#linear actuator

Text

Valves, Actuators and Positioners Market - Forecast(2024 - 2030)

Global Valves Market generated revenue of about $60.56 billion in 2017 growing with CAGR of 3.60% during the forecast period i.e. 2018-2023. APAC occupied the major market share in the valves market generating total revenue of $20.67 billion in 2017.

Request Sample

What is Valves, Actuators and Positioners Market?

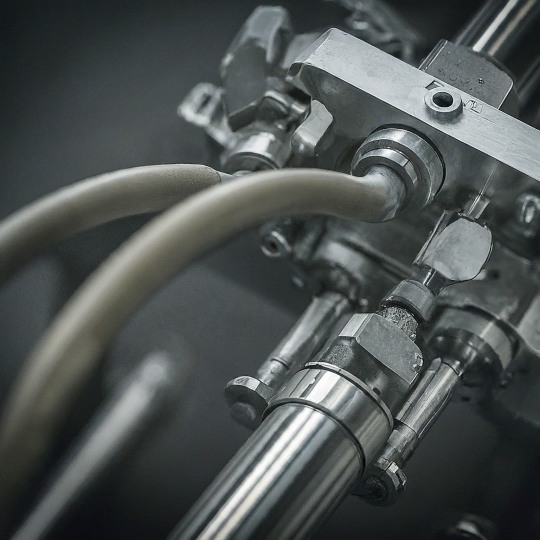

Valves is a control units when electrically energy is passed the valves either shut off or it allows the fluid flow. The actuator takes the form of an electromagnet. When energized, a magnetic field builds up which pulls a plunger or pivoted armature against the action of a spring. When de-energized, the plunger or pivoted armature is returned to its original position by the spring action. Valves, actuators and positioners are segmented based on the type in which there are two way valves, three way valves. Two way valves are shut-off valves with one inlet port and one outlet port whereas the three way valves are provided with a three port connections and two valve seats one valve seal always remains open and the other closed in the de-energized mode. When the coil is energized the mode reverses.

What are the major applications for Valves, Actuators and Positioners Market?

The major applications of valves, actuators and positioners includes in many industries such as aerospace and defense, automobiles, oil and gas, water and waste water treatment, agriculture, mining, paper and pulp and many more. In aerospace and defense valves are used in fuel systems, cockpit locks whereas in automobiles used in gear box and air conditioner systems.

Inquiry Before Buying

Market Research and Market Trends of Valves, Actuators and Positioners Market:

In recent years the gas over oil pipeline actuators are provided with ELB units for line break monitoring. This ELB will enable the operator to monitor the running condition of the gas pipeline and the open, close status of the valves. ELB is provided with an array of programmable alarm and alert indication which can help the operator to close the appropriate valves and solve the problem.

For the connection of valves, number of wire are used by which it has become difficult to connect appropriately. To solve this problem of connection consolidated solenoid wiring is used into a single collective connection on the valve manifold. This method will significantly reduce the cost and complexity as the valve manifold can be moved out of the control cabinet to the point-of-use application located near the pneumatic process which will reduce the delayed responses in operation.

Emerson has acquired Pentairs valves to enhance their portfolio globally in many sectors like chemical, power, refining, mining and Oil and Gas. This acquisition promises long term growth opportunities and provides their customers with appropriate solutions to their toughest challenges.

Who are the Major Players in Valves, Actuators and Positioners Market?

The companies referred in the market research report includes iScaler Ltd., CloudFlare Inc., ChinacacheÂ, Internap Corporation, MaxCDN, Fastly Inc.and more than 10 other companies.

Schedule a Call

What is our report scope?

The report incorporates in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and its impact during the forecast period 2018-2023.

All our reports are customizable to your company needs to a certain extent, we do provide 20 free consulting hours along with purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Buy Now

Key Takeaways from this Report

Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

Analyze the sales and distribution channels across key geographies to improve top-line revenues.

Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

#valves market size#actuators market size#positioners market size#pneumatic#hydraulic actuator#linear actuator#hydraulic cylinder#sprinkler#motor#valve positioners#water treatment#agriculture#mining#fuel systems#cockpit locks

0 notes

Text

The Power of Hydraulics: A Comprehensive Guide to Hydraulic Cylinders, Linear Actuators, and Their Applications

Introduction:

The world around us is driven by motion, and hydraulic cylinders play a crucial role in generating that motion. These powerful workhorses are the backbone of countless machines, from construction equipment to factory assembly lines. But how exactly do hydraulic cylinders function, and what makes them so versatile? This comprehensive guide will delve into the fascinating world of…

View On WordPress

#Displacement#Double-Acting Cylinder#Force#Hydraulic cylinders#Hydraulic Fluid#Linear Actuator#Piston#pressure#Rod Seal#Single-Acting Cylinder#Telescopic Cylinder

0 notes

Text

Dual-Channel Linear Actuator Control Module with ESP32 Processor

As part of a customer project, I, with the help of a capable hardware designer, developed an embedded system to control two linear actuators, specifically the Thomson Electrac HD model with SAE J1939 interface.

0 notes

Text

Advantages of using pneumatic linear actuators in industrial applications

Pneumatic linear actuators offer several advantages that make them a popular choice in industrial applications. Firstly, they provide a high force-to-weight ratio, allowing for efficient and powerful linear motion. This is particularly beneficial in applications where heavy loads need to be moved swiftly and accurately.

Secondly, pneumatic linear actuators are highly durable and can withstand harsh operating conditions. They are resistant to dust, debris, and moisture, making them suitable for use in rugged environments. This durability ensures a long lifespan and reduces the need for frequent maintenance and replacement Pneumatic Linear Actuator.

Additionally, pneumatic linear actuators are known for their simplicity and ease of use. They can be easily integrated into existing systems and controlled with precision. The compressed air used to power these actuators is readily available in most industrial settings, making them a cost-effective choice.

Overall, the advantages of pneumatic linear actuators make them an attractive option for a wide range of industrial applications, including material handling, assembly lines, packaging, and robotics.

0 notes

Text

Four Steps to Choosing the Right Linear Actuator | PV Clean Mobility Technologies

Performance metrics are quantifiable outputs that aid in assessing a product's quality. Actuators can be categorized by a number of performance criteria. Historically, torque, speed, and durability have been the most popular ones. Energy efficiency is now regarded as being equally important. Volume, mass, operating conditions, and other variables are also taken into consideration.

Force or torque

Naturally, one of the most crucial factors to consider when evaluating an actuator's performance is torque. There are two different types of torque metrics to consider in this case – static load and dynamic load. The capacity of the actuator at rest is referred to as the static load torque or force. The torque capacity of the actuator while it is moving is what is meant by the dynamic load.

Speed

Depending on how much weight is being carried, an actuator moves at a different speed. Typically, speed decreases as weight increases. As a result, it is best to look at the speed metric when the actuator is idle.

Durability

The durability of an actuator is determined by the type of actuator and the manufacturer's design. Although hydraulic actuators are thought to be more robust and durable than electric actuators, the manufacturer will determine the exact specifications regarding the quality of the material used.

Energy efficiency

Energy efficiency is becoming an increasingly important metric in all types of machinery due to growing concerns about energy conservation and its direct impact on operational costs. Here, the lesser energy needed for an actuator to accomplish its task, the better.

For air path management, PV Clean Mobility Technologies offers a variety of actuators and valves that regulate air intake and recirculated exhaust gas dose (EGR - Gasoline). The water solenoid valves developed and manufactured by PV Clean Mobility Technologies are available in 2/2 and 2/3 inlet-outlet designs and are warranted to be the highest caliber and leak-proof for the duration of their useful lives. The water solenoid valve uses up to 2A of current and can flow up to 25LPM in both 12V and 24V systems.

Its water solenoid valves have undergone internal testing and validation for efficiency and safety, and they have a fail-safe function (de-energized open-close) and Over-Temperature control to protect hardware components. You won't need to worry about anything when using one because they are made to be extremely durable, burst pressure-proof, leakage-proof, and compatible with all types of coolant water.

