#hydrogel applications

Explore tagged Tumblr posts

Text

youtube

#Bioelectronics hydrogels#cardiac treatment#brain health#implantable devices#medical innovation#neural stimulation#heart health technology#chronic disease treatment#biocompatible materials#brain disease therapy#cardiac monitoring#drug delivery systems#neurotechnology#advanced therapies#biomedical research#healthcare innovation#hydrogel applications#medical implants#neuroprotection#smart medical technology.#Youtube

0 notes

Text

"If you're hoping that reef-restoring coral larvae will settle down in damaged reefs, you can't just sit around and wait for it to happen. You have to get out there and entice the larvae, which is exactly what a new algae-based gel is designed to do.

While we may think of coral reefs' "skeletons" as being composed solely of calcium carbonate produced by coral polyps, much of the material is in fact generated by what are known as crustose coralline algae.

Along with contributing greatly to the structural integrity of reefs, the algae-produced calcium carbonate also serves as a home to planktonic coral larvae. Once those formerly free-swimming organisms settle in and become polyps, they start producing reef-building calcium of their own.

It's a good arrangement for the coral, but it also benefits the algae.

Not only does the reef itself provide the algae with protection from the elements, the coral polyps also emit ammonia which the algae feed upon. It is therefore in the algae's best interest to entice any coral larvae that may be swimming past in the water column. In order to do so, the algae release metabolite chemicals that attract the larvae.

Led by Dr. Daniel Wangpraseurt, scientists at UC San Diego's Scripps Institution of Oceanography have now incorporated those metabolites into a gel that can be applied to degraded coral reefs. Called SNAP-X, the substance reportedly boosts coral larval settlement by up to 20 times as compared to untreated surfaces.

If the algae metabolites were just applied to the coral on their own, they would soon dissipate in the water, leaving the coral larvae unable to follow them to their source. For that reason, the researchers started by encasing the chemical molecules in durable silica nanoparticles. Those particles were then suspended within a biocompatible liquid blend of gelatin methacrylate and polyethylene glycol diacrylate.

When that liquid is sprayed or painted onto a surface – such as a piece of dead coral – then exposed to ultraviolet light, it polymerizes into a hydrogel form. That gel is capable of clinging to the surface for up to one month while immersed in flowing water, gradually releasing its larvae-attracting nanoparticles as it does so.

Initial lab tests showed that application of SNAP-X resulted in a six-fold increase in larval settlement. Subsequent tests that more accurately simulated the water flow on coral reefs, however, produced the 20-times figure.

It should be noted that all of the tests conducted so far have involved a single type of coral, but Wangpraseurt believes the technology should work on other species with a few tweaks.

"I think this material is a breakthrough that can hopefully make a big contribution to coral restoration," he says. "Biomedical scientists have spent a lot of time developing nanomaterials as drug carriers, and here we were able to apply some of that knowledge to marine restoration."

A paper on the research was recently published in the journal Trends in Biotechnology."

-via New Atlas, May 26, 2025

#coral#conservation#ocean#marine biology#ecosystem#ecosystem restoration#ecology#marine science#marine life#coral reef#science news#tidalpunk#biotechnology#good news#hope

1K notes

·

View notes

Text

New 3D printing technique replicates nature's delicate fibers with precision

Researchers have been trying to find new ways to produce and replicate the various useful features observed in nature. Fine hairs and fibers, which are ubiquitous in nature, are useful for various applications ranging from sensory hairs to the fibers that give hagfish slime its unique consistency. MechSE Professors Sameh Tawfick and Randy Ewoldt, doctoral candidate M. Tanver Hossain, and external collaborators have addressed this need with their cutting-edge embedded 3D-printing technique, recently published in Nature Communications. Their article, "Fast 3D printing of fine, continuous, and soft fibers via embedded solvent exchange," discusses the science behind their bioinspired approach to the rapid printing of fine fibers in gel. Unlike traditional 3D-printing methods, in which material is deposited layer by layer in ambient air, embedded 3D printing deposits material in a support medium such as hydrogel. When printing in air, models must be oriented such that each layer can support the subsequent layer or, for structures with complex architecture, removable support structures can be printed and later discarded.

Read more.

#Materials Science#Science#3D printing#Fibers#Materials processing#Biomimicry#Hydrogels#Soft materials#University of Illlinois

22 notes

·

View notes

Text

Catch Up Quick:

The tech was described in a DARPA-funded March 2022 paper authored by researchers from Columbia University, MIT, and George Mason University.

Patent filings confirm Columbia submitted the invention to the U.S. patent system before publishing the study. A U.S. provisional patent was filed on September 29, 2021, followed by an international patent application (PCT/US2022/077135) on September 28, 2022.

The patent (WO2023/107765) is active as of March 2025.

Named inventors on the patent are the same as the lead authors on the paper: Samuel Sia, Rachel D. Field, and Margaret A. Jakus.

