#mesh filter disc

Text

Mesh Filter Discs: Versatile Solutions for Diverse Filtration Needs

Filtration is an essential process in many industries, from food and beverage to pharmaceuticals and wastewater treatment. Achieving optimal filtration efficiency often requires the right equipment, and one versatile solution that stands out is the mesh filter disc. In this article, we'll delve into the world of mesh filter discs, exploring their applications, benefits, and how to select the right one for your specific filtration needs.

Understanding Mesh Filter Discs

Mesh filter discs are circular pieces of material, typically made from metal or plastic, with a mesh-like pattern that allows for the passage of liquids or gases while retaining solid particles. The mesh is characterized by the number of openings or "holes" per square inch, known as mesh count. Higher mesh counts indicate finer filtration.

Applications of Mesh Filter Discs

Food and Beverage IndustryMesh filter discs play a crucial role in food and beverage processing. They are used for tasks such as straining sauces, filtering syrups, and clarifying juices. The fine mesh options are especially effective in removing even the tiniest particles.

Pharmaceutical and Chemical Industries

In pharmaceutical and chemical processes, precision is paramount. Mesh filter discs are employed in tasks like separating crystalline particles, removing contaminants from solvents, and ensuring purity in various reactions.

Oil and Gas Filtration

For oil and gas applications, mesh filter discs are utilized in filtration systems to remove impurities and contaminants from fluids. They help maintain the integrity of equipment and ensure the quality of end products.

Water Treatment

Mesh filter discs are integral components in water treatment systems. They assist in the removal of sediment, debris, and harmful particles, ensuring clean and safe water for consumption or industrial processes.

Benefits of Mesh Filter Discs

Customizable Filtration Levels: With a range of mesh counts available, mesh filter discs offer a high degree of customization. This allows industries to achieve the precise level of filtration required for their processes.

Durable and Long-Lasting: Mesh filter discs are typically made from robust materials, ensuring they can withstand harsh environments and extended use.

Low Maintenance: These discs are relatively easy to clean and maintain, reducing downtime and ensuring consistent filtration performance.

Cost-Effective: Mesh filter discs provide an economical solution for achieving high-quality filtration, often outperforming alternative methods in terms of both cost and efficiency.

Selecting the Right Mesh Filter Disc

When choosing a mesh filter disc, consider factors such as:

Mesh Count: Determine the appropriate mesh count based on the size of particles you need to filter.

Material: Select a material compatible with the substances being filtered and the operating environment.

Size and Shape: Ensure the disc dimensions fit your filtration system.

Conclusion

Mesh filter discs are indispensable tools in a wide array of industries, offering precise and efficient filtration solutions. Understanding their applications and benefits, as well as how to select the right one, is essential for maximizing their effectiveness in your specific processes. By incorporating mesh filter discs into your filtration system, you can achieve higher levels of purity, quality, and efficiency in your operations.

1 note

·

View note

Text

Loop Tie Wire

Anping Dongming Wiremesh Co.,Ltd offers high-quality loop tie wire, a flexible way to secure and fasten things in crops and building applications. Our loop tie wire, which is made of strong components, provides consistent and strong connections. Loop tie wire is a perfect option for securing fencing or bundling rebars.

Phone No. +86-15131872040

Email: [email protected]

Address: Industrial Park, Anping, Hebei, China 053600

#Stainless Steel Wire Mesh#Perforated Metal Mesh#Mild Steel Wire Mesh#Rib Lath#Filter Disc#Hy Rib#Metal Coil Drapery#Stainless Steel Welded Mesh#Metal Fabric#Fan Guard#Stainless Steel Rope Mesh#Welded Razor Wire#Expanded Metal Mesh#Cut Straight Wire#Plaster Mesh#Loop Tie Wire

0 notes

Text

Technologies are evolving every day, In order to provide the demanded protection and yet not impair their function, flexibility and porosity, an optimal woven mesh is a vital component. Our working experience in industry, along with R & D Team always make sure to bring the optimal wire cloth solution for these industries.

Read more about SS Mesh weaves.

