#precisionmachine

Explore tagged Tumblr posts

Text

We are specialized in all kinds of precision machined & transmission machined casting parts in the weight range of 0.5 Kg – 50 Kg. Annually we are producing about 1500 metric tons of Machined parts for various industries. Extensively we are producing 1500 components per year. Year on year we are increasing our capacity to manage customers demand & Spikes. see more:https://www.bestomech.com/ contact us:99449 64743

#precisionmachine#precisionmachinecomponents#industrialsprockets#pulley#pulleys#timingpulley#pulleymanufacture#India

0 notes

Link

Tumblr Post

✨ Transform Alloy Wheels with Cutting-Edge Machines! ✨

Tired of uneven finishes or lengthy repairs? It’s time to upgrade your workshop with the best cutting wheel machines for refurbishing wheel faces!

🌟 Featured Machine: HAISHU CKL26Q CNC Wheel Lathe ✔️ ±0.02mm precision for professional results ✔️ Refurbishes wheels in 10-15 minutes ✔️ Advanced features like laser scanning and automatic tool changers

Whether you’re tackling surface scratches, dents, or corrosion, this machine delivers factory-grade finishes every time.

📌 Read the full guide: [https://haishucnclathe.com/what-is-the-best-cutting-wheel-machine-for-refurbishing-wheel-faces/]

#AlloyWheelRepair #CNCWheelLathe #HAISHUMachinery #PrecisionMachining

2 notes

·

View notes

Text

🔧 HAISHU CK50 CNC Lathe Machine offers precision machining, durability, and efficiency for industries like aerospace and medical.

💡 Key Features: ✔️ ±0.01 mm precision ✔️ Spindle speeds up to 4,000 RPM ✔️ Advanced CNC automation

👉 Learn more: Super CNC Machine Guide

#CNCInnovation #PrecisionMachining

2 notes

·

View notes

Text

👨⚕️🔬 At Total Planning we manufacture precision machining that is essential for the optimal operation of X-ray machines. 🎯 Our precision machining improves the clarity and quality of X-ray images. This enables medical professionals to make better decisions and provide the best possible care for patients. 🤝 If you are a medical equipment supplier looking to improve the efficiency and quality of your equipment, we are your partner. Contact us today to find out how Total Planning can improve your X-ray devices and further support medical professionals in their work.

3 notes

·

View notes

Text

Types of Mandrel for Different Machining and Manufacturing: A Complete Guide

In the world of precision machining and manufacturing, mandrels play a silent but vital role. Whether you're working with metal, drilling operations, or even jewelry design, the mandrel is a go-to tool for holding, supporting, or shaping a workpiece during fabrication.

But what exactly is a mandrel, and why does it matter so much?

A mandrel, also referred to as an arbor, is a cylindrical or tapered rod used to secure workpieces or tooling components during machining. Instead of clamping directly to the machine’s chuck, the workpiece is mounted on the mandrel, which provides better balance, accuracy, and stability. This is especially crucial for items that are delicate or irregular in shape.

Why Use a Mandrel?

Mandrels allow for:

Improved workholding when a chuck or faceplate isn’t suitable

Higher precision in rotating the workpiece around its true center

Reduced deflection or misalignment during machining operations

Types of Mandrels You Should Know

There are many variations of mandrels, each designed for specific tasks:

1. Solid Mandrel: A plain, tapered cylindrical bar ideal for standard, symmetrical workpieces.

2. Step Mandrel: Features stepped diameters for holding parts with different hole sizes. Great for versatile operations.

3. Gang Mandrel: Used to hold multiple hollow workpieces at once—perfect for speeding up production.

4. Collar Mandrel: Has two fixed collars to grip large workpieces with diameters over 100 mm.

5. Screwed Mandrel: Includes a threaded end to securely hold parts with internal threads.

6. Cone Mandrel: Features a sliding cone to adjust for different workpiece diameters, useful for varying inner diameters.

7. Expanding Mandrel: Uses a tapered arbor and split bush design to expand and grip the inside of hollow parts tightly.

8. Ring Mandrel (Triblet): Popular in jewelry, this tapered tool is used to size, form, and shape rings accurately.

How Mandrels Improve Manufacturing

They help in forging and reshaping delicate pieces (especially in jewelry).

Ensure the workpiece rotates concentrically for precision.

Reduce errors and tool wear caused by unstable setups.

Support advanced operations like boring, grinding, or finishing.

From metal lathe operations to intricate ring making, mandrels are indispensable. Their role in securing workpieces and ensuring flawless rotation cannot be overstated. With so many types available, choosing the right mandrel for your application can significantly improve both quality and efficiency.