The patent states: “This invention was made with government support under D20AC00004 awarded by the Defense Advanced Research Projects Agency (DARPA). The government has certain rights in the invention.”

How It Works: The microcapsules are made from a dual-layer hydrogel:

Inner core: High molecular weight dextran mixed with drug payloads.

Outer shell: PEGDA (polyethylene glycol diacrylate), a material that resists premature leakage.

When focused ultrasound (FUS) is applied, it causes inertial cavitation—the collapse of microscopic bubbles—which breaks down the capsule and releases the contents.

The authors wrote: “The amount released by the microcapsule is tunable depending on the applied FUS parameters, which allows for real-time dosage control.”

8 notes

·

View notes

Text

Skin Removal Healing Journal 9/18

First removal of bandage. Very painful and I did scream a bit and had to gag myself for this process. Watched my skin peel off the wounds and had to work the bandage off slowly in sections. The bandage had become moderately saturated since application. As soon as the bandage was off, it started bleeding and we had to apply five small pads of gauze to stop the bleeding. Applying pressure was a less painful process but I still struggled with this task. Not enough hydrogel was applied during the procedure which caused the wound to dry - no doubt in part due to the sorptive nature of the bandage - so peeling caused a manual debridement and some small grains of what were probably coagulated blood were noticeable at the edges.

Day 1 cleaning was painful but not unbearable, worked in stages with wet paper towels although a sterile material would probably be better. First, wetted area by patting it with damp cloth, then lathered antibacterial soap into a new damp cloth. Sponged the target area by patting and squeezing the soapy liquid out onto the wound. Note: this sucked - it stung a lot - and made a little mess. Washed the surrounding area with the same cloth to clean up the blood that had gone down and under my leg.

Repeated this process with a damp cloth to clean the soap out or at least thin it to acceptable levels. Wet cloth with nothing on it felt okay. Pat the area dry with one last paper towel and did need another pad of sterile gauze to clean new blood. Applied more hydrogel, hopefully in sufficient amount, and applied new bandage. Felt dizzy, nauseous, and a little uncoordinated after.

Despite this, we ball, and I'm hoping recovery goes well.

8 notes

·

View notes

Text

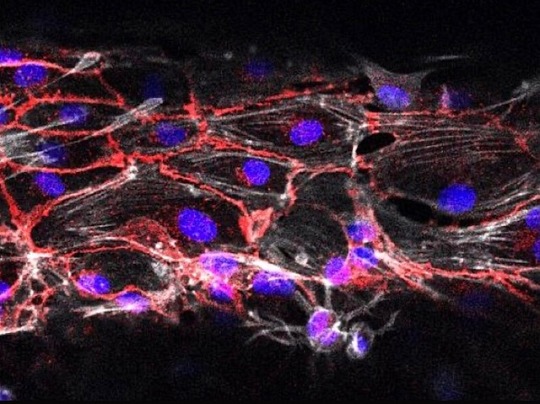

Magnetic Morphing

Using magnetic forces to remotely shape 3D printed hydrogel scaffolds with biomedical applications such as for growing endothelial cells in vessel networks (pictured)

Read the published research paper here

Image from work by Ruoxiao Xie and Yuanxiong Cao, and colleagues

Department of Materials, Department of Bioengineering and Institute of Biomedical Engineering, Imperial College London, London and Department of Physiology, Anatomy and Genetics, Kavli Institute for Nanoscience Discovery, University of Oxford, UK

Image originally published with a Creative Commons Attribution 4.0 International (CC BY 4.0)

Published in Science Advances, February 2024

You can also follow BPoD on Instagram, Twitter and Facebook

#science#biomedicine#immunofluorescence#biology#hydrogel#3d printing#endothelial cells#blood vessels#magnets#bioengineering

15 notes

·

View notes

Text

My boss sent me a fucking English for scientific communications guide bc of the way I structured a few sentences throughout my FIRST DRAFT of this one thesis chapter. Bestie, you do realize I’ve adapted my writing style to yours?

Also I have only had a month and a half to write my thesis. It’s going to be about 300 pages (I’m at 186 right now in my 4th chapter with two appendices and my future work sections to go). Sorry it’s not absolutely perfect on the first go around, but I was trying to get them to her as quickly as possible because she stressed how *she* needs enough time to read and approve my thesis — which is why I scheduled my defense a week later than I wanted (nevermind the fact that I’m the one that has to fucking write it all).

I keep trying to remind myself that I’m actually good at this — I’ve been told academic/scientific reports I’ve written have been the best my professors have seen. I’ve won awards outside of my home department in undergrad for scientific projects. I’ve won creative writing awards in high school too! I did a fucking concentration in ENGLISH in undergrad!

