partitions.

Fencing: Offers security for residential and commercial properties.

Animal Enclosures: Ensures durability and protection in cages and pens.

Expanded Wire Mesh

Expanded wire mesh is produced by cutting and stretching a metal sheet to create a diamond-shaped pattern. This process eliminates waste and produces a lightweight yet strong product.

Features of Expanded Wire Mesh

High Strength-to-Weight Ratio: Ideal for lightweight construction.

Ventilation: Allows air and light to pass through while maintaining structural integrity.

Non-slip Surface: Frequently used in walkways and stair treads.

Applications of expanded wire mesh

Security: Used in window guards, safety grilles, and fencing.

Ventilation: Ideal for air and light filtration in HVAC systems.

Decorative Uses: Frequently applied in modern architectural designs and furniture.

Hexagonal Wire Mesh

Hexagonal wire mesh is characterized by its honeycomb-like pattern, is a staple in fencing and containment. Common materials include galvanized steel and PVC-coated wires.

Features of Hexagonal Wire Mesh

Flexibility: Can be easily shaped and bent without breaking.

Lightweight: Facilitates easy installation and handling.

Corrosion Resistance: Often coated with PVC or galvanized for durability.

Durability and Cost-Effectiveness: The hexagonal pattern ensures flexibility and strength while remaining an affordable option for various applications. Its lightweight nature simplifies installation.

Materials Used

Materials include galvanized steel, PVC-coated steel, and stainless steel.

Applications

Agriculture: Used for fencing poultry, animal enclosures, and garden protection.

Construction: Used in gabions to stabilize slopes, reinforce plastering work and create rockfall protection barriers and prevent soil erosion.

Crafts and DIY Projects: Used in sculptures, floral arrangements, and other creative applications.

Knitted Wire Mesh

Knitted wire mesh by looping wires together, similar to the process of knitting fabric. This creates a flexible and compressible material suitable for specific applications.

Features of Knitted Wire Mesh

Elasticity: Allows the mesh to stretch and return to its original shape.

High Filtration Efficiency: Excellent for removing contaminants in automotive and industrial applications.

Heat and Corrosion Resistance: Suitable for harsh industrial settings.

Damping and Sealing: Absorbs vibrations and seals gaps in automotive and aerospace industries.

Gasketing: Acts as a sealing material in automotive and aerospace industries.

Environmental Protection: Used in mist eliminators to reduce air pollution.

Materials Used

Common materials include stainless steel, copper, aluminium, and Monel.

Applications

Filtration: Used in oil mist separators, air filters, and demisters.

Gasketing: Acts as a sealing material in automotive and aerospace industries.

Soundproofing: Reduces noise in industrial machinery.

Factors to Consider When Choosing Wire Mesh

Material Selection

Different materials like stainless steel, copper, and aluminum cater to specific needs, such as corrosion resistance or conductivity.

Mesh Size and Thickness

The size of the openings and the thickness of the wires determine the mesh’s strength and suitability.

Durability Requirements

Consider factors like load-bearing capacity and environmental conditions when choosing a wire mesh type.

Conclusion

Wire mesh is a vital component in countless industries and applications. By understanding the different types—woven, welded, expanded, hexagonal, and knitted—you can choose the perfect mesh for your needs.

0 notes

Text

How Wire Mesh Manufacturers Are Transforming Industrial Design

In recent years, wire mesh has become a key player in industrial design. This versatile material, with its array of applications, is moving beyond traditional uses and finding a place in innovative and unexpected ways across various industries. From construction and architecture to interior design and even art, wire mesh is reshaping the landscape. This article explores how wire mesh manufacturers are driving this transformation and highlights the exciting possibilities that come with these developments.

1. Introduction to Wire Mesh and Its Applications

Wire mesh, also known as wire cloth or wire fabric, consists of interwoven metal wires that create a grid or net-like structure. Traditionally, wire mesh has been widely used in construction and infrastructure projects. However, its applications have evolved over time, and it is now used in a variety of creative and functional ways. Today, wire mesh is a staple in architectural and industrial design, as well as an attractive element in furniture, artwork, and decorative pieces. The adaptability of wire mesh has enabled manufacturers to develop new uses that meet modern demands.

2. The Rise of Wire Mesh in Modern Architecture

Architects increasingly rely on wire mesh to create visually striking and functional structures. With its strength and flexibility, wire mesh adds a modern, industrial aesthetic while maintaining structural integrity. Manufacturers have developed customized wire mesh solutions that can withstand weather conditions, provide enhanced durability, and support large-scale architectural projects. From façades to railing systems and canopies, wire mesh plays a significant role in the urban landscape.