0 notes

Text

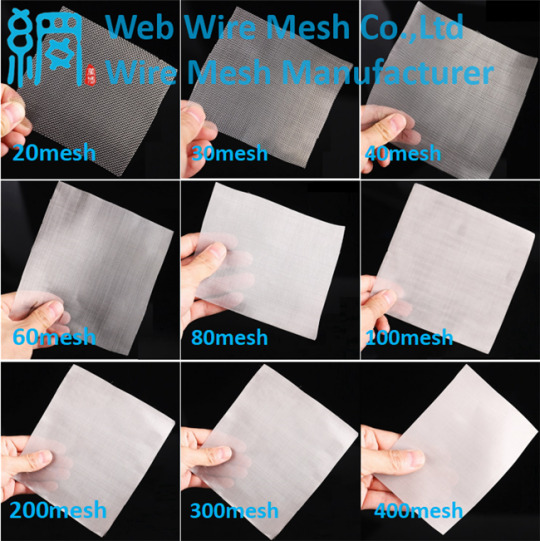

How to choose the woven wire mesh for making filter discs

Generally, the 20mesh to 500mesh (the number of wires per inch) woven wire mesh is the commonly used mesh for making filter discs

The 20 mesh to 40mesh is much heavy mesh for filter discs;

The 40mesh to 200 mesh is light mesh for filter discs;

The 200mesh to 500 mesh is much finer mesh for filter discs.

#woven mesh#woven wire mesh#wirecloth#web wire mesh#wiremesh#stainless steel mesh#filter mesh#filter discs

0 notes

Text

Filter Discs for Coffee and Tea filtration

The filter discs are also used in the coffee and tea filtration .

The wire mesh coffee filter is reusable and designed to be used with the coffee maker. This allows more oils and a fuller bodied cup of coffee. Eliminates the need for paper filters, which is especially convenient when traveling.

This tea strainer is well made with really fine holes to strain out very small particles. Easy to clean just wash under the tap. Usually with dandelion tea have a residue in the cup but this strainer does a very good job of trapping most of the particles

0 notes

Text

The Ultimate Guide to Choosing Water Filters for Agriculture in Gujarat

Water is the lifeblood of agriculture, especially in Gujarat, where irrigation plays a crucial role in crop success. Clean, debris-free water is vital for healthy crops and efficient irrigation systems. This guide provides a comprehensive overview of selecting the best water filters for your agricultural needs, from understanding filtration systems to identifying the top water filter manufacturers company in Gujarat.

Why Water Filters Are Essential for Gujarat's Farmers

Gujarat’s agricultural success relies heavily on effective irrigation systems. However, irrigation water often contains contaminants such as debris, sediments, and microorganisms, which can clog systems and harm crops. Here’s why the right water filter is crucial for Gujarat farmers:

Protecting Irrigation Systems: Sediments and debris can block irrigation nozzles, reducing water flow and causing system failures. Dealing with these issues can be both costly and time-consuming.

Healthy Crops: Contaminated water can harm crops and reduce yields. A proper filtration system ensures your crops receive clean, safe water.

Optimizing Water Use: By filtering out impurities, you can improve water quality and use it more efficiently, maximizing crop growth and minimizing water waste.

How to Choose the Right Agricultural Water Filter

Selecting the right water filter for your farm involves considering factors like the type of irrigation system you use, your water source, and your crops' specific needs. The best filter will ensure smooth system operation without blockages and provide your crops with the clean water they need.

1. Understanding Your Water Source for Optimal Filtration

Knowing your water source is essential in choosing the correct filter, as different sources have varying impurities:

Surface Water (Lakes, Rivers, Canals): Often contains organic debris, algae, and sediments. Disc filters and gravel filters are ideal for handling these impurities.

Groundwater (Wells): Typically contains sand and fine particles. Screen filters and disc filters are effective in removing these contaminants.

Recycled Water: May contain microorganisms and chemical pollutants, requiring a combination of filtration and disinfection systems.

2. Matching Filters to Your Crop Type and Irrigation System

Your choice of filter also depends on your crops and the irrigation system you use:

Drip Irrigation Systems: Prone to clogging, so using disc filters or screen filters is crucial to prevent debris from blocking the system.

Sprinkler Systems: Require clean water; a combination of gravel and disc filters ensures no large particles enter the system.

Micro-Irrigation: Needs high-efficiency filters like the 2-inch PP Disc Filter or 90mm Disc Filter to handle small particles that could clog narrow tubes.

3. Choosing the Best Filtration Type for Your Farm’s Needs

Different types of filters have unique benefits. Here’s a breakdown of the most common types used in agriculture:

Disc Filters: Use grooved discs to trap particles and are effective for filtering organic and inorganic materials. Popular options include the 2-inch PP Disc Filter and the 90mm Disc Filter.