She also got mad at me for introducing quantum physics after talking about classical physics. Apparently, I’m not allowed to introduce electromagnetism and maxwells equations then discuss how time dependent oscillations between electricity and magnetism relate to electromagnetic radiation in the form of waves then use that transition to discuss light and through light the particle interactions that bring about fluorescent states. Nor am I allowed to follow that up with spin state magnetism being extremely important to material properties as a segue to discuss magnetism in materials. Nope, I have to rewrite that entire section because I used planck’s equation after discussing maxwell’s! Oops! (Also I swear this is how it’s discussed in like every physics textbook ever, but clearly I know nothing).

But she is allowed to add THIS sentence: “Moreover, it is bio-orthogonal.” when I talk about click chemistry improving functionalization strategies in polymer synthesis for biomedical hydrogel applications. Like what does that even mean!! Fuck jargon! And I would literally never use the word moreover??? I hate youuuuu. Working with this woman has been the single most invalidating experience of my entire life.

GAH.

#screaming into the void#I realize I have actively become a worse writer working under her#defensive on main#clearly have a very fragile mental state right now#but I’m tired of her never commenting on the things I actually need her help with then nit-picking the things that I never needed her for

4 notes

·

View notes

Text

Hagfish slime is an ultra dilute, elastic and cohesive hydrogel that deploys within milliseconds in cold seawater from a glandularly secreted exudate. The slime is made of long keratin-like fibers and mucin-like glycoproteins that span a network which entraps water and acts as a defense mechanism against predators. Unlike other hydrogels, the slime only confines water physically and is very susceptible to mechanical stress, which makes it unsuitable for many processing operations and potential applications. Despite its huge potential, little work has been done to improve and functionalize the properties of this hydrogel. To address this shortcoming, hagfish exudate was mixed with a soy protein isolate suspension (4% w/v) and with a soy emulsion (commercial soy milk) to form a more stable structure and combine the functionalities of a suspension and emulsion with those of the hydrogel. Hagfish exudate interacted strongly with the soy systems, showing a markedly increased viscoelasticity and water retention. Hagfish mucin was found to induce a depletion and bridging mechanism, which caused the emulsion and suspension to flocculate, making "soy slime", a cohesive and cold-set emulsion- and particle gel. The flocculation network increases viscoelasticity and substantially contributes to liquid retention by entrapping liquid in the additional confinements between aggregated particles and protein fibers. Because the mucin-induced flocculation resembles the salt- or acid-induced flocculation in tofu curd production, the soy slime was cooked for comparison. The cooked soy slime was similar to conventional cooked tofu, but possessed a long-range cohesiveness from the fibers. The fibrous, cold-set, and curd-like structure of the soy slime represents a novel way for a cold coagulation and fiber incorporation into a suspension or emulsion. This mechanism could be used to efficiently gel functionalized emulsions or produce novel tofu-like structured food products.

2 notes

·

View notes

Text

Latest Technology Trends

3 New Inventions That Will Change The World

1. Commercial nuclear fusion power

Nuclear fusion, in its most common form, is the process of energy being released when bits (“atomic nuclei”, if you’re fancy) of hydrogen are exposed to extreme heat and combined. This process releases massive amounts of energy, which humanity is increasingly hungry for. That’s how the sun works too, by the way.

Several countries have heavily invested in fusion research, and private companies are also conducting their own trials. The ITER reactor, which is under construction in France and due to begin operation in 2026, is the first reactor that should produce energy-positive fusion; but dozens of others are being built.

youtube

2. 4D printing

The name 4D printing can lead to confusion: I am not implying that humanity will be able to create and access another dimension. Put simply, a 4D-printed product is a 3D-printed object which can change properties when a specific stimulus is applied (submerged underwater, heated, shaken, not stirred…). The 4th Dimension is therefore Smart Materials.

The key challenge of this technology is obviously finding the relevant “smart material” for all types of uses (namely a hydrogel or a shape memory polymer for the time being). Some work is being done in this space, but we’re not close to being customer-ready, having yet to master reversible changes of certain materials.

The applications are still being discussed, but some very promising industries include healthcare (pills that activate only if the body reaches a certain temperature), fashion (clothes that become tighter in cold temperatures or shoes that improve grip under wet conditions), and homemaking (furniture that becomes rigid under a certain stimulus). Another cool use case is computational folding, wherein objects larger than printers can be printed as only one part.

3. Generative design AI

Generative AI technology uses deep learning to generate creative assets such as videos, images, text and music. This technology is no longer new since it entered the mainstream in late 2022. While you may have played with (and enjoyed!) the likes of ChatGPT and Midjourney, they’re barely more than surface-level distractions.

Tom Cruise riding a t-rex in Hogwarts

Corporate use for generative AI is far more sophisticated. If used to its full extent, it will reduce product-development life cycle time, design drugs in months instead of years, compose entirely new materials, generate synthetic data, optimize parts design, automate creativity… In fact, experts predict that by 2025, 30% of outbound marketing messages from large organizations will be synthetically generated, and by 2030, a major blockbuster film will be released with 90% of the film generated by AI.

