#industrial software Solutions

Link

#absolute reports pvt ltd#industrial software examples#siemens industrial software#industrial software solutions#industrial automation software

1 note

·

View note

Text

Boosting Efficiency: The Role of ERP Software in Modern Manufacturing Operations

In today's fast-paced manufacturing landscape, efficiency is not just a desirable trait; it's a necessity. To stay competitive and meet the demands of the market, manufacturers must streamline their processes, optimize resource utilization, and enhance decision-making capabilities. This is where Enterprise Resource Planning (ERP) software steps in as a game-changer. In this article, we'll delve into the pivotal role of ERP systems in revolutionizing manufacturing operations, particularly in India's thriving industrial sector.

Understanding ERP for Manufacturing Industry

ERP systems for manufacturing are comprehensive software solutions designed to integrate and automate core business processes such as production planning, inventory management, supply chain logistics, financial management, and human resources. By consolidating data and operations into a unified platform, ERP empowers manufacturers with real-time insights, facilitates collaboration across departments, and enables informed decision-making.

Streamlining Operations with ERP Solutions

In the dynamic environment of manufacturing, where every minute counts, efficiency gains translate directly into cost savings and competitive advantages. ERP software for manufacturing offers a multitude of features that streamline operations and drive efficiency:

1. Enhanced Production Planning: ERP systems enable manufacturers to create accurate production schedules based on demand forecasts, resource availability, and production capacity. By optimizing production timelines and minimizing idle time, manufacturers can fulfill orders promptly and reduce lead times.

2. Inventory Management: Efficient inventory management is crucial for balancing supply and demand while minimizing holding costs. ERP software provides real-time visibility into inventory levels, automates reorder points, and facilitates inventory optimization to prevent stockouts and overstock situations.

3. Supply Chain Optimization: ERP solutions for manufacturing integrate supply chain processes from procurement to distribution, enabling seamless coordination with suppliers and distributors. By optimizing procurement cycles, minimizing transportation costs, and reducing lead times, manufacturers can enhance supply chain resilience and responsiveness.

4. Quality Control: Maintaining product quality is paramount in manufacturing to uphold brand reputation and customer satisfaction. ERP systems offer quality management modules that streamline inspection processes, track product defects, and facilitate corrective actions to ensure adherence to quality standards.

5. Financial Management: Effective financial management is essential for sustaining manufacturing operations and driving profitability. ERP software provides robust accounting modules that automate financial transactions, streamline budgeting and forecasting, and generate comprehensive financial reports for informed decision-making.

6. Human Resource Management: People are the cornerstone of manufacturing operations, and managing workforce efficiently is critical for productivity and employee satisfaction. ERP systems for manufacturing include HR modules that automate payroll processing, manage employee records, and facilitate workforce planning to align staffing levels with production demands.

The Advantages of ERP for Manufacturing Companies in India

India's manufacturing sector is undergoing rapid transformation, fueled by factors such as government initiatives like "Make in India," technological advancements, and globalization. In this dynamic landscape, ERP software plays a pivotal role in empowering manufacturing companies to thrive and remain competitive:

1. Scalability: ERP solutions for manufacturing are scalable, making them suitable for companies of all sizes – from small and medium enterprises (SMEs) to large conglomerates. Whether a company is expanding its operations or diversifying its product portfolio, ERP systems can adapt to evolving business needs and support growth.

2. Compliance: Regulatory compliance is a significant concern for manufacturing companies in India, given the complex regulatory environment. ERP software incorporates compliance features that ensure adherence to industry regulations, tax laws, and reporting requirements, minimizing the risk of non-compliance penalties.

3. Localization: ERP vendors catering to the Indian manufacturing sector offer localized solutions tailored to the unique requirements of the Indian market. From multi-currency support to GST compliance features, these ERP systems are equipped with functionalities that address the specific challenges faced by Indian manufacturers.

4. Cost Efficiency: Implementing ERP software for manufacturing entails upfront investment, but the long-term benefits far outweigh the costs. By streamlining processes, optimizing resource utilization, and reducing operational inefficiencies, ERP systems drive cost savings and improve overall profitability.

5. Competitive Edge: In a fiercely competitive market, manufacturing companies in India must differentiate themselves through operational excellence and agility. ERP software equips companies with the tools and insights needed to outperform competitors, adapt to market dynamics, and capitalize on emerging opportunities.

Choosing the Right ERP Software for Manufacturing

Selecting the right ERP solution is crucial for maximizing the benefits and ensuring a smooth implementation process. When evaluating ERP software for manufacturing, companies should consider the following factors:

1. Industry-specific functionality: Choose an ERP system that offers industry-specific features and functionalities tailored to the unique requirements of manufacturing operations.

