#Motion Control Systems

Explore tagged Tumblr posts

Text

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

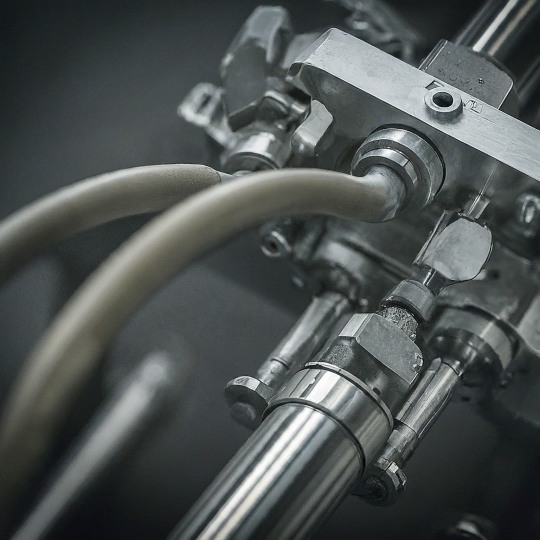

Unlocking Precision and Power: A Guide to Hydraulic Servo Actuators

Introduction: In the realm of automation and motion control, hydraulic servo actuators reign supreme for their unmatched blend of raw power and exceptional precision. These marvels of engineering combine the potent force of hydraulics with the meticulous control of electronic systems. This comprehensive guide delves into the world of hydraulic servo actuators, exploring their inner workings,…

View On WordPress

#Electrohydraulic Actuators#Feedback Mechanisms#Flight Control Systems#High Force Applications#Hydraulic servo actuators#Industrial automation#Linear Actuators#Motion Control Systems#Proportional Valves#Robotics#Rotary Actuators

0 notes

Text

[254 Pages Report] The global motion control market size is estimated to be worth USD 16.5 billion in 2024 and is projected to reach USD 21.6 billion by 2029 at a CAGR of 5.5% during the forecast period.

0 notes

Text

Motion Control Systems Precision and Efficiency in Motion

Motion control systems are the backbone of modern industrial automation, robotics, and countless other applications where precise movement and efficiency are paramount. These sophisticated systems integrate cutting-edge technology to manage the speed, position, and synchronization of mechanical components, ensuring seamless and accurate motion.

0 notes

Text

why the fuck are there two Legend of Zelda games on the DS where you're forced to move with the touch screen.

#I'll give them a fair chance beyond their control schemes but jesus christ.#the touch screen is the DS equivalent to motion controls: forced into everything regardless of its actual utility compared to buttons.#sometimes it works better than buttons. there's just dance for motion controls and 3D picross for the touch screen.#but sometimes it's so pointless (like in a legend of zelda) that I curse the name of whoever implemented it onto the system as a whole.

2 notes

·

View notes

Text

Artoo Standing Guard

STAR WARS EPISODE II: Attack of the Clones 00:12:53

#Star Wars#Episode II#Attack of the Clones#Coruscant#Galactic City#Federal District#Senate Apartment Complex#Senator Padmé Amidala’s apartment#Senator Padmé Amidala’s private quarters#R2-D2#Senator Padmé Amidala#Anakin Skywalker#Trade Federation#Droid Control Ship#Vuutun Palaa#Battle of Naboo#interference pulse stabilizers#polarity sink#electromagnetic field sensor unit#durasteel#spacecraft data slot#spacecraft linkage and control arms#acoustic signaller#system ventillation#hi-power recharge coupling#motion sensor

3 notes

·

View notes

Text

Damn Guilty Gear Judgment is a fun ass game.

#like I was always expecting to enjoy it but wow#fighting game controls translated nigh perfectly to a beat em up format.#I just stress “nigh” cause them motion inputs are tricky on a side scrolling plane#like I be turning the wrong way when I’m tryna use Tyrant Rave n other such moves#but besides that real good shit#I talked about Guilty Gear havin another spinoff and Y’know I really wouldn’t mind another beat em up#with the newer graphics of strive n shit it could be lit.#guilty gear#guilty gear Judgment#arc system works#majesco sy

5 notes

·

View notes

Text

B48 Series Motorized Rotary Stages

Velmex Motorized Rotating Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning or rotating a payload. The B48 Series motorized rotary stages feature an easy to read engraved 360 degree scale for operator convenience. https://velmex.com/

#rotary table controller#motorized xy system#xy table stepper motor#rotary motion control#xy tables#lead screws

0 notes

Text

Unlocking Precision in Robotics with Dynaflex: A Dynalog-US Innovation.

Precision is paramount in today's fast-paced world of automation, with industries such as aerospace, automotive, electronics, and advanced manufacturing requiring robot systems to function with precision, in order for the process to deliver quality and consistent performance. This is where Dynatrol-US Dynaflex provides an unparalleled solution to improve robot calibration and motion control for industrial environments.

