#smart-factory-system

Explore tagged Tumblr posts

Text

Lean Manufacturing – A Guide to Streamlining Your Operations

Lean Manufacturing is a philosophy and set of practices aimed at minimizing waste and maximizing value in manufacturing processes. Originally developed by Toyota as part of the Toyota Production System, Lean principles have since been adopted by companies worldwide to improve efficiency, reduce costs, and enhance quality read more here…

0 notes

Text

5G-Powered Drones: Ericsson, Qualcomm And Dronus Collaboration In Developing Autonomous Drone Solutions

5G mmWave technology for industrial use. Ericsson, Qualcomm, and Dronus Collaboration in developing autonomous drone solutions. The world of industrial automation is on the cusp of a revolution, and at the forefront is a powerful combination, of 5G technology and autonomous drones. A recent collaboration between Ericsson, Qualcomm Technologies, Inc., and Dronus provides a glimpse into this exciting future.

#5G drones#Industrial automation#Indoor drone applications#Warehouse inventory management#mmWave 5G technology#Autonomous drones#Industry 4.0#5G smart factory#(PoC)#Qualcomm QRB5165 processor#Telit Cinterion#mmWave#Industrial M.2 data card#5G Modem-RF System#Native mmWave connectivity#High-performance 5G connection#Bandwidth-intensive industrial operations#drone

2 notes

·

View notes

Text

Red and Yellow Andon: Boosting Manufacturing Efficiency Through Visual Management

In today’s fast-paced industrial environment, the need for real-time communication on the shop floor is more critical than ever. Manufacturers are constantly seeking smarter ways to minimize downtime, improve safety, and ensure smooth operations. One of the most effective tools for achieving this is the Andon system, particularly using Red and Yellow Andon lights.

What is an Andon System?

An Andon system is a visual alert tool used in lean manufacturing to notify operators and managers about production line issues. It helps enhance process visibility, team coordination, and problem resolution.

At Vidgastech, we specialize in designing smart Andon systems tailored for various industrial needs. Our systems use a combination of red and yellow signals to streamline operations and promote rapid response.

Understanding Red and Yellow Andon Signals

🔴 Red Andon Light: This indicates a critical issue that requires immediate attention, such as a machine malfunction, safety hazard, or production stop.

🟡 Yellow Andon Light: A warning signal to show non-critical issues, such as material shortages, minor defects, or preventive maintenance alerts.

These signals help teams act quickly and effectively, reducing downtime and boosting overall productivity.

Benefits of Red and Yellow Andon in Manufacturing

✅ Faster identification and resolution of issues ✅ Improved communication between teams and supervisors ✅ Reduced downtime and higher throughput ✅ Enhanced worker safety and accountability ✅ Supports lean and Six Sigma practices

Why Choose Vidgastech’s Andon Solutions?

At Vidgastech, we understand the unique challenges of modern manufacturing. Our Red and Yellow Andon systems are designed with reliability, clarity, and scalability in mind. We offer:

High-visibility LED Andon lights

IoT integration for real-time monitoring

Custom alerts and configurations

Easy installation and low maintenance

Whether you operate in automotive, electronics, packaging, or food processing, our solutions can be adapted to your specific requirements.

Final Thoughts

Implementing a Red and Yellow Andon system is more than just installing lights—it's about building a culture of responsiveness and continuous improvement. With Vidgastech’s expertise and technology, your facility can achieve greater control, visibility, and operational efficiency.

About Vidgastech Vidgastech is a leading provider of industrial automation solutions, helping businesses transform their shop floors into smart, responsive production environments.

