#silica sand industry

Text

Exploring how Arrowsmith North Silica Sand Project by VRX Silica advances?

Discover the notable progress made by VRX Silica Limited (ASX: VRX) in the approval process for the Arrowsmith North Silica Sand Project. Learn about the commencement of the Public Environmental Review (PER) period and the company's dedication to addressing stakeholder feedback. Get insights into VRX Silica's investor outlook and explore the projects within their expansive silica sand portfolio in Western Australia.

When it comes to sustainable silica sand projects, VRX Silica Limited is making significant strides. With the initiation of the four-week Public Environmental Review (PER) period, following the publication of the Environmental Review Document (ERD), VRX Silica's Arrowsmith North Silica Sand Project is advancing closer to reality.

The acceptance of the Arrowsmith North Environmental Review Document by the Department of Water and Environmental Regulation (DWER) further demonstrates the company's commitment to transparency and environmental responsibility.

During the PER process, VRX Silica understands the importance of addressing all comments received regarding the Arrowsmith North Silica Sand Project proposal. This comprehensive review and response stage serves as the final step before the Environmental Protection Authority (EPA) of Western Australia prepares an assessment report. The recommendations made in the report will play a crucial role in the approval decision by the Western Australian Environment Minister.

Investor Outlook:

VRX Silica's commitment to sustainability and responsible resource extraction has captured the attention of investors. With a share price of AUD 0.125 per share and a 52-week range of AUD 0.093 to AUD 0.190 per share, the company's performance in the market has been notable. As of June 19th, 2023, VRX Silica has a market capitalization of AUD 70 million, with 560.40 million shares issued.

About VRX Silica:

VRX Silica Limited is an ASX-listed pure-play silica sand company with a dedicated focus on driving innovation and sustainable practices. The company's portfolio comprises four silica sand projects in Western Australia. In addition to the Arrowsmith North Silica Sand Project, they also have the Arrowsmith Central Silica Sand Project, located near Eneabba, south of Geraldton. Furthermore, VRX Silica has the Muchea Silica Sand Project, situated north of Perth, and the Boyatup Silica Sand Project, positioned 100 km east of Esperance.

Conclusion:

The Arrowsmith North Silica Sand Project by VRX Silica is making significant progress in its approval process, evident through the commencement of the PER period and the publication of the ERD. By addressing stakeholder feedback and adhering to sustainable practices, VRX Silica is laying a strong foundation for the project's success. With their robust investor outlook and dedication to responsible resource extraction, VRX Silica continues to shape the future of the silica sand industry in Western Australia.

#VRX Silica#Arrowsmith North Silica Sand Project#Public Environmental Review#Environmental Review Document#Department of Water and Environmental Regulation#DWER#Environmental Protection Authority#EPA#Western Australia#assessment report#investor outlook#share price#market capitalization#sustainability#silica sand projects#Arrowsmith Central Silica Sand Project#Muchea Silica Sand Project#Boyatup Silica Sand Project#silica sand industry#resource extraction#ASX-listed#sustainability practices#stakeholder feedback#responsible resource extraction#transparent processes#environmental responsibility#market performance#Western Australian Environment Minister#silica sand portfolio#resource development

0 notes

Text

Global Industrial Silica Sand Market Size, Growth & Trend Analysis 2031

The Global Industrial Silica Sand Market size was estimated at USD 12.0 billion in 2021 and is expected to hit around USD 17.5 billion by 2031, poised to grow at a compound annual growth rate (CAGR) of 4.6% from 2022 to 2031.

The global industrial silica sand market is a critical component of various industries, playing a pivotal role in the manufacturing and production processes. Silica sand, composed primarily of quartz, is renowned for its physical properties such as high heat resistance, chemical inertness, and low thermal expansion. These qualities make it an essential raw material in the production of glass, casting metals, and the manufacturing of a wide range of industrial products. The glass industry, in particular, is a major consumer of industrial silica sand, using it in the production of containers, bottles, and various glass products. Additionally, the metal casting industry relies on silica sand for creating molds and cores in the production of metal components.

The construction sector is another significant driver of the global industrial silica sand market. Silica sand is a key ingredient in the production of concrete, providing the necessary strength and durability to construction materials. The rapid urbanization and infrastructure development in emerging economies contribute to the growing demand for industrial silica sand in the construction industry. As construction activities continue to expand globally, the need for high-quality silica sand as an integral component in concrete mixtures is expected to rise.

The global industrial silica sand market is witnessing several notable trends that are shaping its current scenario. One prominent trend is the increasing demand from the energy sector, particularly for hydraulic fracturing or fracking in the oil and gas industry. Silica sand is a crucial component in fracking operations, where it is injected into wells at high pressure to extract oil and gas from underground formations. As the global energy demand persists, especially with the exploration of unconventional oil and gas reserves, the demand for industrial silica sand in this sector is expected to grow.

Another significant trend is the rising adoption of advanced technologies in silica sand processing. Companies are increasingly investing in advanced techniques to extract, process, and refine silica sand more efficiently. This includes the use of advanced screening and washing technologies to produce high-purity silica sand suitable for various industrial applications. Technological advancements not only enhance the quality of silica sand but also contribute to more sustainable and environmentally friendly mining and processing practices.

Download Free Sample Report

Global Industrial Silica Sand Market Size: A Comprehensive Overview

Industrial silica sand, a versatile and abundant natural resource, finds extensive applications in various industries, including glassmaking, construction, foundry, and hydraulic fracturing. Its unique properties, such as high purity, chemical inertness, and excellent heat resistance, make it an indispensable material in these sectors.

Market Size and Growth Projections

The global industrial silica sand market is estimated to reach a value of USD 10750 million by 2029, expanding at a CAGR of 2.6% during the forecast period 2023-2029. This growth is fueled by several factors, including:

Rising demand for glass products, particularly in the construction and automotive industries

Expanding infrastructure development activities globally

Growing demand for foundry sand in the metal casting industry

Increasing exploration and production of oil and gas using hydraulic fracturing

Key Market Drivers

Several key trends are driving the growth of the industrial silica sand market:

Urbanization and Infrastructure Development: Rapid urbanization and the associated infrastructure development projects are driving the demand for construction materials, including glass and concrete, which utilize silica sand as a key ingredient.

Technological Advancements in Glassmaking: Advancements in glassmaking technology, such as the development of float glass and borosilicate glass, are increasing the demand for high-purity silica sand.

Rising Oil and Gas Exploration: The global oil and gas industry is experiencing a resurgence, leading to increased demand for silica sand used in hydraulic fracturing, a process essential for extracting oil and gas from unconventional reservoirs.

Regional Trends

The Asia Pacific region is currently the largest consumer of industrial silica sand, accounting for over 45% of the global market share. This dominance is driven by the region's rapid economic growth, urbanization, and expanding construction activities. However, North America and Europe are expected to see significant growth in the coming years due to their strong industrial bases and increasing demand for high-purity silica sand.

Future Outlook

The future of the industrial silica sand market looks promising, with several factors contributing to its continued growth. The increasing demand for glass and construction materials, the expanding oil and gas industry, and the growing adoption of sustainable construction practices are all expected to drive market growth. Additionally, rising disposable incomes and increasing awareness of the environmental benefits of silica sand are further fueling the demand for this versatile material.

Conclusion

The global industrial silica sand market is a dynamic and rapidly growing sector with immense potential. As industries worldwide continue to rely on silica sand for a wide range of applications, its demand is expected to remain strong in the coming years. With its unique properties, abundance, and sustainability advantages, silica sand is poised to play a crucial role in shaping the future of various industries.

Related Reports :

About Us:

Organic Market Research Business Consulting is a fast-growing Market Research organization which is helping organizations to optimize their end-to-end research processes and increase their profit margins.

Organic Market Research facilitates clients with syndicate research reports and customized research reports on 10+ industries with global as well as regional coverage.

Mob : +91 9319642100

Noida One Tower Sec 62 Noida 201301

Sales : [email protected]

Website : https://www.organicmarketresearch.com

0 notes

Photo

Top Reasons To Buy Glass Sand From Suppliers in Rajasthan

If you are looking to buy glass sand from a glass silica sand supplier in Rajasthan, a lot of queries may come to your mind. Well, it is not uncommon. This is why you must know what is silica sand, what is glass sand, why high-quality sand is needed, and why you should buy it from sand suppliers in Rajasthan only. Here we are sharing all necessary information in detail.

