#testingmethods

Explore tagged Tumblr posts

Text

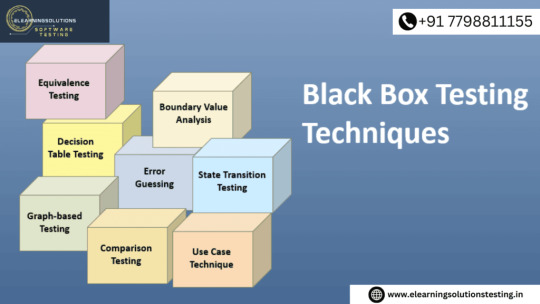

What is Black Box Testing?

Behavioral, opaque-box, closed-box, specification-based, and eye-to-eye testing are other names for black box testing. read more

#BlackBoxTesting#SoftwareTesting#QualityAssurance#TestingTechniques#TestAutomation#BugTesting#QAProcesses#TestingMethods

0 notes

Text

Navigating the World of Software Testing: A Manual Approach

Dive into the intricacies of software testing with our comprehensive manual. From test planning to execution, this guide equips you with the essential tools and techniques to ensure the quality of your software products. Explore real-world scenarios, best practices, and troubleshooting tips to master the art of testing. Plus, enhance your skills with hands-on experience through London School of Emerging Technology (LSET), Software Manual Testing Course, which provides industry-relevant training and certification in software testing methodologies. Take your career to new heights with in-depth knowledge and practical skills from seasoned professionals."

Enrol @ https://lset.uk/ for admission.

0 notes

Photo

Quality Standards and Testing Methods for HB Wires

In today's fast-paced world, where technology is constantly evolving and demands for high-quality products are increasing, it is crucial for industries to adhere to strict quality standards and testing methods. This is especially true for industries that deal with crucial components like HB wires, which are widely used in construction, manufacturing, and other sectors.

Quality standards ensure that the HB wires meet the required specifications and performance criteria, thus ensuring the safety and reliability of the end products. Testing methods play a vital role in verifying the quality of HB wires, identifying any defects or deviations from the standards, and ensuring that the wires meet the desired performance levels.

QualityStandards #HBWires #TestingMethods #IndustrialSafety #ConstructionMaterials #ManufacturingQuality

Adhering to quality standards and employing effective testing methods not only ensures the durability and performance of HB wires but also enhances the overall quality of the products they are used in. This, in turn, helps in building trust among consumers, reducing the risk of product failures, and ultimately improving the reputation and competitiveness of the company.

There are various quality standards that govern the manufacturing and testing of HB wires, such as ISO 9001, ASTM International, and Bureau of Indian Standards (BIS). These standards outline the specifications, testing procedures, and quality control measures that need to be followed to ensure the quality and performance of HB wires.

Testing methods for HB wires include mechanical testing, chemical analysis, dimensional inspection, and non-destructive testing techniques like ultrasonic testing and magnetic particle inspection. These tests help in evaluating the tensile strength, ductility, corrosion resistance, and other key properties of HB wires, ensuring that they meet the required standards and performance criteria.

By investing in quality standards and testing methods for HB wires, companies can not only comply with regulatory requirements but also enhance the overall quality and reliability of their products. This, in turn, can lead to higher customer satisfaction, increased sales, and improved brand reputation in the market.

In conclusion, quality standards and testing methods for HB wires are crucial for ensuring the safety, reliability, and performance of products in various industries. By adhering to these standards and employing effective testing methods, companies can improve the quality of their products, enhance customer satisfaction, and stay competitive in the market. It is essential for companies to prioritize quality standards and testing methods to ensure the success and sustainability of their business in the long run.

Product Page: https://shreejisteelcorp.com/wire-rod/

Website: https://shreejisteelcorp.com/

0 notes

Text

Limit test for sulphate content procedure | limit test for sulphate procedure

0 notes

Link

Check Out latest blog on the final level of testing. Acceptance Testing, Types with Examples - W3Softech

0 notes

Photo

Understand the concept of failover testing and prevent your systems from failures and crashes. Gauge the capacity of a system and ensure your system handles extra resources efficiently. Read more about failover testing here: https://bit.ly/2EFGwyb

#failovertesting#testingtypes#testingtechniques#testingmethods#softwaretesting#SoftwareQualityAssurance#SoftwareQualityModel#QualityTesting#sofware development life cycle

0 notes

Text

Everything you wanted to know about Pair Testing

If you didn’t know Pair testing was a thing, take a look at this article to find out more about it and its benefits. It sure takes two to tango and pair test.

https://www.specbee.com/blogs/pair-testing

0 notes

Link

Bosch has reduced the test time for its #Vivalytic machine 🔬 to 39 minutes with five #Covid19 😷 tests simultaneously in a world first This helps tackle the major #drawback of #throughput and cartridge production for #DNA test 💉 machines and is a world first, says the company.

