#steamengineering

Explore tagged Tumblr posts

Text

Mastering the Art of Basket Strainers: The Unsung Heroes of Industrial Systems

Ever thought about the little guys that keep the big machines from falling apart? No, I'm not talking about the unsung heroes of your favorite TV show—though they do deserve a shoutout. I'm talking about basket strainers! These unsung heroes of the industrial world often go unnoticed, yet they play a crucial role in keeping our systems clean and efficient. In this deep dive, we'll unravel the mysteries of basket strainers, explore their various types, applications, and benefits, and discover why they're so vital to industrial operations.

What Are Basket Strainers?

The Basics: What’s in a Basket?

At their core, basket strainers are filtration devices designed to capture debris and particles from liquids flowing through pipelines. Imagine them as the net that catches the fish before they get to the frying pan—only in this case, the "fish" is all the gunk and greeblies that can cause havoc in your system. They come in various sizes and materials, but their job remains the same: to keep your fluids clean and your equipment running smoothly.

Why You Need One: The Role of Basket Strainers

Picture this: You're running a tight ship, everything's running like clockwork, and then—bam!—a sudden clog brings everything to a screeching halt. Sounds like a nightmare, right? That’s where basket strainers come to the rescue. By trapping particles and debris before they enter your sensitive equipment, they prevent blockages and damage, ensuring that your system operates without a hitch.

Types of Basket Strainers

1. Y-Type Basket Strainers

Named after their Y-shaped body, these strainers are popular for their compact design and efficiency. They’re often used in smaller pipelines and are known for their ease of maintenance. Just unscrew the cover, clean out the basket, and you’re good to go!

2. T-Type Basket Strainers

These strainers have a T-shaped design, making them ideal for larger pipelines or systems where you need a bit more filtration power. Their larger basket allows them to catch more debris, making them a go-to choice for heavy-duty applications.

3. Suction Basket Strainers

If you’re dealing with a high flow rate, suction basket strainers are your best bet. They’re designed to handle large volumes of liquid and are typically used in pumps and other high-demand applications.

Applications of Basket Strainers

1. Water Treatment

In water treatment plants, basket strainers play a crucial role in removing debris from the water before it undergoes further processing. They ensure that the water being treated is free of any particles that could interfere with the treatment process.

2. Chemical Processing

When it comes to handling chemicals, precision is key. Basket strainers help filter out impurities that could compromise the quality of the chemicals being processed, ensuring that the final product meets stringent standards.

3. Oil and Gas Industry

In the oil and gas industry, basket strainers are used to protect pumps and other equipment from debris that could cause damage. They’re an essential component in maintaining the integrity and efficiency of the system.

Benefits of Using Basket Strainers

1. Prevention of Equipment Damage

By catching debris before it reaches sensitive equipment, basket strainers prevent costly damage and repairs. It’s like having a bouncer at the door of a nightclub—keeping the troublemakers out and letting the good times roll!

2. Improved Efficiency

Clean fluids mean smoother operations. By filtering out particles, basket strainers help maintain optimal flow rates and pressure, which in turn enhances the overall efficiency of your system.

3. Reduced Maintenance Costs

Less debris means less wear and tear on your equipment. By using basket strainers, you can extend the lifespan of your machinery and reduce the frequency of maintenance checks and repairs.

Installation and Maintenance Tips

1. Choosing the Right Size

Size matters when it comes to basket strainers. Make sure you choose a strainer that’s appropriately sized for your pipeline to ensure optimal performance. Too small, and it won’t catch enough debris; too large, and it might not fit properly.

2. Regular Cleaning

Keeping your basket strainer clean is crucial for its performance. Depending on the amount of debris in your system, you might need to clean it regularly. Set up a maintenance schedule to ensure it’s done on time.

3. Proper Placement

Place your basket strainer in a location where it’s easy to access for cleaning and maintenance. You don’t want to have to disassemble half your system just to get to it!

Troubleshooting Common Issues

1. Clogging

If your basket strainer is clogging too frequently, it might be too small for your system or the debris might be too fine. Consider upgrading to a larger strainer or one with a finer mesh.