#construction sand for concrete#glass sand in Jaipur#silica for glass industries#silica sand#silica sand supplier

0 notes

Text

Died With a Hammer in His Hand: Unpacking the Myth of John Henry

“John Henry said to his captain:

‘You are nothing but a common man,

Before that steam drill shall beat me down,

I’ll die with my hammer in my hand.’”

— “John Henry, the Steel Driving Man,” recounted by W. T. Blankenship

John Henry is one of America’s most well-known mythic heroes, immortalized in song, statue, postage stamp, and multiple movies (including a 2000 Disney animated short film which I vividly remember watching in elementary school). But if you’re unfamiliar with the legend, here’s a brief summary.

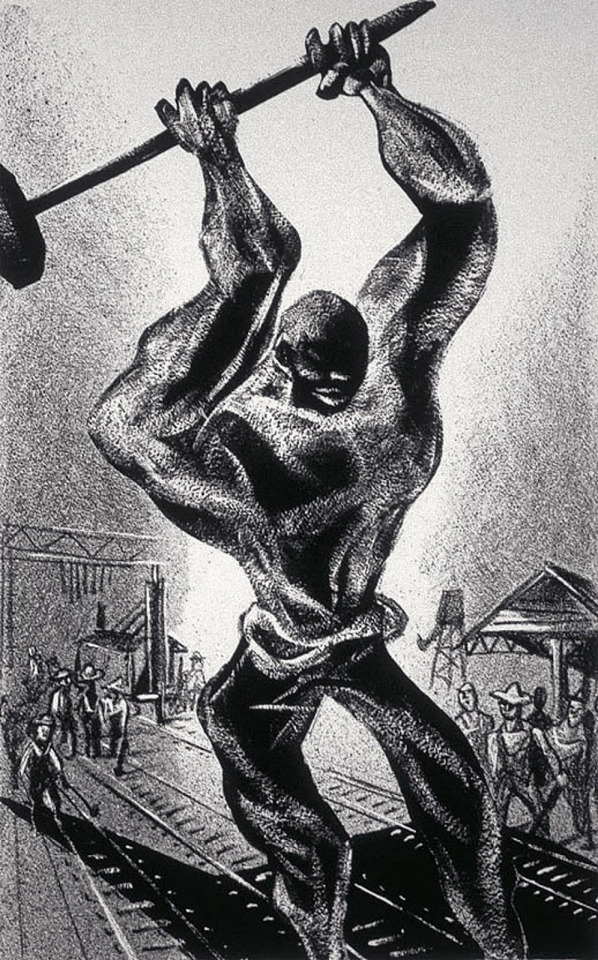

John Henry was a freed slave who found himself working for a railroad company in the years following the Civil War as a steel driver. His job was to drive a steel spike into rock so that dynamite could be placed in the resulting hole, thus opening up a tunnel through the Appalachians.

John Henry was the best on his crew, and he took pride in his work—so when a white salesman brought in a steam-powered drill, claiming that it could drill better than any man, he decided to challenge that claim. Henry entered into a contest with the machine to see who could carve out the deepest hole in the mountain in a single day.

His victory cost him his life.

Henry’s wife—sometimes named Polly Ann, sometimes named Lucy, sometimes not named at all—went to visit him on his deathbed that evening. In many versions of the ballad, Henry’s last words are a request for a glass of water. In other versions, he asks his wife to be true to him when he’s dead, or to do her best to raise their son. Many accounts say that he’s buried by a railroad, where “Every locomotive come roarin’ by, / Says there lays that steel drivin’ man” (lyrics from Onah L. Spencer).

Bronze statue of John Henry near Talcott, West Virginia, sculpted by Charles Cooper.

The general consensus among historians now seems to be that the ballad of John Henry is one such legend that has its roots in historical fact, although the particulars are long obscured by the centuries that have since passed. Henry was born into slavery in the 1840s or 50s, either in North Carolina or Virginia (some accounts of the ballad lend credence to the latter claim). As for how John Henry found himself working for the Chesapeake & Ohio Railway company, University of Georgia history professor Scott Reynolds Nelson posits in his book Steel Drivin’ Man that the man was sentenced to ten years in a Virginia prison for theft at only nineteen years of age, and that he was among many prisoners leased out by the state for labor.

Did you know that the 13th Amendment makes an exception for slavery which is used “as a punishment for crime whereof the party shall have been duly convicted”? (This practice continues to this day, and has become an industry worth tens of billions of dollars. Louisiana State Penitentiary, also known as Angola or simply “The Farm,” is a good place to begin if you’re wanting to look into chain gangs further.) John Henry the legend was a free worker who took on the backbreaking, often dangerous work of railroad labor under his own power and could demand any wage for his work, but John Henry the man may have lived and died in neoslavery.

Speaking of Henry’s death, most retellings of the myth say that he died of sheer exhaustion. Some add in the detail that it was his heart that gave out because he worked himself too hard. However, alternate theories have been proposed for how the man died. Some historians say it was a stroke that killed him, while others posit silicosis.

It’s this latter hypothesis which I find most intriguing. For those who aren’t familiar with it, the American Lung Association describes silicosis as “a lung disease caused by breathing in tiny bits of silica, a common mineral found in sand, quartz and many other types of rock.” It’s been an occupational hazard for construction workers since, well, the time of John Henry. What I find interesting are the implications for the narrative if the real Henry died of silicosis. In the folk ballad, Henry causes his own death by working himself too hard. On the other hand, the ones at fault if the man died of silicosis would be his employers—the ones responsible for the dangerous conditions he worked in.

So why would John Henry’s cause of death change during the transition from fact to legend?

The answer, as with many other fictionalized accounts of historical events, is that it simply makes for a more effective story. But not just that—a more effective message. So what might the ballad be trying to tell those who listen to it?

First, let’s think about who this song was sung by and for. The ballad of John Henry is a work song, its rhythm meant to help railroad workers stay and strike in sync, in the same way a drumbeat helps soldiers march in step. It’s been sung by railroad workers, miners, construction workers, chain gangs, and country musicians. At its core, then, the ballad is a song of and for the American working class—specifically those people doing the same sort of backbreaking physical labor as John Henry himself. Many of these laborers would have been Black, and likely former slaves—especially when it came to Southern chain gangs. (See my above note about how American slavery was only mostly abolished, and then think about why the U.S. has one of the highest incarceration rates in the world. . . but I digress.)

An oil painting of John Henry by Frederick Brown.

We’ve established that John Henry is a hero for working-class Americans during the time of the Second Industrial Revolution. But what sort of hero is he? Is he like Achilles, a paragon of his country’s values and an example for the audience to aspire to? Or is he an Icarus, a cautionary tale sung so the audience won’t repeat his mistakes?

The answer depends on who’s telling the story.

Onah L. Spencer is the source for one version which emerged from a Black community in Cincinnati, Ohio. When he recounted the lyrics to Guy B. Johnson for the latter’s 1929 book John Henry: Tracking Down a Negro Legend, he also stated that the song was used to motivate workers: “. . . if there was a slacker in a gang of workers it would stimulate him with its heroic masculine appeal.”

In cases such as Spencer’s crew, then, John Henry’s death is presented as glorious, and Henry is seen as admirable for working so hard that it kills him. Here, he’s a good example. Taken to the extreme, the Achillean Henry encourages fellow workers to follow in his footsteps—to keep pushing themselves harder and harder until they finally keel over.

This message doesn’t benefit the workers passing it along; it benefits the employers profiting from their labor. This, I think, is where the story blurs the line between myth and propaganda. And while the ballad of John Henry certainly isn’t singlehandedly responsible for the American tendency to overwork ourselves, it does reflect our attitudes about work in a way that’s worth unpacking. To me, this reeks of the Puritan work ethic. The belief was that you had to be working as often as you could; if you didn’t, the devil would be able to influence you. The Puritans were one of America’s foundational cultural influences—of course those values would have influenced the ballad of John Henry.

Henry is a hero because he worked himself to death. If we see him as a good example, what does this say about the effects that capitalism has had on American attitudes? About the internalized belief that our worth as humans only comes from what we can contribute to the economy? Why do we see death from exhaustion as a fitting end for a former slave?

