#precision battery tester

Explore tagged Tumblr posts

Text

Semco SLB 5V 3A 8CH is an 8-channel pouch cell tester designed for precise lithium-ion battery analysis. Widely used in battery R&D and production for its reliability, speed, and smart control.

#Semco SLB 5V 3A 8CH#8CH pouch cell tester#lithium-ion battery tester#battery testing equipment#pouch cell testing machine#lithium battery testing system#multi-channel battery tester#5V 3A battery tester#battery R&D equipment#precision battery tester

0 notes

Text

For two days this week, Hezbollah has been rocked by a series of small explosions across Lebanon, injuring thousands and killing at least 25. But these attacks haven’t come from rockets or drones. Instead, they’ve resulted from boobytrapped electronics—including pagers, walkie-talkies, and even, reportedly, solar equipment—detonating in coordinated waves. As details come into view of the elaborate supply chain attack that compromised these devices, citizens on the ground in Lebanon and people around the world are questioning whether such attacks could target any device in your pocket.

The campaign to compromise key Hezbollah communication infrastructure with explosives was clearly elaborate and involved. The operation, which is widely believed to have been perpetrated by Israel, goes far beyond past examples of hardware supply chain attacks and may be a source of inspiration for future spycraft around the world. But sources tell WIRED that the specific scale and scope of the effort would not be easily replicated in other contexts. And, more broadly, the resources and precision involved in carrying out such an attack would be prohibitively difficult to maintain over time for key consumer devices like smartphones—which are used so widely and regularly scrutinized by researchers, product testers, and repair technicians.

“I do think there is absolutely potential to see more of this in the longer term, not targeting civilians, but generally targeting other military actors,” says Zachary Kallenborn, an adjunct nonresident fellow with the Center for Strategic and International Studies. Kallenborn says militaries are increasingly relying on commercial technology—from drones to communications devices—all of which could be compromised if supply chains can be exploited by adversaries. “These systems are being sourced from all over the globe,” he says. “What that means, then, is that you also have these global supply chains supporting them.”

While full details of the attacks are still coming to light, the devices that detonated were seemingly compromised with explosives before they arrived in Hezbollah members’ hands. Alan Woodward, a cybersecurity professor at the University of Surrey, says he suspects that an attacker would plant explosives in a device during the manufacturing process, rather than intercepting gadgets after they are finished and then taking them apart to plant explosives. Reporting by the New York Times on Wednesday evening seemed to confirm this theory, indicating that Israel directly manufactured the compromised devices via shell companies. Israel has not commented on any of the attacks.

Early theories that cyberattacks caused device batteries to overheat and explode have been ruled out by cybersecurity experts. The force of the blasts seen in on-the-ground footage would not be consistent with battery fires or explosions, especially given the small size of pager and walkie-talkie batteries.

Lebanon’s political landscape and ongoing economic crisis, coupled with regional fighting between Hezbollah and Israel, created specific opportunities for sabotage. Hezbollah is isolated globally, with countries like the United States and United Kingdom classifying it as a terrorist organization while other countries, such as Russia and China, maintain relations. This impacts Hezbollah’s avenues for importing equipment and vetting suppliers.

Amid ongoing violent conflict with Israel, Hezbollah’s digital communications and activities are also under constant barrage from Israeli hackers. In fact, this constant digital assault reportedly played a role in pushing Hezbollah away from smartphone communication and toward pagers and walkie-talkies in the first place. “Your phone is their agent,” Hezbollah leader Hassan Nasrallah said in February, referring to Israel.

The commercial spyware industry has shown it is possible to fully compromise target smartphones by exploiting chains of vulnerabilities in their mobile operating systems. Developing spyware and repeatedly finding new operating system vulnerabilities as older ones are patched is a resource-intensive process, but it is still less complicated and risky than conducting a hardware supply chain attack to physically compromise devices during or shortly after manufacturing. And for an attacker, monitoring a target’s entire digital life on a smartphone or laptop is likely more valuable than the device’s potential as a bomb.

“I’d hazard a guess that the only reason we aren’t hearing about exploding laptops is that they’re collecting too much intelligence from those,” says Jake Williams, vice president of research and development at Hunter Strategy, who formerly worked for the US National Security Agency. “I think there’s also potentially an element of targeting, too. The pagers and personal radios could pretty reliably be expected to stay in the hands of Hezbollah operatives, but more general purpose electronics like laptops could not.”

There are other more practical reasons, too, that the attacks in Lebanon are unlikely to portend a global wave of exploding consumer electronics anytime soon. Unlike portable devices that were originally designed in the 20th century, the current generation of laptops and particularly smartphones are densely packed with hardware components to offer the most features and the longest battery life in the most efficient package possible.

University of Surrey’s Woodward, who regularly takes apart consumer devices, points out that within modern smartphones there is very limited space to insert anything extra, and the manufacturing process can involve robots precisely placing components on top of each other. X-rays show how tightly packed modern phones are.

“When you open up a smartphone, I think the only way to get any sort of meaningful amount of high explosive in there would be to do something like replace one of the components,” he says, such as modifying a battery to be half battery, half explosives. But “replacing a component in a smartphone would compromise its functionality,” he says, which could lead a user to investigate the malfunction.

In contrast, the model of pager linked to the explosions—a “rugged” device with 85 days of battery life—included multiple replaceable parts. Ang Cui, founder of the embedded device security firm Red Balloon Security, examined the schematics of the pager model apparently used in the attacks and told WIRED that there would be free space inside to plant explosives. The walkie-talkies that exploded, according to the manufacturer, were discontinued a decade ago. Woodward says that when opening up redesigned, current versions of older technologies, such as pagers, many internal electronic components have been “compressed” down as manufacturing methods and processor efficiency have improved.

