#field assembling connector

Explore tagged Tumblr posts

Text

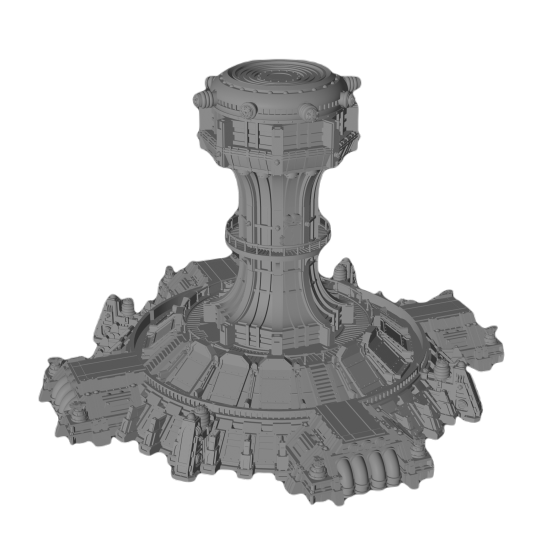

New year, new campaign. My group is going hard into Epic Legions Imperialis and, with the addition of a Bambu P1P to the toolbox, we're expanding our collection of very small scenery with 3d printed parts from Grimdark Terrain.

The end result was really impressive. I had written off filament deposition printing for miniatures when the higher resolution resin printers started being able to compete with store-bought a few years ago, but the level of detail with this extruded PLA is really something else. Some of the undercuts are a little ugly, but you won't be able to see them in the course of regular play.

Conceptually, this piece is a city sector-wide void shield projector akin to the palace aegis network described in Siege of Terra. The massive discharge of exotic energies originate from the elevated dish creating a toroidal field pattern - so you can't just shoot at it from the ground, necessitating its capture by infantry forces if you wish to bring it down. A much more cinematic objective marker than a spare die or token.

If you want to build your own, the list of parts can be found past the break - Rudolf at GDT does some pretty impressive scenery and deserves your support.

Titanomantic Aegis Void Shield Network Projector

#AG-059 - Argos - Megabunker Connection Peg x 8 #AG-063 - Argos - Pavaise VS Projector Coils x 4 #AG-064 - Argos - Pavaise VS Projector Dish x 1 #AG-068 - Argos - Mega Bunker Side Pipes x 4 #AG-070 - Argos - Air Control Tower Base x 1 #AG-072 - Argos - Air Control Tower Top Connector x 1 #AG-073 - Argos - Air Control Tower Circular Balcony x 1 #AG-080 - Argos - Recessed Shield Coil x 4 #AG-083 - Argos - Makro-Bunker Base x 1 #AG-085 - Argos - Makro-Bunker Base Wall 2 x 4 #AG-091 - Argos - Makro-Bunker Pillar 1 x 4

This build utilizes parts from three separate Grimdark Terrain .STL packages; July 2021, February 2022 and November 2022. July and November are critical components for the major assemblies, but if you're stingy you can substitute the Recessed Shield Coils from February by doubling the number of #AG-063 Pavaise VS Projector Coils.

#games workshop#warhammer 40k#warhammer 30k#epic 40k#epic 30k#horus heresy#adeptus titanicus#legions imperialis#3d printing#grimdark terrain#terrain#personal#parts list#aegis void shield network projector

24 notes

·

View notes

Text

Mild Steel Flanges Details

Why MS Flanges Matter

MS flanges, short for Mild Steel flanges, are essential components in the industrial and construction sectors. These flanges, made from mild steel, are prized for their robust strength, cost-efficiency, and versatility. They serve as crucial connectors, fastening pipes, valves, and various machinery, ensuring that everything stays tightly sealed and leak-free.

The Appeal of Mild Steel

Mild steel is a top choice for many due to its durability, ease of use, and affordability. It offers a great balance between performance and cost, making it resistant to moderate corrosion while withstanding significant pressure. Whether you're working on an industrial project or a construction site, mild steel is a reliable material. For the best MS flanges in India, look no further than Udhhyog, a leading manufacturer in the field.

A Closer Look at Different MS Flanges

Slip-On Flanges: Easy and Effective

Slip-on flanges are known for their ease of installation—they slip over the pipe and are welded into place. This makes them perfect for applications where precise fitting is key. They’re commonly used in low-pressure environments and offer an economical solution for various projects.

Weld Neck Flanges: Built for Performance

Weld neck flanges feature a long, tapered neck that smoothly transitions from the pipe to the flange. This design reduces stress concentrations, making these flanges ideal for high-pressure and high-temperature applications. They are often used in critical systems where reliability and strength are crucial.

Blind Flanges: Sealing with Confidence

Blind flanges are designed to close off the end of a pipe or vessel, with no central hole. They are perfect for sealing off pipelines or openings, providing a strong barrier for maintenance or potential expansion in the future.

Socket Weld Flanges: Strong and Reliable

Socket weld flanges have a recessed area where the pipe fits before being welded. This design ensures a smooth bore and a secure connection, making them suitable for high-pressure applications. They’re commonly used in industries where a strong, leak-proof joint is essential.

Real-World Applications of MS Flanges

MS Flanges in Industrial Operations

In industrial environments, MS flanges are critical for connecting various machinery components, such as pumps and valves. They ensure that these parts are securely joined, helping to maintain efficient operations and prevent leaks.

Their Role in the Construction Industry

MS flanges are vital in construction projects, where they link structural steel components. They provide the necessary strength to handle heavy loads and ensure that different parts of a structure are firmly connected.

Crucial for Piping Systems and Equipment

MS flanges play a key role in piping systems, connecting pipes, valves, and other fittings. They help maintain the system's integrity, making it easier to perform maintenance and repairs when needed.

Why Choose MS Flanges?

Cost-Effective and High Value

MS flanges offer a cost-effective alternative to more expensive materials like stainless steel. Despite their lower cost, they do not compromise on quality, making them a popular choice for various applications.

Durability and Robustness

Mild steel flanges are known for their durability and strength. They are built to withstand various pressures and temperatures, making them suitable for a wide range of industrial and construction uses.

Simple Installation and Maintenance

MS flanges are designed for easy installation and maintenance. Their straightforward design makes them easy to assemble and disassemble, which can save both time and effort during installation and upkeep.

How to Select the Right MS Flange

Important Considerations

When selecting an MS flange, it’s essential to consider the type, pressure rating, and compatibility with other materials. Choosing the right flange ensures a secure connection and optimal performance for your specific application.

Sizing and Specification Essentials

Accurate sizing is crucial for a secure and efficient connection. Refer to industry standards and specifications to ensure you select the right size and type of flange for your project.

This version offers another fresh perspective, ensuring the content remains original and engaging while highlighting the key aspects of MS flanges.

3 notes

·

View notes

Text

US launches $1.6B bid to outpace Asia in packaging tech

New Post has been published on https://thedigitalinsider.com/us-launches-1-6b-bid-to-outpace-asia-in-packaging-tech/

US launches $1.6B bid to outpace Asia in packaging tech

.pp-multiple-authors-boxes-wrapper display:none; img width:100%;

The US is betting big on the future of semiconductor technology, launching a $1.6 billion competition to revolutionise chip packaging and challenge Asia’s longstanding dominance in the field. On July 9, 2024, the US Department of Commerce unveiled its ambitious plan to turbocharge domestic advanced packaging capabilities, a critical yet often overlooked aspect of semiconductor manufacturing.

