#mixed slurry of organ

Note

What does bill usually eat and drink? And how often? Does he eat when the rest of the humans do?

First choice:

When there's a meal being served—such as Abuelita cooking dinner or Stan grilling burgers—Bill eats whatever everyone else eats. (Provided he got to see Abuelita cook—to ensure cyanide wasn't an ingredient in his serving.) This accounts for maybe 15% of his meals.

Second choice:

If he happens to be in the kitchen at the same time as someone else, he'll ask them to open the fridge/cabinets to let him get food for himself or, more rarely, ask them to prepare something he isn't allowed to prepare for himself. This means he'll often eat at the same time as them, because swooping into the kitchen while THEY'RE eating means he can get food too.

When he does have full kitchen access, he creates the most disgusting concoctions known to mankind.

Human brains are wired from infancy to find almost all tastes disgusting until they've had them enough to learn to appreciate them (i.e., accept they aren't poisonous)—why kids are generally pickier eaters than adults. The Axolotl trusts that Bill knows enough about human diets to know what is and isn't food—he does—so Bill didn't get given a baby palate. Instead, he's the opposite: he finds almost all tastes okay. Nothing really tastes bad to him.

So his measure for food that "tastes good" isn't QUALITY of taste, but QUANTITY of taste. Bland food is disgusting. The more and stronger flavors a food has, and the more different they are from each other, the more he likes it.

When making his own food he wants maximum flavor for minimum effort. This is why he has a tendency to take as many condiments as he can, no matter how poorly they go together—in fact, ESPECIALLY if they go poorly together—mix them into a slurry, and then drop in enough solid food to cover his body's minimum nutritional needs. (He would do the same thing with spices, but the spices are kept in a cabinet and it's just not worth the trouble to him to specifically ask for access.)

As of chapter 39, he's no longer willing to ask someone else to help prepare something for him, and won't ask Ford to so much as open the fridge for him. Full kitchen access used to account for about 35% of his meals, now it's more like 25%.

Third choice:

If no one's in the kitchen, he won't go looking for someone; he'd rather starve than plea for food from the people who took his food access away. Instead, he'll just eat whatever he can scrounge off the open shelving. That means no food that requires refrigeration, cooking, or microwaving; and no food that's canned, in glass jars, or needs scissors to open. In practice, this means a whole lot of junk food—chips, cookies, candy, jerky, cereal, soda. The most nutritious thing he has regular and easy access to is peanut butter. He has a lot of peanut butter sandwiches. He dislikes peanut butter sandwiches, but he understands nutrition better than most humans and knows chips and jerky can only carry him so far. Scrounging accounts for 60% of his meals.

Beyond all that:

He likes triangle-shaped foods because he is, in fact, that much of an egotistical dork. He will legitimately get angry about nachos with circular or rectangular tortilla chips.

And (with Mabel's encouragement) he's become a fan of dumping sprinkles on as many things as possible. You know how grocery stores sell a bunch of different mixes of sprinkles? Different styles & colors & textures & shapes? Mabel has brought a WIDE variety of sprinkles into the house, and is teaching Bill the fine art of mixing sprinkles artistically for maximum aesthetic value. He likes the fancy-looking gold/silver/white varieties.

He drinks too much—usually, but not exclusively, to get to sleep. This is a bad thing. If called on this, he gets defensive, suggests he needs it like a "medication" to numb the discomfort of fitting a triangular soul in a human body—like taking medicine to prevent a body from rejecting a donor organ—and that the humans wouldn't understand it so they have no room to criticize. This is a VERY bad thing. I'd say he's speedrunning alcoholism, except he's continuing a pattern of substance abuse he had as a triangle, so tbh he was already there.

116 notes

·

View notes

Text

An unorthodox approach to troll reproduction

It’s blood.

Its always been blood, and we’ve all been fooled by our own preconceived notions of how reproduction works. We were given a fill in the blank riddle and got it so wrong that the thousands of fanfics that reference it stand now as a monument to our presumptuousness.

It’s the easiest bodily fluid to get a literal bucket full of quickly. It contains DNA that can be recombined with a partners and utilized by the mother grub. It keeps pairs of any sex/gender viable. And it weirdly explains why rainbowdrinkers are a thing...

First debunking the other possibilities:

From a human perspective the answers to troll reproduction that immediately come would be A) Two sexes with matched-set gemetes, B) All genetically male, or C) Hermaphrodites. Which all come with contradictions.

A) If individuals only produce sperm or eggs, than a statistically significant number of all pairs would be non productive. Given trolls have no concern over the viability of same sex quadrants, there must be a different mechanic in use.

B) If all trolls produce only sperm cells than there would be no mechanism for genetic mixing between individuals. In fact there would be no point in pairing/quadrants at all. Their social system would match ants or bees which forgo reproductive activity outside of one to one interactions with their queen.

Since its been stated that the viability of offspring is effected by the strength of a pair, we know that pairing is a crucial element. Also if trolls are all genetically male, than binary gender has little to no reason to exist (unless sex and gender are also conceptually divorced, which is another theory).

C) The hardest one to knock and the most popular for it. I guess I would pose the question why, in a strongly individualist society, would people form pairs to do what they could technically do all on their own? Or at least why would ‘self-pairing’ not be more common. Sure, pairing allows for more variety but if the gametes paired randomly, half of the resulting mix would still be self fertilized anyways.

Ok but what does blood have to do with anything like this?

The fundamental flaw that lies over all three answers and probably several more is that we’ve applied human physiology to an alien species. Yes they look similar but their quadrants and mother grubs are vastly different from our monogamy and individually assigned reproductive organs.

Blood mixing negates sex pairing issues, allowing any two individuals to produce offspring. It allows for genetic recombination, given it contains plenty of dna and possibly beneficial hormones produced from the emotional virility of a pair. Lastly, it necessitates pairing. Mixed and unmixed blood have some kind of fundamental difference, which disallows an individual from self-pairing.

I’d chalk it up to something with the immune system. It’s like how in humans certain blood types mixing causes an immune response. Which inside of a body is horrible because it bursts the blood cells, but in an external mix, bursting cells leave exposed dna, allowing for easier recombination. The ‘dominant’ blood type (immunologically, not caste related) dismantles and assimilates the ‘recessive’ producing a viable ‘genetic slurry’ to be hauled off to the mother grub.

And there is plenty of room for the social taboo behavior exhibited by trolls throughout the comic. Trolls live on a hell planet where everything, and everyone, everywhere is looking for an opportunity to kill them, all the time. Thus advertising that you’ve recently lost a half gallon of blood and are vulnerable because of it, would be really stupid. It makes sense then, to keep talk down and hide away any evidence. This evolves pretty seamlessly into a close enough match to the typical cagey/secretive behavior humans tend to show around their own reproductive activities. Hence why we perceive a parallel even though the reasoning is different.

tldr: We all assume that trolls connect sex with reproduction because that’s what we do, but they’re aliens, they do weird alien things. If their biology worked exactly like ours, they wouldn’t have a big weird moth laying eggs for them. Also you’re welcome.

#homestuck#troll biology#theory#I like to think hussie planned that from the start and got a nice giggle out before realizing we would never let it go#i know the reality is that it was just a shock thing that gained more momentum than expected#but the image of them suffering our presumptive stupidity as much as we've suffered all the weird shit that's come of this feels cathartic

366 notes

·

View notes

Note

Have you ever went into detail abt how you think bulges/nooks work? Seems simple enough, cooch and tentadick, but I started thinking abt it and like... how the hell does everything on the inside work? Whats really the point of having the "afab" bits if trolls depend on mother grub to reproduce? Gestures vaguely to bulges??? What?????