Screen Filters: Use a mesh screen to catch debris. They are easy to clean and ideal for farms using groundwater with minimal debris.

Gravel Filters: Suitable for large-scale operations dealing with heavy debris and sediments. Robust and can handle high-flow systems.

Combination Filters: Some farms may need a mix of disc, screen, and gravel filters for optimal performance, especially with multiple water sources.

Top Water Filters from Leading Manufacturers in Gujarat

To assist you in making an informed choice, here are some top water filter products that are effective for agriculture in Gujarat:

1. 2 Inch PP Disc Filter: Ideal for Small to Medium Farms

Best for drip or micro-irrigation systems.

Traps fine particles efficiently and can handle high water flow without clogging.

A top choice among Gujarat’s water filter manufacturers due to its durability and effectiveness.

2. 90mm Disc Filter: Perfect for High Flow Irrigation Systems

Suitable for large irrigation systems with high water flow requirements.

Its 90mm size allows it to handle larger water volumes, making it ideal for extensive farming needs.

A popular option among irrigation filter suppliers in Gujarat.

3. PP Screen Filter: Best for Groundwater Filtration

Ideal for farmers using groundwater or well water.

Easy to clean and maintain, effectively removing sand and small particles.

4. Gravel Filters with BW Assembly: For Heavy Debris Management

A robust solution for water sources with significant sediment or debris.

Built to withstand the demands of large-scale farming operations.

5. Drip Irrigation Filters: Specialized for Gujarat’s Irrigation Needs

Designed to handle small particles that can clog drip irrigation systems.

Choose filters tailored to your water source and crop needs for the best results.

Benefits of Choosing a Local Water Filter Supplier in Gujarat

1. Tailored Solutions for Gujarat’s Unique Water Challenges

Local manufacturers understand the region’s specific water challenges, including quality and sediment levels.

They can provide filtration solutions designed for Gujarat’s unique agricultural needs.

2. Quick Access to Products and Support from Local Experts

A local water filter supplier in Gujarat offers faster access to products, parts, and maintenance support, ensuring minimal irrigation system disruptions.

3. Custom Filtration Solutions for Gujarat's Agricultural Sector

Local suppliers can offer customized filtration systems tailored to your farm’s specific needs, ensuring optimal performance and crop health.

Conclusion: Partner with the Right Water Filter Manufacturers in Gujarat

Water is not just a resource in agriculture; it’s the foundation of your farm’s productivity. Investing in the right water filter is essential for maintaining the health of your crops and ensuring efficient water usage.

Whether you need a 2-inch PP Disc Filter, a 90mm Disc Filter, or a more robust solution like Gravel Filters with BW Assembly, partnering with a reputable water filter manufacturers company in Gujarat ensures you have the best filtration technology for your agricultural needs.For those utilizing drip irrigation, understanding the Benefits of Drip Irrigation Systems highlights the importance of having clean, debris-free water. This ensures that your irrigation system operates efficiently, maximizing crop growth and minimizing maintenance issues. With the right filtration system in place, you can focus on what matters most—growing healthy, productive crops and ensuring the long-term success of your farm.

0 notes

Text

What is the work function of foot valve?

A foot valve is a critical component in various pumping systems, particularly in applications involving water and other fluids. It is essentially a type of check valve installed at the suction end of a pump's inlet pipe, submerged in the liquid being pumped. This article explores the purpose, operation, and advantages of foot valves, highlighting their importance in maintaining the efficiency and longevity of pumping systems.

What is a Foot Valve?

A foot valve is a type of check valve combined with a strainer. It allows fluid to flow in one direction only—into the pump—and prevents the fluid from flowing back out when the pump is turned off. The strainer component filters out debris and prevents it from entering the pump, thus protecting the pump from damage and clogging.

Working Principle of a Foot Valve

The foot valve operates on a simple yet effective principle: it opens under the pressure of the fluid being drawn into the pump and closes when the pump is turned off, thereby preventing backflow. Here’s a detailed look at its working:

1. Suction Phase:

- When the pump is activated, it creates a vacuum that draws fluid into the inlet pipe.

- The pressure differential causes the foot valve to open, allowing fluid to flow into the pump.

2. Non-Return Phase:

- Once the pump stops, the pressure inside the pump drops, and gravity or reverse pressure would naturally cause the fluid to flow back down the pipe.

- The foot valve closes automatically under the reverse pressure, preventing the fluid from flowing back out of the pump and back into the source.

