#thermal gap pads

Text

The Key to Electronic Success: Thermal Interface Materials for Efficiency and Reliability

Thermal Interface Material come in various forms, each tailored to specific applications and needs:

Thermal Greases and Compounds: These are semi-liquid materials that fill gaps effectively, ensuring intimate contact between surfaces. They are typically used in applications with irregular surfaces, such as CPU installations.

Thermal Pads: These are solid, pre-formed pads with good conformability. They are ideal for applications where the even distribution of pressure is crucial.

Phase Change Materials: These materials change phase from solid to liquid during operation, ensuring optimal contact. They are well-suited for applications requiring minimal pump-out and a consistent interface.

Thermal Adhesives: In addition to their thermal properties, these materials offer adhesive qualities, making them ideal for applications that require both heat dissipation and component fixation.

Thermal Gap Fillers: These are highly compressible materials, perfect for applications with varying gap distances. They conform to surface imperfections and provide excellent thermal conductivity.

Read more blog : Unlocking the Secret World of Thermal Insulation: Click to Learn More

#thermal gap pads#thermal interface materials market#thermal management#thermal graphite sheet#books#energikey#thermal adhesive#thermal products company#silica grease#thermal gap filler#thermal insulator

0 notes

Text

I see alot of thinspo of people showing photos of what they want to look like. I'm not into bonespo but definitely into thinspo. But what about the small doll aesthetic? What about the kawaii lolita aesthetic? I don't want my ribs pressing threw my skin, I want to see my collar bones, dainty and feminine as a pastel sweater slips off my shoulder. A beautiful thigh gap and thin calves, wrapped by fuzzy thigh high socks as I pad across a wood floor. Dressing in sweet lolita as I go to meetups at a Cafe, a matcha tea I'm my hand as I nibble on a macaron. Feeling so small and dainty as my husband picks me up to put me in our bed after I fall asleep on the couch. Going to meet up with friends and being able to curl up into my husband's arms and dissapear. Layering lace and pearls on my body and looking like a fairy come to life. Having everyone become over protective of me because I'm just so small and fragile. Wearing lolita dresses and looking cute and precious instead of cringey.

I can do this. I haven't. No excuses anymore. I wanted to eat. I knew I would gain weight and did it anyway. That was my choice and sure enough I regret it just as I knew I would. I didn't want to measure out what I ate. I didn't bother checking calories. I assumed it didn't matter since I eat one meal every day and have 1 cup of coffee in the morning. No more. Come next December you will see me, wrapped in sweaters with thigh high socks and thermal leggings and ankle booties, glowing in the snow.

9 notes

·

View notes

Text

How to heat a party tent

In the cold winter, outdoor gatherings often appear less attractive due to the low temperature. However, with the rise of outdoor camping culture and technological advancements, heated party tents have become possible, allowing people to enjoy the beauty of nature while also feeling the warmth of home. Heated party tents not only enhance the comfort of activities, but also extend the season for outdoor activities. So how should we heat up the party tent? Regarding this issue, let's have the party tent manufacturer introduce it in detail below!

Specific steps for heating up a party tent:

1.Choose the appropriate heating equipment

Electric heater: For venues with convenient power access, electric heaters are a fast and efficient choice for heating party tents. Choose electric heaters with waterproof and splash proof designs to ensure safety.

Gas heater: suitable for situations without power or unstable electricity. Choose a gas heater with an automatic shut-off protection device and ensure good ventilation to avoid carbon monoxide poisoning.

Hot stones or baby warmers: For small gatherings or as auxiliary heating, hot stones or baby warmers can be placed in the corner of the party tent to provide local warmth.

Firewood stove or kerosene stove: a traditional and romantic heating method, but special attention should be paid to fire safety, ensuring that it is kept away from flammable materials and has good ventilation conditions.

2.Set up a party tent to optimize warmth retention

Sealed doors and windows: Use windproof cloth or tape to seal the gaps between the doors and windows of the party tent, reducing heat loss.

Double layered tent: If conditions permit, use a double-layer party tent with an inner layer that can isolate moisture and an outer layer that is windproof and warm.

Insulated floor: Party tents are equipped with moisture-proof and thermal pads to reduce the invasion of cold air on the body.

3.Reasonably plan the heating area

Place the heating device in the center of the party tent or in a crowded area to ensure even distribution of heat.

Avoid placing heating equipment directly at people or flammable materials to prevent burns or fires.

4.Monitor and adjust temperature

Use a thermometer to monitor the temperature inside the party tent and adjust the power of the heating equipment according to the number of people and activity intensity.

Pay attention to maintaining appropriate humidity inside the party tent to avoid discomfort caused by excessive drying.

Precautions for heating up party tents:

Safety first: Ensure that all heating equipment meets safety standards, carefully read the instructions before use, and follow the manufacturer's safety guidelines.

Ventilation: Regardless of the heating method used, ensure good ventilation inside the gathering tent to prevent carbon monoxide poisoning or carbon dioxide accumulation.

Fire prevention measures: Keep away from flammable materials such as party tent materials, sleeping bags, etc., and ensure that there are no flammable materials around the heating equipment.

Energy management: Reasonably plan the amount of electricity or gas used, avoid waste, and consider environmental protection.

Health considerations: Prolonged exposure to enclosed spaces requires attention to replenishing fluids to avoid throat discomfort or dehydration caused by dryness.

Conclusion:

Heat a party tent is the key to enhancing the winter outdoor activity experience. By selecting appropriate heating equipment, arranging the gathering tent reasonably, planning the heating area of the gathering tent, and strictly following safety precautions, we can easily create a warm and safe outdoor gathering environment. Remember, no matter what heating method is used, safety always comes first. While enjoying the outdoor fun of winter, let us protect this hard won warmth and comfort together.

0 notes

Text

Flooring Accessories: The Finishing Touches That Make a Difference

Flooring is more than just the surface you walk on; it’s a critical design element that sets the tone of a room. However, achieving a truly polished and cohesive look goes beyond simply laying down beautiful floors. This is where flooring accessories come into play—the often overlooked yet essential components that elevate your flooring from basic to stunning. From trims and mouldings that create seamless transitions to underlays that provide comfort and insulation, these finishing touches make a significant difference in both the aesthetic and functionality of your space. In this article, we’ll explore the key flooring accessories that complete your installation, how to choose the right ones, and tips for achieving a professional finish that will stand the test of time.