2. Scalability and flexibility: Ensure that the ERP software can scale with your business and accommodate future growth and expansion.

3. Ease of integration: Look for ERP systems that seamlessly integrate with existing software applications, such as CRM systems, MES solutions, and IoT devices, to create a cohesive technology ecosystem.

4. User-friendliness: A user-friendly interface and intuitive navigation are essential for ensuring widespread adoption and maximizing user productivity.

5. Vendor support and expertise: Select a reputable ERP vendor with a proven track record of success in the manufacturing industry and robust customer support services.

Conclusion

In conclusion, ERP software has emerged as a cornerstone of modern manufacturing operations, empowering companies to enhance efficiency, drive growth, and maintain a competitive edge in the global market. For manufacturing companies in India, where agility, scalability, and compliance are paramount, implementing the right ERP solution can be a transformative investment that paves the way for sustainable success. By harnessing the power of ERP, manufacturers can optimize processes, streamline operations, and unlock new opportunities for innovation and growth in the dynamic landscape of the manufacturing industry.

#ERP software providers in India#Manufacturing enterprise resource planning#ERP systems for manufacturing companies#ERP system for manufacturing industry#ERP for manufacturing companies#ERP software for engineering company#ERP software for engineering companies in India#ERP software for engineering companies in Mumbai#ERP solution providers in India#ERP for manufacturing industry#ERP systems for manufacturing#ERP solutions for manufacturing#ERP software manufacturing industry#ERP for manufacturing company in India#India

7 notes

·

View notes

Text

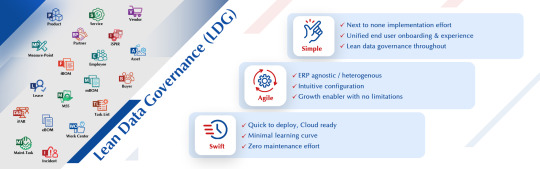

Master Data Governance Solutions - PiLog

Master Data Governance Solutions: Unlocking the Power of Data Control

Master Data Governance (MDG) solutions provide a structured framework for managing, controlling, and ensuring the quality of essential business data. These solutions establish policies, processes, and standards to maintain the integrity, security, and consistency of data across an organization. They focus on governing the lifecycle of critical master data such as customer information, product data, and financial records while making sure it remains accurate and compliant with regulatory requirements.

Key Features of Master Data Governance Solutions:

Data Policy Enforcement: MDG solutions define and enforce policies to maintain consistent data standards across all systems.

Data Stewardship: They assign roles and responsibilities to data stewards, who oversee data quality, resolve issues, and ensure data remains compliant.

Data Quality Monitoring: Continuous monitoring tools detect and correct data quality issues like duplicates, inconsistencies, and inaccuracies.

Audit Trails & Compliance: MDG solutions track changes and ensure that all modifications adhere to industry regulations and internal governance standards.

Workflow Management: Automated workflows manage data validation, approval, and updates across multiple systems.

Benefits of Master Data Governance:

Improved Data Quality: By applying rigorous standards, MDG ensures high-quality data that fuels accurate reporting and decision-making.

Regulatory Compliance: MDG solutions help businesses adhere to global data privacy regulations, reducing the risk of non-compliance penalties.

Enhanced Collaboration: With well-governed data, different departments can collaborate seamlessly, relying on accurate and up-to-date information.

Data Security: Governance solutions ensure that sensitive data is properly protected, with controlled access and strict usage guidelines.

Why Master Data Governance is Essential:

In today’s data-driven world, businesses rely on accurate and trustworthy data to drive strategic initiatives. However, without a strong governance framework, data can quickly become inconsistent, redundant, or insecure. Master Data Governance Solutions enable organizations to take control of their data, ensuring it is reliable, compliant, and ready to support growth.

Learn more at: https://www.piloggroup.com/lean-data-governance.php

#business#data#it solutions#motivation#quality#software#support#technology#transformation#industrial design#success#explore#management#solutions

2 notes

·

View notes

Text

Tired of paper piles? 🚫 Go paperless with Magtec ERP Software! 💻 Streamline your workflow and boost efficiency. It's time to embrace the digital future.

#erp#business#software#management#automation#enterprise#resources#planning#solution#system#cloud#industry#finance#accounting#supplychain#inventory#crm#hr#manufacturing#distribution#retail#healthcare#education#hospitality#smallbusiness#mediumenterprise#largeenterprise#magtecerp#magtec#magtecsolutions

2 notes

·

View notes

Text

ERP Trends 2024: What Engineering and Manufacturing Industries Need to Know

As we navigate through 2024, the landscape of Enterprise Resource Planning (ERP) systems continues to evolve, presenting both opportunities and challenges for engineering and manufacturing industries. Companies in this sector, especially those in key industrial regions like Maharashtra, Mumbai, Pune, and Gujarat, must stay abreast of the latest ERP trends to maintain competitive advantage and operational efficiency. In this blog, we’ll delve into the significant ERP trends of 2024 and their implications for the engineering and manufacturing sectors.

