#screw manufacturing business in india

Text

Screw Manufacturing Business Plan

Hey there, future entrepreneurs! 👋 Ever wondered how to start your own screw manufacturing business? 🤔 Let me show you the ropes! 🛠️ Check out this expert tips and tricks.#screwmakingmachine #screwmanufacturingbusiness #manufacturingbusiness #business

Screw Manufacturing Business – Screws are essential tools used to hold objects together. They can be made by either casting them from molten metal or forging them from a solid piece of metal. Screws are inserted into holes in the object and turned to grip the object tightly. There are different types of screws, each designed for specific purposes. And, the manufacturing industry has been…

View On WordPress

#how to start a screw manufacturing business#manufacturing business ideas#new business ideas#screw manufacturing business#screw manufacturing business ideas#screw manufacturing business in india#screw manufacturing business plan#screw manufacturing machine#screw manufacturing process#screws manufacturing process#steel screw manufacturing business

0 notes

Text

Super Duplex S32760 Flanges Manufacturers in India

The manufacturer and supplier of Very Duplex Steel Flanges made their products in a variety of sizes and forms for the customer in response to interest. The manufacturer, stockist, and supplier of the entire stainless steel item, including this, is Sankalp Alloys Overseas. They provide everything and deliver the product while maintaining excellent quality and price as well.

Super Duplex Steel Flanges are regarded as the best in the series of steel Flanges based on their characteristics and strong points. The austenitic toughened steel is offered in Very Choice with a few components like copper, zinc, and chromium. The majority of businesses use a lot of Duplex steel products since they provide high strength when they come into touch.

There are many kinds of Flanges accessible, for example, Welding Neck Wall It is by and large utilized in low-temperature and high-pressure applications since they required the unhindered liquid stream conveyed by the line framework. Long welding Neck-They is equivalent to a weld neck just contrast in a lengthy welding neck the tightened center point (neck) is expanded and performs like an exhausting expansion. Slip-on Spine It is appended to the fittings or the line by two filet welds, one external the hole and the other one executed inside the rib. They are handily perceived by their minimal and thin shape.

Strung Rib This is attached by screwing the line into the spine rather than using a crease weld. They are typically used in small, low-temperature, low-stress applications like utility and water management. They are legally required in dangerous areas like petrol stations and industries. Since welding associations could be dangerous in this type of environment. Spine Attachment Weld To connect this type of rib to the lines, a single fillet weld is performed on the exterior of the rib. Joint-joint ribs This spine frequently uses an alloy with a stub end and a component with a level spacing. Dark Spine Due to the necessary catapulting forces and the structure pressure, these Flanges reduce outstanding mechanical forces.

A few other exceptional sorts of rib are Nipo rib, Weldo rib, Turn Rib, Elbo Rib, Lactro Rib, Growing spine, and Lessening Rib.

Specification of Super Duplex Stainless Steel S32750/S32760 Flanges

Super Duplex Stainless Steel Flanges Specification: ASTM A182 / ASME SA182

Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size: 1/2" (15 NB) to 48" (1200NB)

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges: BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

11 notes

·

View notes

Text

Fenton Technologies Pvt. Ltd. is a professional Engineering equipment’s Manufacturing and Environmental research and development, production and sales of science and technology enterprises. Since its inception, we always adhere to the spirit of craftsmanship, to provide the industry with water treatment equipment and services and systematic solutions, Company Work in Three Verticals- Sewage Water Projects , Wastewater Products, Swimming Pools Products include MBR Membrane , Oil Skimmer, Screw Press, MBR STP Plant, Bar Screen, Dissolved Air Flotation (DAF) many More water treatment Equipment’s . Fenton is also Associating with Overseas partners to Keep in Forefront . Our Water Treatment Equipment Company always welcome innovation & Advance Technologies Developers for Association in Market .

In product quality improvement, the water treatment equipment company “customer first” philosophy for the development, adhering to the “quality, innovation and service” business purposes, the establishment of a set of international standards of quality assurance management system.

youtube

MBR Membrane Manufacturer

Sewage treatment plant manufacturer in india

water Treatment Equipment Manufacturer

water Treatment Equipment Supplier

Belt Type Oil Skimmer Manufacturer

swimming pool manufacturer in india

2 notes

·

View notes

Text

One of the top wholesalers, suppliers, and importers of a variety of high-quality Fasteners and Fixing including nuts and bolts, metal screws, machine tools, fastener expansion tubes, heavy-duty anchors, anchors for general fixing, pipe clamps, industrial screws, and other items is Kaizen Metals india Screw India.