This move, part of the Biden-Harris Administration’s CHIPS for America program, comes as the US seeks to revitalise its semiconductor industry and reduce dependence on foreign suppliers. Advanced packaging, a crucial step in semiconductor production, has long been dominated by Asian countries like Taiwan and South Korea. By investing heavily in this area, the US aims to reshape the global semiconductor landscape and position itself at the forefront of next-generation chip technology, marking a significant shift in the industry’s balance of power.

US Secretary of Commerce Gina Raimondo emphasised the importance of this move, stating, “President Biden was clear that we need to build a vibrant domestic semiconductor ecosystem here in the US, and advanced packaging is a huge part of that. Thanks to the Biden-Harris Administration’s commitment to investing in America, the US will have multiple advanced packaging options across the country and push the envelope in new packaging technologies.”

The competition will focus on five key R&D areas: equipment and process integration, power delivery and thermal management, connector technology, chiplets ecosystem, and co-design/electronic design automation. The Department of Commerce anticipates making several awards of approximately $150 million each in federal funding per research area, leveraging additional investments from industry and academia.

This strategic investment comes at a crucial time, as emerging AI applications are pushing the boundaries of current technologies. Advanced packaging allows for improvements in system performance, reduced physical footprint, lower power consumption, and decreased costs – all critical factors in maintaining technological leadership.

The Biden-Harris Administration’s push to revitalise American semiconductor manufacturing comes as the global chip shortage has highlighted the risks of overreliance on foreign suppliers. Asia, particularly Taiwan, currently dominates the advanced packaging market. According to a 2021 report by the Semiconductor Industry Association, the US accounts for only 3% of global packaging, testing, and assembly capacity, while Taiwan holds a 54% share, followed by China at 16%.

Under Secretary of Commerce for Standards and Technology and National Institute of Standards and Technology (NIST) Director Laurie E. Locascio outlined an ambitious vision for the program: “Within a decade, through R&D funded by CHIPS for America, we will create a domestic packaging industry where advanced node chips manufactured in the US and abroad can be packaged within the States and where innovative designs and architectures are enabled through leading-edge packaging capabilities.”

The announcement builds on previous efforts by the CHIPS for America program. In February 2024, the program released its first funding opportunity for the National Advanced Packaging Manufacturing Program (NAPMP), focusing on advanced packaging substrates and substrate materials. That initiative garnered significant interest, with over 100 concept papers submitted from 28 states. On May 22, 2024, eight teams were selected to submit complete applications for funding of up to $100 million each over five years.

According to Laurie, the goal is to create multiple high-volume packaging facilities by the decade’s end and reduce reliance on Asian supply lines that pose a security risk that the US “just can’t accept.” In short, the government is prioritising ensuring America’s leadership in all elements of semiconductor manufacturing, “of which advanced packaging is one of the most exciting and critical areas,” White House spokeswoman Robyn Patterson said.

The latest competition is expected to attract significant interest from the US semiconductor ecosystem and shift that balance. It promises substantial federal funding and the opportunity to shape the future of American chip manufacturing. As the global demand for advanced semiconductors continues to grow, driven by AI, 5G, and other emerging technologies, the stakes for technological leadership have never been higher.

As the US embarks on this ambitious endeavour, the world will see if this $1.6 billion bet can challenge Asia’s stronghold on advanced chip packaging and restore America’s position at the forefront of semiconductor innovation.

(Photo by Braden Collum)

See also: Global semiconductor shortage: How the US plans to close the talent gap

Want to learn more about AI and big data from industry leaders? Check out AI & Big Data Expo taking place in Amsterdam, California, and London. The comprehensive event is co-located with other leading events including Intelligent Automation Conference, BlockX, Digital Transformation Week, and Cyber Security & Cloud Expo.

Explore other upcoming enterprise technology events and webinars powered by TechForge here.

Tags: ai, AI semiconductor, artificial intelligence, chips act, law, legal, Legislation, Politics, semiconductor, usa

#2024#5G#Accounts#Administration#ai#ai & big data expo#AI semiconductor#America#amp#applications#Art#artificial#Artificial Intelligence#Asia#automation#betting#biden#Big Data#billion#Business#challenge#China#chip#chip shortage#chips#chips act#Cloud#Commerce#competition#comprehensive

3 notes

·

View notes

Text

Buy Online EFT Frame, EFT Parts, EFT Spreader and EFT Mountings at Best Prices

Building or upgrading your drone requires durable and reliable components and EFT (Excellent Flight Technology) products have become a trusted choice for enthusiasts and professionals alike. Whether you're assembling a new UAV or replacing worn-out components, it's easy and convenient to buy the EFT frame, EFT parts, EFT spreader and EFT mountings online at competitive prices.

Why Choose EFT Drone Components?

EFT is well known for its high-quality drone frames and accessories that offer exceptional strength, stability, and ease of assembly. The EFT frame is typically constructed from lightweight carbon fiber or reinforced materials that ensure maximum flight efficiency without compromising durability. These frames are designed to support various payloads, making them ideal for both agricultural and industrial drone applications.

Get the Right EFT Parts for Your Drone

From arms and landing gear to power distribution boards and connectors, you’ll find a wide selection of EFT parts online to suit your build or repair needs. Authentic EFT parts are manufactured with precision to ensure compatibility with your existing setup, minimizing hassle during installation and maintenance.

EFT Spreader for Spraying Drones

For agricultural drone users, the EFT spreader is a must-have accessory. Designed for efficient and uniform dispersion of seeds, fertilizer or pesticides, the EFT spreader integrates seamlessly with compatible EFT frames and mountings. Its reliable motor system and evenly designed outlets help achieve consistent coverage, improving overall productivity in the field.

Secure Your Equipment with EFT Mountings

Proper mounting is essential for the safe operation of drones, especially when carrying payloads. With EFT mountings, you can securely attach payloads such as tanks, cameras, or sensors to your drone. These EFT mountings are designed for quick installation and easy adjustment, making them perfect for both fixed and modular drone setups.

Shop Online for Best Prices

Purchasing your EFT frame, EFT parts, EFT spreader and EFT mountings online ensures you get access to the latest models and the best deals. Many trusted online retailers offer these components with fast shipping, product warranties and technical support, allowing you to buy with confidence.

0 notes

Text

Absolute EMS and the Evolution of Next-Gen PCB Assembly Services

The assembly of electronics is a vast, evolving field, filled with challenges. Automation has sparked a quiet revolution in the industry, and it continues to shift in that direction. Within this constantly changing horizon of electronics assembly - precision, reliability, and efficiency drive advancement. Absolute EMS, a leader in PCB Assembly Services (PCBA or EMS), offers cutting-edge assembly solutions to demanding high-performance OEMSs. Their technological expertise in press-fit connectors in silicon valley guarantees a strong interconnect without the inconveniences inherent in conventional soldering.

