#hydraulic power units

Text

Hydraulic Power Packs

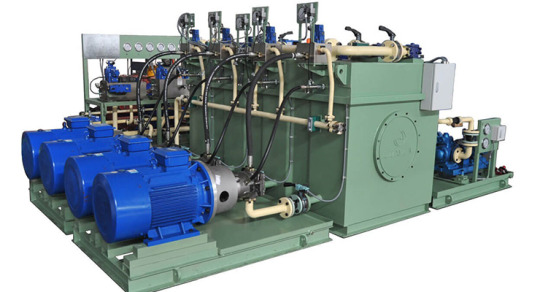

Introducing Hyspec Fluid Power, where power and precision unite! Step into the future of hydraulic systems with our extraordinary hydraulic power units that meet specific requirements. Engineered to perfection, our units combine unparalleled performance with cutting-edge technology, delivering unmatched power and control to your operations. From heavy-duty industrial applications to compact mobile machinery, Hyspec Fluid Power has the perfect solution for your unique needs. With unrivalled reliability and exceptional durability, our Hydraulic Power Packs will redefine your productivity and efficiency standards. Don't settle for anything less than extraordinary. Embrace the power of Hyspec Fluid Power today and embark on a journey of limitless possibilities! Visit our website now and experience true hydraulic excellence.

0 notes

Text

Research on Hydraulic Systems in Low-Temperature Environment

With the increasingly urgent requirements for hydraulic performance at low temperatures in reality, how to apply hydraulic technology to low-temperature environments is the current focus of attention.

Low-temperature start-up characteristics of hydraulic systems

From the perspective of the working characteristics of the hydraulic system in the low-temperature environment, the common challenge is the cold start problem: the hydraulic oil at extremely low temperature is affected by the temperature, and the viscosity is large, which directly affects the self-priming ability of the pump, and may cause the hydraulic power unit to fail in severe cases. The problem of starting thus affects the normal operation of the entire hydraulic system.

However, under some working conditions, in order to ensure the smooth flow of oil, the oil in the oil tank or the oil tank will be heated, while the actuator is still at a very low ambient temperature (such as the deck machinery hydraulic system of polar ships). Thermal shock occurs when heated hydraulic fluid enters the cold section. Under thermal shock conditions, the flow of oil from the hydraulic power unit to the actuator creates heat transfer, and the flowing hydraulic fluid gradually changes the temperature of the components within the hydraulic element. Due to the unbalanced temperature of the internal and external components of the hydraulic components, the change in the fitting clearance of the friction pair of the components will be caused. The greater the temperature difference between the working medium and the low-temperature hydraulic components, the more obvious the change in the friction pair clearance during startup. When the temperature difference reaches a certain value, the friction pair fitting clearance may completely disappear, which directly causes the spool and other moving parts to get stuck. , resulting in the failure of hydraulic components and systems.

During cold start in a low-temperature environment, in order to ensure the safety of the hydraulic power unit, some researchers integrated a cold start valve in the pump for adjustment. After the hydraulic power unit works, it is used to detect the oil pressure of the oil suction port of the hydraulic power unit. When the pressure reaches the set value, the cold start valve will be opened, and the charge pump will drive the hydraulic oil to overflow. At this time, the hydraulic power unit will not output, and it will always be in overflow heating to ensure that the hydraulic power unit starts to work after the oil temperature meets the set conditions; A heater can be installed in the oil tank or a nitrogen pressurizing device and a specially designed gear pump with strong self-priming ability can be used to solve the problem of difficult oil absorption by the pump.

As for the thermal shock of oil, the allowable starting parameters of hydraulic components under thermal shock conditions can be determined through tests and calculations, which can solve the problem of starting under thermal shock. The fundamental design factor that allows start-up parameters is the effective clearance, which defines the size of the gap between the surfaces of the cooperating elements.

The parameters that affect the correct start-up of hydraulic components under thermal shock conditions include the flow rate of the working medium (hydraulic oil), the oil temperature, and the initial temperature of the components corresponding to the ambient temperature. Under thermal shock conditions, if the effective clearance value calculated when the hydraulic component is actuated is a properly positive value, the component will work without failure.

Jiangsu Kerai Hydraulic Pump Co., Ltd. is a high-end equipment manufacturer specializing in the production of high-pressure plunger pumps, motors, hydraulic reducers, and spare parts.

If you have your own opinions on the hydraulic motor, please contact Jiangsu Kerai Hydraulic Pump Co, Ltd.

