#they have a ton of industrial sewing machines

Text

made a belt today!!!!

#found a school of leatherwork/shoemaking BY ACCIDENT yday and was able to snag a 101 class today!!!!#it rocks#they have a ton of industrial sewing machines#and a harness/collar course...#lll

9 notes

·

View notes

Note

Can I gather from the supplies on your table that you are currently doing some embellishing (with beads)? What project are you currently working on if you feel like sharing

Have a good one and I love your content

lots of love

One would think that since I have beads out on my table I must be using them, but no! I bought most of them a few weeks ago and probably won't get around to using them for at least another 2 or 3 weeks.

It's ok though, they don't mind waiting in the fancy dish.

I got dark purple, red, black, and bronze, and I plan to use them to do some beading on my velvet robe. I want to use them outline/fill in some parts of the print, mainly around the front and shoulders.

I have a few things I'd like to finish up before then, and the weather (which was nicely chilly for a week) is currently quite warm, and I doubt I'll feel like sewing with velvet until it's a bit more autumn-y. I'll post pictures of the beading once I start on it!

I always have a ton of unfinished things, but I'm working mainly on 3 things at the moment. There's this pair of yellow silk late 18th century breeches, which are very close to done! I've been dragging my heels, but there's just 10 more buttonholes to go.

The lighting in this picture makes it look dull, but it's quite a bright yellow.

Today I went to work (not clocked in) and used the domestic machine there (mine is old and only does straight stitch, so can't sew stretch) to finish sewing up this swimsuit, which has been in pieces on The Pile for... I can't remember if it's been 2 years or 3. But it's almost done now! I just need to add the buttonholes & buttons.

The materials aren't great, and I worry that it'll be awful saggy when wet, but I'll just be glad to have it done. I don't like swimming much anyways.

Then, after that was all together, I spent a few hours on the industrial machine sewing up these brown corduroy pants. They need a hem, and I need to make and attach the waistband and do the buttons & holes, but the big construction seams are all done.

This is way, WAY more productive than I am on most days!

It's easier to focus on stuff at work because there are no distractions. I've done a bit of my own sewing after finishing on slow days, but I think this is the first time I've gone in just to work on my own stuff.

I should probably do it more often. Unfortunately it's about a 50 minute bus ride to get there, but I can blink and have several hours vanish at home, so it'd be worth it to actually get more work done on stuff.

85 notes

·

View notes

Text

Since I'm no longer employed by a single sewing machine company, and don't have to worry about saying this,

If you are looking to buy a premium sewing machine, if at all possible, absolutely go to a place that can show you multiple brands of machines, including different levels of features and different price points.

There are some brands, including a brand I previously worked for, where the number of features for to the price is just not in any way competitive with the rest of the market.

They're good machines, and I'm not about to get rid of mine in favor of another. However, when one brand's $12,000 machine has more premium features than another brand's $19,000, that should be information that people have when they're looking to buy a new machine.

That said, since many brands do not sell their high-end machines online, if the only place where you can buy a $2,500 embroidery machine is at a little sub-store inside a Joann Fabrics, I can confirm that they're not bad machines. But, y'know, it's very cool that Husqvarna Viking machines at the $15,000 and $19,000 price have a fully-automatic one-step needle threader, but it's worth noting that Babylock has that feature on a $600 machine.

Obviously, the thing you should be basing your purchase on is more than just what the specs are on paper, and you should get a machine that you like, regardless of what my personal opinions are. Again, if you're in any way able to get to a place that sells different brands of machines across different price points, and you can see them out of the box and operating, it's a good thing to do. There's a ton of small elements of a machine that don't get spelled out in an online listing. You might find that you hate something small, like the location of the needle plate screws, where going up or down in price by $70 can get you a machine without that annoying feature. If the people doing sales at your sewing machine store also sew on all the machines, you can get opinions from them about fine details. They're not always able to crap-talk a machine, but I've seen someone say, "Oh no, we've tried changing it a couple times and that tension still looks wrong. Let me show you a machine that doesn't do that," which is sales speak for this machine has tension problems nine ways to sunday and you will be dealing with that forever so i know you liked it online but please don't buy it because there's other machines that aren't more expensive that don't do that.

If you're in a big store, you can also learn about products that you never would have found online. For example, you might have thought you wanted a multi-needle until you got to sit down at an embroidery/sewing combo machine and realized that you're willing to change threads one at a time to save $10,000 and 9 square feet of floor space. You might have thought you want an industrial machine until you realize that Babylock has that Accomplish straight stitch machine that will get you what you need, but still use domestic bobbins and needles and be serviced by household machine service people. You wanted a household machine with a stitch regulator until you tried it in person and decided it's not worth it and you're up to dedicating your entire living room to holding a stand-up long-arm.

When you search for things online, you often end up in a very linear path, finding something you like and then checking for things that are technically very similar. However, online searching is oftentimes very bad at being able to connect things that are functionally very similar but aimed at different markets. I feel like this is like a capcha asking you to prove that you're human by clicking all the pictures that are hedgehogs. If you're a human surrounded by sewing machines aimed at providing machines to a wide variety of customers, it's pretty easy to look at similar machines from different markets. However, if you're online and trying to find an embroidery machine for your home, you're going to be fed whatever google's tunnel vision thinks is a home embroidery machine.

Allllllso if at all possible, don't buy a serger when there's no one to show you how to thread it. And remember, the thread goes in front of the elephant.

51 notes

·

View notes

Text

I think everyone has heard the term “supply chain crisis” at this point. Manufacturing centers were first hit in late 2019 and most to the global lockdowns were in effect by the second quarter of 2020. It is now third quarter of 2022 and we are into year three of this “interruption”, it is time to discard this outdated and frankly wrong from the start system of manufacturing and distribution. Americans in particular were already caught in a state of duality in which much of the public laments that nothing is made domestically, while also discarding anything made by local shops as “overpriced hipster gear”. I have previously stated that for true domestic production to return to America there would need to be enough demand for the products to cause more competition and drive the prices down as domestic supply increased.