Our cutting-edge infrastructure facility located in Jamnagar guarantees standardized product manufacture.

These items, which come in a variety of shapes and sizes, are renowned for their smooth finishes, resistance to corrosion, dimensional precision, and durable construction.

For timely, safe, and secure product delivery to customers, our logistic support specialists leverage a large distribution network.

The superior quality of the things our business creates is the single aspect that supports it, and we never compromise on that in any way.

All of our goods are rigorously tested for their durability and safety. We take steps to ensure that none of our valued customers have ever complained about any of our items.

Our company has achieved an unachievable height that is only attained by a very small number of businesses thanks to our moral business methods and unwavering dedication.

We have been able to provide our clients very consistent and trustworthy items at rock bottom prices because of our extensive experience, thorough understanding of this company range, and the presence of incredibly committed and assiduous employees in our crew.

With the help of a group of knowledgeable, skilled, committed, and diligent individuals, this team approached every assignment with great care. Our staff includes purchasing agents, quality inspectors, packaging specialists, and many more.

These individuals were hired based on their expertise and understanding of their respective fields. Their upbeat demeanor and expert understanding of the field create a productive atmosphere where employees love the work they do. Additionally, this team is periodically refreshed in accordance with the most recent market trends.

#nuts and bolts#metal screw#machine tools#fastener expansion tube#heavy duty anchors#general fixing anchors#pipe clamps#industrial screws#fixings and fasteners#fixings and fastener#screws#bolts#nuts#coach-screws#screw hooks#rivets#cotters#cotter-pins#washers

1 note

·

View note

Text

Lathe Faceplates Market Is Likely to Experience a Tremendous Growth in Near Future

Lathe faceplate is the mechanical equipment that makes a mechanical attachment between a lathe and a wood bowl blank using screws. It is available in different raw materials. The two components of a lathe faceplate are a threaded neck that attaches to the lathe headstock threads and a vertical plate with screw holes to attach the wood bowl blank.

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/72536-global-lathe-faceplates-market?utm_source=Organic&utm_medium=Vinay

Latest released the research study on Global Lathe Faceplates Market, offers a detailed overview of the factors influencing the global business scope. Lathe Faceplates Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Lathe Faceplates The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are Jet Tools (United States), Sherline Products (United States), PSI Woodworking (United States), Teknatool USA, Inc. (United States), Topsdisk (China), Magnaalu (China), State Engineering Corporation (India), IBFEX (Kingdom of Bahrain), Penn State Industries (United States), Rockler Companies, Inc. (United States),

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

0 notes

Text

Supplier of SS Fasteners in Maharashtra

Luvana Metal Corporation is a Manufacturer and Supplier of SS Fasteners in Maharashtra, India.

Established in 2020 in Ahmedabad, Gujarat, India, Luvana Metal Corporation proudly holds ISO 9001:2015 certification, showcasing its commitment to quality and excellence.

We offer a wide array of customizable stainless steel products to fulfill varied industrial needs. Our range encompasses coils, sheets, plates, bars, rods, wires, valves, pipes, fittings, channels, angles, butt weld fittings, flanges, and fasteners.

Stainless Steel Fasteners are the unsung heroes of countless constructions, from towering skyscrapers to intricate machinery.

Crafted from stainless steel, these fasteners boast exceptional resistance to corrosion, rust, and staining, even in harsh conditions.

Our SS fasteners come in a myriad of shapes, sizes, and configurations to suit any application. From bolts and nuts to screws and washers, each component can be tailored to meet specific project requirements, ensuring a perfect fit and optimal performance.

Renowned for their high tensile strength and load-bearing capacity, stainless steel fasteners provide robust support in critical industries.

Beyond their functional benefits, stainless steel fasteners offer aesthetic appeal, adding a touch of sophistication to any design. Their sleek, polished finish enhances the overall look of structures.

Our SS Fasteners is a sustainable material, known for its recyclability and minimal environmental impact. By opting for stainless steel fasteners, businesses can reduce their carbon footprint and contribute to a greener, more sustainable future.