1. Increased Adoption of Cloud-Based ERP Solutions

One of the most significant trends in ERP software for engineering companies in Maharashtra and across India is the shift towards cloud-based solutions. Cloud ERP offers several advantages over traditional on-premise systems, including lower upfront costs, greater scalability, and enhanced accessibility.

Benefits of Cloud-Based ERP:

Cost Efficiency: Eliminates the need for expensive hardware and reduces IT maintenance costs.

Scalability: Easily adjusts to the growing needs of a manufacturing company in Gujarat or an engineering firm in Mumbai.

Accessibility: Provides access to real-time data from anywhere, facilitating better decision-making.

Leading ERP software companies in Pune are increasingly offering cloud-based solutions tailored to the needs of local engineering and manufacturing businesses. These solutions support remote work and ensure business continuity in an increasingly digital world.

2. Integration of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing ERP systems by providing intelligent insights and automating routine tasks. For ERP software for engineering companies in Mumbai, integrating AI can enhance predictive maintenance, optimize supply chain management, and improve production planning.

AI and ML Applications in ERP:

Predictive Analytics: Helps foresee equipment failures and reduce downtime.

Supply Chain Optimization: Enhances demand forecasting and inventory management.

Process Automation: Automates repetitive tasks, freeing up human resources for more strategic roles.

ERP solution providers in Pune are at the forefront of integrating AI and ML into their systems, enabling companies to leverage advanced analytics and improve overall operational efficiency.

3. Emphasis on Cybersecurity

With the increasing digitization of manufacturing processes, cybersecurity has become a critical concern. ERP systems, being the backbone of business operations, are prime targets for cyber-attacks. Engineering and manufacturing companies in regions like Gujarat and Maharashtra need robust cybersecurity measures to protect their sensitive data.

Key Cybersecurity Features:

Data Encryption: Protects data during transmission and storage.

Multi-Factor Authentication: Enhances user authentication processes.

Regular Security Audits: Ensures continuous monitoring and improvement of security protocols.

ERP software for engineering companies in Maharashtra must incorporate these advanced security features to safeguard against data breaches and cyber threats.

4. Enhanced User Experience (UX)

User experience has become a critical factor in ERP adoption and utilization. Modern ERP systems are focusing on intuitive interfaces and user-friendly designs to ensure that all employees, regardless of their technical expertise, can effectively use the system.

UX Improvements:

Intuitive Dashboards: Provide real-time insights and easy navigation.

Mobile Accessibility: Ensures that users can access ERP data on-the-go.

Customization Options: Allow users to tailor the system to their specific needs.

ERP software companies in Pune are prioritizing user experience in their solutions, making it easier for engineering and manufacturing firms to train their staff and increase productivity.

5. Internet of Things (IoT) Integration

The integration of IoT with ERP systems is another trend transforming the manufacturing industry. IoT devices collect vast amounts of data from production lines, equipment, and other operational areas, which can be analyzed by the ERP system to optimize performance.

IoT Benefits in ERP:

Real-Time Monitoring: Provides immediate insights into production processes.

Predictive Maintenance: Schedules maintenance activities based on equipment condition rather than time intervals.

Enhanced Quality Control: Monitors product quality throughout the manufacturing process.

For ERP for manufacturing companies in Gujarat, IoT integration offers a significant advantage by improving efficiency and reducing operational costs.

6. Sustainability and Green Manufacturing

Sustainability is becoming a critical focus for manufacturing companies worldwide. ERP systems are evolving to support green manufacturing practices by tracking and optimizing resource usage, reducing waste, and ensuring compliance with environmental regulations.

Sustainable ERP Features:

Resource Management: Tracks energy and material usage to minimize waste.

Regulatory Compliance: Ensures adherence to environmental laws and standards.

Sustainability Reporting: Provides detailed reports on sustainability metrics.

Engineering and manufacturing companies in regions like Mumbai and Maharashtra can benefit from ERP solutions that incorporate sustainability features, helping them achieve their environmental goals and enhance their corporate reputation.

7. Modular and Flexible ERP Solutions

In response to the diverse needs of engineering and manufacturing firms, ERP solution providers in Pune are developing more modular and flexible ERP systems. These systems allow companies to select and implement only the modules they need, which can be easily scaled and customized as their business grows.

Advantages of Modular ERP:

Cost-Effective: Pay only for the features you need.

Scalability: Easily add new modules as your business requirements evolve.

