#hardwarestartup

Explore tagged Tumblr posts

Text

💼 How Indian Hardware Is Making a Global Mark This episode explores: 🔩 Designer fittings that rival global luxury brands 🌎 Export success stories from Indian factories 🇮🇳 Why Make in India is more than a slogan—it's a global business strategy 🎧 Tune into this inspiring journey only on The Founder's Dream

#branding#podcast#entrepreneur#foundersdreampodcast#founder#business#startup#personal branding#podcasting#MakeInIndia#TFDPodcast#HardwareStartup#ExportIndia#IndianEntrepreneurs

0 notes

Text

The Future of Electronics Starts with the PCB — And It’s Being Built in India

Behind every smartphone, drone, EV, or IoT device, there’s one common core: the Printed Circuit Board (PCB). Often overlooked, yet absolutely essential, PCBs are the unsung heroes of the modern world.

If you're developing a new tech product, here's something you need to know: India is quickly becoming the global hub for PCB fabrication and assembly.

What is PCB Fabrication?

PCB fabrication is the process of manufacturing the actual circuit board — the foundation that holds and connects all electronic components. It involves precise steps such as:

Layering copper and substrate materials

Etching pathways

Drilling and plating vias

Applying solder masks and silkscreens

Electrical testing and inspection

A top-tier PCB fabrication company in India provides quality manufacturing that meets international standards, all while remaining cost-effective and scalable for startups or mass production.

What is PCB Assembly?

Once the board is fabricated, it’s time for PCB assembly — the process of placing and soldering components like resistors, capacitors, and microcontrollers onto the board. Assembly involves:

Surface Mount Technology (SMT)

Through-Hole Technology (THT)

Component placement automation

Reflow soldering and inspection

Functional testing and quality control

A reliable PCB assembly company in India will ensure your product functions flawlessly from the start, and can scale as your demand grows.

Why India is the Smart Choice

Here’s why companies across the globe are turning to India for their PCB needs:

1. Skilled Engineering Talent India has a vast pool of trained professionals with deep expertise in electronics manufacturing and design.

2. State-of-the-Art Facilities Leading PCB companies in India operate world-class cleanrooms and production lines equipped with high-speed SMT machines and automated testing tools.

3. Competitive Costs Get high-quality PCBs at globally competitive prices — without compromising reliability or delivery speed.

4. Fast Prototyping and Mass Production Indian companies support both small-batch prototyping and high-volume orders with quick turnaround times.

5. Compliance and Quality Most Indian manufacturers follow international standards (ISO, IPC, RoHS), ensuring your boards are ready for export or high-performance applications.

Who Needs a PCB Partner in India?

If you're building or scaling a product in any of these industries:

Consumer Electronics

Industrial Automation

Electric Vehicles

Medical Devices

Aerospace and Defense

Telecommunications

IoT and Wearables

Then partnering with a PCB fabrication and assembly company in India could dramatically reduce your time-to-market while keeping production costs under control.

Final Thoughts

The electronics industry is evolving fast. To stay competitive, you need speed, precision, and reliability — right from the circuit board up. By working with a top-tier PCB fabrication or assembly company in India, you're investing in a foundation that’s built for innovation.

India isn't just manufacturing PCBs. It's powering the next generation of technology

#PCB#ElectronicsManufacturing#TechStartup#ProductDesign#PCBIndia#PCBAssembly#HardwareStartup#Innovation#ElectronicsEngineering#PCBFabrication#IndustrialDesign#MadeInIndia

1 note

·

View note

Text

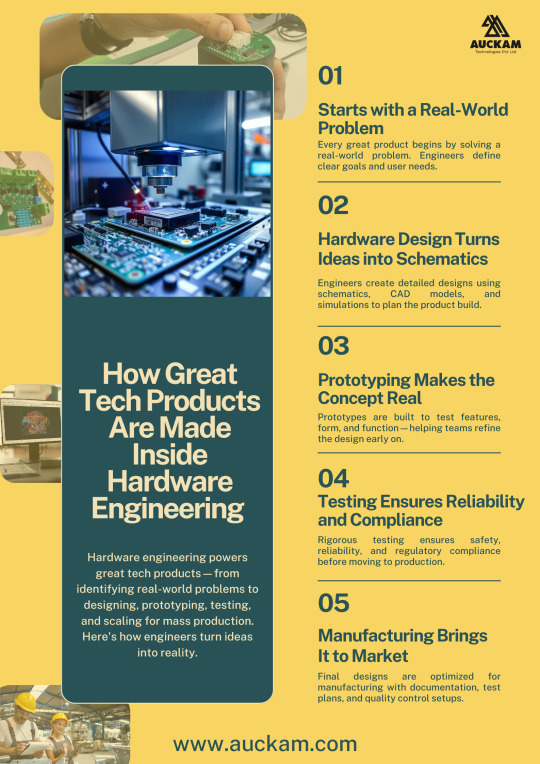

From idea to market, great tech products are built on strong hardware engineering. This step-by-step guide breaks down how real-world problems are transformed into scalable solutions through schematics, prototyping, testing, and manufacturing.