Luvana Metal Corporation is a Manufacturer and Supplier of SS Fasteners in Maharashtra and locations like Ahmednagar, Chandrapur, Daulatabad, Dhule, Jalgaon, Kolhapur, Mumbai, Nagpur, Nanded, Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Ratnagiri, Sangli, Satara, Sevagram, Solapur, Thane, Ulhasnagar, Vasai-Virar, Wardha, Yavatmal.

Please feel free to contact us with any questions or for additional information.

Read the full article

0 notes

Text

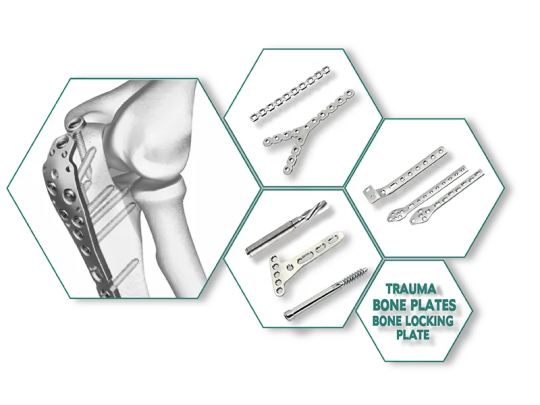

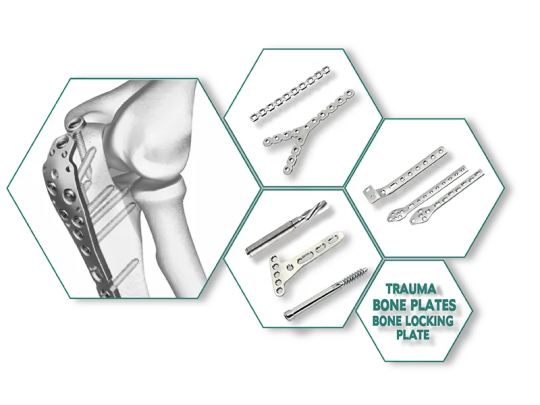

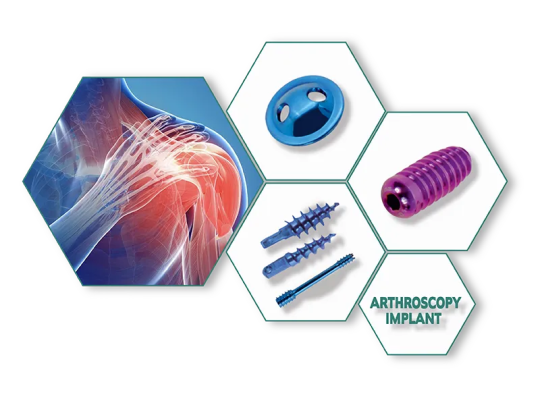

Orthopaedic Implants Manufacturer, Exporter From India - Genius Ortho

Orthopedic Implants Manufacturer, Exporter From India - Genius Ortho

Welcome to

Genius Ortho Private Limited

Genius Ortho Private Limited was found in 2008 by a group of entrepreneurs after having a decade of experience in the field of orthopaedic implants manufacturing. Genius Ortho Private Limited now is the leading company in India specialize in the Orthopaedics Industry. Genius Ortho Private Limited will always achieve this position by professional pursuing excellence and by dedicating ourselves in improving the quality and serving all our customers.

All implants are exclusively made of Stainless Steel 316L , LVM & Titanium Grade V Ti-6Al-4v-ELI.

Our products of Orthopedic implants and instruments are not only qualified with the certification of FDA, CE, GMP regulations, but also compliant with ISO Quality Assurance Standards.

Our Products

1.Orthopaedic Implants:

2.Trauma Implants:

3.Spine Implants:

4.External Fixator:

5.Maxillofacial Implants:

6.Arthroscopy Implants:

7.Prosthesis:

8.Orthopaedic Tibia Nail:

9.Orthopaedic Femur Nail:

10.Orthopaedic Locking Plates:

11.Orthopaedic Locking Screw:

12.Orthopaedic Nailing System:

13.Orthopaedic Bone Screw:

14.Orthopaedic Bone Plate:

Our Services

Manufacturers of Quality Medical Devices

1.Pricing:

We set our pricing fairly and honestly, when buying from us, you do not have to wonder if you received our best price or best deal. Every customer is very important to us.

2. Innovation:

Genius continues to introduce new materials in implants and surgical concepts . you can always discuss with us if you have any specific requirements.