🔗 Learn more at: https://www.vidgastech.com

#Red Andon Light#Yellow Andon Light#Andon System#Lean Manufacturing#Visual Alerts#Production Efficiency#Vidgastech#Smart Factory Solutions

0 notes

Text

🔄 Process Approach Across ISO & IATF Standards with 🚗 OEM Requirements in 2025

✅ Introduction: Why the Process Approach Matters in 2025 The process approach isn’t just a buzzword from ISO standards—it’s the engine behind operational excellence. As we step into 2025, OEMs (Original Equipment Manufacturers) demand more than compliance—they expect traceability, zero-defect culture, and real-time performance. In this guide, you’ll learn: 📌 How the process approach is defined…

View On WordPress

#5W2H model ISO#Automotive manufacturing#automotive quality system#clause 4.4 explained#EHS process compliance#energy management ISO 50001#environmental compliance ISO 14001#IATF 16949 process control#ISO digital integration#ISO standards 2025#lean manufacturing#occupational health ISO 45001#OEM compliance 2025#PFMEA process improvement#process approach ISO#process mapping ISO 9001#process ownership in QMS#quality management ISO 9001#risk-based thinking ISO#SIPOC diagram example#smart factory process control#Turtle diagram QMS

0 notes

Text

Industry 4.0: Powering the Next Industrial Revolution with Intelligence, Connectivity, and Automation

The world is undergoing a radical transformation. As we move deeper into the 21st century, the fusion of digital, physical, and biological systems is reshaping how we manufacture, operate, and innovate. This revolution has a name: Industry 4.0—the fourth industrial revolution. It represents a new era where smart technology, real-time data, automation, and interconnected networks converge to…

#5G Connectivity#Additive Manufacturing#advanced robotics#Artificial intelligence#Automation#Big Data Analytics#Blockchain#Cloud Computing#connected industry#Cyber-physical systems#data-driven operations#Digital Transformation#Digital twin#Edge computing#fourth industrial revolution#IIoT#Industrial Networking#Industry 4.0#intelligent systems#manufacturing innovation#next-gen industry#Predictive maintenance#Real-time analytics#Robotics#smart factory#Smart Grid#Smart logistics#Smart manufacturing#SolveForce#Supply Chain Visibility

0 notes

Video

youtube

Telescopic Sliding Gates | Automatic & Industrial Gate Systems by Secure...

#youtube#telescopic sliding gate#AutomaticGatesIndia#industrial sliding gates#SecureIndiaGates#AutomaticTelescopicGate#HeavyDutyGates#IndustrialGateAutomation#sliding gate system#automatic swing gate#SecurityGatesManufacturer#Automatic Gate Installation#Industrial Entrance Gates#Smart Gate Solutions#Automatic Gate for Factory#Motorized Gate Systems#Commercial Sliding Gate#Automatic Gate Supplier India#Gate Automation Ahmedabad#Entrance Control Solutions#Secure India Security Products#Automated Entry Gates#Perimeter Security Solutions

0 notes

Text

0 notes

Text

Odoo ERP for Manufacturing Industry

🏭 Manufacturers—streamline your operations with Odoo ERP!

From production planning to inventory management and real-time reporting, Odoo gives you full control of your manufacturing process — all in one platform.

✅ Boost productivity ✅ Minimize downtime ✅ Reduce waste & costs ✅ Get real-time insights for smarter decisions

Looking to digitize your factory floor? Our team specializes in implementing Odoo ERP tailored for the manufacturing industry.

🔧 Explore how we can help: https://www.candidroot.com/odoo-manufacturing-erp

#odoo#odoo erp#erp for manufacturing#manufacturing excellence#smart factory#industry 40#digital manufacturing#erpsoftware#erp system

0 notes

Text

#Industrial Automation Training kits in Pune#Hydraulics and Pneumatics Manufacturer in Pune#Hydraulic Training Kit Supplier in Pune#Pneumatic Training Kit Exporter in Pune#PLC Training Kit Manufacturer#Robotics Equipment Exporter#Smart Factory Systems Trader#Mechatronics Training Kit Supplier#Industrial Automation Equipment Manufacturer#CNC Simulators Exporter#Technical Training Solutions Manufacturer#Didactic Equipment Supplier in Pune#Robotics Training kits in Pune#PLC Training kits in Pune#HMI Training kits in Pune#SCADA Training kits in Pune

0 notes

Text

Top Companies for Automation Services in Naperville, IL

Naperville, Illinois, stands out as a technology-driven city with a thriving industrial and commercial sector. As the demand for smarter, more efficient systems continues to grow, companies automation services in Naperville are becoming essential for businesses aiming to stay competitive in today's digital age.