Related news of hydraulic system

How tube fittings and pneumatic accessories affect hydraulic systems

Influence of fuel tank and heat exchanger on hydraulic system

Effects of accumulators and filters on hydraulic systems

0 notes

Text

Flowing Towards the Future: The Hydraulic Power Unit Market

The hydraulic power unit market is a package consisting of various components such as hydraulic motor & pump, reservoir/accumulators and other accessories such as filter, valves, tubes, regulators, and instruments used to monitor the performance of a hydraulic system. It is used to transmit, control, and distribute energy from a pressurized fluid to perform various mechanical tasks and is a main component of hydraulic systems producing enormous amount of power, driving various hydraulic rams and equipment.

HPU has various applications in presses, machine tools, computerized numerical control (CNC), lifts, saws, and in other construction equipment such as fork lifters, cranes, crushers, and excavators among others. It forms the primary component of hydraulic systems and produces enormous amount of power, which can drive hydraulic rams and equipment by controlling and distributing energy from a highly pressurized fluid.

Growth in industrial activities and increasing applications of HPUs for agricultural products are some important factors driving the market growth. However, alternative sources of power transfer using electro-mechanical & electric drives which are cost-effective and highly efficient in terms of shorter lead time are some of the factors hampering the growth of the market. Rise in defense spending and growing automation in industrial processes are some of the areas which display promising growth prospects for the HPU market. Rising cases for product failures form the key market challenge for the growth of HPU market.

The global HPU market is segmented on the basis of operating pressure, applications and geography. On the basis of operating pressure rating, the market is segmented into 0-750 PSI, 750-2000 PSI, 2000-3000 PSI and >3000 PSI. On the basis of applications, the market is segmented into mobile applications, industrial applications and other applications. The world HPU market, based on geography, is segmented into North America, Europe, Asia-Pacific, Latin America, Middle East and Africa (LAMEA).

KEY BENEFITS FOR STAKEHOLDERS

This report offers an in-depth analysis of key driving factors and restraints along with the impact analysis of these factors on the growth prospects of the HPU market

The report offers actionable information on the current market situation, expected future growth trends and key business intelligence parameters

The report offers an insight into the market expansion strategies to capture untapped geographies

The report offers the quantitative analysis of the current market and estimations that helps in identifying the prevailing market opportunities

Competitive landscape scenario in terms of changing market dynamics and major market strategies adopted by key market players to consolidate their presence in the market

Region-wise market status in terms of key development parameters are comprehensively analyzed in the report

Key Market Players : Parker Hannifin Corporation, Hydac International GmbH, Bosch Rexroth AG, Brevini Fluid Power S.p.A, Bailey International LLC, Nachi-Fujikoshi Corporation, Hydro-tek Co Ltd., Eaton Corporation, Weber Hydraulik GmbH

0 notes

Text

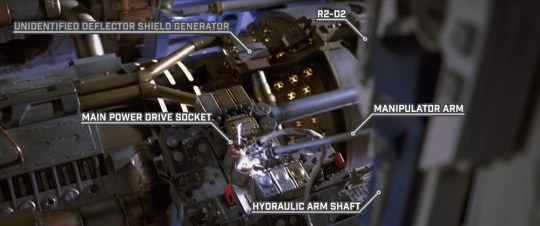

Artoo Making Repairs

STAR WARS EPISODE I: The Phantom Menace 00:26:18

#Star Wars#Episode I#The Phantom Menace#Naboo Royal Starship#R2-D2#R2 unit#astromech droid#deflector shield generator#unidentified deflector shield generator#main power drive socket#hydraulic arm shaft#manipulator arm

0 notes

Link

Hydraulic Power Pack unit owners must know the importance of preventative maintenance if they want their equipment to last as long as feasible. Your hydraulic power unit will need regular maintenance, which you or a hired technician can perform.

Preventative Care for Hydraulic Systems

If a 12V DC Hydraulic Power Pack unit fails, only a certified mechanic should fix it. However, regular preventative maintenance requires less effort. You can perform routine maintenance on the power unit yourself without endangering the safety of anyone using it if you follow the manufacturer’s instructions.

The basics of general maintenance include:

Electric Motor Lubrication

If you have questions about how to care for your electric motor, contact the company that made it. To discover how and when to grease the motor, consult the manufacturer or the user handbook. Maintaining a healthy motor calls for regular lubrication.

0 notes

Text

Standards of turbine oil

A) BSI (British Standards) – BSI BS 489:1999: Specification For Turbine Lubricants.

B) DIN (German Institute for Standardization DIN 51515-1, 51515-2: This document specifies minimum requirements for oils for high thermal stress (high-temperature service) in turbines.

C) ABB (ABB Group) ABB G12106: Ultra-clean turbine oil, Long-life, Rust & Oxidation-inhibited circulating oil.

D) ASTM International – ASTM D4304: Define the properties of the mineral and synthetic oil-based turbine lubricating oils that are functionally interchangeable with existing oils of this type, are compatible with most existing machinery components, and with appropriate field maintenance, will maintain their functionality.