Key Flooring Accessories and Their Roles

Flooring accessories play a vital role in achieving a seamless, polished, and functional finish for any flooring project. These accessories not only enhance the visual appeal but also contribute to the durability and performance of your floors. Below are some key flooring accessories and their roles in completing your flooring installation:

1. Trims and Mouldings

Trims and mouldings are essential for creating smooth transitions between different types of flooring, such as between hardwood and carpet or tile. These accessories hide expansion gaps, protect edges from wear and tear, and provide a clean, finished look. Common types include T-mouldings for even transitions, reducers for height differences, and end caps for finishing exposed edges. By using the right trims and mouldings, you can ensure a professional appearance while protecting your flooring investment.

2. Underlays and Padding

Underlays are placed beneath the primary flooring material and serve several important functions, including cushioning, sound insulation, and moisture protection. For laminate and vinyl floors, underlays help reduce noise, making them ideal for multi-level homes or apartments. They also provide thermal insulation, which adds comfort underfoot and can help improve energy efficiency. Underlays specifically designed for moisture control are essential in areas like basements, where dampness could damage flooring over time.

3. Skirting Boards and Baseboards

Skirting boards, also known as baseboards, cover the joint between the floor and the wall, adding a refined and cohesive finish to any room. They help conceal expansion gaps, protect walls from scuffs and damage, and give the space a completed look. Skirting boards come in various styles and materials, allowing you to match them with the overall design of your room. Whether you opt for a sleek modern style or a more decorative traditional look, these accessories play a crucial role in tying the entire room together.

By incorporating the right flooring accessories, you not only enhance the aesthetics of your space but also improve the overall functionality and longevity of your flooring. These finishing touches are the details that make a significant difference, turning a standard installation into a standout feature of your home.

How to Select the Right Accessories for Your Flooring

Choosing the right flooring accessories is essential for ensuring that your flooring installation is both visually appealing and functionally sound. The right accessories can make all the difference in achieving a cohesive look and maximizing the performance of your floors. Here’s a guide to help you select the best accessories for your specific flooring type and needs:

1. Matching Materials and Colors

When selecting trims, mouldings, and skirting boards, it’s crucial to choose materials and colors that complement your flooring. For hardwood or laminate floors, opt for wood or wood-look accessories that match or contrast elegantly with the floor’s color. If your flooring is tile or stone, consider metal or vinyl trims that harmonize with the material. The goal is to create a seamless transition that enhances the overall aesthetic of the space without drawing unnecessary attention to the accessories themselves.

2. Considering Room Functionality

The function of the room should heavily influence your choice of flooring accessories. For instance, in moisture-prone areas like bathrooms and kitchens, opt for moisture-resistant accessories such as PVC or aluminum trims and water-resistant underlays. In high-traffic areas, durable and scratch-resistant trims are essential to withstand wear and tear. If you’re working with living rooms or bedrooms, focus on comfort and insulation by selecting cushioned underlays that enhance comfort underfoot and reduce noise levels.

3. Balancing Budget and Quality

While it’s tempting to cut costs by opting for cheaper accessories, it’s important to strike a balance between budget and quality. Investing in high-quality accessories ensures that your flooring remains protected and looks great for years to come. Consider the long-term benefits of spending a bit more upfront on durable, well-made accessories that won’t need frequent replacement. Additionally, look for accessories with warranties, as these often indicate higher quality and provide added peace of mind.

4. Assessing Installation Requirements

Before purchasing accessories, evaluate whether you’ll be installing them yourself or hiring a professional. Some accessories are designed for easy DIY installation, while others may require specialized tools and skills. For DIY projects, opt for accessories with user-friendly installation features, such as click-in trims or self-adhesive underlays. If you’re working with more complex materials or high-end finishes, professional installation may be the best route to ensure a flawless result.

By carefully considering these factors, you can select the right flooring accessories that not only enhance the appearance of your floors but also improve their performance and longevity. The right choices will ensure that your flooring installation looks professional, functions efficiently, and stands the test of time.

Installation Tips for a Professional Finish

Installing flooring accessories correctly is just as important as selecting the right ones. Proper installation ensures that your flooring looks polished, functions well, and lasts longer. Whether you’re tackling a DIY project or working with a professional, these installation tips will help you achieve a flawless and professional finish for your flooring accessories:

1. Proper Measurement and Cutting

Accurate measurements are crucial when installing trims, mouldings, and skirting boards. Measure each section carefully and double-check before cutting to ensure precise fitting. Use a miter saw or a similar tool to make clean, angled cuts, especially for corners, to avoid gaps and uneven edges. For skirting boards, ensure that they are cut to fit snugly against the wall and floor, covering any gaps without creating excess pressure that could cause warping over time.

2. Secure Fastening Techniques

Choosing the right fastening method is key to ensuring that your accessories stay in place and maintain their appearance. For trims and mouldings, use adhesive along with nails or screws to secure them tightly. This dual approach prevents movement and minimizes the risk of gaps forming over time. When installing underlays, ensure they are correctly laid flat and securely taped at the seams to prevent shifting, which can affect the stability of the flooring above.

3. Align with Floor Expansion Needs

Floors, especially wood and laminate, expand and contract with temperature and humidity changes. It’s essential to leave appropriate expansion gaps between the flooring and accessories to accommodate this natural movement. Use spacers during installation to maintain consistent gaps, which can later be covered with trims or skirting boards. Failing to account for expansion can lead to buckling or damage to both the flooring and accessories.

4. Sealing and Finishing Touches

For a polished look, seal gaps between accessories and the floor or wall with caulk or a color-matching sealant. This not only enhances the appearance but also prevents dust, dirt, and moisture from getting trapped in the gaps. If painting skirting boards or trims, apply a coat of primer followed by paint or stain after installation to ensure a smooth, even finish that matches the room’s decor.

5. DIY vs. Professional Installation

While many accessories can be installed as a DIY project, some installations—especially those involving intricate cuts, high-end materials, or large areas—are best left to professionals. Professionals have the tools and expertise to handle complex installations, ensuring a high-quality finish. If you’re unsure about any part of the process, consult with a professional installer to avoid costly mistakes and achieve the best possible result.

By following these installation tips, you can ensure that your flooring accessories not only look great but also provide the finishing touch that elevates the overall appearance and durability of your flooring. Whether you’re a DIY enthusiast or hiring a professional, these details make all the difference in creating a standout, polished finish that enhances your space.