2. Leaks

Leaks can occur if the strainer isn’t properly sealed or if there’s damage to the basket. Check for any signs of wear and tear and replace parts as necessary.

3. Pressure Drops

A significant drop in pressure can indicate that the basket strainer is too clogged or that there’s an issue with the installation. Regular maintenance and inspections can help prevent these issues.

Unwrapping the Essence of Our Journey

Basket strainers may not always be in the spotlight, but their role in industrial systems is nothing short of heroic. From keeping your equipment in tip-top shape to ensuring smooth operations, they’re the unsung champions of the industrial world. By understanding their types, applications, benefits, and maintenance needs, you’ll be well-equipped to harness their full potential. So, next time you’re running a system, give a nod to those trusty basket strainers—they’re working hard behind the scenes to keep everything running smoothly!

With this comprehensive guide on basket strainers, you'll never overlook these critical components again. From their basic functions to advanced applications, we've covered everything you need to know to keep your systems in top shape.

0 notes

Video

Steam locomotive waiting to start work por laird.lothar

8 notes

·

View notes

Text

7 notes

·

View notes

Text

#IFTTT#Flickr#bw#film#4x5#tachihara#craigsville#virginia#steamengine#locomotive#buckinghambranch#nw#611

32 notes

·

View notes

Photo

British Industrial Revolution

The British Industrial Revolution (1760-1840) brought innovative mechanisation and deep social change. The process saw the invention of steam-powered machines, which were used in factories in ever-growing urban centres. Agriculture remained important, but cotton textiles became Britain's top export, capital replaced land as an indicator of wealth, and the labour force diversified to include many more women and children.

Continue reading...

36 notes

·

View notes

Text

“Relics 01" (Locomotive 2719)

[Relics series)

by michael mathews

mixed media & collage on cradled panel

12x16x0.75 inches

2023

www.michaelmathewsart.com

#contemporaryart#abstractpaintings#abstractart#abstraction#collage art#fineart#painters#paintings#collageartists#collageart#collagepaintings#analogart#locomotives#steamengines#steamlocomotive#cutandpaste#eau claire wisconsin#michaelmathewsart#20thcentury#art#artmaking#artmakers#saatchiart

16 notes

·

View notes

Text

#mine#my pictures#my picture#photography#amateur photography#nature#netherlands#original content#steam engine#steamengine#water#sunset#windmill#wouda#woudagemaal#zuiderzee#lemmer#fryslan#friesland#unesco#unesco world heritage#world heritage

4 notes

·

View notes

Text

The Unseen Troubles of the Inverted Bucket Steam Trap: A Cautionary Tale

Steam traps: the unsung heroes of industrial steam systems, silently toiling away, ensuring that our processes run smoothly. Yet, not all steam traps are created equal, and among them, the inverted bucket steam traps often stands as a favored option. But is it really the savior it claims to be? As we delve into the intricacies of this seemingly trusty device, you might just find yourself questioning everything you thought you knew about steam management. Let’s embark on a journey through the world of the inverted bucket steam trap and uncover the dark secrets lurking beneath its surface.

The Allure of the Inverted Bucket Steam Trap

A Marvel of Engineering

On paper, the inverted bucket steam trap seems like a stroke of genius. It’s simple, robust, and, at first glance, reliable. The device operates on a straightforward principle: a bucket inverted within a steam chamber floats or sinks depending on the presence of steam or condensate. When steam enters, the bucket rises, closing the trap. When condensate fills the chamber, the bucket sinks, opening the trap and allowing the unwanted water to escape. What could go wrong with such a beautifully simplistic mechanism?

Promises of Efficiency

Manufacturers boast about the efficiency of the inverted bucket steam trap, touting its ability to handle condensate removal effectively without the risk of steam loss. It’s marketed as low-maintenance, long-lasting, and suitable for a variety of applications. These promises paint a rosy picture, making it a popular choice in many industries. But like all too-good-to-be-true scenarios, the inverted bucket steam trap has its skeletons in the closet.

