#Electrohydraulic Actuators

Text

Unlocking Precision and Power: A Guide to Hydraulic Servo Actuators

Introduction:

In the realm of automation and motion control, hydraulic servo actuators reign supreme for their unmatched blend of raw power and exceptional precision. These marvels of engineering combine the potent force of hydraulics with the meticulous control of electronic systems. This comprehensive guide delves into the world of hydraulic servo actuators, exploring their inner workings,…

View On WordPress

#Electrohydraulic Actuators#Feedback Mechanisms#Flight Control Systems#High Force Applications#Hydraulic servo actuators#Industrial automation#Linear Actuators#Motion Control Systems#Proportional Valves#Robotics#Rotary Actuators

0 notes

Text

Step-by-Step Guide: How to Use Your First Electric Valve Actuator

If you're looking for a quick and easy guide on how to use your first electric valve actuator, you've come to the right place. In this blog post, we'll cover everything you need to know, from what an electric valve actuator is to the different types available, to how to choose the right one for your application. So let's get started!

What is an electric valve actuator?

An electric valve actuator is a device that is used to control the flow of liquids or gases. It consists of a motor and a valve, and is operated by an electrical signal. The motor turns the valve to open or close it, depending on the desired flow. Electric valve actuators are used in many industries, such as oil and gas, water treatment, and manufacturing.

The different types of electric valve actuators

Electric valve actuators are devices that use electromechanical or electrohydraulic means to control the movement of a valve. There are three main types of electric valve actuators: linear, rotary, and scotch yoke.

Linear actuators use a linear motion to open and close valves. They typically have a higher torque output than rotary actuators and are better suited for larger valves.

Rotary actuators use a rotating motion to open and close valves. They typically have a lower torque output than linear actuators and are better suited for smaller valves.

Scotch yoke actuators use a reciprocating motion to open and close valves. They typically have a higher torque output than both linear and rotary actuators and can be used for both large and small valves.

How to choose the right electric valve actuator for your application

Electric valve actuators come in a variety of shapes and sizes, each with its own advantages and disadvantages. Choosing the right one for your application depends on a number of factors, including the type and size of valve you are using, the operating environment, and the level of control you need.

The first step is to determine the type of actuator you need. There are three main types: linear, rotary, and scotch yoke. Linear actuators open and close valves using a linear motion. They produce more torque than rotary actuators and are better suited for larger valves. Rotary actuators open and close valves by rotating them. They produce less torque than linear actuators and are better suited for smaller valves. To open and close valves, Scotch yoke actuators use a reciprocating motion. They typically produce more torque than both linear and rotary actuators and can be used for both large and small valves.

The next step is to determine the size of actuator you need. Actuator size is typically expressed in terms of stroke length (the distance the actuator can move) or torque output (the amount of force the actuator can generate). The stroke length will be determined by the size of the valve you are using; for example, a butterfly valve will require a shorter stroke length than a globe valve. The torque output will be determined by the operating environment; for example, an actuated valve in a high-pressure system will require more torque to overcome the fluid pressure than one in a low-pressure system.

Finally, you need to consider the level of control you need from your actuator. Electric valve actuators can be controlled manually, automatically, or remotely. Manual control means that someone has to physically operate the actuator every time the valve needs to be opened or closed; this is typically only used for small valves or in applications where there is no power available. Automatic control means that an external controller (such as a PLC) is used to operate the actuator; this allows for remote operation and gives you more flexibility in terms of when and how often the valve is opened or closed. Remote control means that you can operate the actuator from any location with an internet connection; this is ideal for applications where you need to monitor or adjust the flow of fluid remotely.

When choosing an electric valve actuator, it is important to consider all of these factors in order to select one that is well suited for your particular application.

conclusion

In conclusion, Electric valve actuators are devices that control the movement of a valve using electromechanical or electrohydraulic means. Electric valve actuators are classified into three types: linear, rotary, and scotch yoke.

Linear actuators open and close valves using a linear motion. They produce more torque than rotary actuators and are better suited for larger valves.

Rotary actuators open and close valves by rotating them. They produce less torque than linear actuators and are better suited for smaller valves.

To open and close valves, Scotch yoke actuators use a reciprocating motion. They typically produce more torque than both linear and rotary actuators and can be used for both large and small valves.

