#sound level meter calibration

Text

In a fast-paced world, industries and businesses seek innovative solutions to enhance efficiency and reduce costs. An area that has seen significant advancements is noise monitoring technology, with the development of noise monitoring devices, systems, and equipment.

#ground vibration monitoring equipment#building acoustics#sound level meter calibration#noise monitoring system#noise monitoring device#acoustic analyser#personal noise dosimeter rental#noise detector

0 notes

Text

Ensure accurate flowmeter calibration in the UAE with Arabcal's expert services. Our certified technicians provide precise calibration solutions for all types of flow meters, meeting industry standards and regulatory requirements. Contact us for reliable flowmeter calibration services tailored to your needs.

#Flowmeter Calibration in UAE#Biomedical Test Equipment#Air Quality Monitor Supplier in UAE#asset management in uae#sound level meter supplier in uae#instrument and equipment supplier in uae#megger service center#iso 17025 accredited calibration company in uae#pressure and temperature chart recorder in uae#testing equipment supplier in uae

0 notes

Text

Sound Level Calibrator LSDC-A10 is a noise decibel calibration tool and used for quick and easy calibration

of sound level meters and sound measuring systems. It offers frequency up to 1000 Hz and accuracy is 0.3 dB. Calibrator

employs solid state integrated circuitry that provides accurate and stable performance. It is suitable for field and

laboratory use.

0 notes

Text

people say the worst SI unit is the mole. "ohhh but it's just a number it doesn't even have anything attached it doesn't deserve to be an official unit" BZZZ WRONG

the worst unit is the candela. the candela is stupid.

what's the candela, you ask? well, it measures the brightness of light

"oh that sounds reasonable" you say, "just measure the energy or power emitted!" nope. they would not do anything nearly so simple. a lightbulb emitting a watt of yellow light is more candelas than a lightbulb emitting a watt of red light.

"ok that's weird" you say, "but maybe they're adjusting for that somehow? maybe it measures number of photons?" again, that would be far too reasonable. a lightbulb emitting a fixed rate of yellow-light photons is more candelas than the same rate of purple-light photons.

but what are they even measuring then? what else is there to measure? clearly they ran out of ideas while making up units, because what they're actually measuring is the SUBJECTIVE BRIGHTNESS OF LIGHT TO THE HUMAN EYE. the candela is STUPID

a reasonable question to ask is: how would you even measure the brightness of light to the human eye? aren't a lot of human eyes different? don't different things look bright in different circumstances? aren't there colorblind people in the world?

surely the General Conference on Weights and Measures, which spent millions precisely calibrating magnetic quantum flux to avoid basing the kilogram on a random block in France, has a clever solution!

no. no they don't. the candela is stupid.

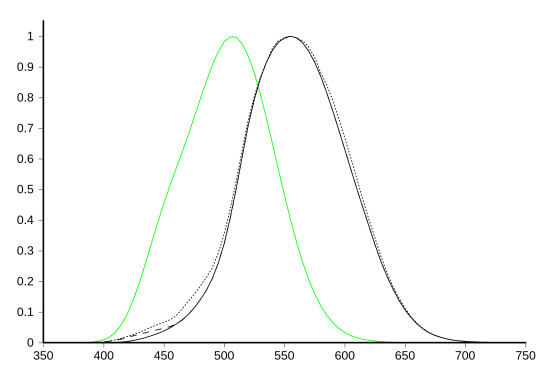

as far as I can tell, what you do is you first measure how much light of each wavelength comes in. Then you multiply each measurement by a "luminosity function", which measures brightness to the human eye:

you will notice that there are multiple functions shown in this diagram. the SI system has five of these, for different lighting conditions. do your lighting conditions not exactly follow one of the Five Official Standardized Lighting Conditions? guess you're out of luck then.

and whose eye are we using? why, the Official Standardized CIE Photometric Observer, of course: the "ideal observer having a relative spectral responsivity that conforms to a CIE-defined spectral luminous efficiency function for human vision"

(and no I can't show you this function because the fine people of the ISO put it BEHIND A PAYWALL. who puts measurements determining a fundamental SI unit BEHIND A PAYWALL. the candela is stupid)

all right, so we're measuring a fundamental unit using a (nonexistent) idealized observer in one of five random lighting conditions. how did they find the values for this? i'm...not entirely sure. but here's a glimpse, based on a few of the most recent studies I found used for this:

"...heterochromatic (minimum) flicker photometric data obtained from 40 observers (35 males, 5 females) of known genotype..."