The Engineering Behind Press-Fit Connectors

Press-fit connectors are a replacement for conventional soldered connections, providing a very reliable mechanical and electrical interface. The connector pins have compliant sections that form a gas-tight joint when pressed into plated through-holes (PTHs) of a PCB. The process provides:

Uniform Contact Pressure: Uniform pressure inside the hole is delivered through elastic deformation of the flexible pin, keeping the micro-movements low and signal attenuation low.

Elimination of Soldering Defects: Defects such as cold joints, solder bridges, and thermal stress are fully eliminated.

Superior Mechanical Retention: High insertion pressure and frictional locking avoid removal by shock and vibration.

Improved High-Frequency Signal Integrity: The uniform contact resistance minimizes electromagnetic interference (EMI) and ensures reliable data transmission in RF and high-speed digital circuits.

Complementary High-Precision PCB Assembly Techniques

Absolute EMS also integrates other cutting-edge methodologies in PCB assembly, ensuring adherence to stringent industry standards such as IPC Class 3 for high-reliability applications. These capabilities include:

High-Density Surface Mount Technology (SMT): Advanced pick-and-place systems handle micro-BGAs, fine-pitch QFNs, and 01005 components for compact, high-performance designs. And large BGA (4k+ balls) pick and place.

Selective Through-Hole Technology (THT): Precision-controlled soldering techniques, including wave soldering and selective soldering, enhance the integrity of mechanical and power connections without disturbing other components on the board..

Hybrid Assembly Solutions: A combination of SMT and PTH and that enables complex multi-layer PCB configurations suited for demanding applications.

Automated Optical Inspection (AOI)and X-Ray Inspection: Ensuring defect-free assembly through real-time analysis and verification of solder joints, component placement, and internal structure.

Final Thoughts

For companies looking for Electronic Manufacturing Services , Absolute EMS provides specialized solutions in press-fit connectors, based in Silicon Valley. They constantly strive to deliver the best technology and their dedication to quality, efficiency, and technology makes them a go-to partner for all the high tech OEMS in Silicon Valley and beyond.

To see their entire range of PCB assembly services, contact Absolute EMS and learn how they can get your product to market faster with their electronic manufacturing processes.

0 notes

Text

How to control the CNC spindle motor?

1.Definition of CNC spindle motor A CNC spindle motor is a critical component in a CNC machine, the main function of the spindle motor is to drive the spindle of the mechanical equipment to rotate, so as to complete tasks such as processing and cutting. Its performance directly affects the processing accuracy, efficiency and stability of the equipment.

2.Working principle of CNC spindle motor The operation of the CNC spindle motor is based on the principle of electromagnetic induction. When AC is applied to the three-phase winding, a rotating magnetic field is generated in the stator. This rotating magnetic field cuts the rotor conductor, thereby generating an induced current in the rotor conductor. The induced current interacts with the rotating magnetic field to generate an electromagnetic force that drives the rotor to rotate. There is a certain difference between the speed of the rotor and the speed of the rotating magnetic field. This difference is called the slip. By controlling the slip, the spindle motor speed can be precisely controlled.

3.Components of CNC spindle motor

Stator:The stator is the stationary part of the motor and houses the windings. It is responsible for generating the magnetic field that interacts with the rotor.

Rotor:The rotor is the rotating part of the spindle motor. It is driven by the magnetic field created by the stator. The rotor is connected to the spindle shaft, which directly drives the cutting tool.

Bearings:Bearings support the spindle and allow it to rotate with minimal friction. High-quality bearings are crucial to ensure that the spindle motor operates smoothly and accurately, as they help to reduce vibrations and ensure precision during operation.

Spindle Shaft:The spindle shaft is the central part that connects the rotor to the tool being used in the machining process.

Cooling System:Cooling systems are vital to keep the spindle motor temperature within safe operating limits, especially during high-speed operation.

Encoder:The encoder provides feedback on the position and speed of the spindle motor. It allows the CNC system to accurately control the motor's speed and positioning by sending signals about the rotor's movement to the machine's control system.

Drive System:The drive system consists of components that convert electrical energy into mechanical energy to rotate the spindle. It includes components like the motor controller, inverter, and drive circuitry.

VFD (Variable Frequency Drive):The VFD is used to control the motor's speed by adjusting the frequency of the electrical supply.

Cooling Fan:A cooling fan (or ventilation system) is sometimes incorporated into the motor assembly to provide active air cooling.

Housing:The housing is the outer casing of the spindle motor that protects the internal components, such as the stator, rotor, and bearings, from dirt, debris, and damage.

Electrical Connections:These are the wiring and connectors that supply power to the motor and interface with the CNC controller and other components.

Feedback System:Some advanced spindle motors include additional feedback systems, such as tachometers or resolvers, which provide more precise information on motor speed and position.

4.The control modes of CNC spindle motor

Constant Speed Control Mode:In this mode, the spindle motor runs at a fixed, constant speed throughout the machining process.It is used for operations where the tool does not need to change its speed dynamically during the process.

Constant Torque Control Mode:This mode adjusts the motor’s speed to maintain a constant torque throughout the operation, ensuring the motor delivers consistent cutting force.This is ideal for machining operations where the cutting load varies but the motor's torque needs to remain steady to prevent tool stalling.

Vector Control (Field-Oriented Control, FOC) Mode:Vector control provides high precision and dynamic control of the motor by controlling the magnetic field inside the motor. It adjusts both the torque and speed based on real-time demands.This mode is particularly useful in high-performance CNC systems, providing smoother operation, better acceleration/deceleration, and high-speed control.

Closed-Loop Control Mode:Closed-loop control involves a feedback system where the motor speed, torque, and position are continuously monitored, and adjustments are made in real-time to keep the system running optimally.Feedback devices like encoders or resolvers help achieve high precision and accuracy by adjusting motor parameters to ensure the desired output is achieved.

Open-Loop Control Mode:In open-loop control, there is no feedback mechanism to adjust the motor’s operation based on real-time performance.The motor is controlled based on pre-set parameters, such as speed or power, without ongoing monitoring or adjustments.

Synchronous Motor Control:Synchronous motors operate at a fixed speed, determined by the frequency of the electrical supply.These motors are typically used when precise speed control is required, as they run at a constant speed without fluctuating under load.

Dynamic Brake Control Mode:Dynamic braking is often used for rapid deceleration of the spindle motor after the machining process is completed.This method uses the motor itself to dissipate the kinetic energy, slowing down the motor quickly by converting it into heat.

Speed and Torque Control Mode (Dual Mode):This control mode combines both speed and torque control to give the spindle motor the ability to adjust both parameters simultaneously.

0 notes

Text

The Advantages and Applications of Flexible PCB in Modern Electronics

Introduction

The electronics industry is constantly evolving, and one of the most significant advancements in recent years has been the widespread adoption of Flexible PCB (Printed Circuit Board) technology. Unlike traditional rigid PCBs, Flexible PCB offers unparalleled adaptability, making it ideal for modern compact and high-performance devices. From consumer electronics to medical equipment, Flexible PCB has revolutionized how circuits are designed and implemented.