Conclusion

Flooring accessories are the unsung heroes of any flooring project, offering the finishing touches that transform a simple installation into a beautifully polished space. From trims and mouldings that provide seamless transitions to underlays that enhance comfort and durability, these accessories play a critical role in both the aesthetic and functional aspects of your floors. By carefully selecting the right accessories that match your flooring type, suit your room’s functionality, and fit within your budget, you can elevate the overall look and longevity of your floors. Proper installation is equally important, as it ensures that these finishing touches are secure, visually appealing, and able to withstand daily wear and tear. Whether you’re renovating a single room or outfitting an entire home, paying attention to the details of your flooring accessories will make all the difference, creating a space that’s not only beautiful but also built to last.

#laminate stair nosing#lvt stair nosing#wooden door bars#amtico stair nosings#laminate flooring stair nose#laminate flooring stair nosing#self adhesive stair nosing#oak nosing for stairs#radiator pipe rose#waterproof vinyl stair nosing#karndean vinyl doorbars#amtico vinyl doorbars#waterproof door bars#wooden stair nosing#wooden door bar#stair nosing laminate#vinyl stair nosing#flooring accessories#wooden nosing for stairs#solid wood door bars#click vinyl flooring doorbars#laminate floor stair nosing

1 note

·

View note

Text

ASRock Radeon RX 7900 XTX 24GB & 20GB Creator GPUs

ASRock Radeon RX 7900 XTX 24GB

ASRock, a prominent global maker of motherboards, graphics cards, and compact PCs, introduced the first blower series graphics cards, the ASRock Radeon RX 7900 XTX Creator 24GB and 20GB, today.

ASRock RX 7900 Creator AMD RX7900 XTX/XT GPUs. These two cards offer multi-GPU collaborative computing and multi-card parallel computing for enhanced performance. Radeon RX 7900 Creator graphics cards contain a VAPOR-CHAMBER heatsink, an efficient blower fan, and a 2-slot thickness. Due to fewer power lines, the single horizontal 12V-2×6 power connector allows installing several ASRock Radeon RX 7900 Creator series graphics cards easy.

A metal frame and 0dB Silent Cooling blower fan make the ASRock Radeon RX 7900 XTX Creator series graphics cards durable and efficient. ASRock Radeon RX 7900 Creator Series graphics cards are great for gamers and crafters.

ASRock AMD Radeon RX 7900 XTX

12V-2×6 Power Connector Easy Assembly

Single horizontal 12V-2×6 power connectors are designed to minimise installation disturbance by avoiding unnecessary wire.

Effective Blower Fan Architecture

The blower fan quickly and effectively removes heat from the back of the graphics card.

Design of Vapour Chamber

The blower fan quickly and effectively removes heat from the back of the graphics card.

Chic Backplate Solid and Cool

Intended to prevent PCB bending. The graphic card becomes more visually legendary due to its fancy perspective. With the backside fitted with superior thermal pads, it also aids in improving cooling.

0dB Quiet Cooling Turn to cool, pause to quiet.

For the best cooling, the fan rotates when the temperature rises, and it stops spinning when the temperature falls for total quiet.

Thermal Nano Paste Excellent Thermal Cooperation

To optimise thermal efficiency and heat transfer, remove any gaps in the contact region.

Superior Heating Pad Increased Heat Transmission

Enhancing heat dissipation, the high-quality thermal pad aids in transferring component heat to the heatsink.

Adjustable Screw TorqueMounting pressure optimised

When putting together its graphics cards, ASRock Radeon RX 7900 XTX uses exact screw torque to maximise the cooler mounting pressure, which improves thermal efficiency without endangering the GPU.

Super Alloy graphics card

SP-Cap in Japanese

It offers exceptional electrical characteristics with a decreased equivalent series resistance (ESR) thanks to the high conductive polymer used as the electrolyte. Furthermore, it excels in heat resistance, dependability, and product operational life.

Smart Power Stage, or SPS

Using the most recent SPS (Smart Power Stage), Dr. MOS developed technology. It is designed to monitor the temperature and current of each phase, allowing for the smoother and more organised delivery of power to the GPU, resulting in improved performance and over-current capabilities.

High-quality 100A power choke

ASRock’s high-end 100A power chokes efficiently increase saturation current by up to three times when compared to conventional chokes, giving the graphics card a higher and better Vcore voltage.

Two-ounce copper printed circuit board

2 oz Copper PCB offers reduced temperature and increased energy efficiency for overclocking since it uses only carefully chosen copper materials for PCB layers.

PCB in matte black

SAV [PCB, Matte Black] a brand-new, enigmatic colour combination of matte black and copper to go with the expensive parts of ASRock‘s flagship graphics card.

High Density Glass Fabric PCB

The High Density Glass Fabric PCB design minimises the spaces between PCB layers to shield the graphics card from humidity-induced electrical shorts.

ASRock Tweak 2.0

An expert and user-friendly tuning tool

Offers instantaneous performance adjustments and intelligent fan speed control.

Support for 8K Resolution

For the best visual experience, it can handle 4K graphics in addition to supporting 8K video output, which is the next generation.

PCI Express 4.0

This graphics card supports PCI Express 4.0 and has 16 GT/s throughput, double PCI Express 3.0 bandwidth. Prepare for PC gaming‘s next wave.

The most cutting-edge game graphics

The AMD Radeon RX 7000 Series, the first gaming GPUs powered by AMD RDNA 3 chiplets, delivers unrivalled performance, graphics, and efficiency at 4K and beyond. AMD Radiance Display Engine’s colour accuracy and AMD FidelityFX Super Resolution and Radeon Super Resolution upscaling technologies deliver gorgeous graphics and faster frame rates.1, 2 AMD smart technologies will boost performance when AMD Radeon RX 7000 Series graphics are used with compatible AMD Ryzen processors.

Breakthrough activity

AMD Radeon RX 7000 Series graphics cards have elevated ultra-enthusiast performance standards. Chiplet technology, swift clock rates, and advanced AMD RDNATM 3 computing units enable smooth, high-refresh rate gaming. Reach previously unattainable performance levels.

