#precision-machined-components-manufacturers

Text

#precision-machined-components-manufacturers#machined-parts-manufacturer#small-parts-manufacturing-machine-shops#precision-parts-manufacturer#high-precision-machine-shop

0 notes

Video

youtube

DY cast & forge a forging is a manufacturing company based on India & Se...

#youtube#www.dycastandforge.com#steelforging#Steel casting#steel machinery#Dy Impex manufactures Precision Machined components & Assemblies through the CNC VMC and Conventional Machines. And having the well known a

2 notes

·

View notes

Text

The Importance of Precision Machined Components in Modern Manufacturing

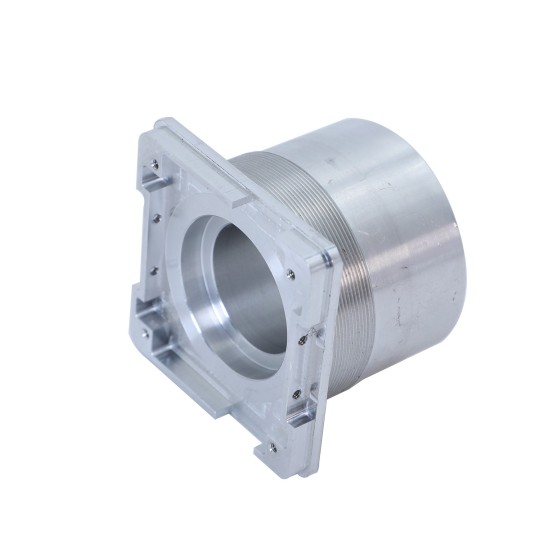

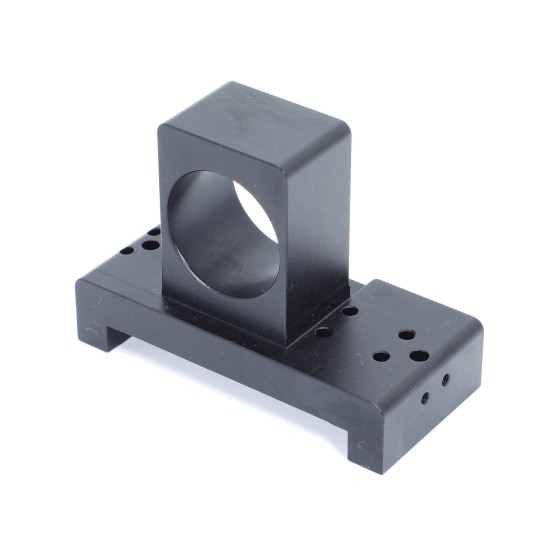

In today’s competitive manufacturing landscape, precision and accuracy are paramount. Precision machined components play a crucial role in ensuring the quality and functionality of products across various industries, from automotive to aerospace. At CMD Precision Products, we specialize in producing high-quality, precision machined components that meet the stringent demands of modern manufacturing.

What Are Precision Machined Components?

Precision machined components are parts or products that have been manufactured to very tight tolerances. This means that every dimension, surface finish, and feature of the component is crafted with exacting precision. These components are typically produced using advanced machining processes such as CNC (Computer Numerical Control) milling, turning, and grinding. The accuracy and repeatability of these processes ensure that each component meets the specified design requirements.

Why Precision Machined Components Are Essential

1. Enhanced Product Performance

Precision machined components contribute directly to the performance of the final product. Whether it’s an engine part, a medical device, or an electronic component, the precision with which these parts are made ensures that they fit together seamlessly and function as intended. For instance, in the automotive industry, precision machined components such as gears and bearings are essential for smooth operation and long-lasting performance.

2. Consistency and Reliability

In manufacturing, consistency is key. Precision machining allows for the production of components with consistent quality, batch after batch. This consistency is critical in industries like aerospace, where even the smallest deviation from the specifications can lead to catastrophic failures. At CMD Precision Products, our state-of-the-art equipment and rigorous quality control processes ensure that every component we produce meets the highest standards of reliability.