Our Electric wastegate actuators are designed to perform wastegate adjustment, consequently, ensuring minimal leakage. The modular lightweight actuator controls the turbocharger boost output. These actuators are ideal for passenger vehicle, Commercial vehicle, Off highway vehicle, and 3 Wheeler, and have been engineered to meet the requirements of modern low emission combustion engines.

1 note

·

View note

Text

Valves, Actuators and Positioners Market

Global Valves ,Actuators and Positioners Market generated revenue of about $60.56 billion in 2017 growing with CAGR of 3.60% during the forecast period i.e. 2018-2023. APAC occupied the major market share in the valves market generating total revenue of $20.67 billion in 2017.

What is Valves, Actuators and Positioners Market?

Valves is a control units when electrically energy is passed the valves either shut off or it allows the fluid flow. The actuator takes the form of an electromagnet. When energized, a magnetic field builds up which pulls a plunger or pivoted armature against the action of a spring. When de-energized, the plunger or pivoted armature is returned to its original position by the spring action. Valves, actuators and positioners are segmented based on the type in which there are two way valves, three way valves. Two way valves are shut-off valves with one inlet port and one outlet port whereas the three way valves are provided with a three port connections and two valve seats one valve seal always remains open and the other closed in the de-energized mode. When the coil is energized the mode reverses.

Request Sample

What are the major applications for Valves, Actuators and Positioners Market?

The major applications of valves, actuators and positioners includes in many industries such as aerospace and defense, automobiles, oil and gas, water and wastewater treatment, agriculture, mining, paper and pulp and many more. In aerospace and defense valves are used in fuel systems, cockpit locks whereas in automobiles used in gear box andair conditioner systems.

Inquiry Before Buying

Market Research and Market Trends of Valves, Actuators and Positioners Market:

In recent years the gas over oil pipeline actuators are provided with ELB units for line break monitoring. This ELB will enable the operator to monitor the running condition of the gas pipeline and the open, close status of the valves. ELB is provided with an array of programmable alarm and alert indication which can help the operator to close the appropriate valves and solve the problem.

For the connection of valves, number of wire are used by which it has become difficult to connect appropriately. To solve this problem of connection consolidated solenoid wiring is used into a single collective connection on the valve manifold. This method will significantly reduce the cost and complexity as the valve manifold can be moved out of the control cabinet to the point-of-use application located near the pneumatic process which will reduce the delayed responses in operation.

Emerson has acquired Pentairs valves to enhance their portfolio globally in many sectors like chemical, power, refining, mining and Oil and Gas. This acquisition promises long term growth opportunities and provides their customers with appropriate solutions to their toughest challenges.

Schedule a Call

Who are the Major Players in Valves, Actuators and Positioners Market?

The companies referred in the market research report includes iScaler Ltd., CloudFlare Inc., ChinacacheÂ, Internap Corporation, MaxCDN, Fastly Inc.and more than 10 other companies.

What is our report scope?

The report incorporates in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and its impact during the forecast period 2018-2023.

All our reports are customizable to your company needs to a certain extent, we do provide 20 free consulting hours along with purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Buy Now

Key Takeaways from this Report

Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

Analyze the sales and distribution channels across key geographies to improve top-line revenues.

Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

#valves market size#actuators market size#positioners market size#pneumatic#hydraulic actuator#linear actuator#hydraulic cylinder#sprinkler#motor

0 notes

Text

Concept: a highly-advanced, sapient android getting its holes railed by an analog-controlled linear actuator.

#“analog-controlled linear actuator” = a very basic thrusting sex machine#or: high-tech fuckbot x low-tech fuckbot#robot x robot#robot fucker#robot fucking#robot nsft#eroticism of the machine#nsft#mine

30 notes

·

View notes

Text

god i really do need to work on the mechanical goggles while im energetic

#at least just to get a functional prototype#proof of concept and all#i need light sensors and figure out is linear actuators or servos would work better#i think servos would react faster but the motion i need is back and forth#ig i could turn rotation into linear motion through gears but thats a lotta failure points