For a deep dive into specifications, design differences, and use cases, check out the full article here: Types of Mandrel for Machining and Manufacturing

#Mandrel#LatheTools#MachiningBasics#ManufacturingTech#PrecisionMachining#MachineShop#Metalworking#ToolTalk#CraftWithLathe#WorkshopGear#JewelryMaking#LatheMandrel#MachiningTools#SolidMandrel#EngineeringTips

0 notes

Text

Swiss Type Screw Machines – Precision Machining by ANJALI T PRECISION

Swiss Type Screw Machines by ANJALI T PRECISION – Engineered for complex geometries, tight tolerances, and flawless finishes. Our multi-axis technology delivers high-volume, high-accuracy results where every micron counts. Trust the experts in precision machining.

📞Call On: +91 77579 70589

✉️ Email Id: [email protected]

🌐 Book An Appointment: www.anjalitprecision.com

#SwissTypeScrewMachine#AnjaliTPrecision#PrecisionMachining#HighAccuracy#TightTolerances#CNCMachining#MultiAxisMachining#ComplexGeometries#MicronLevelPrecision#ManufacturingExcellence#EngineeringSolutions#HighVolumeProduction#MachineryExperts#AdvancedManufacturing

0 notes

Text

Flat Bed CNC Lathe Machines: Precision Engineering for Complex Parts

Flat Bed CNC Lathe Machines are designed for high-precision machining of complex parts. Their rigid structure and advanced CNC technology enable accurate turning, drilling, and threading operations. Ideal for industries requiring detailed and intricate components, these machines offer enhanced productivity and consistent quality in manufacturing processes.

#FlatBedCNC#CNCExpand#LatheMachine#CNCPrecision#ManufacturingAutomation#CNCEngineering#MachineTools#CNCpractices#MillingTechnology#PrecisionMachining#CNCWorkers#LatheDies#CNCOptimization#FlatBedMachining#CNCInnovation#MachiningSolutions#ManufacturingExcellence#CNCManufacturing#CNCWorkshop#TechInManufacturing

0 notes

Text

Enhancing Efficiency with Tungsten Carbide Rotary Burrs

In the realm of metalworking and fabrication, the choice of tools significantly impacts efficiency, finish quality, and overall productivity. Craft Tech Cutting Tools stands at the forefront of this industry with its premium range of Tungsten Carbide Rotary Burrs—engineered to deliver unmatched durability and cutting performance.

Whether you're grinding, deburring, shaping, or removing material from metals like steel, cast iron, or non-ferrous alloys, Craft Tech's rotary burrs ensure consistently high precision and smoother workflow. Their Cylindrical Burrs with End Cut and Radius End Burrs are particularly renowned for producing cleaner finishes and minimizing tool wear, ultimately extending tool life and reducing downtime.

The advanced geometry of these burrs allows for reduced vibration and increased control, making them ideal for use in aerospace, automotive, shipbuilding, and die-making industries. Backed by decades of expertise and a strong commitment to quality, Craft Tech Cutting Tools is a trusted name among professional machinists and manufacturers across India.

Make the smart choice—upgrade your tooling game with Craft Tech Cutting Tools.

#CraftTechCuttingTools#TungstenCarbideRotaryBurrs#CylindricalBurrsWithEndCut#RotaryBurrsIndia#MetalworkingTools#FabricationTools#CuttingToolManufacturer#CarbideBurrManufacturers#PrecisionMachining#RotaryBurrCutter#IndianManufacturing

0 notes

Text

For precision machining, tool grinding is crucial. Yash Machine provides 7 specialised Tool Grinders tailored to grind cutting tools made from the hardest materials with high accuracy and durability. Perfect your tools with us!

For more details, visit - https://www.yashmachine.com/product/drill-point-grinder/tool-grinder

0 notes

Text

CNC Lathe and Milling Excellence our Doosan 2600 CNC Machine

Whether you're tackling high-volume turning or complex part geometries, this box-way lathe delivers the strength and accuracy you need for any CNC lathe and milling application.

This image showcases the robust build and clean design of our 2013 Doosan 2600engineered for precision and built to last.Learn more: https://gospencermfg.com/2013-doosan-2600-cnc-lathe-box-way/

#CNCmachining#LatheWork#MillingMachine#DoosanLathe#CNCtools#PrecisionMachining#CNCLatheAndMilling#ManufacturingExcellence

0 notes

Text

In the heart of modern manufacturing, precision machining ensures accuracy, quality, and consistency. At MacTech Engineering, we deliver high-performance precision machined components for industries that demand nothing less than perfection.