Customization: Tailor the system to fit specific operational needs.

This trend is particularly beneficial for small to medium-sized enterprises (SMEs) in the engineering and manufacturing sectors, enabling them to adopt ERP systems without the burden of high costs or complexity.

8. Focus on Customer-Centric Manufacturing

ERP systems are increasingly supporting customer-centric manufacturing practices, where production processes are aligned with customer needs and preferences. This approach enhances customer satisfaction and drives business growth.

Customer-Centric ERP Features:

Custom Order Management: Handles unique customer requirements and specifications.

Enhanced CRM Integration: Integrates with customer relationship management (CRM) systems for a holistic view of customer interactions.

Real-Time Order Tracking: Provides customers with real-time updates on their orders.

Manufacturing companies in Gujarat and engineering firms in Maharashtra are leveraging these customer-centric ERP features to improve their service levels and build stronger customer relationships.

9. Advanced Analytics and Business Intelligence (BI)

Advanced analytics and BI are becoming integral components of modern ERP systems. These tools provide deep insights into business operations, helping companies make data-driven decisions and improve performance.

Key BI Features:

Data Visualization: Converts complex data into easy-to-understand charts and graphs.

Dashboards: Offer a real-time overview of key performance indicators (KPIs).

Predictive Analytics: Forecasts future trends based on historical data.

ERP software companies in Pune are incorporating advanced analytics and BI capabilities into their systems, empowering engineering and manufacturing firms to gain a competitive edge through better insights and informed decision-making.

10. Globalization and Localization Support

As engineering and manufacturing companies expand their operations globally, ERP systems must support multiple languages, currencies, and regulatory requirements. Globalization and localization features are essential for companies operating in diverse markets.

Globalization Features:

Multi-Language Support: Accommodates users from different regions.

Multi-Currency Handling: Manages transactions in various currencies.

Compliance with Local Regulations: Ensures adherence to regional laws and standards.

ERP solution providers in Pune and other industrial hubs are enhancing their systems to support global operations, enabling companies to seamlessly manage their international business processes.

Conclusion

The ERP landscape for engineering and manufacturing industries is rapidly evolving, driven by advancements in technology and changing business needs. Companies in Maharashtra, Mumbai, Pune, and Gujarat must stay informed about these trends to leverage the full potential of ERP systems. By adopting cloud-based solutions, integrating AI and IoT, prioritizing cybersecurity, and focusing on sustainability, businesses can achieve greater efficiency, competitiveness, and growth in 2024 and beyond.

For engineering and manufacturing firms looking for the best ERP software for engineering companies in Maharashtra or ERP for manufacturing companies in Gujarat, it is crucial to partner with leading ERP solution providers in Pune who understand the unique challenges and opportunities in this sector. Embracing these trends will not only enhance operational efficiency but also drive innovation and sustainability in the engineering and manufacturing industries.

By staying ahead of these ERP trends, companies can position themselves for success in an increasingly digital and interconnected world. Whether you are an engineering firm in Mumbai or a manufacturing company in Gujarat, the right ERP system can transform your operations and pave the way for a prosperous future.

#ERP software in Vadodara#Manufacturing ERP software in Gujarat#ERP software companies in Vadodara#ERP software providers in Vadodara#ERP for manufacturing company in Gujarat#ERP software#ERP system#cloud ERP#ERP solutions#software development#engineering ERP#management software#engineering services#engineering industry

4 notes

·

View notes

Text

Healthcare Industry with Custom AI Software Development - SSTech System

We are living in an era of technology. By glancing around, it is obvious that technology has affected every inch of our lives. Artificial Intelligence (AI) is the contemporary technological trend. It is reshaping the entire landscape. Healthcare is no exception. AI Software Development of today is having a great influence on how medical care is delivered nowadays.

AI-driven web development has brought a very important change in the way patients are diagnosed. It has not only changed the way doctors diagnose and treat patients but also how patients manage their health. Custom AI software development truly has been revolutionized as the game-changer. It also provides a good foundation for creativity and saving.

Would you like to find out about the ways AI is transforming the healthcare sector?If yes, read on! In this article, we are going to expose the way AI is changing healthcare.

AI & Healthcare Web Development

AI in Healthcare can be a very effective option of efficient healthcare. It can empower the healthcare sector more than ever before. It improves medical outcomes. This adds to the fact that it improves operations and results in cost and time savings. Well, it is not just a passing fad, but it is a trend that will remain forever.

According to data, the worldwide AI market is poised for remarkable growth. It is set to grow at an anticipated compound annual growth rate (CAGR) of 37.3% between 2023 and 2030. By 2023, it is expected to soar to a staggering $1,811.8 billion, showcasing the immense potential and rapid expansion of the AI industry.

