#propylene

Explore tagged Tumblr posts

Text

Cobalt catalyst rivals platinum in key industrial reaction

Propane dehydrogenation is a key industrial route to producing propylene without relying on oil. However, its current production processes rely heavily on precious-metal catalysts such as Pt-based materials. Developing efficient alternatives using Earth-abundant metals has remained a challenge. In a study published in Nature Catalysis, Prof. Xiao Jianping's group from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences, and collaborators, have developed a high-performance cobaltosilicate zeolite catalyst (CoS-1) via a hydrothermal synthesis method. The catalyst has solely tetrahedral cobalt sites and none of the unstable cobalt species, achieving a propylene productivity as high as 9.7 kgC3= kgcat–1 h–1, surpassing that of an industrial PtSn/Al2O3 catalyst.

Read more.

5 notes

·

View notes

Text

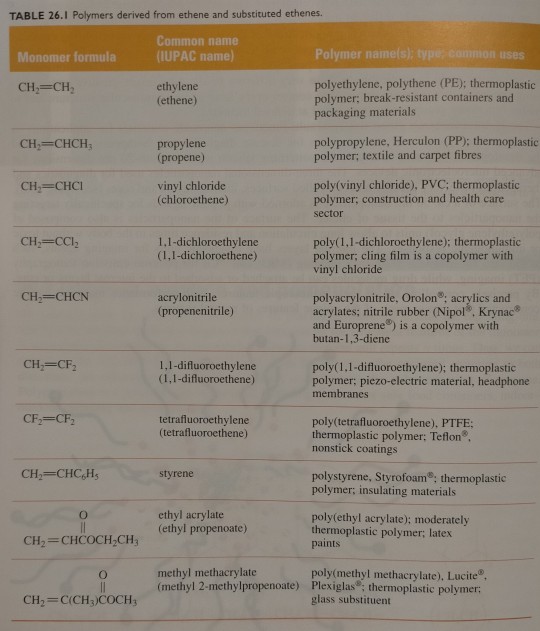

Table 26.1 gives some examples of polymers formed from compounds related to ethene, along with their common names and most important uses.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#polymers#ethene#ethylene#propene#propylene#chloroethene#vinyl chloride#dichloroethene#dichloroethylene#propenenitrile#acrylonitrile#difluoroethene#difluoroethylene#tetrafluoroethene#tetrafluoroethylene#styrene#ethyl propenoate#ethyl acrylate#methyl methylpropenoate#methyl methacrylate

2 notes

·

View notes

Text

The reason polyester (PE) is used for so many things is because the ingredients to make it are waste products of crude oil cracking. In fact, there was so much of this waste product that polyethylene was seen as somewhat of a miracle when its creation was discovered. (Yes, it was an accident, haha) Polypropylene (PP) also comes from this process.

When oil comes out of the ground, it needs refining before it can be used for things like gasoline or natural gas. Below is a diagram showing the refinery of petroleum and what the byproducts are used for.

Due to the oil and gas industry, there is a LOT of this waste product. That is why PE and PP are so incredibly cheap- MUCH cheaper than more reusable, recyclable, and/or sustainable alternatives, like glass, metal, natural fibers, etc. You can make a LOT more money if you bottle your soda with PP or make clothes out of PE.

So, the best solution, imo, to minimising plastic pollution is not recycling, or making plastics illegal. It is RENEWABLE ENERGY SOURCES.

If we all powered our cars with electricity from wind, solar, or hydro, we would have less need for oil- therefore minimising the amount of product that can be turned into plastics. This would make plastics more expensive due to scarcity, and would (hopefully) encourage companies to return to using infinitely recyclable metal and glass. (By the way, PE is the number one made plastic in the WORLD. PP is second place.)

Sorry this is off topic but i wanted to chip in!

The closest experience I've ever had to discovering "the vitamin" was buying a 100% wool outfit and wearing it in the winter.

Not only was I not freezing anymore, I was not sweating and overheating either. The horrible sensory nightmare of winter clothes disappeared.

In particular, I bought a pair of wool pants. They were a thrifted pair of fancy dress pants like you would wear at an important office job, and they were easily the most comfortable pair of winter-appropriate pants i'd ever worn. I wore them Every Single Day.

From that point on I realized a lot of my clothes were making me feel bad, and the common thread was polyester. Especially polyester blends.

It's a trap because the polyester clothes are the ones that always feel sooooo silky soft when they are in the store, whereas cotton, linen and wool can feel comparatively rough and scratchy. But when actually wearing them for hours throughout the day, it's the natural fibers that feel more comfortable.

Maybe the secret to sensory comfort is not about the presence of softness, but the absence of overloading sensations. Or maybe the sensory stress and agony is not triggered by texture of the fabric, but by how it breathes and regulates temperature.

Then there's the problem of clothing life span: polyester blends, no matter how soft they seem at first, become rough and scratchy and covered in hard, itchy pills after wearing them 10 or 20 times, whether or not they have been tumble-dried or even washed at all. (I tested it!) Linen and cotton become softer and more comfy the more you wear them, polyester but ESPECIALLY polyester blends become a constant stressor. Polyester blend t-shirts I used to love for their softness now feel bristly and irritating.

So now I'm trying to change my wardrobe to as many natural fibers as possible, and the more natural fiber clothes i have the more I realize that the plastic fibers stress me out. It's so easy to overheat or freeze in them and they're always degrading and becoming less comfortable and it sucks.

#polymer science#polymers#plastic#polyethylene#polypropylene#pp#pe#ethylene#propylene#renewable energy#renewablepower#crude oil#sustainability#recycling#clean energy

30K notes

·

View notes

Text

Propylene Prices Index: Trend, Chart, News, Graph and Demand

In the first quarter of 2025, the North American propylene market displayed a fluctuating price trajectory, initially experiencing a rise followed by a correction. January saw a price increase driven by heightened global demand ahead of the Lunar New Year and constrained domestic availability. This short-term bullish sentiment helped push quarterly prices in the U.S. up by 2.2% compared to the previous quarter. However, the upward trend was short-lived. By February, prices began to retreat amid falling crude oil values, prompting manufacturers to adjust their offers downward. Improving inventory levels and the relaxation of earlier supply chain disruptions further contributed to the softening of the market. Entering March, bearish pressure persisted due to market uncertainty stemming from evolving trade policies and potential tariffs. While there were intermittent gains in downstream polypropylene prices, these failed to stimulate sustained demand. Buyers remained cautious, particularly in the textile and polyester industries, where purchasing activity was subdued due to excess stock and a lack of forward visibility.