Then again, maybe we’re not supposed to.

A lithograph of John Henry, from the series American Folk Heroes, by William Gropper.

Remember how I noted earlier that many of the laborers who first sang Henry’s ballad would themselves have been former slaves? It’s important because there’s a long history of American slaves using work songs as a tool of resistance against their oppressors, and these Black laborers—these “freed” slaves—would have carried that tradition with them into the Second Industrial Revolution.

The ballad of John Henry, then, might have been sung with the intent of helping other workers survive the brutal conditions on the railroads. Here, Henry becomes an Icarus—a warning of what happens if you push yourself too hard. One version of the ballad recorded by Edward Douglas of the Ohio State Penitentiary contains lyrics which suggest that not every Henry was meant to be emulated.

“John Henry started on the right-hand side,

And the steam drill started on the left.

He said, ‘Before I’d let that steam drill beat me down,

I’d hammer my fool self to death,

Oh, I’d hammer my fool self to death.’”

Don’t do what John Henry did, this version warns the audience. Be wiser than he was. Don’t push yourself quite so hard. Think of the people you’d be leaving behind if you’re not careful.

Perhaps even the creation of this mythos was an act of defiance in and of itself. At this point, I think it bears mentioning that I myself am not Black and can only hypothesize based on what I’ve heard from people who are, but I see something radical in the act of raising up one of your own as your hero rather than venerating the people you’ve been told are superior to you.

Remember, John Henry’s contest was versus a white man’s machine. It costs him everything, but he triumphs over the expectations of that steam drill salesman and proves his worth as a laborer and a person. John Cephas, a blues musician from Virginia who was interviewed by NPR for a report on John Henry back in 2002, had this to say of the myth:

“It was a story that was close to being true. It’s like the underdog overcoming this powerful force. I mean even into today when you hear it (it) makes you take pride. I know especially for black people, and for people from other ethnic groups, that a lot of people are for the underdog.”

Americans love underdog stories. Our own national origin myth is one! John Henry’s assertation of power and skill, the ballad’s declaration that Black people have the right to be proud of themselves too. . . no wonder this myth has resonated with so many people. No wonder it’s survived for a century and a half.

In this light, then, John Henry once again becomes a hero for us, the audience, to emulate. In the fight against oppression, endurance like Henry’s becomes key. Justice is almost never won quickly. The odds stacked against us may seem impossible, but it’s worth trying anyways, even if we have to fight to our dying breaths.

Artwork of John Henry as a defense worker by James Daugherty.

John Henry has meant and been many things to a lot of people in the past two centuries. A representative of capitalist exploitation, a cautionary tale for workers, an inspiration to oppressed people in America, even a communist icon—but I’d like to take a moment to talk about what his story means to me. It’s not something I’ve seen discussed in my research, and I think it’s worth exploring.

John Henry reflects fears of workers during the Second Industrial Revolution who saw how technology was evolving—how machines were being created that could do their jobs not just faster, but cheaper, because you don’t have to pay a machine like you would a person. They feared that they would be replaced, and that they would be left destitute while their former bosses grew richer and richer. And despite the centuries between us, this is a fear that I can understand.

Often, I feel it myself.

As an artist existing in online spaces during this new influx of AI-generated “art” and writing, I have witnessed many fears that we will be replaced by AI. Yes, there is a certain human quality to art that a generative learning model cannot replicate, but who’s to say that the much-vaunted free market will care? We can hope that art as a profession will survive, but we just don’t know.

In John Henry’s struggle, I see my own. In the steam drill salesman, I see tech bros on the platform formerly known as Twitter showing off their latest batch of beautiful, hollow, AI-generated “art.” I see John Henry’s passion, his pride, his triumph.

And I see hope.

By his life and death, the mythic John Henry reassures me that human beings aren’t so easy to replace after all. He tells me that machines can be defeated. That one day, my vindication as an artist and writer will come, and the world will see our worth.

The ballad of John Henry has endured like a mountain for a hundred and fifty years, and I hope it will survive for hundreds more—that John Henry’s hammer will continue to ring true throughout the ages. But in the midst of American mythos, it’s important not to lose sight of the historical facts behind it. Legends are interesting and inspirational and wonderful, but the real stories have something to tell us, too.

Don’t forget to listen.

Works Cited

American Lung Association - Silicosis

Ballad of America - This Old Hammer: About the Song

Constitution of the United States - Thirteenth Amendment

Encyclopedia Britannica - John Henry

Flypaper by Soundfly - The Lasting Legacy of the Slave Trade on American Music

Folk Renaissance - John Henry: Hero of American Folklore

How Stuff Works - Was There a Real John Henry?

ibiblio.org - John Henry: The Project

National Park Service - The Superpower of Singing: Music and the Struggle Against Slavery

NPR - Present at the Creation: John Henry

NPR - Talk of the Nation: The Untold History of Post-Civil War ‘Neoslavery’

PBS - Mercy Street Revealed Blog - Singing in Slavery: Songs of Survival, Songs of Freedom

Prof. Scott Reynolds Nelson - Steel Drivin’ Man: John Henry, the Untold Story of an American Legend

World Population Review - Incarceration Rates by Country 2024

#john henry#american mythology#analysis#essay#black history month#ari speaks#hi I wrote this for my english class and I felt compelled to share it here

13 notes

·

View notes

Text

Humans are Weird - Sketchy - Let's Work It Out - Audio Narration and Animatic

Original Post: http://www.authorbettyadams.com/bettys-blog/humans-are-weird-sketchy

“It is so rare that we get to observe a human creating art,” Tstk’sk said as he eagerly slipped his paws into the protective coverings this planet’s brittle ground cover demanded; glass sand, the humans called it.

The rolling ground was home to a wide variety of fungal growths that ranged from larger than the humans to small enough to grow between the hairs of a Trisk’s mandibles. It just so happened that the species most adapted to growing on the footpaths was a silica rich strain that shattered into dangerous fragments when trodden on by the humans’ massive feet. On the positive side, the humans had entire industries dedicated to specialty footwear, and the light green coverings that Tstk’sk had been gifted by his father were both pleasing to the eyes and comfortable; or at least as comfortable as something that pushed in on all of your sensory hairs at once could be.

“I do not really see the novelty in this,” Grinds observed as he slid into his belly armor. The low slung reptile boasted feet that were more than rated for the silica rich sand of the paths, but they would collect the sand up in between their belly scoots if they spent too much time outside without protection. “I have a notebook full of human art, the majority of it from this human.”

“Scientific diagrams don’t count,” Tstk’sk explained. “That is just showing what something is on the outside. That isn’t real art.”

“I do not understand the difference,” Grinds insisted as he moved to the airlock and indicated a point between his shoulder blades with a flick of his tongue.

Tstk’sk scrambled over and climbed up to the offered perch. The reptile could not move nearly as fast as a human over long distances, but his average walking speed was still quite a bit faster than that of a Trisk, making the riding style a better option than for Tstk’sk to try and keep up the pace. Tstk’sk secured his data pad in a carry pouch and focused on balancing.

“The sketches that Human Friend James did in your notebook are mostly of engine diagrams,” Tstk’sk explained. “They are simple and literal depictions of the visual surface of the objects in question. There is nothing transformative about them… there is no meaning that Human Friend James is trying to express. They are not art.”

“I object to the statement,” Grinds spoke up after a polite pause as they left the cleared area of the base behind and entered the swirling tunnels of the fungal forests. “The art is entirely transformative. Human Friend James went to great effort to choose colors and textures that I could understand. You know that those graphite pencils they favor scatter light terribly for anyone capable of properly differentiating the electromagnetic spectrum. Then he had to take the critical elements of the engine and translate them into a two-dimensional form. He was expressing what he thought was the important element of the design.”

“There is certainly technical skill involved in the process,” Tstk’sk admitted. “But just look at this forest around us.”

He waved a gripping paw at the spirals upon spirals that made up the interior of the game tunnels of the fungal forests. Countless colors spread out from the shimmering opalescent fibers that served as the main bodies of the massive ultra-organism that covered nearly the entire planet. Dotted at intervals, turgid orbs of blue and winding coils of a shade of yellow that was so distinct at least three universities had seen spectral analysis teams attempt to record it mixed to give the impression that the forest was full of gravity-defying masses.