Smartphone production lines also operate under stricter security measures, especially for high-cost devices like Apple’s iPhones and Google’s flagship Pixel phones. This is partly to guarantee production quality, but also to ensure that employees don’t leak trade secrets or prototypes. Not all low-end Android phones are manufactured with such intense oversight, but it would be more difficult to secretly take over manufacturing of a smartphone than a forgotten pager model. In countries like China, where many devices are manufactured, there is always the possibility of a domestic operation to plant backdoors, but such a scheme would need to be elaborate to skirt international scrutiny of the devices

To find exploding cell phones, you have to go back to 20th century tech. In 1996, Palestinian bombmaker Yahya Ayyash was killed when his mobile phone exploded as he answered a call. His old-style phone—which the New York Times said was ”reportedly a small, slim model that fits in a pocket”—had 50 grams of explosives planted inside it, likely by Israel’s security services. The explosion was reportedly triggered by a radio signal emitted from a plane flying above. And unlike the pager and walkie-talkie attacks this week, Ayyash’s phone was part of a highly targeted attack on him alone.

Even if this week’s exploding device campaign doesn’t have immediate implications for every smartphone in every pocket, though, it expands enormously the specter of hardware supply chain attacks.

“I think that every shady organization worldwide will now be checking their new devices—especially those ordered in bulk from the manufacturer—for explosives,” says a longtime hardware hacker and tech procurement specialist who asked to be identified as Null Pointer. “This hit so hard because it was novel and no one in that community knew to look for it. It's ingenious.”

6 notes

·

View notes

Text

This is a low cost IR Tester for Lithium battery, suitable for single battery or battery pack with voltage no more than 200V

Specification:

Vapcell YR1030 Internal resistance tester is a great tester. Portable, easy, efficient, precise to test many types of batteries .

It can test lead acid, li-ion, Lipo, Lifepo4, alkaline cell ,dry cell, nickel hydrogen, nickel cadmium, coin cell, etc.

2 notes

·

View notes

Text

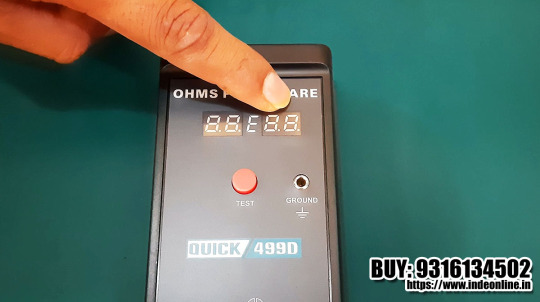

ESD Surface & Grounding Digital Resistivity Tester Model: 499D

Tests antistatic materials and insulations in compliance of ASTM Standard D-257.

Specifications:

Test range: 10³ ~ 10¹² Ω

Power: 9V battery

Resolution ratio: 0.1 order of magnitude

Precision: ±10%

Condition: 0°C~49°C, RH 0%–80%

Size: 130(L)×72(W)×35(H)mm

Weight: about 170 g (battery included)

#tester#Esdtester#esd tester#testers#static shock#static#tumblr engineering#engineering#repair#computer repair#tv repair near me

2 notes

·

View notes

Text

Growth of the EV Battery Testing Equipment Market

The EV Battery Electrical Testing Equipment Market plays a critical role in ensuring the safety, performance, and reliability of electric vehicle batteries. The necessity of stringent testing, inspection, and certification procedures has been highlighted by the rise in EV battery component failures. Additionally, the emergence of digital technologies is changing testing practices and making real-time, more accurate diagnosis possible. Manufacturers are investing in cutting-edge testing apparatus that supports battery cells, modules, packs, and Battery Management System (BMS) Hardware-in-the-Loop (HIL) simulation as battery technologies advance, opening the door for improved quality control and market expansion.

Key Growth Drivers

Increase of EV Battery Issues: High-accuracy testing solutions are in greater demand as the failure rate of EV battery components rises. To guarantee long-term safety, dependability, and battery life, these instruments are crucial for identifying even the smallest defects.

Testing's Digital Transformation: Battery testing is becoming much more accurate and efficient thanks to technologies like artificial intelligence (AI), machine learning, and real-time analytics. The market's growth is further supported by these tools, which make predictive maintenance, more intelligent diagnostics, and quicker decision-making possible.

Market Challenges

Regulatory Standards Are Changing: Manufacturers are constantly under pressure to upgrade their testing procedures and equipment due to changing testing laws, which can be expensive and time-consuming.

Connecting Legacy Systems: There may be financial and technical challenges when integrating cutting-edge testing technology with outdated infrastructure. This intricacy could increase implementation costs and hinder market penetration.

Key Market Players

Arbin Instruments

Tektronix

Keysight Technologies

Rohde & Schwarz

Dynamic Manufacturing, Inc.

ATEC

Chroma ATE

Fluke Corporation

Yokogawa Electric Corporation

Market Segmentation

By Application

Battery Cell

Battery Module and Pack

BMS HIL

By Product

Oscilloscopes

Digital Multimeters

Source Measure Units (SMUs)

Battery Management System Testers

By Region

North America

Europe

Asia-Pacific

Rest of the World

Download TOC for this report!

Learn more about Automotive Vertical. Click Here!

Conclusion

The need for dependable battery testing equipment is anticipated to increase significantly as the global shift to electric vehicles picks up speed. Stricter regulations, quick technological breakthroughs, and a quest for safer, better-performing batteries are all influencing the industry. The emphasis on digital precision and innovation places this market as a pillar of the EV industry's future success, despite obstacles including legacy system integration and standardization.

#EV Battery Testing Equipment Market#EV Battery Testing Equipment Industry#EV Battery Testing Equipment Report#automotive

0 notes

Text

Accurate Battery Probes Designed for Cable Testers

Use our Battery Contacts Probes to obtain precise readings. Explore our selection of dependable and accurate cable testing options at equip-test.com. Place your order right away to test effectively with our premium probes, which are perfect for your cable testing requirements. For additional details on this please call us at +361 533 3165.