Going beyond the most headline-grabbing use cases, studies have shown that Gen. AI increases productivity for a variety of tasks, with specific benefits for low-ability workers and less experienced employees. Put simply, these tools will level the playing field.

This is happening today, and will continue to happen, with increasing success, over the coming decade. That is, if we can navigate the many risks associated with generative AI. I’m particularly worried about deep fakes, copyright issues, and malicious uses for fake news.

#inventions#newinventions#newtechbasedinventions#techhub#inventologyhub#technews#newtechs#technology#Youtube

2 notes

·

View notes

Text

Polyacrylamide: A Versatile Polymer for Various Applications

Polyacrylamide, often abbreviated as PAM, is a synthetic polymer with a wide range of applications. It has gained significant attention due to its excellent performance and versatility. In this article, we will explore the uses, properties, and preparation of polyacrylamide while highlighting its significance in different industries.

Polyacrylamide is commonly used in water treatment processes. It acts as a flocculant, helping to separate solid particles from wastewater and improving the overall water quality. With its high molecular weight and charge density, polyacrylamide effectively aggregates suspended particles, facilitating their removal during sedimentation or filtration.

The water treatment industry extensively utilizes polyacrylamide to treat various types of wastewater. Whether it's municipal sewage, industrial effluents, or agricultural runoff, polyacrylamide proves to be an efficient solution for reducing pollutant levels and ensuring environmental compliance.

Furthermore, polyacrylamide finds applications in diverse fields such as medicine, food, and cosmetics. In medicine, it is utilized for drug delivery systems, tissue engineering, and wound healing. Its unique ability to form hydrogels makes it an ideal candidate for controlled release and targeted drug delivery.

In the food industry, polyacrylamide is employed as a thickening agent and stabilizer in processed foods, providing improved texture and shelf-life. Additionally, it finds use in cosmetics for its film-forming and moisturizing properties, making it valuable in skincare products.

When it comes to the preparation of polyacrylamide, it can be synthesized through free radical polymerization of acrylamide monomers. Various factors such as temperature, initiator concentration, and reaction time influence the polymerization process and result in polyacrylamide with different molecular weights and structures.

It's important to note that polyacrylamide is non-biodegradable and thus requires cautious handling and disposal. However, its non-toxic nature at low concentrations ensures its safe usage in various applications.

The price of polyacrylamide varies depending on factors like grade, purity, and quantity. Generally, it is priced per ton or per kilogram. For specific pricing details, it is advisable to contact reliable polyacrylamide suppliers who can provide accurate information based on your requirements.

In conclusion, polyacrylamide offers numerous advantages and finds extensive use in various industries. Its water treatment capabilities, along with its significant role in medicine, food, and cosmetics, make it an indispensable polymer. By understanding the properties and uses of polyacrylamide, industries can harness its potential to address challenges and improve processes.

3 notes

·

View notes

Text

3D Cell Culture Market Regulatory Landscape and Investment Opportunities 2032

In 2024, the global 3D cell culture market was worth around USD 2.54 billion. It’s expected to grow steadily, reaching about USD 6.29 billion by 2032, with an annual growth rate of 12.1%. North America led the market in 2024, holding the biggest share at 45.15%, thanks to strong research activities and advanced healthcare infrastructure.

The 3D cell culture market is witnessing significant growth as researchers and pharmaceutical companies increasingly shift toward more physiologically relevant models for studying cell behavior, disease progression, and drug responses. Unlike traditional 2D cultures, 3D cell culture systems better replicate in vivo environments, making them valuable tools in areas like cancer research, tissue engineering, and drug screening. The 3D cell culture market is segmented by product type, technology, application, and end user, offering tailored solutions for diverse research needs. While high costs, complexity of techniques, and standardization challenges act as restraining factors, continuous innovation, automation, and growing support from regulatory and academic institutions are helping overcome these barriers. Regionally, the 3D cell culture market is led by North America and Europe, while Asia Pacific emerges as a rapidly expanding region due to increased research funding and biotechnological advancements.

Continue reading for more details: https://www.fortunebusinessinsights.com/3d-cell-culture-market-109009

Market Segmentation

By Product Type: Includes scaffold-based systems, scaffold-free systems, bioreactors, and cell culture media—defining segments within the 3D Cell Culture Market.

By Cell Type: Human, animal, and stem cells represent major categories shaping the 3D Cell Culture Market.

By Application: Drug screening, disease modeling, regenerative medicine, and tissue engineering form critical applications of the 3D Cell Culture Market.

By End-User: Pharmaceutical & biotech companies, academic research institutes, CROs, and hospitals are primary stakeholders in the 3D Cell Culture Market.