Electric valve actuators are available in a variety of shapes and sizes, each with its own set of benefits and drawbacks. The right one for your application is determined by a variety of factors, including the type and size of the valve used, the operating environment, and the level of control required.

Cair Euromatic Automation is a leading manufacturer and supplier of electric valve actuators in India.We offer a vast range of electrical actuators for rotational and linear motion.

3 notes

·

View notes

Text

Aviation Actuator Systems Market Analysis 2023 Dynamics, Players, Type, Applications, Trends, Regional Segmented, Outlook & Forecast till 2033

The competitive analysis of the Aviation Actuator Systems Market offers a comprehensive examination of key market players. It encompasses detailed company profiles, insights into revenue distribution, innovations within their product portfolios, regional market presence, strategic development plans, pricing strategies, identified target markets, and immediate future initiatives of industry leaders. This section serves as a valuable resource for readers to understand the driving forces behind competition and what strategies can set them apart in capturing new target markets.

Market projections and forecasts are underpinned by extensive primary research, further validated through precise secondary research specific to the Aviation Actuator Systems Market. Our research analysts have dedicated substantial time and effort to curate essential industry insights from key industry participants, including Original Equipment Manufacturers (OEMs), top-tier suppliers, distributors, and relevant government entities.

Aviation Actuator Systems Market Benefits

Aviation Actuator Systems research reports provide critical insights for strategic decision-making. They help businesses understand market trends, customer preferences, and competitive landscapes. By analyzing data on market size, growth potential, and consumer behavior, companies can identify new opportunities and mitigate risks. These reports also guide product development, pricing strategies, and marketing campaigns, ensuring alignment with current market demands. Furthermore, market research reports enhance forecasting accuracy and help in benchmarking performance against competitors. Ultimately, they inform investment decisions, optimize resource allocation, and foster innovation, contributing to sustained business growth and a competitive edge.

Key Report Highlights:

Key Market Participants: The report delves into the major stakeholders in the market, encompassing market players, suppliers of raw materials and equipment, end-users, traders, distributors, and more.

Comprehensive Company Profiles: Detailed company profiles are provided, offering insights into various aspects including production capacity, pricing, revenue, costs, gross margin, sales volume, sales revenue, consumption patterns, growth rates, import-export dynamics, supply chains, future strategic plans, and technological advancements. This comprehensive analysis draws from a dataset spanning 12 years and includes forecasts.

Market Growth Drivers: The report extensively examines the factors contributing to market growth, with a specific focus on elucidating the diverse categories of end-users within the market.

Data Segmentation: The data and information are presented in a structured manner, allowing for easy access by market player, geographical region, product type, application, and more. Furthermore, the report can be tailored to accommodate specific research requirements.

SWOT Analysis: A SWOT analysis of the market is included, offering an insightful evaluation of its Strengths, Weaknesses, Opportunities, and Threats.

Expert Insights: Concluding the report, it features insights and opinions from industry experts, providing valuable perspectives on the market landscape.

Receive the FREE Sample Report of Aviation Actuator Systems Market Research Insights @ https://stringentdatalytics.com/sample-request/aviation-actuator-systems-market/12265/

Market Segmentations:

Global Aviation Actuator Systems Market: By Company

• Sitec Aerospace

• Rockwell Collins

• Honeywell

• Eaton

• Moog

• SAAB

• Parker

• Woodward

• UTC

• Curtiss Wright

• Beaver

• Merrill

• GE Aviation

• Arkwin

• Electromech Technologies

Global Aviation Actuator Systems Market: By Type

• Electric

• Electromechanical

• Electrohydraulic

• Electrohydrostatic

Global Aviation Actuator Systems Market: By Application

• Commercial Market

• Military Market

Regional Analysis of Global Aviation Actuator Systems Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Aviation Actuator Systems market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Aviation Actuator Systems Market Research Report @ https://stringentdatalytics.com/purchase/aviation-actuator-systems-market/12265/

Report includes Competitor's Landscape:

➊ Major trends and growth projections by region and country

➋ Key winning strategies followed by the competitors

➌ Who are the key competitors in this industry?

➍ What shall be the potential of this industry over the forecast tenure?

➎ What are the factors propelling the demand for the Aviation Actuator Systems?

➏ What are the opportunities that shall aid in significant proliferation of the market growth?

➐ What are the regional and country wise regulations that shall either hamper or boost the demand for Aviation Actuator Systems?