This article explores the benefits, applications, and future trends of Flexible PCB, highlighting why it has become a cornerstone of innovation in electronics.

What is a Flexible PCB?

A Flexible PCB is a type of printed circuit board made from flexible materials such as polyimide or polyester. Unlike rigid PCBs, which use fiberglass, Flexible PCB can bend, twist, and fold without breaking, enabling more versatile designs.

Key Components of a Flexible PCB

Substrate Material – Typically polyimide, known for its heat resistance and flexibility.

Conductive Layers – Copper traces that form the electrical pathways.

Protective Coating – A coverlay or solder mask to shield the circuits from damage.

Adhesives – Used to bond layers together while maintaining flexibility.

Advantages of Flexible PCB

1. Space and Weight Reduction

One of the biggest advantages of Flexible PCB is its ability to fit into tight spaces. Since it can bend and conform to different shapes, it eliminates the need for bulky connectors and wiring, reducing both size and weight. This makes it perfect for smartphones, wearables, and aerospace applications.

2. Enhanced Durability

Flexible PCB can withstand vibrations, shocks, and repeated bending, making it more durable than rigid PCBs. This is particularly useful in automotive and industrial applications where reliability is critical.

3. Improved Signal Integrity

With fewer interconnects and shorter signal paths, Flexible PCB reduces electromagnetic interference (EMI) and signal loss. This is essential for high-frequency applications like 5G devices and advanced medical imaging systems.

4. Cost-Effective Assembly

Although Flexible PCB may have higher initial material costs, it simplifies assembly by reducing the need for connectors and additional wiring. This leads to lower labor costs and improved production efficiency.

5. Thermal Management

Polyimide-based Flexible PCB can handle high temperatures, making them suitable for applications where heat dissipation is crucial, such as LED lighting and power electronics.

Applications of Flexible PCB

1. Consumer Electronics

Flexible PCB is widely used in smartphones, tablets, and laptops, enabling slimmer designs and foldable screens. Companies like Samsung and Apple rely on Flexible PCB for their cutting-edge devices.

2. Medical Devices

In the medical field, Flexible PCB is used in wearable health monitors, implantable devices, and diagnostic equipment. Its lightweight and biocompatible properties make it ideal for patient-friendly solutions.

3. Automotive Industry

Modern vehicles incorporate Flexible PCB in dashboard displays, sensors, and lighting systems. Its ability to endure harsh environments ensures long-term performance.

4. Aerospace and Defense

Flexible PCB is crucial in satellites, drones, and military equipment due to its lightweight nature and resistance to extreme conditions.

5. Industrial Automation

Robotics and industrial machines use Flexible PCB for reliable signal transmission in dynamic and high-stress environments.

Future Trends in Flexible PCB Technology

1. Stretchable Electronics

Researchers are developing stretchable Flexible PCB that can expand and contract, opening new possibilities for wearable tech and biomedical applications.

2. Integration with IoT

As the Internet of Things (IoT) grows, Flexible PCB will play a key role in connecting smart devices with minimal space requirements.

3. 3D Printed Flexible Circuits

Advancements in 3D printing may allow for custom Flexible PCB designs with even greater complexity and efficiency.

4. Eco-Friendly Materials

Sustainable Flexible PCB materials, such as biodegradable polymers, are being explored to reduce electronic waste.

Conclusion

The rise of Flexible PCB has transformed the electronics industry by offering unmatched flexibility, durability, and efficiency. From smartphones to space technology, its applications are vast and continually expanding. As innovation progresses, Flexible PCB will remain at the forefront of electronic design, enabling smarter, lighter, and more resilient devices.

For engineers and manufacturers, adopting Flexible PCB technology is not just an option—it’s a necessity for staying competitive in a rapidly evolving market.

1 note

·

View note

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] KM OHM 8501 digital DC low resistance meter, also known as micro-ohmmeter, ohmmeter, equipotential tester, adopts microprocessor technology, four-wire method for testing, safe, precise and reliable. Mainly used to measure the wire resistance of cables, the contact resistance of switches, connectors, relays, the resistance of coils, motors, transformer windings, and equipment enclosures, lightning protection belts, ground beams, structures, cabinets, steel bars, water pipes, windows, guardrails, and heat dissipation. Test the connection resistance between metal components of objects such as devices, assembly lines, etc. It is widely used in telecommunications, electric power, meteorology, computer rooms, oil fields, power distribution lines, tower transmission lines, gas stations, factory grounding grids, lightning rods, etc. KM OHM 8501 digital DC low resistance meter is composed of host, monitoring software, test line, communication line, etc. The large-screen LCD display of the main unit is clear at a glance, and the port overload prevention function prevents the instrument from being burned out by misoperation. Can store 500 sets of data, resistance measurement range: 0.001mΩ~300.0KΩ. The upper computer software has functions such as historical data reading, consulting, saving, and reporting. Wide Resistance Range: Measure resistance from 0.001mΩ to 300.0KΩ, offering flexibility for various testing applications. High Resolution: With a resolution of 1mΩ, this meter provides precise and accurate readings for low resistance measurements. Superior Accuracy: Features a high accuracy of ±0.1%FS, ensuring reliable performance and trustworthy results. Data Storage Capacity: Store up to 500 sets of data, making it convenient to log and review multiple tests. USB Data Upload Function: Easily upload stored data to your PC via USB, enabling efficient data analysis and reporting. [ad_2]

0 notes

Text

The KSARIA Corporation manufactures and installs aerospace and military cable for the plant communication infrastructure. KSARIA provides fiber optic and copper cables, shipboard, connectors, as well as assembling the cables. It also installs and repairs cable plant for military and commercial aircraft. They also provide services for military bases, ships, and tactical equipment (“Wards Business Directory” 191). Moreover, it conducts cable interconnect and design services. KSARIA provides logistical operations management for its materials through the on-site installation and testing, service termination, cleaning, repair kits, tools, and consumables. The KSARIA Corp. also offers field services including cable plant installation, on site plant management, shipside logistic support, in-situ testing and field terminations as well as research and development of cable design services (“Wards Business Directory” 161). Despite the provision of these services, KSARIA Corp. is facing numerous challenges especially in Positioning and Assembly of Fiber Optics.The current outstanding deliverable gap that affects the productivity in its service delivery is inefficient qualification methods of repairing the damaged fiber optic cable particularly on the naval aircraft. The solution to this problem has been replacing the damaged cables with effective cables. Notably, this measure is intensively expensive and time consuming (“Wards Business Directory” 177). This leads to operation gap that incorporates complete cleaving has a method of preparing the ends of the optical fibers for splicing. This method is not effective since its leads to low yields and requires high technical skills that KSARIA lacks. Additionally, the method has proven immensely sensitive to be applied or deployed in harsh military environments.The most challenging task is the optical fiber and component alignment and positioning is often experiences during the photonics assembly. This problem often interferes with the accuracy of submicron thereby interfering with the high stability and reasonable resolution required when coupling optic fire with laser light. This process is referred to active alignment, and it involves coupling light sources including laser. The process requires one end of the optical to define the optimal position of the fiber component (“Wards Business Directory” 188). These operations need precision; otherwise, they often interfere with the Military aircraft industry that leads to management with poor precision. The application of laser light often aims at the amount of signal that occurs across the component-to-fiber junction or component-to-component; thus, loss of signal during transmission interferes or undermines the core or intended functions function of the fiber optics. The main function of photonics assembly nanopositioning is to align transmission and receiving components thereby minimizing the light lose during optical coupling. It is the responsibility of KSARIA Corp. to line up the fiber core through assembling. In most cases, the assemblers have misaligned these fiber cores leading to loss of signals. KSARIA Corp. management blames this challenge on the miniature nature of the optic fibers. Moreover, they say that the nature of optic fibers is not the same all times since they are manufactured by different manufacturing processes. KSARIA Corp. is also challenged by the unique nature of the optical components physical parameter that interferes with a degree of accuracy during assembling process (“Wards Business Directory” 184).Despite these Deliverable Gaps of KSARIA Corp., the management must ensure that their clients operations depend on the accuracy of these systems. Therefore, KSARIA Corp. should reevaluate the effective and convenient ways of meeting or serving its customers interest. KSARIA Corp. is currently operating with skilled human operators who might to p_ Read the full article