Automation is no longer just an advantage—it’s a necessity for businesses looking to scale operations, reduce labor-intensive tasks, and increase efficiency across various departments. Whether in manufacturing, logistics, commercial buildings, or process industries, automation technologies are transforming how companies in Naperville operate, manage resources, and deliver value.

Why Automation is Crucial for Businesses in Naperville

Automation is revolutionizing the way Naperville-based companies handle their day-to-day operations. Here are several reasons why local businesses are investing in automation:

Increased productivity: Automation reduces the need for manual labor, leading to faster production cycles and reduced downtime.

Cost savings: Automated systems can significantly lower operational expenses over time.

Accuracy and consistency: Automated machines and software ensure precise execution of tasks with minimal errors.

Real-time data and analytics: Intelligent systems provide insights that help improve decision-making.

Workforce optimization: Employees can focus on high-value tasks rather than repetitive or dangerous duties.

Compliance and safety: Automation helps meet strict regulatory standards and safety requirements.

For Naperville’s growing tech and industrial scene, these benefits position automation as a long-term strategic asset.

Key Industries Leveraging Automation in Naperville

Naperville businesses across multiple industries are adopting automation technologies to streamline their operations:

Manufacturing: Robotics, CNC machinery, and industrial automation are optimizing production lines.

Warehousing and logistics: Automated conveyors, barcode scanners, and inventory systems ensure smooth supply chain operations.

Healthcare: Automation helps in diagnostics, lab testing, and administrative workflows.

Retail and service sectors: POS automation, customer service chatbots, and order tracking systems are improving customer experiences.

Building management: Building automation systems (BAS) regulate lighting, HVAC, and security systems for commercial properties.

As Naperville continues to attract diverse business investments, the demand for reliable automation companies is on the rise.

Types of Automation Services Offered by Naperville Companies

Automation companies in Naperville, Illinois offer a broad range of services tailored to specific business needs. These include:

PLC Programming and Integration: Custom logic programming for industrial control systems.

SCADA and HMI Design: Supervisory control systems with user-friendly interfaces.

Robotics Integration: Installation and configuration of robotic arms for precise and repetitive tasks.

IoT and Smart Systems: Device interconnectivity for real-time monitoring and control.

Building Automation Solutions: Energy-efficient systems for HVAC, lighting, and building access.

Custom Software Development: Development of automation software for scheduling, reporting, and analytics.

Each service is designed to help companies improve their workflows and align with modern operational standards.

Choosing the Right Automation Partner in Naperville

Not all automation companies offer the same level of expertise. When selecting a provider in Naperville, consider the following factors:

Experience and specialization: Choose companies with a proven track record in your specific industry.

Technical capabilities: Ensure they can handle the level of system complexity required.

Scalability: Look for solutions that can grow with your business.

Customer support: Strong post-installation service is key to long-term success.

Customization: Your business needs a partner that can tailor solutions to your workflow.

Certifications and compliance: Check for relevant industry certifications like UL, ISO, or OSHA compliance.

A trusted partner can help you navigate technology decisions, integrate systems, and train staff effectively.

Automation Trends Transforming Naperville Businesses

The landscape of automation is constantly evolving. Here are some top trends influencing Naperville’s commercial and industrial environments:

AI-Powered Automation: Machine learning algorithms enhance predictive maintenance and production optimization.

Edge Computing: Local data processing reduces latency and improves response time in real-time systems.

Cloud-Based Control Systems: Enables remote access, monitoring, and updates.

Green Automation: Energy-efficient solutions aligned with sustainability goals.

Cybersecurity for Automation Networks: Enhanced protection of control systems from cyber threats.

Staying ahead of these trends is key for companies looking to maintain a competitive edge in the Naperville market.

Benefits of Automation for Small and Medium Enterprises (SMEs)

Automation is not exclusive to large corporations. In Naperville, small and medium businesses are increasingly investing in automation technologies for:

Inventory management and procurement

Workflow automation in administrative tasks

Customer relationship management (CRM) systems

Automated billing and invoicing

Smart energy control in small office buildings

The accessibility and affordability of modern automation tools make them an excellent investment for SMEs aiming to scale without hiring extensively.