➑ How has the covid-19 impacted the growth of the market?

➒ Has the supply chain disruption caused changes in the entire value chain?

Why to Purchase Aviation Actuator Systems Market Report?

Purchasing a market research report provides valuable, reliable insights that are often beyond a company's in-house capabilities. These reports deliver comprehensive data on market trends, customer behaviors, competitive analysis, and industry forecasts, saving time and resources on extensive data collection and analysis. They offer expert perspectives and methodologies, ensuring credible, up-to-date information. By accessing tailored, actionable intelligence, businesses can make informed decisions, reduce uncertainty, and identify opportunities for growth. Additionally, these reports enhance strategic planning, risk management, and competitive positioning, making them a crucial investment for companies seeking to stay ahead in their industry and drive innovation.

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected] ), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

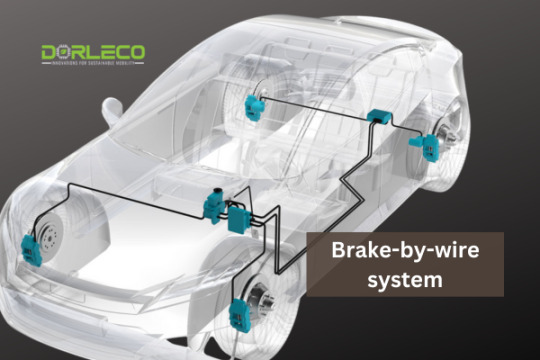

Brake-by-wire system

April 16, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Introduction to brake-by-wire system

The brake-by-wire system, which has swept the automotive industry in recent years, includes brake-by-wire. The fundamental idea behind all brake-by-wire systems is the same: by substituting electrical connections for mechanical linkages and connections, the assemblies can be made lighter, simpler, and easier to integrate. This also applies to brake-by-wire, even though it allows for the integration of numerous systems and features, including traction control, electronic stability control, and automated emergency braking (AEB), with the brake system.

How do you use a brake-by-wire system?

The amount and haste with which the pedal is pressed are the two pieces of information that the pedal position sensor must convey to the brake control unit. Using this information, the brake control unit determines how much braking force must be given to the wheels. After receiving the necessary signals from the control unit, the actuator performs the desired deceleration, which correlates the braking force with the required pressure.

Brake-by-wire also makes it possible to customize the brake feel for specific driving modes, which is highly helpful for the interaction between the car and the driver. Even though most systems have had a similar architecture up until this point, the type of brake-by-wire system being used can affect how the caliper is actuated.

Designing Brake-By-Wire systems with redundancy

The primary distinction between brake-by-wire systems is whether or not a hydraulic circuit is used to apply pressure to the caliper. All pedal-to-caliper connections are electronic, but the industry hasn’t yet fully embraced “dry” brake-by-wire, or caliper actuation that is solely electrical.

To provide redundancy to the system, a hybrid system with one axle having a partial hydraulic circuit is employed. The electrohydraulic actuators receive the electrical signal and use their combined strength to apply hydraulic pressure to the calipers.

When the control unit detects a problem, a valve opens, cutting off all electronics and enabling a traditional hydraulic system to operate. This contributes to redundancy and raises system safety as a whole.

Safety Aspects of Wire-Based Brake Systems

Automakers can progress toward vehicle autonomy using brake-by-wire, which makes it easier to integrate the brake system with other safety measures and contributes to a safer driving experience.

1. Control of traction

The basic method of traction control is to measure wheel spin to estimate the amount of accelerative traction that is available. Then, to regulate this traction, either apply more braking pressure to a wheel that is spinning too quickly using anti-lock braking or limit the amount of power that is given to that wheel by utilizing the electronic throttle control.

Because electronically controlled braking systems allow you to adjust the amount of pressure applied to different wheels, they may be simply connected with traction control systems.

2. Control for electronic stability (ESC)

Electronic stability control is one of the most essential safety elements found in modern “smart” cars. It is just a traction control system with a few more algorithms, a more potent processor, and more electrical sensors.

When this system is engaged, the control unit controlling the motion of the vehicle makes sure that the car maintains its stability while doing particular actions. This helps to improve vehicle control by preventing oversteer and understeer, which is accomplished by adjusting the amount of braking force applied to either of the wheels on the same axles.