19 notes

·

View notes

Text

in case you're wondering what im getting into these days, the answer is mechanical keyboards, and this was initially as a disability support mobility aid type thing because my fingers are really fucked up, but now im actually unironically getting into them and let me tell you: never do that. mechanical keyboards are a mistake. if you want a mechanical keyboard go to someone you know who is into mechanical keyboards and make them build you one or pick the ideal one for you and then never, ever do any research into it do not spend your money on this get someone else to do it for you and pay them to do it because i guarantee they'll say yes

#do not ask me about my switches.#dont.#do not.#im getting 39g linear sakuras from akko bc i want to test the lower actuation force#but im honestly seriously considering swapping to tactiles after using tactile lavender 40g for a few days#and getting 36g actuation tactiles bc they should be low enough to not hurt my hands#and im back in my 43g clear linears and like#its not even about the sound its about knowing how little i have to press my keys.#.....sound is nice also tho.#lowkey like the sound also#thock.#thonk.#help.

37 notes

·

View notes

Text

Understanding Pneumatic Linear Actuators: A Comprehensive Guide

Pneumatic linear actuators have become essential components in various industries, enabling efficient and precise movement through the use of compressed air. These devices transform energy into linear motion, playing a crucial role in automation, manufacturing, robotics, and more. This comprehensive guide explores the principles, components, advantages, applications, and future trends of pneumatic linear actuators.

What Are Pneumatic Linear Actuators?

A pneumatic linear actuator is a mechanical device that converts compressed air energy into linear motion. When air is introduced into a cylinder, it pushes a piston, creating movement in a straight line. This simple yet effective mechanism allows for a wide range of applications in settings where quick and reliable movement is needed.

Key Components

Piston: The heart of the actuator, it moves within the cylinder when compressed air is applied.

Cylinder: The housing that contains the piston, designed to withstand high pressure.

Air Supply System: Comprises valves, filters, and regulators to manage the flow of compressed air, ensuring consistent performance.

Mounting Hardware: Allows for flexible installation in various machinery or equipment.

How It Works

When compressed air enters the cylinder, it forces the piston to move. The speed and distance of the piston’s movement can be controlled by adjusting the air pressure and the design of the actuator. This makes pneumatic actuators highly versatile, capable of performing a variety of tasks with precision.

Advantages of Pneumatic Linear Actuators

1. Speed and Responsiveness

Pneumatic actuators are known for their fast response times. This quick movement is crucial in environments where speed is essential, such as manufacturing lines and robotics.

2. Simplicity and Cost-Effectiveness

The straightforward design of pneumatic systems means fewer components and less complexity compared to electric or hydraulic systems. This simplicity leads to lower initial costs and reduced maintenance needs.

3. Durability

Pneumatic actuators are built to withstand harsh conditions. Their robust construction allows them to operate effectively in environments with dust, moisture, and extreme temperatures.

4. Safety and Environmental Considerations

Using compressed air minimizes the risk of electrical hazards, making pneumatic systems safer. Additionally, pneumatic actuators do not require hydraulic fluids, reducing environmental risks.

Applications of Pneumatic Linear Actuators

Pneumatic linear actuators are utilized across a wide range of industries, thanks to their versatility:

1. Manufacturing

In manufacturing, these actuators are used for assembly, packaging, and material handling. Their speed and precision help streamline production processes.

2. Robotics

Pneumatic actuators provide motion for robotic arms and grippers, allowing for rapid and precise manipulation of objects in various tasks.

3. Food and Beverage

In the food industry, pneumatic actuators are essential for packaging, bottling, and sorting, ensuring hygiene and efficiency in operations.

4. Medical Devices

They play a critical role in medical equipment, enabling precise movements in surgical instruments and diagnostic tools.

5. Aerospace

Pneumatic actuators are used in various aerospace applications, such as landing gear and control surfaces, where reliability and rapid response are vital.

Maintenance and Best Practices

To ensure optimal performance and longevity of pneumatic linear actuators, regular maintenance is essential. Here are some best practices:

Regular Inspections: Check for leaks, wear, and proper alignment. Early detection can prevent larger issues.

Air Quality Management: Use filters to ensure clean, dry air is supplied to the system, minimizing contamination.