In the Asia-Pacific region, propylene prices followed a similar trajectory of early gains followed by subsequent declines. At the beginning of January, prices in Thailand rose due to constrained supply from South Korea and elevated feedstock crude oil costs that inflated production expenses. Despite this bullish start, gains were tempered by weak demand from the downstream polypropylene segment. On a quarterly basis, propylene prices in Thailand climbed 3.7% compared to the fourth quarter of 2024. However, February brought a slowdown as the Lunar New Year holidays disrupted business activity. Operating rates in the downstream sector declined, crude oil prices softened, and production costs eased. While supply conditions improved slightly thanks to reduced freight costs and stable export levels from South Korea, demand remained sluggish. By March, the market continued to struggle under the weight of poor demand from the polypropylene and polyester sectors and broader macroeconomic concerns, including uncertain trade dynamics and potential tariff implementations.

Get Real time Prices for propylene : https://www.chemanalyst.com/Pricing-data/propylene-51

In Europe, propylene prices surged by 11.1% during the first quarter of 2025 when compared to the last quarter of 2024, driven largely by supply-side constraints rather than robust demand. The German market, in particular, saw continuous price increases throughout the quarter. These gains were fueled by ongoing production disruptions, logistical challenges, and rerouting of shipments that tightened availability. In January, the situation was exacerbated by planned and unplanned plant shutdowns, low operational rates across the polymer and petrochemical sectors, and minimal cracker activity. February was marked by worsening logistical issues, including vessel shortages and port congestion in key hubs such as Hamburg, which further hindered the free flow of materials. Despite subdued consumption from downstream polypropylene users, the constrained supply environment helped sustain upward price momentum. By March, prices in Germany reached USD 1053/MT for Propylene FD Hamburg, reflecting the ongoing supply pressure and limited inventory levels.

In the Middle East and Africa (MEA), the propylene market followed an overall upward trend in Q1 2025, with prices rising 2.9% from the previous quarter. January witnessed an uptick in trading activity in Saudi Arabia, driven by restocking efforts in preparation for the Lunar New Year. However, market sentiment remained cautious amid shifting demand patterns, geopolitical instability, and seasonal considerations. Supply was further strained due to maintenance shutdowns at major production sites, including NATPET and Petro Rabigh. Tensions in the region, particularly disruptions in the Red Sea shipping lanes, led to increased freight costs and delays, adding upward pressure to prices. By March, though, the market began to cool. Demand from key downstream sectors such as polypropylene and polyester weakened, and the approach of Ramadan contributed to reduced market activity, shorter business hours, and subdued buying behavior. Although February experienced a brief rise in demand driven by seasonal expectations, it fell short of projections, and market fundamentals failed to sustain any significant upward momentum.

In South America, propylene prices recorded a mixed pattern over the first quarter of 2025. January began with an uptick, particularly in Brazil, fueled by a combination of strong global demand leading up to the Lunar New Year and limited domestic supply. As a result, prices increased by 5.9% over the quarter when compared with the last quarter of 2024. However, this positive trend was reversed as crude oil prices softened, prompting a reduction in propylene offers by local producers. Improvements in supply chain efficiency and inventory availability added to the bearish outlook. By March, market sentiment had weakened further due to growing concerns about international trade regulations and possible tariff impositions, which created an atmosphere of hesitation among buyers. Although there was a temporary rise in prices for downstream polypropylene, it failed to generate a corresponding increase in demand. The textile and polyester industries continued to face sluggish activity, as customers refrained from large-scale procurement amid ongoing inventory overhangs and market instability.

Get Real time Prices for propylene : https://www.chemanalyst.com/Pricing-data/propylene-51

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Propylene#Propylene Price#Propylene Prices#Propylene Pricing#Propylene News#Propylene Price Monitor

0 notes

Text

Revuele serum vitamina C: cosmética low cost

Hay otra cosmética más allá de las grandes marcas y sus altos precios: Revuele ¡Descúbrela! Hola, Curly. Ya sabes que siempre estoy buscando productos que ayuden a que nuestra piel luzca mejor. Y muchas veces esa tarea, que parece sencilla, la mayoría de las veces significa gastar dinero o por lo menos antes era sí. Porque gracias a democratización de la belleza. Las grandes marcas ya no tienen…

#agua#cosmética barata#cosmética low cost#crema hidratante#crema viatmina C#Glycol#Hyaluronate#igualar tono#niacinamida#PEG 40 Hydrogenate#precios#Propylene#prtección SPF20#revuele#rostro#sodium#vitamina b3#vitamina c#xanthan

0 notes

Text

Propylene: A Versatile Monomer for Plastics, Chemicals, and Fuels

Propylene, also known as Propylene, is an important industrial organic compound used for the production of numerous polymers and chemicals. With the chemical formula C3H6, Propylene is a colorless gas that is highly flammable and slightly less dense than air. It is one of the three most important olefins produced industrially, along with ethylene and butadiene.

Sources and Production of Propylene

Naturally, Propylene is produced as a byproduct during oil refinement and natural gas processing. However, most Propylene manufactured today is produced through two key processes - steam cracking of hydrocarbons and fluid catalytic cracking (FCC) of crude oil fractions. Steam cracking involves heating petroleum feedstocks like naptha, liquefied petroleum gas or ethane in the presence of steam to produce lighter alkenes like ethylene and Propylene. FCC uses a zeolite catalyst at elevated temperatures to convert heavier hydrocarbon fractions into gasoline and lighter alkenes. Refineries and petrochemical facilities use these cracking techniques to maximize alkene yields and recover Propylene on an industrial scale.

Uses and Derivatives of Propylene

By far the largest application of Propylene is for the production of polyPropylene plastics. In fact, Propylene demand is dominated by polymerization which accounts for over 60% of its end uses. PolyPropylene possess desirable properties like flexibility, transparency, resistance to moisture and chemicals and is commonly used in packaging films, textiles, plastic parts and various industrial applications. Other major derivatives of Propylene include Propylene oxide, acrylonitrile, cumene and alcohols. Propylene oxide forms the basis for specialized polyether polyols used in rigid and flexible foams. Acrylonitrile is a key precursor to acrylic fibers and plastics. Cumene, or isopropylbenzene, is primarily used to manufacture phenol and acetone. Propylene also finds usage as a petrochemical intermediate in various chemical processes.

Applications in Fuels and Transportation

Due to Propylene's molecular structure and fuel properties, it is increasingly being evaluated as an alternative transportation fuel, especially in diesel engines. Propylene is more reactive and has a higher cetane value compared to longer chain alkanes like diesel. As a result, it produces cleaner burning exhaust with reduced emissions. It has led to interest in developing Propylene-diesel fuel blends. Furthermore, Propylene derived alkylate - a high-octane component obtained from isomerization and alkylation refining - improves gasoline engine performance and is a major gasoline additive. This has created new potential avenues for Propylene consumption in transportation fuels in addition to the chemical sector.