That is the current situation as I see it, so now what do we do about it? In the last decade one particular technology has taken off, once a novelty and hyper expensive tool for industrial prototyping, 3D printers have become affordable, commonplace, and surprisingly capable. While still used by many to produce novelty items and in industrial roles, this technology is akin to the movable-type printing press of the mid-1400s in that it represents an upset to the established order if utilized effectively. Now before this is dismissed I am aware of the limitations of what can be printed at home. More exotic and expensive versions are used to produce high strength items. But this is where it gets interesting, because it isn’t about everyone having a printer. It’s about everyone using home printers to get a head start on skills, hobbies, and trades they couldn’t afford to break into otherwise and then using those skills to work with each other.

Lathes or milling machines are both often said to be machines that make machines. 3D printers should be included in that list. Now there is nothing made on this machine that can’t be done with other tools and methods, but few that allow the low cost of entry and ease within a home settings. Open source software and thousands of free files allow anyone and everyone to make tons of tools, dies, forms, jigs, stencils, etc. as needed. I've seen sheet steel stamped on dies made from common PLA on a cheap press from Harbor Freight, or even just stuck with hammers. My cousin makes brackets for electronics with an entry level printer while his wife makes custom cookie cutters for various events on the same machine.

And that’s the thing about this, the broad range of applications combined with people’s varied and personal interests. With the addition of a chop saw and drill for extruded or tubular metal you can make strong supports for printed pieces to form a much larger machine. If you can make a drill press or milling machine, you can make a lathe, manually operated or CNC. I’ve seen people make large format CNC router tables that can quickly and efficiently cut and trim an entire sheet of plywood for assembly. If within a community most people have the ability to make their own simple plastic or resin tools and utensils, while someone has a garage metal shop, another a carpentry shop, a couple down the road a leather shop and sewing studio, someone else a pottery studio, even a small foundry for smelting and casting, you would have a far more self-reliant community than anything seen in a hundred years in much of the western world.

I was originally going to link a bunch of videos showing the possibilities and I still might add some later on about specific applications. But I really want everyone to give this some serious thought on their own. Is there a hobby or trade you are interested in but you’re concerned about the investment? Look at what the essential components are. Can the more complex ones be found used? The cheaper ones made at home? We, as in all of us, are in a massive web of unsustainable distribution and centralized manufacturing. I don’t believe the key is to change where that center is, but to replace it with local and regional decentralized networks of skilled individuals whom own their own tools and shops.

#self reliance#sustainability#decentralisation#3d printer#trades#hobbies#skill set#new skills#casting#welding#machining#carpentry#pottery

38 notes

·

View notes

Text

stainless steel investment casting|ss investment casting| steel investment casting india.

STAINLESS STEEL INVESTMENT CASTING<a href=" https://investmentcastings.in/about.html"> about</a>

Trident steel PRECISION CASTINGS POUR A WIDE VARIETY OF STAINLESS STEELS AT OUR FOUNDRIES in INDIAN AND Karnataka.

Our stainless steel investment casting follows our unique, award-winning process and is used in a wide range of industries, from our precision medical castings to our robust aerospace units, with a wide range of commercial castings in-between.

Trident is a renowned Alloy stainless Steel investment Casting. We are well known for our flawless and smooth ss casting here.

The production capacity is 360 metric tons per annum for manufacturing all ferrous grades such as carbon steel, alloy steel, stainless steel, super alloy.

We offer Stainless Steel Investment Casting by Lost Wax Process steel castings& non-ferrous castings in Steel alloys, Bronzes & aluminum alloys.

Investment Castings have many and varied applications.

Trident Steels also manufactures Stainless Steel investment casting of pipe fittings in S.S304 and S.S316grades. These are machined on CNC machines.

trident Steels solicits work from India as well as international buyers to meet its spare

capacity. SS (stainless steel) investment casting refers to the application of the

investment casting process specifically for stainless steel materials. Stainless

steel is a popular choice for investment casting due to its durability, corrosion

resistance, and aesthetic appeal.

There are numerous products that can be produced using SS investment

casting. Some examples We are currently supplying various industries like valves,

pumps, textile, sewing machines, automobile, electrical / electronic and general

engineering industries.

Engine and turbine components, medical instruments, and implants, marine

and under water equipment, food processing equipment, Architectural and

decorative hardware,

These examples represent just a fraction of the wide range of products that

can be made using stainless steel investment casting. The process allows for

intricate and complex designs, precise dimensional accuracy, and the ability

to replicate fine details, making it suitable for many different applications

across various industries. It is combining one or more alloying components with regular carbon steel, alloy steel is

created, which is an iron-carbon alloy. Some of the property the alloy steel can acquire good strength, high hardness, toughness, ductility, weldability, fatigue strength, resistance

to corrosion, good permeability, better resistance and non-magnetic, in addition to otherspecial features, depending on the various additional components and the worthy processing technology. High alloy steel and low alloy steel are the two primary divisions. Low alloy steel is frequently used in the investment casting of alloy steel.

Alloy steels can be produced with a wide range of properties. The physical properties of alloy steel change significantly; depending on chemical composition and heat treatment. They are selected to match the performance requirements of the intended application.And required product.

These all properties or alloying and specialized heat treatments improve a casting’s ability to repel loads and stresses.

Address:

40, Machhe Industrial Area,

Machhe, Belgaum - 590014, KA, India.

91 831-2411936

0 notes

Text

DTF Printing VS Sublimation, DTG, Screen Printing

DTF Printing Technology is possessed and worked by a printing organization that has been available for the most amazing aspect of 10 years. Which began as a little side problem, ultimately developed into a cutting edge print shop. Throughout the long term, we've acquired a ton of information and direct involvement in all of the previously mentioned printing techniques. This is the way they contrast with DTF initially.

Sublimation Printing

Masters:

Extremely modest and open. More often than not you can just top off an old printer with sublimation inks and you are all set. You might pull off printing on customary office paper as opposed to utilizing costly sublimation sheets.

Requires insignificant support. Sublimation ink doesn't to obstruct without any problem.

Deals with various items, for example, mugs, keyrings, napkins and so on.

On industrials scale, an assortment of all over print cut and sew items can be produced utilizing huge organization printers.

Cons:

You are restricted to polyester pieces of clothing. Cotton sublimation is conceivable with utilization of extra sublimation splashes and transfer powders, which can be a mind boggling process.

You are restricted to light shaded items. You can't sublimate onto dark shirts.

DTG Printing

Professionals:

DTG printed shirts have potentially the best feel to them. You can't beat the delicateness, quality and launderability of a very much printed DTF shirt.