0 notes

Text

Best Quality Computer Power Cord Manufacturer

The Role of Computer Power Cord Manufacturers: A Spotlight on Concord Industries

In today’s highly interconnected world, where technology drives almost every aspect of our daily lives, the reliability of electrical components such as computer power cords cannot be overstated. These often-overlooked devices are critical to the performance and safety of computer systems. Computer power cord manufacturers, like Concord Industries, play a vital role in ensuring that these essential products meet the stringent standards of modern technology.

Understanding the Importance of Computer Power Cords

A computer power cord manufactuere is the connection between a computer system and the electrical outlet. Its primary function is to supply the necessary power to keep the system running. These cords are designed to handle different levels of voltage and current, depending on the specific requirements of the computer. Without a reliable power cord, a computer may face performance issues, or worse, become susceptible to electrical hazards like short circuits or fires.

As technology has evolved, so has the demand for higher-quality, more durable, and safer power cords. Manufacturers like Concord Industries have risen to this challenge by developing products that ensure a steady, reliable power supply while adhering to strict safety regulations and quality standards.

Concord Industries: A Leader in Power Cord Manufacturing

Concord Industries has established itself as a trusted name in the manufacturing of power cords, including those for computers. The company specializes in producing a wide range of electrical components, from simple power cords to more complex assemblies designed for various types of equipment. Their experience and commitment to quality make them a key player in the field of power cord manufacturing.

One of the company’s key strengths lies in its ability to adapt to the needs of the modern technological landscape. As businesses and consumers continue to demand higher performance and more eco-friendly solutions, Concord Industries has responded by incorporating advanced materials, innovative designs, and eco-conscious manufacturing processes into their products. This adaptability has made the company an industry leader, with clients from various sectors, including consumer electronics, telecommunications, and industrial equipment.

Innovation in Power Cord Design and Manufacturing

Concord Industries places a strong emphasis on the innovation and development of their power cords. They are constantly working to improve their products by incorporating cutting-edge technologies, such as enhanced insulation materials that offer superior heat resistance, and cable jackets that are more durable and resistant to wear and tear. Additionally, the company employs advanced manufacturing processes to ensure that each power cord is rigorously tested for safety and performance.

For example, their power cords are often designed with safety features like over-current protection, which prevents electrical overloads and protects both the computer and the user. In addition, they incorporate various plug types and connectors to meet the needs of international markets, ensuring that their products are compatible with computer power outlets cord manufacturer worldwide.

Environmental sustainability is another focus for Concord Industries. As demand for eco-friendly products grows, the company has committed to using materials that are more sustainable without compromising on quality. By opting for lead-free and halogen-free cables, Concord helps reduce the environmental impact of their products.

Quality Assurance and Compliance with Industry Standards

Safety is paramount when it comes to power cords. A faulty or substandard power cord can result in severe consequences, including electrical fires, device damage, or even injury. As such, manufacturers like Concord Industries ensure their products comply with a host of international standards, including UL (Underwriters Laboratories), IEC (International Electrotechnical Commission), and RoHS (Restriction of Hazardous Substances).

Concord Industries maintains a rigorous quality assurance program to meet these standards. Each power cord is subjected to thorough testing procedures that simulate real-world conditions to assess its durability and performance. This ensures that every product leaving their facility is safe for use in a variety of settings, from home offices to industrial environments.

Meeting Global Demand and Custom Solutions

In today’s global market, consumers and businesses expect products that meet not only functional requirements but also regulatory compliance across various regions. Concord Industries has positioned itself as a flexible and customer-focused manufacturer, offering tailored solutions to meet the unique needs of their clients. Whether a business requires specific power cord lengths, custom plug designs, or cords built to withstand extreme environmental conditions, Concord Industries can provide customized solutions to meet these requirements.

By leveraging its extensive manufacturing capabilities, the company ensures fast and efficient delivery of large orders without compromising quality. This ability to meet both bulk orders and smaller, custom requests has solidified Concord’s position as a preferred supplier for businesses worldwide.

Conclusion

The role of computer power cord manufacturers like Concord Industries is vital in today’s technology-driven world. Through innovation, high-quality manufacturing, and a commitment to safety and environmental sustainability, Concord Industries continues to provide products that meet the ever-evolving needs of the market. Whether you're a consumer looking for a reliable power cord for your personal computer or a business requiring custom solutions for your industrial operations, companies like Concord Industries ensure that technology continues to run smoothly and safely.

Visit:- https://concordindustries.in/computer-power-cord-manufacturer/

1 note

·

View note

Text

How Do MIM Parts Compare to Other Manufacturing Methods?

The world of manufacturing is constantly evolving, with Metal Injection Molding (MIM) emerging as a groundbreaking technology for creating high-precision, complex metal parts. Mike Shopping Room, known for its diverse product offerings, has stepped into the industrial market with its specialized MIM Parts collection. This article delves into the significance of MIM parts, their advantages, applications, and how Mike Shopping Room is positioning itself as a trusted supplier of high-quality MIM components.

What are MIM Parts?

Metal Injection Molding (MIM) is an advanced manufacturing process that combines the flexibility of plastic injection molding with the strength and integrity of metal materials. This process is particularly suitable for producing small, intricate metal parts with exceptional precision and mechanical properties. It has gained popularity in industries where precision, repeatability, and cost-efficiency are crucial.

Benefits of MIM Parts:

1. Complex Geometries: MIM allows for the creation of intricate shapes and complex geometries that would be difficult or impossible to achieve through traditional machining techniques. This makes it ideal for industries requiring precision components.

2. Cost Efficiency: The MIM process offers significant cost savings for high-volume production. By combining molding and sintering techniques, manufacturers can eliminate costly secondary machining steps.

3. High Material Utilization: MIM parts are known for their high material efficiency, reducing waste compared to conventional machining processes, making it both an economical and environmentally friendly solution.

4. Excellent Mechanical Properties: The finished MIM components boast high strength, corrosion resistance, and durability, making them suitable for demanding environments, including automotive, medical, and aerospace sectors.