Components of a Foot Valve

1. Valve Body: The main structure that houses the internal components and connects to the suction pipe.

2. Disc or Flap: The moving part that opens to allow fluid flow and closes to prevent backflow.

3. Strainer: A mesh or perforated cover that surrounds the valve, filtering out debris and preventing clogging.

4. Spring (optional): In some designs, a spring mechanism aids in closing the valve more quickly and effectively.

Benefits of Using a Foot Valve

1. Prevents Loss of Prime:

- In pumping systems, "priming" refers to the process of filling the pump and suction line with liquid to remove air. A foot valve ensures that the pump stays primed by preventing the liquid from draining back out of the suction line when the pump is off.

2. Protects the Pump:

- By preventing backflow, a foot valve minimizes the risk of damage caused by reverse flow pressure, which can harm the pump's internal components.

- The strainer component helps keep debris out of the pump, reducing wear and tear and prolonging the pump’s lifespan.

3. Enhances Efficiency:

- Maintaining a continuous prime reduces the time and energy required to restart the pump. This leads to more efficient operation and lower energy costs.

4. Reduces Maintenance:

- With a foot valve in place, the risk of clogging and damage due to debris is minimized, which can reduce the frequency and cost of maintenance.

Applications of Foot Valves

1. Water Wells:

- Foot valves are commonly used in well water pumping systems to ensure that the pump remains primed and ready for operation.

2. Irrigation Systems:

- In agricultural settings, foot valves are essential for maintaining efficient and reliable irrigation by preventing backflow and debris entry.

3. Industrial Pumping:

- Industrial applications that involve pumping various fluids often use foot valves to maintain pump efficiency and protect against contaminants.

4. Marine Applications:

- Foot valves are used in bilge pumping systems on boats to ensure that water is effectively pumped out and does not flow back in when the pump is off.

Foot valves play a crucial role in maintaining the efficiency and reliability of pumping systems by preventing backflow and protecting pumps from debris. Their simple yet effective design ensures that pumps remain primed and ready for operation, reducing the risk of damage and minimizing maintenance needs. Understanding the function and benefits of foot valves is essential for anyone involved in designing, operating, or maintaining fluid handling systems. Whether for residential, agricultural, industrial, or marine applications, foot valves are indispensable components that contribute to the smooth and efficient operation of pumps.

0 notes

Text

How to Make an Arduino Floor Cleaner Robot

Welcome back to another captivating instructable. In this endeavor, I’ve crafted an Arduino-powered floor cleaner robot, which operates significantly quieter than typical models.

Yes, you heard that correctly! This is a straightforward yet fully operational dry floor cleaner capable of picking up items from the floor such as paper scraps, hair, foam fragments, leftover chips from a party, and much more!

Materials Needed

To replicate this project, I’ve listed all the necessary components that are easily accessible. Should you wish to construct this robot, I’ve provided detailed instructions in this guide, enabling anyone to assemble and enjoy the process.

Arduino Uno (Available on Amazon)

Ultrasonic Sensor (HC-SR04)

L298N Motor Driver Module

DC fan, switch, and battery source

Sturdy Cardboard

Two BO Motors with wheels

Two 18650 Batteries

Battery Holder with Separate Switch

Jumper Wires

Paper glue

Plastic wire mesh

Spare wheel

Piece of steel or toothpick

Super glue and hot glue

Soldering iron and wire

Arduino IDE and programming cable

Please note that using Amazon affiliate links may provide me with a small commission at no extra cost to you, which helps support my projects.

How Does This Robot Operate?

The functionality of this robot is quite elementary. The board is programmed so that upon activation, the robot advances forward, with the HC-SR04 sensor scanning for obstacles. When an obstruction is detected, the robot halts, reverses, and then continues forward in a different direction. This cycle repeats, ensuring most floor areas are covered. During this process, the fan remains active, collecting debris from the floor.

To empty the collected debris, simply lift the robot, position it over a dustbin, and turn off the fan, causing the particles to drop out.

Step-by-Step Guide

Step 1: Constructing the Frame

The frame is crucial as it houses all the electronics and mechanisms. Though cardboard might seem flimsy, using a recycled package container and reinforcing it with multiple layers provides sufficient strength. I crafted discs from the cardboard, adhered them with paper glue, and allowed them to dry thoroughly. Marking areas for the fan and wheels, I cut the base accordingly.