3.Partnership:

Our experienced team is always at your service and we look forward to developing a long-term partnership with you Kindly Fill below form to discuss Exclusive partnership with us…!

Our Related Blogs

1.Top Orthopedic Implants Manufacturers in India:

2.Bone Locking Screw Manufacturers in India:

3.Malleolar Screw Suppliers in India:

4.Semi Tubular Plate Suppliers in India:

5.Locking Plate System Suppliers in India:

Get in Touch

OFFICE ADDRESS

201,2,3 Business Terminal, Opp. Shastri Nagar, Nana Mava Main Road, Rajkot - 360 004(Gujarat)

+91-922-746-6598

FACTORY ADDRESS

G-2019, Bh. Kishan Auto Parts, Phase-3, Kishan Gate No.3, G.I.D.C. Metoda, Dist. : Rajkot (Gujarat)

+91-942-691-6893

#Orthopaedic Implants Manufacturer#Orthopedic Implants Exporter#orthopeadic implants#trauma implants#orthopedic trauma implants.

0 notes

Text

Premier Mechanical Vacuum Boosters Manufacturer: Boosting Industrial Efficiency with Swamatics

In the fast-evolving landscape of industrial applications, efficiency and reliability are paramount. At Swamatics, we specialize in manufacturing top-tier mechanical vacuum boosters that are designed to enhance the performance of your vacuum systems. As a leading mechanical vacuum boosters manufacturer, we are committed to providing solutions that meet the highest standards of quality and innovation.

Why Choose Mechanical Vacuum Boosters?

Mechanical vacuum boosters play a critical role in various industrial processes. They are designed to increase the capacity and efficiency of vacuum pumps by reducing the pressure within the system, thus enabling faster processing and improved productivity. Here are a few key benefits:

1. Enhanced Performance: Mechanical vacuum boosters significantly improve the overall performance of vacuum systems by accelerating the evacuation process and maintaining high pumping speeds.

2. Energy Efficiency: By optimizing the vacuum process, these boosters help in reducing energy consumption, leading to cost savings and a smaller carbon footprint.

3. Versatility: Suitable for a wide range of applications, from chemical processing to pharmaceuticals and food packaging, mechanical vacuum boosters are versatile tools in modern industrial operations.

Read More: Swam dry screw vacuum pumps

Swamatics: Your Trusted Vacuum Boosters Supplier in India

Swamatics stands out as a premier vacuum boosters supplier in India, offering a comprehensive range of products tailored to meet the diverse needs of our clients. Swamatics mechanical vacuum boosters are crafted with precision engineering and robust materials to ensure durability and long-term reliability. Here’s what sets us apart:

1. Innovative Design: Our products incorporate the latest technological advancements, ensuring optimal performance and efficiency.

2. Quality Assurance: Each mechanical vacuum booster undergoes rigorous testing and quality checks to meet international standards.

3. Customer-Centric Approach: We believe in building long-term relationships with our clients by providing exceptional customer service and technical support.

Applications of Swamatics Mechanical Vacuum Boosters

Swamatics mechanical vacuum boosters are used across various industries due to their high performance and reliability. Some of the key applications include:

• Chemical Processing: Enhancing the efficiency of distillation, drying, and other chemical processes.

• Pharmaceuticals: Ensuring the purity and efficiency of manufacturing processes.

• Food Packaging: Maintaining the quality and freshness of packaged foods through effective vacuum sealing.

• Automotive: Supporting various manufacturing and testing processes in the automotive industry.

Conclusion

At Swamatics, we are dedicated to driving industrial efficiency with our state-of-the-art mechanical vacuum boosters. As a trusted mechanical vacuum boosters manufacturer and a leading vacuum boosters supplier in India, we are here to support your business with innovative solutions and unparalleled service. Discover the difference that Swamatics can make in your operations today.

0 notes

Text

Discovering the ideal screw compressor manufacturer in India is simplified with "The Ultimate Guide." This comprehensive resource navigates through key factors crucial for decision-making, including quality, reliability, and cost-effectiveness. From assessing technological advancements to evaluating customer reviews, this guide empowers businesses to make informed choices, ensuring seamless operations and enhanced productivity in the dynamic Indian market.

0 notes

Text

Demystifying Hydraulic Fittings: Understanding Their Importance and Types

Introduction:

Hydraulic fittings might not be something you think about every day, but they're crucial components in many machines and systems that power industries worldwide. Let's take a closer look at what hydraulic fittings are, why they're essential, and the different types available.