So okay. Honestly much like the drone season thoughts I posted a while ago, this makes sense to me if you consider a species that has the reproductive strategy they do, but consider them several millennia ago.

It makes sense for buckets to be a convenient adaptation that trolls came up with but it doesn't make sense for them to be a pre-requisite for their species to breed! So instead, in lieu of buckets, it makes sense to me trolls would just have an organ that's meant entirely for fluid storage and was hooked to both nook and bulge, and would just mix genetic material via fucking each other so it mixed internally. They don't need a uterus to gestate babies; by the same token, an organ that just exists to hold fluid and keep it body temperature and genetically viable before eventually expelling it after long-term storage is not something the human body needs, but would be pretty necessary if you procreate like trolls but don't have the technology of buckets yet lol.

In that case, the nook would basically be an entry point for that storage organ, which I don't know if I personally have ever mentioned by a name in a fic, although I know I've made reference to a seedflap which in my head is the entry point for it--about where a human might have a cervix, although in this case much more intended for potential ingress, depending on relative sizes. And the bulge would just be the means of getting genetic material into your partner so they could store it.

various points of note that come to mind:

This does mean that whenever a troll in Ancient Times fucked a partner, if they hadn't emptied out recently, the odds aren't bad that they would actually have some mixture of their own genetic material and somebody else's in there. And would not come entirely your own come, which is a wild concept as a human.

A reasonable excuse if you were pretending to be a slightly different shade than you were and got caught because of slurry: uhhh I fucked somebody yellow-blooded, that's why it looks lime instead of jade. BYE!!

Also means that although there was no concern about getting somebody pregnant, any form of STI that trolls could contract would be a pretty huge deal before vessels/buckets became a thing and it became more reasonable to clean out after fucking a single partner. Anything that spreads through fluid exchange, highly transmissible and dangerous!

Because most trolls in modern days haven't had to retain large amounts or for long, they tend to get cramping and a feeling of fullness for much smaller amounts than their ancient relatives would have.

Not wanting a bucket immediately after you fucked would have some connotations--old-fashioned, but romantic. A little sexy and kinky.

Modern trolls just don't have the carrying capacity they used to. >:I Buckets have ruined our bodies!!! Retain your slurry, it's natural!!! It gives you the power of your natural connection with the Mother Grub!!! << the modern troll's equivalent of the nofap guy.

Anyway there you go that's been my general theory in the porn I'm writing, ta-da~~

32 notes

·

View notes

Text

this is easily my most self indulgent train of thought re:troll bio but...

i've been reading more about siphonophores (for a portuguese man o' war sonic oc obviously) and i've been captivated by this concept of a colonial organism whose constituent parts are in essence actually the same organism. which is to say; while a typical biological colony consists of a multitude of related but genetically distinct organisms (i.e. animals of the same species but not clones), a portuguese man o' war is a colony of genetically identical animals, all born from the same source, who simply take on different shapes in order to serve different purposes in the colony (digestive, reproductive, locomotive, etc.)

and in the past i've talked as well about how much i love the idea that the inside of a troll reflects the world around them in that, just as on alternia the line between machine and organism is blurred, the dissection of a troll might have trouble distinguishing between "organ" and "parasite". where a human has stomach bacteria, a troll has stomach mites; or even a mite for a stomach, a centipede where a mammal's intestines would go. and like gut bacteria, this microbiome changes as the eras pass; diets shift, medicine evolves, and the ecosystem grows. but is this a truly "natural" change in gut flora? or is it a form of cyborgism? where does the microbiome end and the techno-macrobiome begin? indeed, if the troll itself is a parasite that attaches itself to a lusus, so then is the troll race a mixed colony organism? but i digress...

maybe you see where i'm going with this. we know trolls are born from a slurry formed from the genetic material of every single mature member of their race. the legend goes that if two trolls are fated partners, their genes will find each other and overpower all else, but even in this perfect scenario a troll egg can never just be "a" troll egg. sometimes a human finds themselves sharing a womb with another human and is forced to absorb their twin to survive, but how does a troll survive when they share a sac with dozens, hundreds of their ilk?

we know that troll infanthood is brutal; the first theatre of many in a warrior's long, violent life. but even before a larva has mandibles to bite, legs to grasp, spinnerets to choke, perhaps there's another avenue toward survival entirely? we know, too, that trolls are social insects whose bodies pupate into a myriad of different castes and morphs to best serve the specific niche in the colony which needs filling. some become armored drones, built not for warring with the colony's enemies but for picking off aberrations within the colony itself; others never pupate at all, but become larger and larger grubs until their limbs are powerless to relocate their cavern-sized egg chambers. but would you consider morphing even further beyond recognition if it was your one chance at survival? would you become just a small part of a colony organism led by a grub with stronger genes if it meant you could perform even a small role in the hive? would you compromise, if it meant you didn't have to fight? would you become a stomach mite? would you become an intestinal centipede? would you become an organ-parasite whose sole purpose is digestion, reproduction, locomotion?

39 notes

·

View notes

Text

Sourdough - A Baker's Dozen TedTalk

I’ve mentioned sourdough a few times in A Baker’s Dozen but I never dedicated a chapter to it even though it’s probably my personal favourite to bake. So to make up for that, I’m indulging in making a whole post about my other obsession, sourdough bread!

I love baking with sourdough because the process behind it is like magic to me. Flour, water and salt, three ingredients, and you can get the most delicious bread. The magic, unseen, ingredient is of course those wild yeast bacteria that live around us.

My mum was always the one who baked sweet things around the house when I was a kid, my dad made the bread. When he first got into it he produced bricks. You legit could’ve used some of his loaves as a foundation for a house. And I’ve produced my fair share of bricks in my baking career too… But he got better and for most of my life I had the luxury of having fresh, homemade bread for breakfast. That’s where my need to make my own bread came from and once I got past the novelty of being “allowed” to buy bread from the store after moving out of my parent’s house, I got into making my own bread pretty fast.

I started baking with sourdough about ten years ago when I stumbled on a blog about it. My first loaves were flat as pancakes and it took A WHILE before I graduated from baking in bread tins to managing to make loaves that actually held their shape. Sourdough dough does not behave like regular yeasted dough… But when I did manage to make my first proper levain, you know one of those beautiful golden loaves with nice holes and crunchy crust? I ate the whole loaf in one day. I couldn’t stop. Just butter, some sea salt and that was my food for the whole day. I’d never tasted bread so good. It’s tangy and flavourful in a way that yeasted bread just can’t imitate.

I’m no expert but here is how I make and manage my starter and my bread. Important to remember is that flour, water and climate, especially the humidity, has a HUGE effect on the dough and the bread. No recipe will have the same results and to a certain extent, it’s a process of trial and error and learning how to bake in YOUR kitchen.

In order to make sourdough, you need a starter and it’s surprisingly easy to make and maintain. I have a tiny starter, only about half a cup in size. The starter is your “yeast”, a small colony of yeast bacteria that you feed and culture so that you have enough for whatever you want to bake.

The starter takes about 5-7 days to make and once you have it, you can keep it in the fridge and just feed it before you want to bake.

So to make it you need:

Organic whole wheat flour, stone milled if you can find it.

Organic will contain more yeast spores and make the process easier. Don’t use old flour, check the expiration date of the flour you have at home. Flour can actually go rancid and wreck your bread.