3. Cost-Effectiveness

While the initial investment in precision machining equipment and processes can be high, the long-term benefits often outweigh the costs. Precision machined components reduce the need for rework, minimize waste, and improve assembly efficiency. This leads to significant cost savings in the production process. Additionally, the longevity and reliability of precision components can reduce maintenance costs and extend the lifespan of the final product.

4. Innovation and Customization

Precision machining opens up a world of possibilities for innovation and customization. Manufacturers can design complex, intricate components that were previously impossible to produce with traditional machining methods. This capability is particularly valuable in industries such as medical devices and electronics, where miniaturization and precision are critical. CMD Precision Products works closely with our clients to develop custom solutions that meet their specific needs, ensuring that they stay ahead of the competition.

The Role of Technology in Precision Machining

Advancements in technology have played a significant role in the evolution of precision machining. CNC machines, for example, have revolutionized the industry by allowing for greater automation, precision, and repeatability. These machines are controlled by computer programs that can execute complex machining operations with incredible accuracy. At CMD Precision Products, we leverage the latest CNC technology to deliver precision machined components that meet the most demanding specifications.

Quality Control in Precision Machining

Quality control is a critical aspect of precision machining. Even the slightest deviation from the specifications can compromise the integrity of the final product. This is why rigorous inspection and testing processes are essential. At CMD Precision Products, we employ advanced measurement tools and techniques, such as coordinate measuring machines (CMMs) and optical inspection systems, to ensure that every component we produce meets the required tolerances.

Applications of Precision Machined Components

Precision machined components are used in a wide range of industries, including:

- Automotive: Engine parts, transmission components, and braking systems.

- Aerospace: Aircraft engines, landing gear, and structural components.

- Medical Devices: Surgical instruments, implants, and diagnostic equipment.

- Electronics: Connectors, housings, and micro-components.

- Energy: Turbine blades, valves, and pumps.

Each of these industries relies on precision machined components to ensure the safety, performance, and reliability of their products. CMD Precision Products has extensive experience in producing components for these industries, and we understand the unique challenges and requirements that each one presents.

CMD Precision Products: Your Partner in Precision

At CMD Precision Products, we are committed to delivering the highest quality precision machined components to our clients. Our team of skilled machinists and engineers work tirelessly to ensure that every component we produce meets the exact specifications of our clients. We pride ourselves on our ability to tackle even the most complex and challenging projects, and our dedication to quality and customer satisfaction is unmatched.

Conclusion

Precision machined components are the backbone of modern manufacturing, enabling the production of high-quality, reliable, and innovative products. At CMD Precision Products, we are proud to be at the forefront of this industry, providing our clients with the precision components they need to succeed. Whether you are in the automotive, aerospace, or electronics industry, you can trust CMD Precision Products to deliver the precision and quality you require.

Investing in precision machined components is investing in the future of your products and your business.

0 notes

Text

Global Precision - leading CNC machined components manufacturers. Get high-quality CNC custom machined parts, and customized solutions for your needs.

#global precision#CNC machined components#CNC machined components manufacturers#CNC components manufacturer delhi

1 note

·

View note

Text

Precision Machined Components for Superior Performance

Discover the excellence of precision machined components, essential for various industries including automotive and aerospace. Our expertise in manufacturing precision machining parts ensures high-quality machine parts that meet stringent standards. As a leading machine parts manufacturer, we provide innovative solutions tailored to your needs, enhancing efficiency and reliability in your operations. Trust us for your precision machining requirements and experience unparalleled quality and performance in every component.

#precision machined components#machining components#precision machining parts#machine parts manufacturer

0 notes

Text

Reliable Precision Parts Manufacturer in Ahmedabad

Scharf Precision Engineering is a well-known manufacturer of precision parts in Ahmedabad. We specialize in manufacturing precision parts with excellent expertise and cutting-edge technology as per the customer’s specific design and requirement at the best price.

#Precision Parts#Precision Parts Manufacturing#Precision Parts Manufacturer#Precision Components#Precision Machined Parts#Micro Components Manufacturer#Ahmedabad

1 note

·

View note

Text

Unitritech Leading the Way in Aerospace Machined Components Manufacturing

In the highly specialized field of aerospace manufacturing, precision and reliability are paramount. Among the key players in this industry, Unitritech stands out as the premier manufacturer of aerospace machined components. With a steadfast commitment to quality, innovation, and customer satisfaction, Unitritech has earned its reputation as the best in the business.