The Devil is in the Details

Vulnerability to Water Hammer

One of the less-talked-about issues with the inverted bucket steam trap is its vulnerability to water hammer. When condensate accumulates and is suddenly expelled, it can cause a rapid pressure change, leading to a violent water hammer effect. This phenomenon can damage not only the steam trap itself but also the surrounding piping and equipment. The impact can be severe, causing downtime and costly repairs.

Prone to Blockages

While the design seems straightforward, it’s not immune to blockages. Debris and sludge in the steam system can find their way into the trap, causing the bucket to stick or the orifice to clog. Once blocked, the trap becomes ineffective, either failing to discharge condensate or allowing steam to escape. Regular maintenance is necessary, contradicting the low-maintenance claim often made by proponents of the inverted bucket steam trap.

Temperature Sensitivity

The inverted bucket steam trap isn’t particularly forgiving when it comes to temperature fluctuations. In environments where the temperature varies significantly, the trap’s performance can be compromised. The bucket’s buoyancy changes with temperature, leading to improper operation. This sensitivity can result in inefficiencies, with the trap either failing to open or staying open when it shouldn’t.

Wear and Tear

Despite claims of durability, the inverted bucket steam traps is subject to wear and tear like any mechanical device. The constant movement of the bucket and the repeated opening and closing of the trap take their toll over time. Seals and components wear out, leading to leaks and failures. The supposed longevity of the trap often falls short of expectations, resulting in more frequent replacements and higher costs than initially anticipated.

The Real-World Impact

Case Study: Manufacturing Mayhem

Consider a large manufacturing plant that relies heavily on steam for its processes. The plant management, enticed by the promises of efficiency and low maintenance, installs inverted bucket steam traps throughout their system. Initially, everything seems to be working perfectly. However, as months go by, issues start to surface.

First, there’s the occasional loud bang — water hammer strikes. Workers become uneasy, and production is briefly halted each time an incident occurs to inspect for damage. Then, the plant starts noticing an increase in maintenance costs as more traps need cleaning or replacement due to blockages and wear. Downtime becomes more frequent, affecting productivity and profits.

The plant’s engineers, initially advocates for the inverted bucket steam trap, begin to regret their decision. They hadn’t accounted for the real-world conditions that expose the trap’s weaknesses. The promised efficiency and reliability turned out to be more marketing than reality.

Hidden Costs

The financial implications of these issues are significant. Frequent maintenance and replacement parts add up, and unplanned downtime can cost thousands in lost production. Additionally, the constant risk of damage from water hammer means that the plant must invest in reinforcing its piping system, an expense they hadn’t budgeted for.

In an industry where margins are often slim, these hidden costs can be the difference between profit and loss. The initial savings from choosing a supposedly low-maintenance steam trap are quickly overshadowed by the long-term expenses.

Alternatives to the Inverted Bucket Steam Trap

Thermodynamic Steam Traps

Given the pitfalls of the inverted bucket steam trap, exploring alternatives becomes imperative. Thermodynamic steam traps offer a different approach, using the principles of thermodynamics to control condensate discharge. They are compact, relatively simple, and handle a wide range of pressures. Though they have their own set of challenges, such as susceptibility to rapid cycling, they often prove more reliable in fluctuating conditions.

Float and Thermostatic Steam Traps

Float and thermostatic steam traps combine the best of both worlds — the mechanical operation of a float and the temperature sensitivity of a thermostatic element. These traps can handle varying loads efficiently and are less prone to the problems that plague inverted bucket steam traps. They require careful selection and sizing but can offer a more stable and reliable performance in many applications.

Bimetallic Steam Traps

Bimetallic steam traps use the expansion and contraction of bimetallic strips to control the discharge of condensate. They are known for their durability and ability to handle superheated steam, making them a robust alternative. While they may not be suitable for all situations, in environments where durability and reliability are paramount, they can be a superior choice.

Making the Right Choice

Assessing Your Needs

When selecting a steam trap, it’s crucial to assess the specific needs of your system. Consider factors such as operating pressure, temperature variations, condensate load, and the nature of the steam application. Understanding these parameters can help you choose a trap that is better suited to your unique requirements.