0 notes

Text

Best Car Battery Tester for 12V Batteries: Top Picks

Best Car Battery Tester for 12V Batteries is essential for maintaining your vehicle’s performance. A reliable tester helps you monitor battery health and ensures your car runs smoothly. Car battery testers are essential tools for checking battery status. They help diagnose issues early, preventing unwanted breakdowns. For 12V batteries, finding the best tester can be a game changer for car maintenance. With various options available, choosing the right one might seem daunting. It's important to consider features, ease of use, and accuracy. An ideal tester provides clear readings and is user-friendly. Whether you're a car enthusiast or just want peace of mind, having a good battery tester is key. In this guide, we'll explore top picks that will keep your car's battery in top shape.

Introduction To Car Battery Testers

Car battery testers are essential tools for vehicle maintenance. They help you check the health of your car battery. With them, you can avoid unexpected breakdowns. These devices can save time and money by preventing battery failures. Understanding how a car battery tester works is crucial. It ensures your vehicle starts reliably every day. This knowledge gives peace of mind and enhances safety. Purpose And Importance The primary purpose of a car battery tester is to assess battery health. It detects issues before they cause problems on the road. Regular testing can extend the lifespan of your battery. It also prevents being stranded with a dead battery. Car battery testers are vital for identifying weak batteries. They help decide if your battery needs charging or replacement. This can improve vehicle performance and reliability. Common Features Most car battery testers come with an easy-to-read display. This feature shows important information like voltage and battery status. Some testers also offer digital or analog readings. Another common feature is the ability to test different battery types. Many testers support lead-acid, AGM, and gel batteries. This versatility makes them suitable for various vehicles. Some testers have advanced features like load testing. This checks the battery's ability to perform under stress. Such features provide a comprehensive assessment of battery health.

Credit: www.amazon.com

Key Factors To Consider

Choosing the best car battery tester for 12V batteries involves checking accuracy, ease of use, and durability. Ensure it provides clear display results and supports multiple battery types. Portability is also important for quick diagnostics on the go. Choosing the best car battery tester for your 12V batteries can feel like a daunting task. With so many options available, pinpointing the right one requires a careful look at several critical factors. Let's dive into the key aspects you should consider before making a decision. Accuracy And Reliability Accuracy is paramount when selecting a car battery tester. Imagine you're about to leave for a long road trip, and your battery tester gives a faulty reading. You could be stranded miles from help. Look for testers with a proven track record of precise measurements. Reliability goes hand-in-hand with accuracy. A reliable tester will give consistent results, ensuring your car’s battery health is monitored effectively. Consider models that have received positive reviews for their long-term performance. Brands with a history of producing quality automotive tools are often a safe bet. Ease Of Use A complex gadget can be frustrating, especially when you need quick results. Opt for a battery tester that's user-friendly. Check if it comes with a clear display and intuitive controls. A tester that requires minimal setup saves you time and hassle. Have you ever struggled with an overly technical manual? A good tester should have straightforward instructions that guide you through the process seamlessly. Some models even offer video tutorials online. Prioritize a tester that fits comfortably in your hand and is easy to connect to your battery. After all, convenience can make your car maintenance tasks more enjoyable. Ultimately, the best car battery tester is one that aligns with your needs and preferences. What features are most important to you? By focusing on accuracy, reliability, and ease of use, you're sure to find a tool that keeps your vehicle running smoothly.

Top Picks Overview

Choosing the best car battery tester for 12V batteries can be a daunting task with so many options available. You want something reliable, easy to use, and affordable. Let’s dive into the top picks that stand out in the market. Brand Reputation When selecting a car battery tester, considering the brand's reputation is crucial. Brands like Schumacher, NOCO, and Foxwell have built trust over the years. Their products are known for durability and accurate readings. Personally, I once bought a battery tester from a lesser-known brand, and it failed within a month. This taught me the importance of sticking with reputable brands that offer warranties and customer support. Trust can save you both time and money. User Reviews User reviews provide real-world insights that can guide your purchase. A tester with consistent five-star ratings often indicates reliability. Look for reviews that highlight features like ease of use and accuracy. Have you ever bought a product based on a friend’s recommendation? User reviews work similarly. They share honest experiences that can help you avoid potential pitfalls. Make sure to check multiple sources to get a well-rounded view. Ultimately, the best car battery tester for you will depend on your specific needs. Are you looking for something portable or more advanced with extra features? Consider what matters most to you in a tester and use this information to make an informed decision. Your car battery deserves the best care, and the right tester is the first step.

Credit: www.aliexpress.com

Noco Battery Tester

When you're stranded with a car that won't start, it's often the battery that's to blame. Knowing whether your battery is dead or just needs a charge can save you time and frustration. The NOCO Battery Tester is a handy tool designed to help you quickly assess the health of your 12V battery. This compact device provides accurate readings, making it an essential addition to your car maintenance toolkit. Features And Benefits The NOCO Battery Tester offers a range of features that make it stand out. It measures battery health and charge status, giving you precise data in seconds. It's compatible with most 12V batteries, ensuring you can use it with different vehicles. Its user-friendly design is another highlight. The tester provides easy-to-understand results, so you don't need to be a mechanic to interpret them. Plus, it’s small enough to keep in your glove box, so it's always ready when you need it. Imagine never having to guess whether your battery will hold up for that long road trip. This tester gives you peace of mind, letting you know exactly where your battery stands. Pros And Cons Using the NOCO Battery Tester comes with its advantages and disadvantages. On the plus side, it's quick and reliable. You get results in seconds, allowing you to make informed decisions without delay. Another benefit is its portability. You can easily carry it around or store it without hassle. However, while it offers great features, it might not suit every budget. Some users find it slightly pricier compared to basic models. Have you ever bought a tool you thought was perfect, only to find it had limitations? While the NOCO Battery Tester is excellent, it doesn't diagnose other car issues. It's focused solely on battery health, so you'll need other tools for a complete car check-up. So, how do you ensure your battery never lets you down? Investing in a reliable tester like NOCO could be the first step. Are you ready to take control of your car's battery health?