Unitritech's expertise in producing high-precision machined components ensures that every part meets the stringent standards required for aerospace applications. Their state-of-the-art manufacturing facilities are equipped with the latest technology, allowing for unparalleled accuracy and consistency. This dedication to excellence extends to their rigorous quality control processes, which guarantee that every component is meticulously inspected and tested before it reaches the customer.

One of the key factors that set Unitritech apart is their ability to handle complex and challenging projects. Whether it's producing intricate parts for commercial aircraft or custom components for military applications, Unitritech's skilled team of engineers and technicians possess the knowledge and experience to deliver exceptional results. Their innovative approach to problem-solving and continuous improvement ensures that they remain at the forefront of the industry.

In conclusion, Unitritech's commitment to precision, quality, and innovation makes them the best choice for aerospace machined components manufacturing. Their dedication to exceeding customer expectations and their proven track record of excellence solidify their position as industry leaders.

#High Precision Aerospace Machined Components#Advanced Aerospace Component Manufacturing#Custom Aerospace Machining Services#Leading Aerospace Machined Parts Supplier#Top Aerospace CNC Machining Company#Aerospace Precision Machining Experts#Quality Aerospace Manufacturing Solutions#Reliable Aerospace Machined Parts Manufacturer

0 notes

Text

Reasons to Use Aluminum for Die-Casting

There are various popular processes you can use to form aluminum; however, one of the most common processes that a designer considers is aluminum die casting.

Nowadays, Aluminium Die Casting Companies use the method for many automotive, industrial, and telecommunication products. In fact, it is also utilized to create electrical hydraulic, and lighting components.

Overview of Aluminum Die Casting

To put it simply, it is a metal-forming process that enables the design of intricate aluminum parts. To initiate the process aluminum alloys are heated to excessively high temperatures until they are molten.

Furthermore, under high pressure, liquid aluminum is inserted into the hole of the steel die. Since the die is made up of two halves, the solid molten aluminum gets separated and displays the aluminum part. The product is developed explicitly with a soft texture and usually needs the tiniest and no machining process.

The Advantages of Aluminum Die-Casting

Its Weight

Aluminum is hugely favored for its lightweight quality. Since it is the lightest metal, it is no great surprise that Aluminum Die-Cast parts are highly sought after in the aviation and motor industries.

Flexibility

Are you looking for a metal that’s easy to work? Aluminium is the answer! Since it is the second malleable metal and ductile – it is hard to beat in terms of flexibility.

Conductivity

Aluminum is a great electrical and thermal conductor. Though copper is even more conductive – it is heavier which can often be a disadvantage. It is only a third of the weight of copper. Adding to the fact, that aluminum is non-sparking – it is the chosen metal for various applications including electrical products, computer parts, and LED lighting.

Resistance to Corrosion

Thanks to the strong oxide film – it forms on the surface of aluminum when it is exposed to air or water. It is highly resistant to corrosion. The coat of aluminum oxide hardens the surface and keeps the metal free from corrosion.

Bottom Line

Aluminium is 100% recyclable. Aluminum can be melted down and reused without its favorable quality. Apart from the topmost quality – there are more advantages to using aluminum in die casting.

#precision manufacturing#precision machining companies#cnc machining service#die casting companies#die cast metal#aluminium die casting#aluminum alloy die casting#medical device companies#machining medical devices#medical equipment parts#medical component supplier#optical manufacturing#medical parts supplier

1 note

·

View note

Text

What are the Industrial Applications of Precision Machined Components?

Aerospace Industry: Precision machined components are extensively used in aerospace applications, including aircraft engines, landing gear systems, and avionics. These components must meet stringent standards to ensure safety and reliability in aerospace operations.

Automotive Sector: In the automotive industry, precision machined components are found in engines, transmissions, steering systems, and chassis components. These components contribute to vehicle performance, efficiency, and safety.