E) GE (General Electric) GE: GEK-32568: Lubricating Oil Recommendations for Gas Turbines With Bearing Ambients above 500°F (260°C)

Also read: https://www.linkedin.com/pulse/mandatory-properties-steam-gas-turbine-oil-anshuman-agrawal-mlt-1-/

We at Minimac study your maintenance needs and provide the best solution. We believe in Discern, Design & Deliver.

Call +91 7030901266 for Mechanical Maintenance & Oil Check.

#oil & gas#power#oil purification#oil flushing#Condition Monitoring#hydraulic oil filter#Lube Oil Filter#filters#oil filteration#frf#lvdh#minimac systems#minimac#filter machine#oil cleaning machine#oil cleaning unit#transformer oil#mining#steel

1 note

·

View note

Text

Hydraulic Power Units – Total Guide

The hydraulic power units (sometimes called the hydropower pack) are independent systems that typically comprise a motor, a reservoir of fluid, and a pump. It provides the required hydraulic pressure to power motors, hydraulic cylinders, and other components of a particular hydraulic system.

Read More: Hydraulic Power Units – Total Guide

0 notes

Text

Hydraulic Power Pack

#The hydraulic power pack manufacturers in pune unit manufactured by us is composed of an oil tank.#https://saynakhydraulics.in/mainproducts.php?id=77#Hydraulic Power Pack manufacturers in pune#https://saynakhydrualic.blogspot.com/2022/10/hydraulic-power-pack.html#hydraulicpowerpack#powerpack#hydraulics

0 notes

Text

#4 units of DPHP-Z100 paywelder were shipped#features as following:#1. Sany-Palfinger kunckle boom with remote controller: max lifting capacity 5580kg#crane radius 8m#2. LCD monitor and vehicle backing radar in cab#3. Hydraulic gas cylinder lifting device with preheating fucntion---8 gas cylinders can be placed in and preheated#4. One paywelder can supply power for 4 units of welding source#More details,please visit https://www.dppipemachine.com/paywelder/#pipeline

0 notes

Text

Our group has the experience and ability not exclusively to repair your unit yet additionally to give proposals to improve plan and productivity.

Power Hydraulics has worked with all the significant segment manufactures and approaches the total scope of extra parts.

0 notes

Text

How Hydraulic Power Packs Drive Advancements In Various Industries?

Introducing Hyspec Fluid Power, the leading provider of Hydraulic Power Packs. Our state-of-the-art hydraulic power packs Australia are designed to provide reliable and efficient power to a wide range of hydraulic systems. With years of experience in the industry, we have developed a reputation for delivering high-quality products that meet the needs of our customers. Our hydraulic power packs are built to last, with durable components and advanced technology that ensures optimal performance. Whether you need a hydraulic power pack for industrial, agricultural, or marine applications, we have the perfect solution for you. Trust Hyspec Fluid Power for all your hydraulic power pack needs. Contact us today to learn more!

0 notes

Text

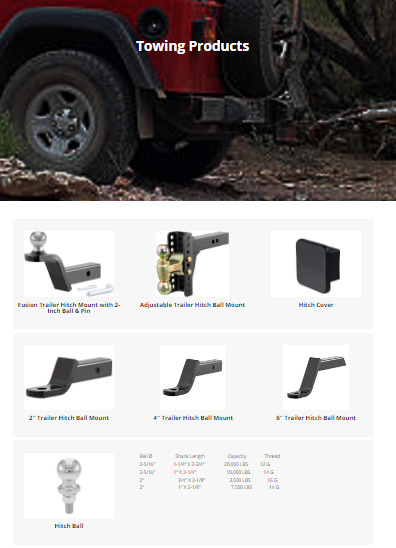

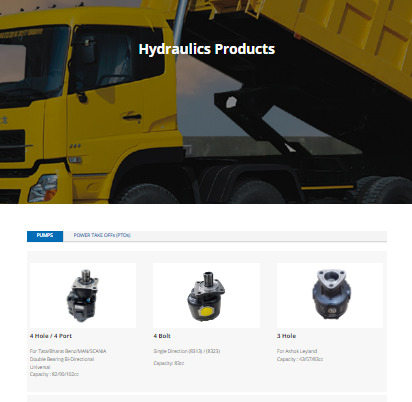

#hydraulic Pump Manufacturer India#gear pump manufacturer India#truck power takeoffs manufacturer India#D.R. Industries#an India (Punjab) based manufacturing unit. We are among the top hydraulic pump manufacturer in India. Our mission is to deliver top-qualit

1 note

·

View note

Text

Flowing Towards the Future: The Hydraulic Power Unit Market

The hydraulic power unit market is a package consisting of various components such as hydraulic motor & pump, reservoir/accumulators and other accessories such as filter, valves, tubes, regulators, and instruments used to monitor the performance of a hydraulic system. It is used to transmit, control, and distribute energy from a pressurized fluid to perform various mechanical tasks and is a main component of hydraulic systems producing enormous amount of power, driving various hydraulic rams and equipment.