So, what exactly is Dynaflex?

Dynaflex is sophisticated real-time calibration developed by Dynalog-US- a leader in robotic accuracy solutions. These advanced dynamic performance assessment tools were developed specifically for robot systems. Dynaflex measures the dynamic performance (how robots behave while they operate), versus static calibration tools (preset calibration baked into the robots programming) by evaluating robot compliance and flexibility in real-time. This type of dynamic assessment provides potential for accuracy to industries where tolerances must be tight and conditions demand high levels of performance reliability.

Simply put Dynaflex gives practitioners visibility and insight into how a robot responds dynamically while at work and if sufficient stress or force signatures, behaviour is exhibited. In many cases, this is no different than creating significant and costly rework..

Why is Dynaflex so Important?

When robots perform jobs such as welding, painting, and assembling, even the most minor deviation in motion can create defects or misalignment. Traditional calibration methods consider positioning, but often don't consider the dynamic changes in robot posture due to many different factors such as: gravity, speed and payload. Dynaflex effectively takes calibration to the next level by adding dynamic variables to the calibration equation.

With the Dynaflex system, manufacturers can:

Measure and minimize robot compliance (flexibility under load)

Achieve better path accuracy with complex work processes

Validate robot performance in real-world conditions

Identify mechanical anomalies before they can become major catastrophes

Maximize repeatability and process consistency

These are meaningful relationships to ensure that the robot moves correctly on paper, but that it also can perform accurately on the production floor.

How Does Dynaflex Work?

Dynaflex implements a series of highly sensitive measurement tools and calibration routines that allow engineerings to visualize how the end effector of a robot moves while under load, or at high speed. By measuring real-time flexing, oscillation and inertia, Dynaflex creates a comprehensive map of the robot's behavior.

Once the data has been collected, the data is used to adjust the robot's motion algorithms and account for mechanical variation.

Who is Dynaflex for?

Dynaflex is ideal for companies and industries that expect critical congruency and which themselves use robotic automation, including:

Automotive manufacturing

Aerospace and defence

Medical devices

Electronics assembly

Metal fabrication

3D printing and additive manufacturing

If your company relies on multi-robot cells, automated welding cells, or pick-and-place systems, introducing Dynaflex to your calibration operations will provide great benefit.

Dynalog-US: The Experts in Robot Calibration

Dynalog-US was founded to provide accurate and reliable robotic systems and has been a leader in robot performance technology for several decades. Their products are being used by leading world manufacturers, many of whom are in the Fortune 500.

Whether it is for robotic inspection, Tool Center Point (TCP) calibration or improving robot cell accuracy, Dynalog has a history of introducing products to the marketplace that demonstrate thoughtful engineering, industry leading performance, and great customer support.

Dynalog's market leading solutions, to include Dynaflex, come with documentation, field training, and technical consulting, which is more than just selling a product; Dynalog provides a partnership to achieve your production success.

Many companies have seen measurable improvements after adding Dynaflex to their robotic workflow:

Up to 40% improvement in path accuracy Considerably less joint stress and less component wear Reduction of rework and scrap percentage Faster ROI from robotic systems

One aerospace customer even found that Dynaflex helped them to achieve their tolerance requirements that they previously thought could be accomplished only with standard robots or off-the-shelf robotic equipment.

Future of Robotic CalibrationAs AI, machine Learning, and Industry 4.0 technologies evolve, the need for ongoing performance validation to and compliance will become more valuable. Also, autonomous systems will validate performance more often, and human interventions will be using tools like Dynaflex to ensure safety, quality, and efficiencies.

With Dynaflex by Dynalog-US, businesses now have a scalable and future-proof calibration platform to leverage for future use and to enhance work processes while accomplishing productivity and accuracy improvements in the immediate.

Conclusion

When you invest in robots, investing in robot performance has to be a given. Properly calibrating robot performance starts with the initial calibration when it is stationary, when it is in motion, while it is under load, and evaluating at the full-speed capability.

Dynaflex by Dynalog-US is a calibration device that provides the measurement data (metrics) to give you a competitive advantage for an ever-evolving automated world.

Ready to take the next step in robotic precision? Visit www.dynalog-us.com to learn more about Dynaflex and schedule a consultation with the experts at Dynalog-US.

#Dynaflex#Dynalog-US#Robot Calibration#Robotic Accuracy#Industrial Automation#Robot Compliance#Dynamic Robot Calibration#Robot Motion Control#Manufacturing Technology#Industry 4.0#Advanced Robotics#Robot Performance#Calibration Systems#Automation Solutions#Robot Path Accuracy#Robot Inspection Tools#Robot Flexibility Measurement#Dynaflex Calibration#Robotic Workflow Optimization#Robotic Precision Engineering

0 notes

Text

Revolutionizing Servo Control: How Spectrum Engineering Leverages High-Order Controller Auto-Tuning

In today’s fast-paced industries, precise servo control is vital for robotics, automation, and precision machinery. Tuning controllers to balance stability, speed, and robustness—while addressing friction, backlash, or sensor noise—is complex. Spectrum Engineering, with over 25 years of expertise in control system design consulting, transforms these challenges into opportunities, delivering control and dynamics innovation using the high-order controller auto-tuning method.