With the emergence of AI, healthcare businesses are quickly shifting to custom AI software. It empowers them to make the best of the power of AI tailored. They can tailor the solutions as per their unique requirements.

Are you also planning to level up your healthcare business? If so, AI software development can be beneficial. Wondering how? Let’s move to the next section, where we will tell you some key benefits of custom AI software development.

Benefits Of Custom AI Software Development

AI is growing massively. It has impacted businesses across sectors. If we talk about Healthcare, AI has made things super easy. Below are some key benefits of AI software development:

Enhanced diagnostic accuracy:

Custom AI solutions for your healthcare business enable to make the analysis of large amounts of medical data. It is also able to analyze patient records, laboratory results, and imaging scans.

This however is not the only advantage; AI algorithms are also able to uncover patterns. Moreover, it can recognize abnormalities which human eyes may miss. Generally, this brings about better diagnoses and prompts treatment.

Personalized treatment plans:

AI-driven insights assist healthcare professionals in the creation of individualized treatment plans. They may personalize medical solutions to patients’ needs. It harnesses patient data, genetic information, and treatment history. It assists in suggesting tailored strategies.

Improved operational efficiency:

AI-enabled automation decreases clerical duties. For instance, it assists with appointment scheduling, billing, and inventory management. Thus, they can devote more time to patient care. It also helps in the integration of AI into the existing workflow. It will increase efficiency and productivity in the organization as a whole.

Predictive analytics:

AI has the superior predictive power. Developing AI healthcare software can pre-empt disease outbreaks, anticipate bed demand, and identify high-risk patients. It allows for proactive planning and resource allocation. AI algorithms can furnish strategic decision-makers with actionable insights to guide strategic decision-making and resource planning.

Enhanced patient engagement:

AI-driven chatbots and virtual assistants are always on standby to extend support to patients. It answers their questions anytime. Moreover, it provides medication reminders, as well as tailored health suggestions. You can hence build an AI chatbot and integrate it into websites and applications.

We have seen how AI can improve healthcare. However, are you aware of the common AI applications in the healthcare industry? Let’s find out!

Custom AI Solutions for Healthcare

AI can be used in multiple ways. Here, we have listed down some typical custom AI solutions in the medical industry:

AI-enabled diagnostics:

Custom AI algorithms can analyze medical images. It helps radiologists in X-rays, MRIs, and CT scans in detecting abnormalities and identifying disease. AI-powered diagnostic tools offer rapid and accurate results.

Predictive analytics:

Custom AI models can analyze electronic health records (EHRs). It also allows for demographic data, and environmental factors to predict disease trends, identify at-risk populations. With predictive analytics, healthcare providers can intervene proactively.

Remote patient monitoring:

Custom AI software enables remote monitoring of patients with chronic conditions. AI algorithms can analyze real-time data from wearable devices, sensors, and IoT devices to detect deviations from normal parameters and alert healthcare providers to potential issues. It enables timely interventions and preventing complications.

Drug discovery and development:

Custom AI solutions accelerate the drug discovery process by analyzing vast datasets, simulating molecular interactions, and predicting drug efficacy and safety profiles. AI-driven drug discovery platforms expedite the identification of promising drug candidates, reducing costs and time-to-market for new therapies.

AI Software Development Tools

Well! When it comes to AI software development tools, you get a variety of options. Here, we have noted the most important tools that can make a positive difference for your business:

Machine learning libraries:

Tools such as TensorFlow, PyTorch, and sci-kit-learn provide potent frameworks for developing custom AI models tailored to healthcare applications. These libraries offer a wide range of machine-learning algorithms and tools for data preprocessing, model training, and evaluation.

Natural language processing (NLP) tools:

NLP frameworks like spaCy and NLTK enable the development of AI-driven chatbots and virtual assistants for healthcare applications. These tools support text processing, sentiment analysis, and language understanding, facilitating the creation of conversational interfaces for patient engagement and support.

Deep learning platforms:

Deep learning frameworks such as Keras and MXNet offer advanced capabilities for developing custom AI models, including convolutional neural networks (CNNs), recurrent neural networks (RNNs), and generative adversarial networks (GANs). These platforms empower healthcare organizations to leverage state-of-the-art deep learning techniques for image analysis, natural language processing, and predictive modelling.

Custom AI software development has become crucial for businesses. Professional AI/ML developer helps in unlocking the full potential of AI by providing the best-in-class custom healthcare software development services for the healthcare industry.

With AI revolution in healthcare lets you enhance diagnostic accuracy, personalize treatment plans, improve operational efficiency, and empower patients to take control of their health. SSTech System a professional AI software development company, the future of Healthcare holds great potential for innovation, efficiency, and improved patient outcomes.