In the worst-case situation, the AEB system seeks to prevent or lessen the impact of a collision by activating total braking if the car still doesn’t slow down enough. Electronic control is more appropriate than mechanical control for this system since it needs to react more quickly than a typical braking technique.

3. Development of Brake-By-Wire Controls at Dorleco

Multiple safety elements can therefore be integrated with a brake-by-wire system. Granted that a brake-by-wire system that is entirely electrical can be fatal, the industry hasn’t fully embraced it yet.

However, the hybrid method will undoubtedly assist automakers in putting this technology into place and enhancing the general safety and responsiveness of future vehicles. At Dorleco, we are creating control software for brake-by-wire systems, as well as integrating and testing them in prototype cars and on a test bench.

Send an email to [email protected] if you would like to talk about potential partnerships for electronically-controlled braking systems.

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

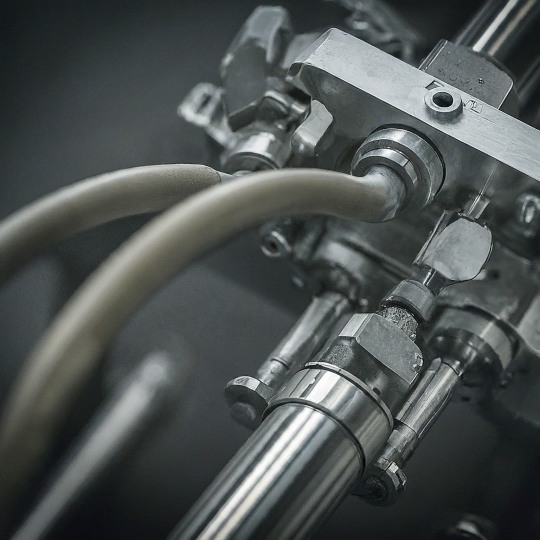

A compact powerhouse that creates hydraulic pressure to lower and raise the trim tabs. It employs two solenoid valves to direct the flow of fluid to the actuators. The solenoid valves lock tightly to secure the tabs in place. Strength to lower and hold even the largest tabs in place. Lexan cover protects electrohydraulic unit from occasional wash down and translucent reservoir allows fluid check at a glance.

Measures 4" x 7 1/2" x 5 1/2". Uses automatic transmission fluid. Includes pump, solenoid valves, reservoir and cover.

0 notes

Text

0 notes

Text

Electro Hydraulic Servo Valve Market - Forecast (2023 - 2028)

View More @ https://tinyurl.com/4fvzs6w4

The electrohydraulic servo valve (EHSV) is a core component of servo control systems. Due to its advantages such as high level of control precision, quick response, light weight, small volume and high immunity to load variations, EHSV has been applied in many fields, such as astronavigation, aviation, navigation, and military equipment. EHSV is one of the most failure prone components, and has a direct and significant impact on the performance and reliability of the entire servo control system. Thus, it is very important to analyze the failure mode, failure effects, failure mechanism and failure rate of EHSV.

The key driving factors for the electro hydraulic servo valves are growing demand for quality and smart control. There have been many design innovations as it has been implied across the sectors to control air/fluid flow. The aerospace industry was the driver in earlier times but growing industrial use has been on the higher side in the recent times.

What are Electro Hydraulic Servo Valves?

The term servo valve traditionally refers to mechanical feedback valves, where a spring element (feedback wire) connects a torque motor to the main-stage spool. Servo valve has come to mean a valve whose main spool is positioned in proportion to the electrical input to the valve, where the spool movement is achieved through internal hydraulic actuation. The size of metering orifices is controlled by the spool movement thus enabling the valve to control flow; however this flow is dependent on the pressure difference across the orifice unless some form of pressure compensation is used. Spool displacement causes the wire to impart a torque onto the pilot-stage motor. The spool keeps position when the torque from an electromagnetic field induced by the current through the motor coil equals torque from the feedback wire's deflection. These two-stage valves contain a pilot stage or torque motor, and a main or second stage. Sometimes the main stage is referred to as the power stage and there may be more than two stages also involved in regulation.

A Hydraulic Servo Valves is a device that maneuvers the flow of fluid (oils) in response to an electrical input signal or command to control position, velocity, pressure or force in some type of machine or device (usually through a piston or cylinder). Servo Valves are closed-loop control devices that can be single stage, two-stage or three stage designs.