IMAGINATIVE IMAGES

With High-Performance Rendering, which combines upscaling technologies and compute-based AMD FideltyFX capabilities, you can experience gameplay at unprecedented speeds and fidelity while still obtaining top-notch images. Continue to submerge

SUITABLE IN UNITY

Pair Ryzen processors with Radeon RX 7000 Series graphics cards with AMD smart technologies. You can perform really well to gain an advantage in the game. Utilise the AMD Software to enhance your AMD Radeon RX 7000 Series GPU: Edition of Adrenalin

IMPROVE PERFORMANCE EXTEND FIDELITY

The level of upscaling technology is increased with AMD FidelityFX Super Resolution technology. delivering amazing picture quality and increasing framerates for compatible games. With AMD Radeon Super Resolution (RSR)2, you may enjoy improved performance in thousands of games by utilising FSR technology at the driver level.

Read more on govindhtech.com

#ASRockRadeon#RX7900#XTX24GB#20GBCreator#gpu#motherboard#graphicscards#ASRockRadeonRX7900#amd#monitor#ASRock#pcgaming#AMDRDNA3#AMDRadeonRX7000Series#gameply#AMDRyzenprocessors#AMDFidelityFX#technology#technews#news#govindhtech

0 notes

Text

Filling the Void: The Relationship Between PSU Employment and the GATE Exam

The Graduate Aptitude Test in Engineering (GATE) is a crucial exam for engineering graduates in India's ever-changing job options landscape. While assessing students' comprehensive understanding of a variety of science and engineering undergraduate courses is GATE's primary goal, it also serves as a gateway to a plethora of opportunities beyond the classroom. One such route is employment opportunities at Public Sector Undertakings (PSUs), a crucial part of India's economy. Let's investigate the connection between the GATE exam and employment at PSU and see why so many applicants take this route.

Profitable employment prospects are offered by PSUs, which are well-known for their dependability, job security, and range of career alternatives. These industries include engineering, management, finance, and human resources. The advancement of the country's economy and infrastructure depend on these groups. But getting hired in PSUs is extremely competitive, and applicants frequently have to pass stringent screening procedures.

This is the point at which the GATE exam becomes relevant. Many PSUs use GATE scores as a standard recruiting criterion for engineering graduates. These results serve as a standard for assessing a candidate's aptitude for technical proficiency, critical thinking, and problem-solving. Furthermore, by providing an unbiased and transparent assessment platform for PSU recruiting, GATE results ensure merit-based selections.

The correlation between GATE scores and PSU posts is evident in the hiring practices of leading PSUs, including Indian Oil Corporation (IOCL), Bharat Heavy Electricals Limited (BHEL), National Thermal Power Corporation (NTPC), and Oil and Natural Gas Corporation (ONGC), among others. These institutions consider GATE scores while forming a shortlist of candidates or when making the final decision.

A primary benefit of utilizing GATE scores in PSU hiring is the matching of applicants' technical proficiency with the particular job specifications. PSUs are able to choose applicants with specialized expertise catered to their organizational needs because GATE assesses candidates across a variety of subjects. This guarantees that individuals who are hired have the necessary abilities to make a positive impact on the company right away.

In conclusion, this link indicates a mutually beneficial relationship between the GATE exam and jobs at PSU. For engineering graduates looking to achieve their professional aspirations of landing stable, rewarding jobs in the public sector, GATE serves as a launching pad. When PSUs use GATE scores in their hiring processes, they can access a pool of intelligent individuals with the skills needed to promote innovation and growth inside the organization. The synergy between GATE and PSU jobs is shaping the future of engineering talent in India by continuing to bridge the gap between academic achievement and real-world applications.

start your preparation with: https://gameacademy.in/ / https://clppenny.page.link/cTBm

0 notes

Text

Best Attic Insulation South Florida for Winters

According to real estate experts, it is best to insulate your attic before the cold season starts. Most places in the USA enjoy added relief in the winters because of an insulated, heat-protected attic in the winters that keeps the ceilings warm.

Thermal Protection for Winters in Florida

Florida winters are mild, with temperatures typically in the 60° to 70° Fahrenheit. Cold snaps can occur, especially in the north, because of which we do need season-long protection. The South is relatively milder but can suffer from cold showers!

The same Attic Insulation Dania Beach project will help you out double during the scorching heat of the next coming season - summer. But starting the insulation in fall itself will give you your long protection from several different problems!

3 Easy Steps To Prepare Your Attic For The Cold

Winters are dry with sub-optimum temperatures at night. Without proper insulation, not only does your attic become practically unlivable but the rooms right beneath it also appear risky for human health!

Performing an Energy Audit

An Energy Audit is a process that has been recommended by the US Department of Energy themselves. Usually, it involves measurement of trapped heart, weatherstripping signs, air thermometer checks, etc.

Sach kind of audit can easily identify problem areas so that we can produce results with extra efficiency.

Such an audit is performed by professionals using tools like thermal cameras, furnace efficiency meters, and airflow detectors. It usually also provides cost-reduction solutions as well as trustable alternatives for sustainability!

Cleaning for Pests and Mold

Before you select the right Attic Insulation Belle Glade, it might be suitable to think of other repair and cleaning services that you might require!

If the foundation is not clean, insulation will not last for long. It will start getting corroded with fungus and pest growth from the inside. Mice and mold might thrive better in the humid, heat-protected environment than you think!

Similarly, renovating problem areas is also a must. We start by removing debris, sealing air leaks, and repairing any damage that can compromise insulation effectiveness.

Choose The Right Material

Right before you start installing the insulation, don't forget to review the right raw materials. There are two main processes involved in attic insulation and you are to choose one - fiberglass rolls or blown-in cellulose insulation.

Fiberglass rolls are insulation materials that are added as paddings between the joists and used to reduce heat transfer in buildings. They trap air pockets to slow heat flow. They are a very affordable way of doing insulation.

Blown-in insulation covers every inch of the area, ceiling it from the rest of the world. It is made from recycled paper treated with fire-retardant chemicals. We apply it using a blower machine and it protects us from not only heat but also external noise.

Final Words

Once installed, the Best Attic Insulation South Florida provides close to a year-long protection after which you might need to either repair or upgrade various parts of the insulated corners. Maintenance typically involves checking for gaps, settling, or moisture issues. Replace or add insulation as needed to maintain optimal energy efficiency and comfort in your home!