You can print on print on basically anything you can fit on your flatbed. Unpleasant surface handbag? Don't worry about it! A shoe? Simple!

Cons:

Over the top expensive to get into. You can purchase a modest Chinese flatbed printer for £2000 yet those aren't anything contrasted with a legitimate £13,000 machine or a modern printer. Consumables are costly, support is costly, saves are costly. You can go on YouTube and look for "Why I sold my DTG printer" or "Why my shirt business fizzled" and you will understand that DTG is just not monetarily reasonable for a beginning business.

You should pretreat your shirts. This cycle can be surprisingly interesting. In a perfect world you would purchase a pretreatment machine and a nice dryer, setting you back considerably more cash.

White DTG ink is popular for its stopping up and day to day support prerequisite. Each time you leave your printer inactive for a couple of days you risk demolishing a £1800 printhead.

Screen Printing

Masters:

Most effective way to efficiently manufacture shirts on a tight spending plan.

Ace screen printers can create astonishing outcomes.

Cons:

Not so much for one off orders. It requires a long investment to set everything up for each plan. In any case, when everything is running you can rapidly print an enormous amount of shirts.

Screen printing is a work of art. It has a precarious expectation to learn and adapt and will require a great deal of training to do well.

Requires more space

One of the more chaotic printing techniques includes showering, washing, ink blending, synthetic compounds and so on.

So what's the decision?

By and large, DTG printing is as yet lord. In the event that it was reasonable, I would suggest it quickly. Unfortunately, DTG simply looks bad for a private venture. Modest flatbed printers are rubbish and costly ones have neither rhyme nor reason monetarily. DTF does all that you want. It will permit you to print on 100 percent cotton and dark pieces of clothing, it will have incredible feel and launderability. You will actually want to print on request rapidly and helpfully, without stressing over sitting inactive for a couple of days. DTF printing technology make an ideal arrangement for a developing business. Set aside some cash, center around fostering your image, satisfy your clients.

0 notes

Text

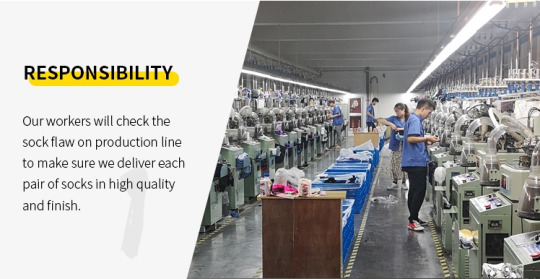

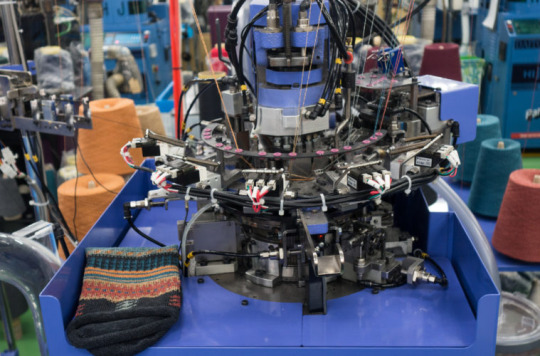

wool sock factory

Different modified socks from MOQ 300 sets, various examples, Logo, varieties and sizes. Redone socks made of brushed cotton, fleece, polyester, supported flexible, bamboo, and so forth. Recognizable Material Socks. SGS Evaluated Sock Plant. Competitor Socks. Pressure Socks.

With more than decade of involvement with making fleece socks, we realize everything necessary to produce quality fleece socks with one or the other merino or cashmere yarns. Long periods of hand-on experience empower us to give a far reaching answer for our clients from plan to assembling and brief conveyance to where you are. As a sock producing organization, we enjoy the accompanying benefits:

► Situated in the Sock City of Datang, Zhuji City, where a total sock industry chain is laid out covering yarn fabricate, kicking the bucket plants, bundle and frill providers.

► A group of very much experienced and skilled originators.

► North of 300 arrangements of most recent sock sewing machine and handling gear.

► QC group to control quality all through the creation interaction.

► A very much associated organization of transportation specialist and forwarders to convey your products in the most brief and conservative manner.

sock producer. Request Now! Driving B2B Entryway. China's B2B Effect Grant. SGS Inspected Providers. Quality China Items.

Shaoxing Annor Material Co., Ltd.

Shaoxing Annor Material Co., Ltd. is one of the top socks producers situated in Shaoxing city, Zhejiang territory, China. The organization works in the assembling of different sorts of socks, gloves, and so on.

Are Gold Toe socks made in China?

Gold Toe Brands, Inc., has moved quite a bit of its assembling to China, especially the Zhejiang region. Despite the fact that its essential market is men's dress socks, Gold Toe Brands has extended to different sections of the sock market.

How to Make Your Fleece Socks?

Q: Can you uniquely craft socks for me with my own plan?

A: Yes and sure, we are industrial facility direct and can make any socks you need. Simply send us your craftsmanship including size, yarn type and organization, plan, bundle choice and so on, and a model will be made only for you.

Q: In the event that I simply have a few unpleasant thoughts regarding how I maintain that my socks should be, might you at any point assist me with working out a legitimate plan and make an example for me?

A: That is not an issue by any stretch of the imagination as we have a layout pool of thousands of sock plans prepared for you to browse and we can choose the ones that match your thoughts most and further develop them till you get your fantasy configuration, in light of which an example will be created for your endorsement.

Q: I'm a beginning up and can't manage the cost of a major request for the present, what's the least amount you can take?

A: As a sock producer, no organization is excessively little for us, not only for business. There ought to be somebody some place to work with new companies. Yippee! The main thing is the greater the request the lower the expense. Anything your request is, you'll get the immediate cost without increase. In this way, don't stress over a little request, we will take care of you.