Schumacher Battery Tester

Schumacher Battery Tester stands out as a reliable choice for 12V batteries. Its user-friendly design ensures easy operation and accurate readings. Perfect for quickly diagnosing battery health, making it ideal for both beginners and experienced users. When you're on the lookout for a reliable car battery tester, the Schumacher Battery Tester should be on your radar. Known for its precision and user-friendly design, it offers a straightforward way to assess your 12V battery's health. Whether you're a seasoned mechanic or a car owner who enjoys a bit of DIY, this tool can make battery testing a breeze. Features And Benefits The Schumacher Battery Tester is packed with features that make it stand out. It's designed to test a variety of 12V batteries, including standard automotive, deep-cycle, and even AGM batteries. This tester provides clear digital readings, so you don't have to guess what's wrong with your battery. It even tells you the exact charge level and any potential faults. With its compact size, you can easily store it in your glove box or tool kit. Think about how handy it would be to test your battery on the spot without needing to visit a mechanic. Pros And Cons When considering the pros, the Schumacher Battery Tester is easy to use. Its intuitive interface means you don't need technical knowledge to operate it. Plus, the clear instructions ensure you get accurate results every time. Another pro is its durability. Built to last, it can withstand frequent use without any issues. On the downside, it doesn't offer Bluetooth connectivity, which some other modern testers do. If you're tech-savvy and love gadgets, this might feel like a missing feature. Also, it requires a separate power source to operate. This means you'll need to ensure you have the right setup before testing your battery. Have you ever found yourself stranded with a dead battery? A good tester like the Schumacher could save you from such situations. Why not add it to your toolkit and drive with peace of mind?

Topdon Battery Tester

If you've ever been stuck with a dead car battery, you know the frustration it brings. The TOPDON Battery Tester is a savior for those unpredictable moments. Designed to test 12V batteries, it's a reliable tool that ensures your vehicle is always ready to hit the road. This smart device gives you instant insights into your battery's health, preventing unexpected breakdowns. Features And Benefits The TOPDON Battery Tester is packed with features that make it a must-have tool in your garage. It delivers accurate readings in seconds, helping you diagnose battery issues swiftly. With a user-friendly interface, even those who aren't tech-savvy can operate it effortlessly. Imagine having a device that not only checks the battery's voltage but also evaluates its internal resistance. This tester offers that, providing detailed reports that help you understand the battery's condition better. It's compact and portable, meaning you can carry it around without hassle. Pros And Cons Let's weigh the advantages and disadvantages of the TOPDON Battery Tester. On the plus side, its precise measurements ensure you get reliable data every time. The ease of use is another highlight; you don't need a manual to figure it out. It's perfect for those who value convenience. However, like every product, it has its downsides. Some users might find its detailed reports overwhelming if they're only looking for a simple yes-or-no answer about their battery's health. Also, while it's designed for 12V batteries, it might not be suitable for other types. Have you ever found yourself questioning whether your car battery will last through your next road trip? With the TOPDON Battery Tester, those doubts are a thing of the past. What would it mean for you to have peace of mind knowing your battery's status? This tool offers just that, making it a worthy investment.

Comparing Top Models

Choosing the right car battery tester ensures your 12V battery performs well. With numerous models available, selecting the best can be challenging. Each tester has unique features and benefits. Let's delve into the top models for 12V batteries. We'll compare their performance and price. Performance Analysis Performance determines a tester's effectiveness. The Foxwell BT100 offers quick results. It checks battery health accurately. The Schumacher BT-100 delivers consistent performance. Ideal for both beginners and experts. The ANCEL BA101 boasts advanced technology. It diagnoses complex issues with ease. Choose based on your specific needs. Price Comparison Price matters when selecting a battery tester. The Foxwell BT100 is budget-friendly. Perfect for casual users. The Schumacher BT-100 sits in the mid-range category. It offers a balance of cost and features. The ANCEL BA101 is pricier. Its advanced features justify the cost. Consider your budget and requirements.

Credit: www.obdresource.net

Conclusion And Recommendations

The choice of the right car battery tester ensures your vehicle's reliability. Selecting the best tool prevents unexpected breakdowns. Different testers cater to various needs and budgets. Let's explore the best options for 12V batteries. Best Overall Choice The top choice for most users is the NOCO Battery Tester. It provides accurate results quickly. It is user-friendly and has a clear display. This tester works for both beginners and experienced users. It also comes with durable clamps and a compact design. Its reliability makes it the best overall choice. Value For Money Option The Ancel BA101 stands out for its affordability. It offers reliable performance at a lower cost. The device is easy to operate, with a straightforward interface. It tests various battery types efficiently. Users appreciate its clear readings and simple setup. It delivers great value without breaking the bank.

Frequently Asked Questions

What Is The Best Way To Test A 12v Battery? Use a multimeter to test a 12V battery. Set it to DC volts. Connect probes to terminals. A healthy battery reads around 12. 6 volts. Lower readings indicate a weak or dead battery. Regular testing ensures optimal performance and longevity. What Is The Most Accurate Tool To Use When Testing A Battery? A digital multimeter is the most accurate tool for testing a battery. It measures voltage, current, and resistance precisely. Ensure the multimeter is set correctly for the type of battery being tested. This tool helps in identifying battery health and performance efficiently. How Reliable Are Car Battery Testers? Car battery testers are generally reliable for quick diagnostics. They assess voltage and charge levels accurately. However, results can vary with tester quality. Ensure your tester is compatible with your battery type for precise readings. Regular maintenance and professional checks enhance battery reliability. Choose trusted brands for dependable testing results. What Size Multimeter Do I Need To Test A Car Battery? Choose a multimeter with a DC voltage range of at least 20 volts. It should accurately measure 12-volt car batteries. Ensure it has a digital display for easy reading. Compact and user-friendly designs are ideal for automotive use. Prioritize multimeters with a durable build and reliable brand reputation.