#digitalevolution#fasttesting#covidtesting#sampletesting#diseasetesting#testingmethod#highthroughput#digitalhealth#epidmiology#testingpopulation

0 notes

Text

Different Types of Yarn Tests and Testing Methods

Different Types of Yarn Tests and Testing Methods #yarntest #yarntesting #testingmethods

Yarn Testing in Textile: Testing has never been more important in the textile industry than at present, with the increasing accent and premium on high-quality products, whether for domestic markets or export trade. Important characteristics of yarn quality being tested are discussed subsequently. The yarn represents the final outcome of the fiber processing or yarn manufacturing part of the fiber…

View On WordPress

1 note

·

View note

Text

A Review on Plastic Behavior of Polymer Sheets and Forming Process-Juniper Publishers Authored by Eun Ho Lee

Introduction

Polymer is one of widely used material due to the great availability and low cost. For mass production, moulding and extrusion technologies have been widely employed for polymer processing in industries [1]. Recently, automotive industries are trying to reduce the weight of the vehicles for improving the fuel efficiency [2]. For the reason, they have an interest in polymer materials, and many researchers have studied mechanical behavior of polymer materials. Figure 1(a) shows an example of 1-dimensional tensile test which is the most widely used material testingmethods to obtain the material’s behavior. When a material is getting deformed, the material has aproportional relation between stress and strain within a range of strain and this proportional relation iscalled elastic modulus. This strain rage is called elastic range and the stress is called yield stress. In theelastic range, the deformed material can recover the original shape, as shown in the path A. However, if thestrain level is over the elastic limit, a permanent deformation remains on the material even though thematerial slightly recovers the strain [3,4]. This recovered strain is called elastic strain, and the permanentdeformation is called plastic strain, as shown in path B of Figure 1(a). Figure 1(b) shows general behaviors ofpolymer materials. The elastic behavior is almost the same for all the materials. However, right after theelastic limit, rigid plastic easily leads to a material failure while other materials have more margin to bedeformed. For the reason, rigid plastic material does not show plastic behavior. This break point determinesthe elongation, the ration between the deformed length and the original length until the break point. Table 1 shows a summary of the mechanical property of polymer materials [5].

During the plastic deformation, the stress-strain relation is given as below [6,7]:

then the increment of the plastic strain is given with the flow rule,

dσ is the increment of stress, D is the elastic modulus matrix, dε is the increment of total strain. dε e represents the increment of elastic strain, dε p is the increment of the plastic strain. q is the plastic potential function, and p dε is the equivalent plastic strain. In order to obtain the dε p , below three conditions should be employed,

σ is equivalent stress, ρ is flow stress model, and H is the slope of stress-strain curve. Equation (3-1) is the yielding condition, (3-2) is about the return mapping stress, and (3-3) is the hardening behavior. Solving the equations from (3-1) to (3- 3) provides the increment of the plastic strain and stress. Then the strain and stress are used in numerical analysis of the plastic behavior.

As an application of the plastic behavior, some researchers have developed forming technologies for polymer materials. Thermoforming is one of the most popular forming processes for polymer sheets. As shown in Figure 2 [8], the thermoforming process consists of three steps; heating, shaping and trimming. Withthe thermoforming, a polymer sheet is heated to a target temperature, then formed to a specific shape in a mold. The formed sheet is trimmed to make a product. The vacuum forming is very similar to the thermoforming. In the vacuum forming, a polymer sheet is heated to a target temperature, then stretched onto a mold, and forced against the mold with a vacuum condition to reach the target shape.

The thermoforming and vacuum forming requires a mold to form a polymer sheet to the target shape. The investment cost of the mold is expensive. In addition, a mold cannot be used for another shape. To reduce the cost, some researchers started studying incremental forming for polymers [9,10]. Figure 3 shows the concept of the incremental forming. A polymer sheet is locally deformed by a forming tool which moves on the surface of the polymer sheet. Since the moving tool is following a defined path in 3-dimensional space, this forming process is flexible to be applied to arbitrary shapes.