Final words

AI software development services for healthcare are no less than a paradigm shift in medical technology. It allows for a smarter and more efficient way of medical care and healthcare app development. If you are also a healthcare business and looking to integrate AI into your healthcare business, it is time for you to go professional. So what are you waiting for? Hire AI developers today and take your business to new heights.

#AI Solutions for Healthcare#Hire AI developers#AI software development#software development#sstech system#healthcare industry#Custom AI software#Healthcare Web Development#healthcare#b2b

2 notes

·

View notes

Text

#Business Consulting Solutions#IT Services#digital transformation consulting#top consulting firms#software development company#india consulting#it company in usa#high tech industry

2 notes

·

View notes

Link

#Predictive Maintenance#predictive maintenance solutions#predictive maintenance for factory#predictive maintenance for manufacturing#predictive maintenance smart factory#predictive maintenance in manufacturing industry#predictive maintenance for pumps#predictive maintenance semiconductor#predictive maintenance semiconductor industry#preventive maintenance semiconductor#factory automation software#manufacturing automation software solutions

3 notes

·

View notes

Link

The business world is currently undergoing enormous change. Why? The CRM system is to blame. CRM consulting services are in high demand due to their influence. Let's first define CRM before moving on, shall we?

CRM, or customer relationship management, is a tool that aids in creating enduring relationships with customers. It is essential to effectively handle and utilize information if you want your firm to succeed. CRM offers a wonderful answer in this situation!

Learn the details of how a CRM solution and CRM consulting services help in transforming business performance digitally. Get the most out of your business.

#salesforce consulting services#CRM solutions#CRM Consulting Services#crm consultancy#CRM Consulting#CRM Consultants#best CRM consultants#Manufacturing CRM#Fintech CRM#Healthcare CRM#Retail CRM#CRM for startups#CRM in Healthcare#Salesforce CRM in Healthcare#CRM software#Salesforce is a cloud-based CRM software#salesforce implementation consulting#salesforce implementation company#customer relationship management consultants#Industry CRM#Salesforce CRM

3 notes

·

View notes

Text

SAP Business One for Chemical Industry

With all its benefits, global chemical manufacturing companies are incorporating SAP B1 at an increased rate for chemical production. Not only does it help in improving business efficiency and enhancing collaboration but it also aids in increasing customer satisfaction and increasing revenue by up to 10-30%. With the change in business dynamics and fluctuations in demand, robust ERP software can empower chemical businesses to take advantage of their competition while adhering to safety, quality, and compliance requirements. SAP b1 solutions are already used by nearly 6500 chemical industry businesses and more are soon to follow.

Managing costs effectively is an essential aspect of chemicals and any industry. In the chemical industry, SAP Business One provides intuitive planning and scheduling to manage time and resources efficiently and cut down on business costs to control every aspect. The cost of materials can also be estimated by analyzing the production data history and past purchases in a single click to simplify business processes. SAP chemical industry best practices optimize different processes, improve workflow efficiency, and reduce overtime costs by 48%.

#sap business one#SAP Business One Partner in India#SAP Business One partner#SAP Business One ERP Solution#SAP Business One for Manufacturers#SAP chemical industry#ERP Software#best erp software#best erp software in india#food beverage erp software#erp software for construction#erp#enterprise software#ERP Solution#SAP ERP#erp for small business#erp development company#erp consulting services#enterprise resource planning#erpsystem

2 notes

·

View notes

Text

Build Your Advanced Taxi Dispatch Software

Want to expand your taxi/cab booking business online? Build your own taxi dispatch solution like Uber with Quickworks. We offer a complete technology suite that includes Customer App, Driver App & Admin Panel to help you grow your taxi business by 10x. Book a free demo now! Feel Free To call us at +1 (512) 872 3364 or email us at [email protected]

#saas development company#b2b saas#saas technology#technology#taxi dispatch software#taxi app solution#taxi industry#taxi business

0 notes

Text

How Manufacturers Can Manage Growth with ERP

Introduction:

In the dynamic landscape of manufacturing, where growth is the ultimate goal, the ability to adapt and streamline operations is paramount. Enter ERP (Enterprise Resource Planning), a powerful solution that has revolutionized the way manufacturers operate. In this blog, we'll explore the significant role of ERP software for manufacturing industry and how it serves as a catalyst for sustainable growth. Whether you're in traditional manufacturing or a software development company, ERP solutions are key to optimizing processes and managing growth effectively.

Understanding the Essence of ERP Software for Manufacturing:

1. Efficiency Unleashed:

ERP system for manufacturing industry is designed to enhance operational efficiency by integrating various business processes. From order management and procurement to production planning and inventory control, ERP systems bring together disparate functions into a unified platform, eliminating silos and enhancing overall efficiency.

