#stainless steel wires

Text

Bansal stands out as an example of excellence, demonstrating a dedication to quality, innovation, and customer satisfaction. Several aspects separate Bansal Stainless Steel Wires and establish us as industry leaders.

0 notes

Text

Flux core Wire Types & Sizes

Choose the Right Wire for the Job: A Comprehensive Guide to Flux Core Welding Wires

If you're new to flux core welding or even if you're a seasoned pro, it can be tough to keep track of all the different wires available on the market. With so many options out there, how are you supposed to know which one is right for your project? And once you've chosen a wire, what size should you use?

In this comprehensive guide, we'll break down everything you need to know about flux core welding wires so that you can make the best decision for your next project.

Flux Core Welding Wires Defined

At its core, flux core welding is very similar to MIG welding. Both processes use an electrode fed through a wire reel and both use shielding gas to protect the weld puddle from contamination.

However, there is one key difference between the two: with flux core welding, the electrode used is composed of a tubular wire filled with flux powder. This flux powder serves several purposes.

First, it protects the weld puddle from oxidation by forming a slag over the top of the weld. Second, it increases arc stability and reduces spatter. And last but not least, it provides extra filler material to help build up thicker welds.

Different Types of Flux Core Welding Wires

Now that we know what makes flux core welding wires unique, let's take a look at some of the most common types of wires available on the market today. The three most common types of flux core wires are mild steel wires, stainless steel wires and aluminum wires.

Mild steel wires:

Mild steel wires are by far the most popular type of welding wire used in the United States. They are relatively cheap and easy to find, and they work well for a wide variety of projects.

If you're just getting started with flux core welding or you don't do a lot of welding, mild steel wires are a great place to start.

Stainless steel wires:

Stainless steel wires are another popular option among welders. They are more expensive than mild steel wires but they offer better corrosion resistance and they're less likely to cause problems like porosity and cracking. If you're planning on doing any welding on stainless steel projects or projects that will be exposed to salt water or other corrosive materials, stainless steel wires are a good choice.

Aluminum wires:

Aluminum wires are the third type of common flux core wire. They are seldom used in home or hobby applications because they require special equipment and they're very difficult to work with. However, if you're planning on doing any professional aluminum welding, they're an essential part of your toolkit. Aluminum wires have a much lower melting point than mild steel or stainless steel wires; as a result, they can be used to weld thinner materials without burning through them. They also create extremely strong welds thanks to their high conductivity.

Conclusion:

So there you have it! A comprehensive guide to choosing the right flux core wire for your next project. remember: Mild steel wires are good for general purpose applications Stainless steel wires work well for projects that will be exposed to corrosion and aluminum works best for thinner materials or when high conductivity is required . Thanks for reading!

A guide about welding: MiG Welding Wire Types

0 notes

Text

These are currently available on my Etsy.

Left is stainless steel chain, right is aluminum.

Link is in my bio 🫶🏼

#mine#my art#jewelry#handmade jewelry#artists#artists of tumblr#Etsy#Etsy shop#Etsy seller#energy#skeleton#ghost#barbed wire#chain necklace#barbed wire necklace#stainless steel#spooky aesthetic#spooky art#spooky season#spooky vibes#halloween#skeleton jewelry#skeleton art#ghosts#halloween jewelry#halloween accessories#halloween aesthetic#halloween art#etsy store#etsy small business

8 notes

·

View notes

Text

beaded fish skeleton hoop earrings, handcrafted by me! 🐟

~ the hoop bases and the hooks are handmade with stainless steel wire, the fish charms are stainless steel, and the beads are glass 💙

~ These are no longer available 💙

#handmade jewelry#wire wrapped jewelry#jewelry making#beaded jewelry#beadwork#stainless steel#stainless steel jewelry#fish#fish jewelry#ocean jewelry#sirencore#mermaidcore#spirituality#witchblr#jewelry#south texas#hoop earrings#earrings