Some researchers have tried to build lightweight structures with polymers sheets. Figure 4(b) shows a pyramidal kagome structure made of a polypropylene sheet. Since the polymer sheet was not able to be deformed to reach the target shape in room temperature, a heated die set was employed to increase the formability of the polymer sheet, as shown in Figure 4(a). This study showed a possibility to make a complex shape by a polymer sheet forming process. Polymer sheets can be employed as a medium material to help metal flow in sheet metal forming processes. Figure 5 shows a viscous pressure bulge (VPB) test under biaxial state of stress. Since the viscous medium help the flow of the sheet metal, the VPB forming process was able to reach large strain state. As shown in above examples, forming process of polymer sheets has many chances to be employed in industrial applications.

Conclusion

This paper briefly reviews the plastic behavior of polymer materials and forming technologies as an application. To make more application of the plastic behavior, forming limit [13] and joining technologies [14] should be accounted. Because of the low cost and great availability, the demand of polymer is getting growing, and both fundamental and practical studies are required [15].

For more Open Access Journals in Juniper Publishers please click on: https://juniperpublishers.com

For more details Academic Journal of Polymer Science please click on: https://juniperpublishers.com/ajop/index.php

To read more…Full Text in Juniper Publishers click on https://juniperpublishers.com/ajop/AJOP.MS.ID.555558.php

0 notes

Text

How to approach Usability Testing in UX design

The success and failure of any software depends on its usability, accessibility and responsiveness as felt by its end users or customers. It is observed that designers don’t always take into account the ‘user experience’ while designing a product, for they are mainly guided by its objective as specified by the company. When such a product goes into the market without proper evaluation of its user experience, the inherent issues from the perspective of end users turn it into a non starter. To avoid such a scenario, usability testing is needed to be carried out prior to a product’s release into the market. Post this testing, any lingering issues related to the user interface and overall responsiveness of the product gets addressed. However, usability testing methods should be robust enough to identify the real issues.

A lot of thought goes into designing a product. After the designing phase the product goes into development phase, where individual components or units are developed and tested for desired outcomes. However, more often than not the product is only checked from the perspective of developers and not the end users. In such a case, even though the product or application comes out looking fabulous, it might possess inherent flaws such as a poor user interface, lack of accessibility, delay in loading, slow scrolling, an unimaginative layout, erroneous content, etc. These flaws when faced by the end users end up as poor user experience. As there are many competitors of the product in the market, end users will not think twice before latching onto some other. This not only reduces the viability of the product, but also dents the brand image of the company producing it.

To avoid getting into such a situation in the first place, companies need to perform usability testing in UX design for the product or application. Usability testing involves testing of the product by its end users or customers. While testing, the behaviour of users using the product is keenly observed by testers and key areas where some difficulties are faced get noted down. The areas of concern are addressed later before releasing the product into the market thus increasing its market viability.

UX design or simply user experience design (also UX, UXD, XD, or UED) enables applications or products to work better for the end user. It includes designing a better user interface, incorporating cool ergonomics and delivering faster responsiveness such that the end user does not find any difficulty, while navigating or operating the product.

Best practices for usability testing

What is to be tested: The first step is to identify the application or a particular feature of the same that is to be tested. In a majority of cases, the whole application is tested for usability, accessibility and responsiveness.

Who should be tested: The second step is to identify specific users who are going to use the product for all practical purposes. The users should be chosen carefully as a wrong choice of users would be costly and time consuming – for the testers as well as users. For example, a medical app meant for doctors should not have laymen as users, but only medical professionals.

How many should be tested: A small group of end users should be asked to run the application testing as it will be easier to observe them navigate and operate. They should be asked to ‘think out loud’ while navigating, so that the testers observing them can make informed choices about glitches. A large group will be unwieldy.

Who should watch the testing: It is important to involve all stakeholders during testing, as the difficulties faced by users will be visible to all. Unless the difficulties are observed in person, there are chances of them being lost in transmission or translation.

Michael Works is a software Tech enthusiastic & works at Cigniti Technologies. I'm having a great understanding of today's software testing quality that yields strong results and always happy to create valuable content & share thoughts.

0 notes

Link

Among all the tests performed on a software product, functional testing carries great significance. It is one testing technique that not only helps validate the quality of the software but also ensures its accurate functioning, based on the Software Requirements Specifications (SRS).

#functional testing#testing types#testingtechniques#testingtypes#testingmethods#testingprocess#testing#sdlc

0 notes