Conclusion

Choosing the right car battery tester matters. It ensures your battery's health and longevity. With many options available, focus on features that suit your needs. Look for ease of use, accuracy, and durability. A reliable tester saves time and money in the long run. Regular checks help avoid unexpected battery failures. So invest wisely and keep your car running smoothly. A good battery tester is essential for all car owners. Keep your 12V battery in top condition with the right tools. Make smart choices for peace of mind on the road. Read the full article

0 notes

Text

What Tools Are Used for Professional Truck Battery Replacement in Dandenong?

A good fleet is crucial to any Carrum Downs and Dandenong-based business. A key component to such reliability is the health and fitness of your truck batteries. Should replacement be necessary, it being professionally and efficiently carried out is necessary in preventing downtime and ensuring optimal output. Battery Boost & Key Rescue knows this and uses the right tools and expertise for top-notch truck battery replacement services. The following article talks about the professional truck battery replacement tools in Dandenong and why choosing the right service provider is important, especially when you need truck battery replacement in Carrum Downs.

Key Tools of the Trade

Truck battery replacement in Dandenong is more than can be done with a wrench and spare battery. Battery Boost & Key Rescue employs an advanced set of tools to bring safety, precision, and quality workmanship. Consider some of the most relevant components:

Battery Load Tester: It is utilized for testing the ability of the battery to provide power in the loaded condition. Pre-replacement load test indicates the true state of the battery in order to prevent unnecessary replacement and potential faults of the charging system. You may need to have this test conducted if you have problems at Dandenong or require assistance in truck battery replacement at Carrum Downs.

Digital Multimeter: A digital multimeter is essential in taking voltage, current, and resistance measurements. It verifies the resting battery voltage, searches for parasitic drains that siphon off a battery, and tests the charging system to ensure it's functioning correctly. With this precise measuring tool, technicians can accurately diagnose battery problems.

Battery Terminal Cleaner and Protector: Terminal corrosion is one of the primary causes of starting difficulty. Heavy-duty cleaners dissolve corrosion with ease, leaving a clean, tight connection. Protective sprays prevent corrosion in the future, extending the life of the new battery and its performance.

Wrench Set (Imperial & Metric): Trucks use various sizes of battery terminals, and a complete wrench set in imperial and metric is needed. This ensures proper and secure tightening of the battery terminals to prevent loose contacts and electrical issues.

Battery Lifting Strap/Caddy: The battery packs are usually heavy and awkward to handle. A battery carrier or a lifting strap provides a safe, ergonomic way to pull out and install the battery, reducing the risk of injury.

Memory Saver: Modern trucks are founded upon a great deal of electronic controls. Battery disconnection can cause loss of beneficial settings such as radio presets, seat positioning, and engine control module (ECM) adjustments. Memory saver provides the electrical system of the vehicle with momentary power when the battery is disconnected, thus preserving these beneficial settings.

Safety Equipment: Personal Protective Equipment (PPE) to start with. Safety glasses protect the eyes from acid splash, and gloves protect the hands from chemicals and electrical shock as well. Technician safety is of highest concern.

OBD-II Scanner: Many new trucks need to have battery replacement followed by resetting some of the parameters on the engine control unit (ECU). A mechanic can use an OBD-II scanner to communicate with the ECU and erase any error codes that may have been created in the process of replacing the battery. This is especially necessary for trucks that use advanced battery management systems.

Why Professional Tools Matter for Truck Battery Replacement

With the right equipment, not only is the battery replaced safely and effectively but also diagnosed accurately and properly installed within the system. Replacing a truck battery without the right equipment may lead to:

Vandalization of the Vehicle's Electrical System: Incorrect disconnecting or reconnecting the battery may damage sensitive electronic circuits.

Loss of Vehicle Settings: As mentioned earlier, battery disconnect without the use of memory saver can lead to irretrievable loss of settings.

Incorrect Battery Installation: Loose fitting terminals causing corrosion and sloppy connections can also lead to electrical problems.

Personal Injury: Handling big batteries and electricity is dangerous without protective equipment and procedure.

Battery Boost & Key Rescue: Your Trusted Partner for Truck Battery Replacement

Whenever you need reliable truck battery replacement in Carrum Downs or professional truck battery replacement in Dandenong, Battery Boost & Key Rescue is your answer. We combine advanced technology and very skilled technicians to offer a hassle-free and smooth service.

We understand the necessity of minimizing downtime for your operations. We're 24/7 mobile, visiting you rather. We have a wide array of premium quality truck batteries featuring a variety of makes and models to match for optimal performance and longevity.

Contact Battery Boost & Key Rescue today for expert truck battery replacement in Dandenong and truck battery replacement in Carrum Downs. Let us keep your fleet running smoothly and efficiently.

#truck battery replacement Hallam#truck battery replacement Lyndhurst#truck battery replacement Cranbourne#truck battery replacement Pakenham#truck battery replacement in Carrum Downs#Truck Battery Replacement in Dandenong

0 notes

Text

Mobile Game Testing Services Optimized for All Devices

Deliver a seamless mobile gaming experience with Testers Hub’s mobile game testing services. We run tests on many iOS and Android devices, uncovering issues like lag, crashes, UI misalignment, and battery consumption. Whether you're preparing for a beta or app store launch, trust our mobile game testing services for precision and performance.

0 notes

Text

Why Semco SI-K BCDS 120V 50A 4CH is a Game-Changer in Battery Testing?

The Semco SI-K BCDS 120V 50A 4CH Battery Tester is a high-efficiencylithium-ion battery testing solution designed for R&D labs and battery manufacturers. It provides multi-channel charge-discharge testing and supports advanced protocols like CAN communication for seamless BMS integration.

What Sets It Apart?