“It is a lovey sight certainly,” Grinds confirmed. “I do not see that Human Friend James’s attempts to replicate it in his sketchbook would be anymore ‘art’ than his attempt yesterday to give me an accurate idea of where he suspected the blockage to be was.”

Tstk’sk refrained from answering as one of the lumbering native life forms came down the path. Grinds chose a thin place in the wall of the tunnel and used his powerful tail to thrash out a small den where they waited until the creature the humans called a caterpillar-corgi passed. Usually a human would just step over the creatures, but the lower slung bodies of the reptiles didn’t have that option.

“Does the movement of that creature’s caudal end suggest anything in particular to you?” Grinds suddenly asked as they slipped out of the temporary refuge they had made.

“Do you mean to ask if I see the booty-bounce the humans like to laugh at?” Tstk’sk asked absently as he was more focused at the moment in cleaning the fast growing forest fibers off of his smart green paw-coverings. “I see the motion and can identify it, but I cannot find the fascination in it that humans do.”

“Human Friend James drew an entire series of sketches on the subject,” Grinds went on. “He was quite delighted when he showed them to me. He wanted me to judge if he had managed to capture the booty-bounce sufficiently in the series of still images.”

“Why did he ask you?” Tstk’sk asked in surprise.

“I suspect it was largely because I was nearby and off duty,” Grinds replied, “but he said that as I had a very nice tail myself and was used to observing caudal motion aspects of language, he judged me ideal to analyze his attempt at capturing the caterpillar-corgi booty-bounce.”

“What was your judgment?” Tstk’sk asked.

“Well, you know how the graphite scatters light,” Grinds replied, “but I do think it was a fairly accurate representation of the movement.” There was a moment of silence as they paused to consider the living image of the recalled sketch. “So,” Grinds finally asked, “if sketches of the forest count as art, but sketches of engine dynamics don’t, do sketches of booty-bounce count as art?”

HAW Book 3 – Available on Indiegogo October 2022

Humans are Weird Previous Books

54 notes

·

View notes

Text

Tek's Respirator FAQ for faceups & modding Ball Jointed Dolls

Copied from DenofAngels original posted date: Sep 21, 2010 Last edited by a moderator: Oct 10, 2016

Are you qualified to talk about this?

Yes. I [Tekenduis] am a Certified Respiratory Protection Tester/Trainer with extensive training in respiratory protection. I work at a company where my staff are exposed on a daily basis to some of the most harmful chemicals in industry. They can and will be exposed to things like silica, isocyanates and cyanide gas. Their short and long-term health is in my hands and I take that very seriously. Deadly seriously, in fact.

What is respiratory protection?

Respiratory protection is a part of your Personal Protective Equipment (PPE) designed to filter or block harmful substances from reaching your respiratory system. The hobbyists primary form of respiratory protection is the respirator. There are a great number of types of respirators, some useful only for certain applications (see more on this below). The two most common respirators for hobbyists are the disposable respirator and the half-face respirator.

The half-face respirator is a mask that covers your nose and mouth, and has cartridges that clip on, screw on, or otherwise attach to ports on the mask.

The disposable respirator looks like a dust mask or surgeon's mask. It is, as the name implies, made to be disposed of after a short period of time.

Why do I need it?

Many of the items that we work with as doll customizers are toxic and many of them are cumulatively toxic. You may feel ill for a while and then get better, but the sorts of diseases that can be caused by sanding processes and spraying processes can come back to haunt you many years down the road. These products can cause Cancer and Pneumoconiosis. Cancer may be treatable if caught early enough. Pneumoconiosis, which is respiratory diseases like asbestosis, silicosis and coalworker's "black lung" disease, is NOT TREATABLE. Your doctors will work hard to make you comfortable while you die. That is the most they will be able to do for you. If you get Pneumoconiosis you will DIE.

☠️ Are you scared? You should be. This is life and death. Do not play Russian Roulette with your health. ☠️

What do I need?

That depends on the application that you are going to be using your respiratory protection for.

Sanding

For sanding applications (including sanding of resin, apoxie and other sculpting materials, and wood), you need a respirator that provides at least N95 level protection. It should say N95 somewhere on the mask itself. If it doesn't say, it is not good enough. There is a scale to protection levels and anything above N95 is also acceptable (of course).

The levels are:

N95

P95

N100

P100

What does this mean?

The prefix ahead of the number will tell you if the mask is Oil Proof or Not.

The number will tell you the percentage effectiveness of the filter against particles of less than 0.3 Microns. An N100 or P100 filter may also be known as a HEPA filter.

On the bright side, having a small supply of these types of respirators will mean that you are following CDC and WHO recommendations for infectious disease outbreaks, which may or may not include the Inevitable Zombie Apocalypse.

P100 filters are also effective in welding applications.

N95 and above filters are most commonly found in the disposable variety and may also be referred to as "dust masks" or "surgical masks". Remember, if it doesn't say N95 (or one of the other codes listed above) it is not good enough!**

Spray

This includes all types of spray applications, whether you are spraying sealant (like MSC or Testors) or airbrushing or spraying paints.

The process of spraying releases aerosols (and this is true whether or not you are using an aerosol spray can product. Airbrushing paint creates aerosols too!) for which an N95 filter is not effective.

At this point, you will need to move into a mask that protects you against Organic Vapors AND has an N95 filter. This will mean moving into a half-face respirator.

Your respirator is no longer disposable and can be used again and again without ill effect; the only thing that will need replacing is your filter and (if applicable) your prefilter. Some respirator brands have an N95 filter built right into the Organic Vapour cartridge, but I recommend looking for one that does not, for ease of replacement. Cartridges and filters have different life spans and it is more economical to replace only the part that requires replacing (more on this below!).

Okay! I've got my mask, I'm totally safe now right?

No. There are three things that can negatively impact the safety of your mask; poor fit, improper maintenance and environmental levels.

Poor Fit

A respirator (of any type) is completely and utterly useless if it is the wrong size for you and is not fitted properly. Please ensure you've read the section on fitting your mask to ensure that your mask is correctly fit.

How do I know if it fits?

According to my local Occupational Health and Safety Code, a respirator cannot legally be used in a workplace environment if it has not been correctly Fit Tested. Keep in mind that half-face respirators come in various sizes. Most women and men wear a medium but if you have a particularly slender or wide face, you may need a small or large. If you have a crooked nose, or sinus problems, look for a mask made of silicon; you will find it more comfortable than plastic or rubber.

Improper Maintenance

Your respirator is equally useless if you are not properly maintaining and caring for it. This includes care of the mask between uses and replacement. Please see the section on maintaining your mask for more information.

Environmental Levels

Environmental levels are important to take into account, as your mask can only protect you against the things it was designed to protect you against up to a certain concentration. since I'm sure none of us have the money or inclination to commit to environmental testing of our workspaces, the best way to ensure this is to make sure that the area in which you are working is properly ventilated before you start your project, and until well after you are finished.

Open your windows, PREFERABLY PLEASE work outside so that there is fresh air circulating in the area you're working in.

If the air is particularly still (no breeze) while you're working, it is worth investing in a simple fan. Set it up in your window, with the fan blowing out the window (ie: the front of the fan where the air blows from facing towards the window). This will help pull the toxins out of your room. Alternately, if you are working outdoors, set the fan up on your table to help promote air movement.

Fit Testing

Fit testing uses a noxious but harmless substance (usually either irritant smoke or Bitrex; an additive used to create bitterness in household cleaners to prevent children from tasting them) to ensure that the seal between the mask and the face is tight and proper. Qualitative fit testing is the most common type, and requires the user of the mask to confirm the presence of the noxious substance. In some cases (depending on chemicals in the environment or failure of the Qualitative test) Quantitative fit testing may be required; this type of fit testing uses scientific sensors to record levels inside the mask. If you have access to fit testing, especially with a half-face respirator, I encourage you to take advantage of it! Fit testing needs to be redone every two years, in the case of weight loss or gain of more than 15 lbs or in the case of surgery (including dental) involving the face.

And if I don't have access?