World Supply and Demand Dynamics

On a global scale, over 60 million tons of Propylene are produced annually to meet the growing polymer and chemical demands. The Asia Pacific region dominates both production and consumption with China leading as the largest Propylene market. Key refining and petrochemical industries based along the U.S. Gulf Coast and parts of Europe like Germany, Belgium and Italy also contribute significantly. International trade plays a critical role since Propylene supply-demand balances vary regionally. Propylene trade occurs through ship tank or intra-pipeline transports to equalize regional surpluses and shortfalls. Overall, Propylene is an indispensable petrochemical that serves as backbone to the plastics industry and leverages oil and gas refinery infrastructure worldwide.

Environmental and Process Safety Aspects

Like other industrial organic chemicals, Propylene manufacturing and handling requires compliance to strict environmental and process safety standards. Propylene plants are potential sources of air pollutants due to fugitive emissions and combustion byproducts that necessitate robust emission control systems. Propylene's higher reactivity also increases risk of fires and explosions that demand sophisticated risk prevention through equipment design, operating procedures and operator training. Effective waste management is equally important since process residues may contain hazardous compounds. Regulatory compliance backed by robust risk governance helps realize Propylene's societal benefits while minimizing workplace and community impacts. Overall stewardship across the Propylene supply chain is crucial given the chemical's extensive role in modern products and technologies.

Propylene stands out as one of the most widely used petrochemical intermediates supporting numerous downstream derivatives. Its contributions to plastics, chemicals and fuel applications underscore Propylene’s strategic importance to modern industries and economies worldwide. Continued innovation to maximize Propylene yields from fossil feedstocks along with alternative production pathways will be paramount to sustain this key industrial monomer’s role in the future.

Get more insights on Propylene

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

0 notes

Text

The Propylene Carbonate Market is expected to expand from USD 225.3 million in 2024 to USD 348.4 million by 2032, reflecting a compound annual growth rate (CAGR) of 5.60%.Propylene carbonate, a versatile and essential chemical compound, has garnered significant attention in various industries due to its wide range of applications and properties. As a cyclic carbonate ester derived from propylene glycol and carbon dioxide, propylene carbonate exhibits unique characteristics that make it a valuable component in numerous sectors, including pharmaceuticals, cosmetics, electronics, and energy. This article delves into the propylene carbonate market, examining its growth drivers, applications, and future prospects.

Browse the full report at https://www.credenceresearch.com/report/propylene-carbonate-market

Market Growth Drivers

1. Rising Demand in Electronics: One of the primary factors propelling the propylene carbonate market is its increasing use in the electronics industry. Propylene carbonate serves as a solvent in lithium-ion batteries, which are crucial for powering modern electronic devices such as smartphones, laptops, and electric vehicles. With the burgeoning demand for portable electronics and the rapid adoption of electric vehicles, the need for efficient and reliable battery components is on the rise, subsequently driving the demand for propylene carbonate.

2. Expanding Pharmaceutical Applications: The pharmaceutical industry is another significant driver of the propylene carbonate market. This compound is utilized as a solvent and excipient in the formulation of various drugs, including injectable medications and topical solutions. Its biocompatibility and low toxicity make it a preferred choice in pharmaceutical applications, contributing to the market's growth.

3. Growth in Personal Care and Cosmetics: In the cosmetics and personal care sector, propylene carbonate is used as a solvent and viscosity regulator in products such as creams, lotions, and makeup. The increasing consumer demand for high-quality and innovative personal care products is fueling the demand for propylene carbonate, as manufacturers seek to enhance the performance and stability of their formulations.

4. Eco-Friendly Nature: The environmental advantages of propylene carbonate also play a crucial role in its market growth. As a biodegradable and non-toxic compound, it aligns with the growing emphasis on sustainability and green chemistry. Industries are increasingly adopting propylene carbonate as a safer and more environmentally friendly alternative to traditional solvents.

Key Applications

1. Energy Storage: The role of propylene carbonate in the energy storage sector, particularly in lithium-ion batteries, cannot be overstated. It acts as an electrolyte solvent, facilitating the movement of ions between the battery's electrodes. This application is critical for the development of high-performance batteries with improved energy density, stability, and safety.

2. Pharmaceuticals: In the pharmaceutical industry, propylene carbonate is used as a solvent in drug formulations, ensuring the solubility and stability of active pharmaceutical ingredients (APIs). Its use in injectable drugs and transdermal patches highlights its importance in drug delivery systems.

3. Personal Care Products: Propylene carbonate's role in cosmetics and personal care products extends to enhancing the texture, consistency, and overall performance of formulations. It is commonly found in skincare products, hair care solutions, and makeup, where it helps achieve the desired sensory attributes and stability.

4. Industrial Applications: Beyond the aforementioned sectors, propylene carbonate finds applications in various industrial processes. It is used as a solvent for polymers, resins, and coatings, where it aids in dissolving and dispersing materials. Additionally, it is employed in the production of adhesives, sealants, and cleaning agents.

Future Prospects

The future of the propylene carbonate market appears promising, driven by several emerging trends and opportunities:

1. Advancements in Battery Technology: With the ongoing research and development efforts focused on improving battery performance and efficiency, the demand for high-quality electrolyte solvents like propylene carbonate is expected to surge. Innovations in energy storage, including solid-state batteries and next-generation lithium-ion batteries, will further boost market growth.

2. Sustainable Manufacturing Practices: The shift towards sustainable and eco-friendly manufacturing practices is likely to enhance the adoption of propylene carbonate across industries. Its biodegradable and non-toxic nature aligns with the increasing regulatory emphasis on reducing the environmental impact of chemical processes.

3. Expanding Pharmaceutical Sector: The continuous expansion of the pharmaceutical industry, driven by the development of new drugs and therapies, will contribute to the steady demand for propylene carbonate. Its role in drug formulation and delivery systems ensures its relevance in the evolving pharmaceutical landscape.