12 notes

·

View notes

Text

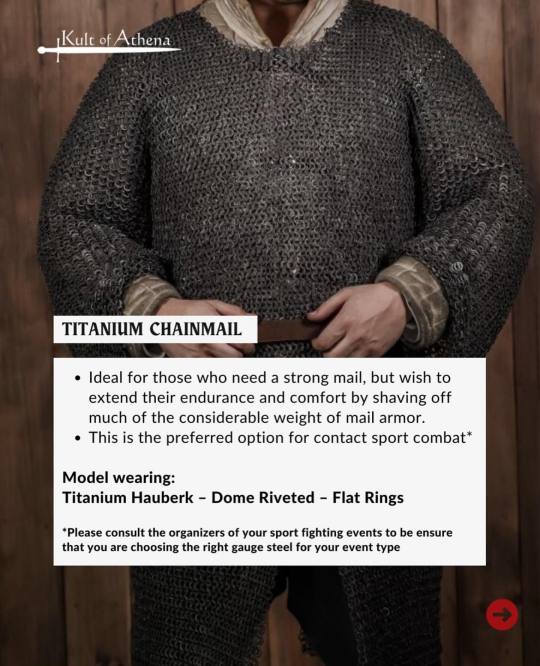

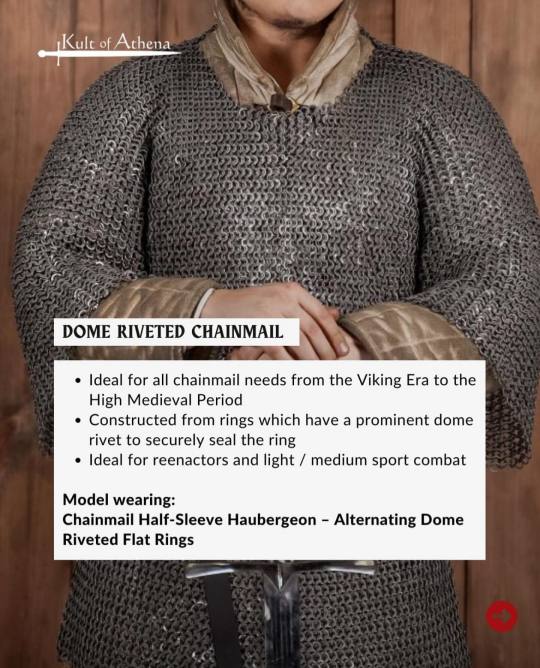

With all of this talk about chainmail, you’re probably wondering: what type is right for me? Swipe to see a curated selection of chainmail from Lord of Battles, available on Kult of Athena.

Dome Riveted: A method of riveting an open mail ring that uses a steel pin or thick wire which is then pressed and riveted to “mushroom” into a dome shape that holds the ring in place. This style of mail is common from Classical Antiquity until the later years of the High Medieval Period (Approx: 3rd Cent BC to 1300 AD)

Wedge Riveted: A method of riveting and open mail ring that uses a triangular wedge of metal which is then pressed to flatten and peen itself over the ring to hold the ring closed. Wedge-riveted mail has the advantage of the rivets having a flatter profile which is less likely to entrangle and catch on other rings and is less abrasive to any clothing or accessories worn over the mail. This style of mail becomes dominant in the later part of the High Middle Ages and the Late Medieval Period. ( Approx. 1300 to 1550 AD)

Butted: Butted Rings are Round or Flat rings which are not riveted closed, but instead have the open ends butted up and pressed against one another to close the ring. Not historically accurate.