3. Interior Design: Embracing Industrial Chic with Wire Mesh

The trend of industrial chic in interior design has brought wire mesh into the spotlight. Interior designers appreciate the raw, rugged look of wire mesh, using it to create room dividers, shelving, and decorative panels. The versatility of wire mesh means it can suit various styles, from rustic to minimalist, creating an industrial edge in any space. Manufacturers have adapted by producing wire mesh in different finishes, such as powder coating and galvanization, to match different interior design aesthetics.

4. How Wire Mesh Supports Sustainability in Industrial Design

One of the most significant contributions of wire mesh is its sustainable properties. Made from materials like stainless steel, carbon steel, and aluminum, wire mesh is highly durable and recyclable. Manufacturers have adopted eco-friendly production processes to reduce waste, and wire mesh can often be reused or repurposed in different projects. As a result, wire mesh is an environmentally friendly choice in an era where sustainability is essential.

5. Wire Mesh as a Security Solution

The strength and durability of wire mesh make it a popular choice for security applications. From fences to security screens, wire mesh provides a barrier without obstructing visibility. Many high-security facilities use wire mesh in fencing to safeguard restricted areas. Manufacturers have introduced anti-climb and reinforced wire mesh products, which are widely used in prisons, airports, and military facilities, offering maximum protection while blending seamlessly with the surroundings.

6. Wire Mesh in Ventilation and Filtration Systems

One practical application of wire mesh is in ventilation and filtration systems. Its open, grid-like structure allows air and liquids to pass through while keeping out larger particles and contaminants. Wire mesh filters are used in HVAC systems, automotive engines, and even kitchen appliances. Wire mesh manufacturers have developed specialized mesh filters that vary in porosity, strength, and size to accommodate the specific requirements of each industry.

7. Creative Use of Wire Mesh in Art and Sculpture

The flexibility of wire mesh has led artists to adopt it as a medium for sculpture and installation art. Sculptors use wire mesh to create complex forms and structures that would be challenging to achieve with other materials. Its transparency and ability to manipulate light make it an intriguing choice for installations. Many wire mesh manufacturers now cater to the needs of artists by providing customized mesh shapes and materials, expanding the possibilities for artistic expression.

8. Wire Mesh in Furniture Design

Furniture designers have discovered the aesthetic and functional benefits of wire mesh. From tables and chairs to storage solutions, wire mesh adds a distinctive look that can enhance both indoor and outdoor spaces. Its durability and ease of maintenance make it ideal for furniture that needs to withstand wear and tear. Many manufacturers now offer bespoke wire mesh furniture options, catering to clients who seek unique and resilient pieces for their homes and businesses.

9. How Manufacturers Are Innovating with New Materials and Techniques

Wire mesh manufacturers continue to innovate by developing new materials and production techniques that enhance the properties of wire mesh. For example, Timex Metals use advanced alloys or coating techniques that improve resistance to corrosion or provide additional strength. Additionally, 3D wire mesh weaving technology has opened doors to more complex shapes and designs, allowing manufacturers to create products tailored to specific industries, such as automotive or aerospace.

10. The Future of Wire Mesh in Industrial Design

As technology advances, so does the potential of wire mesh in industrial design. Wire mesh manufacturer are continually pushing boundaries, and future innovations are likely to include smart wire mesh that integrates with digital systems, such as sensors that monitor structural health in buildings. These advancements could revolutionize architecture and design, providing sustainable, functional, and aesthetic solutions for modern challenges.

Strength and Versatility: Discover India’s Premier Wire Mesh Manufacturers!

Wire mesh is a foundational element in many industries, ranging from construction and agriculture to automotive, filtration, and even art. It’s a product known for its strength, versatility, and durability, making it an essential component in projects and applications worldwide. Yet, the significance of wire mesh goes beyond its functional properties. It's a product that connects industries, provides safety and security, and plays a pivotal role in advancements across engineering and manufacturing. We are also a Demister Pad Manufacturer in India.

Strength and Versatility: Discover Premier Wire Mesh Manufacturers in India delves deep into the thriving industry of wire mesh manufacturing in India. Known for its robust and high-quality manufacturing sector, Timex Metals has positioned itself as a global leader in wire mesh manufacturers, thanks to its access to quality raw materials, state-of-the-art manufacturing facilities, and a skilled workforce committed to excellence.

For More Details:

Website: timexmetals.com

Product: Wire Mesh Supplier in India

Other Product: Mesh Demister Manufacturers in India.