What are Hydraulic Fittings?

Hydraulic fittings are connectors used to join hydraulic hoses, tubes, and pipes in hydraulic systems. These systems use liquid fluid power to perform work, such as lifting heavy loads, operating machinery, or controlling equipment.

Why Are They Important?

Hydraulic fittings play a vital role in ensuring the proper functioning and efficiency of hydraulic systems. Here's why they're important:

1. Leak Prevention:

Hydraulic fittings create sealed connections between components, preventing hydraulic fluid from leaking out and air from entering the system. This is crucial for maintaining system integrity and preventing performance issues.

2. Flexibility:

Hydraulic fittings allow for flexible routing of hoses and pipes, enabling hydraulic systems to adapt to different configurations and operational requirements.

3. Pressure Management:

Properly selected and installed hydraulic fittings help manage fluid pressure within the system, ensuring safe and efficient operation without leaks or bursts.

4. Maintenance and Repair:

Hydraulic fittings facilitate easy assembly, disassembly, and maintenance of hydraulic systems, reducing downtime and maintenance costs.

Types of Hydraulic Fittings:

There are several types of hydraulic fittings, each designed for specific applications and connection requirements. Here are some common types:

1. Threaded Fittings:

These fittings have threads on their ends, allowing them to screw into corresponding threaded ports on hydraulic components. They come in various thread types, such as NPT (National Pipe Thread) and BSPP (British Standard Pipe Parallel).

2. Flared Fittings:

Flared fittings feature a conical flare on the end of the fitting, which mates with a matching flare on the hydraulic component. They provide a secure, leak-resistant connection and are commonly used in high-pressure applications.

3. Crimp Fittings:

Crimp fittings require a hydraulic crimper to attach them to hoses or tubes. They provide a strong, permanent connection and are widely used in heavy-duty hydraulic systems.

4. Quick Disconnect Fittings:

These fittings allow for fast and easy connection and disconnection of hydraulic hoses without the need for tools. They're ideal for applications requiring frequent hose changes or temporary connections.

Stainless Steel Hydraulic Fittings Manufacturer in India

Ladhani Metal Corporation is one of the leading SS Hydraulic Fittings Manufacturers in India. We are an experience-driven business that seeks to enhance both the organization and the lives of its clients by making the best use of available resources and technological advancements. For its manufacturing facility, we also have access to approved subcontractors and outside vendors, which helps us support urgent orders as well as large project orders.

Conclusion:

Hydraulic fittings are essential components in hydraulic systems, enabling seamless connections, efficient fluid power transmission, and reliable operation. Understanding the different types of hydraulic fittings and their applications is crucial for designing, assembling, and maintaining hydraulic systems across various industries. Whether it's in construction, agriculture, manufacturing, or aerospace, hydraulic fittings play a vital role in powering the machinery and equipment that drive modern civilization.

0 notes

Text

Monel K500 Forged Fittings Manufacturers in India

Technolloy Inc. is proposing to its purchaser's assortment of Monel K500 Forged Fittings to meet explicit application attractiveness without any problem. The item is created exclusively with the assistance of the premium nature of alloy, which is noticing the extreme standards of value that are as per different unrefined component norms. This has caused it to be very popular and is tracked down and utilized in different enterprises for fulfilling different applications. These forged fittings are effectively accessible in various details according to the purchaser's requests. They are offering the item at sensible rates to the purchasers.

The forged fittings at the business are rigorously going through different tests that guarantee a superior nature of fittings. The scopes of the tests directed are: positive material distinguishing proof test, intergranular consumption test, pitting opposition test, hardness test, full scale/miniature test, alloy examination, mechanical test, and so forth.

The MTC, or factory test accreditation, proposed to the benefactors is as per EN 10204/3.1B. The test accreditation given to the clients is a purchaser's test report, a lab test report, and an outsider review organization's test report.