A Breakthrough in High-Order Tuning

Traditional tuning, often limited to PID designs, struggles with complex systems needing higher-order controllers for superior performance. However, research by Yaron Zimmerman and Per-Olof Gutman pioneers control and dynamics innovation by auto-tuning high-order controller implementation using unconstrained optimization within the Quantitative Feedback Theory (QFT) framework. By minimizing a cost function that balances performance and stability—without requiring a detailed plant model—this method ensures robust control across uncertainties like mechanical constraints. The Nelder-Mead Simplex Method optimizes parameters efficiently, reducing design time while achieving precision.

Spectrum Engineering’s Practical Solutions

Spectrum Engineering applies these principles to deliver tailored servo control solutions. Their automatic tuning algorithms optimize high-order controllers for embedded systems, addressing issues like saturation or dead zones. For instance, a client in industrial automation achieved faster response times and enhanced stability after their control system design consulting tuned their system to handle backlash. Beyond tuning, they implement Kalman filters to reduce noise, design algorithms for unique challenges, and support mechanical and electronic integration.

Why Choose Spectrum Engineering?

Through control system design consulting, patent collaboration, or team training, Spectrum Engineering offers flexible services. Why build an in-house control team when their expertise in control and dynamics innovation delivers high-performance systems? Their research-inspired approach ensures precision without complexity.

Leading the Future of Control Systems

As control systems grow intricate, Spectrum Engineering leads with advanced auto-tuning and practical know-how. Contact them for control system design consulting or explore their training to elevate your servo systems. With Spectrum Engineering, precision and performance are within reach.

#control and dynamics innovation#control system design consulting#Active magnetic bearing solutions#Controller implementation#Dynamics consulting#Dynamics performance optimization#Signal processing consulting#Custom control consulting services#Advanced control systems#Innovative control solutions#Motion control training#Control systems solution#Control loop tuning and optimization

0 notes

Text

The Role of AI in Advancing Robotic Motion Control Systems

The integration of Artificial Intelligence (AI) into robotic motion control systems has revolutionized the field of automation. AI-driven robotics are enhancing precision, efficiency, and adaptability in various industrial applications, enabling robots to perform complex tasks with human-like decision-making capabilities.

0 notes

Text

[254 Pages Report] The motion control market is estimated to be worth USD 16.5 billion in 2024 and is projected to reach USD 21.6 billion by 2029 at a CAGR of 5.5% during the forecast period.

0 notes

Text

Unleashing the Power of Custom Motors: Revolutionize Your Applications with Tekmatic

In today's fast-paced world, customization is the key to unlocking innovation and staying ahead of the competition. When it comes to custom motors, off-the-shelf options may not always meet your specific requirements. That's where Tekmatic comes in.

0 notes

Text

there's something both reassuring and terrifying that throughout history people don't really change

#reading 'reflektorem w mrok' and oh man#all the texts there were written almost 100 years ago#tadeusz boy żeleński talks about the lack of sex education and no access to safe abortions ostracising women who decide to have an abortion#how the justice system is inadequate regarding them#the overwhelming control of the church on the laws and medicine that actually causes more fatalities#(nuns not having to go through the sanitizing procedures at hospitals because they're 'holy' took me out)#how the church's attachment to the idea of preserving tradition actually cripples the motion of change and evolution#man it could've been written yesterday and the contents would change so little#both sad and kind of predictable that we had so little development regarding those issues#also unrelated śmiesznie się czyta te fragmenty pod tytułem#'kiedyś to było teraz to wszyscy siedzą na tych dansingach i w kinach a kobiety są takie niezależne' w kontekście lat 30.#Boy you've got a big storm coming#jules txt

1 note

·

View note

Text

I wanted to throw a knife at the gargoyle but i guess my character had other plans.

#i hate motion control gestures#are you happy? did you get it out of your system?#now please throw the knife. please i'm begging you#elden ring

0 notes

Text

Material Handling Motion Control System Market: Global Industry Analysis, Size, Share, Trends and Forecast by 2032

Material handling motion control system is manufacturing technology that manages moving parts of equipment in a skillful manner to reduce manpower, minimize industrial hazards, and to maintain safety at workplace. Material handling control system cater to industries such oil & gas, food & beverages, aerospace & defense, automotive, semiconductor & electronics, metal & machinery manufacturing,…

0 notes