HPU has various applications in presses, machine tools, computerized numerical control (CNC), lifts, saws, and in other construction equipment such as fork lifters, cranes, crushers, and excavators among others. It forms the primary component of hydraulic systems and produces enormous amount of power, which can drive hydraulic rams and equipment by controlling and distributing energy from a highly pressurized fluid.

Growth in industrial activities and increasing applications of HPUs for agricultural products are some important factors driving the market growth. However, alternative sources of power transfer using electro-mechanical & electric drives which are cost-effective and highly efficient in terms of shorter lead time are some of the factors hampering the growth of the market. Rise in defense spending and growing automation in industrial processes are some of the areas which display promising growth prospects for the HPU market. Rising cases for product failures form the key market challenge for the growth of HPU market.

The global HPU market is segmented on the basis of operating pressure, applications and geography. On the basis of operating pressure rating, the market is segmented into 0-750 PSI, 750-2000 PSI, 2000-3000 PSI and >3000 PSI. On the basis of applications, the market is segmented into mobile applications, industrial applications and other applications. The world HPU market, based on geography, is segmented into North America, Europe, Asia-Pacific, Latin America, Middle East and Africa (LAMEA).

KEY BENEFITS FOR STAKEHOLDERS

This report offers an in-depth analysis of key driving factors and restraints along with the impact analysis of these factors on the growth prospects of the HPU market

The report offers actionable information on the current market situation, expected future growth trends and key business intelligence parameters

The report offers an insight into the market expansion strategies to capture untapped geographies

The report offers the quantitative analysis of the current market and estimations that helps in identifying the prevailing market opportunities

Competitive landscape scenario in terms of changing market dynamics and major market strategies adopted by key market players to consolidate their presence in the market

Region-wise market status in terms of key development parameters are comprehensively analyzed in the report

Key Market PlayersParker Hannifin Corporation, Hydac International GmbH, Bosch Rexroth AG, Brevini Fluid Power S.p.A, Bailey International LLC, Nachi-Fujikoshi Corporation, Hydro-tek Co Ltd., Eaton Corporation, Weber Hydraulik GmbH

0 notes

Text

Sort of hydraulic Power pack manufacturers pune We fabricate :

They have a wide application range. delight's hydraulic power pack manufacturers pune are planned agreeing an incorporated particular arrangement of valves for the different capabilities.This features the hardware's minimized nature, the groundwork of its superior exhibition levelThe essential parts of the power packs are:a complex block with holes for different sorts of valvesan exceptionally calm, high-effectiveness gear siphonan electric engine (DC or AC)a supply (plastic or steel)a few discretionary extrasBenefits of Compact power pack:Smaller and secluded development, set number of parts, speedy and simple get togetherMost extreme adaptability - various circuits can be worked from only the couple of essential formsValve holes adjust to worldwide normsAdvancement of engine siphon unit produce expanded effectiveness and low working commotion levelUncompromising hydraulic Power pack manufacturersUtilized where there required constant creation , numerous tasks , high tensions are required , are to be done by drive pack on modern machines , process plants like steel businesses , concrete plants , machine apparatus fabricating organizations , shaping , projecting plants , Rubber industry , parts producing machines , food and medications ventures , water medicines , and a lot more , there power pack are furnished with return line channels , heat exchangers unit water cooled or air cooled relying on the applications , being redone we can fabricate them to give the result we wanted from the chambers or servo frameworks making them energy proficient and successful

#hydraulic power pack#Hydraulic Power Unit Market#Hydraulic power pack manufacturers#hydraulic power pack pune#hydraulic power#hydraulic power pack manufacturers pune

0 notes

Link

Krishna Engineering Works is the leading manufacturer, and exporter of Hydraulic Power Packs, Web Guiding systems, and Web Aligner Units. We have the capacity to supply 100-150 units per month. We have a systematic workflow chart & updated technology to produce the machine at very high speed and great perfection. National and International, we invite inquiries of Hydraulic Power Packs, Web Aligner and Web Guiding System from machinery manufacturers also to purchase the units in bulk orders. For more information:

Website: krishnaengineeringworks.com

Email: [email protected]

Contact Us: +91-7940085305

#Hydraulic Power Packs#Hydraulic Power Unit#Hydraulic Power Pack for Sale#Hydraulic Power Pack Price#Hydraulic Pack#Portable Hydraulic Power Pack#Mini Hydraulic Power Pack#Hydraulic Power Pack Unit#Hydraulic Power Pack System#Web Guiding System#Web Guiding#Web Aligner System

1 note

·

View note