Key Player Analysis

LyondellBasell Industries

Shandong Depu Chemical

BASF

Empower Materials

Shida Shenghua Chemical

Daze Group

Huntsman Corporation

AVX Corporation

MegaChem Ltd

Hi-Tech Spring Chemical

Segments:

Based on Form:

Aqueous Solutions

Pellets

Based on Application:

Paints and Coatings

Cleaning and Detergents

Personal Care and Cosmetics

Textile Dyeing

Lithium-Ion Batteries and Electronics

Others

Based on the Geography:

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/propylene-carbonate-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Kinetics and Mechanism of the Process of Obtaining Liquid Products from the Catalytic Cracking Gases_Crimson Publishers

Abstract:

The goal of the kinetic study of the process along with chemical and physicochemical methods is to establish the most probable mechanism of the reaction and to build on its basis an adequate mathematical model of kinetics. In addition to the purely theoretical significance of the study of the regularities of the reaction, the creation of an adequate mathematical model of the reaction is a prerequisite for the successful application of mathematical modeling techniques for the optimization and scaling of chemical processes that make it possible to study the reaction in the laboratory in the shortest possible time and proceed to its industrial implementation.

Read More About this Article: https://crimsonpublishers.com/pps/fulltext/PPS.000506.php

Read More Articles: https://crimsonpublishers.com/pps/index.php

#crimson publishers#progress in petrochemical science#peer review journals#open access journals#gases#petrochemicals#propylene#methane

0 notes

Text

Propylene’s Manufacturing Techniques and Multiple Applications

Propylene is a vital chemical in the field of chemical engineering as it is considered as one of the most important basic chemicals that are used for the production of a number of other compounds. From Propylene oxide to acrylonitrile, cumene and acrylic acid, the derivatives derived from Propylene are a crucial factor in the production of a diverse range of products that we use in our everyday life. These chemicals are used in the production of films, fibers, containers, packaging materials and caps and closures to demonstrate the significance and usefulness of Propylene in modern industry. Let us explore the role of Propylene in various industries and the new solutions it inspires.

Introduction

Propene, also referred to as Propylene, serves as a crucial building block akin to ethene, particularly in the production of poly(propene) or Polypropylene. Unlike ethene, propene readily participates in substitution reactions, yielding a diverse array of significant chemicals. Its primary applications include the production of Polypropylene, acrolein, acrylonitrile, cumene, Propylene oxide, and butanal. These derivatives are instrumental in the manufacturing of acrylic polymers, phenol, acetone, polyurethanes, and surface coating solvents, showcasing propene's pivotal role in various industrial processes and product formulations.

Manufacturing Process

The production of Propylene is not direct, but indirectly through various other major industrial processes. Here are the two main ways Propylene is produced:

Steam Cracking: This is one of the largest processes accountings for the bulk of Propylene in the world today. Steam cracking is a process in which heavier hydrocarbons such as naphtha or natural gas liquids are cracked in a cracking furnace at high temperatures and with the use of steam. This process produces a mixture of several hydrocarbons with different chain lengths – the main product is ethylene and Propylene as a by-product.

Fluid Catalytic Cracking (FCC): This process is carried out in FCC units in refineries. FCC is mainly used to upgrade heavier gas oil from crude oil into gasoline. This process also produces a lighter stream of byproducts consisting of Propylene and other hydrocarbons. The significance of FCC as a Propylene source is expanding because it can process different feedstocks and likely to meet the growing Propylene demand.

Steam Cracking Units

The steam cracking process plays a pivotal role in the petrochemical sector, serving as the primary method for producing light olefins like ethylene and Propylene. It involves thermal cracking, utilizing either gas or naphtha, to generate these olefins. This review focuses on the naphtha steam cracking process, which primarily involves straight run naphtha sourced from crude oil distillation units. To qualify as petrochemical naphtha, the stream typically requires a high paraffin content, exceeding 66%.

Cracking reactions take place within the furnace tubes, and a significant concern and constraint for the operational lifespan of steam cracking units is the formation of coke deposits in these tubes. These reactions occur at elevated temperatures, typically ranging from 500°C to 700°C, depending on the feedstock's properties. For heavier feeds like gas oil, lower temperatures are employed to minimize coke formation.

The steam cracking process is characterized by high temperatures and short residence times. While the primary focus of a naphtha steam cracking unit is typically ethylene production, the yield of Propylene in such units can reach up to 15%.

Fluid Catalytic Cracking (FCC)

Presently, a significant portion of the Propylene market relies on steam cracking units for supply. However, a considerable share of the global Propylene demand stems from the separation of LPG generated in Fluid Catalytic Cracking Units (FCC).

Typically, LPG generated in FCC units contains approximately 30% Propylene, and the added value of Propylene is nearly 2.5 times that of LPG. In local markets, the installation of Propylene separation units proves to be a financially rewarding investment. However, a drawback of separating Propylene from LPG is that it results in a heavier fuel, causing specification issues, particularly in colder regions. In such cases, alternatives include segregating the butanes and redirecting them to the gasoline pool, adding propane to the LPG, or supplementing LPG with natural gas. It's important to note that some of these alternatives may decrease the availability of LPG, which could pose a significant constraint based on market demand.

A challenge in Propylene production lies in the separation of propane and Propylene, a task complicated by their close relative volatility of approximately 1.1. Traditional distillation methods struggle due to this narrow gap, necessitating distillation columns with numerous equilibrium stages and high internal reflux flow rates.

Two primary technologies employed for Propylene-propane separation are Heat-Pump and High Pressure configurations. The High Pressure approach relies on conventional separation methods, requiring sufficient pressure to condense products at ambient temperature, with a reboiler utilizing steam or another heat source. However, this method's reliance on low-pressure steam availability in refining hardware can be limiting. Alternatively, the Heat-Pump technology utilizes the heat from condensing top products in the reboiler, effectively combining the reboiler and condenser into a single unit. To address non-idealities, an auxiliary condenser with cooling water may be installed.

Implementing Heat-Pump technology enables a reduction in operating pressure from approximately 20 bar to 10 bar, thereby increasing the relative volatility of Propylene-propane and simplifying the separation process. Typically, Heat-Pump technology proves more attractive when distillation becomes challenging, particularly when relative volatilities are below 1.5.

Several variables must be considered when selecting the optimal technology for Propylene separation, including utility availability, temperature differentials in the column, and installation costs.

Propylene produced in refineries typically adheres to specific grades: Polymer grade, with a minimum purity of 99.5%, is directed towards the Polypropylene market, while Chemical grade, with purities ranging from 90 to 95%, is allocated for other applications. A comprehensive process flow diagram for a standard Propylene separation unit utilizing Heat-Pump configuration is illustrated in the following Figure.