WHY Pick US

15 years woolen texture and yarn creation experience

3 million meters fleece texture creation limit and 10 million tons yarn limit

Solid Research and development groups working with Renowned design organization like: ARMANI,PRADA,FENDI,GUESS ,ZARA ,H&M and so forth

Proficient outreach group working for abroad clients with best assistance and right items wool sock factory

CONTACT

UNITEX Production ,NO #55,WEST TANGSHI Road, YANGSHE TOWN, ZHANGJIAGANG, SUZHOU, JIANGSU, CHINA

WhasApp: +8618118118222

Versatile: +86-18118118222

Wechat: +86 18118118222

1 note

·

View note

Text

Replica Hermes Belts, Designer Pretend Hermes Chaep Sale

259.5K individuals have watched this. Watch quick videos about #hermesblanket on TikTok. #hermesblanketchallenge

Hermes leather always has an indentation alongside the sting of the leather. The purse, bracelets, belts, and so forth. they have this indentation. Hermes belts are all the time reversible and a pair of colors. https://skel.io/replica-designer-belts/hermes-belts-replica.html If u have a hermes in ur space go in and really feel a belt. If there is a ring, there isn't a separation. Hermes belts, bags, etc do NOT include orange playing cards or orange velvety pouches.

The model with a front that has a brushed look additionally has polished edges, and the backs of their buckles at all times have a sort of matte end which could be very constant. This reveals they have attention to element. A higher-end way to finish off edges is to start with a wider piece of leather and thin down the edges of the within , after which fold over the perimeters and sew every thing collectively. That means the highest and bottom fringe of your belt truly has full exterior leather and no reduce edge that’s seen.

Obviously, you don’t get the H buckle with both the Montblanc or the Fort Belvedere belt system, but you get other basic buckles which are very attractive. Of course, Duret is Duret and Hermes is Hermes, so if the status symbol is important to you, then a small producer or a craftsman can’t provide you with that. That being said, the custom belt is out there in one size, and whilst you could possibly make it reversible, it doesn’t have the entire system that Hermes presents you. Traditionally, a hand-made belt would be welted by a saddle stitch which is the very same sew that you just use when you sew on. Traditionally, a hand-made belt would be welted by a saddle sew , using one thread with needles at both ends. In 1880, the household moved the Hermes shop to the world-famous 24 Rue u Faubourg Saint-Honoré in Paris.

wikipedia belt Also, the stamp on the buckle and the leather. Ohhhh....and the hermes stamp on the buckles is not going to seem like it was stamped by a machine. These prestigious sellers are industry leaders and symbolize the very best echelon for item quality and design. I'm fairly positive the answer here is an unequivocal 'no'. You can purchase a top quality belt for a fraction of that value, after which have tons of of dollars to expand your wardrobe in other methods.

#hermes belt replica#replica hermes belt#knock off hermes belt#hermes belts replica#fake hermes belts#high quality replica hermes belt#hermes h belt replica#replica belts hermes

0 notes

Text

Victorian era characteristics

The Victorian stands as a milestone because of multiple factors. As a matter of some importance, it was during the very period that England turned into the world's most impressive and most extravagant nations by administering a fourth of the total populace consequently having the biggest realm. Likewise, the interest for products like food, garments, and lodging expanded considerably as an outcome of the expansion in populace from 16 million to 37 million.

The two significant explanations behind the equivalent were: richness rate which was because of the superior way of life of individuals because of which the quantity of ladies who might have kids expanded while death rate brought down as there was no pestilence and furthermore on the grounds that the wellbeing offices improved.

Attributes of the Victorian time

England becomes industrialized

One more Victorian time trademark was the industrialisation of Britain.

Various production lines spread up prompting huge enhancements in the living as well as working guidelines of individuals. This additionally brought about the rise of different towns. Rail lines were built which supplanted the conventional pony drawn carriages as a method of transport.

Aside from this, a ton of logical innovations occurred like the phone, the radio, rail lines, sewing machines and so forth were concocted.

Victorian Era trademark - modern age

Development: Work started on the extension in 1836 under the oversight of Isambard Kingdom Brunel

Victorian Era attributes: Architecture, craftsmanship, and culture

Culture, as well as design, thrived during this period. The Gothic Revival engineering was important bringing about the conflict among Gothic and traditional standards. Furthermore, in 1851, the Great Exhibition which showed the best developments of the nineteenth century was additionally coordinated which was the first of its sort.

Photography likewise arose during this period, the primary photo being that of Queen Victoria herself. She turned into the main ruler to be shot. Posthumous photography was one more key element of the Victorian age.

1 note

·

View note

Text

Sometimes I think about the very human necessary work that gets left out of a lot of sci-fi just because... well, it goes unconsidered, beyond the usual realm of what the creators of games/movies (and often but not always books) have experience in or close connection to... and it feels like it goes assumed it can be ‘optimized’ out of necessity once we get Advanced Enough to Print Anything or what have you.

but like... until people are practically no longer people, we simply can’t optimize our way out of certain jobs. Robots simply aren’t and can’t be optimized enough to do the work. Sewing is one example*; we literally can’t ‘robot’ the fashion business (and not just bc it’s a nightmare for labor rights and fast fashion is a blight), but because the work is so fine-tuned to humanity, to countless tiny decisions made with infinite levels of craft and deft handwork, and it’s simply not replicable by robots until literally the point of robot sentience - and deftness of hand. And machinists - there’s a reason we don’t just 3D print all our metalwork and fine fiddly bits despite how much better its gotten. It goes a ways, sure, but machinists are craftspeople and its an art, knowing the machines and their needs and countless details about environment, wear and tear, necessity, human error, and more.***

Countless trade jobs, in general; anything that isn’t number crunching, anything that requires judgement and humans and their ability to work with context.****

(There’s a reason that despite corporations’ best efforts and wishes, they simply can’t robot their entire workforce - at best they can get a ton of machines that eliminate ‘some’ humans, ‘grunt work’ humans - who still deserve respect and a living wage dammit - but those machines still require human operation.)

(.... Don’t get me started on the problems & horrors in arguing that you’ll create ‘better’ jobs with turning crafts and trades people into machine operators....)

... but a lot of sci-fi sort of accidentally sterilizes the messy humanity (or other sentient species) of our endlessly layered systems of existence. Besides the occasional ‘is replicator food Real Enough??’ debate or ‘how True/Good are holo-sims’ and so on, man, we just don’t see a lot of that - even in ones that have the ‘oh no we exported Capitalism into our Space Dystopia’ angle.

Maybe that’s why I love Space Engineers so much. It’s kinda the closest we get to acknowledging the sentient person element of it all on a level lower than military/strategy/researcher, etc. People elbow deep in their space ships, keeping exponentially complicated spacecraft going, the only thing between you and the cold vacuum of space. Even in stories not focused on that element, there’s a common thread of acknowledging that there is something to maintaining -crafts, be they space- or otherwise, that transcends programming and robots and just has to be done with your hands.