Lubrication: Regularly lubricate moving parts to reduce friction and wear.

Pressure Monitoring: Keep an eye on the air pressure to ensure it remains within the recommended range for optimal operation.

Future Trends

As technology continues to advance, the future of pneumatic linear actuators looks promising. Emerging trends include:

Integration with IoT: Smart technology integration will allow for real-time monitoring and control, enhancing automation capabilities.

Advanced Materials: New materials can improve performance, reduce weight, and enhance durability.

Increased Customization: As industries demand more specialized solutions, manufacturers are likely to offer customizable options for pneumatic actuators.

Conclusion

Pneumatic linear actuators are vital to modern automation and control, offering speed, efficiency, and reliability across various applications. Understanding their components, advantages, and applications can help industries leverage this technology effectively. As innovations continue to shape the landscape of pneumatic systems, these actuators will remain at the forefront of automation, driving productivity and enhancing operational efficiency in diverse sectors. By harnessing the power of compressed air, pneumatic linear actuators are set to play an increasingly significant role in the future of industrial automation.

Contact Us

21225 FM 529 Rd

Houston, TX 77433

Cypress Area

Phone: +1-713-934-0171

Fax: +1-713-934-9099

0 notes

Text

Mastering Machine Control: A Guide to Limit Switch Sensors in Sharjah, Dubai, UAE (Including Roller Plunger and Linear Limit Switches)

Limit switch sensors are the silent guardians of industrial automation in Sharjah, Dubai, and across the UAE. These unassuming devices play a critical role in ensuring machinery operates efficiently and safely. But with various types and functionalities, choosing the right limit switch can feel overwhelming. This article serves as your guide to navigating the world of limit switch sensors in the UAE, focusing on roller plunger and linear limit switch options.

Understanding Limit Switch Sensors:

At its core, a limit switch sensor detects the position or movement of an object and triggers an electrical response. This allows machines to automate tasks, prevent collisions, and activate specific functions based on object presence or absence.

Types of Limit Switch Actuators:

The "trigger" for a limit switch comes from the actuator, a component that interacts with the machine to activate the switch. Common actuator types in Sharjah, Dubai, and the UAE include:

Basic Levers: Simple and cost-effective for basic on/off control.

Fork Levers: Designed to straddle objects for precise detection.

Roller Lifters: Ideal for detecting the presence or absence of materials.

Focus on Roller Plunger Limit Switches:

A popular choice for precise positioning applications, roller plunger limit switches feature a spring-loaded roller that presses a plunger to activate the switch. This design offers several advantages:

High Versatility: Roller plungers can detect a wide range of objects, making them adaptable to various applications.

Precise Control: The spring-loaded mechanism allows for accurate detection of object presence or absence.

Durability: Roller plungers are often built tough to withstand harsh industrial environments.

Linear Limit Switches for Long Travel Detection:

Linear limit switches excel in applications requiring detection over extended distances. These switches have a long, linear actuator that activates the switch upon reaching a specific position. Here's what makes them valuable:

Ideal for Long Strokes: Linear switches are perfect for conveyor systems, material handling equipment, and other applications with long travel distances.

Compact Design: Despite their long actuator travel, linear limit switches can have a surprisingly compact housing, saving valuable space.

Variety of Actuators: Linear switches come with diverse actuator options, such as rods, slides, and fork-style attachments, catering to specific detection needs.

Finding the Right Limit Switch Solution in Sharjah, Dubai, and the UAE

With a vast selection of limit switch sensors and actuators available in Sharjah, Dubai, and the UAE, choosing the right combination can feel daunting. However, by understanding your application's requirements, such as travel distance, object type, and desired level of precision, you can narrow down your options. Additionally, consulting with local automation specialists can ensure you find the perfect limit switch solution for your needs in the UAE.