Water

I use tap water but if you live somewhere with chlorinated water, use bottled water. The chlorination will kill all bacteria, the good and the bad.

A clean jar with a lid.

It doesn’t have to be a clear glass jar but it’s pretty handy because it makes it easy to see what’s going on.

Ok, now that we’ve got everything, let’s start.

Day 1 - Evening

1 tablespoon flour

2 tablespoons tepid water (roughly body temp, maybe a bit cooler)

The amount of water you need to add can vary depending on how your flour has been milled. The mixture should be like gruel, not porridge. If two tablespoons isn’t enough, add a little bit more water until you have a fairly loose and liquid slurry.

Mix together in the jar, put the lid on top but don’t screw the lid on. Leave for 48 hours in a warm place. Inside the oven (turned off) is a pretty good place.

You can check on your jar after 24 hours. It’s pretty liquid and should smell warm and a bit sweet, almost like honey. If you see any brighter colours in it, red, yellow, orange, I’m sorry, but you have to toss it. That’s mold and that’s not what we want. So throw it out, start again (this is one benefit of this method, all you lost was a tablespoon of flour).

Day 3 - Evening

Ok, so if your flour/water mix is looking good, a bit liquidy, maybe it’s separated a bit, maybe a bit bubbly and frothy, we’re all good for the next step.

Add 1 tablespoon of flour and mix in. Leave it overnight.

Day 4 - Morning

If the starter is on the right track now, you should begin to see small bubbles on the side of it, inside the glass jar. It should smell sour and yeasty, “bready”.

Add 2 tablespoons of flour and two tablespoons of water and mix it in. Leave until evening.

And that’s it! By evening you might/should see that there’s activity in the jar, bigger bubbles forming, the starter will rise up in the jar and expand, just like a dough. If it doesn’t, feed it 1 tablespoon of water and flour again and leave it overnight. Like I said at the beginning, lots of different factors are at play here so despite the fact that it’s all chemistry, it’s not an exact science (well it is, but since we can’t measure all the factors in each individual kitchen, we need to depend on a bit of trial and error).

So now you have a starter and can start playing around with making bread. I won’t go into that because there are so many good instructional videos online. I can really recommend Claire Saffitz’s video, I’ll link it below.

Obviously this starter is very small. Many recipes I’ve seen online call for much bigger starters and then discard half of it when they feed it but that always seems very wasteful to me. So what I do with my tiny little starter is just keep it in the fridge in its jar. When I plan on baking I take about 30 grams of starter and put it in a bowl and mix with 100g water and 100g strong bread flour. That is then the base for my bread the next day. To that mix I add whatever flour I’m baking with. The starter gets fed another tablespoon of flour and water and stays on my countertop overnight. That replenishes the starter and gives me enough for the next time I want to bake. In all, I usually have about 150-200 ml of starter in the fridge at any time.

If I’m not baking, the starter stays in the fridge. I’ve had it there for a month without feeding (I was away travelling) and when I got home, I just fed it like above and left it out overnight. I had to feed it a couple of times before it got back to full strength. But the yeast bacteria don’t seem to die very easily, they just go dormant and are easily revived with flour and water.

Fun fact, the actual science behind the yeast bacteria is that they eat the carbs in the flour and then convert that into energy and emit the gas carbon dioxide. The gluten strands in the dough traps that gas and makes the dough rise. So essentially, farts make the dough rise, tiny bacteria farts. I love science :D

What else did I want to say about sourdough? Oh yeah, TIME! Time will make your bread taste better! And this goes for regular yeasted bread too. By letting the dough cold proof in the fridge the yeast activity is slowed down but at the same time, flavour develops. With sourdough, you get a tangier, more sour bread. I usually keep my loaves in the fridge for 24 hours before baking them, same for my pizza dough.

So thanks for coming to my TedTalk about sourdough! It’s amazing and frustrating and a real pain sometimes but when you get it right and you get to cut into that perfect loaf that YOU MADE and it tastes better than anything you’ve had, that’s real magic.

youtube

9 notes

·

View notes

Text

Some days were more difficult than others.

And that had been true beforehand, but this was...

W o r s e . . .

His body won't stay stable. His body won't stay together. It's too hot. Too hot. He can't pull himself together - he must be more flour than flesh at this point and he's trying to push globs of himself back on but they keep falling down onto the floor which is getting closer every second, the skin keep running down his body, pink bleeding over black and white cloth, sweat dripping into exposed organs, what was probably blood starting to ooze out of their vessels and his clothes aren't fitting anymore they're falling off of his body as he feels everything start to blend together into grey and then his sight is failing his sight is going dark and all he can think is is this death?! is this dying?! because this is all it can be it's all he can think of it being and he can't breathe his lungs are liquefying and becoming part of the slurry that is him and his ears ring before it all goes quiet and his tongue sticks to the bottom of his mouth as his throat folds in on itself and his fingers are all stuck together so he can't even reach out to mold himself back to normalcy and - and - and - and -

Pino wakes up in the tub. Cold water mixed with foam that used to be bath soap sits at the bottom. A clogged drain keeps the dirty water from going down as the showerhead continues to rain on him.

Scraps of his own doughy skin line the edges of the tub.

He shudders, reaching out to dig his peeled skin out of the drain. His eyes refuse to focus. All his mind does is replay that horrible dream.

Please stay just a dream...

please...

#!pino#!drabble#body horror tw#like major body horror description here#you wanna hear about a melting man? here you go#consider this a vent drabble

3 notes

·

View notes

Text

Febuwhump day 18: too weak to move

Whumpee: Four

Whump Rating: 4/10

TWs: throwing up

Stepping past the threshold of the portal, Four almost instantly collapsed. The world spun around him at a dizzying rate, twisting and melding into a blur of colors as his body fell limp in the grass.

Distantly, he could hear voices, but he was too caught up in his own mind. Much like his vision, Four’s colors were mixing together as well, an odd slurry of Green, Blue, Red, and Vio like liquid in his skull.

There was a hand resting on his back, sturdy and supportive as Four’s chest heaved. Portals were always a bad experience for him, but this one felt particularly nasty. Drool pooled in his mouth as he swallowed it, trying to hold back the bile that was already rising up his throat.

Of course, some things can’t be helped, and sure enough, vomit came pouring past his lips and onto the grass below. Someone moved him away from the mess once he was finished, lying him on his side so he wouldn’t choke. Four’s eyes were already shut, but now they were squeezed in a tight expression, brows furrowed as he panted heavily.

The smithy was vaguely aware of someone wiping at his face– presumably to remove vomit– as he struggled to catch his breath. Even without any visual input, the world spun around him in a nauseating way, leaving Four’s mind spinning dizzily. The feeling was all-encompassing– he could barely move, with the way it affected him– and horribly disorienting.

“Smithy? Four?” A familiar voice– perhaps Twilight?– called, placing a gentle hand on his shoulder. “Link? Can you hear me?”

Four just groaned weakly in response.

“You alright, buddy? You’re lookin’ a lil sick.” The smithy managed to crack an eye open, glaring at a blur he assumed to be the rancher. Twilight chuckled lightly, patting Four on the shoulder. “Portal, I assume? Need to be carried?”

Four groaned again, shutting the eye he managed to open. Too many colors…

A squeak of surprise escaped his throat as Twilight picked him up. Four floundered and nausea threatened to creep back up as he was turned and moved around, his own body too weakened from the effects of the portal to help stabilize himself.