2. Real-time Insights:

One of the key advantages of ERP solutions is the ability to provide real-time insights into business operations. Manufacturers can make informed decisions based on up-to-date information, helping them respond swiftly to market changes, manage resources effectively, and capitalize on growth opportunities.

3. Scalability Matters:

As a manufacturer, scalability is a constant consideration. Whether you're a growing traditional manufacturing unit or a software development company expanding its operations, ERP systems offer scalability to accommodate changing needs. The modular nature of ERP solutions allows businesses to add or modify functionalities as they evolve.

4. Improved Collaboration:

Collaboration is the bedrock of successful manufacturing. ERP fosters better communication and collaboration by providing a centralized platform where employees across different departments can access and share information seamlessly. This not only enhances teamwork but also accelerates decision-making processes.

ERP Software for Manufacturing Industry: Tailoring Solutions for Success

1. Production Planning and Scheduling:

In the manufacturing realm, effective production planning and scheduling are crucial for meeting customer demands and maintaining optimal inventory levels. ERP systems facilitate streamlined production processes, enabling manufacturers to create realistic production schedules, allocate resources efficiently, and minimize downtime.

2. Supply Chain Management:

A well-integrated supply chain is essential for manufacturers. ERP solution for the manufacturing industry ensures smooth coordination between suppliers, manufacturers, and distributors. This results in better inventory management, reduced lead times, and ultimately, improved customer satisfaction.

3. Quality Control:

Maintaining consistent product quality is non-negotiable in manufacturing. ERP solutions provide tools for comprehensive quality control by enabling real-time monitoring of production processes, tracking defects, and ensuring adherence to quality standards. This not only boosts customer confidence but also reduces wastage and rework costs.

4. Financial Management:

The financial aspect is the backbone of any business. ERP systems for manufacturing offer robust financial management capabilities, including invoicing, expense tracking, and financial reporting. This level of financial control is invaluable for manufacturers looking to manage growth effectively and make strategic financial decisions.

ERP for Software Development Company: Tailoring Solutions to Tech

1. Project Management:

For software development companies, managing projects efficiently is critical. ERP solutions designed for the software development industry offer project management modules that help track project timelines, allocate resources effectively, and ensure that development projects stay on course.

2. Resource Planning:

In the software development realm, talent is a primary resource. ERP systems tailored for software companies facilitate resource planning by providing insights into employee availability, skills, and project commitments. This ensures optimal resource allocation for project success.

3. Version Control and Collaboration:

Version control and collaboration are key aspects of software development. ERP solutions for software companies include features that enable version control, code collaboration, and documentation management. This ensures that development teams work cohesively, leading to efficient project outcomes.

4. Compliance and Security:

In the software development industry, compliance and security are paramount. ERP systems for software companies often include modules that help manage compliance with industry standards and ensure data security. This is especially crucial in an era where data protection is a top priority.

Conclusion:

As manufacturers navigate the complexities of growth, ERP software emerges as an indispensable tool for success. Whether you're in traditional manufacturing or a software development company, the benefits of ERP systems are far-reaching. From enhancing operational efficiency and providing real-time insights to tailoring solutions for specific industry needs, ERP is the key to managing growth effectively. Embrace the power of ERP, and propel your manufacturing operations into a future of streamlined processes, informed decision-making, and sustained success.

#Go-To-Market#GTM#Supply-Chain-Management#Technology#India#ERP-India#ERP#Business-Solutions#Manufacturer#Engineering#Inventory-Management#ERP Software for Manufacturing Industry#ERP System for Manufacturing Industry#ERP for Software Development Company#ERP Solutions for Manufacturing

7 notes

·

View notes

Text

Building Scalable Applications: Strategies for Handling Growth and Performance

Introduction

In today’s digital landscape, the ability to build scalable applications is crucial for businesses aiming to adapt to rapid growth and changing user demands. A scalable application can handle increased loads without compromising performance, ensuring a seamless user experience. Here are some effective strategies for building scalable applications.

1. Microservices Architecture

One of the most effective approaches to scalability is adopting a microservices architecture. This method breaks down a large application into smaller, independent services that can be developed, deployed, and scaled individually. Each service handles a specific function, allowing teams to work on different components simultaneously. This not only speeds up development but also makes it easier to scale services based on demand. For instance, if a particular service experiences high traffic, it can be scaled up without affecting other parts of the application.

2. Load Balancing

Load balancing is essential for distributing incoming network traffic across multiple servers. By ensuring that no single server is overwhelmed, load balancing enhances application availability and reliability. It acts as a traffic manager, directing requests to the least busy server, which improves response times and prevents bottlenecks. Implementing load balancers can significantly enhance the performance of your application during peak usage times, making it a vital strategy for scalability.