5. Design Flexibility: Designers can experiment with innovative part geometries, consolidating multiple components into a single part, further reducing assembly time and costs.

Applications of MIM Parts:

1. Automotive Industry: The automotive sector relies heavily on high-performance metal components for engines, transmissions, and safety systems. MIM parts are commonly used for:

2. Medical Devices: Precision is critical in the medical field, and MIM parts meet these stringent requirements. They are often used in: Surgical instruments, Orthopedic implants, Dental devices, Minimally invasive surgical tools

3. Electronics and Consumer Goods: MIM parts enable the creation of miniaturized components essential for modern electronics and personal gadgets. Examples include: Smartphone hinges, Camera components, Laptop connectors. Wearable device frames

4. Aerospace and Defense: In the aerospace sector, MIM parts contribute to lightweight, high-strength components that improve performance and fuel efficiency. These include: Aircraft brackets, Control system components, Sensor mounts,Firearm components in the defense industry

5. Industrial Tools and Equipment: powdered metal gears ability to produce strong, wear-resistant parts makes it a popular choice for industrial equipment and tools, such as: Cutting tools, Hydraulic components, Locking mechanisms

Mike Shopping Room’s Commitment to Quality MIM Parts:

At Mike Shopping Room, customers can browse a comprehensive range of MIM parts tailored to different industry needs. From small consumer product components to precision medical and aerospace parts, Mike Shopping Room ensures that every customer finds the right solution for their application.

Sourcing and Quality Control:

Mike Shopping Room partners with reputable manufacturers who specialize in MIM technology. Every part undergoes rigorous quality checks, including:

Customization Capabilities:

Understanding that many industries require custom-designed components, Mike Shopping Room offers tailored MIM solutions. Customers can provide specifications, and the team works closely with manufacturing partners to deliver parts that meet exact requirements.

Competitive Pricing: By leveraging direct sourcing relationships, Mike Shopping Room offers high-quality MIM parts at competitive prices, making advanced manufacturing technology accessible to businesses of all sizes.

Why Choose MIM Parts from Mike Shopping Room?

1. Comprehensive Product Catalog: With a diverse selection of MIM parts covering numerous industries, customers can find solutions for even the most specialized applications.

2. Trusted Manufacturing Partners: Every MIM component is sourced from established manufacturers with proven expertise in metal injection molding, ensuring consistent quality and performance.

3. Transparent Product Information: Each product listing provides detailed specifications, including material properties, dimensions, tolerances, and recommended applications, allowing customers to make informed purchasing decisions.

4. Reliable Delivery: Mike Shopping Room understands the importance of on-time delivery, especially for businesses with tight production schedules. Efficient logistics networks ensure prompt and reliable delivery of all MIM parts.

5. Expert Customer Support: The dedicated support team at Mike Shopping Room assists customers with product selection, customization inquiries, and order tracking, ensuring a smooth purchasing experience from start to finish.

Environmental Responsibility:

The MIM process already offers improved material utilization compared to traditional machining methods, but Mike Shopping Room takes this commitment further by partnering with manufacturers that adopt eco-friendly practices. These include:

To stay ahead of market demands, Mike Shopping Room actively explores new materials, improved sintering techniques, and enhanced quality control methods to deliver even more reliable and versatile MIM components.

Expansion into Emerging Markets:

As industries like electric vehicles (EV), renewable energy, and IoT (Internet of Things) continue to grow, the demand for precision MIM parts is expected to rise. Mike Shopping Room aims to expand its offerings to serve these emerging sectors, ensuring businesses have access to cutting-edge components.

Technological Integration:

Mike Shopping Room plans to integrate digital tools like AI-powered product recommendations and augmented reality previews, allowing customers to explore products in a virtual environment before purchasing.

Strengthening Partnerships:

To maintain its leadership in the MIM parts space, Mike Shopping Room will continue to forge partnerships with innovative manufacturers and technology leaders, ensuring continuous access to the latest advancements in MIM technology.

Conclusion

Mike Shopping Room is rapidly emerging as a trusted supplier of MIM parts, offering high-quality, precision-engineered components for a wide range of applications. With its focus on quality assurance, competitive pricing, customization options, and customer-centric service, the platform is well-positioned to meet the evolving needs of modern industries. Whether you’re a manufacturer seeking reliable automotive components, a medical device company requiring surgical instrument parts, or a tech firm looking for precision electronics components, Mike Shopping Room provides a comprehensive solution for all your MIM part needs.

0 notes

Text

Dielectric Insulation Properties of PTFE Film Tape: Key to Safe Electrical Applications

In electrical applications, the choice of insulating materials is critical to ensuring safety and efficiency. Skived PTFE tape, known for its exceptional dielectric properties, plays a pivotal role in insulating high-temperature coils and various electrical components. This tape, also referred to as Skived PTFE tape or Teflon film tape, provides reliable insulation that withstands harsh conditions, making it a preferred option in industries such as aerospace, telecommunications, and manufacturing.

Understanding Dielectric Properties

Dielectric materials possess the ability to insulate against electrical currents while also storing electric energy within an electric field. The dielectric constant, or relative permittivity, is a key measure of a material's ability to resist the flow of electric current. Materials with a high dielectric strength can withstand considerable voltage without breaking down.

Why PTFE Excels as a Dielectric Material

PTFE (Polytetrafluoroethylene) has impressive dielectric properties, which stem from its molecular structure. This synthetic polymer is characterized by strong carbon-fluorine bonds, resulting in an extremely low dielectric constant and excellent dielectric strength. These attributes make skived PTFE film tape particularly suitable for various electrical applications.

High Dielectric Strength: PTFE film tape can handle voltages of up to 5000 volts, making it an ideal choice for high-voltage applications. Its ability to maintain integrity under stress helps prevent electrical failures in devices.

Low Dielectric Constant: With a dielectric constant typically around 2.1 – 2.2, PTFE provides excellent insulation while minimally affecting signal transmission. This feature is crucial in applications where signal integrity is paramount, such as in RF (radio frequency) and microwave technologies.

Thermal Stability: PTFE maintains its properties across a wide temperature range, from -450°F to 500°F (-268°C to 260°C). This thermal stability allows PTFE film tape to perform effectively even in extreme conditions.

Applications of PTFE Film Tape in Electrical Insulation

The outstanding dielectric properties of PTFE film tape make it suitable for a variety of applications. Let’s examine some specific uses:

1. Insulating High-Temperature Coils

In applications such as motors and transformers, high-temperature coils are essential for efficient operation. PTFE film adhesive tape can be used to insulate these coils, shielding them from environmental factors and ensuring safety during high-temperature operations. For instance, in electric motors, PTFE insulation not only protects the coils but also reduces the risk of short circuits caused by heat degradation of other insulating materials.

2. Electrical Components Insulation

Components such as capacitors, inductors, and connectors often require superior insulation to meet performance standards. By employing skived PTFE tape, manufacturers can enhance the reliability of these components. For example, using PTFE tape to insulate connectors in automotive electrical systems provides resistance to moisture and chemicals while maintaining a robust electrical barrier.