I have done hundreds of fit tests for staff at my place of employment and I can usually tell how well a mask is likely to fit prior to the fit test being done. This is done with a simple self test. In order to be effective this test must be done every single time you use the respirator (even if you pull it down to talk to someone and put it right back on!).

For Disposable

Step 1: Put your respirator on.

Step 2: Cup your hands tightly over your mouth and nose, over top of the respirator.

Step 3: Suck in a long breath. You will get air, but it should all be coming in through the small cracks between your fingers. You should not feel any air coming in from around the nose piece or under your chin. If you do, refit the mask and try again. If you cannot complete this successfully, you will need either a larger or smaller mask.

Step 4: With your hands still over your mouth and nose, blow out. Again, you should feel the air moving past your fingers, and never around the bridge of your nose or under your chin.

For Half-Face

Step 1: Put on your mask and make sure the straps are tight.

Step 2: Cover the cartridge, as much as possible, with the palm of your hands and suck in. The mask will likely deflate slightly. You should feel some air coming in through the cartridge but no air coming in from the sides, under your chin, or around your nose. If you do, adjust the mask and try again. If you cannot complete this step successfully, you will need either a smaller or larger mask.

Step 3: Cover the exhalation valve of your respirator with the palm of your hand and blow out. You should feel the mask inflate slightly and again, you should feel no air escaping from the side of your mask, under your chin or around your nose.

😷 How do I maintain my mask?

Respirator maintenance is exceptionally simple, takes very little time, and ensures that you are not exposing yourself to toxins. Take the extra few minutes to ensure that your respirator is working right!

Before you put it on

For Disposable

Do a quick visual check of the respirator. Is it dirty? A little discolouration from the dust is fine, but too much might mean that your respirator is clogged. I'll discuss this a bit further down. Check that your straps are still in good condition. Check that the foam piece at the nose is intact (if applicable) and that the metal part that bends across your nose is not bent out of shape. If your mask is clogged or not in good condition, replace it.

For Half-Face

Do a quick visual check of the inside and outside of your mask. Make sure that the valves (the little rubbery seals on the inhalation and exhalation points) are present and in good condition. Make sure there are no cracks or tears in your mask. Ensure that your filters are firmly attached. Correct any of these issues before proceeding with your work.

After you take it off

For disposable

Do another quick visual check of your mask. If everything is still in order, seal your mask inside a baggie and put it somewhere safe.

For Half-Face

Wipe all surfaces of the mask that touch your face with a respirator cleaning wipe. If you don't have any, use the following:

For masks made of natural rubber, use a non-alcohol based antimicrobial wipe.

For masks made of silicone or plastic, wipe with isopropanol (isopropyl alcohol, or rubbing alcohol).

This step is less about the effectiveness of your mask and more about preventing build up of oils from the skin which can degrade the mask over time, necessitating replacement, as well as causing skin breakouts!

Seal your mask inside of a baggie or well-sealed (and clean!) coffee can and put it somewhere safe.

🧼 Once a month you should remove the cartridges and clean your mask with soap and water, and hang it up to dry. This keeps the inside of your mask smelling pleasant. Sweat and condensation from your breathing can build up in there over time and cause the mask to smell unpleasant.

🤔 How often do I need to replace my respirator, or cartridges?

Filters will only last so long! Keep in mind that whether or not you are actively breathing through your respirator (IE: wearing it) it is still filtering the air around you. The average Organic Vapour filter, which is what you should be wearing at the least for spraying, lasts approximately 24–48 hours. That's it! Not very long, right?

The good news is that you can extend the life of your filters dramatically by placing them into a sealed container, like a baggie or coffee can, as discussed in the section above. My staff generally see a lifetime of 1–2 weeks from their filters, and most staff are using their filters at least once a day.

💁 How do I know it's time to replace them?

For Disposable, N95 and above

Your respirator is a simple filter made up of layer of material that filter out small particulates from the air. Eventually your respirator will become clogged and need to be replaced. This is not a matter of time, it is a matter of volume of filtering, something not easily tracked.

As a general rule of thumb, when your filter is ready to be replaced, you will know it because it will get harder to suck a good deep breath in. As soon as you start to feel this, replace your respirator.

For Half-Face

Organic Vapour Cartridge – Because this is filtering vapours (or aerosols), you will know it is time to replace it the moment you smell or taste anything through the filters; even the tiniest bit. Throw them out and get new ones.

N95 Prefilter

Please see the explaination for disposables above, your prefilter works the same way. If your prefilter is built into your organic vapour cartridge, it is a matter of volume of filtering, something not easily tracked.

I've got this bandana/old respirator of my uncles/some other thing…

❌ Cloth is not an effective filter against either particulate or vapours. ❌

Your respirator needs to be yours. Quite aside from the obvious sanitation issues, if the respirator belongs to someone else, it may not fit correctly and is therefore ineffective.

You're just trying to scare us. No one actually gets sick from this.

☠️ ☠️

There are several people here on the [DenofAngels] forums that have stepped up to talk about the health problems that they have suffered as a result of exposure to chemicals in either this hobby or others.

NON ORIGINAL POST NOTE:

Before you dismiss the risks involved please realize that even my friend, a professional artist has experienced the direct effects of long term exposure to harsh chemicals and resins for both film and personal BJD casting even when frequently taking proper protection.

🛍️ 🛒 Where do I get these things?

Disposable respirators are readily available in home improvement stores and pharmacies; just make sure you get one that says N95, or above, as discussed earlier. You can also refer to post #3 below for a Shopping Guide.

Half-face respirators are sometimes available in home improvement stores, but are also readily available from safety suppliers (many of which are open to the general public) and online.

🤢 I worked without my mask and now I'm not feeling well. Am I going to be okay?

This question is best discussed with your Doctor. My speciality is prevention, not treatment. I can tell you what results you may incur, but I cannot and will not attempt to diagnose your health, especially not over the internet.

Masks & Respirator Purchase links:

⚠️⚠️⚠️ THIS LIST IS FROM 2010⚠️⚠️⚠️

I AM ONLY INCLUDING PRODUCTS THAT STILL EXIST:

Disposable Respirators ("Dust Masks")

3M 8210

Lowes & Home Depot

3M 8210 Plus

As above, but with a fabric elastic strap, so they last longer, but tend to be a bit more expensive.

3M 8511

Similar to the 8210 series, but these have an exhalation valve, which can prove more comfortable in hot or humid environments.

Half-Face Respirators (Rubber)

3M 6000 Series Half-Face Respirator

Amazon (Small)

Amazon (Med.)

3M 6001 Organic Vapour Cartridges & 3M 5N11 N95 Prefilters

Cartridges

Amazon Resupply Kit (OV Cartridges and Prefilters)

Starter Kits

Amazon

Half-Face Respirators (Silicon)

3M 7500 Series Half-Face Respirator

Amazon (Small)

Amazon (Medium)

Amazon (Large)

Starter Kits

Amazon (Small)

Amazon (Medium)

Amazon (Large)

This is not my original post, I am simply sharing this information as not everyone can access the DenofAngels forums! Stay safe and creative guys!

13 notes

·

View notes

Note

hello excellent dirt person. do you know anything about kaolin? i am curious if so, what the Dirt Person view on it would be

So the long and short of it is I have no view on it because kaolin is just, a thing that exists. I have no view on steel or grapes. They exist. There's a lot of commercial grade uses for rock and soil that lay people wouldn't anticipate but are entirely common within certain industries, from gravel and sand mining, to the mining of rocks and soils bearing certain clay minerals or rich in certain elements. Kaolin in particular has uses valuable to ceramics and the paper industry but I know very little about either of those.

However, I do know things about the clay mineral that is actually what's extracted from kaolinite and what an excellent opportunity to talk about phyllosilicates, aka, clays and micas!

I am, more technically speaking, an environmental soil chemist, and though I lean on the last one of those titles the least, here we're going to have to take a quick detour onto chemical bond angles and crystals. This is a very brief oversimplification but deeply relevant.

Atoms bind together in order to be more stable, but the bonds themselves are charged, and therefore repel each other. Imagine an atom as an orb with things sticking out of it:

If you have two bonds, as far apart on a circle means 360/2, so the bond angle will be 180, and they'll be on opposite ends (examples: CO2)

If you have three, 360/3 means 120, and so you get something that looks like a triangle.