Automation and Economic Development in Naperville

Automation is playing a key role in Naperville’s economic growth. As companies become more efficient and competitive, they attract more business and create high-skill job opportunities. Local schools and training institutions are also responding by offering specialized programs in automation, robotics, and engineering—helping to create a talent pipeline that supports long-term innovation.

With Naperville’s continued investment in infrastructure and technology parks, the city is well-positioned to be a hub for automation excellence in Illinois.

Empowering Naperville Through Smart Automation

From small businesses to large enterprises, the ability to implement smart automation systems is critical for long-term success. The right automation partner can help you optimize operations, increase profits, and stay agile in an ever-changing market. As demand for precision, speed, and efficiency increases, Naperville businesses are finding automation to be one of their most strategic investments.

Partner with a Trusted Automation Company in Naperville

If you're seeking high-quality automation solutions tailored for your Naperville business, Xtreme Automation LLC delivers the expertise and support needed to elevate your operations. Whether you require industrial controls, building automation, or full-system integration, their team is committed to delivering scalable, efficient, and customized automation solutions. Learn more at xtremeautomationllc.com.

#automation companies Naperville IL#industrial automation Naperville#automation engineering Naperville Illinois#smart factory solutions Naperville#Naperville automation systems

0 notes

Video

youtube

E cigarette display #customdisplays #vaperetail #factorydirect #retailin...

#youtube#Customizable Smart Future-Ready. Modular Designs: From compact countertop units to sprawling wall systems tailor sizes layouts and branding#E-cigarette display Factory-Built Precision Delivered Globally With 10+ years of expertise our state-of-the-art factory produces 10000+ di

0 notes

Text

https://glansa.com/andon/

Discover how Industry Automation in India is revolutionizing manufacturing with smart solutions like Andon systems. Glansa Solutions offers a real-time alert and monitoring system to reduce downtime, improve efficiency, and support Industry 4.0 implementation. Explore how Indian industries are leveraging automation to stay globally competitive.

#Industry Automation in India#Andon System#Manufacturing Automation#Industrial Solutions India#Smart Factory#Glansa Andon#Industry 4.0 India#Real-time Production Monitoring

0 notes

Text

Smart Factory with 7 Axes Robot and Digital Twin Manufacturer in Pune India

Manufacturer and Supplier of Smart Factory solutions with 7 Axes Robots and Digital Twin technology in Pune. We provide flexible manufacturing systems (MPS), connected machines, and SCADA training.

#Flexible Manufacturing Systems Manufacturer Pune#Smart Factory with 7 Axes Robot Pune#Smart Factory Manufacturer Pune#Flexible Manufacturing System Pune#MPS Manufacturing System Pune#Connected Machines Pune#SCADA Training Pune#Digital Twin Pune#Flexible Manufacturing Systems Pune#Digital Twin for Manufacturing Pune#SCADA Solutions Pune

0 notes

Text

Face mask appearance inspection machine, Intsoft Tech machine vision solution

#face mask making machine#integrated machine vision solutions for the smart factory#custom automated mechanical machines#optical inspection#deep learning for vision systems#computer system validation in pharmaceutical industry

1 note

·

View note

Text

youtube

#china android led tv hard reset#china android tv setting#china android led tv#china android led tv software#China Android TV Reset#Android TV Recovery method#China Wisdom Share Smart Cloud TV Hard reset#China Android TV#TV reset#TV recovery#Android TV issues#TV troubleshooting#TV performance issues#TV software bugs#TV factory reset#TV restore#TV system reset#TV firmware update#TV maintenance#TV repair#TV support#TV help#china smart tv hard reset#Youtube

0 notes

Text

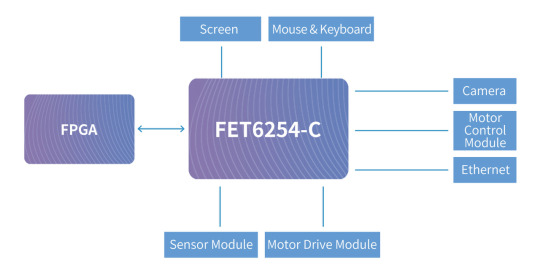

Industrial Data Acquisition and Control System Solution Based on FET6254-C SoM

Against the backdrop of rapid development in communication and networking technologies, smart factories are gradually achieving data-driven, networked, and intelligent management. In this trend, the utilization of the Industrial IoT has become an indispensable key step in achieving industrial data collection and control.