#Kult of Athena#KultOfAthena#chainmail#chain mail#Lord Of Battles#WorldOfKoa#LARP#battlefield#Live Action Role Play#Butted Chain Mail#Wedge Riveted Chain Mail#Dome Riveted Chain Mail#Loose Chain Mail#Zinc Coated#Mild Steel#Aluminum#High Tensile Wire#Stainless Steel#Roman Chainmail

9 notes

·

View notes

Text

hate knowing this much about the fluctuating price of aluminium, did not see aluminium price knowledge in my future

#it's because you're always building that damn aviary#crying and weeping i invested in 'test materials' today. 6m of aluminium 15mm tube and some metres of cheap wire mesh#because the stainless steel mesh and 20mm aluminium tubes are simply too expensive to be the victim of my first attempt#after i'm done i will either use this to protect plants. or take it apart and use the wire mesh create concrete mosaic tiles and the tubes#well idk. i'm sure i'll use them for some nonsense#sculpture maybe <- lord save me from instinct to turn everything into fucking sculpture.

3 notes

·

View notes

Photo

Melbourne Beach Style Deck

Ideas for a sizable coastal backyard deck renovation featuring a container garden with an awning

#awnings#deck#timber deck#merbau deck merbau handrail#stainless steel wire balustrade#merbau decking

2 notes

·

View notes

Photo

Deck Melbourne

Ideas for a sizable coastal backyard deck renovation featuring a container garden with an awning

#awnings#deck#merbau decking#merbau deck merbau handrail#stainless steel wire balustrade#timber deck

3 notes

·

View notes

Photo

Mesmerizing Human Faces Emerge From Carefully Sculpted Metal Wires

Human faces come to life in the industrial sculptures of Darius Hulea. The Romania-based artist uses iron, stainless steel, brass, and copper as the materials for expressive portraits inspired by history and mythology. Inspired by the sketches of old masters, Hulea translates the quickness and fluidity of drawing into three-dimensional forms.

#darius hulea#artist#art#sculptor#sculptures#human faces#metal wires#industrial sculptures#romania-based artist#iron#stainless steel#brass#copper#mythology#portraits

2 notes

·

View notes

Text

Super AA Scrap Metal in Dandenong, VIC

Super AA Scrap Metal is the best scrap yard in Dandenong. Sell scrap metal in Dandenong, Victoria at very good price to us. We are a trusted company and buy all types of scrap metal. We buy Copper scraps, Brass Scraps, Aluminum scraps, Stainless Steel scraps, Electronic Motors scraps, Batteries scraps, PVC Wire and Cables and Engines scraps.

Copper

In today's world, it is believed that almost 75% of copper products are manufactured using recycled copper. Mining, refining, and smelting copper generate emission of harmful greenhouse gases but recycling copper helps to reduce it. Recycling Copper reduces the carbon footprint and protects vast areas of landfills from getting contaminated and unfertile.

Aluminium

Aluminum is one of the most used material. It is used for building various items. But aluminum has ability to pollute landfills. However, Aluminum's recycling ability is on next level. So, you can sell alumium scrap in Dandenong, Victoria to make some good money out of it. Plus, we are here to help you to do just that. No wonder why we are the best scrap buyer in Dandenong, Melbourne.

Brass Scrap

Brass is basically a gold colored alloy made up of two materials; zinc and copper. It is mainly used in household appliances as well as other electrical equipments. Likewise, brass is durable, hard, strong, corrosion resistant and has high electrical conductivity and high thermal conductivity which makes it perfect for various uses in various sectors and equiments.

Stainless Steel scrap

Stainless Stell are used very widey. From watches, to smartphones to equipments and accessories to vehicles, staniless steel are used in almost everything possible. This is exactly the reason why it is most commonly found as scrap in high quantity. If you come to have such scrap, we are ready to offer the best price for your stainless steel scrap.

Wire and Cable

Another item used widely in household to commercial to industrial sector is PVC cables and wires. It is used to conduct electricty and are installed in very large amount. Therefore, after it becomes scrap, it's quantity still remains the same. It contains high amount of copper and can cause severe environmental damage if not recycled and just thrown away.

4 notes

·

View notes

Text

Essential Tips for Installing Wire Mesh Cable Trays in Your Next Project

When it comes to managing cables in any construction or renovation project, wire mesh cable trays are a popular choice due to their flexibility, durability, and ease of installation. Whether you’re working on a commercial building, industrial facility, or even a residential project, these tips will help ensure a smooth and efficient installation process.