“Sorry, sorry,” the rancher apologized, finally managing to get Four comfortable and still in his arms. The smithy was being carried like a child, but he really couldn’t care less at this point, so it would have to do. The less he was jostled, the better– his stomach was still churning maliciously, and it would be great if he didn’t have to be sick again. Once was plenty, thank you.

Twilight, to his credit, carried Four as carefully as he could. But considering they had to hike through the woods on what may or may not be a real path, it was a bumpy ride, despite the rancher’s best efforts. The smithy curled himself into a tight ball (once he was able to move enough to do so), leaning his head in the crook between Twilight’s neck and shoulders. The coarse furs of his wolf pelt tickled at Four’s skin, a sensation that brought him comfort.

The overwhelming nausea and disorientation of the portal was beginning to wear off. Four’s colors were more distinct and separate now, instead of a rainbow-colored soup in his mind. Opening his eyes was a daunting task, but once the initial surprise faded, he was left with a scene that barely blurred or spun around him.

Things were getting easier. It wasn’t so bad anymore. Four still needed to be carried for a little longer, but it was mostly for safety and not out of necessity. But one thing was for certain:

Four didn’t like portals.

–> support me on ao3!

#febuwhump#febuwhump 2024#febuwhumpday18#tw throwing up#linked universe#lu four#lu twilight#linked universe fanfic#ao3#riv writes

5 notes

·

View notes

Text

Rapid Installation GFS Tanks Used as Pharmaceutical Wastewater Tanks

Rapid Installation GFS Tanks Used as Pharmaceutical Wastewater Tanks

Shijiazhuang Zhengzhong Technology Co., Ltd, also known as Center Enamel, is a leading GFS tanks manufacturer providing cutting-edge storage solutions for a wide range of industries, including the pharmaceutical sector. Our bolted steel tanks are an ideal choice for handling pharmaceutical wastewater due to their superior durability, corrosion resistance, and rapid installation capabilities. These wastewater tanks are designed to meet the unique challenges posed by the pharmaceutical industry's stringent environmental and safety requirements.

Why Choose GFS Tanks for Pharmaceutical Wastewater Storage?

Pharmaceutical wastewater is often highly contaminated, containing a mix of chemicals, organic substances, and residues from drug manufacturing processes. This makes it essential to have robust and corrosion-resistant wastewater tanks capable of containing such materials without deterioration. Center Enamel’s Glass-Fused-to-Steel (GFS) tanks are engineered to provide the ideal solution for these storage needs.

As a leading storage tank manufacturer in China. Center Enamel can provide Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized steel tanks and aluminum geodesic dome roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Key Benefits of GFS Tanks for Pharmaceutical Wastewater:

Corrosion Resistance: Our GFS tanks feature a unique fusion of glass and steel, resulting in a smooth, inert coating that protects against the highly aggressive and corrosive nature of pharmaceutical wastewater. This makes them a durable choice, extending their service life even in challenging conditions.

Rapid Installation: The bolted steel tank design allows for fast on-site assembly. With prefabricated panels manufactured in a controlled environment, our tanks can be transported to the site and assembled quickly, reducing construction time and minimizing downtime for pharmaceutical companies.

Compliance with Industry Standards: Center Enamel's wastewater tanks meet international standards such as AWWA D103-09 and are designed to comply with stringent environmental regulations. This makes our bolted steel tanks a reliable choice for pharmaceutical companies seeking compliance with industry regulations for wastewater treatment and storage.

Customizable Solutions: Our GFS tanks are available in a wide range of sizes and capacities, ensuring they can meet the specific requirements of any pharmaceutical wastewater treatment project. Whether the project requires small-scale tanks or large-capacity storage, our solutions are tailored to fit.

Easy Maintenance: The smooth interior surface of the GFS coating prevents the build-up of sludge and other residues, making cleaning and maintenance simple. This ensures that the tanks operate efficiently over their entire lifespan, further reducing costs for the pharmaceutical industry.

Applications of GFS Tanks in the Pharmaceutical Industry

Wastewater Treatment: The pharmaceutical industry generates a significant amount of wastewater that needs to be treated before disposal. Our bolted steel wastewater tanks are used as key components in wastewater treatment plants, helping pharmaceutical companies safely contain and process wastewater.

Wastewater Storage: Our GFS tanks serve as storage units for untreated or treated pharmaceutical wastewater, providing a secure and leak-proof solution that meets environmental regulations. These tanks can be easily expanded or relocated as storage needs evolve.

Chemical Containment: GFS tanks are suitable for storing chemicals and other hazardous substances used in the pharmaceutical manufacturing process. Their corrosion resistance and durability make them a safe and efficient choice for long-term chemical containment.

Why Center Enamel?

With over three decades of experience, Center Enamel has established itself as a global leader in the manufacturing of bolted steel tanks. Our GFS tanks are used across various industries and have been exported to over 100 countries. We pride ourselves on delivering reliable and high-quality wastewater tanks that exceed customer expectations. As a trusted wastewater tank manufacturer, we offer tailored solutions, industry expertise, and unmatched support to help our clients manage their wastewater storage and treatment needs effectively.

Center Enamel’s Glass-Fused-to-Steel tanks provide an efficient, rapid, and cost-effective solution for pharmaceutical wastewater storage and treatment. With their corrosion resistance, ease of installation, and compliance with environmental standards, these tanks are the perfect choice for pharmaceutical companies looking to manage their wastewater safely and sustainably. Whether you require a small-scale wastewater storage tank or a large-capacity treatment solution, Center Enamel’s GFS tanks are designed to meet your needs with precision and reliability.

For more information on how our bolted steel tanks can enhance your pharmaceutical wastewater treatment process, contact us today.

0 notes

Text

Quantra Quartz Countertops: Sustainable and Eco-Friendly Options

Introduction

In recent years, there has been a boom in demand for sustainable and eco-friendly building materials, driven by increased environmental consciousness and a dedication to green living. Quartz countertops, particularly those made by Quantra, have grown popular among homeowners and builders looking for environmentally friendly solutions. This article will look at the sustainability of Quantra quartz countertops, including its eco-friendly features, manufacturing procedures, and overall environmental impact.

Understanding Quartz Countertops

Quartz countertops are engineered stone products composed of natural quartz crystals mixed with resins, dyes, and other components. This combination results in a long-lasting, non-porous surface that is both visually appealing and very useful. Quantra, a well-known name in the market, has built a reputation for providing high-quality quartz countertops that meet strict environmental standards.

The Sustainability of Quartz

Material Composition:

Natural Quartz: The basic component of quartz countertops is natural quartz, a common mineral found in the Earth's crust. Using natural quartz reduces the need to quarry other, less abundant materials.

'Because the entire product is prefabricated to micron precision, our installations assure near zero debris and near zero ecological waste.'

Durability and Longevity:

Quartz countertops are renowned for their excellent durability. They are scratch, stain, and heat resistant, making them a durable solution for kitchens and bathrooms. This endurance decreases the need for frequent replacements, which lowers the overall environmental impact of manufacture and disposal.

Eco-Friendly Production Processes

Quantra employs several eco-friendly practices in the production of their quartz countertops:

Energy Efficiency:

The manufacturing process of quartz countertops requires energy-intensive operations such as mining, crushing, and heating. Quantra has invested in energy-efficient solutions to reduce its carbon footprint. These technologies include energy-efficient machinery, enhanced manufacturing processes, and the utilization of renewable energy sources whenever available.