#attic insulation boca raton#attic insulation boynton beach#Best Attic Insulation South Florida#Attic Insulation Near Me#Insulation Contractor South Florida

0 notes

Text

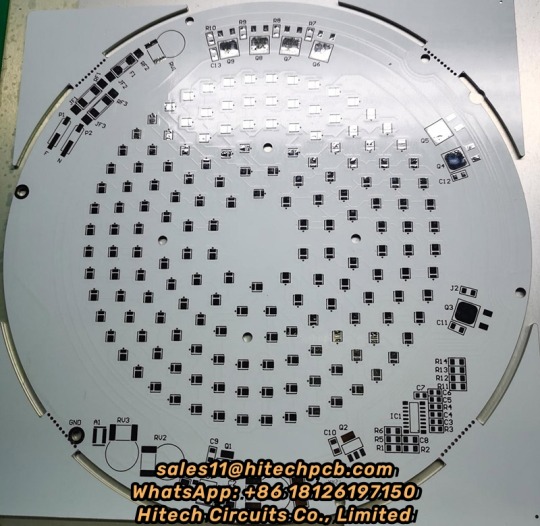

Aluminium PCB

1. What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Aluminum LED PCB with White Solder Mask

The retail price of Aluminum LED lights has dropped dramatically in recent years, while the energy efficiency and brightness of LED lights have improved. These technological advances have led some to predict annual growth of 45% over the next five years. With the development of the LED industry, the demand for LED PCBS and solder masks is also increasing. Solder shield is a protective coating applied to exposed printed circuit boards. The exposed PCB board is covered with a mask to prevent accidental solder bridging during PCB assembly and to protect the PCB from the environment. Solder masks are traditionally green, and are expected to withstand the high temperatures that occur in reflow soldering, as different colors such as blue, red, or black will occasionally appear. Increased production of Hitch Aluminum LED PCB requires increased whiteness and color stability of the mask. Aluminum LED PCB commonly used LPI welding color is white and black, of which white welding color is the most commonly used to achieve high brightness and perfect light reflection. White Aluminum LED PCB ensures no darkening and will not affect the color temperature of LED smd. At the same time, it also helps to increase the life of LED applications. Looking for reliable Aluminum LED PCB suppliers, Hitech is a good choice.

6. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

7. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

8. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

9. Technical requirements for Aluminum LED PCB

The main technical requirements are:

1. Dimensional requirements: including panel size and deviation, thickness and deviation, perpendicularity and warpage; Appearance, including cracks, scratches, burrs and delimitation, aluminum oxide film, etc.

2. Performance requirements, including peel strength, surface resistively, minimum breakdown voltage, dielectric constant, combustion and thermal resistance requirements.

10. Special test method for Aluminum-based copper clad plates

One is the measurement method of dielectric constant and dielectric loss factor. It is the series resonance method with variable Q value. The sample and tuned capacitor are connected to the high-frequency circuit in series to measure the Q value of the series circuit.

The other is the measurement method of thermal resistance, which is calculated by the ratio of temperature difference and heat conduction between different temperature measurement points.

11. The Aluminum LED PCB manufacturing process in Hitechpcba

(1)Substrate cutting

a. cutting process: material → cutting

b. Note: ① Check the size of the first piece; ② Pay attention to Aluminum surface scratching and copper surface scratching; ③ Pay attention to the layering of the board edge and the tip.

(2)Plate drilling

a, drilling process: pin → drilling → inspection plate

b, matters needing attention: ① check the number of drilling holes, the size of the empty chestnut chain; ② Check the plate burr, hole deviation; ③ Avoid scratching the substrate; ④ Check and replace the drill nozzle.

(3) Imaging transfer

a, graphic imaging process: grinding plate → film → exposure → development

b, precautions: ① Check whether there is an open circuit after development; ② Pay attention to the poor line caused by the board wipe; ③ There can be no air residual exposure to prevent poor exposure; ④ Whether there is deviation in developing counterpoint; ⑤ After exposure, the development should be done at rest for more than 15 minutes.

(4)Solder mask and Silkscreen process

a, kill row silk printing resistance welding, character process: screen printing → pre-baking → exposure → development → character

b, matters needing attention: ① Check whether there is foreign body on the board; ② Pay attention to the cleaning of the net board; ③ Pre-bake for more than 30 minutes after screen printing, to avoid bubbles in the line; ④ Pay attention to the thickness and uniformity of screen printing; ⑤ After the pre-baked plate to completely mutual cooling, avoid touching film or damage to the ink surface gloss.

(5)E-test or flying probe test

a, test process: line test → withstand voltage test

b, precautions: ① How to distinguish after the test how to store qualified and unqualified products.

(6)FQC, FQA, packaging, shipping

a. Process: FQC→FQA→ Packaging → shipping

b. Note: ① FQC should pay attention to the confirmation of the appearance of the finished Aluminum LED PCB in the process of eye inspection and make a reasonable distinction; ② FQA does spot check and verify the inspection standards of FQC; ③ We should confirm the number of packages to avoid mixed plates, wrong plates and package

12. Application of Aluminum LED PCB

1. Audio devices: input, output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier.

2. Power Supply: switching voltage regulator, DC/AC converter, SW voltage regulator, etc.

3. Communication electronic equipment: high frequency amplifier, filter, transmitter circuit

4. Office automation equipment: motor drive, etc

5. Automobile: electronic regulator, ignition device, power controller, etc.

6. Computer :CPU board, floppy disk drive, power equipment, etc.

7. Power module: converter, solid relay, rectifier bridge, etc

8. Lamps and lighting: A variety of colorful LED energy-saving lamps are well received by the market, and Aluminum LED PCB used in LED lights has also begun to be applied on a large scale.

13. Aluminum LED PCB Storage Conditions

Aluminum LED PCB are generally stored in a dark and dry environment. Most Aluminum LED tube lighting metal core pcb are prone to dampness, yellowing, and blackening. Generally, they should be used within 48 hours after opening the vacuum package.

14. Specification for the manufacture of Aluminum LED PCB

a. Aluminum LED PCB is often used in power devices, power density is high, so the copper foil is thicker. If copper foils over 3oz are used, the etching of thick copper foils requires engineered line width compensation, otherwise the line width will be out of tolerance after etching.

b. The aluminum base surface of aluminum substrate must be protected by protective film in advance during PCB processing, otherwise, some chemicals will etch the aluminum base surface, resulting in appearance damage. And the protective film is easy to be hurt, resulting in gaps, which requires the whole PCB processing process must be inserted.

c. The hardness of the milling cutter used by the glass fiber board gong board is relatively small, and the hardness of the milling cutter used by the aluminum substrate is large. In the process of manufacturing glass fiber board milling cutter speed, while the production of aluminum substrate is at least two thirds slower.

d, computer milling glass fiber board is just the use of the machine's own cooling system, but the processing of aluminum substrate must be in addition to alcohol heat dissipation for the gong head.