Step 2: Circuit Diagram and Codes

To simplify the circuit explanation:

Ultrasonic Sensor:

VCC to 5V on Arduino

GND to GND on Arduino

Trig to Pin 8 on Arduino

Echo to Pin 9 on Arduino

Arduino Uno Connection with Motor Driver and Battery:

Vin pin to 5V pin of the driver

GND to GND of driver

12V pin to positive pin of driver

L298N Motor Driver Connections with Uno:

IN1 to D4 on Arduino

IN2 to D5

IN3 to D6

IN4 to D7

ENA to D10 and ENB to pin D11

GND to GND on Arduino

VCC to Battery positive

Motor 1 Outputs to Motor 1

Motor 2 Outputs to Motor 2 Terminals

Fan:

The DC fan requires 12V for optimal performance. Using a 7.4V battery source, connect the battery to the fan and control it with a simple switch.

After assembling the circuit, connect the USB to Arduino, upload the code, then disconnect the USB.

Step 3: Suction Fan and Front Wheel

Install the DC fan, ensuring no obstacles hinder its operation. Attach the fan to the frame with glue. For movement, two BO motors control the robot, and an additional wheel installed at the front stabilizes it.

Step 4: Adding the Circuit

Secure the circuit components firmly to the base to prevent loose connections. Glue the electronics first, then attach the BO motors and wheels using hot glue. Ensure the glue isn’t too hot to avoid deforming the motor frame. Secure the power source with zip ties.

Step 5: Suction Cylinder

The suction cylinder collects lightweight objects. The powerful DC fan lifts the debris, and a plastic mesh filters and contains it, allowing air to flow freely. Construct the cylinder with cardboard, sealing one end with the mesh and gluing the other end to the frame.

Step 6: Finishing and Testing

Ensure all components are securely attached to the frame. Connect the battery, turn on the fan and main circuit switches, and test the robot. Place light objects like paper bits or foam pieces in its path to see the robot in action.

Conclusion

The project should now be fully operational. Remember, this robot is designed to pick up only lightweight objects and is not suitable for liquids or larger items.

Explore more engaging projects and enhance your coding skills with our specialized courses:

Python for Kids Course: A beginner-friendly introduction to Python programming.

Java Course: Comprehensive lessons on Java programming.

AI Discovery Course: Learn the fundamentals of AI and its applications.

AI Evolution Course: Understand the progression of AI technologies.

Do you have questions regarding our STEM program?

Contact us anytime.

Take your first step into the magical world of coding for kids

0 notes

Link

0 notes

Text

Standard material quality: SS304, SS304L, SS316, SS316L. Special alloys such as C-276 Alloy C-276, Alloy 400, Alloy 600, SS904, SS904L, and 2205 double-phase stainless steel.

Standard size: 1000mm*500mm 1200mm*600mm 1000mm*1000mm according to customer requirements.

Sintered filter disc can effectively solve the problem of woven wire mesh with large flow resistance, easy deformation, low strength, and short service life.

During the production process in petroleum and chemical industry, the demand separation during the production process is divided into three grains. Regularly used woven wire mesh, short service life. We used sintered filter disc. Sintered filter disc multiple layer structure, general branch layer, protection layer and precision layer.

A multi-layer sintered filter disc is a multi-layer metal casing. In general, we have created a special engineering system, vacuum heating, etc., which has advanced mechanical strength, combined mechanical strength, and a variety of new advanced materials. The holes in each layer are mutually interchangeable, the formation is uniform and the ideal structure, the disadvantages of ordinary metals are low strength, the difference in stiffness, the hole shape is undefined, and the size of the holes in the material is large and small. Transparent performance harmony strength characteristic progression rational distribution design. The equipment has excellent overflow accuracy, overflow resistance, mechanical strength, abrasion resistance, heat resistance and workability. Other types of materials such as coal powder, ceramics, textiles, cloth, paper, etc. that have good performance in combination.

Advantages of Sintered filter disc:

High strength and good rigidity: It has high mechanical strength and compressive strength, good processing, welding and assembly performance, and is easy to use.

Uniform and stable precision: Uniform and consistent filtration performance can be achieved for all filtration precisions, and the mesh does not change during use.

Wide range of use environments: It can be used for filtration in temperature environments ranging from -200°C to 600°C as well as acid and alkali environments.

Excellent cleaning performance: good countercurrent cleaning effect, can be used repeatedly, and has a long service life (can be cleaned with countercurrent water, filtrate, ultrasonic, melting, baking, etc.).