-------

* There’s a short Wired article if you’re interested on Why Robots Can’t Sew Your T-Shirt, and while I remain horrified by the lack of critical thought or challenge put to the start-ups attempting to make these robots/machines**, it does a solid job of describing the ‘tech’ where its at - and why its so complicated. To whit, there’s too many variables, and the skilled people who make our clothes, however underpaid, can’t simply ‘be replaced’ (you capitalist jerks)

** if you’re interested in more thoughtful breakdowns of people in the fashion industry, especially non-mass-produced fashion - more ethical/well-sourced/etc - I definitely recommend looking into it. If you’re interested, there’s a great example of how sewing can’t be so simply boiled down to fancy machinework in the topic of lace (and lingerie) here - yes this is a site called Lingerie Addict, no it is not kinky/etc lol. Fascinating insight into just the one topic, how even with machine made lace the machines have to be set and threaded by hand because the threading requires so much care and experience to handle and ensure quality of.

*** Hell, did you know there are seven types of machinist certifications (in the USA alone)??

**** Artists and fine craftsmen are one example, but what about farmers and ranchers? Drivers and delivery workers, especially in remote areas? Locksmiths? Electricians & plumbers? Cleaners/janitors?***** Road maintenance workers? Massage therapists & physical wellness professionals? Gardeners? Public sanitation workers?

***** Unless you want to be living in a powerwashable, largely featureless/bolted down cube the rest of your sci-fi life, I’m afraid human/sentient judgement about What Can Be Cleaned How Intensely How Often and With What While Putting The Valuables and Fragiles Where, robots aren’t doing much more than vacuuming and windows and the like.

#sci fi thoughts#oops late night workers rights and representation thoughts#lethalhoopla muses about things

178 notes

·

View notes

Photo

‘Mask’

I just finished my entry for the 2021 Foundations Revealed costume competition and got it entered a few hours before the deadline. Whew. It’s been... a long week.

I came across a poem, ‘Mask’ by Beth Bachmann and had the sudden idea... “Hey, that costume competition was for a literature character this year, wasn’t it? I wonder when that ends...” 11 days. It ended in 11 days. And with the business still shut down and me in isolation, I decided... why not? What else am I REALLY going to DO with the next 11 days anyhow? Could a mask count as a character? Here’s to hoping it does!

I made a mask from the pattern by @mctreeleth and also a jacket pieced from the giant pile of cabbage left after making over a thousand face masks while in quarantine.

I started by pulling a pattern off my husband’s old patched 4XLT work shirt that has become my favorite house coat during the pandemic, so I had a fairly simple pattern to make out of the fabric I was going to piece.

My original plan was to have an ombre effect on the jacket, light at the shoulders to dark at the hem. When I started laying out the pieces, it ended up also having a rainbowy effect from reds on the left to blues and purples on the right. It took about two days to sort and cut all the pieces of fabric from the mask scraps - the largest is 4″x 5″, and I drew the line at the smallest being 2″x 2″. When I wasn’t sure in what order to put the brighter colors in terms of going from light to dark, I pulled out my phone and used it as a tool to look at them in greyscale mode, and went with what order they looked like they should go when the color wasn’t involved.

I pieced each panel over top of the pattern piece it was going to be on, and added a little extra for wiggle room, then thread traced each piece onto the panel, stay-stitched just under 1/4″ from the edge, and cut. I bagged out the bottom hem as I flat-lined each piece to stash fabric that had been too loosely woven for masks, but was perfect for lining fabric. I then joined everything together with french seams and boom - quilted patchwork jacket.

Making the mask took longer than I expected. Based on the amount of Bridgerton and Fate: The Winx Saga that played in the background while I was working, it took about 14 hours from start to finish.

Printing the mask pattern onto interfacing was brilliant - although trying the DIY scotch tape/interfacing trick didn’t go so well. The time it took me to unjam the printer isn’t part of the 14 hours. I did manage to print it onto a 8-1/2 x 11 commercial poplin meant for printing your own photos onto fabric to put into craft projects - then I added Heat ‘N’ Bond onto the backs before cutting out the pieces. That went wonderfully and made the mask pretty sturdy once it was finished.

For the most part, I followed the instructions that were with the pattern - but I did end up making a few changes:

I didn’t bother to top-stitch the bottom center seam. There’s no way to go all the way to the tip of the beak by machine, and nobody’s going to be looking at the bottom of the mask much anyhow. I just pressed the seam open very well on a sleeve board.

I didn’t add a fabric face strap - instead, I put two eyelets at the top and bottom of piece #10 after I was done and ran a lanyard through them with a cord lock, which worked very well.

On the round eye pieces, I edge stitched a line on the inside after flipping the lining around to the back side to keep everything smooth and in place.

Rather than folding the edge of the large circle down and pinning a ton of tiny pleats in place, I ran a line of small gathering stitches around the edge of the larger piece and used it like a drawstring to pull the large circle to the back side of the eye pieces and hold it in place. I ironed it well, and ran the gathering strings through the eyehole to the inside of the mask. I didn’t cut them off until after I had the eye pieces stitched down onto the mask. (I wish I’d taken a picture of this step, because it’s a lot quicker than the pinning - alas, it was 2 am and I didn’t think to.)

I didn’t slip stitch the eye pieces down onto the front of the mask. I pinned them in place, with pins situated kind of like spokes on a wheel. I edge stitched the eye pieces onto the mask by machine, walking the machine over each pin by hand. (Note - I was using an industrial sewing machine that handles thick fabric just fine and has a much heavier foot pressure than most home machines, so that probably helped this turn out well.)

If I were making this again, I would attach the bias for the eye holes from the front and fold it around to the back instead of the other way around - just for an aesthetic factor. It was a lot easier to make the final line on the bias look clean - which, sadly, will never be seen inside the eyepiece. The line around the bias inside the mask is the one part of mine that looks a bit messy.

Over-sized round “John Lennon” Sunglasses worked perfectly for lenses on this. After a while, they do fog up - I’m betting that wipes meant to keep the inside of goggles from fogging up will probably fix this.