Long-Term Costs vs. Short-Term Savings

It’s tempting to opt for a steam trap that promises low initial costs and minimal maintenance. However, as the inverted bucket steam trap has shown us, short-term savings can lead to long-term expenses. Evaluating the total cost of ownership, including maintenance, downtime, and potential damage, provides a clearer picture of the real investment required.

Consulting with Experts

Don’t underestimate the value of consulting with steam system experts. Their experience and knowledge can guide you toward the best solution for your specific situation. They can help you navigate the myriad options and avoid the pitfalls that come with choosing the wrong steam trap.

The inverted bucket steam traps, with its allure of simplicity and efficiency, often seems like the perfect choice for managing steam condensate. However, as we’ve seen, its vulnerabilities can lead to significant problems in real-world applications. From water hammer to blockages, temperature sensitivity to wear and tear, the inverted bucket steam trap can turn from a hero to a headache in no time.

While it may still have its place in certain scenarios, being aware of its limitations and considering alternatives can save you from the hidden troubles that lurk beneath its surface. In the end, making an informed choice and looking beyond the marketing hype will ensure your steam system runs smoothly and efficiently, without the costly surprises.

#inverted bucket steam traps#steamtechnology#steamengineering#manufacturer#industrial#valves#steam traps#condensatemanagement

0 notes

Video

Full Steam Ahead...... por howard1916 - A Man and his camera Por Flickr: Berwyn Station, Llangollen, Mid Wales

11 notes

·

View notes

Text

It’s been a couple of years since I’ve posted about this engine but have just re done it with a better video and content so I’d thought I would share it again.

So this Horizontal duplex rotative steam fire pump often referred to as a donkey engine was used until 1930 to pump water to rising mains for the purpose of fighting fires in Victoria Mill, (H. Masons Ltd) Shipley made by George Mills of Radcliffe around 1880. There were around 400 textile mills around the Bradford which was at one point the one-time wool capital of the world.

The fire circuit at Victoria Mills at the time was made up of 16 men, who were also part-time mill workers. In view of the inadequacy of the 19th century horse drawn fire engines and the limited pumping capacity of their steam plants, large mills usually installed their own equipment. The pump has 2 cylinders, 14 inches in diameter with a stroke of 18 inches and the water rams being 9 inches in diameter. The large vessel over the pump contains a quantity of air to cushion the intermittent pressure of the pumps to ease the water pressure on the cast iron mains.

In 1971 the pump house was demolished during building works and the pump was moved to Bradford Industrial Museum where it's currently run off an electric motor and is in motion at specific times of day subject to availability.

Take a look at my other videos for more engines and history, and the odd bit of Meccano 🙂

1 note

·

View note

Text

Have you always wanted a spaceship, a cryopod, automatic doors and a loss of sanity? Sektar: Echoes of Fear is all you need. Add it to your wishlist on Steam now!

#steam#avalailableonsteam#wishlist#steamengine#newgame#gamingcommunity#gaming#horror#indiegames#indie#indiegamedev#games#gamer#videogame#play#gamedevelopment#Sektar#EchoesofFear#EndofFileStudio#EoF#spacestation#scifi#sciencefiction#HAN#HANUniversityofAppliedSciences#HANArnhem#scarygame#dev

1 note

·

View note

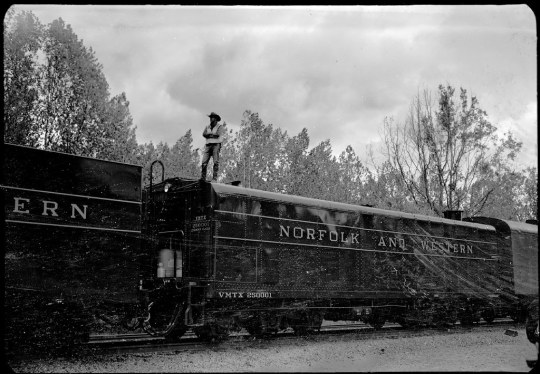

Text

#IFTTT#Flickr#bw#film#microfilm#railroad#buckinghambranch#victoriastationgoshen#steamengine#virginiascenicrailway#cowboy

16 notes

·

View notes

Text

CP&LE Cedar Point & Lake Erie Train Leaves Station Cedar Point Cedar Poi...

youtube

0 notes