The LPG extracted from the FCC unit undergoes a series of separation processes to isolate the light fraction, primarily comprising propane and Propylene. This fraction is then directed to a deethanizer column, while the heavier fraction, containing butanes, is either routed to the LPG or gasoline pool, depending on refinery configuration. The lighter fraction from the deethanizer column is often recycled back to the FCC unit for incorporation into the refinery fuel gas pool. Alternatively, it may be directed to petrochemical plants for the recovery of light olefins, particularly ethylene. The bottom fraction from the deethanizer column undergoes further separation in the C3 splitter column to separate propane and Propylene. Propane is recovered from the bottom of the C3 splitter and sent to the LPG pool, while Propylene is directed to the Propylene storage park. Before processing, the feed stream undergoes a caustic wash treatment to remove contaminants, such as carbonyl sulfide (COS), which can adversely affect petrochemical processes and may be produced in the FCC unit through the reaction between carbon monoxide and sulfur in the Riser.

Major Technologies Used for Producing Propylene

Process: OCT Process

Lummus Technology, one of the leading technology providers, presents two deliberate pathways to Propylene: Olefins Conversion Technology (OCT), which employs olefins metathesis, and CATOFIN propane dehydrogenation.

Traditionally, commercial on-purpose Propylene production methods have contributed to less than 5% of the global Propylene output, with the majority sourced as a by-product of steam crackers and fluid catalytic cracking (FCC) units.

Through the OCT process, low- value butylenes are subjected to reaction with ethylene to yield Propylene. The ethylene feedstock can range from diluted ethylene, typical of an FCC unit, to polymer-grade ethylene. Potential C4 feedstocks encompass mixed C4s generated in steam cracking, raffinate C4s from MTBE or butadiene extraction, and C4s produced within an FCC unit.

The ultra-high purity Propylene yielded by the OCT process surpasses polymer-grade specifications and promises potential cost savings in downstream Polypropylene facilities.

The mixture of ethylene feed and recycled ethylene is combined with the C4/C5 feed and recycled butenes/pentenes, and then heated before entering the fixed-bed metathesis reactor. Within the reactor, the catalyst facilitates the reaction of ethylene with butene-2 to produce Propylene, and the conversion of ethylene and pentenes to Propylene and butenes, while also isomerizing butene-1 to butene-2. Some coke buildup occurs on the catalyst, necessitating periodic regeneration of the beds using nitrogen-diluted air. The process is engineered for high utilization of olefins, typically ranging from 90 to 97%, with a Propylene selectivity of around 94 to 95%. After cooling and fractionation to remove ethylene for recycling, a portion of the recycle stream is purged to eliminate methane, ethane, and other light impurities. The bottoms from the ethylene column are directed to the Propylene column, where butenes/pentenes are separated for recycling to the reactor, and some are purged to eliminate unreacted butenes, isobutenes, butanes, unreacted pentenes, isopentenes, pentanes, and heavier compounds from the process. The overhead product from the Propylene column constitutes high-purity, polymer-grade Propylene.

Applications of Propylene

Polypropylene

The vast majority of Propylene, a key industrial ingredient, goes into making Polypropylene. This versatile plastic is used in everything from clothes and water bottles to patio furniture and countless other items. The most prominent among Propylene’s stars is Polypropylene (PP). This is a strong plastic that is used in packaging and is significantly lightweight. PP dominates the food container and beverage bottle market as well as the textile bag and carpet industry. It is resistant to moisture, chemicals, and heat that makes it ideal for food packaging and protecting some items when being transported. And its price makes it the first choice of the manufacturers.

Cumene

Cumene, a crucial intermediate compound, is predominantly synthesized through the Friedel-Crafts alkylation process involving Propylene and Benzene. This organic chemical holds significant value and finds widespread application in various products including plastics, pharmaceuticals, and adhesives. Moreover, cumene's exceptional solvency properties make it a preferred solvent in formulations for paints, inks, and cleaners. Its derivatives play a pivotal role in the production of polymers such as PET and polycarbonates, essential materials utilized in packaging, electronics, and construction industries. Additionally, cumene serves as an effective octane booster in gasoline, enhancing combustion efficiency and engine performance while reducing exhaust emissions.

Oxo Alcohol

Oxo alcohols form an important class of chemical intermediates that are used to produce plasticizers, coatings, and detergents. Oxo alcohols are used in a wide variety of industries from plastics and coatings to pharmaceuticals and cosmetics industries thus emphasizing their significance in various industrial processes.

Isopropanol

In the indirect-hydration method, Propylene undergoes a reaction with sulfuric acid to generate mono- and diisopropyl sulfates, which are subsequently hydrolyzed to produce isopropanol. This versatile compound is commonly diluted with water and employed as a rubbing-alcohol antiseptic, and it also serves as a key ingredient in aftershave lotions, hand lotions, and various cosmetic products. In industrial applications, isopropanol functions as a cost-effective solvent for cosmetics, medications, shellacs, and gums, in addition to its role in denaturing ethanol (ethyl alcohol).

Market Outlook

The majority of globally produced Propylene is utilized in the manufacturing of Polypropylene through polymerization. Propylene and its derivatives play crucial roles in various industries, including packaging, electronics, automotive, textiles, cosmetics, food and beverage, pharmaceuticals, construction, and others. Polypropylene stands as the predominant thermoplastic polymer, serving as a pivotal material for plastic components across a multitude of industries such as packaging, electronics, automotive, textiles, and beyond. Furthermore, various derivatives of Propylene are utilized across an array of sectors including cosmetics, personal care, food and beverage, pharmaceuticals, construction, automotive, and others, encompassing textiles, paper, pulp, electronics, consumer goods, and chemicals. As these sectors expand, the demand for Propylene is expected to increase.

Propylene Major Global Producers

Notable players in the Global Propylene market are Reliance Industries Limited, Indian Oil Corporation Limited, HPCL-Mittal Energy Limited, Haldia Petrochemicals Limited, Mangalore Refinery & Petrochemicals Ltd, Brahmaputra Cracker and Polymers Limited, Shenhua Ningxia Coal Group Corporation Limited, Bharat Petroleum Corporation Limited, Hindustan Petroleum Corporation Limited, GAIL (India) Limited, Nayara Energy Limited, Fujian Refining & Petrochemical Co Ltd, Zhong Tian He Chuang Energy, Sinopec Sabic Tianjin Petrochemical Co., Ltd., Wanhua Chemical Group Co., Ltd, and Others.

Conclusion:

In summary, Propylene can be considered as a highly important, versatile and indispensable chemical compound that is used as an input for various industries around the globe. Its importance as a major producer of Polypropylene, an important thermoplastic material used in packaging and automobile industries, among others, attests to its significance in the economy. Furthermore, Propylene and other derivatives are used in various chemical industries such as cosmetics, pharmaceuticals, and construction industries. The anticipated growth of the Polypropylene industry is expected to significantly propel the market in the coming years. Additionally, various derivatives of Propylene, including Propylene oxide, acrylic acid, acetone, IPA, Polypropylene glycol, and cumene, find extensive applications across numerous industries, further driving demand for Propylene in the forecast period. Moreover, the rapidly expanding construction, automotive, and packaging industries present promising growth prospects in the global Propylene market.