I paired the jacket and mask with my pre-quarantine garb skirts and leather hat (shaped much like the quintessential illustration of a plague doctor), a shirt from my closet, and a cotton duck corset I had already finished as an experiment in color (Each external faux bone casing is in a different color radiating around half of the corset.) and also as an experiment in edge shaping - I made the corset extra-long, and then hand drew scallops around the bottom of the corset - not quite deep enough to count as tabs. I wanted to see if the bones were enough to keep these down and flat on the corset, or were they long enough they would flip up when worn? (Spoiler: They actually sit flat - yeay!)

Also learned on this project - when your husband is taking the photographs, and he is much taller than you, every picture that isn’t of your back will end up being a boob shot. XD

1K notes

·

View notes

Note

hey what do you use for organizing your sewing stuff? ive been getting into it bc the clothes i wanna wear are expensive and im having a hard time keeping my space clean and organizing my projects. thanks for the help in advance!

I mostly utilize stacking bins and my wall space for as much stuff as possible.

Those spool racks are available at Joann Fabrics (use a coupon tho) and Amazon. They have hardware on the back to hang them up with nails or command tabs (use wire hook command tabs though, like these. The plastic hook ones aren't shaped right to fit in the hanging hardware). You can also use those command tabs to hang other things to keep them out of your way, like cutting mats, embroidery hoops, and rulers.

For stacking storage boxes, I bought this huge set from amazon but it's pricey and it's for 12 bins. If you have one nearby, Harbor Freight sells similar bins individually though they're a smidge smaller. Menards sells a variety of stacking bins but you have to purchase them in varying qtys, so check that on the listing before to buy any. I use bins to store medium sized things like zippers, elastic spools, velcro, boxes of buttons, bag of fabric clips, tailor's chalk, awls, bias tape, yarn, some cut fabric I'm putting off sewing, a bag of sewing machine feet, and my shipping scale.

You will inevitably end up with a bunch of bobbins if you aren't using plain bobbin thread so get a bobbin box. I used to use this one but outgrew it and upgraded to this one. Also for pins, I started keeping mine in a jewelry dish so I could pick them up easier. They came in a little snap-top box which was handy but it was hard for me to dig pins out of there. Something with more surface area was more helpful to me because it spread the pins out a bit. It's easier to spill them though lol. I have a bunch of fabric clips too but they're just dumped in a sandwich baggie. They came in a cute little tin but the tin didn't fit in my storage bins so I got rid of it.

Pens and cutting tools I store in some cute mugs. I also have a small basket sort of hidden in the lower right behind that ivy where I keep small things like extra needles and hardware. Everything is organized in there using portion control baggies (get them at a grocery store, amazon prices are awful). I like the "portion control" style because they're tall rather than wide so they fit into that basket nicely and are easy to flip through to find what I need. The wide snack size baggies just form a pile of stuff that's hard to root through.

If you buy patterns keep the bags and put the pattern pieces back inside when you're done with them. But if you're like me and you print patterns yourself a lot, get these oversized plastic envelopes to hold your pieces. They hold a lot and you don't have to fold your pattern pieces a ton to fit them inside. Folding printer paper too much really smashes it up so I prefer these huge envelopes over regular envelopes or folders. Also label your pattern pieces if you're printing them off or making them by hand on paper!! I have sooo many mystery pattern parts right now because I'm dumb and didn't label anything...

If you plan on hoarding fabric, I recommend getting a plastic storage tub to keep everything safe from dust and pet hair. A storage tub also makes it easy to move the fabric around and it's stackable. I keep a small pile of fabric beside my desk on that shelf but everything I don't plan on using soon is in a storage bin in my closet.

This is totally unreasonable to expect of anyone, but I also put a huge industrial shelf in my office to hold all my crafting tools and bulky materials (like rolls of batting, big pieces of leather, and faux fur) lol. But I have like a knitting machine, tufting gun, soldering tools, etc. I also needed to store so I was desperate for a place for it all. A small version of this shelf (like this one) may come in handy if you need more storage space but can't put a 7 foot shelf in your room. Wall mounted shelves are also an option (my wobbuffets are on one of these, brackets sold separately) but it's kind of a pain to anchor stuff into walls safely.

Other than that, to maximize space I use a tabletop ironing board because it's small and easy to store out of the way. I originally got this when I had an apartment and didn't have room for a full size ironing board but it came in handy now that I'm doing all my sewing in my office! Also for space management: if you need a light I recommend a clamp desk light. They're handy because you can bring the light to wherever you need it but the lamp takes up maybe 2 square inches of desk space so it's not wasting space.

13 notes

·

View notes

Text

Put in his Place

Here is a one-off of Bertrum and Nathan playing a prank on Joey. This is going to be really goofy.

After this, I’m doing the two-part Lacie x Abby story. That’ll be a lot more serious. So if this kind of thing isn’t your cup of tea, stay tuned!

—-

Bertrum’s visits to oversee the construction of Bendyland were rarely eventful. Lacie generally had everything under control, as she did now. Seeing all his men (and women) constructing the rides that he’d designed was like watching the coming together of a masterpiece, or the precise work of a machine.

“You there!” he boomed at one of his men, who turned to him, terrified. “Those bolts need to be tighter. Keep up like that and you’ll get someone killed!”

“O-okay, sir!” The young man replied. Bertrum smiled and nodded to let him know it was okay. And it was- Lacie would have caught the mistake.

Despite the client, coming out of retirement had not been a mistake.

“Oooh, Beertiee!” came a voice.

Oh, the client. Joey Drew. The young man turned to look at the unfolding scene, but immediately turned back to his work once he caught Bertrum’s glare. Bertrum took a deep breath, and turned to the most loathsome part of his job. “Yes, Mr. Drew?”

“A very important person is coming to the studio. I was just wondering if you could make it look... I don’t know... better in here? I mean, the air is just thick with sawdust, and the lighting conditions aren’t exactly the best... and maybe you could have at least a few rides up and going for tomorrow afternoon?”

Bertrum clenched his jaw, took a deep breath, and managed to answer this callow excuse for a business owner in a dignified manner. “Mr. Drew, in case you haven’t noticed, we’re in a warehouse. There is going to be sawdust everywhere no matter how often we sweep because people are cutting pieces of wood. The lighting conditions of the warehouse you rented are not in my control. As for getting the rides up and going, no, I cannot do that three months before our negotiated deadline. Do you understand?”

“Oh, but I thought you could do it. With all your experience and competence... I kind of thought I’d show it off to my good pal Mr. Arch! He’s coming for a tour tomorrow and I want to impress him. And I mean, what does it say if you can’t pull it off?”