Standard Specification For Monel K500 Forged Fitting

Specifications : ASTM B564 & ASME SB564

Standard : ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size : 1/8” NB to 4” NB (Socketweld & Screwed-Threaded)

Class : 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

Type : Socketweld Fittings, Screwed-Threaded Fittings

K500 Monel Forged Fittings Equivalent GradesSTANDARDWERKSTOFF NR.UNSMonel K5002.4375N05500

Chemical Properties Of Monel K500 Forged Threaded FittingsGradeCMnSiSCuFeNiK5000.25 max1.5 max0.5 max0.010 max27.00 – 33.000.5 – 263.00 min

0 notes

Text

Marine Compressor Market Analysis by Top Key Players, Industry Overview, Supply and Consumption Demand Analysis to 2031

The global "Marine Compressor Market Market" report indicates a consistent and robust growth trend in recent times, projecting a positive trajectory expected to persist until 2031. A significant trend observed in the Marine Compressor Market market is the rising consumer inclination towards environmentally sustainable and eco-friendly products. Furthermore, a notable advancement in this market is the increasing incorporation of technology to elevate both product quality and efficiency. Cutting-edge technologies like artificial intelligence, machine learning, and block chain are actively employed to develop innovative products that outperform traditional options in terms of effectiveness and efficiency. The Marine Compressor Market Market Research Report for 2024 highlights emerging trends, growth opportunities, and potential scenarios envisioned up to the year 2031.

By delving into the latest trends, the report keeps businesses abreast of the dynamic market environment, helping them identify emerging opportunities and navigate potential challenges. The meticulous analysis covers various aspects, offering valuable insights into the historical performance of the market and presenting the current (CAGR) status.

Get a Sample Copy of the Report at: https://www.proficientmarketinsights.com/enquiry/request-sample-pdf/1885

Who are the biggest Marine Compressor Market manufacturers worldwide?

Atlas Copco (Sweden)

KAESER KOMPRESSOREN (Germany)

TANABE (Japan)

Ingersoll Rand (U.S.)

Hi-Sea Marine (China)

Burckhardt Compression (Switzerland)

DHV Marine (Germany)

Teknotherm Marine (Norway)

The Marine Compressor Market Market is described briefly as follows:

The Global Marine Compressor Market size was modified to USD 3172.8 million in 2024, and the market is projected to touch USD 3745.8 million in 2031, showing a CAGR of 2.40% during the forecast period

SWOT Analysis of Marine Compressor Market Market:

A SWOT analysis involves evaluating the strengths, weaknesses, opportunities, and threats of a particular market or business. In the case of the keyword market, we'll be looking at the factors that can impact the industry's performance.

Pestle Analysis of Marine Compressor Market Market:

To better comprehend the market environment, a five-force analysis is performed, which takes into account the bargaining power of the customer, the supplier, the threat of substitutes, the threat of new entrants, and the threat of competition.

Get a Sample Copy of Marine Compressor Market Market Report

What are the Types in Marine Compressor Market Market?

Reciprocating Type

Rotary Screw Type

Rotary Vane Type

Other

What are Applications in Marine Compressor Market Market?

Yachts

Merchant Ships

Navy Vessels

Other

Inquire or Share Your Questions If Any before the Purchasing This Report: https://www.proficientmarketinsights.com/enquiry/queries/1885

Geographical Segmentation:

Geographically, this report is segmented into several key regions, with sales, revenue, market share, and Marine Compressor Market market growth rate in these regions, from 2017 to 2028, covering

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia, and Vietnam)

South America (Brazil etc.)

Middle East and Africa (Egypt and GCC Countries)

Some of the key questions answered in this report:

Who are the worldwide key Players of the Marine Compressor Market Industry?

How the opposition goes in what was in store connected with Marine Compressor Market?

Which is the most driving country in the Marine Compressor Market industry?

What are the Marine Compressor Market market valuable open doors and dangers looked by the manufactures in the worldwide Marine Compressor Market Industry?

Which application/end-client or item type might look for gradual development possibilities? What is the portion of the overall industry of each kind and application?

What centered approach and imperatives are holding the Marine Compressor Market market?

What are the various deals, promoting, and dissemination diverts in the worldwide business?

What are the key market patterns influencing the development of the Marine Compressor Market market?

Financial effect on the Marine Compressor Market business and improvement pattern of the Marine Compressor Market business?