#propylene#propyleneprices#propylenemarket#propylenenews#propylenepricetrend#propylenepriceforecast#propylenedemand#propylenesupply#propylenemarketprice#priceofpropylene

1 note

·

View note

Text

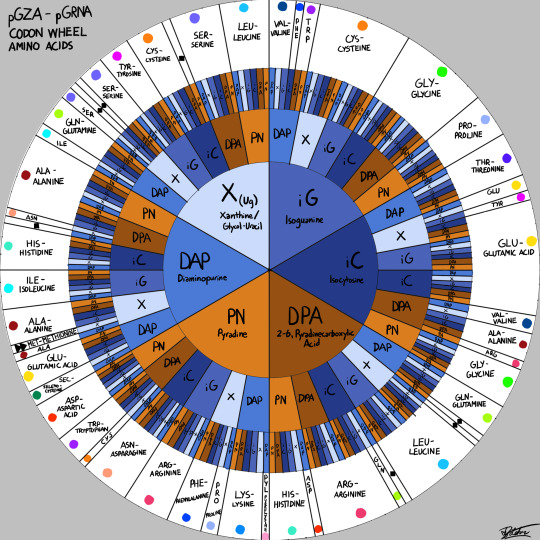

Codon Amino Acid chart for pGZA, the building block of life on Jom'Gol

pGZA is the abbreviation for Propylene-Glycol Nucleic Acid, which all cellular life on Jom'Gol uses. pGZA uses the sugar Propylene Glycol and a standard phosphate base.

Instead of Adenine, Thymine/(Uracil), Guanine, and Cytosine, pGZA instead uses Diaminopurine, Xanthine, Isoguanine, Isocytosine, 2-6, Pyradinedicarboxylic acid, and Pyradine.

Rather than (DNA):

A-T (Hydrogen Bond)

C-G (Hydrogen Bond)

pGZA uses:

DAP-X (Hydrogen Bond)

iC-iG (Hydrogen Bond)

PN-DPA (Copper ii ion Bond)

Each Codon combination in pGRNA production results in the production of one of 23 amino acids when read by the xenoribosome in any Jomgolian creature's cell, with the addition of one start codon and several stop codons.

#art#digital art#artists on tumblr#worldbuilding#speculative biology#speculative evolution#spec evo#spec bio#xenobiology#dna#jomgol#propylene glycol#xenonucleic acid

39 notes

·

View notes

Text

update on my experiments i like running on myself:

leg braces: success. i mostly just will wear em for an hour or two after work to stretch out my gastrocnemius but it has made a HUGE impact on day to day pain both at work and after

potassium alum: positive results. i work in hazmat gear essentially for 10 hours straight so anything to stop sweat is something i will try. have been applying the alum after i shower and top up problem areas just before work; positive results in sweat heavy areas like pits, minimal body odor even without deodorant. less effective in places like inner elbow, back of knee, etc with presumably less apocrine glands. tried some on forehead as well with similar moderate results but it DID kill a big acne cyst on my forehead so hell yeah. no itching and no irritation from the metal salts

#postingviolence#for reference alum salts are the same thing as used as an antiperspirant in most commercial bars and one of the main ingr of styptic pencil#some people get irritation but alum in general does very little in the human body + most such products have other shit more irritating#like propylene glycol or essential oils#there's record of human use of alum for antipersp for like multiple thousands of years. we have been putting rocks in our armpits forever#so it is prooooooooobably fiiiiiiiiiiine

3 notes

·

View notes

Text

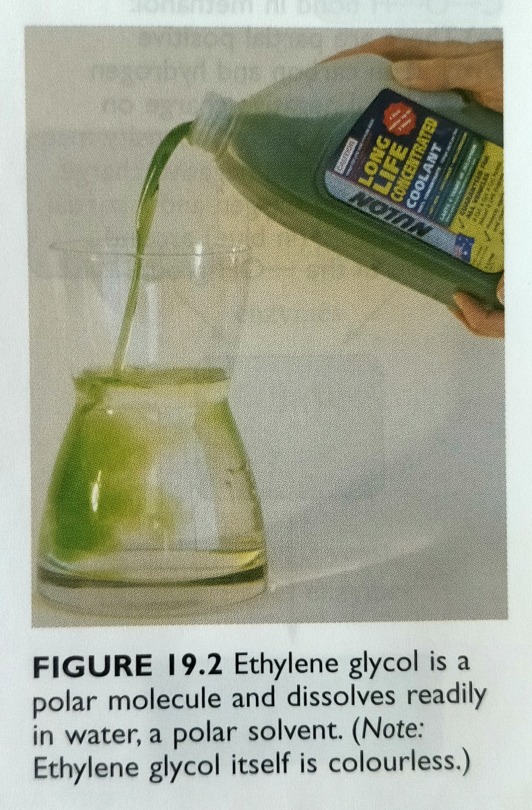

Ethylene glycol (see figure 19.2) and propylene glycol are synthesised from ethylene (ethene) and propylene (propene) respectively, hence their common names as shown below.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#ethylene glycol#propylene glycol#ethylene#ethene#propylene#propene#synthesis#polarity#ethane#propane

4 notes

·

View notes

Text

my allergies (? pending. might be smth else who knows at this point) have been acting up so bad lately in ways they haven't before and I'm Over It

#I have this fun reaction to propylene glycol (don't @ me if that's misspelled)#which is in virtually everything bc it's a preservative#and I get rashes from it#and I'm reacting like that on my face/around my eyes but To Nothing#like I haven't put anything but water or regular ass soap on my face why 😭

8 notes

·

View notes

Text

Propylene Prices, News, Trend, Graph, Chart, Monitor and Forecast

The global propylene market plays a crucial role in the petrochemical industry, influencing a wide range of downstream products such as polypropylene, acrylonitrile, propylene oxide, and cumene. Over the past few years, propylene prices have experienced significant fluctuations due to various economic, geopolitical, and supply chain factors. The market dynamics are primarily driven by crude oil prices, production capacities, demand from end-use industries, and global trade policies. As an essential feedstock in the chemical sector, propylene prices are closely tied to refinery operations, cracker margins, and global energy trends. The demand for propylene is largely dictated by the growth of industries such as packaging, automotive, construction, and textiles, where polypropylene and other derivatives are extensively used.