"To obtain an estimate of the mean L-cone fundamental, we weighted [weird variables] according to the ratio of 0.56 L(S180) to 0.44 L(A180) found in the normal, male Caucasian population...and averaged them together"

that's right, our Official Objective Brightness Unit is probably sexist and racist. none of the other SI units have a chance to be sexist and racist. a meter is a meter in every country on Earth. 6.022*10^23 For Women is still 6.022*10^23. but the candela is-- probably-- the white man's candela, because you can absolutely bet that genetic drift around the world gives different values for this stuff.

in summary: my opinion, as you might have guessed, is that the candela is stupid. hopefully you agree with me after reading this that we need to completely eradicate it from the planet. failing that could we at not give it the same level of officialness as the meter or the kilogram?

604 notes

·

View notes

Text

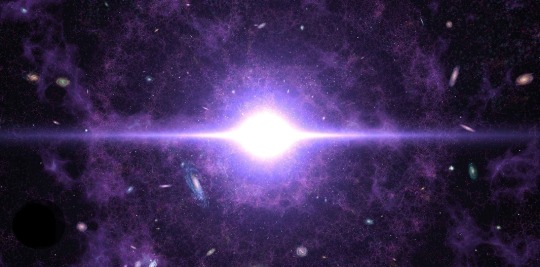

A MISSING PIECE IN THE BIG BANG THEORY HAS SURFACED??

Blog#411

Wednesday, June 19th, 2024.

Welcome back,

Combining different pieces from Big Bang cosmology could help explain an issue we have today.

The Hubble constant, the speed of expansion of our universe, is not observed with consistency.

These scientists suggest that not-well-understood quantum gravity could account for the gap.

In research published earlier this year, physicists from the University of Hyderabad in India say they’re on the path to solving one of the universe’s biggest outstanding problems. Since Edwin Hubble realized the universe is always expanding nearly 100 years ago, scientists have used the “Hubble constant” in calculations on virtually every scale in the universe.

But today, estimates for the Hubble constant don’t always align, with a difference of up to 10 percent between calculations made using different methods. (When someone at NASA mixes up meters and yards and loses an entire spacecraft, that’s not even a full 10 percent deviation.)

The paper appears in the peer reviewed journal Classical and Quantum Gravity. The journal has an ongoing, periodically updated “focus issue” specifically about this measurement tension, and the editors explain the problem there—scientists can’t say for sure that the different Hubble constants measured are actually different, rather than just observation or calibration issues.

But the authors of the new paper, physicist P.K. Suresh and his research fellow (referred to as just Anupama B.) say that most measurements taken now are reliable. Instrumentation only continues to improve—we’ve all seen those generation-defining, poster-quality photos of the far-out planets, for example. If the measurements on the local and faraway levels are indeed sound, then something is missing.

It’s here where they introduce quantum gravity as a possible factor. This variable—which, to be honest, is another enigmatic “placeholder” in some ways—could close the gap in Hubble constant observations. That’s because, as the authors propose, quantum gravity could have affected the rate of change at which the universe expanded itself. When a constant can have a variable rate of change, it’s easy to see why researchers tend to drop the ‘constant’ label and instead call the fatcor simply H0, H1, and so on to designate which version of the measurement is in play.

The researchers explain that during inflation—the rapid growth of the universe immediately following the Big Bang—there may not have been a single, uniform inflation zone. Instead, more and more scientists are theorizing around the idea of “multi field” inflation. The idea originated to explain another measurement discrepancy: the number of particles in particular places or times, compared with the massive speed of inflation overall.