By Technology: Segments include hydrogel-based scaffolds, microcarrier beads, spheroids, organoids, and lab-on-a-chip platforms within the 3D Cell Culture Market.

List Of Key Companies Profiled:

Sartorius AG (Germany)

Thermo Fisher Scientific Inc. (U.S.)

Corning Incorporated (U.S.)

Merck KGaA (Germany)

Avantor Inc. (U.S.)

MIMETAS B.V. (Netherlands)

REPROCELL Inc. (Japan)

Market Growth

The 3D Cell Culture Market is witnessing robust expansion driven by rising demand for more physiologically relevant in vitro models.

Technological advancements like bioprinting, scaffold-free systems, and microfluidics are accelerating innovation within the 3D Cell Culture Market.

Growth in the 3D Cell Culture Market is supported by increasing R&D expenditure in pharmaceuticals and biotechnology sectors.

Strategic collaborations between life sciences companies and academic institutions are fueling development in the 3D Cell Culture Market.

Enhanced adoption in drug discovery, regenerative medicine, and oncology research is propelling momentum in the 3D Cell Culture Market.

Retaining Factors

High demand for accurate, predictive cellular models supports continuous investment in the 3D Cell Culture Market.

Standardization of protocols and reproducibility improvements foster confidence and retention in the 3D Cell Culture Market.

Integrations with AI-driven analytics, imaging, and automation technologies enhance platform stickiness in the 3D Cell Culture Market.

Ongoing training and technical support for researchers ensure steady adoption in the 3D Cell Culture Market.

Regulatory support for non-animal testing models and growing ethical concerns about animal use reinforce growth in the 3D Cell Culture Market.

Regional Analysis

North America: Leads the 3D Cell Culture Market with significant research funding, advanced infrastructure, and strong biotech presence.

Europe: Well-established academic clusters and regulatory incentives make it a key hub in the 3D Cell Culture Market.

Asia Pacific: Rapidly growing region in the 3D Cell Culture Market, driven by expanding biotech industry, government funding, and CRO activity.

Latin America: Emerging adoption of 3D cell culture platforms in academic and pharmaceutical sectors is shaping this region's share in the 3D Cell Culture Market.

Middle East & Africa: Early adoption in research and innovation hubs reflects potential for growth in the 3D Cell Culture Market, backed by increased funding and infrastructure development.

Contact us:

Fortune Business Insights™ Pvt.

Phone: USA: +1 833 909 2966 (Toll-Free),

United Kingdom: +44 808 502 0280 (Toll-Free)

APAC: +91 744 740 1245

Email: [email protected]

0 notes

Text

PhD position on smart polymers and mechanobiology at University of Pavia

A PhD position will be available at University of Pavia in Italy starting November 2025. Interested candidates are encouraged to contact Prof. Giulia Scalet ([email protected]). The candidate will work on new computational approaches for the simulation of smart polymers and hydrogels and their application to mechanobiology studies. A Master degree in Engineering is mandatory. The candidate…

0 notes

Text

Butterfly-inspired 4D printing of smart hydrogels enables precise micro-nano deformation

A Chinese research team has developed a single-step femtosecond laser 4D printing technology that enables rapid and precise micro-scale deformation of smart hydrogels. This innovation, inspired by the hierarchical structure of butterfly wings, holds significant promise for applications in flexible electronics and minimally invasive medicine. The findings were published online in ACS Materials Letters on February 17. Led by Prof. Liu Lianqing from the Shenyang Institute of Automation of the Chinese Academy of Sciences and Prof. Li Wenjung from the City University of Hong Kong, the researchers drew inspiration from the wing structure of Papilio maackii, a butterfly species known for its remarkable balance of lightness and toughness.

Read more.

9 notes

·

View notes

Text

Bone Regeneration Market Growth Driven by Rising Orthopedic Procedures and Aging Global Population Trends

The Bone Regeneration Market is experiencing significant growth, largely propelled by the increasing number of orthopedic surgeries and a rapidly aging global population. As medical technologies evolve and life expectancies rise, the demand for bone grafts, scaffolds, and regenerative therapies has surged, creating a dynamic and competitive marketplace.

Aging Population and Bone Health: A Growing Healthcare Concern

One of the most significant factors driving the bone regeneration market is the demographic trend toward an older population. According to the World Health Organization, by 2030, one in six people globally will be aged 60 years or older. This shift comes with an increased prevalence of degenerative bone diseases such as osteoporosis and osteoarthritis, both of which often result in bone fractures or structural defects requiring surgical intervention and regeneration therapies.

Older adults are particularly susceptible to fragility fractures—especially in the hip, spine, and wrist—prompting a growing need for effective bone regeneration solutions. The natural decline in bone density and healing capacity with age further underscores the importance of advanced therapeutic strategies that can promote bone repair, minimize recovery time, and restore mobility.