15. Aluminum LED PCB circuit fabrication

(1) Mechanical processing: Drilling of aluminum substrate can be done, but no burr is allowed on the edge of the inner hole after drilling, which will affect the pressure test. Milling the shape is very difficult. And punching shape, need to use advanced mold, mold production is very skilled, as one of the difficulties of aluminum substrate. After shape punching, the edge should be very neat, without any burr, and do not hurt the welding resistance layer on the edge of the plate. Usually the use of soldier die, hole from the line, shape from the aluminum surface, circuit board punching force is cut down, and so on are skills. After punching the shape, the warpage of the board should be less than 0.5%.

(2) The whole production process is not allowed to wipe the aluminum base surface: aluminum base touch, or by a certain chemical will produce surface discoloration, blackening, which is absolutely unacceptable, re-polishing aluminum base some customers do not receive, so the whole process does not touch the aluminum base surface is one of the difficulties in the production of aluminum base plate. Some enterprises use passivation process, some in hot air leveling (spray tin) before and after each pasted protective film.

(3) Over-high voltage test: the aluminum base board of the communication power supply shall be tested at 100% high voltage. Some customers require direct current or alternating current. The voltage shall be 1500V or 1600V, and the time shall be 5 seconds or 10 seconds. Dirt on the board, holes and aluminum edge burr, line saw tooth, damage to any little insulation layer will lead to high voltage test fire, leakage, breakdown. Pressure test board stratification, foaming, are rejected.

1 note

·

View note

Text

What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

6. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

7. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

0 notes

Text

SILICONE HEAT TRANSFER: PROCESS AND BENEFITS

Silicone heat transfer is a regularly utilized technology in various industries, including electronics, automotive, and aerospace. It uses silicone-based materials to transport heat from one surface to another to provide appropriate thermal management. An in-depth examination of silicone heat transfer’s various advantages will be covered in this article.

The Silicone Heat transfer Process

Thermal interface materials (TIMs) based on silicone are utilized in silicone heat transfer to convey heat effectively. Typically, these chemicals are pads, gels, greases, or adhesives. A thin layer of silicone TIM is applied as part of the procedure between the heat-generating component (like a CPU or power transistor) and the heat sink or cooling system.

This Silicone heat transfer uses silicone-based polymers to dissipate or transmit heat from one component to another. We shall analyze silicone heat transfer in this essay and its advantages.

Selecting silicone TIMs

Selecting a suitable silicone-based thermal interface material for efficient heat transfer is vital. Thermal conductivity, viscosity, electrical insulating characteristics, and compatibility with the cooled goods are all things to consider.

High thermal conductivity silicone TIMs offer increased heat transmission, while low viscosity allows for facile application and thin layers for improved thermal performance.

Surface Cleaning

Before applying silicone TIMs, it is vital to make sure the surface is adequately prepared. The heat sink and the heat-generating component must be immaculate and free of contaminants, such as dust or oil.

Alcohol wipes or speciality cleaning solutions can be used for this. Better adhesion and greater heat conduction are encouraged by a clean surface.

Application Strategies

Multiple application methods can be used depending on the silicone TIM type being utilized. Direct placement between the pieces is sufficient for pads or films.

However, a spreading technique might be required to attain comparable thickness and coverage with gels or greases, such as using a spatula or stencil. Applying the TIM evenly prevents air bubbles or gaps from blocking heat transfer.

Silicone Heat Transfer Advantages

Here are some benefits of Silicone heat transfer:

Improvements in Thermal Performance

The capacity of silicone heat transfer to boost thermal performance is one of its primary benefits. Heat can be efficiently transported from the heat-generating component to the cooling system by applying silicone TIMs with high thermal conductivity. Lower operating temperatures, a decreased chance of overheating, and higher system performance are the effects of this.

Higher dependability

Good heat transmission is vital to maximize the longevity and dependability of electronic devices. Silicone heat transfer materials give better control over temperature changes and minimize the possibility that a component may fail from overheating.

Silicone-based TIMs help boost the lifespan and dependability of many electronic components by minimizing thermal stress.

Energy Insulation

Electrical insulating characteristics of silicone heat transfer are another advantage. Silicone TIMs give electrical insulation instead of metal-based thermal solutions, preventing electrical leakage or short circuits. They are consequently excellent for purposes involving fragile electronic components.

Reusability and straightforward application

Due to their low viscosity and adaptability to diverse application methods, silicone-based TIMs are often straightforward. Furthermore, some silicone TIMs may be applied repeatedly if required, making them more economical than one-time-use choices.

Conclusion

Silicone heat transfer is a helpful method with various uses across multiple sectors. By efficiently dispersing heat, silicone-based thermal interface materials improve thermal performance, dependability, electrical insulation, ease of application, and reusability. Organisations may make intelligent judgments when choosing thermal management solutions by understanding the advantages of silicone heat transfer and how it works. If you need any help, Aa-star.net is there for you.

source:https://www.ausadvisor.com/silicone-heat-transfer-process-and-benefits/

0 notes

Text

Mastering the Art of Cozy: Your Guide to Staying Warm While Camping

Picture this: a crisp night under a star-studded sky, surrounded by the tranquility of nature. Camping is a magical experience, but the plummeting temperatures can quickly turn the enchantment into an icy challenge. Fear not, intrepid adventurers! We've got the lowdown on how to stay warm and snug during your outdoor escapades.

Layer Like a Pro: The key to conquering the cold lies in the art of layering. Opt for moisture-wicking base layers to keep sweat at bay, insulating mid-layers for warmth, and a weather-resistant outer layer to shield against wind and rain. It's like wrapping yourself in a cozy cocoon of warmth!

Heat Up Your Cuisine: Turn your campfire into a culinary sanctuary. Warm up from the inside out by whipping up hot meals and beverages. A steaming cup of cocoa or a hearty stew not only fuels your adventure but also radiates warmth that lingers long after the last bite.

Embrace Thermal Bliss: Invest in premium thermal clothing that goes beyond the ordinary. Our sustainable, soft thermal wear is designed for nature enthusiasts who crave both comfort and style. With these luxe layers, you'll be the epitome of outdoor chic while staying toasty on chilly nights.