If a theory could help explain one gap in our codified equations for how inflation works, it makes sense to try that theory to find other missing pieces. These researchers used what is called the hybrid inflationary model, which describes two fields: one inflating and one rolling over like a waterfall. By accounting for quantum gravity, they found they were able to reconcile H0—the current Hubble constant—with both H1 (during inflation) and HT (during phase transition). Just one adjusted equation with a parameter for quantum gravity could draw a curve that includes all three data points.

Originally published on www.popularmechanics.com

COMING UP!!

(Saturday, June 22nd, 2024)

"WHAT IS THE OLDEST BLACK HOLE IN OUR UNIVERSE??"

#astronomy#outer space#alternate universe#astrophysics#universe#spacecraft#white universe#space#parallel universe#astrophotography

74 notes

·

View notes

Text

Recording Studio Tech

⚠️ High pitched frequency warning! ⚠️ This frequency may trigger tinnitus.

This is the tedious work behind your favorite music that you rarely get to see. When i was an engineers apprentice, this was the sound that accompanied the start of every morning. In this video a studio apprentice is adjusting the calibration and alignment of the Studer A80 tape machine at Omega Recording Studio. The MRL Calibration Tape plays a 1khz frequency at 250nWb/m. The Weber is the unit of magnetic flux, or in layman’s terms, magnetic strength. It is an important measurement for getting signals on and off of magnetic tape (whether digital or analog). One Weber is much too large a unit to be relevant with tape recorders, so the nanoweber (one billionth of a Weber) is a standard unit of measurement. The recorded level of tape is expressed in nanowebers per meter of tape. Especially in analog recording, the signal level to tape is a critical component in the performance of the tape. Too high a level, and you get distortion and lack of headroom, but with too low a level, your signal-to-noise is compromised. The proper recording level for tape depends a lot on the formulation of the tape and the electrical/magnetic characteristics of the recorder. Recorders are thus aligned using standard reference tapes containing tones at known levels rated in nanowebers per meter. Once the machine is calibrated to a reference, it becomes possible to optimize its levels for the particular formulation of tape desired through another alignment procedure. Recording to tape is just as much an artform as making the music itself.

#studio aesthetic#recoding studio#daddysmusic#analog tape#magnetic tape#studer tape machine#sound engineer#recording engineer#gear geek#studio rat#studio geek#music geek#technology geek

3 notes

·

View notes

Text

2 notes

·

View notes

Text

The Ultimate Guide to Conducting a Noise Survey

Introduction

Noise is a constant presence in our lives, affecting our health, productivity, and overall quality of life. Whether in workplaces, homes, or public areas, it is essential to understand and manage noise levels. One of the best ways to achieve this is through a noise survey. In this blog, we'll explore what a noise survey is, its importance, how to conduct one, and the benefits it provides.

What is a Noise Survey?

A noise survey is a detailed assessment of noise levels in a particular environment. It involves measuring sound intensity at different locations and times to identify noise sources, their intensity, and their impact on the area. The data from a noise survey can be used to check compliance with regulations, assess health risks, and develop noise control strategies.

Why Conduct a Noise Survey?

Health and Safety: Long-term exposure to high noise levels can cause hearing loss, stress, sleep disturbances, and other health problems. A noise survey helps identify harmful noise levels and implement protective measures.

Regulatory Compliance: Many countries have strict regulations regarding allowable noise levels in various environments. A noise survey ensures compliance with these laws, avoiding legal issues and fines.

Improved Productivity: In workplaces, excessive noise can reduce productivity and increase error rates. Identifying and reducing noise sources can create a more productive working environment.

Community Well-being: In residential areas, noise surveys help maintain a peaceful environment, improving residents' quality of life.

How to Conduct a Noise Survey

Planning: Define the survey's scope. Determine the locations, times, and duration of measurements. Identify potential noise sources and select suitable equipment.

Equipment: Use a calibrated sound level meter or dosimeter that meets industry standards and is appropriate for the expected noise levels and frequencies.

Data Collection: Measure noise levels at different points and times. Record the type of noise, its source, and the duration of exposure. Take measurements at ear level and under various conditions.

Analysis: Analyze the data to identify patterns and sources of high noise levels. Compare the results with regulatory standards and guidelines.