Rising Volume of Orthopedic Procedures Worldwide

Parallel to demographic changes, the number of orthopedic procedures performed globally is on a steady rise. Elective surgeries such as joint replacements, spinal fusions, and fracture repairs are becoming more common due to both lifestyle-related injuries and chronic musculoskeletal conditions. Sports injuries, motor vehicle accidents, and workplace hazards also contribute significantly to the demand for bone repair and regeneration products.

The increased accessibility to orthopedic care in emerging markets—combined with enhanced surgical outcomes due to technological advancements—has widened the scope for bone regeneration applications. Surgeons today are more likely to recommend regenerative grafts over traditional bone harvesting techniques, which are often associated with pain, infection, and donor-site morbidity.

Technological Innovations Reshaping the Market Landscape

The bone regeneration field has seen transformative innovations that are reshaping both clinical practice and market dynamics. Among the most notable are advancements in biomaterials, including bioactive ceramics, collagen matrices, calcium phosphate, and composite scaffolds that mimic the natural bone structure and promote cellular integration.

Cell-based therapies and tissue engineering are also gaining momentum. The use of autologous or allogeneic stem cells to promote osteogenesis represents a promising area of research and commercialization. Additionally, 3D printing technology is enabling the creation of customized implants and scaffolds tailored to the patient's anatomy, significantly improving fit and function.

Another frontier in innovation involves growth factors such as bone morphogenetic proteins (BMPs), which have shown to accelerate bone healing when combined with scaffolds or grafts. However, regulatory hurdles and high costs have limited their widespread use, making them an area of high interest for future development.

Shift Toward Minimally Invasive Procedures

Minimally invasive orthopedic surgeries are gaining preference among both physicians and patients due to reduced pain, lower infection risk, shorter hospital stays, and quicker recovery times. These techniques require advanced tools and biomaterials that can integrate seamlessly into the surgical environment, thereby boosting demand for injectable bone grafts, hydrogels, and bioresorbable implants.

The compatibility of bone regeneration products with arthroscopic and endoscopic techniques is becoming a key differentiator in product development. Companies that offer flexible, ready-to-use solutions are well-positioned to capture market share, especially as the global trend toward outpatient and day-care surgical models continues to grow.

Regional Growth Patterns and Emerging Markets

North America currently dominates the bone regeneration market, driven by robust healthcare infrastructure, high adoption of advanced therapies, and strong R&D investment. The presence of leading market players, favorable reimbursement policies, and growing awareness about regenerative medicine contribute to this dominance.

However, the Asia-Pacific region is expected to witness the fastest growth in the coming years. Countries such as China, India, and South Korea are investing heavily in healthcare modernization and infrastructure, leading to increased surgical volumes and greater demand for cost-effective bone regeneration solutions. Moreover, rising disposable incomes, expanding insurance coverage, and government initiatives to improve healthcare access are encouraging more patients to seek surgical treatments for bone-related conditions.

Challenges and Future Outlook

Despite the promising outlook, the bone regeneration market faces certain challenges. High treatment costs, limited reimbursement in some regions, and the risk of post-operative complications may hinder adoption, particularly in price-sensitive markets. Moreover, stringent regulatory approval processes for novel biomaterials and cell therapies can slow down commercialization timelines.

Nonetheless, ongoing clinical research, strategic partnerships, and growing public-private investments in regenerative medicine are helping to address these challenges. The focus is increasingly shifting toward personalized medicine, with companies developing targeted solutions that cater to specific patient demographics and clinical needs.

Conclusion

The bone regeneration market is poised for robust expansion, fueled by macroeconomic trends such as the aging population and a global increase in orthopedic surgeries. Technological advancements and shifting treatment paradigms are creating new opportunities for innovation and investment. As the demand for safer, faster, and more effective bone healing solutions continues to rise, the market is expected to remain a focal point of growth in the broader regenerative medicine landscape.

0 notes

Text

Window-sized device taps the air for safe drinking water

New Post has been published on https://sunalei.org/news/window-sized-device-taps-the-air-for-safe-drinking-water/

Window-sized device taps the air for safe drinking water

Today, 2.2 billion people in the world lack access to safe drinking water. In the United States, more than 46 million people experience water insecurity, living with either no running water or water that is unsafe to drink. The increasing need for drinking water is stretching traditional resources such as rivers, lakes, and reservoirs.

To improve access to safe and affordable drinking water, MIT engineers are tapping into an unconventional source: the air. The Earth’s atmosphere contains millions of billions of gallons of water in the form of vapor. If this vapor can be efficiently captured and condensed, it could supply clean drinking water in places where traditional water resources are inaccessible.

With that goal in mind, the MIT team has developed and tested a new atmospheric water harvester and shown that it efficiently captures water vapor and produces safe drinking water across a range of relative humidities, including dry desert air.