Whether you're designing IoT systems, MedTech devices, or industrial automation tools, Auckam Technologies helps bring your product vision to life with precision and reliability.

👉 Explore full-service hardware engineering at: www.auckam.com

#HardwareEngineering#TechInnovation#PCBDesign#ProductDevelopment#ElectronicsDesign#EmbeddedSystems#IoTDevices#Prototyping#ElectronicsManufacturing#EngineeringProcess#SmartProductDesign#TechStartupTools#HardwareStartup#ProductToMarket#EngineeringWorkflow#AuckamTechnologies

0 notes

Text

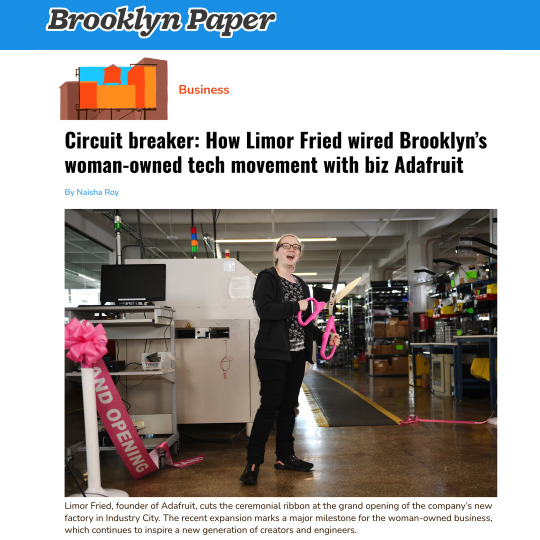

Circuit breaker: How Limor Fried wired Brooklyn’s woman-owned tech movement with biz Adafruit 🔧💡👩💻

Article from Brooklyn Paper, by, Naisha Roy - Limor Fried's journey in founding Adafruit, a Brooklyn-based, woman-owned electronics company. Limor started the business during her MIT studies, creating open-source hardware projects. Adafruit has since grown, focused on inspiring creators through STEM education and DIY electronics kits. Brooklyn Paper is a local publication covering news, business, and cultural stories in Brooklyn, focusing on community-driven content - thanks Naisha!

#adafruit#industrycity#brooklyn#brooklyntech#womenintech#makersmovement#opensourcehardware#techinnovation#electronicsengineering#stemeducation#hardwarehacking#nycstartup#femaleentrepreneurs#techpioneer#buildthefuture#diyelectronics#womanownedbusiness#engineerlife#handsonlearning#techcreators#innovationlab#makersgonnamake#brooklynbusiness#hardwarestartups

12 notes

·

View notes

Text

From Brainstorm to Breakthrough, In Just Days!

Got a brilliant product idea? Don’t let it collect dust on the drawing board. With CreateProto’s Rapid Prototyping & Tooling, you can bring your vision to life faster than ever.

Whether you're fine-tuning a product, pitching to investors, or validating a bold concept, speed is your secret weapon, and CreateProto delivers it with precision.

Turn ideas into impact. https://createproto.com/services/rapid-prototyping-and-tooling/

#RapidPrototyping#InnovationInMotion#CreateProto#ProductDevelopment#HardwareStartups#DesignSprint#FromIdeaToReality#EngineeringExcellence#SpeedToMarket

0 notes

Link

#ComputingInfrastructure#GlobalTechEcosystems#HardwareStartups#Open-SourceHardware#RegionalDevelopmentStrategies#RISC-V#semiconductorinnovation#TechnologyCommercialization

0 notes

Text

🤖 YOUR $50k Prototype Budget Just Got Fired! GreatLight Instant Win: ✅ 0-Second Quotes ✅ DFM AI Doctor kills design flaws ✅ 100+ Materials/FINISHES”

🔥 GET SAMPLE IN 72H SCAN CODE → NO SETUP FEE! https://glcncmachining.com/cnc-machining-online-quotation/

RapidPrototyping #DFM #ProductDevelopment #HardwareStartup #CNCMachining #Manufacturing #Engineering #SupplyChain