Reporting: Create a detailed report that includes methodology, findings, and recommendations for noise control. Use charts, graphs, and maps to illustrate the data.

Key Considerations

Time of Day: Noise levels can vary greatly between day and night. Take measurements at different times to get an accurate assessment.

Weather Conditions: Weather can affect noise levels. Note the weather conditions during each measurement.

Human Activity: Consider peak activity periods when noise levels may be higher.

Benefits of a Noise Survey

Enhanced Health and Safety: Identifying and reducing harmful noise levels protects people from health risks associated with noise exposure.

Regulatory Compliance: Ensuring compliance with noise regulations avoids legal issues and fosters good community relations.

Improved Quality of Life: Reducing noise pollution in residential areas improves residents' well-being.

Informed Decision-Making: Noise survey data provide a solid foundation for making informed decisions about noise control measures.

Conclusion

A noise survey is an essential tool for assessing and managing noise levels in various environments. By understanding noise sources and impacts, individuals and organizations can take proactive steps to mitigate adverse effects, ensuring healthier and more productive surroundings. Whether you're a business owner, community planner, or concerned resident, conducting a noise survey is a crucial step toward a quieter, healthier, and more harmonious environment.

If you're interested in conducting a noise survey or need professional help, contact engineering company in UAE today. We offer comprehensive noise survey services tailored to your specific needs, ensuring accurate assessments and effective noise management solutions.

0 notes

Text

Calibration Services

covering disciplines as below:

Discipline

Parameters / Instruments taken up for Calibration

Electro-Technical

AC Voltage/AC Current/ DC voltage/ DC Current/ Resistance/Low Resistance/Temp. Simulation (Indicator/Controller)/Frequency/Timer/Stop Watch/ Active Power/Capacitance/AC Power Energy Single/Three Phase Active/Power Factor/Inductance/High Voltage(0-100KV)/Tan Delta

Thermal & Relative Humidity

Black Body Source/IR Thermal Imager / IR Thermometer/Infrared Temp. Sensor/ Contactless Temp. Sensor/Transmitter/Thermal Imaging/Camera/IR Gun/Radiation Pyrometer/IR Detector/Thermal Imager/Laser Pointed/IR Pyrometer/Temp. Indicator of Freezers/Oven/Environment Chamber/Incubator/Liquid Bath/ Dry Block Furnace/Metrology Well/Dry Block Calibrators/Muffle Furnace/BOD Incubator/Temp. Transmitter RTD’s Thermocouples /Glass Thermometer/Temp. Switch/Data Logger/Temp. Gauge/Thermal Mapping(Multiple Position)/Heating Chamber/Furnaces/Cold Room/Humidity Sensor with Indicator of Humidity Chamber/Climate Chamber/Temp. & Rh sensor with indicator/Thermo-Hygrometer/Data Logger with Internal-External Sensor

Mechanical

Tachometer/Digital Tachometer/Speed Sensor/ RPM Sensor with Indicator/

Centrifuge/Sound Level Meter/Bore Gauge/Coating Thickness Gauge/Dial Gauge/Plunger Dial Gauge/Dial Thickness Gauge/ External Micrometer/

Plunger Dial/Micrometer Head -L.C0.0001 mm/Inside Dial Caliper/Inside Pistol Caliper/Internal Micrometer/Magnetic V Block/Foils/Feeler Gauge/Height Gauge/Mould Cube/Snap Gauge/Test Sieves/Thread measuring pins/Ultrasonic Thickness Gauge/Vernier Caliper/Bevel Protractor/Combination set/Digital Angle Protractor/Cylindrical Measuring pins/ Comparator Stand/Depth Caliper/Depth Micrometer/ Elongation Index/Flakiness Index Apparatus/Plain Gauge/Steel Scale/Wheel Distance Gauge/Measuring Tape/Laser Distance Meter/Length Bar/Micrometer Setting Rod/Micrometer Extension Rod/Riser Rod/Height Setting Master/Outside Pistol Caliper/Outside Caliper Gauge/Caliper Checker/Step Gauge/Electronic Probe/Digimatic Indicator/LVDT-0.0001mm/Plunger Dial/Rubber Hardness Tester/Pressure Gauge/Vacuum Gauge/Pressure Transmitter/Pressure Transducer/Torque Wrench/Bench Centre/Surface Plate/Profile Projector/Surface Roughness Tester/ Weighing Balance

We prioritize customer satisfaction and strive to deliver exceptional service with fast turnaround times. Additionally, our competitive pricing ensures that you receive excellent value for your investment and offer onsite calibration services for your convenience.