Flow control servo valves produce hydraulic flow output proportional to electrical current input. p/Q valves control flow and regulate pressure (upper or lower limiting pressure) and can be used for both pressure regulation as well as applying a pressure-limit. They are used to regulate emissions, increase productivity and reliability at the same time. More and more functionalities are controlled by software that reduces complexity and enables regional design, manufacturing and customer specific variants.

What are the major applications for Electro Hydraulic Servo Valves?

Embryonic electro hydraulic servo valves where developed for military applications in the Second World War, such as for automatic fire control (gun aiming).Such servo valves typically consisted of a solenoid driven spool with spring return. These were able to modulate flow, but with poor accuracy and a slow response.

Servo valve development in the 1950’s, was largely driven by the needs of the aerospace industry (particularly missiles). The technical status and available products at that time are well documented in a series of reports commission by the US Air Force.

The electro hydraulic servo valve finds applications in wide range of industries such as steel industry, power industry, chemical industry, construction sector and still more.

Market Research and Market Trends of Electro Hydraulic Servo Valves Ecosystem

There has been a thorough research on alternative valve designs for the improved response, reducing leakage from the valves by various manufacturers and also to achieve ease in manufacturability process.

Most investigations have involved new ways of actuating the spool, often using active materials such as piezoelectric crystals have been used on certain experimental models to achieve better dynamic response. It is difficult to use them because of high susceptibility to vibration, temperature changes, and electrical noise and because of the difficulty in obtaining sufficiently large displacements from the crystals.

Magnetostriction is a material phenomenon which can be used to create a ‘smart‘ actuator. Magnetostrictive spool valve is another way to actuate valves action. The challenges for this technology introduction to actuate the valves are similar to piezoelectric actuation, including limited displacement, hysteresis, and temperature sensitivity.

The torque motor still finds applications in providing an alternative, although there have been breakthroughs in piezoelectric actuator technology, including drive electronics and hysteresis compensation methods. There are other reliable options available such as electronic automation controls which pose a tough competition to valve market.

Many manufacturing constraints for e.g. in designing valve bodies and other hydraulic components are not present due to additive manufacturing, particularly where manufacturing volumes are not too large (such as in aerospace). These provides a constraint free environment to innovators to further research and develop new ways to implement these motors and keeps the window open for new manufacturing technologies to be exhibited in future.

A further continuing trend in electro hydraulic servo valve market is increased valve intelligence. Integration of self-tuning functions, condition monitoring, and increased communication capability are continuously being adopted in industrial application side of the valves and are now being incorporated into aerospace field also.

Who are the Major Players in Electro Hydraulic Servo Valves market?

The key companies to the market mentioned in report include Moog Inc., Bosch Rexroth AG, Parker Hannifin Corporation, Honeywell International Inc., Eaton Corporation Plc, Woodward, Inc., Voith GmbH, Schneider Kreuznach, Aviation Industry Corporation of China (AVIC), Oilgear Company

What is our report scope?

The report incorporates in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and its impact during the forecast period 2018-2024.

All our reports are customizable to your company needs to a certain extent, we do provide 20 free consulting hours along with purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Key Takeaways from this Report

Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

Analyze the sales and distribution channels across key geographies to improve top-line revenues.

Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

#electro hydraulic servo valve market#electro hydraulic servo valve market size#electro hydraulic servo valve market shape#electro hydraulic servo valve market forecast#electro hydraulic servo valve market analysis#electro hydraulic servo valve market share#electro hydraulic servo valve market price#electro hydraulic servo valve market report#electro hydraulic servo valve market research#Chemical

0 notes

Text

Unveiling Precision: A Guide to Electrohydraulic Servo Valve Technology

Introduction:

In the realm of industrial automation and high-performance machinery, electrohydraulic servo valves (EHSVs) reign supreme. These marvels of engineering bridge the gap between electrical control signals and the potent world of hydraulics. By translating subtle electrical commands into precise hydraulic fluid motion, EHSVs empower motion control systems with unmatched accuracy and…

View On WordPress

#Digital control#Electrohydraulic servo valve technology#Feedback loop#Flapper-nozzle#Frequency response#Hydraulic actuator#Motion control system#Piezoelectric actuator#Proportional valve#Spool valve#Two-stage design