Wide voltage range (5V–120V) and ±50A per channel

Cycle life and capacity testing

Overcharge, discharge, and pulse simulations

Internal resistance (DCIR) evaluation

Superior Software & Communication

Run tests using a user-friendly Windows platform with real-time data plotting and export features. The system also supports RS232, RS485, and CAN 2.0.

Safety-First Design

Integrated protections against:

Overcurrent and reverse polarity

Over-temperature

Short circuits

Power-off memory for emergency stops

Efficiency and Expandability

>90% charging/discharge feedback efficiency

Low noise <75 dB

Auxiliary inputs for voltage and temperature monitoring

With 4 independent channels, this battery charge-discharge tester is perfect for high-volume production and precision testing environments.

#Semco SI-K BCDS 120V 50A 4CH#battery testing system#lithium-ion battery tester#battery charge discharge system#battery validation equipment#multi-channel battery tester#high-precision battery testing

0 notes

Text

GIM-5 Multi-channel Intelligent Resistivity & IP Meter: Redefining Subsurface Imaging Standards

Technological Paradigm Shift: From Conventional Methods to Intelligent ERT Systems

The High-Density Electrical Method, as an advanced evolution of DC Electrical Sounding, achieves 2D/3D Electrical Resistivity Imaging through intelligent electrode array networking. At its core lies Electrical Resistivity Tomography (ERT), which constructs millimeter-precision geological models by analyzing the three-dimensional distribution of subsurface electrical parameters.

Traditional single-channel systems are constrained by low data acquisition efficiency (daily coverage <0.5 km²) and limited detection depth (<500m). The GIM-5 system revolutionizes this with its 5-channel parallel acquisition architecture and patented segmented cabling technology, delivering:

400% efficiency improvement (daily coverage >5 km²)

Detection depth exceeding 1,500m

8x higher data density compared to conventional methods

Core Innovation: Engineering Implementation of Intelligent Acquisition

1. Multi-mode Electrode Management System

Featuring titanium alloy deep-water electrode arrays and bidirectional cascade controllers, the system enables:

IP68 underwater operation (100m depth endurance)

20% electrode fault tolerance

Auto grounding detection (±5Ω accuracy)

Technical Parameter Comparison:MetricConventional SystemsGIM-5Max Channels15/10 (expandable)Voltage Accuracy1%±5μV0.3%±1μVDynamic Range±24V±48VPower Output800W3,200W

2. Hybrid Array Synchronization Technology

Breaking through traditional Wenner-Schlumberger array limitations, GIM-5 pioneers the Tripole-Bipole Hybrid Mode:ρa=K⋅IΔV

With dynamically adjusted K-values, this innovation achieves:

30% vertical resolution enhancement (0.1m thin-layer identification)

50% lateral coverage expansion

40% reduction per measurement cycle

Full-scenario Applications: From Mineral Exploration to Urban Underground Space

1. Environmental Engineering Monitoring

In contaminant plume tracking Project, GIM-5’s 4D resistivity imaging demonstrates:

300×300m site scanning in 48 hours

Precise identification of 3 chloride sources (positioning error <2m)

Dynamic diffusion model accuracy R²=0.93

2. Urban Geological Surveys

In Metro Extension Project results using cross-hole measurement:

0.5m³ karst cavity detection at 30m borehole spacing

92% geological anomaly prediction accuracy

60% cost reduction vs traditional drilling

Intelligent Data Processing: Forward Modeling to Dynamic Inversion

1. Forward Modeling Optimization

GIM Studio software integrates FEM-BEM Coupled Algorithms, significantly accelerating modeling:

Complex geology modeling time: 6.8 minutes (vs 42 minutes conventionally)

Grid precision: 0.1m×0.1m×0.1m

2. Inversion Algorithm Advancements

ANN-TD Hybrid Inversion Architecture performance:Algorithm TypeResolution GainTime CostMemory UsageConventional LSQBaseline120min8GBNeural Network+40%25min3GBTime-Dynamic+65%18min5GB

Sustainable Engineering Solutions

GIM-5’s modular design enables full lifecycle management:

SPB900 Smart Power Unit: 850WH Li-ion battery with multi-unit series support

Segmented Cable System: 70% replacement cost reduction

OTA Wireless Updates: Firmware upgrades without factory return

Explore Revolutionary GIM Series Now

Visit Product Page Now https://geotechcn.net/products/electrical-instrument/gim-1-single-channel-intelligent-resistivity-ip-meter%e4%b8%a8high-density-resistivity-tester/

Whether you’re engaged in environmental monitoring, mineral exploration, or urban underground space development, the GIM Series DC Electrical System delivers tailored solutions. Our product page features:

Technical comparisons of full series (GIM-1/GIM-5/GIM-10)

Latest underwater detection kit specifications

Typical engineering configuration packages

Global case study video demonstrations

0 notes

Text

Essential PAT Testing Equipment: The Complete Guide for Safe and Compliant Electrical Testing

Introduction to PAT Testing Equipment

When it comes to electrical safety, few practices are as crucial as Portable Appliance Testing (PAT). Whether you're managing a commercial property, running a business, or overseeing rental properties, ensuring your electrical appliances are safe is a legal and ethical responsibility. And at the heart of effective PAT testing is the equipment you use.

In this guide, we’ll explore the types of PAT testing equipment, what to look for when purchasing them, and how using the right tools can keep your workplace safe and compliant with UK regulations.

What is PAT Testing?

PAT testing, or Portable Appliance Testing, involves the routine inspection and testing of electrical appliances to ensure they’re safe for use. This process detects potential hazards like faulty wiring, damaged plugs, or insulation problems before they become dangerous.

While visual inspections are a part of PAT testing, dedicated PAT testing equipment ensures comprehensive and reliable results by measuring earth continuity, insulation resistance, and leakage current.