0 notes

Text

Metart Building Tech: Innovating Woven Wire Mesh Solutions for Architectural and Industrial Excellence

Metart Building Tech as a Woven Wire Manufacturer: Delivering Architectural and Industrial Wire Mesh Solutions – Meta Woven Wire Netting Coil For Fence Metart Building Tech is one of the earlier companies which do woven wire manufacture. It is because in their ability to provide and implement wire mesh solutions, they are arguably the best in the world both for industrial and architectural use. The establishment of the company was in 2004 and since then has continued to integrate old crafts with modern equipment, and this has enabled them to provide the best high quality wire mesh ever known. With time, the company has considerably changed as well, and with more modern lines and ideas topping the list as the preference of the architects, designers and the industrial world.

In Pursuit of Quality

Metart Building Tech commenced operations with an objective which was quite precise and therefore informed the reason why they wanted to shatter the monopoly that was metal- for most, to enhance its rigidity whilst turning it into a beautiful and desirable object for contemporary children. The obvious trend here is the application of the broad category of woven wire products that the company produces for the construction, filtration and architectural design. The company has demonstrated an unbroken period of creativity leading to the incorporation of the most modern processes in manufacturing such as precision wire weaving, CNC punching, laser cutting and welding which ensures modern products of high quality and precision.

Woven Wire Mesh: The Central Product of Metart

Woven wire Meshes is one of the several products that Metart Building Tech has. Such metallic meshes are constructed from stainless steel, copper, brass, bronze among other metals suitable for the application. There is a multitude of such fabrics for molding because of the ease of manipulating them in different shapes, these days they are no more just used for industrial sieving but even include decorative architecture.

In those fields, the woven wire meshes that the manufacturing company Metart produces Are most intended for the filtration operation only. Synthetic stainless steel wire cloth and also known as sintered wire cloth are well reputed for their performance and come along with other features such as ease in filtering, rigidity and resistance to corrosion; these applications are common in petrochemical, pharmaceutical and wastewater industries. These meshes assist in enhancing the quality of the products and efficiency of the processes by helping to separate vapours and liquids from gases and other vapors assisting in cooling.

With regards to how the article is written, woven wire mesh is used to increase both the architecture of the buildings and their performance . Inside Metart, standard and decorative architectural mesh panels are available which can be used as canopies, external claddings, internal partitions, wall cladding panels etc. Color, texture, and shapes of the constructed images help the architects’ imagination run wild. The METART-S05 decorative cage consists of stainless steel and copper wires which brings fashion into any design.

Wider Variety and Functions of The Material

It is not surprising that one of the characteristic features of Metart Building Tech is the Ability to Hit Unlike Will Many Building Tech Competitors. Different varieties of woven wire mesh, all some of which quality are incomparable different kinds, are presented by the company. The genetic factor includes: Stainless Steel. This is the wire that is mostly used for architectural as well as industrial purposes since it is highly strong and durable free from rust. Marine grade 316 is one the grades in Metart which is used in extreme conditions and applications such as coastal industries. . They are utilized in security screening systems, facades and filtration systems.

Copper, Brass and Bronze: Such materials mostly serve more on a decorative level, affording a pleasing finish that is quite tough. Copper for instance is also used in a lot of high class architectural projects since it provides some antimicrobial action making it a great degree used as a decoration. Brass and bronze wire meshes are still most sought for use with interior designs as they add warmth and have a classic appeal for any designer.

Aluminum and Special Alloys: Metart has aluminum meshes that are ideal for such applications where low weight and high strength are of major consideration in that they are useful for security screens and decorative feature part of building. Alloy wires for those special high wearing and demanding machine applications can be produced as well.

Where Design and Performance Intersect

Love for the woven wire products of Metart runs so high with most if not all architects due to their aesthetic appeal and utility. Metart’s decorative wire mesh panels as per the clients’ variations and needs, however, decorate the exterior and interior of buildings as they are installed. These wire meshes are used in a wide range of architectural applications including cladding, partitions, railings and ceilings.

The hybrid woven wire mesh METART-WW34MSSRB is an excellent illustration of their success in this area, which includes the use of copper in stainless steel mesh to make it look very appealing without compromising on strength and quality. In addition, the company’s wire mesh partitions and cladding systems are perfect means of accomplishing interior space design and provide ample flexibility in terms of material selection and design.

Without embroidered wire meshes, Metart incorporates beautiful mesh-up designs into her special projects. This is a low frequency and high preponderance company in high demand especially for built-in systems. The company can be ranked among the best structured companies in the market with such skills that keep on competitive high growing industry enabled by the requirements of the industry.