Water Conservation:

Water is an essential resource in the manufacturing of quartz countertops, especially during the cutting and polishing processes. Quantra has used water recycling systems to cut their water consumption. By treating and reusing water within their facilities, they reduce the environmental impact on local water resources.

Waste Management:

Waste management is another critical component of Quantra's sustainability initiatives. Quartz countertop manufacture generates waste, such as offcuts, dust, and slurry. Quantra has created effective waste management procedures to repurpose or recycle these products, thereby minimizing the amount of garbage sent to landfills.

Environmental Certifications and Standards

Quantra quartz countertops meet several environmental certifications and standards, demonstrating their commitment to sustainability:

GREENGUARD Certification:

Quantra quartz countertops are GREENGUARD certified, indicating that they fulfill UL Environment's high chemical emissions standards. This accreditation assures that the countertops help to improve indoor air quality by generating minimal levels of volatile organic compounds (VOCs).

NSF Certification:

The National Sanitation Foundation (NSF) certification confirms that Quantra countertops are suitable for use in food preparation areas. This certification demonstrates the company's commitment to delivering hygienic and environmentally safe products.

ISO 9001 Certification:

Quantra's production facilities are ISO 9001 certified, and involves measuring quality in key areas like management responsibility, customer satisfaction, and resource management.

Health and Safety Benefits

Sustainable construction materials should not only be environmentally friendly, but also beneficial to the health and safety of occupants. Quantra quartz countertops have numerous health and safety advantages:

Non-Porous Surface:

Quartz countertops are non-porous, which makes them resistant to germs, mold, and mildew. This feature is especially helpful in kitchens and bathrooms, where hygiene is a priority.

Low VOC Emissions:

As previously stated, Quantra countertops release low amounts of VOCs, which contributes to improved indoor air quality. This is critical for lowering the risk of respiratory disorders and other health problems caused by poor air quality.

Aesthetics and Design Flexibility

Sustainability does not mean compromising on aesthetics or design flexibility. Quantra quartz countertops offer a wide range of colors, patterns, and finishes, allowing homeowners and designers to create beautiful, customized spaces. The ability to mimic the appearance of natural stone while offering superior performance makes quartz countertops an attractive and sustainable choice.

The Broader Environmental Impact

The environmental impact of using sustainable building materials goes beyond the immediate benefits for homeowners. Consumers may help to advance better building standards by supporting firms like Quantra that promote sustainability. This move has the potential to prevent environmental deterioration, conserve natural resources, and lower greenhouse gas emissions.

Reduced Resource Extraction:

The use of recycled materials in Quantra quartz countertops lowers the need to extract new raw materials, which frequently involve environmentally destructive mining activities. This resource conservation helps to protect natural ecosystems and lowers the environmental impact of construction operations.

Lower Carbon Footprint:

Quantra countertops have a lower carbon footprint due to their energy-efficient production techniques and usage of renewable energy sources. As the construction industry adopts more sustainable methods, the cumulative effect might considerably reduce global greenhouse gas emissions.

Promotion of Sustainable Practices:

By choosing eco-friendly products such as Quantra quartz countertops, consumers send a clear message to the market about their need for sustainable solutions. This motivates other manufacturers to adopt greener techniques, resulting in industry-wide transformation and encouraging a culture of sustainability.

Conclusion

Quantra quartz countertops are a sustainable and environmentally beneficial choice for current building projects. Their composition, production practices, and certifications demonstrate the company's dedication to environmental stewardship. By using Quantra countertops, homeowners and builders may get the benefits of long-lasting, beautiful surfaces while also contributing to a more sustainable future. As the demand for green building materials rises, companies like Quantra play an important role in establishing a more ecologically conscious construction industry.

0 notes

Text

Top 5 Applications of Submersible Pumps in Industrial Settings

Submersible pumps are highly versatile and widely used in various industrial settings due to their ability to operate efficiently underwater. Here are the top five applications of submersible pumps in industrial environments:

1. Mining Operations

Dewatering Mines: In mining, submersible pumps are essential for removing water from mining shafts, tunnels, and open-pit mines. These pumps handle water that may contain sediments, slurries, and other abrasive materials, helping to keep the mining area dry and safe for operations.

Handling Slurries: Submersible pumps can be used to move slurries containing ore, sand, or other solid particles. They are built to withstand the harsh conditions of mining environments, including corrosive and abrasive fluids.

2. Wastewater Treatment

Sewage and Sludge Management: Submersible pumps are a key component in wastewater treatment plants. They are used to pump sewage and sludge from one part of the treatment facility to another. These pumps are designed to handle solids and debris, ensuring the efficient movement of wastewater through the treatment process.

Aeration: In some wastewater treatment processes, submersible pumps are used for aeration, helping to mix air with the wastewater to promote the breakdown of organic materials.

3. Oil and Gas Industry

Offshore and Onshore Drilling: Submersible pumps are used in the oil and gas industry to manage water produced during drilling operations. This water often contains hydrocarbons, making it necessary to use robust pumps that can handle corrosive and explosive environments.

Subsea Operations: In offshore oil production, Submersible Pumps are deployed on the seabed to boost oil flow from wells to production platforms. These pumps operate under extreme pressure and temperature conditions, making them critical to the efficiency of subsea oil extraction.

4. Construction and Civil Engineering

Dewatering Construction Sites: Construction sites, particularly those involving excavation, often require dewatering to prevent flooding and maintain a dry work environment. Submersible pumps are used to remove groundwater and surface water, ensuring that construction can proceed without delay.

Foundation Work: In deep foundation projects, such as building basements or tunnels, submersible pumps help manage water ingress, ensuring that construction can be carried out safely and effectively.

5. Industrial Manufacturing

Cooling Systems: In manufacturing plants, submersible pumps are often used in cooling systems to circulate water or other cooling fluids. These systems are crucial for maintaining the temperature of machinery and preventing overheating.

Process Water Management: Submersible pumps are also employed to manage process water, including the transfer of water used in various manufacturing processes, from cleaning and rinsing to chemical mixing and waste disposal.

Submersible pumps play a crucial role in a wide range of industrial applications, from ensuring the safety of mining operations to supporting the complex processes in wastewater treatment and oil extraction. Their ability to operate efficiently in harsh and submerged environments makes them indispensable in industrial settings. For more info contact Submersible Pump Suppliers in UAE or call us at +971 4 2522966.

#Submersible Pumps#Submersible Pump Suppliers in UAE#Submersible Pump Suppliers in Dubai#Submersible Pump Suppliers

0 notes

Text

From Farm to Table: How Sugarcane Bagasse Transforms into Eco-Friendly Plates and Bowls

In an era where sustainability is paramount, finding alternatives to traditional disposable tableware is crucial. Enter sugarcane bagasse—an innovative material that transforms agricultural waste into eco-friendly plates and bowls. This journey from farm to table not only provides a sustainable solution but also showcases the incredible potential of renewable resources. Let's delve into the lifecycle of sugarcane bagasse products and understand how they contribute to a greener future.

Step 1: Harvesting Sugarcane

The journey begins in the lush fields where sugarcane is cultivated. Sugarcane, a tall perennial grass, is harvested primarily for its juice, which is processed to produce sugar. Once the juice is extracted, what remains is bagasse—a fibrous, pulpy residue.

Eco-Friendly Benefit: Utilizing bagasse for tableware manufacturing helps reduce agricultural waste, turning a byproduct into a valuable resource.