Snuggle-Worthy Sleep Gear: Upgrade your sleep setup with insulated sleeping bags and pads. These high-tech wonders trap heat, ensuring a cozy night's sleep under the stars. Don't forget a snug beanie to keep your noggin warm—because a happy head equals a happy camper.

Fire It Up: Master the fire-making arts! A roaring campfire not only provides a mesmerizing ambiance but is also a reliable heat source. Gather 'round with your fellow explorers, share stories, and bask in the warmth of nature's very own fireplace.

Hot Rocks and Water Bottles: Harness the power of geothermal engineering by heating rocks in the fire and placing them strategically around your campsite. Tuck warm rocks into your sleeping bag or wrap them in a cloth to create makeshift heating pads. For a longer-lasting heat source, fill a durable water bottle with hot water and cuddle up with your newfound warmth buddy.

Insulated Shelter: Your tent is your fortress against the elements. Invest in a quality, insulated tent to shield yourself from biting winds. Seal any gaps, and consider adding a reflective emergency blanket to the interior for an extra layer of insulation. You'll be cozily cocooned in your own weatherproof haven.

There you have it, fellow adventurers—your ultimate guide to staying warm while camping. But why settle for ordinary when you can indulge in the extraordinary? Elevate your outdoor experience with our premium, sustainable, and irresistibly soft clothing. Nature and luxury, hand in hand—because every camper deserves to be wrapped in warmth and style. Explore our collection now and embark on your coziest adventure yet! 🏕️✨

Stay warm while camping by clicking here

#menswear#organic products#sustainability#adventure#sustainable#cotton#cotton fabric#eco friendly#ecofriendly#ecommerce#nature hikes#pullover hoodie#hoodie#hoodies#merch#apparel

0 notes

Text

Intrigued? For you there's a world of knowledge waiting on the other side of that link. Click to learn how thermal insulation quietly but profoundly impacts our lives by making them more comfortable, efficient, and eco-friendly.

#education#thermal gap filler#thermal adhesive#thermal insulator#thermal gap pads#energikey#university#thermal graphite sheet#thermal products company#thermal management#business

0 notes

Text

Horiaki's Pioneering Approach: Elevating Industries with Thermal Conductive Materials

In the ever-evolving landscape of modern technology and industry, efficient thermal management is a crucial aspect of ensuring optimal performance and reliability. Horiaki, a frontrunner in manufacturing excellence, stands out with its innovative approach to Thermal Conductive Materials Manufacturers, offering solutions that redefine standards in heat dissipation across diverse applications.

Thermal conductive materials play a pivotal role in dissipating heat from electronic components, machinery, and various industrial systems. Horiaki's commitment to pushing the boundaries of thermal management is evident in its range of advanced materials designed to meet the stringent requirements of modern industries.

At the heart of Horiaki's thermal conductive materials is a meticulous selection of high-performance substances. The company employs cutting-edge materials such as thermal interface pads, gap fillers, and phase change materials, each chosen for its specific thermal conductivity properties. This strategic material selection ensures that Horiaki's thermal conductive solutions excel in efficiently transferring and dissipating heat, contributing to enhanced performance and reliability in applications ranging from electronics to automotive systems.

Precision engineering is a hallmark of Horiaki's thermal conductive material manufacturing process. The company leverages advanced techniques to create materials with consistent thermal conductivity characteristics, ensuring reliable performance across a broad spectrum of operating conditions. This precision not only contributes to the effectiveness of the materials but also extends the lifespan of the systems they serve.

Horiaki's customer-centric philosophy is reflected in its thermal conductive material solutions. The company collaborates closely with clients, understanding the unique thermal challenges of their applications, and offering customized materials that address specific needs. This tailored approach has positioned Horiaki as a trusted partner, providing tThermal Conductive Materials Manufacturers that contribute to the efficiency and longevity of diverse industrial processes.

In conclusion, Horiaki's thermal conductive materials stand as a testament to the company's dedication to innovation and excellence. As industries continue to demand superior thermal management solutions, Horiaki remains at the forefront, delivering materials that set new benchmarks in efficiency, reliability, and adaptability. In the dynamic world of thermal management, Horiaki's commitment to advancing technology and industry is evident, making them a key player in the evolution of heat dissipation solutions.

0 notes

Text

0 notes

Text

Thermal Interface Materials Market| Global Growth Landscape

As per Triton Market Research, the Global Thermal Interface Materials Market report is segmented by Product Type (Thermal Pads, Greases & Adhesives, Tapes & Films, Phase Change Materials, Metal-Based Materials, Other Product Types), Application (Automotive Electronics, Computers, Consumer Durables, Industrial Machinery, Medical Devices, Telecom, Other Applications), and Regional Outlook (Middle East, North America, , Latin America, Africa, Asia-Pacific, and Europe).

The report highlights the Market Summary, Industry Outlook, Impact Analysis, Porter’s Five Forces Analysis, Market Maturity Analysis, Industry Components, Key Buying Impact Analysis, Key Market Strategies, Market Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology & Scope, Global Market Size, Forecasts & Analysis (2023-2030).

As per the Triton’s research report, the global thermal interface materials market is anticipated to progress with a CAGR of 10.17% over the forecasting years 2023-2030.

Thermal interface materials are substances that enable effective heat transfer between any two surfaces. The heat transfer is managed by filling the air gap that occurs between the interfaces between components. The application of thermal interface materials in electronic devices prevents overheating and increases the durability of the device.

There is an increasing need for advanced electronics, telecom devices, and digital gadgets with fast processing and multiple functions. In order to have optimal performance and reliability from these products, temperature regulation and effective heat transfer management is crucial. Thus, thermal interface materials (TIM) will witness a demand rise in order to maintain these electronic systems within specified temperature limits. Additionally, increasing urbanization leads to an increase in the consumption of electronic devices that are heat efficient and last longer. Thus, there is tremendous scope for thermal interface materials in diverse applications in diverse industries like automotive parts, household electronics, GPUs, etc.

Additionally, the key players in the market tend to invest in research for innovating TIM products, which will lead to further technological advancements in the market.

Asia-Pacific is expected to witness the fastest growth in the thermal interface materials market. Developing countries in this region will undergo a rapid phase of industrial expansion by setting up advanced driver-assistance systems, data centers, and 5G technology. There is a thriving demand in the manufacturing and electronics sector, particularly in South East Asian countries. All these industries, manufacturing units, and electronic devices require TIM to have an effective thermal management solution. Thus, in order to adopt an efficient heat management system, demand for thermal interface materials is growing, thereby fueling the market’s development.