One of the primary influences on propylene pricing is the cost of crude oil and natural gas, as both are key sources of propylene production through steam cracking and fluid catalytic cracking (FCC). Crude oil price fluctuations directly impact the cost of production, making the propylene market highly sensitive to energy market trends. The geopolitical landscape, including conflicts in oil-producing regions and OPEC+ production policies, further contributes to price volatility. Additionally, the global economic environment, including inflation rates, interest rates, and industrial output, plays a significant role in shaping the pricing trends of propylene. During periods of economic growth, demand for consumer goods and infrastructure development surges, leading to higher consumption of propylene derivatives, which in turn drives prices upward.

Get Real time Prices for Propylene: https://www.chemanalyst.com/Pricing-data/propylene-51

The supply side of the propylene market is influenced by production capacities, refinery operations, and unplanned shutdowns. Many countries with large petrochemical hubs, such as the United States, China, and the Middle East, continuously invest in expanding their production capacities to meet the rising demand. However, supply chain disruptions caused by factors such as extreme weather events, transportation bottlenecks, or regulatory restrictions can lead to short-term price spikes. The shift toward sustainability and the increasing focus on bio-based and recycled propylene also impact market dynamics, as companies invest in greener alternatives to reduce their carbon footprint. Regulations regarding emissions and plastic waste management further shape the production strategies of key players in the market.

The Asia-Pacific region remains a dominant force in the propylene market, driven by strong industrial growth, rising consumer demand, and expanding manufacturing capacities. China, in particular, plays a significant role in global propylene pricing due to its massive refining and petrochemical sector. The country's strategic investments in integrated refinery-petrochemical complexes ensure a steady supply of propylene, impacting regional and global price trends. Other Asian countries such as India, South Korea, and Japan also contribute to the dynamic pricing landscape, with demand from packaging, automotive, and construction industries driving consumption. The region's reliance on imported crude oil makes it susceptible to external market shocks, further adding to the price volatility.

North America is another key player in the propylene market, with the United States leading the production due to its abundant shale gas reserves. The rise of propane dehydrogenation (PDH) plants has significantly altered the supply structure, making the region more self-sufficient in propylene production. The advantage of low-cost feedstocks from shale gas has provided a competitive edge to North American producers, helping them expand their footprint in the global market. However, weather-related disruptions such as hurricanes affecting Gulf Coast refineries can lead to supply constraints and price spikes. The region's strong demand for polypropylene in packaging, automotive components, and consumer goods continues to support propylene price stability, despite occasional fluctuations due to external factors.

In Europe, the propylene market is influenced by refinery operations, energy policies, and regulatory frameworks. The region's emphasis on sustainability and circular economy initiatives has led to increased investments in bio-based and recycled propylene. However, high energy costs and dependence on imported crude oil pose challenges for European producers, making the market susceptible to price fluctuations. The ongoing transition toward greener alternatives, coupled with stringent environmental regulations, affects the operational strategies of refineries and petrochemical plants. Additionally, trade relations with key suppliers such as the Middle East and Russia impact supply security and pricing trends in the region.

The Middle East, known for its abundant hydrocarbon resources, is a major supplier of propylene and its derivatives to global markets. Countries such as Saudi Arabia, the UAE, and Iran benefit from low production costs and integrated refining-petrochemical complexes, allowing them to maintain competitive pricing. The region's strategic focus on expanding petrochemical capacities to diversify away from crude oil exports has bolstered its position in the global propylene market. However, geopolitical tensions and trade sanctions can create supply disruptions, leading to price fluctuations. The region's growing investments in downstream industries, including polypropylene production, further shape market dynamics.

Latin America and Africa also contribute to the global propylene market, albeit at a smaller scale compared to other regions. Brazil, Mexico, and Argentina have notable petrochemical industries that influence regional pricing trends. However, economic instability, regulatory challenges, and limited refining capacities often impact supply consistency. In Africa, emerging industrialization and infrastructure development are driving demand for propylene-based products, though supply constraints and logistical challenges remain key concerns for market participants. Both regions have potential for growth, especially with increasing foreign investments in refining and petrochemical projects.

The future outlook for propylene prices remains closely tied to energy market trends, technological advancements, and sustainability initiatives. The growing adoption of propane dehydrogenation technology is expected to enhance supply security and stabilize prices in key markets. Additionally, the increasing emphasis on circular economy principles and recycling initiatives will play a role in shaping production strategies. As industries continue to shift toward sustainable materials and bio-based alternatives, the propylene market is likely to witness structural transformations. While short-term price fluctuations are inevitable due to geopolitical and economic uncertainties, the long-term trajectory is expected to align with global industrial growth and evolving consumer preferences.

Market participants, including producers, traders, and end-users, must closely monitor key factors such as crude oil prices, supply chain dynamics, and regulatory developments to make informed decisions. The integration of digital technologies and data analytics in supply chain management is also expected to enhance market efficiency, reducing the impact of unexpected disruptions. With the continued expansion of production capacities and the rise of sustainable alternatives, the global propylene market is poised for dynamic changes, offering opportunities for stakeholders across the value chain.

Get Real time Prices for Propylene: https://www.chemanalyst.com/Pricing-data/propylene-51

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Propylene#Propylene Price#Propylene Prices#Propylene Pricing#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Look, I get where you're coming from, but I think you've swung too far in the other direction here. NSAIDs and acetaminophen are, in most places as far as I'm aware, the only options available for non-prescription pain medications. They're available without prescription because, if used infrequently and within the recommended dosages, they are relatively safe and low in side effects. HOWEVER. it is very difficult to get a prescription for pain medication, and even if you do, those medications also come with dose limits and side effects. So the bottom line is that many, MANY people are relying on NSAIDs and acetaminophen for the primary management of chronic pain. And in that context, it is absolutely possible to severely hurt yourself. Which I think people absolutely deserve more knowledge and awareness of - even if they find it somewhat alarming.

This is especially true where people are brushed off by doctors to "just use advil" for pain that is quite frankly, too severe and ongoing for advil to safely handle. The dismissive way in which doctors treat NSAIDs gives the impression that they are harmless, and many people are desperate for relief. This leads people to use NSAIDs heavily and without precautions, causing lasting harm to themselves which could have been averted, or at least mitigated, by taking steps towards safer use - like those outlined in the original post. NSAIDs work on several biochemical pathways at once - they reduce inflammation, relax muscles, decrease pain signalling of nerves, and slightly inhibit blood clotting, and they also increase the production of stomach acid and decrease the production of protective mucus lining the stomach. This function is pretty much baked in, there's no way around it. So it's not an issue of "some people's stomachs are sensitive to NSAIDs," it's an issue of "NSAIDs cause some damage directly to the stomach lining every time you take them". It's not very much damage from one dose, and if that's the only dose you take for a while, it'll heal right back up. But if you keep taking them, multiple doses back to back, for days or weeks on end.... the damage starts to add up. Or even if you don't use them that much, but take maybe a dose every day to help with muscle soreness after work... or a couple times a month, for migraines or period cramps.... point is, if the damage to the stomach lining is happening faster than it can heal, you start to get problems - but you probably won't notice anything is wrong until it gets pretty bad.