Purchase this Report (Price 3200 USD for A Single-User License) at: https://www.proficientmarketinsights.com/purchase/1885

TOC of Global Marine Compressor Market Market Research Report 2023

1 Marine Compressor Market Market Overview

2 Market Competition by Manufacturers

3 Marine Compressor Market Production by Region

4 Marine Compressor Market Consumption by Region

5 Segment by Type

6 Segment by Application

7 Key Companies Profiled

8 Industry Chain and Sales Channels Analysis

9 Marine Compressor Market Market Dynamics

10 Research Finding and Conclusion

11 Methodology and Data Source

0 notes

Text

Conveyor System Manufacturers in India - Santek

Welcome to Santek Equipments, your premier destination for top-quality conveyor systems in India. With years of expertise and a commitment to excellence, we pride ourselves on being one of the leading conveyor system manufacturers in the country.

At Santek Equipments, we understand the critical role that conveyor systems play in various industries, from manufacturing and logistics to food processing and pharmaceuticals. That's why we design and manufacture conveyor solutions that are reliable, efficient, and tailored to meet the unique needs of our clients.

Our extensive range of conveyor systems includes belt conveyors, roller conveyors, chain conveyors, screw conveyors, and more. Whether you require a standard conveyor solution or a customized system built to your exact specifications, our team of experts is here to deliver.

What sets Santek Equipments apart is our unwavering commitment to quality and customer satisfaction. We use the finest materials and cutting-edge technology to ensure that our conveyor systems are built to last and perform flawlessly, even in the most demanding environments.

In addition to manufacturing conveyor systems, we also provide comprehensive installation, maintenance, and support services to ensure that your equipment operates at peak performance throughout its lifespan.

Partner with Santek Equipments today and experience the difference that our superior conveyor systems can make for your business. Contact us to learn more about our products and services, and let us help you take your operations to the next level.

Unmatched Expertise In Conveyor Systems

Our journey in the world of material handling solutions began with a vision – to design and manufacture conveyor systems that would set new standards in efficiency, reliability, and versatility. Today, we are proud to say that we have achieved and exceeded this vision.

Our Range Of Conveyor Systems

We offer a diverse range of conveyor systems tailored to meet the unique needs of various industries. Whether you require belt conveyors, roller conveyors, chain conveyors, or custom-designed solutions, we have the expertise to deliver precisely what you need.

Why Choose Santek's Conveyor Systems?

Quality Beyond Compromise : Our conveyor systems are built to last, featuring robust construction and high-quality materials. They are engineered to withstand the rigors of industrial environments, ensuring longevity and minimal maintenance.

Precision Engineering: : Each conveyor system we manufacture undergoes rigorous quality checks to ensure optimal performance, accuracy, and safety.

Customization : We understand that every industry has unique requirements. That's why we offer customization options, allowing us to tailor our conveyor systems to fit your specific needs.

Efficiency Redefined : : Santek conveyor systems are designed to enhance workflow efficiency, reduce downtime, and optimize material handling processes.

Dedicated Support : : Our commitment to your success doesn't end with the sale. We provide comprehensive after-sales support to ensure your conveyor systems continue to perform at their best.

At Santek Equipments Private Limited, we are not just manufacturers; we are creators of seamless motion in industries across India. With an unwavering commitment to excellence, we have earned our reputation as one of the leading Conveyor System Manufacturers in India.

#Conveyor System Manufacturers in India#Conveyor System Manufacturers in Pune#Conveyor System Manufacturers in Maharashtra#Conveyor System Manufacturers near me#Conveyor System#Conveyor System Manufacturers

0 notes

Text

Global Bolts Market Size Expected To Reach USD 43,099.31 Million With CAGR 5.10% By 2030

Market Overview:

The global bolts market has witnessed substantial growth and is expected to continue its upward trajectory. In 2022, the market size was reasonably estimated to be approximately USD 28,950.00 Million, and it is projected to reach USD 43,099.31 Million by the end of 2030, exhibiting a CAGR of around 5.10% from 2022 to 2030. Bolts are essential threaded fasteners with external male threads requiring matching pre-formed female threads, such as nuts. They play a vital role in securing various components mechanically and are widely used in construction, automotive, aerospace, and other industries.

Major Key Players:

Würth Industries Service GmbH & Co. KG (Germany), REYHER (Germany), AB Steel Inc. (Canada), Keller & Kalmbach GmbH (Germany), Rockford Fastener Inc. (U.S.), Viha Steel & Forging (India), Brunner Manufacturing Co. Inc. (U.S.), Kd Fasteners Inc. (U.S.), Big Bolt Nut (India), Fabory (Netherlands), Fastenal Company (U.S.), B&G Manufacturing (U.S.), Jignesh Steel (India), Other Major Players.