0 notes

Text

0 notes

Link

0 notes

Text

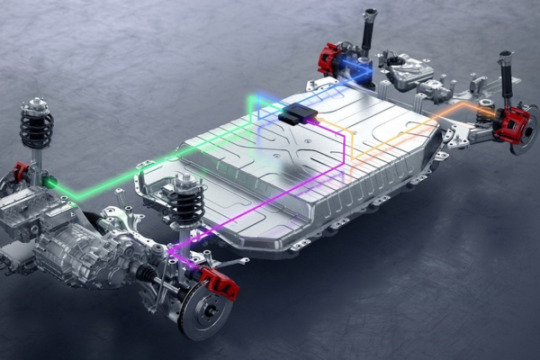

Brake-By-Wire

Brake-By-Wire is a part of the drive-by-wire technology that has been taking the automotive industry by storm in recent times.

The core concept of every drive-by-wire system is identical: replace the mechanical connections and linkages with electronic connections in order to make the assemblies lighter, simpler, and easier to integrate.

Brake-by-wire is no different, although it has room for a lot of different systems and features to be implemented through integration with the brake system, such as automatic emergency braking (AEB), electronic stability control, and traction control.

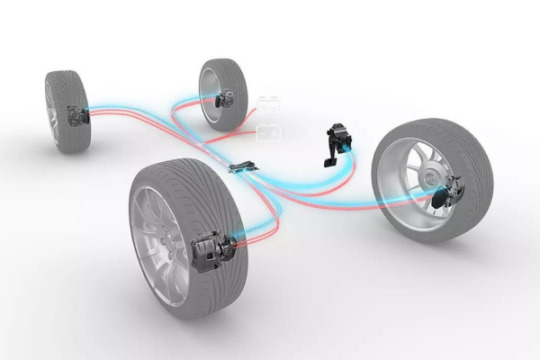

Any Brake-By-Wire system consists of a brake control unit (BCU), brake pedal position sensor, and electromechanical or electrohydraulic actuators, instead of the traditional hydraulic system.

Thus, it takes the mechanical connection between the brake calipers and pedals out of the equation, and the braking pressure is applied through electronic connections.

How does a Brake-by-wire system work?

The pedal position sensor is responsible for communicating two pieces of information to the brake control unit – the extent to which the pedal is actuated, and the urgency with which it is actuated.

Using this information, the brake control unit calculates the amount of braking force that needs to be applied to the wheels.

The brake-by-wire also allows the brake feel to be tailored to certain driving modes, which can be very useful in terms of human-vehicle interface.

While most systems follow a similar architecture up to this point, the actuation of the caliper can vary based on what type of Brake-By-Wire system is being used.

Redundancy in designing Brake-By-Wire systems

Brake-By-Wire systems are mainly categorized based on whether or not the pressure is applied to the caliper by using a hydraulic circuit.

The connection between the pedal and calipers is electronic in all cases, but purely electrical actuation of the caliper (“dry” brake-by-wire) hasn’t been completely accepted by the industry yet.

Source: https://www.mdpi.com/2076-0825/9/1/15

Hence, a hybrid system is used, where one of the axles contains a partial hydraulic circuit, thus providing redundancy to the system.

The electrical signal is sent to the electrohydraulic actuators, which convert the electrical energy into hydraulic pressure to apply to the calipers.

If, at some point, the control unit realizes that something is wrong, a valve opens up bypassing all electronics, and a conventional hydraulic system starts functioning.

This helps in providing redundancy and increasing the safety of the entire system.

Safety Features for Brake-By-Wire Systems

Brake-by-wire allows for ease of integration of the brakes system with other safety features, thus helping in making the drive much safer, while also enabling automakers to move along on the path towards vehicle autonomy. These features include:

Traction control

Traction control essentially consists of measuring the wheelspin to get an idea of the accelerative traction available.

This traction is then controlled by using anti-lock braking to apply extra braking pressure on a wheel spinning too fast or using the electronic throttle control to limit the power sent to that wheel.

An electronically-controlled braking system can thus be easily integrated with a traction control system, as it allows for varying the amount of pressure acting on different wheels.

Electronic stability control (ESC)

One of the most integral safety features used in “smart” vehicles nowadays is electronic stability control.

It is essentially a traction control system along with additional electronic sensors, a more powerful processor, and a few extra algorithms.

On activating this system, the control unit governing the vehicle motion ensures that there is no loss in stability of the car while executing specific maneuvers.