Types of PAT Testing Equipment

The type of PAT testing equipment you need depends on the nature of your premises, the number of appliances you manage, and the complexity of the testing involved. Here’s a breakdown of the common types:

1. Manual PAT Testers

These are simple, cost-effective devices ideal for smaller premises or for those carrying out occasional testing. They typically provide basic pass/fail results for earth continuity, insulation resistance, and polarity.

2. Digital PAT Testers

More advanced than manual testers, digital PAT testers provide precise numerical readings. Many models offer additional features like leakage current tests, data storage, and printout capabilities.

3. Downloadable PAT Testers

Ideal for businesses managing large appliance inventories, these testers allow you to store data for each appliance and download test results to a computer for easy record-keeping and reporting.

4. Dual Voltage PAT Testers

These testers can operate at different voltages (110V and 230V), making them suitable for testing construction site equipment or appliances used in different environments.

Key Features to Look for in PAT Testing Equipment

Investing in high-quality PAT testing equipment means greater accuracy, reliability, and ease of use. Here are the key features you should consider:

Automatic Testing Sequences: Saves time by automating test sequences.

Clear Pass/Fail Indicators: Visual indicators for instant, on-site results.

Data Logging and Storage: Essential for large facilities or businesses with numerous appliances.

Built-in Printer Connectivity: Enables direct printing of PAT test labels.

Battery and Mains Operation: Flexibility for testing in various locations.

User-friendly Interface: Intuitive menus and clear displays reduce errors and training time.

Top Brands for PAT Testing Equipment

When it comes to choosing reliable and trusted PAT testing equipment, several brands stand out in the UK market:

Seaward: Known for robust, professional-grade testers with advanced features.

Megger: Offers a wide range of testers from basic models to fully featured devices with downloading options.

Kewtech: Popular for their ease of use and reliability, suitable for both professionals and occasional testers.

Fluke: Renowned for high-quality electrical testing tools with durable construction.

How to Use PAT Testing Equipment

PAT testing equipment typically comes with comprehensive user manuals, but the general testing process involves:

Visual Inspection: Check for obvious signs of damage like frayed cables, cracked plugs, or missing insulation.

Connect the Appliance to the Tester: Attach leads to the appropriate points on the appliance.

Run the Required Tests: Depending on the device and test type, this could include earth bond tests, insulation resistance tests, and leakage current tests.

Record the Results: Store the results manually or electronically.

Label the Appliance: Attach a PAT test label indicating pass or fail, date of test, and next test due.

Legal Requirements for PAT Testing in the UK

While the UK doesn’t mandate a fixed frequency for PAT testing, regulations such as the Health and Safety at Work Act 1974, the Electricity at Work Regulations 1989, and the Provision and Use of Work Equipment Regulations 1998 require employers and landlords to maintain safe electrical equipment.

Having the right PAT testing equipment is critical to meet these obligations efficiently and to demonstrate compliance through proper record-keeping.

Benefits of Investing in Professional PAT Testing Equipment

Enhanced Safety: Reduces risks of electrical fires, shocks, and appliance failure.

Regulatory Compliance: Ensures you meet legal obligations with documented evidence.

Operational Efficiency: Speeds up testing processes, especially in larger facilities.

Reduced Maintenance Costs: Identifies minor faults before they lead to costly repairs.

Peace of Mind: Knowing your environment is safe for staff, tenants, and visitors.

Where to Buy PAT Testing Equipment

You can purchase PAT testing equipment from specialist electrical suppliers, online retailers, or professional service providers like City PAT Testing. It’s important to choose certified equipment from trusted sources to guarantee quality and compliance.

If you need advice on the best PAT testing tools for your business, City PAT Testing is always ready to help. Visit our website for expert guidance, PAT testing services, and the latest in portable appliance safety.

Conclusion

Investing in the right PAT testing equipment is not just about compliance — it’s about creating a safer environment for everyone. Whether you’re an office manager, landlord, or construction site supervisor, using quality testing tools ensures your appliances remain safe, operational, and legally compliant.

Stay proactive, stay safe, and choose the right equipment for the job with expert support from City PAT Testing.

Call us : 01423 534 666 Email : [email protected] Website : https://citypat.co.uk/

0 notes

Text

Key Players and Competitive Landscape in EV Battery Testing Equipment Market

The EV Battery Electrical Testing Equipment Market plays a critical role in ensuring the safety, performance, and reliability of electric vehicle batteries. The necessity of stringent testing, inspection, and certification procedures has been highlighted by the rise in EV battery component failures. Additionally, the emergence of digital technologies is changing testing practices and making real-time, more accurate diagnosis possible. Manufacturers are investing in cutting-edge testing apparatus that supports battery cells, modules, packs, and Battery Management System (BMS) Hardware-in-the-Loop (HIL) simulation as battery technologies advance, opening the door for improved quality control and market expansion.

What factors are driving growth in the EV battery testing equipment market?

Increased Cases of EV Battery Component Failures: The requirement for strict quality control has increased due to the growing number of EV battery component failures and faults. The need for high-precision testing tools that can identify even small flaws to guarantee battery longevity, safety, and dependability is being fueled by this development.

Integration of Digital Technologies: The accuracy and effectiveness of battery testing procedures are being greatly improved by the use of cutting-edge digital technologies, such as artificial intelligence (AI), machine learning, and real-time data analytics. Better diagnostics, predictive maintenance, and quicker decision-making are made possible by these advancements, which propel market expansion even more.

What are the key challenges faced by manufacturers of EV battery testing equipment?

Challenges with Evolving Testing Standards: Manufacturers must constantly update and modify testing procedures and equipment to be compliant due to the ongoing evolution of testing requirements.

Integration Difficulties with Legacy Systems: There are financial and technological obstacles when integrating new digital technologies and sophisticated testing techniques with legacy systems. This intricacy may hinder market expansion by delaying acceptance and raising operating expenses.

Who are the key manufacturers of EV battery electrical testing equipment?

Arbin Instruments

Tektronix

Keysight Technologies

Rohde & Schwarz

Dynamic Manufacturing, Inc.