Traditional industrial data collection and control systems typically require connection to multiple data collection devices, perform high-speed communication, handle complex data processing, and achieve high-definition multimedia display functions. The embedded system based on ARM+FPGA architecture has rich peripheral interfaces, high-definition display high-speed transmission, and other functions, which are more capable of high-speed industrial data acquisition tasks. The flexibility and performance of this embedded system make it an ideal choice to meet the needs of smart factories, which can effectively improve the efficiency and accuracy of industrial data processing.

In the industrial data acquisition and control system, high-speed data acquisition system and embedded human-computer interaction system cooperate closely to build an intelligent industrial management system. The main task of the high-speed data acquisition system is to collect the key data in the industrial production process in real time and ensure the accuracy and timeliness of the data. This involves high-speed communication with multiple data acquisition devices, as well as sophisticated data processing and multimedia display capabilities.

As the main control center, the embedded human-computer interaction system coordinates and manages each module and resource, and is responsible for receiving the data from the FPGA terminal. It not only visualizes the data to the user, but also achieves more flexible control through human-computer interaction. The system also realizes the connection with the industrial MES + ERP system through the communication module, and transmits the collected data to the cloud for storage. This design not only improves the efficiency of data processing, but also greatly reduces the risk of manual data entry, and realizes the intelligent management of industrial data.

The whole system architecture provides a more comprehensive and efficient data management solution for enterprises. This not only helps to reduce human errors in the production process, but also makes better use of human resources and improves production efficiency. With the continuous development of communication and network technology, such industrial data acquisition and control system will become an important support for industrial intelligence in the future.

The main control device of the industrial data acquisition control system can adopt Forlinx Embedded FET6254-C SoM, which is based on TI's AM62x series industrial processor design, with the main frequency up to 1.4GHz, is a multi-core heterogeneous processor, adopting the Cortex-A53+Cortex-M4F combination of processing core + control core architecture; the functional safety features can be realised by the M4F core and its dedicated peripherals, and the startup and operation of the M4F core no longer depend on the A53 core. The M4F core and its dedicated peripherals enable functional safety features, and the M4F core is no longer dependent on the A53 core for startup and operation.

It can provide excellent data processing capability and human-computer interaction experience, and can control the motor drive module in real time to meet the requirements of data processing, task scheduling and human-computer interaction of the real-time control system.

It support parallel bus support for ARM high-speed communication with the FPGA to provide access. FET6254-C supports TI processor-specific general-purpose memory controller interface GPMC, high data read and write rate of up to 100MB / s, support for multiple chip selection, the configuration is more flexible, and at the same time can provide a variety of methods to connect with the peripheral devices and a wide range of external devices can be communicated.

The FET6254-C SoM integrates a rich set of functional interfaces. It supports two Gigabit Ethernet with TSN support, which provides fast data transmission and connection capability to meet the demand of industrial data acquisition and control systems for high bandwidth and low latency; it also supports three communication interfaces, such as CAN FD, I2C, I2S, which provide a reliable, high-speed and real-time data transmission method for the normal operation and efficient performance of industrial data acquisition and control system; with rich interface resources such as USB, UART, PWM, SPI, etc., it can be used to connect various sensors, actuators, motor drive modules, and mouse and keyboard devices.

The control system provides support for normal operation and efficient performance; with rich interface resources such as: USB, UART, PWM, SPI, etc., can be used to connect a variety of sensors, actuators, motor drive modules, as well as the mouse, keyboard devices, etc., can be achieved in industrial data acquisition and control of a variety of signals and data, to achieve the monitoring and control of the production process; the SoM adopts an industrial-grade temperature and wide range of design, to ensure that the stability and reliability of the product to meet the requirements of industrial application environment.

Originally published at www.forlinx.net.

0 notes