Medical Devices: Precision machined components are crucial in the manufacturing of medical devices such as surgical instruments, implants, and diagnostic equipment. These components must meet precise specifications to ensure accuracy and reliability in medical procedures.

Electronics and Technology: Industries like electronics and technology rely on precision machined components for the production of consumer electronics, computer hardware, and telecommunications equipment. These components facilitate the miniaturization and functionality of electronic devices.

Oil and Gas Sector: In the oil and gas industry, precision machined components are utilized in drilling equipment, valves, pumps, and pipeline systems. These components are designed to withstand harsh operating conditions and ensure efficient extraction and transportation of oil and gas resources.

Defense and Military Applications: Precision machined components are essential in defense and military equipment, including firearms, missiles, aircraft, and naval vessels. These components must meet strict quality and performance standards to ensure mission success and national security.

In conclusion, precision machined components play a pivotal role in various industrial applications, contributing to efficiency, reliability, and safety across various sectors. For top-quality precision machined components tailored to your specific requirements, consider Om Steel Co as your trusted supplier. With their expertise and commitment to excellence, they are your ideal partner for precision machined components. Visit their website to explore their extensive range of products and services.

0 notes

Text

Precision CNC machining service for defence, automotive, medical, government, mining, aerospace, electronics and telecommunication industries.

#machinery#cnc machined components#electronic components#spareparts#manufacturer#factory#cnc machining#machining parts#precision machining#machinist

0 notes

Text

Usha Precision

We are renowned manufacturer & supplier of a wide range of industrial flat head rivets as well as round head rivets, Our various types of solid metal rivets are made using superior quality material which is tested before the production process.

#Micro Rivets#Micro Screws#Steel Rivets#Stainless Steel Rivets#Metal Rivets#ss rivet#stainless steel dowel pins#stainless steel dowels#precision turned components#machined parts#stainless steel#metal parts manufacturing

0 notes

Text

#custom-aluminum-milling#MachinedPartsManufacturer#Prototype-machining-services-in-Savannah#Precision-Machined-Components-Manufacturers

0 notes

Text

7 Advantages of Precision Turned Parts

Keeping a competitive advantage is essential for businesses in the fast-paced industrial manufacturing sector. Using precision-turned components in your production processes is one competitive advantage method. Many sectors that demand high-accuracy, high-quality, and dependable parts depend on precision-turned components. Turned components find application in various fields, including electronics, electrical, medicine, and automotive. A high quality turned components are needed for many business sectors. Turned components are only way to acquire optimal and durable components. Continue reading about the advantages of precision-turned parts:

User Friendly and Safe

The precision and consistency of CNC machined components raises their safety and user-friendliness rating, reducing the possibility of DOA parts and early mechanical malfunctions. It also saves you and your end users money on maintenance and repairs over time. Choose reputed machined components manufacturers, to buy the durable turned components.

Guaranteed Precision

The ability to achieve incredibly high levels of accuracy is one of the main advantages of precision machined components. The accuracy that the CNC machines can provide is 0.005. Big businesses mainly depend on Turned Components Manufacturers because of their exceptional level of precision. Furthermore, several components can be worked on simultaneously. It is possible to make multiple components of a single product precisely simultaneously.

Cost-efficiency

Even while accuracy is expensive, in the end, it saves your company money. Acquiring precision-turned components of exceptional quality leads to a reduction in defects, the need for rework, and instances of downtime. This improves your overall operational efficiency in addition to saving you money. Choose the best precision machining parts manufacturer who offers high-quality products at an affordable price.

Improves Production Efficiency

Using precision turned components in your application can boost overall productivity and optimize production processes by reducing human error and increasing accuracy. The performance of your machinery and equipment can be greatly improved by using precision-turned components. The accuracy of these parts guarantees a seamless and effective functioning in the automotive, aerospace, and medical sectors. Consequently, there is an increase in customer happiness and product quality.

High Repeatability

Precision turned components must have a high repeatability to manufacture identical parts in consumer applications. CNC machines are ideal for mass production scenarios where multiple items must be repeatedly machined to strict specifications because they can continuously create identical parts across an endless number of manufacturing cycles.