The new device is a black, window-sized vertical panel, made from a water-absorbent hydrogel material, enclosed in a glass chamber coated with a cooling layer. The hydrogel resembles black bubble wrap, with small dome-shaped structures that swell when the hydrogel soaks up water vapor. When the captured vapor evaporates, the domes shrink back down in an origami-like transformation. The evaporated vapor then condenses on the the glass, where it can flow down and out through a tube, as clean and drinkable water.

MIT engineers test a passive water harvester in Death Valley, CA. The window-sized setup is made from an origami-inspired hydrogel material (black) that absorbs water from the air, and releases it into tubes where researchers can collect the moisture as pure drinking water.

Credit: Courtesy of the researchers; MIT News

Previous item Next item

The system runs entirely on its own, without a power source, unlike other designs that require batteries, solar panels, or electricity from the grid. The team ran the device for over a week in Death Valley, California — the driest region in North America. Even in very low-humidity conditions, the device squeezed drinking water from the air at rates of up to 160 milliliters (about two-thirds of a cup) per day.

The team estimates that multiple vertical panels, set up in a small array, could passively supply a household with drinking water, even in arid desert environments. What’s more, the system’s water production should increase with humidity, supplying drinking water in temperate and tropical climates.

“We have built a meter-scale device that we hope to deploy in resource-limited regions, where even a solar cell is not very accessible,” says Xuanhe Zhao, the Uncas and Helen Whitaker Professor of Mechanical Engineering and Civil and Environmental Engineering at MIT. “It’s a test of feasibility in scaling up this water harvesting technology. Now people can build it even larger, or make it into parallel panels, to supply drinking water to people and achieve real impact.”

Zhao and his colleagues present the details of the new water harvesting design in a paper appearing today in the journal Nature Water. The study’s lead author is former MIT postdoc “Will” Chang Liu, who is currently an assistant professor at the National University of Singapore (NUS). MIT co-authors include Xiao-Yun Yan, Shucong Li, and Bolei Deng, along with collaborators from multiple other institutions.

Carrying capacity

Hydrogels are soft, porous materials that are made mainly from water and a microscopic network of interconnecting polymer fibers. Zhao’s group at MIT has primarily explored the use of hydrogels in biomedical applications, including adhesive coatings for medical implants, soft and flexible electrodes, and noninvasive imaging stickers.

“Through our work with soft materials, one property we know very well is the way hydrogel is very good at absorbing water from air,” Zhao says.

Researchers are exploring a number of ways to harvest water vapor for drinking water. Among the most efficient so far are devices made from metal-organic frameworks, or MOFs — ultra-porous materials that have also been shown to capture water from dry desert air. But the MOFs do not swell or stretch when absorbing water, and are limited in vapor-carrying capacity.

Water from air

The group’s new hydrogel-based water harvester addresses another key problem in similar designs. Other groups have designed water harvesters out of micro- or nano-porous hydrogels. But the water produced from these designs can be salty, requiring additional filtering. Salt is a naturally absorbent material, and researchers embed salts — typically, lithium chloride — in hydrogel to increase the material’s water absorption. The drawback, however, is that this salt can leak out with the water when it is eventually collected.

The team’s new design significantly limits salt leakage. Within the hydrogel itself, they included an extra ingredient: glycerol, a liquid compound that naturally stabilizes salt, keeping it within the gel rather than letting it crystallize and leak out with the water. The hydrogel itself has a microstructure that lacks nanoscale pores, which further prevents salt from escaping the material. The salt levels in the water they collected were below the standard threshold for safe drinking water, and significantly below the levels produced by many other hydrogel-based designs.

In addition to tuning the hydrogel’s composition, the researchers made improvements to its form. Rather than keeping the gel as a flat sheet, they molded it into a pattern of small domes resembling bubble wrap, that act to increase the gel’s surface area, along with the amount of water vapor it can absorb.

The researchers fabricated a half-square-meter of hydrogel and encased the material in a window-like glass chamber. They coated the exterior of the chamber with a special polymer film, which helps to cool the glass and stimulates any water vapor in the hydrogel to evaporate and condense onto the glass. They installed a simple tubing system to collect the water as it flows down the glass.

In November 2023, the team traveled to Death Valley, California, and set up the device as a vertical panel. Over seven days, they took measurements as the hydrogel absorbed water vapor during the night (the time of day when water vapor in the desert is highest). In the daytime, with help from the sun, the harvested water evaporated out from the hydrogel and condensed onto the glass.

Over this period, the device worked across a range of humidities, from 21 to 88 percent, and produced between 57 and 161.5 milliliters of drinking water per day. Even in the driest conditions, the device harvested more water than other passive and some actively powered designs.

“This is just a proof-of-concept design, and there are a lot of things we can optimize,” Liu says. “For instance, we could have a multipanel design. And we’re working on a next generation of the material to further improve its intrinsic properties.”