From Inconel and Titanium Alloys to Stellite and Nickel-based Alloys, our expertise in hard machining and complex materials sets us apart. Whether it’s aerospace, defense, or energy, our precision machining services are tailored to meet tight tolerances and high standards.

As a leading Precision Machining Company in India, MacTech is your trusted partner for reliability, innovation, and engineering excellence.

#MacTechEngineering#PrecisionMachining#CNCMachining#MachinedComponents#TitaniumMachining#StelliteParts#InconelMachining#ManufacturingSolutions

1 note

·

View note

Text

Upgrade your machining capabilities with our Universal Swivel Head Milling Machines. Designed for reliability and versatility, these machines are perfect for heavy-duty industrial operations as well as intricate precision tasks.

For more details, visit - https://www.bhavyamachinetools.com/products/universal-swivel-head-milling-machine

#bhavyamachinetools#MillingMachine#SwivelHeadMilling#UniversalMillingMachine#IndustrialMachinery#PrecisionMachining#HeavyDutyMachinery#MachiningSolutions#MetalworkingTools#EngineeringEquipment

0 notes

Video

youtube

🎥 Welcome to our channel! If you’re tired of complicated setups and imprecise results in wheel hub machining, we’ve got you covered. In this video, discover how advanced tool tip detection technology makes your lathe operations more economical, precise, and effortless. Let’s revolutionize your workflow!

Part 1: Why Tool Tip Detection is a Game-Changer

🛠️ Why is tool tip detection essential? Without accurate tool tip detection, you could face: Poor machining quality. Increased material waste.

Higher operational costs due to errors and rework. With cutting-edge detection systems, you’ll achieve:

✅ Consistent precision,

✅ Cost savings,

✅ And faster production cycles!

Part 2: Features of Advanced Tool Tip Detection

✨ What makes this technology a must-have? Economical: Reduces waste and downtime. Cuts costs without sacrificing quality. Precise: Aligns tool tips with sub-millimeter accuracy. Guarantees flawless wheel hub finishes. Effortless Operation: User-friendly interface for all skill levels. Automated calibration saves time and effort. Versatile: Compatible with various lathe machines, including CNC and manual setups.

🔧 Whether it’s for professional manufacturing or small-scale workshops, this tool tip detection system is your key to better results.

Part 3: Step-by-Step Instruction for Tool Tip Detection

📝 How to use the tool tip detection system: Install the Sensor: Attach the detection sensor to your wheel hub lathe. Calibrate the System: Activate the detection feature through the lathe’s interface. The system will automatically align the cutting tool with the workpiece. Verify Alignment: Review the detection results displayed on the screen. Adjust manually if needed. Start Machining: Confidently begin machining, knowing your tool tip is perfectly aligned. This process ensures precision, saves time, and improves efficiency.

Part 4: Real-Life Results: A Workshop Transformation

📊 Case Study: A mid-sized automotive workshop adopted this tool tip detection system and: Reduced machining time by 30%. Lowered material waste by 20%, saving thousands annually. Improved machining precision even for complex wheel hub designs.

Part 5: Conclusion and Call to Action

🚀 Ready to elevate your machining operations? With advanced tool tip detection for wheel hub lathes, you’ll enjoy: Lower costs, Better precision, And effortless operation.

👉 Don’t forget to subscribe for more machining tips and tech updates!

👉 Click the link in the description to learn more about this tool tip detection system and how to get started.

🔗 Learn more here: [Your Website Link or Product Page] #PrecisionMachining #WheelHubLathe #ToolTipDetection #CNCInnovation #MetalProcessing

2 notes

·

View notes

Text

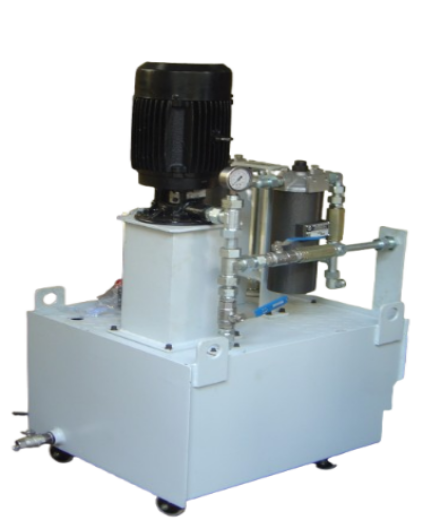

Precision Machining with High Pressure Through Coolant Systems by Lex Technoaid

Lex Technoaid’s High Pressure Through Coolant System enhances CNC machining efficiency by delivering clean, pressurized coolant directly to the cutting zone. Designed for high-performance metal cutting applications, it helps extend tool life, maintain temperature control, and improve surface finish. Ideal for modern manufacturing setups seeking precision and productivity.