0 notes

Photo

Follow us on telegram : https://t.me/sharesbazaar Facebook page: Sharesbazaar India Website link in bio For the knowledge on stock market Also, you can always contact our team for any of your queries regarding stock Market on the below mentioned contact details: 18001201448 +919966600084 +919966999086 [email protected] #renderweekly #productrendering #productdaily #rendershot #id_curated #techinspiration #designburger #weeklydesignchallenge #dopely #lemanoo sh #designwanted #keyshot #rendering #yankodesign #produkthunter #designboom #hardwarestartup #designbunker #productdaily #productdesign #Industrialdesign #designinspiration #designporn #industrialdesigner #productdesigner #designstudio (at shares bazaar) https://www.instagram.com/p/CCVhcaNlHS9/?igshid=mc2m6jqv98uz

#renderweekly#productrendering#productdaily#rendershot#id_curated#techinspiration#designburger#weeklydesignchallenge#dopely#lemanoo#designwanted#keyshot#rendering#yankodesign#produkthunter#designboom#hardwarestartup#designbunker#productdesign#industrialdesign#designinspiration#designporn#industrialdesigner#productdesigner#designstudio

0 notes

Link

Despite the anti-patent position that Mark Cuban and many VCs take regarding investment in startups, owning or not owning patents makes a difference - a HUGE difference.

During the past three years of Unicorn, Inc., I focused on building a robust, strategically developed patent position for my startup - now with about three dozen patents in the works. Here’s why ... http://andygibbs.com/mark-cuban-says-my-startups-patents-aint-worth-jack-s_-_t/

1 note

·

View note

Photo

Finally! Our webshop is online again! Pre-order your SmartPlane Pro today! -> https://shop.tobyrich.com #webshop #smartplane #smartplanepro #moskito #rcplane #rchobby #rcflying #rcairplane #drohne #modellbau #gründer #gründen #bremen #hardwarestartup #fpvdrone #fpvracing #dhdl #tobyrich #avgeek #bluetooth #djispark #durinum #modellflug #modellflugzeug #slowflyer #parkflyer (at TobyRich)

#drohne#bremen#hardwarestartup#gründer#bluetooth#dhdl#fpvracing#gründen#rchobby#djispark#modellbau#modellflug#parkflyer#smartplanepro#rcflying#slowflyer#fpvdrone#webshop#rcairplane#tobyrich#durinum#smartplane#rcplane#avgeek#modellflugzeug#moskito

0 notes

Photo

As Ferris Bueller once said: "Life moves pretty fast. If you don't stop and look around once in a while, you could miss it." . It's been a blast working with @cyrclephone, @mymaimineee, and @cyrchristina these last few weeks! So excited to FOLLOW their FIRST LOOK Tour journey this fall. . 🙌🥂🤗 . P.S. Highly recommend @wework Labs Seattle! @aileenmcgraw and Elizabeth Scallon work super hard to connect teams with resources and collaboration opportunities. #GoTeam #BeNonRectangular #WeWork #WeWorkLabs #WeWorkLabsSeattle #SeattleStartup #FemaleEntrepreneur #FemaleFounder #Marketing #WomeninTech #WomeninBusiness #AlwaysLearning #EntrepreneurLife #StartupLife #StartupGrind #StartupJourney #NewTech #Engineering #Electronics #HardwareStartup #WomeninHardware #WomeninEngineering via Instagram https://ift.tt/2NtNbhG

0 notes

Text

Hardware Innovation: Manufacturing 101 & PCB Factory Tour @techdesign_com is joining forces with @AnchorTaiwan to bring an informative training session in June. #ElectronicManufacturing #EMS #HardwareStartup #hardware #PCB Details: https://www.facebook.com/events/205030110282488/ …pic.twitter.com/wL0DSV7yG9

Hardware Innovation: Manufacturing 101 & PCB Factory Tour @techdesign_com is joining forces with @AnchorTaiwan to bring an informative training session in June. #ElectronicManufacturing #EMS #HardwareStartup #hardware #PCB

Details: https://www.facebook.com/events/205030110282488/ …pic.twitter.com/wL0DSV7yG9

source https://twitter.com/techdesign_com/status/991579747288207361

View On WordPress

0 notes

Text

Explore a detailed look at a professional PCB layout used in advanced electronics. Ideal for hardware engineers, embedded system designers, and tech creators looking for real-world circuit board inspiration. Perfect for IoT, robotics, and product development projects.

Your future begins today! Explore smart solutions that shape tomorrow. Click to learn more!

www.auckam.com

#PCBDesignInspiration#CircuitBoardDesign#ElectronicsProject#TechHardware#EmbeddedSystems#DIYIoT#PCBLayoutIdeas#ElectronicsEngineering#PCBArt#SmartDeviceDesign#IoTProjects#EngineeringDesign#PrototypeDevelopment#HardwareStartup

0 notes

Photo

If you only have 24 hours in a day, may one of them be about building and scaling hardware companies. Great to share lessons learned with the teams at @startupbootcamp this morning. #startup #startuplife #speaking #hardware #hardwarestartup #startupbootcamp https://ift.tt/2EGvEPU

0 notes

Text

Laurence on Manufacturing

Manufacturing.