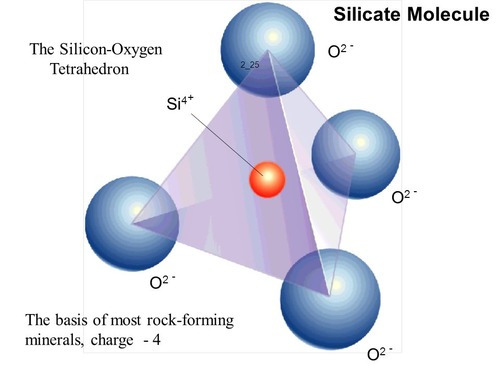

If you have four, then things get fun, because the previous two have been two dimensional shapes, and what you actually get instead is a three dimensional tetrahedron with an average bond angle of ~109. And when you get into silicates, tetrahedrons are your basic building block

If you have six, then your average bond angle is 90 degrees; imagine four in a square plane and two at the 'poles'. Remember these for later!

Silicates dominate our world. If carbon forms everything living, then silicon forms everything non-living. Over 90 percent of the earth's crust is formed by silicate minerals, which are as astounding diverse and varied as big brother carbon's molecules. This diversity comes in spite of the fact that silicon is near-exclusively bound in the form of the silica tetrahedron seen above.

Where we move from bond angles to crystals is the fact that each oxygen in a silica tetrahedron has two charges, meaning oxygen can be bound to two different silicon atoms, which creates a crystal lattice structure of repeating units of silica tetrahedra. Depending on how silca tetrahedra are linked together, you get the following structures:

(Fun fact! Quartz and Zeolites are some of the most chemically and mechanically stable minerals on earth, and the Tectosilicate arrangement is the exact same crystalline pattern that makes up diamonds. Anyways!)

Focusing down on phyllosilicates, the structures that form are vast molecule thin sheets of repeated chained circles of silica, which is just one of the many ways math that may seem abstract emerges in the natural world, as what forms as a result is a tesselation. Now although silicates are dominated by silica, they are not exclusively silica tetrahedra for the simple fact that the real world conditions in which these form are messy, but secondly, the tetrahedral shape means that in a sheet crystal, silica has leftover oxygens that it could share with other ions. And so what you get in nature is that phyllosilicates are not just sheets of silica tetrahedra, but are two to three layers of repeating tetrahedra/octahedral units bound to a silica backbone.

(src paper; good resource for those who want to know more)

Now these phyllosilicates, literally "sheet-silicates", are very strong and chemically resistant molecule thin layers. But the thing about being so strongly attached to itself means that the actual attraction between layers is governed by an entirely different form of chemical bond (IMFs, which we won't get into), and ranges from no real binding to tightly bound to weakly bound.

And finally, it's time to talk about kaolinite!

Kaolinite is the clay mineral named for kaolin, the rocks/sediment that bears a lot of it. Kaolinite, pictured above, has very uniform physical properties, is very chemically stable, is quite cheap, and has abundant material use.

But, time for a shock and a swerve, I spent all this time talking about clay minerals to talk about smectite instead! You fool!

Smectitic clays differ from kaolinite substantially in ways we won't get into, but the short answer of it is that bonds form between sheet layers, but weak bonds. Strong bonds will basically not really come apart and aren't an issue. No bonds aren't an issue. Weak bonds are an issue.

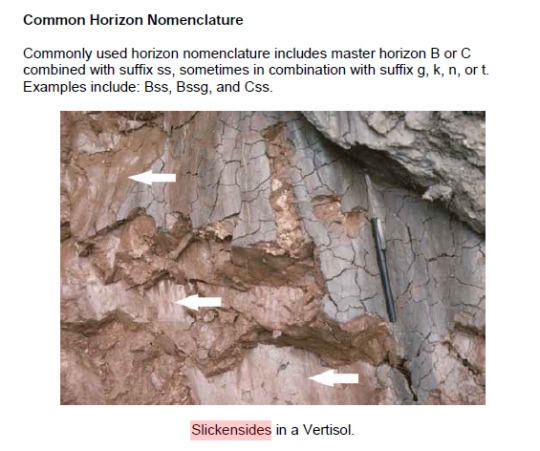

What weak bonds between layers leads to is a shrinking and swelling of clay layers over time, as water enters clay layers in the fall through spring, then leaves in the summer, causing the entire soil to shrink and swell with moisture, like thermal expansion joints on bridges but much more pronounced. This also leads to a lot of interesting soil properties, so much so there's an entire soil order named for soils with smectitic clays, the Vertisols.

What's shown here with the slickensides are literal smooth surfaces that form as large units of soil shrink-swell and rub against each other. Very strange stuff!

On the human scale, soils with vertic characteristics cause a lot of headaches in the places I grew up, meaning a lot of people in North to Central Texas spend time watering their lawns in deep summer heat to avoid foundations cracking. I've seen new homeowners in Texas who didn't know about it have their entire fence come down because of soil cracks, especially wood fences that catch the wind.

And that's how clay will ruin your foundation.

(PS: Clay mineralogy is foundational to soil chemistry but we'll get into that at a later date. To simplify: clay mineralogy is variable by geology and essentially serves as the most chemically active site in soils, but you kind of have to get real in the weeds on it and I do not have time to get into ion substitution and why every mineral's chemical formula looks like a fucking math equation just so I can talk about cation exchange capacity right now.)

17 notes

·

View notes

Text

Calcium Carbonate

LimeStone Granules ( Feed )

LimeStone Lumps ( Calcite )

Silica Sand ( Glass )

Foundry Sand

Frac Sand ( Proppant Sand )

Silica Flour ( Quartz Powder )

Cullet ( Broken Glass )

Glass Powder ( Cullet Flour )

Rock Gypsum

Agriculture Gypsum

Gypsum Plaster ( POP - Plaster of Paris )

Poultry Meal

Rock Phosphate

Quick Lime

Hydrated Lime

Bentonite

Barite

#calcium carbonate#raw materials#foundry sand#silica sand#limestone#Cullet#Poultry_Meal#$Silica_Sand

2 notes

·

View notes

Text

Is Sand Casting Strong? Unveiling the Strength of Sand Cast Components

When it comes to manufacturing metal parts, sand casting has remained one of the most traditional yet highly effective processes in the foundry industry. But one question that frequently arises is, Is sand casting strong? To truly understand the strength of sand-cast components, we must dive into the process, material characteristics, and factors that contribute to the strength of sand casting.

Understanding Sand Casting

Sand casting is a versatile and widely used method for producing metal parts. It involves creating a mold from sand, pouring molten metal into the mold cavity, and allowing it to solidify into the desired shape. The process is highly flexible and cost-effective, making it popular in a wide range of industries such as automotive, aerospace, agriculture, and heavy equipment manufacturing.

The materials used in sand casting molds are usually silica sand mixed with bonding agents like clay or chemical binders. This combination creates a highly heat-resistant mold that can withstand the temperatures required for casting various metals, including iron, aluminum, steel, and bronze.

The Mechanics of Sand Casting: What Influences Strength?

The strength of sand-cast components depends on several factors, including the choice of metal, the design of the casting, the sand used in the mold, and the casting process parameters. To better understand the question, "Is sand casting strong?" let’s examine the key aspects influencing the strength of sand-cast products.

1. Material Selection

The strength of sand-cast parts is significantly influenced by the type of metal being cast. Different metals have inherently different mechanical properties, such as tensile strength, hardness, and durability. For instance:

Aluminum is lightweight but has lower tensile strength compared to other metals like steel or cast iron.

Cast iron provides excellent compressive strength, making it suitable for components subjected to high loads.

Steel offers the best balance between tensile and compressive strength, providing exceptional durability for various applications.

Therefore, the choice of metal depends on the end-use of the component. A sand casting company specializing in high-performance materials can tailor their casting process to maximize the strength properties of the chosen metal.

2. Sand Mold Quality

The quality and composition of the sand used in the casting mold play a crucial role in determining the final strength of the cast product. Factors such as sand grain size, moisture content, and the type of binder affect the surface finish, dimensional accuracy, and structural integrity of the casting.

Fine-grained sand leads to smoother finishes and more intricate detail in castings, but it may be less permeable, which can affect metal flow and cooling.