Keywords: Limit Switch Sensor, Roller Plunger Limit Switch, Linear Limit Switch, Limit Switch Actuator, Sharjah, Dubai, UAE

#Limit Switch Sensor#Roller Limit Switch Types#Limit Switch Plunger Type#Roller Plunger Limit Switch#Linear Limit Switch#Limit Switch Actuator

0 notes

Text

Unlocking Precision and Power: A Guide to Hydraulic Servo Actuators

Introduction:

In the realm of automation and motion control, hydraulic servo actuators reign supreme for their unmatched blend of raw power and exceptional precision. These marvels of engineering combine the potent force of hydraulics with the meticulous control of electronic systems. This comprehensive guide delves into the world of hydraulic servo actuators, exploring their inner workings,…

View On WordPress

#Electrohydraulic Actuators#Feedback Mechanisms#Flight Control Systems#High Force Applications#Hydraulic servo actuators#Industrial automation#Linear Actuators#Motion Control Systems#Proportional Valves#Robotics#Rotary Actuators

0 notes

Text

Linear Actuator Types

Linear actuators produce straight line motions, and are therefore useful for machines that require linear movement. They are used in industrial machinery and peripherals of computers like printers and disk drives, as well as dampers and valves. Linear motion is inherent in gas or liquid cylinders. However, some equipment like the one used in DVD players requires linear motion.

Manufacturers offer a variety of linear actuators to their customers. These include:

Linear Actuators: This unit combines a ball-screw with a DC motor gearbox. The actuator comes complete and is ready to be installed in a variety of applications from medical, agricultural, and industrial.

Worm Drive Actuators - These actuators are fitted with acme screws for common use in lifting chairs and other medical equipment. They can be purchased with or without power supply, and they are UL-approved Pneumatic Linear Actuator.

Acme Screw Actuators are a combination of acme screw and DC motor gearbox in one easy-to-install unit. These linear actuators are the best choice for those who require reliable and rugged performance. These actuators are also used for ventilation, solar tracking and gardens and lawns.

VSJ Series: These actuators can be used in floor cleaning equipment, industrial machines and home healthcare equipment. These actuators are made up of acme screws that can be fitted in either DC or AC versions.

VI Series: These actuators are versatile and can be used in a variety of applications, including lawns and gardens, medical equipment, and agricultural and ATV devices. They are available in either an acme or a ball screw range and can be ordered in DC or AC depending on the task.

The VMD series Small Compact: These are very compact linear actuators. These actuators are useful in food preparation, office and automotive applications, as well as light loads.

They can be classified according not only according to market availability but also according to their mechanisms of operation. There are:

Mechanical actuators: These can be either mechanical with digital micrometer readingout or traveling screw-in roller screw actuator. These mechanical actuators can convert rotary motion into linear motion using one of the following mechanisms.

Screw: The rotating nut of an actuator is the screw shaft. This is how screw jacks, lead-screws and roller screw linear actuators work.

Cam: They work like wedges, but they have very little travel.

Wheel and Axle - Linear actuators that work according to this principle include winch, rigid chain drive, rigid chains, belt drive and winch.

Liquid under Pressure Actuators: The pressure is applied to a piston. A liquid is then conveyed to a load piston. Finally, the external load is moved. These include equipment controlled by hydraulic pumps or the hydraulic carjack.

Compressed gas actuators are similar to hydraulic actuators in principle, but use gas instead of liquid.

Piezoelectric actuators: These actuators use voltage to cause materials to expand or move outside objects.

Electro-mechanical actuators are: An electric motor replaces the handle or control knob on a mechanical actuator.

Small compact actuators: These motors are specially designed to reduce the bulk of linear actuators. They combine an actuator with a motor in the smallest possible form. Motors are made small by removing the screw and drive.

0 notes

Text

Small servo motors are compact electromechanical devices designed to provide precise control over angular or linear motion. Unlike conventional motors, servo motors are equipped with feedback mechanisms such as encoders, enabling accurate positioning and velocity control. These motors are characterized by their high torque-to-volume ratio, making them ideal for applications where space is limited.

0 notes

Text

Transform your vehicle with top-tier auto accessories available at MyPushcart! Conveniently shop online and explore our diverse range of high-quality accessories, including car security systems, turnkey products, and remote start kits, to enhance your driving experience. Visit our website and order now for a seamless shopping experience.

1 note

·

View note