We would like to invite you to review the attached documents containing our profile, certificates, scope, and additional details. Furthermore, we extend a warm invitation for you to visit our calibration facility. We are eager to collaborate with you and provide our esteemed services.

Please find enclosed the profile and other pertinent details of Quality Calibration Testing Solutions and same can be found on company’s website as below:

If you have any questions or would like to schedule calibration services, please don't hesitate to contact us. We would be delighted to discuss your requirements further and demonstrate how our calibration solutions can benefit your organization.

Thank you for considering our services. We look forward to the opportunity to work with you and deliver our exceptional services.

1 note

·

View note

Text

Noise level meter

Understanding Sound Level Meter: A Comprehensive Overview

In an increasingly noisy world, monitoring and controlling sound levels are crucial for various industries, workplaces, and even residential areas. Sound level meters (SLMs) are essential tools used for precisely this purpose. These devices, also known as noise level meters, are designed to measure sound pressure levels (SPL) in decibels (dB), providing valuable insights into environmental noise levels. In this article, we delve into the functionalities and features of several sound level meters, namely the MR-SLM34, MR-SLM7D, and MR-SLM16, including their applications and benefits.

Sound Level Meter MR-SLM34:

The MR-SLM34 is a compact and portable sound level meter renowned for its accuracy and reliability. Equipped with advanced technology, it offers precise measurements across a wide frequency range, making it suitable for various applications such as environmental noise monitoring, industrial hygiene assessments, and occupational noise evaluations. Its user-friendly interface and intuitive controls make it accessible to professionals and non-experts alike.

Key features of the MR-SLM34 include:

High Accuracy: Utilizing state-of-the-art sensors and calibration mechanisms, the MR-SLM34 delivers accurate and consistent measurements even in challenging environments.

Real-time Monitoring: With real-time data display and logging capabilities, users can monitor sound levels continuously, enabling prompt intervention when necessary.

Data Logging: The device is equipped with data logging functionalities, allowing users to record sound level data over extended periods for detailed analysis and reporting.

Compact Design: Its compact and lightweight design ensures portability, making it convenient for fieldwork and on-site assessments.

Long Battery Life: The MR-SLM34 is powered by long-lasting batteries, ensuring uninterrupted operation during extended monitoring sessions.

Data Logger Sound Level Meter MR-SLM7D:

The MR-SLM7D is a feature-rich sound level meter designed for professionals who require comprehensive data logging capabilities. This device goes beyond basic SPL measurements, offering advanced functionalities for in-depth noise analysis and compliance monitoring.

Highlighted features of the MR-SLM7D include:

Multi-parameter Measurements: In addition to SPL, the MR-SLM7D can measure various parameters such as frequency weighting, time weighting, and peak sound levels, providing a comprehensive view of the noise environment.

Data Storage and Retrieval: With extensive data storage capacity, users can store large volumes of sound level data for future reference and analysis. The device also allows easy retrieval of stored data for reporting purposes.

Integration with PC Software: The MR-SLM7D is compatible with PC software for data analysis and visualization, enabling users to generate detailed reports and trends effortlessly.

Remote Monitoring: Through wireless connectivity options, users can remotely monitor sound levels in real-time, facilitating proactive management of noise-related issues.

Compliance Tracking: The device offers features for tracking regulatory compliance, allowing users to ensure adherence to noise regulations and standards.

Sound Level Meter MR-SLM16:

The MR-SLM16 is a rugged and versatile sound level meter designed for demanding industrial environments. Built to withstand harsh conditions, it offers reliable performance in challenging settings such as construction sites, manufacturing facilities, and heavy machinery operations.