3. Database Optimization

As an application scales, so does the demand on its database. Database optimization strategies such as indexing, partitioning, and using read replicas can greatly improve performance. Indexing allows for faster data retrieval, while partitioning divides large datasets into smaller, more manageable pieces. Additionally, read replicas can help offload read requests from the primary database, improving overall response times and reliability. Choosing the right database technology—like NoSQL for unstructured data or relational databases for structured data—can also impact scalability.

4. Caching Mechanisms

Implementing caching mechanisms is another effective strategy for enhancing performance. By storing frequently accessed data in memory, applications can retrieve it quickly without querying the database each time. This significantly reduces latency and improves user experience. Popular caching solutions like Redis or Memcached can be integrated to store session data, user profiles, and other frequently accessed information. By minimizing database load, caching allows applications to scale more efficiently.

5. Auto-scaling

In cloud environments, auto-scaling is a powerful feature that automatically adjusts the number of active servers based on current demand. This ensures that applications have enough resources to handle fluctuations in traffic without manual intervention. By setting thresholds for CPU usage or request rates, auto-scaling can help manage costs while maintaining performance. This on-demand resource allocation is crucial for applications with unpredictable traffic patterns, ensuring they remain responsive at all times.

6. Monitoring and Performance Analysis

Finally, continuous monitoring and performance analysis are essential for maintaining a scalable application. Tools like New Relic, Datadog, or Prometheus provide real-time insights into application performance, helping identify bottlenecks and areas for improvement. Regularly reviewing metrics such as response times, server loads, and user behavior enables developers to make informed decisions about scaling strategies and optimizations.

Conclusion

Building scalable applications requires careful planning and the right strategies to handle growth and performance. By leveraging microservices architecture, load balancing, database optimization, caching mechanisms, auto-scaling, and continuous monitoring, developers can create robust applications that meet user demands effectively. As businesses continue to grow and evolve, the ability to scale efficiently will be a key differentiator in the competitive digital landscape.

0 notes

Text

https://pmtrackerp.in/erp-software-company-in-chennai/

We are a leading manufacturing ERP software company in Chennai, with core values that include providing dependable business management solutions, flawless customer support, and proven technical expertise in ERP-based software for companies in Chennai.

#Best ERP solution Electronics manufacturing#ERP solution#Best ERP software#ERP software Company#Electronics manufacturing ERP Solution#Electronics Industry ERP Solution

0 notes

Text

MDM Tools - PiLog

Master Data Management (MDM) tools are essential solutions for organizations seeking to manage and maintain high-quality, consistent, and accurate data across various systems and departments. These tools are designed to centralize critical business data, such as customer information, product details, financial records, and supplier data into one unified source. By integrating, standardizing, and cleansing data from multiple sources, MDM tools eliminate errors, duplicates, and inconsistencies, ensuring businesses work with a single version of the truth.

Key Features of MDM Tools:

Data Integration:

MDM tools consolidate data from different platforms (ERP, CRM, etc.) into one centralized hub, ensuring consistency across the organization.

Data Quality Management:

These tools enforce rules for cleansing, deduplicating, and validating data, which improves its accuracy and reliability.

Data Governance and Compliance:

MDM tools help implement data governance policies, ensuring proper management, access control, and adherence to regulatory requirements.

Multi-Domain Data Management:

MDM tools can manage different types of master data—such as customer, product, supplier, and financial information—within a single platform.

Workflow Automation:

Automating tasks like data validation, approval processes, and updates, MDM tools reduce manual effort and enhance operational efficiency.

Why MDM Tools Matter:

In an era where data is a key competitive asset, MDM tools are essential for businesses aiming to optimize their data management processes. They provide the foundation for better decision-making, higher operational efficiency, and improved customer engagement. Whether you’re managing customer relationships, supply chains, or financial reporting, MDM tools ensure that your data is trustworthy, high-quality, and aligned with your business goals.

#business#technology#software#data#it solutions#motivation#quality#support#transformation#industrial design#tools#product design#solutions

0 notes

Text

Construction Management Software: A Comprehensive Overview

Construction management software (CMS) is a vital tool for modern construction projects, enabling professionals to manage various aspects of project execution efficiently. With the construction industry facing increasing complexities and demands, CMS has become essential for improving productivity, reducing costs, and enhancing collaboration among stakeholders.

Courtesy: CRM.org

Key Features of…

#cloud-based construction software#construction efficiency tools#construction industry software#construction management software#construction project planning#construction scheduling software#document management systems#field management solutions#mobile construction apps#project management tools#project tracking software#real-time collaboration tools#resource allocation software#risk management in construction

0 notes