This includes the prevention of oversteer and understeer, which is achieved by varying the amount of braking force being sent to either of the wheels on the same axles, thus helping in controlling the vehicle in a better way.

Sending a variable amount of braking force to the right and left wheels is easier to achieve through an electronically-controlled braking system than a mechanically-controlled one. Hence, the Brake-By-Wire system can be easily integrated with ECS.

Automatic Emergency Braking (AEB)

Active safety features are being integrated into modern vehicles, and the automatic emergency braking system is one of the most important ones of these.

It keeps monitoring the distance between any potential obstacle and the host vehicle and can stop the car completely in case of an emergency.

Most AEB systems consist of two stages – partial braking and complete braking. Partial braking is often accompanied by a Forward Collision Warning (FCW) system, which alerts the driver and gives him/her a chance to take control of the vehicle.

If the vehicle still doesn’t slow down sufficiently, the AEB system activates complete braking and tries to avoid, or in the worst-case scenario, mitigate the effect of a collision.

Since this system requires a quicker response than a normal braking maneuver, electronic control is better suited than mechanical control.

Brake-By-Wire Controls Development at Dorleco:

Thus, a brake-by-wire system can allow for the integration of several safety features. Yes, the industry hasn’t completely accepted the purely electrical brake-by-wire system yet owing to the fatal consequences of a system failure, but the hybrid approach will definitely help automakers implement this system and improve the overall safety and response of the vehicles of the future.

At Dorleco, we are working on developing controls software for brake-by-wire systems, and integrating and testing such systems on the test bench as well as prototype vehicles.

If you wish to discuss possible collaborations regarding electronically-controlled braking systems, write to [email protected].

Related

X-by-Wire SystemsDecember 2, 2022In "eMOBILITY CONTROLS"

Throttle By WireDecember 2, 2022In "eMOBILITY CONTROLS"

Steer-By-WireMarch 23, 2023In "eMOBILITY CONTROLS"

Tags: No tagsPrevious PostAdvanced Driver-Assist Features: Part 2

Add a Comment

Logged in as dorleco. Log out?

COMPANY

About

Careers

OFFICE

USA: 39255 Country Club Dr Ste B12 Farmington Hills, MI 48331

INDIA: Plot No. 7, Shivaji Co-op Housing Soc., SB Road, Pune – 411016

Email: [email protected]

Phone: +1 (248) 987-2781 (USA) | +91 92843 48846 (India)

Subscribe to Newsletter

SERVICES

System Simulation

Controls & Software Development

Systems Engineering

Verification And Validation

Vehicle Communication And Diagnostics

Safety And Security

Processes (V Cycle, Aspice, Agile)

Prototype Build

Sizing, Selection And Sourcing

Brochure

PRODUCTS

SmartCase Pro (Vehicle Control Unit + Compute Module)

SmartCase EZ (Vehicle Control Unit)

ToughCase (Vehicle Control Unit)

SmartView (Display)

RapidBench (Portable HIL Bench)

BodyCode

evCode

eBikeCode

SimEV

Facebook Linkedin Youtube

Terms of Service

Privacy Policy

Cancellation and Refund Policy

Shoppi

0 notes

Link

0 notes

Text

Electrohydraulic Actuator Market Size, Share, Growth Opportunity and Trends by Growing CAGR Till 2026

The global Electrohydraulic Actuator Market report offers a comprehensive assessment of the market for the forecast years. The report contains several segments and an analysis of the market trends and growth factors that are playing a vital role in the market. These factors encompass the drivers, restraints, and opportunities. This globe industry offers an outlook on the strategic development of the market in terms of revenue profits over the forecast period 2021-2026.

The key market players for the global Electrohydraulic Actuator market are listed below:

Rexa

Moog

Emerson

Rotork

Voith

HOERBIGER

Zhongde

Schuck

KOSO

BOSCH

AVTEC

HollySys

Tefulong

Bell

SAMSON

HYDAC

Reineke

Rotex

RPMTECH

Others

Click here to get a FREE Sample Copy of the Electrohydraulic Actuator Market Research Report @ https://www.decisiondatabases.com/contact/download-sample-19433

The Global Electrohydraulic Actuator Market Report is equipped with market data from 2016 to 2026. The report gives a market overview covering key drivers and risk factors. The report is bifurcated by top global manufactures mentioning sales, revenue, and prices as applicable. It also evaluates the competitive scenario of the leading players. The report expands to cover regional market data along with type and application. The report forecasts sales and revenue from 2021 to 2026. The detailed sales channel is also covered in the study.