Step 2: Extracting Bagasse

After the sugar extraction process, the bagasse is collected and prepared for further processing. This involves drying the fibrous material to remove excess moisture, making it ready for the next phase.

Eco-Friendly Benefit: This process ensures that the maximum potential of the sugarcane plant is harnessed, promoting a zero-waste approach.

Step 3: Pulping and Molding

The dried bagasse is then pulped into a fine consistency and mixed with water to create a slurry. This slurry is poured into molds and subjected to high pressure and heat, forming sturdy and durable plates and bowls.

Eco-Friendly Benefit: The manufacturing process is energy-efficient and uses significantly less water compared to traditional paper production methods.

Step 4: Sterilization and Finishing

Once molded, the tableware undergoes sterilization to ensure it meets hygiene standards. The finished products are then trimmed, inspected, and packaged for distribution.

Eco-Friendly Benefit: The sterilization process ensures that the products are safe for food contact, maintaining the eco-friendly integrity without compromising on quality.

Step 5: Distribution and Use

Ecolates, a leader in sugarcane bagasse products in India, distributes these eco-friendly plates and bowls to businesses and consumers alike. From restaurants to households, these products serve as a sustainable alternative to plastic and styrofoam tableware.

Eco-Friendly Benefit: By choosing bagasse products, businesses and consumers reduce their reliance on non-renewable materials, significantly lowering their environmental footprint.

Step 6: Composting and Returning to Nature

One of the most remarkable aspects of sugarcane bagasse tableware is its compostability. After use, these plates and bowls can be composted, breaking down into organic matter that enriches the soil.

Eco-Friendly Benefit: Composting bagasse products closes the loop on waste, turning used tableware back into valuable nutrients for the earth, thereby supporting a circular economy.

The Environmental Impact: A Holistic View

The transformation of sugarcane bagasse into eco-friendly plates and bowls

offers multiple environmental benefits:

Reduction in Plastic Waste: Switching to bagasse products helps mitigate the pollution caused by single-use plastics.

Lower Carbon Footprint: The production process of bagasse tableware emits fewer greenhouse gases compared to plastic manufacturing.

Conservation of Resources: Utilizing agricultural byproducts conserves natural resources and reduces the demand for raw materials.

Ecolates: Pioneering Sustainable Tableware

Ecolates is at the forefront of this sustainable revolution, providing high-quality, eco-friendly plates and bowls made from sugarcane bagasse. Our commitment to environmental responsibility drives us to innovate and offer products that meet the needs of today while preserving the planet for future generations.

Why Choose Ecolates?

Durability: Our products are designed to be sturdy and reliable, ensuring they can handle various types of food without compromising on performance.

Eco-Friendly: Every plate and bowl is biodegradable and compostable, aligning with global sustainability goals.

Aesthetic Appeal: Our tableware is not only functional but also aesthetically pleasing, making it perfect for any occasion.

Conclusion: Embrace the Change

The journey of sugarcane bagasse from farm to table highlights the incredible potential of renewable resources in creating sustainable solutions. By choosing eco-friendly plates and bowls made from sugarcane bagasse, you are not only opting for a high-quality product but also contributing to a greener planet. Join Ecolates in embracing this change and make a positive impact on the environment, one plate at a time.

0 notes

Text

Portable Biogas Plant for Home: A Sustainable Solution

What is a Portable Biogas Plant?

A portable biogas plant is a compact, movable unit designed to digest organic waste materials, such as kitchen scraps, vegetable peels, and garden clippings. Through anaerobic digestion, these materials are broken down by bacteria in the absence of oxygen, producing biogas — a mixture of methane and carbon dioxide. The process also yields a nutrient-rich slurry that can be used as a fertilizer for plants.

Benefits of a Portable Biogas Plant for Home

**1. **Waste Reduction: One of the primary benefits of using a portable biogas plant for home is its ability to significantly reduce household waste. By converting kitchen and garden waste into biogas, you can decrease the amount of garbage that ends up in landfills, contributing to a cleaner environment.

**2. **Renewable Energy Production: Biogas produced by a portable biogas plant can be used for various energy needs at home. It can fuel gas stoves, heat water, and even generate electricity, providing a sustainable alternative to fossil fuels.

**3. **Cost Savings: Using biogas can reduce your dependency on traditional energy sources, leading to lower utility bills. Additionally, the by-product of the biogas process, a nutrient-rich slurry, can replace chemical fertilizers, saving you money on gardening supplies.

**4. **Environmental Impact: By opting for a portable biogas plant for home use, you help reduce greenhouse gas emissions. Methane, a potent greenhouse gas, is captured and used as a fuel instead of being released into the atmosphere from decomposing organic waste.

How to Set Up a Portable Biogas Plant at Home

Setting up a portable biogas plant for home use is relatively straightforward. Here are the basic steps:

**1. **Choose the Right Location: Select a spot with adequate sunlight and ventilation. The biogas plant should be placed on a stable surface, preferably close to the kitchen for easy waste disposal.

**2. **Install the Plant: Follow the manufacturer’s instructions to assemble the biogas plant. Ensure all connections are secure and the unit is properly sealed to prevent gas leaks.

**3. **Feed the Plant: Start by adding a mix of water and cow dung to activate the bacterial culture. Once the bacteria are active, gradually introduce kitchen waste, vegetable peels, and garden clippings.

**4. **Maintain the Plant: Regularly feed the biogas plant with organic waste and check for any maintenance needs. Stirring the contents occasionally can help maintain efficient digestion.

Applications of Biogas

A portable biogas plant for home use can provide several practical applications:

**1. **Cooking: Biogas can be used as a clean and efficient fuel for cooking, reducing reliance on LPG or other non-renewable energy sources.

**2. **Heating: Use biogas to heat water for domestic purposes, such as bathing and washing, thus cutting down on electricity consumption.

**3. **Electricity Generation: In some setups, biogas can be used to power small generators, providing a backup source of electricity for your home.

A portable biogas plant for home is an excellent way to embrace sustainability while managing waste and generating renewable energy. As more people recognize the benefits of this technology, it is likely to become a common feature in households striving for a greener future. By investing in a portable biogas plant for home use, you can take a significant step towards environmental conservation and energy independence.

#biogas#biogas in kerala#biogas in thrissur#biogas plant in kerala#biogas plant for home#incinerator manufacturers in kerala

0 notes

Text

How Batteries Are Made?

Have you ever wondered how batteries are made? This article explores the fascinating process of creating these essential power sources. We'll delve into the components that make up batteries, the step-by-step manufacturing process, how quality is ensured, and exciting innovations shaping the future of battery technology. Ufine Battery, a reliable lithium-ion battery manufacturer with a mature production process, demonstrates these advanced techniques. Learn how companies like Ufine Battery lead the way in battery technology.

Part 1. Understanding Battery Components

Essential Components of a Battery

Anode and Cathode:

The anode is typically made of a metal or alloy that releases electrons (such as lithium in lithium-ion batteries) during discharge.

Conversely, the cathode usually comprises a different material (like cobalt oxide in lithium-ion batteries) that accepts electrons during discharge.

This electron flow creates the electrical current necessary for powering devices.

Electrolyte:

The electrolyte is a chemical medium that allows ions to move between the anode and cathode.

It consists of a solvent (such as organic carbonates in lithium-ion batteries) and dissolved salts (like lithium salts), facilitating ion flow and ensuring efficient battery operation.

The specific composition of electrolytes can influence battery performance, including energy density and safety.