ATEC

Chroma ATE

Fluke Corporation

Yokogawa Electric Corporation

What types of electrical testing equipment are used for EV batteries?

To assess EV batteries, a variety of electrical testing tools are necessary. Voltage testers for monitoring voltage stability, charge/discharge testers to simulate real-world usage, insulation resistance testers to ensure safety and prevent electrical faults, and battery analyzers for measuring overall capacity and performance are a few examples. When used in tandem, these resources contribute to the reliable, safe, and effective operation of EV batteries over the course of their lifetime.

Which regions have the highest demand for EV battery electrical testing equipment?

Asia-Pacific (especially China, Japan, and South Korea) leads due to strong EV manufacturing, followed by North America and Europe with expanding EV adoption.

Download TOC for this report!

Learn more about Automotive Vertical. Click Here!

Conclusion

The market for EV battery electrical testing equipment is expected to grow significantly as the global electric car market picks up speed. Innovation in testing methods is being fueled by the growing need for safer, more effective batteries as well as by the quick development of new technologies and the tightening of regulatory standards. The market's emphasis on digitization and precision testing prepares it for ongoing growth, despite difficulties with standardization and system integration. As such, it is a crucial enabler of the future success of the EV ecosystem.

#EV Battery Testing Equipment Market#EV Battery Testing Equipment Industry#EV Battery Testing Equipment Report#automotive

0 notes

Text

Accurate Battery Probes Designed for Cable Testers

Use our Battery Contacts Probes to obtain precise readings. Explore our selection of dependable and accurate cable testing options at equip-test.com. Place your order right away to test effectively with our premium probes, which are perfect for your cable testing requirements. For additional details on this please call us at +361 533 3165.

0 notes

Text

Why and how are LED headlights legal? They are so bright that they are a real hazard at night.

The legality of LED headlights is based on their compliant design, strict regulatory certification and correct installation, but in reality, there are indeed glare problems caused by abuse, inferior modifications or optical mismatch. The following is an in-depth analysis of technical, regulatory and social factors:

1. The core reasons for the legality of LED headlights

1. Regulatory certification standards

North America (DOT/SAE):

The FMVSS 108 standard limits the brightness of the low beam (≤ 20,000 candela) and the height of the beam cutoff line (to prevent direct light from oncoming drivers).

Europe (ECE R112):

Requires that the low beam must have an asymmetric Z-shaped cutoff line (lower on the left and slightly higher on the right) to ensure that the road signs are illuminated but not dazzling.

China (GB 25991):

The LED color temperature must be between 4300K–6000K, and high color temperature blue light (>6500K) is prohibited.

2. Design guarantee of original LEDs

Optical precision: Original assemblies (such as Audi Matrix LED) have built-in lenses and reflectors to ensure that the light pattern strictly complies with regulations.

Adaptive function: Automatically adjust the beam angle (according to vehicle speed/turning) or shield oncoming vehicles (such as Mercedes-Benz Digital Light).

3. Energy efficiency and safety progress

LEDs save 50% energy compared to halogen lamps, reduce battery load, and have no mercury pollution (in compliance with environmental regulations such as EU RoHS).

2. LEDs become the root cause of "road pollution"

1. Illegal modifications are rampant

Directly replace halogen bulbs:

The original car reflector is not optimized for LEDs → beam scattering (NHTSA statistics show that such modifications lead to a 23% increase in the risk of night accidents). Using LED headlight bulbs with adjustable lamp bodies and light patterns can be adjusted to standard light patterns to avoid beam scattering.

Using uncertified products:

Inferior LEDs have falsely marked lumens (nominal 20,000 lumens, only 9,000+ in actual measurement), and the color temperature exceeds the standard (7000K cold white light, with light blue light at the edge of the light pattern).

2. Installation error

The self-modifier did not adjust the beam angle (the low beam should be less than 0.7 meters at 50 meters from the ground), causing the actual cutoff line to be tilted, thus causing glare to the oncoming driver.

3. Vehicle height difference

The LED headlights of SUVs/pickup trucks are installed at a high position, which will cause downward glare to car drivers even if they are compliant (IIHS calls for the establishment of height compensation standards).

III. Global measures to deal with LED glare

1. Technical improvement

ADB (Adaptive High Beam):

Identify oncoming vehicles through cameras and dynamically block part of the beam (such as Toyota AHS).

Laser auxiliary lighting:

The laser module of the BMW i8 is only activated on high-speed straights to avoid urban use.

2. Strengthening regulations

United States: In 2021, NHTSA proposed that new cars should be equipped with automatic dimming as standard (ANPRM 2021-0082).

EU: In 2023, new cars will be required to be equipped with ADB (ECE R149).

3. Law enforcement and education

Tightening annual inspections: Some areas in China use glare testers (threshold ≤ 225 cd/lx) to screen illegal modifications.

Public education: AAA in the United States issued the "Guide to the Correct Use of Headlights" to popularize the method of beam adjustment.

IV. User response suggestions

Purchase compliant products: Look for compliance certification marks to avoid unbranded goods on Amazon/eBay.

Professional installation and debugging: After modification, be sure to use a headlight calibrator to adjust the angle (cost 20–50).

Anti-glare tools: Wear yellow polarized glasses for night driving (filter blue light below 450nm).

Use an anti-glare rearview mirror (such as an automatic anti-glare rearview mirror).

Future Outlook

Smart road projection: Mercedes-Benz Digital Light can project zebra crossings or warning symbols to replace high beam communication.

V2X collaborative dimming: The Internet of Vehicles enables lighting collaboration between vehicles and globally optimizes lighting safety.

Legal LED headlights are an improvement, but the simultaneous evolution of regulations, technology and public awareness is needed to eliminate hidden dangers.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#american cars#cars#car culture#car#classic cars#car light#legal#legal advice#headlight bulb#headlamp#headlight

1 note

·

View note