Request for Sample: -

https://introspectivemarketresearch.com/request/16634

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Inquire Before Purchase: -

https://introspectivemarketresearch.com/inquiry/16634

Bolts Market Segmentation:

Segment Analysis of the Bolts Market:

Type:

Half Screw Bolt

Full Screw Bolt

Material:

Metal

Plastic

Application:

Construction

Automotive

Aerospace

Others

For this report, Introspective Market Research has segmented the Bolts Market based on region:

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Recent Developments:

In March 2022, Fabory acquired Fastto Nederland BV, a well-known fastener expert with a relevant product line and dedicated patrons, showcasing a strong strategic fit between the two experts in fasteners.

In February 2021, Würth Industry announced the acquisition of Atlantic Fasteners Inc., a major player in the structural industry, manufacturing structural bolts, and distributing standard and specialty fasteners.

Acquire This Report: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=16634

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to helping our clients grow and successfully impact the marketplace. Our team at IMR is ready to help our clients grow their businesses by offering strategies to achieve success and monopoly in their respective fields. We are a global market research company, specializing in the use of big data and advanced analytics to gain a broader picture of market trends. We help our customers to think differently and build a better tomorrow for all of us. As a technology-driven research company, we consider extremely large data sets to uncover deeper insights and provide conclusive consulting. We don't just provide intelligence solutions, we help our clients achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1049

Email: [email protected]

#Bolts#Bolts Market#Bolts Market Size#Bolts Market Share#Bolts Market Growth#Bolts Market Trend#Bolts Market segment#Bolts Market Opportunity#Bolts Market Analysis 2024#US Bolts Market#Bolts Market Forecast#Bolts Industry#Bolts Industry Size#china Bolts Market#UK Bolts Market

0 notes

Text

Industrial Conveyor Manufacturer in Noida, Industrial conveyor manufacturer

Parthax, a pioneering Industrial Conveyor Manufacturer in Noida, stands as a beacon of innovation and reliability in the realm of industrial automation. With an unwavering commitment to quality and customer satisfaction, Parthax has carved a niche for itself in the market.

Utilizing state-of-the-art technology and engineering expertise, Parthax designs and manufactures a diverse range of industrial conveyor systems tailored to meet the unique needs of various industries. Whether it's for automotive, food processing, pharmaceuticals, or any other sector, Parthax delivers robust, efficient, and durable conveyor solutions.

From belt conveyors to roller conveyors, chain conveyors to screw conveyors, Parthax offers a comprehensive suite of products to streamline material handling processes and enhance productivity. Each conveyor system undergoes rigorous testing to ensure adherence to international quality standards, making Parthax the preferred choice for businesses seeking reliable and high-performance conveyor solutions in Noida and beyond. Trust Parthax for seamless conveyor solutions that propel your operations forward.

https://www.parthax.com/noida/industrial-conveyor

Plot No 120,Udyog Kendra Ext–II,Sector–Ecotech-III, GreaterNoida, U.P – 201 306 , (U.P.) India

+91-7048981077,+91-9871374601

[email protected] , [email protected]

0 notes

Text

Monel 400 Nuts Manufacturers In India

Chhajed Fasteners is one of the main Manufacturers, Supplier and Exporters of Priemium quality Monel Fasteners in Mumbai, India. These Monel Fasteners items are produced with the most recent advancements utilizing high grade crude materials. We offer Monel Fasteners in numerous kinds evaluations, for example, Bolts, Nuts, Screws, Sockets, Studs, Screw, Hex Set Screw, Socket Screw, Cap Screw and more according to the customers requirments. These are broadly utilized in different application industry, for example, oil and gas, pharma, atomic power, sugar, compound and concrete and so on.

Monel Alloy 400 besides offers fine mechanical properties from underneath zero temperatures up to around 480C. Our things are referenced in a few different nations and we fundamentally pass on expansive shipments in a short structure. Monel 400 catch are perceived in the market for their characteristics, for example, solid progression, dimensional exactness and confirmation against breaking down and scratched zone. These Monel fittings find applications in various business experiences and parts and are suggested for segments, for instance, dimensional precision, use verified and better execution. Monel 400 usually discovers application in marine organizing, development and hydro-carbon preparing, warm exchangers, valves and siphons. Purchase Alloy 400 Fasteners at sensible rates from us. We make these things to your custom points of interest, and we affirmation to meet your development plan.

0 notes