Being careless until you get a proto-ulcer, or an ulcer, or acid reflux, or a bleeding lesion in the duodenum - is not a great tactic. And I will tell you, pretty much everyone I know who is careful about taking their NSAIDs with food or antacids, has become careful after suffering AT LEAST one of the above. And many people end up, as OP said, unable to take NSAIDs at all, because the chronic damage to the stomach is too easily aggravated. Which is not great! So it's good to get in the habit of safer use, before you find yourself in a situation of heavily using pain meds without realizing they could cause lasting damage! Because the underlying issue is stomach acid causing damage to the stomach lining, you can: - take NSAIDs with food, or after eating, so the food dilutes the stomach acid - take NSAIDs with an antacid, like tums (although avoid aluminum-based antacids with ibuprofen) - take NSAIDs with an H2 blocker, a relatively fast-acting medicine that reduces acid produced by the stomach - take a daily PPI medication, which reduces acid produced by the stomach over the long term

Now, H2 blockers and PPIs are other (non-prescription) medications which have their own potential for side effects and interactions - so do your research if you want to add either of them to your medication regimen. But they can be very helpful, especially for healing up if damage has already been caused. Now all that being said. Acetaminophen is a COMPLETELY different story. And what pushed me to reply to this post was the way you were lumping together information on max dosages, which I think is dangerously misleading, even if the numbers are not technically incorrect. See, the risk with NSAIDs is chronic damage from long-term use, but they are relatively safe drugs in the acute sense. For Ibuprofen in particular - the bottle will tell you not to take more than 400mg at once, but if pressed a doctor will say you can take up to 800mg and it's perfectly safe if you don't make too much of a habit of it, and hypothetically you could even take a much higher dose than that and not die, although you wouldn't have a very good time. So, while it is certainly not recommended to take more than 800mg at once or more than 1600mg a day to avoid long-term consequences.... it happens. Which can perhaps teach a person the wrong lessons about dose safety. The risk with acetaminophen is acute toxicity. If you take too much at once, it causes liver toxicity, and then liver failure, and then death. This process can be stopped, but not reversed, so survival depends strongly on early diagnosis and treatment. You might think that the toxic dose in enough higher than the treatment dose that it'd be difficult to overdose accidentally - but that's not necessarily the case. From a National Institute of Health summary on Acetaminophen toxicity: "Acetaminophen toxicity is the second most common cause of liver transplantation worldwide and the most common cause of liver transplantation in the US. It is responsible for 56,000 emergency department visits, 2,600 hospitalizations, and 500 deaths per year in the United States. Fifty percent of these are unintentional overdoses." Sure, relative to the total population, overdoses aren't *that* common - but if 50% are accidental, I think people need to be better informed. The major issue with acetaminophen is that it is present as an active ingredient in many, many multi-drug medications, which people often don't realize. So an overdose can occur if, for example, a parent who has already given their child a Tylenol to get their fever down also gives them a dose of cough syrup - each alone at the recommended dose, but it adds up. (Children are at a greater risk of overdose on anything, because toxic dosage is relative to body size, and kids are small.)

So yes, acetaminophen is a great drug and relatively safe if you know how much you are taking. Always check the active ingredients on any medicine you take, especially if you're taking multiple things at once. And for acetaminophen especially, don't take more than the recommended dose at once, don't take more than the maximum dose per day, and wait at least 4 hours between doses - even if the effect has worn off. Don't push it!

Every time I see another ibuprofen post on this site I'm like STOP

STOP

Stop.

Take that after a meal. Take it with a big glass of water. Don't take it on an empty stomach EVER. Don't take it with alcohol. You will destroy your stomach. You will end up with an ulcer. You will vomit blood. I'm not exaggerating.

Yes, you. Yes, it will happen to cute little you. With your cute little bottle of miracles. Ibuprofen really does that to your body.

Love, an adult person over 35 who can't take NSAIDs anymore

#if you live in a place where doctors are accessible + affordable + helpful + take you seriously#then yes you have no reason to be afraid of using medications off the shelf as labeled and going to a doctor for anything serious#would that we all lived in such a situation!#it is my experience that generally everyone is pushing the limits of what can be done with the meds they can access#in which case you absolutely need to know where the hard boundaries on safety lie#and what the safer use practices are to mitigate harm up to those hard boundaries#I'm sorry if my information on what's available etc is US centric; i know what i know#I tried to avoid using “OTC” as a term because it has at least two distinct meanings and I didn't want to deal with disambiguating#Also I was EXTREMELY baffled by the claim that propylene glycol was more toxic than acetaminophen so i did a bit of searching#and there seems to have been a nasty issue where the propylene glycol used in some cough syrup was contaminated with ethylene glycol#which is extremely toxic. and a bunch of kids got poisoned.#not to disregard how awful that is but drug contamination is a WHOLE other can of worms.#also for any of you meds nerds who were wondering about ''stomach safe nsaids'' and why i didn't get into that#those all got recalled. because it turns out mucking with the mechanism of action of nsaids to make it not do the stomach damage thing#makes them give you heart problems instead!#multipurpose enzymes are a bastard. hard to wrangle.#it'd be neat if we eventually got medications that targeted prostaglandin receptors rather than production - we could be much more selectiv#but we're not there yet#long post#long tags

75K notes

·

View notes

Text

Gaskets, Washers, Rubber Gaskets, Manufacturer, Mumbai, India

Click here to get more information of Gaskets, Washers, We are manufacturer, supplier, dealer and best service provider of Rubber Gaskets, Filtration Gaskets in Mumbai, India.

#Rubber Products#Moulded Rubber Parts#Extruded Rubber Parts#Sponge Moulded Parts#Metal Bonded Parts#Manufacturers Of Rubber Components#Manufacturers Of Moulded Rubber Parts#Manufacturers Of Extruded Rubber Parts#Rubber Moulded Parts#'O' Rings#Oilseal#U Seal#V Seal#Chevron Packing For Pumps#Hydraulics Seal#Mechanical Seal#Neoprenen Rubber#Nitrile Rubber#Epdm Rubber#Hypalon Rubber#FKM Rubber#Natural Rubber#Polymers#Flourinated Rubber#Silicone Rubber#Polyurethane Rubber#Ethylene Propylene Terpolymers#Synthetic Rubber#Chemical Resistance#O Rings

0 notes