The major competitive companies in the thermal interface materials market are Dow Chemical Company, Aavid Thermalloy LLC, 3M, Shin-Etsu Chemical Co Ltd, Momentive Performance Materials Inc, Honeywell International Inc, Laird Technologies Inc, Indium Corporation, Wakefield Thermal Inc, Parker Hannifin Corporation, Timtronics, and Henkel AG & Co KGAA.

The supply chain of the thermal interface materials market is affected by fluctuations in raw material costs like polyethylene, aluminum hydroxide, polymerized liquids, polypropylene, and PVC. These raw materials are acquired by refining and processing oil and natural gas. Volatility in oil prices pushes up the cost of raw materials, manufacturing, and shipping. Thus, uncertain price behavior poses a challenge for the companies to determine the operational costs of thermal interface materials for end-users.

0 notes

Text

Thermal Interface Materials Market: Top 4 Applications

Thermal interface materials (TIMs) play a pivotal role in electronics and thermal management. They help improve the thermal conductivity between components, ensuring efficient heat dissipation and preventing overheating. By filling microscopic gaps between surfaces, TIMs facilitate heat transfer, and in turn, improve the reliability and performance of electronic devices. According to Inkwood Research, the global thermal interface materials market is set to progress with a CAGR of 9.91% during the forecast years 2023 to 2032, reaching a revenue of $7044.80 million by 2032.

With the rising development and adoption of increasingly compact and powerful electronics, TIMs are becoming indispensable for maintaining optimal operating temperatures, prolonging the lifespan of devices, and ultimately ensuring their seamless functionality. TIMs are available in many forms, including gels, pastes, and greases; they offer excellent thermal conductivity, high-flexibility and better fill larger gaps.

Thermal Interface Materials Market: Enhancing Performance in Electrical Applications

Through the efficient conduction of heat away from critical components such as processors and semiconductors, TIMs prevent overheating and ensure the longevity and reliability of electronic devices. This enhanced thermal management results in improved performance, reduced downtime, and increased energy efficiency, making them an indispensable component of modern electrical applications. Here’s how –

Automotive Electronics:

Thermal conductive materials play a pivotal role in dissipating heat generated by various automotive electronic systems, such as engine control units, infotainment systems, advanced driver-assistance systems (ADAS), and electric vehicle (EV) components. TIMs facilitate heat transfer between electronic components and heat sinks, ensuring that delicate automotive electronics operate at optimal temperatures. For example, the DOWSIL™ 3-6752 by Dow Chemical Company (United States) is a thermally conductive adhesive used for bonding organic as well as ceramic substrates to heat sinks for electronic control modules in automotive applications.

Market Position: As per Inkwood Research, the automotive electronics segment, under the application category, is set to grow with the highest CAGR of 11.08% between 2023 to 2032.

In addition to performance improvements, these materials also aid in energy efficiency, which is a major concern in the automotive industry. By preventing overheating and ensuring the longevity of vital components, these materials enhance the reliability and performance of modern automotive electronics, thereby contributing to the safety and efficiency of automobiles.

Computers:

Computers, encompassing various devices such as desktops, laptops, servers, and data centers, produce a significant amount of heat during their operation. The use of thermal interface materials, in this regard, is common for enhancing heat dissipation from critical components like CPUs, GPUs, and memory modules to their respective cooling solutions or heat sinks.

The demand for efficient TIMs in computers is projected to increase during the forecast period, driven by the growing popularity of gaming PCs, the expansion of artificial intelligence applications, and the increasing utilization of data-intensive tasks. Additionally, the emergence of technologies like 5G and the Internet of Things (IoT) is fostering the need for robust thermal management solutions in edge computing devices and cloud data centers, as well.

Telecom:

Thermal interface materials (TIMs) are employed in telecom equipment in order to efficiently transfer heat from high-power electronic components, ensuring that devices operate within the required temperature range. Thermal greases, phase-change materials, and thermal pads are commonly used in these applications. As the telecom industry transitions towards 5G, while preparing for the future with 6G technology, the demand for thermal conductive materials is anticipated to increase further.

Aligning with this, telecom is expected to be the dominating application during the forecast period, capturing a revenue share of 24.80% by 2032 (Source: Inkwood Research). Several leading companies are actively engaged in the telecommunications infrastructure space, predominantly with regard to thermal interface materials. These include Henkel AG & Co KGaA (Germany), Parker Hannifin Corporation (United States), and Indium Corporation (United States).

Medical Devices:

Efficient thermal management is critical in medical devices in order to ensure accurate and reliable performance during medical procedures. TIMs assist in heat dissipation from high-powered medical electronics, preventing overheating and maintaining optimal operating temperatures. As pharmaceutical R&D and industrialization continue to grow in major regions, such as Europe, the demand for thermally conductive compounds in medical devices is expected to rise further. For example, Germany’s robust pharmaceutical and medical device sectors highlight the demand for TIMs in medical applications.

With a substantial number of companies in the medical equipment and supplies sector, Italy’s mature market necessitates precise temperature control in medical devices. Likewise, the robust export value of the Polish medical devices and equipment sector, reaching €3.2 billion in 2021, also demonstrates the critical role of TIMs in healthcare technology. These growth factors, in turn, further propel the market demand in the region. Accordingly, as per Inkwood Research, the Europe thermal interface materials market is set to grow with a notable CAGR of 10.15% during the forecast period, 2023 to 2032.

As technology continues to evolve, the need for efficient heat management becomes increasingly crucial. Moreover, with industries and consumers alike demanding smaller, faster, and more powerful devices, the use of TIMs is set to play a pivotal role in maintaining optimal operating temperatures and ensuring the longevity of modern electronics. These factors, in turn, are expected to boost the growth of the global thermal interface materials market during the upcoming years.

FAQ

What is the size of thermal interface materials?

Typically, several interfaces exist between the heat-generating element as well as the eventual heatsink. Their thickness can vary from several hundredths of an inch to a few thousandths of an inch.

Are there eco-friendly TIM options available to reduce environmental impact?

Yes, various TIMs are designed to be environmentally friendly, offering low volatile organic compound (VOC) content and longer lifespans, which reduce waste and environmental impact.

#thermal interface materials market#thermal interface materials#CHEMICALS AND MATERIALS#ADVANCED MATERIALS#inkwood research#market research reports

0 notes