“We imagine that you could one day deploy an array of these panels, and the footprint is very small because they are all vertical,” says Zhao, who has plans to further test the panels in many resource-limited regions. “Then you could have many panels together, collecting water all the time, at household scale.”

This work was supported, in part, by the MIT J-WAFS Water and Food Seed Grant, the MIT-Chinese University of Hong Kong collaborative research program, and the UM6P-MIT collaborative research program.

0 notes

Text

Hydrogel-based Drug Delivery Market Drivers: Exploring Catalysts Behind the Growth Surge

The hydrogel-based drug delivery market is witnessing rapid evolution, driven by a convergence of technological advancements, clinical needs, and regulatory shifts. As a smart and responsive system capable of controlled drug release, hydrogels are transforming therapeutic delivery mechanisms across a spectrum of diseases. This article explores the primary drivers that are accelerating the growth of the hydrogel-based drug delivery market, highlighting the synergy of innovation, demand, and industry support.

Rising Demand for Targeted and Controlled Drug Delivery

One of the most prominent drivers is the increasing preference for targeted and controlled drug delivery systems. Traditional drug delivery often suffers from poor bioavailability and systemic side effects. Hydrogel-based platforms, in contrast, offer site-specific delivery and tunable release profiles, minimizing adverse reactions and enhancing treatment efficacy. This capability is particularly beneficial in oncology, wound care, and chronic disease management, where precision is critical.

The hydrogel matrix can encapsulate a wide variety of therapeutic agents—including small molecules, proteins, and nucleic acids—and release them in response to physiological stimuli such as pH, temperature, or enzymes. This smart responsiveness is compelling to pharmaceutical developers aiming to improve patient compliance and therapeutic outcomes.

Increasing Incidence of Chronic Diseases

Chronic diseases such as diabetes, cancer, and cardiovascular disorders are rising globally, creating a heightened need for innovative drug delivery systems. Hydrogels are playing a vital role in developing long-term, sustained-release drug delivery methods suitable for chronic disease patients who require regular dosing. Their ability to provide localized delivery and sustained therapeutic effect reduces dosing frequency, improves adherence, and enhances the quality of life.

In diabetes care, for instance, hydrogel-based systems are being developed for glucose-responsive insulin delivery, offering a promising alternative to multiple daily injections. Such applications are driving R&D investments and attracting attention from biotech companies and academic research institutions.

Advancements in Biomaterials and Nanotechnology

Technological advancements in polymer science and nanotechnology have significantly improved the performance of hydrogel-based systems. Modern hydrogels can be engineered to have enhanced mechanical strength, biocompatibility, and biodegradability. Incorporating nanostructures into hydrogel matrices has further expanded their functionality, allowing for dual drug delivery, multi-stimuli responsiveness, and enhanced targeting capabilities.

These innovations are enabling the development of next-generation hydrogel systems suitable for a range of administration routes including transdermal, ocular, subcutaneous, and intranasal. The flexibility in formulation and adaptability to different therapeutic areas makes hydrogels a versatile platform for pharmaceutical developers.

Favorable Regulatory Environment and Government Funding

Government support and evolving regulatory guidelines are another significant driver of growth. Regulatory bodies such as the FDA and EMA are increasingly recognizing the potential of advanced drug delivery technologies, including hydrogels, and are adapting frameworks to expedite their approval. Concurrently, public and private research funding is promoting innovation in biomaterials and drug delivery technologies.

For example, agencies like the National Institutes of Health (NIH) and European Commission have funded several initiatives focused on hydrogel-based systems for drug delivery and tissue engineering. This institutional backing is crucial in translating laboratory innovations into commercial therapies.

Growing Applications in Regenerative Medicine and Tissue Engineering

Beyond conventional drug delivery, hydrogels are gaining traction in regenerative medicine due to their high water content, tunable properties, and similarity to natural extracellular matrices. They are used to deliver growth factors and stem cells in tissue repair and organ regeneration applications. This dual utility in drug delivery and tissue engineering is expanding the market scope for hydrogel technologies.

For instance, injectable hydrogels loaded with stem cells or bioactive molecules are being developed for cartilage repair, spinal cord injury treatment, and myocardial regeneration. The ability to combine structural support with drug delivery further strengthens the commercial appeal of hydrogels.

Strategic Collaborations and Industry Investment

Biopharmaceutical companies are increasingly partnering with hydrogel technology firms and academic research groups to accelerate product development. These strategic collaborations are driving innovation, reducing time-to-market, and expanding the global footprint of hydrogel-based drug delivery solutions.

Major industry players are also making significant investments to expand their hydrogel technology portfolios through acquisitions and in-house R&D. These investments indicate strong confidence in the commercial viability and long-term potential of hydrogel-based delivery systems.

0 notes