Features of Sintered filter disc:

First of all, sintered filter products are widely used in the separation and filtration of gases and liquids during use. At the same time, this equipment can also be used for the separation of solid particles. It can be used as dispersed cooling material in high-temperature environments, distribution control of air flow, enhanced mass and heat transfer, noise reduction, flow limiting and throttling, flame retardant and explosion-proof, and in aerospace. It can also be used in industries such as , petrochemical and pharmaceutical industries.

Secondly, the sintered filter disc has high strength during use. After sintering, it has extremely high mechanical strength and compressive strength. At the same time, the product has high porosity and even airflow distribution, and can break down faults such as short circuits and blockages during later use, thereby extending the product's service life.

In addition, the fluidization effect of the sintered filter disc is also relatively good during use. Therefore, using this product for filtration has high efficiency and low energy consumption. At the same time, the product is easy to process and form during production and has good weldability.

0 notes

Text

Plastic Pulverizer Machine

MF series plastic grinder pulverizer machine is a prefect machine for processing and grinding thermoplastics material, such as PVC, PE, PP, EVA, PLA, ABS etc, with high output and thin powder.

This pulverizer machine for plastic series is disc-type plastic grinding mill series, which has the advantages of high-yield and low-power.

Plastic Grinder Pulverizer Machine Features

Focused on generating plastic powder from plastic granules and scraps. The whole system consists of a feeding hopper, grinding chamber, vertex receptacle, shaking filter, regrinding system, dust cleaner.

Both the board and the cutting blade are made of abrasion-resistant steel, which has excellent efficiency after warm treatment.

Straightforward exchangeable of premium knives, and also it can be used consistently after grinding.

As the new disc design is used, our plastic pulveriser machine has the features of high yield and strong resistance. The life of the grinding disc is double that of the ordinary.

QINGCHENYU plastic pulverizer machine has low power intake, high yield, a good-designed framework as well as simple installation.

Professional bearings & high rotation rate. One drive motor ensures the efficient grinding crash, which greatly saves the time and operation of machinery and control engineering.

The installation and maintenance of our pulverizer machine for plastic are easy. Simply open the door to cover clean-up. Milling process of the whole seal, without dust leakage. Full automatic feeding, the materials and sorting. Grinding gap adjustment is simple, use the plug-foot bolts and adjustments can be fine-tuning (10-120 mesh).

The host used the water and wind double system; Rational design of a smaller cross-section of the grinding chamber, grinding is almost flat vertical surface. Material entered the grinding chamber as soon as caught, ground, and then rapidly removed, which eliminates the grinding chamber of the surge in materials, heating materials to avoid decomposition, resulting in improved production.

In virtue of automated feeding, automated splitting up as well as automated discharging, this plastic pulveriser machine is completely air-proof and with no dirt leakage.

The powder excellence can be readjusted because the device has 10-120 meshes to choose from. It just needs to use a filler gauge and change screw to understand precise modification.

0 notes

Text

Find a Trusted Wire Mesh Manufacturer for the Benefit of Your Business Growth

For the majority of us, conducting business internationally is unthinkable. However, some people will always start making purchases from Plaster Mesh manufacturers since they wish to have a chance to become wealthy. There you will also find high-quality Welded Razor Wire, and other materials.

Phone No. +86-15131872040

Email: [email protected]

Address: Industrial Park, Anping, Hebei, China 053600

#Stainless Steel Wire Mesh#Perforated Metal Mesh#Mild Steel Wire Mesh#Rib Lath#Filter Disc#Hy Rib#Metal Coil Drapery#Stainless Steel Welded Mesh#Metal Fabric#Fan Guard#Stainless Steel Rope Mesh#Welded Razor Wire#Expanded Metal Mesh#Cut Straight Wire#Plaster Mesh#Loop Tie Wire

0 notes

Text

Stainless Steel Filter

China’s biggest leading Stainless Filters Factory customize all range of filters products with stainless steel. Shop for Stainless Steel Mesh Filters, Disc Mesh Filters.Stainless Steel Filter

About Company:-

Anping Zhehan Filter Equipment Co.,Ltd. is an ISO9001 : 2015 certificated company, specializing in the production and processing of stainless steel filter element and stainless steel filters. Zhehan Filter Equipment Co., Ltd. is located in Anping County, the hometown of wire mesh, is an earlier professional manufacturer engaged in the production of filter equipment, with a history of nearly 16 years.