Versatility And Customization

Extremely adaptable, precision-turned components can be customized to match the unique requirements of your application. These components can be customized to meet your requirements, be it detailed detailing, unique materials, or complex shapes. Modern production relies heavily on flexibility, and precision-turned components are made with this in mind.

Decreased Maintenance

Precision turned components provide several benefits, one of which is their reduced maintenance requirements. Your machines will last longer because of their superior quality and great precision, which make them less prone to wear and tear. This results in more uptime and cheaper maintenance expenses.

Final Thoughts

As a result, those mentioned above are about the advantages of precision-turned parts. Visit Arek Solutions to purchase various types of machinery parts. To ensure that they are using the correct raw material to manufacture their products, all suitable raw materials are retested at an NABL or similar approved laboratory.

#machined components manufacturers#precision machined components#precision machining parts manufacturer#machining parts texas#machine parts manufacturer texas

0 notes

Text

Precision Machined Components Manufacturers | CMD PPL

CMD Precision Products specializes in manufacturing precision machined components. Trusted sheet metal manufacturers and experts in tool and die manufacturing.

1 note

·

View note

Text

A Buyer's Guide to Choosing Custom CNC Machined Parts Manufacturers

In today's market, the demand for custom CNC machined parts is soaring across industries, including aluminum CNC turning parts. Selecting the perfect CNC machined components manufacturer is essential for quality and value. This article offers a concise guide to help you make an informed choice for your project.

Material Selection: Custom machined parts can be crafted from a variety of materials, including aluminum for CNC turning parts. Choose the right material based on your project's needs, properties, and cost, consulting your CNC machining parts factory for the best fit.

Assess Supplier Capabilities: Not all CNC machined components manufacturers are equal. Evaluate their expertise, experience, and equipment for the required machining processes and complexity, especially for aluminum CNC turning parts. Check their track record and references for reliability and quality.

Quality Control and Assurance: Ensure your chosen CNC machined components manufacturer follows stringent quality control processes, such as ISO 9001 certification, to guarantee precision and quality in your aluminum CNC turning parts.

Lead Time Management: Custom parts often have longer lead times. Understand your CNC machining parts factory's lead times to meet your project deadlines with effective communication & planning.

Pricing and Value: Compare quotes from multiple CNC machined components manufacturers, considering material and machining costs, along with additional services for aluminum CNC turning parts. Prioritize overall value and reliability over the cheapest option.

Effective Communication: Opt for a CNC machining parts manufacturer with strong communication skills. Clear and timely communication is vital for addressing questions or issues during production.

Post-Processing Services: Check if the manufacturer offers post-processing services such as deburring, polishing, anodizing, or painting, especially for aluminum CNC turning parts. Consolidating these services with one vendor can save time and effort.

Packaging and Shipping: Ensure the CNC machining parts factory can package and ship your parts securely to prevent transit damage, including your aluminum CNC turning parts. Confirm they can meet your specific shipping requirements.

Intellectual Property Protection: If your custom CNC machined parts involve proprietary designs or technology, ensure the manufacturer has policies to protect your intellectual property.

The right CNC machined parts manufacturer, including aluminum CNC turning parts, is crucial for your project's success. Considering these factors, you can make an informed decision and establish a productive partnership with a CNC machining parts factory that meets your quality, service, and value requirements.

#custom cnc turning parts#cnc parts manufacturer#cnc turned parts manufacturer#cnc machining parts manufacturer#small batch cnc machining#low volume cnc machining#machining components#machined plastic parts#aluminum parts machining#custom aluminum parts#prototype cnc machining#cnc precision parts

0 notes

Text

Finest Quality Precision Components

Are you looking for precision components manufacturer in Ahmedabad? Scharf Precision Engineering is a leading precision components manufacturer provides premium quality precision components, precision machined parts and micro components at best price. We are consistently been fulfilling the diverse high precision components demands of our local and global clients.

#Precision Components#Precision Parts#Precision machined Parts#Micro components manufacturer#Ahmedabad

1 note

·

View note