Key attributes of the MR-SLM16 include:

Durable Construction: Featuring a robust housing and reinforced components, the MR-SLM16 is resistant to dust, moisture, and mechanical shocks, ensuring longevity and reliability in harsh environments.

Wide Measurement Range: With an extended measurement range, the device can accurately capture sound levels from quiet ambient environments to high-noise industrial settings.

Dynamic Range Compression: The MR-SLM16 employs dynamic range compression technology to maintain accuracy across a wide range of sound levels, minimizing the risk of saturation or distortion.

Built-in Alarms: The device is equipped with configurable alarms that alert users when sound levels exceed predetermined thresholds, enabling prompt action to mitigate noise-related risks.

Easy Calibration: Calibration procedures are straightforward, allowing users to calibrate the device quickly and accurately for reliable measurements.

In conclusion, sound level meters play a vital role in monitoring and managing noise levels across various settings. Whether it's ensuring compliance with regulations, protecting workers' health and safety, or minimizing environmental impact, these devices offer indispensable functionalities for professionals across industries. From compact and portable models to feature-rich data loggers and rugged industrial-grade instruments, there's a sound level meter suited for every application and requirement.

0 notes

Text

Beyond Petrochemicals: The Curious Case of Control Valves in Unexpected Industries

In the industrial world, control valves often conjure images of towering petrochemical refineries, pulsating with volatile fluids and echoing with the roar of machinery. But their reign of flow control extends far beyond the realm of hydrocarbons, venturing into surprising corners of human endeavor. So, buckle up, fellow curious adventurers, as we embark on a journey to uncover the unconventional uses of control valves in unexpected industries.

First Stop: The Culinary Symphony: Imagine a perfectly poached egg, the delicate dance of white and yolk suspended in pristine water. Behind this culinary masterpiece lies a hidden maestro – the control valve. In sophisticated kitchens, these unsung heroes regulate the flow of water in sous vide baths, ensuring precise temperature control for consistent, restaurant-worthy results. From simmering broths to temperamental chocolate fountains, control valves orchestrate the culinary symphony, guaranteeing impeccable taste and texture.

Next Step: The Brewing Bonanza: Forget the industrial giants; some control valves thrive in the cozy confines of microbreweries. They meticulously meter precise amounts of hops and grains into kettles, ensuring the perfect balance of bitterness and flavor in your favorite craft beer. Whether it's a hoppy IPA or a smooth stout, these micro-regulators play a crucial role in crafting the magic in every pint.

A Dive into the Deep: The Ocean Symphony: Beyond the surface, in the silent world of underwater explorations, control valves play a vital role in submersibles and research vessels. They manage the flow of hydraulic fluids that power robotic arms, manipulate delicate sampling equipment, and maintain crucial pressure levels in diving chambers. Their silent dedication ensures the safety and success of oceanographic missions, unveiling the secrets of the deep.

A Musical Interlude: The Sound of Silence: Even the world of music owes a debt of gratitude to these flow guardians. In concert halls and recording studios, control valves regulate the flow of compressed air in pneumatic instruments, like organs and harmoniums. Their precise modulation ensures the smooth, uninterrupted flow of melodies that captivate audiences and fill concert halls with the magic of sound.

The Grand Finale: The Dance of Life: Our journey culminates in the most sacred realm of all – healthcare. In hospitals and research labs, control valves contribute to life-saving advancements. They precisely calibrate the flow of fluids in dialysis machines, ensuring the delicate balance of electrolytes in patients' blood. They regulate the oxygen and medications delivered through ventilators, sustaining fragile lives. In this noble cause, the silent symphony of control valves becomes a symphony of life itself.

So, the next time you savor a gourmet dish, raise a toast to your favorite craft beer, or marvel at the mysteries of the deep, remember the unsung heroes who orchestrate these unexpected wonders – the control valves. Their dedication to precise flow control lies at the heart of diverse industries, shaping our world in ways we often don't realize. Now, go forth, curious adventurers, and let the hunt for unexpected uses of control valves begin! You might just be surprised at what you uncover.