Wire Mesh Cable Tray Manufacturer

Plan Your Layout Carefully

Before you start installing the cable trays, take the time to plan out the layout. Consider the path the cables will take, the locations of power sources, and any obstacles that might be in the way. A well-thought-out plan can save you time and prevent issues down the line.

Choose the Right Size and Type

Wire mesh cable trays come in various sizes and types. Select a tray that can handle the weight and volume of your cables. Ensure it meets the specific requirements of your project, such as load capacity and environmental conditions.

Ensure Proper Support

Proper support is crucial for the stability and longevity of your cable tray system. Install supports at regular intervals, typically every 4 to 6 feet, depending on the weight of the cables. Use appropriate brackets and hardware to secure the trays firmly.

Wire Cable Tray

Maintain Adequate Clearance

Ensure there is enough clearance around the cable trays for easy access and maintenance. This includes vertical and horizontal clearances to avoid interference with other systems and to allow for future cable additions or modifications.

Follow Safety Standards

Adhere to all relevant safety standards and regulations during installation. This includes grounding and bonding the cable trays to prevent electrical hazards. Make sure to use appropriate personal protective equipment (PPE) and follow best practices for working at heights if necessary.

Label and Organize Cables

Labeling and organizing cables within the trays can save a lot of time and hassle in the future. Use cable ties, labels, and color-coding to keep everything neat and easily identifiable. This will make troubleshooting and maintenance much simpler.

Wire Mesh Cable Tray

Allow for Expansion

Plan for future expansion by leaving some extra space in the cable trays. This foresight can save you from having to redo the entire installation if you need to add more cables later on.

Regular Inspections and Maintenance

Once the installation is complete, set up a schedule for regular inspections and maintenance. Check for any signs of wear, corrosion, or damage, and address any issues promptly to ensure the system remains in good condition.

Consider Environmental Factors

When installing wire mesh cable trays, consider the environment in which they will be placed. For outdoor installations or harsh environments, choose trays with corrosion-resistant coatings or materials like stainless steel. This will enhance the durability and lifespan of your cable management system.

SS Wire Mesh Cable Tray

Use Proper Tools and Equipment

Ensure you have the right tools and equipment for the installation. This includes cutting tools for the wire mesh, appropriate fasteners, and safety gear. Using the correct tools will make the installation process smoother and more efficient.

Implement Cable Management Accessories

Utilize cable management accessories such as dividers, covers, and drop-outs to organize and protect your cables. These accessories can help prevent tangling, reduce wear and tear, and improve the overall aesthetics of your installation.

Optimize Cable Routing

Optimize the routing of your cables to minimize bends and twists. This not only reduces the risk of damage to the cables but also ensures better performance and easier maintenance. Use gentle curves and avoid sharp bends to maintain the integrity of the cables.

Wire Mesh Cable Tray

Ensure Proper Ventilation

Proper ventilation is crucial to prevent overheating of cables, especially in densely packed trays. Ensure there is adequate airflow around the cable trays to dissipate heat and maintain optimal operating conditions for your cables.

Conclusion

Installing wire mesh cable trays can be a straightforward process if you follow these essential tips. Proper planning, choosing the right materials, and adhering to safety standards will help you create a reliable and efficient cable management system for your project. Happy installing!

0 notes

Text

Effective cable management is crucial in today’s data centers, commercial buildings, and industrial facilities. Wire mesh cable trays offer a practical and efficient solution for organizing and supporting various types of cabling, whether it's power, communication, or data cables. Let’s break down how wire mesh cable trays can simplify cable management:

1. Flexibility and Adaptability

Wire mesh trays are highly versatile. Their open-grid design allows for easy cable entry and exit at any point along the tray, making them adaptable to changes in layout. This is particularly useful in environments where cable paths need frequent modifications, upgrades, or re-routing.