Our company has advanced equipment and standardized management. The main products are: sintered wire mesh, stainless steel wedge wire filter element, stainless steel filter cartridge, stainless steel filter element, sintered mesh filter element, various stainless steelfilters, filter bags, filter discs, cone filter cartridges, and various precision stamping parts and more than 300 kinds of filter equipment products.

Click Here For More Info:- https://www.zhehanfiltration.com/

Location:- Anping County,Hebei Province, China

Social Media Profile Links:-

https://www.instagram.com/zhehanfilter.marry/

0 notes

Text

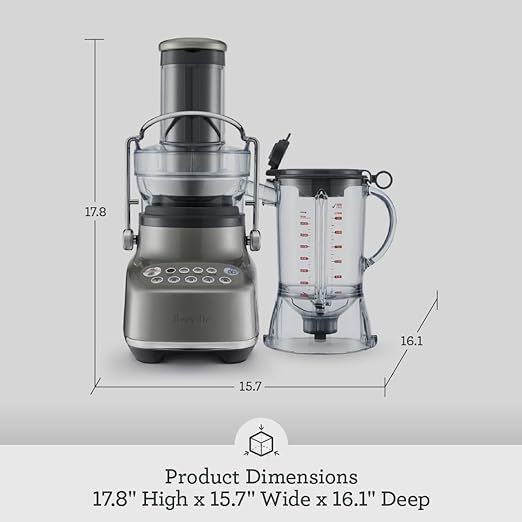

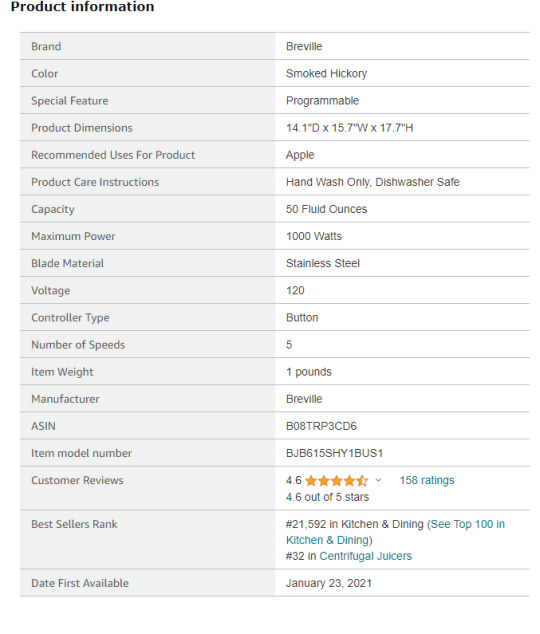

Breville BJB615SHY the 3X Bluicer Blender & Juicer in one, Smoked Hickory

Buy-On-Amazon

Product Link* : https://amzn.to/48ka5zb Price:212.00 $

Brand Breville

Color Smoked Hickory

Special Feature Programmable

Product Dimensions 14.1"D x 15.7"W x 17.7"H

Recommended Uses For Product Apple

About this item

*The Breville 3X Bluicer is a blender and juicer in one; With a 3.5 inch wide chute, Cold Spin Technology, 4 one touch programs and 5 speed settings, you can extract fresh juice straight into a 50 oz jug and create smoothies, cocktails and much more

*The 3X Bluicer's versatility allows you to blend, juice or combine fresh juice with blended mixes to enjoy all the nutrients and create more vibrant, healthier creations; Maximize the freshness and get 3X the flavors, variety and fun

*4 ONE TOUCH PROGRAMS: The Smoothie program optimizes time and speed for smoother dairy smoothies; Turn ice into snow with Pulse/Ice Crush or easily create fresh cocktails with the Frozen Cocktail one touch program; Auto Clean function for easy clean

*SPACE SAVING DESIGN: Save space using one base to blend, juice or bluice; With the pulp bin located behind the product base, the 3X Bluicer features a new and unique space saving design for a better use of your countertop space

*KINETIX BOWL AND BLADE SYSTEM: The bluicer combines the functionality of a powerful blender with some food processing tasks for versatility and convenience; Crush and chop to turn ice into snow, fold and aerate for creamy smoothies and soups

*COMPATIBLE WITH THE VAC Q: The Vac Q removes air from the jug before blending, providing smoother textures, brighter colors and richer flavors to your blend; The vac Q is sold separately

*COLD EXTRACTION SYSTEM: The Breville bluicer's Cold Spin Technology allows juice to flow up and through the stainless steel cutting disc surrounded by an Italian-made mesh filter to ensure an insignificant temperature increase, less than 1.8°F

Buy-On-Amazon

Product Link* : https://amzn.to/48ka5zb Price:212.00 $

From the manufacturer

the 3X Bluicer

Make the most of your fresh ingredients with the 3X Bluicer. This high performance blender juicer features our Kinetix contoured blade & bowl system and a 3.5 inch extra wide chute. With Cold Spin Technology you can extract fresh juice straight into a high capacity 50 oz blender jug and create delicious fresh, slushie, smoothies, cocktails and much more.