0 notes

Text

Calibration of Sound Level Meter

0 notes

Text

Sound Level Calibrator

Sound Level Calibrator is a noise decibel calibration tool and used for quick and easy calibration of sound level meters and sound measuring systems. It is suitable for field and laboratory use. Shop online at Labtron.us

0 notes

Text

Journal Week 12 - Master Bus

Why is gain staging important?

Gain staging is about having enough level coming into the mixer that the audio engineer can work with while creating a mix. It is also managing the levels of each track to prevent any noise or distortion. It's about creating a mix that is louder, clearer, and more dynamic, and also having enough headroom so the master bus isn't peaking or distorting.

Why start with the low-end in your mix?

The low end has more energy and is harder to control, I find it is also the sweetest spot where the toe-tapping starts, so getting this area right is very important. The lower frequencies can also take up a lot of the lower half of the EQ spectrum and mask other instruments in the process. Keeping the lower to upper mid frequencies clear can be more difficult.

What are some differences between a VU meter and a Peak Meter?

The VU (Volume Units) metre is a representation of how the human ear hears sounds and is used to see the energy and intensity of a sound or track better. While a peak metre (True Peak) only measures the highest levels of a signal, and move around a lot more erratically than the VU meter. Peak Meters are good for seeing if there is any clipping in your track.

Where do you put your VU meter?

The VU meter is applied to the master bus at the beginning of a mix

What is a suitable VU dB calibration level for people ‘listening at home’ and to get a track Mastered?

Set the VU meter to -14db, then when mixing in each element of the mix make sure the VU meter is bouncing at around -5 db to -7db. This creates enough headroom for a better mix when it comes to the mastering process.

END JOURNAL WEEK 12 MUSIC PRODUCTION 2

0 notes

Text

Sound Level Meter Calibration

Ensuring Accuracy in Noise Measurement

Sound level meters are essential tools in various fields, from occupational safety and environmental monitoring to architectural acoustics. They play a crucial role in quantifying noise levels and assessing compliance with noise regulations.

However, the accuracy and reliability of sound level meters are only as good as their calibration.

The Significance of Calibration

Calibration is the process of adjusting and validating the accuracy of a sound level meter. It is essential because sound level meters, like any measuring instrument, can drift over time due to wear and environmental factors. Calibrating sound level meters is vital for several reasons:

Regulatory Compliance: Many industries and workplaces are subject to noise regulations that require precise noise level measurements.

Safety: Inadequate calibration can lead to inaccurate measurements, potentially resulting in unsafe noise exposure for workers or inadequate environmental protection.

Consistency: Accurate noise measurements are vital for assessing long-term trends, comparing data from various sources, and ensuring that interventions to reduce noise are effective.

Legal and Liability Issues: Inaccurate measurements could lead to legal disputes and liabilities, making calibration a legal necessity in some cases.

Arabian Calibration is a company specializing in calibration services, based in the GCC region. Arabcal provides service to a wide range of industries such as manufacturing, healthcare, marine, aviation and engineering, helping businesses maintain the precision and quality of their equipment.

Visit website to learn more

https://www.arabcal.com/power-energy

#Sound Level Meter supplier in UAE#Air Quality Monitor Supplier in UAE#Biomedical Test Equipment#Testing equipment supplier in UAE#Thermal Imager Supplier in UAE

0 notes

Text

The MCT-2000 acoustic cavitation meter is a cutting-edge device designed to measure cavitation performance in ultrasonic cleaning and sonoprocessing tasks. When paired with the HCT-0320 hydrophone, it instantly calculates four primary parameters:

Base Frequency, FO

Initial Field Pressure, PO

Consistent Cavitation Pressure, PS

Short-lived Cavitation Pressure, PT

These measurements are derived from the calibrated acoustic spectrum, which identifies various pressure elements. Transducers produce mechanical sound waves that vibrate at the base frequency, leading to the initial field pressure. Swift pressure variations in the fluid form cavities, termed "cavitation". Consistent cavitation indicates a fluctuating cavity, causing micro-streaming effects. Short-lived cavitation emerges past a certain pressure level, causing the cavities to burst, leading to jetting actions and shockwaves.

1 note

·

View note