#CoolantSystem#HighPressureCoolant#CNCManufacturing#MachiningSolutions#IndustrialFiltration#ToolLifeExtension#PrecisionMachining#MetalCuttingTechnology#ManufacturingInnovation#LexTechnoaid

0 notes

Text

The Marvel of High - Precision Stainless - Steel Metal Washers

Hey there, Tumblr fam! Ever wondered about the unsung heroes of precision engineering? Let's talk about high - precision stainless - steel metal washers.

Our team dives deep into the world of micro - tolerances to create these little wonders. We start with the finest stainless - steel, a material renowned for its strength and resistance to rust and corrosion. But it's not just about the raw material; it's the process that makes our washers stand out.

Using state - of - the - art machinery and advanced machining techniques, we carve and shape each washer with an accuracy that's mind - blowing. These aren't your average washers you find in a hardware store. Our high - precision versions are designed for industries where even the slightest deviation can spell disaster, like aerospace, medical devices, and high - tech electronics.

Whether it's a washer for a delicate medical implant or a crucial component in a high - speed aircraft engine, we've got the skills and technology to deliver. So, the next time you see a complex machine working flawlessly, remember, there might just be one of our high - precision stainless - steel metal washers quietly doing its job, ensuring everything runs smoothly.

this Tumblr - style post capture the essence of what you want to convey about your washer processing? If you have any specific elements like a more personal touch or additional technical details, I can refine it further.

#cnc swiss#precision#machining#precision hardware products#precision machining#StainlessSteel#PrecisionMachining#MetalWashers

0 notes

Text

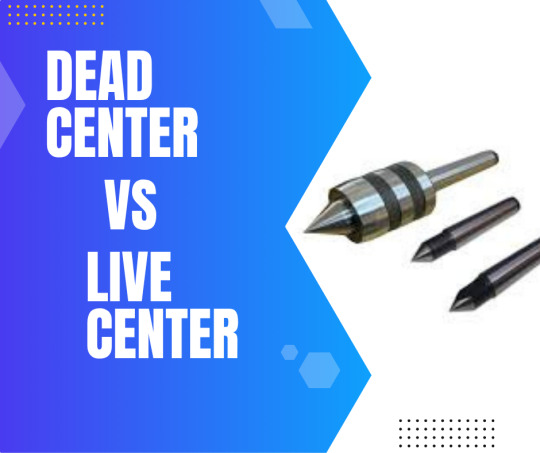

Dead Centers vs Live Centers: Key Difference That Could Save Your Project

What if the reason your lathe work isn’t quite perfect… is simply the center you're using?

Let’s talk about something that might seem small—but can have a major impact on your turning results: Dead centers vs live centers. It’s one of those topics machinists and woodturners encounter early, yet few fully grasp how deeply it affects performance, wear, and finish.

I didn’t think twice about it either… until a project went sideways—literally. And all because I picked the wrong center.

So, what's the actual difference? It boils down to motion and friction.

Dead Centers are fixed—they don’t spin. They sit stationary in the tailstock while your workpiece spins around them. This creates friction at the contact point, which can lead to heat buildup and wear over time. Think old-school, raw, dependable—but high maintenance.

Live Centers, on the other hand, have internal bearings. The center rotates with the workpiece. Less friction. Less wear. A smoother ride, especially at higher speeds or longer sessions. Modern, efficient, and easier on your materials.

Still, it’s not about which one is “better.” It’s about choosing what suits your task.

When to use which?

✅ Use a dead center when: – You’re working at lower speeds – You want extra rigidity (common in grinding operations) – You’re prioritizing alignment over convenience

✅ Use a live center when: – You’re turning at high speeds – You need reduced heat and friction – You want longevity and smoother finishes

My personal take? After switching to a live center for most of my turning, the difference was night and day. Less burn marks. Quieter operation. And a way more enjoyable workflow. But for certain precise alignments? Dead centers still hold their place.

Final thought: The tool you pick isn’t just about “getting the job done”—it’s about how well you do it, and how long your gear lasts.

If you’re curious to dive deeper, this is a great read: 👉 Dead Centers vs Live Centers: Full Breakdown

Let’s hear it: Have you ever made the switch and noticed a difference? Or still team Dead Center all the way?

🔁 Reblog to share with your fellow makers 🗨️ Drop your turning setup below—what works best for you?

#deadcentersvslivecenters#machinistlife#lathework#woodturningtips#metalworkingtools#turningtools#workshopwisdom#makersofTumblr#tooltalk#precisionmachining#lathelove#diyworkshop

1 note

·

View note