Separator:

The separator is a critical component that physically separates the anode and cathode while allowing ion transport.

It is often a porous membrane made from polyethylene or ceramic-coated fibers.

The separator prevents direct contact between the electrodes, preventing short circuits and maintaining the battery's integrity and lifespan.

Types of Batteries

Primary vs. Secondary Batteries:

Primary batteries are non-rechargeable and designed for single-use applications, such as alkaline batteries in remote controls and flashlights.

Secondary batteries are rechargeable and can undergo multiple charge-discharge cycles, like lithium-ion batteries in electric vehicles and portable electronics.

Common Battery Chemistries:

Alkaline Batteries: Known for their reliability and affordability, they are commonly used in everyday devices due to their long shelf life and stable performance.

Lithium-ion Batteries: Valued for their high energy density and lighter weight, they are suitable for portable electronics like smartphones and tablets.

Nickel-Cadmium Batteries: Recognized for their robustness and ability to handle high discharge rates, they are often used in power tools and emergency backup systems.

Part 2. Battery Manufacturing Process

1. Raw Material Preparation

Material Sourcing:

Raw materials like lithium, cobalt, nickel, graphite, electrolytes, and plastics are sourced globally from specialized suppliers.

Suppliers ensure materials meet stringent purity and quality standards to enhance battery performance and safety.

Purification and Processing:

Metals undergo refining processes to achieve high purity levels suitable for battery applications.

Chemicals and solvents undergo purification to remove contaminants that could affect battery performance.

2. Electrode Manufacturing

Mixing and Coating:

Active materials such as lithium cobalt oxide or graphite are mixed with binders and solvents to form a slurry.

This slurry is then uniformly coated onto thin metal foils (copper for cathodes, aluminum for anodes) using precision coating techniques.

Drying and Calendering:

Coated foils undergo drying in controlled environments to remove solvents and achieve optimal electrode thickness.

Calendering processes compress electrode layers to specific thicknesses, improving density and conductivity.

3. Cell Assembly

Stacking or Winding:

Electrodes and separators (polymer membranes) are stacked in precise layers to form a jelly-roll structure for cylindrical batteries.

Pouch and prismatic batteries involve folding or stacking flat electrode layers with separators.

Electrolyte Filling:

After assembly, batteries are filled with electrolytes that enable ion transport between electrodes during charge and discharge.

Careful filling techniques ensure consistent electrolyte distribution and prevent air pockets.

4. Formation and Aging

Initial Charging (Formation):

New batteries undergo formation cycles where controlled charging activates electrode materials and stabilizes cell chemistry.

This process optimizes battery capacity, performance, and longevity.

Aging and Testing:

Batteries undergo comprehensive testing to validate performance metrics such as capacity, cycle life, and temperature sensitivity.

Quality control tests ensure compliance with industry standards and regulatory requirements before batteries are released to market.

Part 3. Battery Quality Control and Testing

1. Inspection Techniques

Visual and Mechanical Inspections:

Visual inspections involve examining batteries for physical defects such as leaks, swelling, or damage to the casing.

Mechanical inspections assess the structural integrity by checking for proper assembly and alignment of components.

Electrical Testing:

Voltage testing measures the battery's electrical potential to meet specified voltage ratings.

Capacity testing evaluates the amount of charge a battery can store and deliver, which is crucial for assessing performance over time.

Internal resistance testing identifies impediments to current flow within the battery, which can affect efficiency and longevity.

2. Safety and Compliance

Standards and Regulations:

Batteries must comply with international standards such as IEC 62133, UL 2054, and UN 38.3, which outline design, construction, and testing safety requirements.

Compliance ensures that batteries are safe to use and transport globally, minimizing risks of fire, leakage, or other hazards.

Environmental Considerations:

Manufacturers implement eco-friendly practices throughout battery production to reduce environmental impact.

This includes using recyclable materials, minimizing waste generation, and adhering to disposal regulations for spent batteries.

Sustainable manufacturing practices aim to mitigate environmental harm and promote responsible end-of-life battery management.

Part 4. Advances in Battery Manufacturing

1. Innovations in Materials

New Electrode Materials:

Recent developments include silicon anodes, which can store up to ten times more energy than traditional graphite anodes.

Researchers are exploring lithium-sulfur batteries, which offer higher energy density and lower cost than lithium-ion batteries.

Another innovation is using graphene, a single layer of carbon atoms, which improves conductivity and enhances battery life.

Solid-State Electrolytes:

Solid-state electrolytes replace liquid electrolytes, making batteries safer by reducing the risk of leaks and fires.

These electrolytes improve energy density, allowing for longer-lasting batteries.

They also enable lithium metal anodes, which can significantly increase battery capacity.

2. Manufacturing Technologies

Automation and AI:

Automation in battery manufacturing ensures precision and reduces human error. Robots handle repetitive tasks like electrode coating and cell assembly.

AI optimizes production by predicting equipment maintenance needs and adjusting real-time parameters to improve yield and quality.

Machine learning algorithms analyze data from manufacturing processes to detect and correct anomalies, ensuring consistent battery performance.

3D Printing and Advanced Fabrication:

3D printing technology allows for the creation of custom battery designs that fit specific device shapes and sizes.

This technology can produce batteries with complex internal structures, improving energy density and reducing weight.

Advanced fabrication techniques, such as roll-to-roll processing, enhance the scalability of battery production, making it more cost-effective.

Part 5. Conclusion

Advances in battery manufacturing are driving better performance, safety, and efficiency. New materials and modern technologies are making batteries last longer and work better. As these innovations continue, batteries will meet the growing demands of our tech-driven world. This progress is essential for the future of energy storage and sustainability.

0 notes

Text

Sustainable Living with a Biogas Plant for Home Use

As sustainability becomes a necessity, installing a biogas plant for home use is an excellent way to make your household more eco-friendly. This article explores the steps and benefits of setting up a biogas plant for home use, transforming waste into valuable energy.

Understanding a Biogas Plant for Home Use

A biogas plant for home use converts organic waste into biogas through anaerobic digestion. This biogas can be utilized for various household applications, making it a versatile and renewable energy source.

Benefits of a Biogas Plant for Home Use

Eco-Friendly Solution: Reduces the amount of waste sent to landfills.

Energy Savings: Lowers energy bills by providing a free source of fuel.

Nutrient Recycling: Produces nutrient-rich slurry that can be used as natural fertilizer.

Steps to Set Up a Biogas Plant for Home Use

Site Selection: Choose a site with enough space, good ventilation, and access to sunlight.

Choosing the System: Decide between a fixed dome, floating drum, or prefabricated biogas plant.

Construction Process:

Digester Tank: Install a tank for anaerobic digestion.

Gas Storage: Set up a gas storage unit to collect the biogas.

Feedstock Inlet: Install an inlet for feeding organic waste into the digester.

Slurry Outlet: Ensure there is an outlet for removing the digested slurry.

Initial Feeding: Start with a small amount of organic waste mixed with water and gradually increase the quantity.

Regular Maintenance: Keep the plant functioning efficiently by feeding it regularly and checking for any leaks or blockages.

Practical Tips for Maintaining a Biogas Plant for Home Use

Optimal Temperature: Maintain a temperature around 35°C for optimal biogas production.

Balanced Feedstock: Use a mix of kitchen waste, agricultural residues, and animal manure for efficient digestion.

Safety Measures: Ensure the biogas plant is well-ventilated to prevent gas accumulation.