Product Description

More flavors, more variety, more fun. Make the most of your fresh ingredients with the 3X Bluicer. This high performance blender juicer features our Kinetix® contoured blade & bowl system and a 3.5 inch extra wide chute. With Cold Spin Technology® you can extract fresh juice straight into a high capacity 50 oz blender jug and create delicious fresh, slushie, smoothies, cocktails and much more.

Buy-On-Amazon

Product Link* : https://amzn.to/48ka5zb Price:212.00 $

0 notes

Text

Edge Types of Filter Discs

Filter discs have different edge types to suit different applications, which includes,but not limit to, common,welded,rimmed,sintered

0 notes

Text

Ambica Engineering & Wire Industries: Pioneering Excellence in Extruder Screens and Wire Cloth Manufacturing

In the realm of industrial manufacturing, where precision and quality reign supreme, Ambica Group stands high as one of India's leading manufacturers and suppliers of extruder screens, melt filters, and woven wire cloth. Established in 1972 by Mr. Vinod Patel, Ambica Group has etched its legacy on the pillars of 'Quality, Assurance, and Reliability.' This article delves into the rich history and remarkable journey of Ambica Engineering & Wire Industries, highlighting its diverse product range, commitment to innovation, and unwavering dedication to customer satisfaction.

A Legacy of Quality and Reliability

Ambica Group's inception was marked by a singular vision: to create products that set the industry standard for quality and reliability. Starting with wire mesh and extruder screens, the company soon embarked on a path of expansion, venturing into the development of various shapes and sizes to meet evolving industry demands.

Evolution Over Five Decades

With over five decades of industry experience, Ambica Group has honed its manufacturing processes, establishing itself as a symbol of trust and excellence. The journey has been marked by continuous innovation, adaptability, and a relentless pursuit of customer-centric solutions.

Innovation and Research

At the heart of Ambica Group's success lies its avant-garde Research & Development Centre. This dedicated facility is a hub of innovation, constantly pushing the boundaries to meet evolving industry requirements.

Customer-Centric Approach

Ambica Engineering & Wire Industries takes pride in its team of in-house experts who work closely with customers to identify the ideal solutions for their filtration needs. The company's commitment to providing high-quality products and exceptional customer experiences remains unwavering.

Product Portfolio

Ambica Group's product portfolio is as diverse as it is comprehensive, catering to the needs of various industries. Some of its key offerings include:

Circular Screens

Circular screens also known as melt filters; play a pivotal role in the extrusion process. Ambica Group's circular screens are renowned for their precision and durability, ensuring seamless production.

Multilayer Circular Screen Packs

Spot Welded Multilayer Circular Screen Packs are a testament to Ambica's commitment to innovation. These packs enhance filtration efficiency, ensuring superior product quality.

Multilayer Cylindrical Screen Pack

Candle filters, part of the Multilayer Cylindrical Screen Pack range, are designed for applications requiring the highest level of filtration accuracy.

Multimesh Circular Screen

Ambica Group offers various types of Multimesh circular screens, including Plain Dutch Weave and Twill Dutch Weave Filter Cloth, catering to a wide range of filtration requirements.

Designer Screens

For specialized applications, Ambica Group provides designer screens that combine form and function, meeting the most demanding industry standards.

Filter Discs

Filter discs are essential components in various filtration processes, and Ambica Group manufactures them with precision and consistency.

Stainless Steel Wire Mesh

As a trusted source for stainless steel wire mesh, Ambica Group ensures the highest quality in every weave, meeting stringent industry specifications.

Stainless Steel Hopper Magnet

Ambica Group's stainless steel hopper magnets contribute to product purity and equipment protection, enhancing overall production efficiency. Ambica Group's journey from its inception in 1972 to becoming a frontrunner in the field of Plastic & Rubber Industry is a testament to its commitment to excellence. With a legacy built on quality, reliability, and innovation, Ambica Group continues to shape the industry and offer unparalleled value to its customers.

1 note

·

View note