3. Aerospace Applications

The aerospace industry demands materials that can withstand extreme temperatures and harsh environments. Teflon film tape is widely used in this sector for insulating wiring and electrical assemblies. Its lightweight properties combined with excellent thermal stability make it ideal for aircraft systems where weight reduction and reliability are vital. Skived PTFE tape helps keep critical systems operational, even under severe conditions.

4. Telecommunications

As telecommunication technologies evolve, the need for reliable insulation in high-frequency applications becomes increasingly important. PTFE’s low dielectric loss is a significant advantage in radio frequency applications, ensuring efficient communication signals. For example, in cable assemblies, PTFE film tape provides effective insulation that minimizes signal interference, allowing for clear and consistent communication.

Advantages of Using PTFE Film Tape

Incorporating PTFE film tape into electrical applications offers several benefits:

1. Exceptional Performance

The dielectric properties of PTFE film tape enable it to perform in demanding conditions without compromising safety or functionality. This performance ensures that electrical components remain effective over extended periods.

2. Chemical Resistance

PTFE’s resistance to a wide range of chemicals further enhances its utility in electrical applications. It can endure exposure to solvents, acids, and bases without degrading, making it ideal for use in environments where chemical contact is a risk.

3. Easy Application and Flexibility

Skived PTFE tape is lightweight and easy to manipulate, allowing for quick and efficient application in a variety of complex configurations. This ease of use can save time during assembly processes, increasing overall productivity.

4. Longevity and Cost-Effectiveness

The durability of PTFE film tape contributes to reduced replacement and maintenance costs. By extending the lifespan of insulation materials, businesses can achieve considerable long-term savings.

Examples of PTFE Film Tape in Action

To illustrate the practical applications of PTFE tape, consider a company that designs high-performance electric motors. By using Teflon film tape to insulate the coils, they ensure that the motors can operate at high temperatures without risk of electrical failure. In another example, an aerospace manufacturer may use skived PTFE tape to insulate sensitive electronics, providing peace of mind that these critical components will perform reliably throughout their service life.

Conclusion

The exceptional dielectric insulation properties of PTFE film tape make it a vital component in ensuring safe and efficient electrical applications. Its high dielectric strength, low dielectric constant, and thermal stability ensure it exceeds performance expectations across various industries. Whether insulating high-temperature coils, electrical components, or applications in aerospace and telecommunications, skived PTFE tape proves indispensable.

By selecting the appropriate PTFE film tape, businesses can enhance the reliability and safety of their electrical systems, meeting the highest standards demanded by today’s advanced technologies. As industries continue to develop, the relevance of PTFE film tape will grow, securing its place in the future of electrical applications.

0 notes

Text

Unlocking Quality with Aeliya Marine’s Electronic Components: A Must-Have for Modern Projects

In today’s fast-paced world of innovation and technology, having access to reliable, high-quality electronic components is crucial for building anything from advanced marine systems to everyday electronics. Aeliya Marine, a trusted name in the industry, offers a wide array of electronic components designed to meet the needs of both hobbyists and professionals. Whether you’re working on a marine project or an electronic engineering task, their collection of products provides the perfect solution.

Why Choose Aeliya Marine's Electronic Components?

1. Premium Quality Aeliya Marine prides itself on offering only the highest quality products in the electronic component market. Their components are sourced from reputable manufacturers, ensuring that they meet the strictest performance standards. This focus on quality translates into longevity and reliability for your projects, helping you achieve lasting results.

2. Wide Selection The range of electronic components available at Aeliya Marine covers all the essentials needed for complex and simple electronic applications alike. From connectors and cables to circuit boards and sensors, their collection caters to a diverse set of requirements, whether you're working on power systems, navigation systems, or other electrical engineering tasks.

3. Specialization in Marine Electronics For those specifically working within the marine industry, Aeliya Marine stands out with its specialized electronic components designed to withstand the harsh marine environment. These components are built to resist corrosion, exposure to saltwater, and extreme temperatures, ensuring that your systems remain functional in even the toughest conditions.

4. Affordable Pricing Despite offering high-end, industry-grade components, Aeliya Marine is committed to ensuring competitive pricing. They provide value without compromising on performance, making it easier for individuals and businesses to access premium-grade products without stretching their budgets.

Some Popular Categories from Aeliya Marine’s Electronic Collection

Connectors and Adapters: For a seamless integration of your system, Aeliya Marine offers a variety of connectors and adapters suited to different power and data transmission requirements. These components are durable, easy to install, and designed to maximize your setup's functionality.

Switches & Relays: If you need reliable control in your projects, Aeliya Marine’s selection of switches and relays is up to the task. Their robust designs ensure long-term operation, even in challenging environments.

Marine Navigation Electronics: When navigating open waters, accuracy and reliability are crucial. Aeliya Marine provides high-quality sensors, GPS systems, and navigation electronics that ensure you stay on course, even in unpredictable conditions.

Power Management Components: These include items like power inverters, regulators, and batteries, which are essential for managing the power flow in various systems. Whether you're creating a self-sustaining power grid or optimizing an existing setup, Aeliya Marine’s components help ensure efficiency and safety.

Soldering and Assembly Tools: For those working on electronic assembly, Aeliya Marine offers soldering tools that facilitate quick, safe, and effective component connections. These tools are built for precision and ease of use, making them ideal for both beginners and professionals.

How Aeliya Marine Is Different From Other Suppliers?

Customer-Centric Service: Aeliya Marine focuses on delivering an excellent customer experience by offering prompt responses to queries, technical support, and hassle-free returns. Their dedication to customer satisfaction sets them apart from many other suppliers in the field.

Technical Expertise: Whether you need advice on the best component for your project or help with troubleshooting, Aeliya Marine’s team of experts is always ready to assist. Their deep understanding of marine and electronic systems ensures that you get the right solutions for your specific needs.

Global Reach: Aeliya Marine ships to various international locations, ensuring that no matter where you are, you can access the components you need for your projects.

Conclusion

If you are looking to bring your electronic project to life with precision and reliability, Aeliya Marine’s electronic components collection offers everything you need. With high-quality products, specialized marine solutions, and exceptional customer service, they are a one-stop shop for engineers, hobbyists, and marine professionals alike. Visit Aeliya Marine's Electronic Components Collection today to explore their extensive catalog and elevate your projects to the next level!

0 notes

Text

Testing Equipment, Current Parts Supply, and Electronic Part Distributors: A Total Blueprint!

In the current state-of-the-art scene, the positions of testing equipment wholesalers, present-day parts suppliers, and electronic part shippers are the keys to ensuring smooth action and the capability of collecting and mechanical cycles. These wholesalers structure a fundamental piece of the stock organization, giving the gadgets endless parts expected to keep adventures working at ideal levels. Each trader order serves a stand-out capacity, offering specific things and organizations for various present-day necessities. Could we dive into each arrangement to fathom their significance and how they add to organizations worldwide?

The Best Services of testing equipment distributors

Testing equipment is central to significant control, prosperity, and progress across different regions. From the aerodynamic exchange to equipment and clinical development, testing equipment is crucial for affirming product execution, ensuring security standards are met, and detecting potential issues before large-scale assembly or course. Testing equipment distributors offer many instruments to check, assess, and endorse the introduction of various products and systems. These distributers offer equipment for various testing needs, including electrical, mechanical, and environmental testing.