Bertrum was unphased by Joey’s attempt at manipulation. “You do not judge a chef by how a meal looks when it is half-cooked. Wait, did you say ‘Mr. Arch?’” Nathan Arch supplied Bertrum with the steel for his rides, and Bertrum had met him a few times at business conventions and fancy parties and the like. They’d gotten along well enough.

Joey nodded.

“Trust me, Mr. Drew- Nathan knows what a construction site looks like. Because he’s a business man who has overseen a few of them in his lifetime. He won’t see this as a mess but as a well-functioning machine.”

The condesension Joey was used to, but he was stunned as soon as he heard the word, “Nathan” from Bertrum’s lips.

“Yes, Joey, we've met. Perhaps the three of us should do this little tour together.”

“Sounds like a great idea, Bertie! Meet me in my office at nine tomorrow!”

---

Joey was on cloud nine. Nathan had been letting Joey take him on these annual (well, aside from the ones Nathan missed, which was most of them) tours for a decade, and each time Joey had done his best to impress him. This year, he’d wanted to show Nathan some Bendyland attractions, but this was even better! What better way to show Nathan that he was in the big leagues than to have this tour alongside the industry legend he’d befriended. On his way to his office, Joey checked his suit and hair for the millionth time- which was really unnecessary, since he’d decided on black everything to avoid ink stains, but one couldn’t be too careful.

Joey opened his office door to find that Nathan and Bertrum were already there, sitting in chairs facing the door and smiling at him. Suddenly, Joey felt a lot less confident. And he should have- Berturm had been pleased to find out that Nathan thought of Joey as just as much of a try-hard nouveau-riche as he did, and they had made a plan to put him in his place.

“Nathan. Hi. I see you’re already acquainted with my business partner, Bertie. How was your flight from New Orleans?” In hindsight, the fact that Bertrum didn’t react to his nickname should have been the first sign.

“Wonderful. Joey, Bertrum and I were just talking about how you’ve bloomed as a businessman since he started working with you. He’s very proud. I never realized that you were real deal until now, but, well! I have to apologize. All this time I was refusing to treat you like a rich man. Are you ready to be treated like a rich man, Joey?”

Joey was stunned and ecstatic. He’d been vying for Nathan’s respect since they’d met, and he’d finally done it! “I- I- yes! Thank you for finally realizing how brilliant I am, Nathan, old buddy! Now, are you ready for a tour?”

“I am.”

With that, they went. Joey took Nathan on a tour of the animation department and showed off his fancy new technology, the toy department complete with waterfall, the plans for Bendyland (but not the dirty, dusty warehouse), and even snuck in a tour of the music department while Sammy was on lunch- he wasn’t about to let Nathan know that he let Sammy call shots on when he could visit his own music department! Today, he was to be large and in charge.

At fair amount of time into the tour, as the trio overlooked the toy department, Nathan spoke up. “It seems like your company is growing, Joey! When did you start investing in the steel wool of this place?”

There was a pause as Joey tried to figure out how to respond.

“Oh come on, Joey. Steel wool. The thing that all successful businessmen know about. The measurement by which other high-class men will know to judge your business’ future chances of success. When did you start investing in it?”

Joey’s face was beginning to flush with embarrassment as he looked into Bertrum and Nathan’s completely calm, understanding faces. “Um, I, started investing in it in 1936. Can we take a little detour, boys? My company is just doing so well that I think I should go order more steel wool right now. Nathan, how much would you suggest?”

“Hmm... about seventy or eighty tons should do it.”

“Great! Follow me.”

Joey led the two of them to the accounting and finance department and knocked on the door of their director of finance. The door opened to a weary-looking man who did not seem at all happy to see them.

“Grant- I’d like you to increase our stockpile of steel wool. Increase it to ninety tons!”

Grant nodded slowly, trying to work out how much that would cost. When one’s boss regularly asks you to account for items such as coffins and electric chairs, one learns not to ask unnecessary questions.

Bertrum, not wanting his financially precarious client to throw out so much money over a prank, shoved Joey aside and whispered something in Grant’s ear.

Whatever it was, it put a coy smile on Grant’s face. “Wow. Ninety tons of steel wool this year. Well, Joey, it sure is good to work under such a rich man, and with such a promising company.”

Joey beamed. Thank God Grant was playing along with him having bought it previously. But soon, he’d have that important status symbol, and respect amongst his peers.

The door closed, and (over the faint sound of snickering) Bertrum spoke up. “You know, Mr. Drew, steel wool isn’t just an item. It’s also in one’s personal style.”

“Oh? And how would you rate mine, Bertie?”

“Hmm... middling,” Nathan replied.

“Yes, ‘middling’ is a good word for it.”

Joey’s face fell. “Oh. Well, I was about to update my wardrobe. Maybe you could help me find something better?” God, he hated asking for help, but clearly he didn’t know much about being a rich man yet.

“We’d be pleased to!” Bertrum beamed, putting an arm around Joey’s shoulders. “It’s been so long since I had a young, inexperienced, callow little business boy under my wing!”

Given the circumstances, all Joey could do was smile and fantasize about rearranging Bertrum’s anatomy.

Soon, they were in a high-end tailor shop. “Just tell him what you want,” Nathan advised, “he’s a rich man, he’ll know what to do.”

Joey nodded and rang the bell on the front desk. The tailor, who had been at the other side of the room at his sewing machine, came right over.

“Hello, I’d like to buy an outfit that lets people know that my company has a lot of steel wool.”

The shopkeeper squinted at Joey like he was an alien.

“Why don’t we help you find the style he’s looking for while he takes his measurements?” Nathan suggested.

As soon as Joey getting his measurements in the changing room, Bertrum and Nathan explained the situation to the tailor, and by the time Joey came out, they’d selected the perfect outfit for him. It was a glittering silver suit with a purple tie. The light from an open window hit it and nearly blinded Joey.

“What... is that?” Joey asked, starting to wonder if he was being messed with.

“I believe we have found your new outfit,” Bertrum asserted, “the perfect embodiment of steel wool.”

“Cutting edge- in a few months, everyone will be wearing them, but you’ll be among the first,” Nathan added.

“No, it can’t be. I mean, you’re saying this, but the two of you are wearing plainly coloured stuff...”