Coarser sand can improve mold permeability and cooling rates, but may result in a rougher surface finish.

Additionally, the strength of the mold itself is essential for withstanding the thermal and mechanical stresses of casting. Mold failure or deformation can lead to defects in the casting, compromising its strength.

3. Pouring and Cooling Process

The pouring and cooling phase of sand casting is another critical factor influencing the strength of the final product. Rapid or uneven cooling can lead to internal stresses, warping, and even cracks in the metal, all of which weaken the component.

A well-controlled cooling process ensures uniform solidification, preventing the formation of voids, cracks, or unwanted stress concentrations. Sand casting companies use advanced techniques like simulation software and thermal analysis to optimize the cooling phase, ensuring the mechanical strength of cast components.

4. Casting Design

The design of the casting is vital for both functionality and strength. Features such as wall thickness, fillet radii, and draft angles must be considered carefully to prevent weak points and stress concentrations in the final component. For example:

Thicker sections in a casting are more prone to shrinkage defects during cooling, potentially reducing the strength of the part.

Sharp corners can act as stress risers, leading to crack initiation under load.

Therefore, optimizing the casting design for strength is a critical step in producing durable, high-performance components.

Comparing Sand Casting with Other Casting Methods

To put sand casting strength into context, it’s helpful to compare it with other popular casting methods, such as die casting and investment casting.

1. Die Casting

Die casting uses a permanent metal mold and high pressure to force molten metal into the mold cavity. It produces parts with excellent dimensional accuracy and surface finish, and it is often used for high-volume production.

While die-cast parts are typically stronger due to the denser microstructure produced by high-pressure casting, sand casting offers greater flexibility in terms of size, material choice, and design complexity. For large or complex components, sand casting remains a viable option where die casting may be impractical.

2. Investment Casting

Investment casting, also known as lost-wax casting, produces parts with exceptional precision and surface finish. However, it is generally more expensive and time-consuming than sand casting, making it less suitable for producing larger components or those with less stringent dimensional tolerances.

In terms of strength, investment-cast parts can be comparable to sand-cast parts, depending on the metal used and the specific application. However, for heavy-duty industrial components, sand casting remains a popular choice due to its ability to produce robust, large-scale parts at a lower cost.

Common Applications of Sand Casting

Despite advancements in casting technology, sand casting continues to be a preferred choice for various industries due to its unique advantages. Its strength and versatility make it suitable for a wide range of applications, including:

1. Automotive Industry

Sand casting is extensively used in the automotive sector to produce engine blocks, transmission housings, and other critical components. The ability to cast metals like aluminum and cast iron, along with the flexibility of design, allows manufacturers to produce strong, lightweight, and cost-effective parts.

2. Aerospace and Defense

The aerospace and defense industries rely on sand casting to produce complex, high-strength components such as turbine blades, engine parts, and structural components. The ability to work with high-performance alloys ensures that sand-cast parts meet the stringent strength and durability requirements of these industries.

3. Agricultural and Heavy Equipment

For agricultural and heavy machinery, strength and durability are paramount. Sand casting is used to produce components like gears, housings, and brackets that must withstand heavy loads and harsh operating conditions. The versatility of the sand casting process allows manufacturers to create rugged, long-lasting parts that are vital to the performance of these machines.

Enhancing the Strength of Sand-Cast Components

While sand-cast components are inherently strong, various post-casting processes can further enhance their mechanical properties. Techniques such as heat treatment, surface finishing, and machining can improve the strength, hardness, and wear resistance of the cast parts.

Heat treatment can be applied to alter the microstructure of the metal, increasing its strength and toughness.

Surface finishing techniques, such as shot blasting or grinding, can remove surface imperfections and improve the overall durability of the component.

Many sand casting companies offer these value-added services to ensure that their cast components meet the specific strength requirements of their clients.

Conclusion: Is Sand Casting Strong?

The short answer is yes—sand casting is strong. The strength of sand-cast components depends on various factors, including material selection, mold quality, casting design, and casting process control. While it may not always offer the same level of precision as methods like die casting or investment casting, sand casting excels in producing robust, durable components for a wide range of industrial applications.

With the right expertise and equipment, a sand casting company can tailor its processes to produce high-strength components that meet the rigorous demands of industries like automotive, aerospace, and heavy machinery. By understanding and optimizing the factors that influence strength, manufacturers can ensure that sand cast parts perform reliably in even the most demanding applications.

So, if you're considering sand casting for your next project, rest assured—it’s not just a cost-effective method, but a process capable of producing parts with exceptional strength and durability.

0 notes

Text

Kaolin Market Intelligence Report Offers Growth Prospects

Kaolin Industry Overview

The global kaolin market size was valued at USD 3.98 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 4.0% from 2024 to 2030.Increasing investment in construction and infrastructure industry is propelling demand for paints & coatings, ceramic-based products, and cement, which is driving market growth.

Global construction industry is expected to witness lucrative growth over shifting inclination towards green construction, which in turn is expected to provide a significant growth opportunity for kaolin market. For instance, according to the World Bank’s new IFC report, green construction is anticipated to make investment opportunities worth USD 1.5 trillion for emerging markets.

Gather more insights about the market drivers, restrains and growth of theKaolin Market

Investments in construction, infrastructure development, and automotive production are expected to contribute to market growth over the forecast period. Growth of construction industry in the U.S. is a key factor contributing to demand for kaolin in the country. According to U.S. Census Bureau, total construction spending (residential and non-residential) grew by 3.5% in June 2023 on a y-o-y basis. The spending on single-family housing increased by 2.1% and multi-family housing by 1.5%.

Growing demand for painting due to rising investments in construction is leading companies to engage in strategic measures such as mergers & acquisitions, which are expected to influence the market demand positively. For instance, in November 2021, GDB International, Inc., a producer of paints & coatings, acquired a paint manufacturing plant in Illinois, U.S. This plant has a production capacity of 5 million gallons per year and can produce both water and solvent-based paints.

Further investments in medical industry are another driving factor for the market. For instance, in December 2021, Pfizer announced that it would acquire Arena Pharmaceuticals for about USD 6.70 billion. This deal was completed in March 2022 and is expected to help advance its presence in treatment of several immuno-deficiency diseases. Such developments indicate healthy growth for country’s pharmaceutical and medical industries. This is anticipated to have a positive impact on demand for kaolin in pharmaceuticals and medical application segment.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The India kaolin market size was estimated at USD 349.6 million in 2023 and is expected to grow at a CAGR of 5.2% from 2024 to 2030. The increasing construction and infrastructural developments, paper manufacturing, and growing paints and coating industries are driving growth for kaolin.

The global HDPE and LLDPE geomembrane market size was estimated at USD 1.36 billion in 2023 and is expected to grow at a CAGR of 5.6% from 2024 to 2030.

Key Companies profiled:

BASF SE

EICL Ltd.

Imerys S.A.

I-Minerals Inc.

KaMin LLC

LB Minerals Ltd.

Maoming Xingli Kaolin Co. Ltd.

Quazwerke GmbH

Sibelco

Thiele Kaolin Company

Key Kaolin Company Insights

Some of the key players operating in the market include KaMin LLC, Imerys S.A. and Sibelco.

KaMin LLC acquired the kaolin business from BASF SE in September 2022. The divestiture consists of the production hub with sites Toddvile, Edgar, Deweyville, and Gordon mines, mills, and reserves in the U.S.

Imerys S.A. specializes in the production & processing of minerals. It sells its products through three business segments: Performance Minerals Americas, Performance Minerals Asia Pacific, and Performance Minerals Europe, Middle East, and Africa.

Sibelco’s product portfolio includes dry sand, wet sands, kaolin, silica flour, frac sand, ball clay, cristobalite, feldspar, filtration sand, olivine sand, spherical silica, high-purity quartz, quicklime, coated sands, red clay, prepared bodies, hydrated lime, diatomite, nepheline Semite, olivine flour, and lithium minerals. The company manufactures kaolin for producing fine ceramics. The company’s kaolin reserves are in UK, Czech Republic, France, Germany, Spain, Portugal, and Ukraine.

WA Kaolin Limited and Maoming Xingli Kaolin Co., Ltd. are some of the emerging market participants.