They supply autonomous devices and complex test structures that combine different testing abilities into one phase. Testing gear traders provide excellent equipment and habitually offer change organizations, specific assistance, and training to guarantee the equipment is utilized accurately. In endeavors where precision and consistency are crucial, these wholesalers play an essential role in maintaining the decency of testing techniques and ensuring that devices satisfy the standard rules.

An Advancement of Industrial Parts Supply

Industrial Parts Supply vendors through the best platform like Pacific IC Source expect a central job in the smooth course of collecting and making workplaces. They give the normal substances, new parts, and contraption parts vital for keeping machines running and thwarting costly available energy. From headings, cogwheels, and valves to treatments, seals, and motors, these suppliers ensure that organizations approach the parts expected to stay aware of and fix their equipment.

Industrial parts supply wholesalers are fundamental to maintaining the continuity of exercises. Vehicle breakdowns, mining, energy, and gathering equipment breakdowns can cause significant financial misfortunes. By having quick access to critical new parts, associations can reduce the risk of obstruction. Likewise, present-day parts dealers often offer parts from various manufacturers, permitting associations to pick parts that best suit their prerequisites and monetary plans.

Why is Electronic Component Distributors Vital?

With movements in development, various current parts suppliers have combined mechanized stages where associations can organize parts on the web, track stock, and even get revamped plans. This is a massive shift towards streamlining acquisition processes and further creating efficiency in adventures relying on collecting and making plans just under the wire. Electronic Component Distributors play a fundamental role in the device business, providing the parts that power current equipment, from cells and computers to clinical contraptions and present-day mechanical assemblies.

These wholesalers supply many parts, including resistors, capacitors, semiconductors, facilitated circuits (ICs), diodes, and connectors. The meaning of electronic parts in the present mechanical world couldn't be more critical. As organizations continue creating, there is an interest in the better execution of electronic parts than in helping types of progress in computerization, fake mental ability, media correspondences, and various fields. Electronic part wholesalers ensure that creators and architects have a strong induction of the parts expected for thing headway, fixing, and upkeep.

Conclusion

Testing equipment traders, current suppliers, and electronic parts deals are fundamental in modern adventures. They structure the underpinning of the stock organization for gathering, developing, and creating regions, ensuring associations can access the instruments and parts expected to maintain high applicable standards and avoid extremely unsettling influences. As the cutting-edge world continues to evolve, these dealers will remain essential to the development and success of association’s worldwide, contributing fundamental resources for progression and capability.

0 notes

Text

Top Benefits of M12 Waterproof Custom Cable Assembly in Vietnam

Custom cable assemblies play a significant role in applications that require reliability, durability and accuracy. In particular, the M12 waterproof custom cable assembly in Vietnam has received much attention as it can ensure consistent, reliable connections in harsh conditions. As industrial automation, robotics, and sensor technologies evolve, there is an increasing demand for high-quality wire assemblies. The advantages of M12 waterproof cable assemblies and the reasons Vietnamese firms choose them will be discussed here.

What Are M12 Waterproof Cable Assemblies?

M12 waterproof cable assemblies are unique cables with strong connectors for extreme environments. These assemblies are waterproofed with an IP67 or IP68 construction and resistant to dust, moisture, and other contamination. Because such assemblies can be integrated into a broad spectrum of applications, depending on their configurations, assemblies can be applied to diverse applications, from industrial automation, for example, and robotics to sensor systems. Popular products include:

M12 molded cable with male and female connectors

M12 to RJ45 Ethernet cables

M12 panel mount cables

M12 cordsets with shielded cables

M12 circular connectors with 8-pin configurations

The fine designs of these options allow manufacturers to tailor them to the functional needs of the operational unit(s).

Benefits of M12 Waterproof Custom Cable Assembly in Vietnam

Superior Protection in Harsh Environments

M12 waterproof cable assemblies operate in challenging conditions. Their IP67 or IP68 rating ensures that the device is completely sealed against dust and immersion in liquids and is thus suitable for outdoor and industrial use. Vietnamese industries, including manufacturing, agriculture, and logistics, are based on these packages and are used in, for instance:

Industrial automation

Robotics systems

Environmental sensors

This durability ensures uninterrupted performance, even in extreme environments.

Flexibility and Versatility

With various configurations such as "M12 straight cables", "M12 angled connector", and "rapid-disconnect cords," they are also sufficiently general-purpose to be able to be used in a wide range of application networks. They are compatible with different systems, whether you require:

M12 sensor cords with quick disconnects

M12 extension cables with strain relief

M12 power cables

This adaptability allows businesses to use a single solution for multiple applications saving time and costs.

Enhanced Connectivity and Signal Integrity

A characteristic of the M12 cable assemblies is the strong signal integrity. Shielded cables and PUR jacketed cables are advancements to prevent electromagnetic interference (EMI) and mechanical stressing. It is efficient in high-speed data transfer-related applications (such as robots and industrial Ethernet, etc. For example, M12 D-coded cordsets for Profibus can reliably provide bilateral communication for large and complex automation networks.

Space-Saving Design

M12 waterproof cable assemblies are compact yet robust. The inclusion of splitters like the M12 SR splitter cable allows one signal to be distributed to multiple outputs minimizing the need for additional cables and connectors. It is valuable for space-constrained setups, making these assemblies famous for Vietnam's rapidly modernizing industries.

Easy Installation and Maintenance

Installation and maintenance are easy. Additional ease-of-use characteristics are quick-disconnect cords, right-angle connectors, and strain-relieving elements, which have all played a significant role in simplifying setup and replacement, reducing downtime. Products with field-operable M12 connectors and M12 over-molded cord sets with PUR jackets exhibit secure connections and fast-release capabilities when needed.

Applications in Vietnam

Industries are using custom cable assembly in Vietnam to perform a broad range of demanding applications:

Industrial Automation: For connecting sensors, actuators, and controllers in innovative factories.

Robotics: Enabling precise movement and data communication in robotic systems.

Environmental Monitoring: Provide robust connections for outdoor applications, including agricultural and environmental applications, etc.

The adaptability of these assemblies makes them indispensable across multiple sectors.

At SINNHONG ELECTRONICS CO., LIMITED, customers with a demanding need for a high-quality, unique custom cable assembly in Vietnam can obtain the best-in-class custom solutions to their specific needs. The company's experience in producing M12 waterproof custom cable assembly in Vietnam enables the maintenance of high quality and high performance of all product lines.

Future Trends in Custom Cable Assembly

As Vietnam's industries evolve the demand for advanced cable assemblies will rise. Emerging technologies like IoT, smart factories and autonomous systems will require enhanced connectivity solutions. Custom cable assembly in Vietnam will enable these advancements offering products that combine durability, efficiency and customization.

SINNHONG ELECTRONICS CO., LIMITED's investment in custom cable assembly in Vietnam is a step toward better connection, increased operational effectiveness and future-proofing industrial processes. Select the best option now to guarantee your business stays ahead of the curve in Vietnam's ever-changing industrial scene.

0 notes