2. Improved Airflow

Unlike solid cable trays, the mesh structure promotes better airflow around the cables. This minimizes heat buildup, which can reduce wear and tear on the cables and improve the overall lifespan of the infrastructure.

3. Easy Installation and Maintenance

Wire mesh trays are lightweight and easy to handle, reducing installation time and labor costs. They can be mounted on walls, ceilings, or under floors, and their design facilitates quick and straightforward maintenance. This reduces the time spent tracing cables, making upgrades or repairs simpler.

4. Cost-Effective

The modular design of wire mesh trays allows for easy customization without the need for specialized tools, making them a cost-effective solution for both small and large-scale cable management projects. The open design also minimizes material use, which further reduces costs.

5. Enhanced Cable Support and Safety

The sturdy metal framework provides excellent support for cables, reducing sagging and protecting them from physical damage. The mesh also minimizes the risk of cable overheating by dissipating heat efficiently. With proper grounding, wire mesh trays can help shield cables from electromagnetic interference (EMI).

6. Aesthetic and Neat Appearance

Wire mesh trays contribute to a clean, professional look by keeping cables organized and off the floor. This is particularly important in open office spaces or commercial settings where aesthetics matter. Cables are kept visible and accessible without being tangled or cluttered.

7. Environmentally Friendly

Wire mesh trays are often made from recyclable materials like steel, making them an eco-friendly choice. Their durability also reduces waste by minimizing the need for replacements.

Conclusion

Wire mesh cable trays provide a simplified, efficient, and flexible approach to cable management. Their benefits extend beyond ease of installation to include improved cable lifespan, enhanced safety, and cost savings. Whether you’re managing cables in a data center or a commercial facility, wire mesh trays offer a scalable solution that can grow with your needs.

stainless steel wire mesh cable tray,

0 notes

Text

youtube

Top Grade Stainless Steel Wire Mesh | Steel Woven Mesh Manufacturer | YKM Group

#stainless steel mesh#stainless steel woven mesh#woven mesh stainless steel#steel woven mesh#wire mesh stainless steel#Youtube

0 notes

Text

Handcrafted Silver Pearl Strand Earrings

I love the strand style and the 2 different pearls!

~ Handcrafted by me with light blue freshwater potato pearls, champagne freshwater baroque pearls, stainless steel wire, stainless steel jump rings, and silver-plated floral earring hooks ✨️

~ Pearls represent love, beauty, peace, fertility, the element of Water, the West cardinal direction, and the Heart chakra 💙

~ This pair is available to claim! If interested in these or any of my other jewelry pieces, please feel welcome to dm me here! <3

#handmade jewelry#handmade earrings#earrings#silver jewelry#silver earrings#pearls#pearl jewelry#pearl earrings#jewelry#stainless steel#stainless steel jewelry#spirituality#south texas#ocean jewelry#mermaid jewelry#sirencore#siren aesthetic#mermaidcore#fairycore#witchcraft#witchblr#jewelry making#wire wrapped jewelry#wire wrapping#wire wrap

4 notes

·

View notes

Text

Best Cable Railing Kits Online - Senmit

Senmit's best cable railing kits give everything you need to install a high-quality railing system. Designed for easy installation, these materials include all the factors necessary for a professional-grade finish. The stainless steel lines and tackle ensure strength, continuity, and erosion resistance, making them perfect for both inner and out-of-door operations. Ideal for balconies, decks, and stairways, Senmit's cable railing materials offer a satiny and ultramodern aesthetic that enhances the visual appeal of any space.

1 note

·

View note

Text

Stainless Steel Wire Manufacturers in Italy | Bansal Wire

Bansal Wire tops the list of stainless steel manufacturer in Italy. We offer quality stainless steel wires for steel ropes, ss bright bar, steel cold heading, spring, welding wire etc .

#Stainless Steel Wire#Stainless Steel Wire Manufacturers#Stainless Steel Wire Manufacturers in Italy

0 notes