WA kaolin is a mineral exploration, mining, and processing company. In November 2020, the company completed its definitive feasibility study of Wickepin Kaolin Project and in 2022 the company commissioned stage 1 of the Wickepin Processing plant

Maoming Xingli Kaolin Co., Ltd. has a high-quality mine named acicular kaolin mine that spreads across 800 acres. The company offers several products such as bone china clay, clay for porcelain, kaolin clay, porcelain clay, and others. Its key focus is on washed kaolin (without acid), 90-degree ball clay, and 90- degree kaolin.

Recent Developments

In November 2023, KaMin LLC and CADAM announced a price increase of their kaolin products by up to 9% starting from January 2024. This is to offset cost increase due to inflation, increase in mining cost, stringent environmental and regulatory requirements, and increase in electricity rates in the U.S. and Brazil, and labor cost.

In January 2024, the Federal Government of Nigeria announced that it has started to explore the possibility of production of salt and kaolin in Abuja. This is expected to increase global supply, hence providing price favorability to end users at a regional level.

Order a free sample PDF of the Kaolin Market Intelligence Study, published by Grand View Research.

0 notes

Text

Arrowsmith North Silica Sand Project: A Milestone in Environmental Approvals

VRX Silica Limited (ASX: VRX) has reached a significant milestone in its Arrowsmith North Silica Sand Project as the Department of Water and Environmental Regulation (DWER) approved the publication of the Environmental Review Document (ERD). This approval marks the beginning of a four-week Public Environmental Review (PER) period, showcasing VRX Silica's dedication to transparency and environmental responsibility.

Starting on June 19th, 2023, the public environmental review process allows stakeholders to provide their comments and feedback, which VRX Silica is obligated to address. Following the PER, the Environmental Protection Authority of Western Australia (EPA) will prepare an assessment report with recommendations for the Western Australian Environment Minister's review and consideration for project approval.

Managing Director Bruce Maluish expressed his delight, stating, "We are delighted that the environmental approvals process has moved to this next important stage. This is a significant milestone for the process." Maluish further highlighted VRX Silica's unique rehabilitation method for the mined area, emphasizing the potential economic contribution to the Irwin Shire and Western Australia as a whole.

With over 40 years of involvement in the mining industry, Bruce Maluish brings a wealth of experience and expertise to VRX Silica. Holding a bachelor's degree in Applied Science in Surveying from the Western Australian Institute of Technology, Maluish has held vital positions in esteemed organizations throughout his career. His extensive knowledge and experience in resource sectors make him a valuable asset to VRX Silica.

The Arrowsmith North Silica Sand Project's approvals process has witnessed several milestones. VRX Silica previously obtained confirmation from the Commonwealth Department of Climate Change, Energy, the Environment, and Water for an accredited assessment. The company has conducted extensive environmental studies since 2017, demonstrating its commitment to meeting regulatory standards.

The project was referred to the EPA for assessment under the Environmental Protection Act 1986 (WA) Act, which determined that a Public Environmental Review was necessary. VRX Silica's Environmental Scoping Document (ESD) received approval from the EPA in March 2022, signifying progress in the project's assessment.

An essential feature of VRX Silica's proposal is the unique Vegetation Direct Transfer (VDT) rehabilitation methodology for site restoration in the Arrowsmith North Silica Sand Project. Throughout the approval process, VRX Silica has actively addressed information requests from DWER, culminating in the acceptance of the final ERD on June 8th, 2023.

Moving forward, the Department of Water and Environmental Regulation will collect and review public submissions during the four-week PER period, and VRX Silica will diligently respond to these submissions. The Environmental Protection Authority will then compile an assessment report with recommendations for the Western Australian Environment Minister's decision on the Proposal's approval. The issuance of a Ministerial Statement upon successful approval will signify a crucial milestone for the project.

Investors have shown confidence in VRX Silica, reflected in the 31.818% jump in the company's share price during a single trading session on June 9th, 2023. As of that date, VRX Silica's market capitalization stood at AUD 61.64 million, with a share price range of AUD 0.093 to AUD 0.190.

VRX Silica, listed on the ASX, is a leading pure-play silica sand company focused on advancing its portfolio of four Western Australian silica sand projects. In addition to the Arrowsmith North Silica Sand Project, the company is also developing the Arrowsmith Central Silica Sand Project, the Muchea Silica Sand Project, and the Boyatup Silica Sand Project.

For the latest updates and details on VRX Silica and its projects, visit the official website at https://vrxsilica.com.au/. With its commitment to responsible and transparent development, VRX Silica is poised for continued success in the silica sand industry.

#Arrowsmith North Silica Sand Project#VRX Silica Limited#environmental approvals#Environmental Review Document#public environmental review#Bruce Maluish#rehabilitation methodology#Western Australian Environment Minister#Environmental Protection Authority#mining industry#resource sectors#sustainability#transparency#responsible development.

0 notes

Text

Unlocking the Potential of Quartz Powder in Manufacturing

Quartz powder, a finely ground form of crystalline silica, is an essential industrial material used in various sectors such as glass manufacturing, electronics, ceramics, construction, and more. It is highly valued for its physical and chemical properties, including durability, high melting point, low electrical conductivity, and resistance to wear. Industries across the globe are reliant on high-quality Quartz Powder Manufacturers to create products ranging from everyday household items to advanced technological components.

When it comes to sourcing premium-grade quartz powder, Sudarshan Group has established itself as a leading manufacturer and supplier in the market. With decades of experience and a commitment to innovation, Sudarshan Group has become a name synonymous with quality and reliability in the mineral industry. In this article, we will explore the importance of quartz powder, its applications, and why Sudarshan Group stands out among quartz powder manufacturers.

What is Quartz Powder?

Quartz powder is derived from natural quartz, a mineral composed primarily of silicon dioxide (SiO2). It is abundant in the Earth’s crust and occurs in a variety of forms, including large crystals, sand, and finely ground powder. Quartz has exceptional hardness, chemical stability, and optical properties, making it ideal for use in multiple industrial applications.

The process of creating quartz powder typically involves mining quartz deposits, crushing the raw material, and then grinding it to the desired particle size. High-purity quartz powder, which has fewer impurities such as iron and other trace minerals, is often used in specialized applications, especially in electronics and high-tech industries.

Applications of Quartz Powder

Glass Manufacturing: One of the most well-known applications of quartz powder is in the glass industry. Quartz is a key ingredient in the production of glass, contributing to the material’s strength, transparency, and resistance to high temperatures. The silica content in quartz powder acts as a flux, lowering the melting point of the raw materials used in glassmaking. This allows for the production of various types of glass, including soda-lime glass, borosilicate glass, and specialty glass used in laboratory equipment and optics.

Ceramics: In the ceramics industry, quartz powder is used as a filler material to enhance the mechanical strength of the final product. It helps improve the thermal shock resistance and overall durability of ceramic items, making them suitable for use in high-temperature environments. The fine particle size of quartz powder also ensures a smooth surface finish for ceramics, contributing to their aesthetic appeal.

Construction: Quartz powder is widely used in the construction industry, particularly in the production of concrete and mortar. The addition of quartz powder improves the strength, durability, and weather resistance of these materials, making them ideal for building structures that need to withstand harsh environmental conditions. In addition, quartz is used in engineered stone products, such as countertops and flooring, which combine beauty with practicality.

Electronics: High-purity quartz powder plays a critical role in the electronics industry. It is used in the production of semiconductors, integrated circuits, and solar cells due to its excellent electrical insulation properties. Quartz also has piezoelectric properties, meaning it can generate an electrical charge when subjected to mechanical stress. This makes it an essential component in devices like oscillators, sensors, and watches.

Paints and Coatings: In the paints and coatings industry, quartz powder is used as a filler material to improve the durability, gloss, and resistance of paints. It helps create coatings that are resistant to chemicals, heat, and wear, making them suitable for use in harsh environments. Quartz powder also enhances the adhesion of paint to surfaces, ensuring a long-lasting finish.

Foundry and Refractory Applications: Quartz powder is used in foundries to create molds for casting metals. Its high melting point and resistance to thermal expansion make it ideal for producing molds that can withstand extreme temperatures. In refractory applications, quartz powder is used to create heat-resistant materials that are essential for lining furnaces, kilns, and other high-temperature processing equipment.

Leading the Way in Quartz Powder Manufacturing