COVID-19 Impact Analysis on Electrohydraulic Actuator Market

The global pandemic COVID-19 has affected the Electrohydraulic Actuator market directly or indirectly. This study covers a separate section giving an explicitly clear understanding of the aftereffects of this pandemic. The detailed study highlights the probable outcomes of this global crisis on the Electrohydraulic Actuator industry. The impact study on production, supply-demand, and sales provides a holistic approach to the future.

Do You Have Any Query Or Report Customization? Ask Our Market Expert @ https://www.decisiondatabases.com/contact/ask-questions-19433

Why Purchase this Report?

A robust research methodology has been followed to collect data for the report. Data, thus collected passes through multiple quality checks to ensure the best quality is served.

The report gives a holistic view of the competitive scenario of the Electrohydraulic Actuator market

The latest product launches along with technological changes and development are covered in the report.

The data analysis in the report helps in understanding the anticipated Electrohydraulic Actuator market dynamics from 2021 to 2026.

DecisionDatabases has a vast repository of data, therefore, we can accommodate customized requirements also.

The graphs, tables and pie charts, and info-graphics covered in the report will help in a better understanding of the report.

The market drivers, restraints, upcoming opportunities, and anticipated restraints cited in the report will assist in making an informed decision.

To better understand the market scenario, the Electrohydraulic Actuator market is segmented as below:

By Types:

Control Type Electrohydraulic Actuator

Switch Type Electrohydraulic Actuator

By Applications:

Oil and Gas

Power

General Industry

Others

By Regions:

North America (U.S., Canada, Mexico)

Europe (U.K., France, Germany, Spain, Italy, Central & Eastern Europe, CIS)

Asia Pacific (China, Japan, South Korea, ASEAN, India, Rest of Asia Pacific)

Latin America (Brazil, Rest of L.A.)

The Middle East and Africa (Turkey, GCC, Rest of Middle East)

The content of the study subjects includes a total of 14 chapters:

Chapter 1: To describe Electrohydraulic Actuator product scope, market overview, market opportunities, market driving force, and market risks.

Chapter 2: To profile the top manufacturers of Electrohydraulic Actuator, with price, sales, revenue, and global market share of Electrohydraulic Actuator in 2018 and 2019.

Chapter 3: The Electrohydraulic Actuator competitive situation, sales, revenue, and global market share of top manufacturers are analyzed emphatically by landscape contrast.

Chapter 4: The Electrohydraulic Actuator breakdown data are shown at the regional level, to show the sales, revenue, and growth by region, from 2015 to 2020.

Chapter 5 and 6: To segment the sales by type and application, with sales market share and growth rate by type, application, from 2015 to 2020.

Chapter 7, 8, 9, 10 & 11: To break the sales data at the country level, with sales, revenue, and market share for key countries in the world, from 2016 to 2021 and Electrohydraulic Actuator market forecast, by regions, type, and application, with sales and revenue, from 2021 to 2026.

Chapter 12, 13 & 14: To describe Electrohydraulic Actuator sales channel, distributors, customers, research findings and conclusion, appendix, and data source.

Directly Purchase the Complete Global Electrohydraulic Actuator Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-19433

About Us:

DecisionDatabases.com is a global business research report provider, enriching decision-makers, and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research reports, customized research reports, company profiles, and industry databases across multiple domains. Our expert research analysts have been trained to map client’s research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise, and meaningful data at a lightning speed.

For more details:

DecisionDatabases.com

E-Mail: [email protected]

Phone: +91 90 28 057900

Web: https://www.decisiondatabases.com/

Referral Source - https://view.publitas.com/decisiondatabases-com-_vzxge7jabyb/electrohydraulic-actuator-market-research-report-from-2021-to-2026/

#Electrohydraulic Actuator Market#Electrohydraulic Actuator Market Report#Electrohydraulic Actuator Market Growth#Electrohydraulic Actuator Market Trends#Electrohydraulic Actuator Market Forecast#Global Electrohydraulic Actuator Industry Report#Electrohydraulic Actuator Market Manufacturers#Electrohydraulic Actuator Market Analysis#Electrohydraulic Actuator Market Factors#Electrohydraulic Actuator Market Demand

0 notes