Conclusion

A biogas plant for home use is a significant step towards sustainable living. It aids in waste management, reduces energy costs, and contributes to environmental conservation. By following the outlined steps, you can successfully set up and maintain a biogas plant for home use, making your household greener and more self-sufficient.

#biogas in kerala#biogas plant for home#incinerator manufacturers in kerala#portable biogas plant for home

0 notes

Text

Tape-casting: Method for producing electronic ceramic sheets

High-performance ceramic materials have the characteristics of high strength, high hardness, wear resistance, and corrosion resistance, and are widely used in energy, information, aerospace, electronics, biology and medicine, and other fields. The ceramic molding method is an important factor in determining ceramic performance, and tape casting is currently one of the commonly used methods for producing electronic ceramic sheets.

Tape-casting

Tape casting refers to a molding method in which solvents, dispersants, binders, plasticizers, and other ingredients are added to ceramic powder to obtain a uniformly dispersed and stable slurry, and a film of the required thickness is produced on a tape casting machine.

Compared with other molding processes, tape casting has many advantages: the equipment and process are simple and can be produced continuously; single-phase or multi-phase ceramic sheet materials can be prepared; the product has small defects, uniform performance, high production efficiency, and can be operated continuously; uniform It can be produced in large and small batches and is suitable for industrial production. The biggest feature of tape casting is that it is very suitable for the preparation of large thin plate ceramic parts, which is difficult to achieve by pressing or extrusion molding processes. However, there are also some problems with tape casting. The main reason is that the binder content is high, so the shrinkage rate of the blank is large during the discharging glue process, and the thin sheets are prone to defects such as cracking, curling, and uneven thickness.

Tape-casting process

Tape casting was first used in the fields of papermaking, paint, and plastics. It is a long-standing molding technology that mainly includes processes such as slurry preparation, ball mill mixing, molding, drying, degreasing, and sintering.

Process flow chart for preparing ceramic substrates by tape casting

First, the ceramic powder and dispersant are added to the solvent (water or organic solvent), and the particles are agglomerated through ball milling or ultrasonic oscillation, and the solvent is allowed to wet the powder, and then the binder and plasticizer are added, and the particles are obtained by secondary ball milling. Stable and uniform slurry; then the slurry is formed on a casting machine to obtain a green body; then dried to evaporate the solvent, and the binder forms a network structure between the ceramic powders to obtain a green body film; and then the green body is formed The raw film is machined to obtain the specific shape required; finally, the required finished product is obtained through degreasing and sintering.

Application

Due to its simple equipment, continuous operation, high production efficiency, and uniform body performance, the tape casting method has become an important method for preparing large-area, ultra-thin ceramic substrates and is widely used in the electronics industry, energy industry, and other fields.

Also used in monolithic capacitor tiles, Al2O3 substrates for thick film and thin film circuits, piezoelectric ceramic diaphragms, structural ceramic sheets, capacitors, thermistors, ferrite and piezoelectric ceramic bodies, and hybrid integrated circuit substrates. It is also used in the field of mobile phone ceramic covers.

0 notes

Text

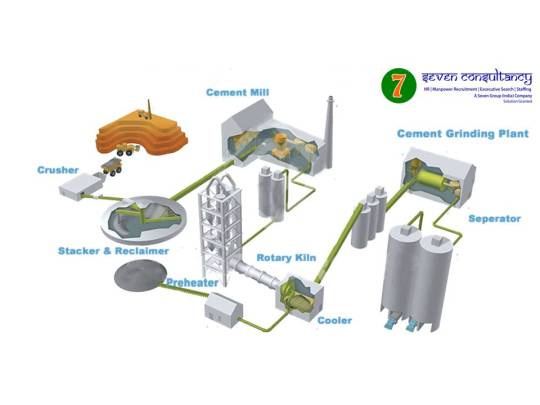

Being the top Cement plant recruiting nation, India provides the best workforce from different regions

Cement is a material that's used to build very strong, hard surfaces and structures. Cement is an ingredient in both mortar, which holds bricks together, and concrete, with which dams and roads and buildings are constructed. The making process of portland cement in the modern industry can be divided into the wet process, dry process, and semi-dry process. Nowadays, the dry process is the most popular cement making process which is widely adopted by cement plants all over the world for its great advantages in energy saving and environmental protection. The significant component in making cement is limestone which is first crushed then sent for pre-blending via belt conveyor. After this activity, the material is stored with other materials. These components are then extracted in precise proportions taking assistance of electronic weigh feeder. At the end the material is sent to raw mill for further fine grinding. The excavated materials are transported to the crushing plant by trucks, railway freight cars, conveyor belts, or ropeways. They also can be transported in a wet state or slurry by pipeline. Generally, limestone is 80% and remaining 20% is the clay. In the cement plant, the raw mix is dried, heavy wheel type rollers and rotating tables blend the raw mix and then the roller crushes it to a fine powder to be stored in silos and fed to the kiln.

As a leader in the cement and mining industries, they have taken on the responsibility of developing sustainable solutions. They have an ambition to engineer the zero emissions cement plant and the zero emissions mining process by 2030. And your know-how and innovative mindset will take them from idea to action. As Manager Standardization you will be heading a team of people who supports on the design automation across Mining products in the areas of Proposal, Pricing documents along with product optimization. Your responsibilities are estimate the time line and efforts required to complete the tasks or activities and communicate them to the counterpart, track the projects/tasks on its status and challenges with the onsite team, head the product Standardization team and execute various Standardization projects, organize gate meeting with stake holders and review the project progress, define the design automation required for the project/product and communicate with the team member, maintain the productivity and efficiency of the team, monitor the status of the projects/tasks and provide periodic update to the onsite team. Cement Plant Recruitment Agency in India provides services recruitment.

Recruitment is the process of actively seeking out, finding candidates for a specific position or job. The recruitment definition includes the entire hiring process, from inception to the individual recruit’s integration into the company. Searching out the sources from where required persons will be available for recruitment. If young managers are to be recruited then institutions imparting instructions in business administration will be the best source. Developing is the techniques to attract the suitable candidates. Best Cement Plant Recruitment Agency in India also provides consultancy service. They seek professionals through internal references from their employees, job postings on popular job search portals and recruitment consultants. You are invited to submit your resume on their website for current or future openings. They will maintain it in their database and will contact you in case your profile is suitable for a particular position. Outsourcing is an indirect source of talent. It is a major feature in the oil and gas and building sectors, with many key functions often subcontracted. Taken to the limit, the result is a virtual company directly employing little more than its directors. Finally, the cement industry needs people who can shape its future and create value. Looking to that future, leaders need to be aware that younger workers that they currently employ seek fulfillment, appreciation and being part of a greater goal, rather than just job security.

The last decade or so has seen a lot of growth in the outstanding capacity of cement production and consumption in India. Top Cement Plant Recruitment Agency in India also provides in consultancy sectors. They were already known to be one of the largest producers of cement in the world, and the future is only going to make that position stronger. With digitalization, a mystery can be revealed. Raw meal can be finely controlled to ensure the optimal mix to meet quality targets, while avoiding overspend on additives and higher-quality materials. This optimization brings benefits in terms of lower energy consumption and less wear on mechanical parts. All of which is great for the long-term sustainability of the industry. At higher levels of fuel substitution, such as those implied by BCG, that instability can only be controlled with the aid of digital control solutions.

#CementPlantRecruitmentAgencyinIndia#BestCementPlantRecruitmentAgencyinIndia#TopCementPlantRecruitmentAgencyinIndia

0 notes