Industrial Solutions: Beyond Filtration – Towards Security

Venturing beyond the architecture domain, Metart Building Tech decorates other industries as well and develops woven wire mesh for the filtration, security and a number of other different core functions. Their stainless wire mesh for security is very widely utilized in high security protective screens, protecting doors & windows. This mesh uses Marine Grade 316 stainless steel which is very strong but resistant to corrosion and so is used mostly in places where there are extreme weather conditions.

Metart's woven wire mesh acts as great assets for the disintegration system in almost all industries. Be it removing contaminants during chemical processes or filtering waste water at waste treatment plants, meshes of Metropolitan are aimed at operational effectiveness and longevity. The company has a commendable range of sintered wire meshes that have the distinction of allowing the separation of fine particles without the meshes collapsing with excessive knocking pressure.

Progress and Environmental Protection

Since it belongs to the leading manufacturers of woven wire meshes Metart Building Tech has reasonable answers to the forthcoming problems, in this case – to the sustainable development of the enterprise. Waste shielding and other innovative technologies introduced in the last few years by the company’s advanced manufacturing technologies actively help in minimizing waste generation and energy consumption in their production processes.

Also, their wire meshes have further surface processes like powder coating, electropolishing and painting with PVDF. These treatments add to the overall performance, reliability and aesthetics of the wire meshes, as they are among many features that increase the longevity of the wire meshes for construction and industrial use.

Conclusion

Metart Building Tech is remarkable as a woven wire manufacturer who fuses art and engineering with modern technology. The organization’s wide variety of high-quality woven wire and its value-adding services has propelled the company into the global arena. Most if not all of the products manufactured by Metart are useful in construction, security, and even industrial installations. When great demand for creativity in odd wire meshes exists, disregard for potential applications, creation, form and odd wire meshes are commonplace. Just like any other nonprofit organization, Metart has clients all over the globe and provide them with requisite products.

0 notes

Text

Nylon Fibers Market : Future Demand, Market Analysis & Outlook to 2024

Nylon fibers, a type of synthetic polymer, are among the most widely used materials in various industries due to their exceptional strength, elasticity, abrasion resistance, and chemical stability. These fibers are primarily used in the textile and automotive industries but also have significant applications in industries such as aerospace, electronics, and industrial machinery. The Nylon Fibers Market has experienced steady growth, driven by demand for durable and versatile materials in a range of applications.

The Nylon Fibers Market was valued at USD 34.39 billion in 2023. The industry is projected to grow from USD 35.42 billion in 2024 to USD 48.86 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 6.50% during the forecast period (2024 - 2032).

Market Dynamics and Growth Drivers

Several key factors are driving the growth of the Nylon Fibers Market Share is:

Textile Industry Demand: Nylon fibers are extensively used in the textile industry for producing a variety of fabrics, including hosiery, activewear, swimwear, and outerwear. Their durability, elasticity, and ability to retain shape make them ideal for clothing and accessories.

Automotive Industry Growth: In the automotive sector, nylon fibers are used in the production of airbags, seatbelts, tire cords, and upholstery due to their high tensile strength and resistance to wear and tear.

Advancements in Nylon Technology: Innovations in nylon fiber production, such as the development of bio-based nylons and improved manufacturing processes, have expanded the applications and performance of these fibers.

Growth in Industrial Applications: Beyond textiles and automotive, nylon fibers are used in various industrial applications, including conveyor belts, ropes, and fishing nets.

Competition from Other Fibers: Nylon faces competition from other synthetic and natural fibers, such as polyester, cotton, and wool. E

What Is Included In MEANylon fibers Market Segmentation?

By Type Nylon-6,6, Nylon-6, Nylon-6,10, Nylon-11, and Others

By Application : Technical Textile, Textile, Filtration, Fishing, Consumer Goods, and Others

MEANylon fibers Market Companies Are:

Evonik Industries AG (Germany), BASF SE (Germany), Solvay (Belgium), Radici Partecipazioni SpA (Italy), Shenma Industrial Co., Ltd. (China), Ascend Performance Materials (US), INVISTA (US), Asahi Kasei Corporation (Japan), DuPont de Nemours, Inc. (US), EMS-CHEMIE HOLDING AG (Switzerland), Shakespeare Company, LLC. (US), and LIBOLON (Taiwan)

Future Outlook

The future of the Nylon Fibers Market looks promising, with continued growth expected across various industries. The development of bio-based and recycled nylon fibers will likely play a crucial role in addressing environmental concerns and meeting the demand for sustainable materials. fibers.

About Market Research Future: At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services. MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients.

Contact us: Market Research Future (part of Wantstats Research and Media Private Limited), 99 Hudson Street, 5Th Floor, New York, New York 10013 United States of America +1 628 258 0071 Email: [email protected] Website: https://www.marketresearchfuture.com

0 notes