A word with two feet in the past and a hand pointed firmly towards the future.

To me, “manufacturing” conjures images of outdated industries and bygone eras as freely as it does iPhones and tablets. In the fast-paced, blink-and-you-miss it world of today, where tech startups can go from 0 to 100,000 users in a day, the monolithic, meticulous process of manufacturing feels wildly out of place.

At Hammerhead, and in this rapidly-expanding universe of connected devices, manufacturing is necessary to bring our product to you. We’re creating a physical tool to be used by many thousands of people. Yet for many companies in our position, the very mention of the word manufacturing sparks fears of complication and feelings of stress. Why? Because in the vast ocean of opportunity and possibility of the tech startup industry, manufacturing is a steel anvil. In skilled hands, this anvil can be used to forge effective, beautiful products. Make a mistake, though, and it can drag you straight to the briny deep. When we hit our crowdfunding goal with Hammerhead, setting ourselves on a course to manufacture thousands of devices, one might say we tied that anvil to our legs and tossed it overboard.

It is precisely this thinking that makes so many startups steer clear of manufacturing altogether. Software is something that can be released to the world in phases. When a company releases an app, they are able to continue working on it long after its initial release. That process is approachable, low overhead, and allows for great creativity and flexibility. With hardware, something that will one day sit on a shelf (or, in our case, on your handlebars), you have to get it right the first time. There is no room for error. No chance to push out an update on that feature that doesn’t work the way you thought it would. Hardware - cue cliche - is hard. And it is doubly hard when the ‘first time’, is your first time.

Stories abound of crowdfunded hardware startups whose inexperience with manufacturing led to substantial delays and inferior products. Then there’s the lurking fear that even if everything goes well your product may be irrelevant by the time it is released. Now,that is a heartbreaking outcome. The lag time between ideation and execution with hardware is so terrifically long that it is often years before someone will use the brilliant tool you’ve dreamed up. With Hammerhead, we knew at the outset that going the hardware route was going to present massive challenges. So we applied an ancient, oft-ignored strategy - one passed down from generation to generation in my family. We asked for help.

A challenge we initially faced was gaining access to experienced product developers. Having an idea and building it in your garage, setting those first LED’s alight, is getting easier thanks to 3D printing, Arduino’s and off-the-shelf bluetooth modules from places like Sparkfun, Adafruit, Polulu, Seedstudio, Inventables and the mighty Grainger. However, there is a distinct chasm between this and the experience of a plastics engineer or the oversight of an electronics engineer with a history of successful products. At our infancy we were fortunate to have incredible mentors with decades of experience in the manufacturing world. It is important to realize that as a hardware startup, we are in the minority of the startup community. There is a vast network of mentors and helpers out there just waiting to be activated. I encourage all hardware hopefuls to seek these people out early and communicate with them often!

For all these reasons and more, we feel extremely fortunate to be part of the inaugural class of the R/GA Techstars Hardware Accelerator program. By guiding us towards the right questions, linking us with experienced advisors to model our costs correctly and challenging our assumptions about tooling and component selection, the team at R/GA Techstars has helped us take Hammerhead to the next level. Quite honestly, with the expertise and help we have access to here, manufacturing has transformed in my mind from an anvil to a balloon, carrying us skywards away from what we thought was possible.

We’re still worried about getting it right the first time, of course. But I’m pretty sure the folks at Apple, Samsung and the like are worried about that, too.

That's all for now - we're in a sprint to get new prototypes ready!

Laurence

#Hammerhead#HammerheadNav#Startups#Hardwarestartup#Manufacturing#Electronics#Adafruit#Sparkfun#Polulu#Seedstudio#Inventables#Grainger

0 notes

Text

🚀 From CAD to CASH! Low-Volume Parts at Warp Speed

GreatLight’s Secret Sauce: ✅ 5-Axis Magic: Complex geometries in 1 setup ✅ 4-Axis Power: 70% faster than 3-axis milling ✅ ZERO MOQ: 1pc prototype → 500pcs production

⚡️ UPLOAD CAD → GET INSTANT QUOTE 👉 https://glcncmachining.com/cnc-machining-online-quotation/

RapidPrototyping #CNCMastery #LowVolumeManufacturing #HardwareStartup #5AxisCNC #4AxisMachining #EngineeringExcellence #OnDemandMfg

0 notes