“No, they’re right,” the shopkeeper interjected, “I’ve actually received many, many orders of these from wealthy business owners. In fact, this is the last one I have!”

Joey grumbled, but he put on the suit, which was stiff and uncomfortable and was shedding glitter into his hair and leaving a trail behind him. He paid the shopkeeper a sizable amount of money and left in a huff.

The shopkeeper stuck his head out the door. “Remember- we do exchanges, but no refunds!” he called.

The summer sun was beginning to dip below the horizon. Bertrum and and Nathan had talked about taking Joey to a party to be laughed at, but Bertrum had decided it would make it too obvious that this was a prank. And anyhow, they’d come up with a better idea.

“Well, Joey, I think I should be getting back to my hotel room. But, maybe you could come with me, and I could show you one more aspect of what it means to be higher class. It’s obvious that you could use the help.”

“I- fine. Whatever. I don’t care.”

“Wonderful idea,” Bertrum said, “and on the cab ride over, I could give you some pointers of my own.”

“Oh, and Joey? Step into the shade, please. It seems that that suit turns you into a blinding hazard when the sun is low.”

After a miserable cab trip listening to Bertrum ramble incoherently about things Joey barely understood and using terms he’d never heard of (which made Joey feel simultaneously even more like he knew nothing and even more like he was being toyed with), the trio pulled up to the hotel that Nathan was staying at. Once they were in Nathan’s hotel room, Nathan kicked off his shoes and socks and laid on the bed with his feet hanging off of it. Normally, Joey would have some sort of teasing quip for him, but he was feeling a little worn down and just wanted to get the rest of the visit over with.

“So, Joey, the last thing we’re going to teach you about acting like you’ve got it, is how to give a good foot massage.”

Joey flinched in disgust. Then, he stopped. “Actually, I think it’s time I taught the two of you a lesson- this one on storytelling. You see, there’s this thing called the suspension of disbelief- and you just broke it. There is no ‘steel wool,’ this suit is a crime against humanity, and there is no way that it’s custom for rich men rub each others’ feet.”

Nathan laughed, and Bertrum laughed with him, doubling over in laughter and using Nathan’s shoulder to steady him once he collected himself. “Mr. Drew, you do realize that the only way you could believe that is if no other rich man had ever offered you a foot massage, right?”

“Humiliating.”

“You really told on yourself there.”

Tears were forming in Joey’s eyes- which was ridiculous because he was still sure that this was fake. He also knew that surviving two plagues had left Bertrum a considerable germaphobe. “Alright then, Bertie, show me your technique! Show me how a rich man does it!” he took off his shoes and threw them one at a time into Nathan’s arms.

“Okay, okay, we were joking!” Bertrum admitted before Joey could remove any more clothing.

“But... I think we made our point.”

“What point could you have possibly made except that you’re a bunch of assholes?!” Joey yelled.

“That compared to us, you’re new. We know it, you know it, stop trying to convince us or yourself otherwise. You wouldn’t have fallen for any of that unless some part of you realized that we know better than you on some things. And disrespecting Mr. Piedmont isn’t going to change that.”

Anger built up in Joey’s chest. He screamed in rage, punched a wall, and left, slamming the door on his way out. Then, less than a minute later, he knocked on the door. Bertrum opened it.

“Uh, could I use the phone? I need to call my accountant so he won’t buy dozens of tons of cleaning supplies.”

“Oh, we explained it to him. He won’t be ordering a thing. See you at our next weekly meeting.”

Without another word, Joey left. He could never look Bertrum or Nathan straight in the eye again.

18 notes

·

View notes

Text

@thatotherginger said: what machine do you have? I’m…quarantine dream shopping rn bc my machine is driving me nuts

i have a janome skyline s9 (that was a gift from my mother and grandmother ♥♥♥ which i found on a 45% off sale...) through i understand if that’s a bit more then you were looking for;;;

i would still recommend a janome sewing machine model if you are on the look out for a new one

mine is a quilting/embroidery machine combo the interface is straightforward and intuitive with a lot of options and detailed control of your project for all sorts of sewing and even options if a foot paddle is not easy for you to use

it has a lot of options that are handy, it can detect if your thread rips and stops on that stitch (this option is hit and miss sometimes but if it does catch it its really helpful) it lets you know if the bobbin is running low (you can adjust this option!) so you don’t start on some embroidery only to run out half way

you can also design your own embroidery stitches (and store up to 40 of them at a time on the sewing machine it self)

it came with some of the biggest embroidery hoops that were commercially available when i bought it

now the drawbacks (none of which i find especially abhorrent but should be kept in mind if you are considering it) the sewing foot is wider then average! this is to allow for all sorts of embroidery but that means most machine feet will not fit it, fortunately it comes with a ton by default.

its top speed is a bit slow (it’s mainly an embroidery/decorative stitching machine so it needs to go slower to do those things) certainly no industrial speed here

it’s a digital sewing machine so sometimes it’s “too smart” and you can’t really brute force some things, and it’s not especially good at doing tiny doll sized buttonholes close to an edge (i am talking less then 5 mm here; a really fine nit pick lol) you need to get creative to get it to work

12 notes

·

View notes

Text

Are Woven Polypropylene Bags Waterproof?

Are pp woven bags waterproof? As far as the woven bag itself is concerned, because the woven bag is made of warp and weft tapes, there is only overlap between the tapes, which does not have sealing property. Therefore, the liquid will be left through the gap between the tapes, so the woven bag itself is not waterproof.

However, due to the special requirements of chemical industry, cement, chemical fertilizer, sugar and other industries for packaging, a considerable number of plastic woven bags must have the function of waterproof and sealing. At present, there are mainly two types of waterproof and sealed woven bags produced and applied in the market: one is the ordinary separate combined packaging bag with outer woven bag and inside liner inserted or stitched bag. The other is the composite woven bag coated with a layer of plastic film on the PP woven cloth, which will include two types also, either polypropylene coated woven bag or pp woven laminated bag.

The production equipment and process of the first kind of separated inner lining membrane woven bag are relatively simple, the equipment investment is low, and the application is very wide. The inner and outer bags are separated. The inner bag is blown film bag, which can be divided into LDPE and HDPE. The outer bag is ordinary PP woven bag, and the length and width of the inner bag are slightly larger than the outer bag. When loading materials, the inner and outer bags are uneven and easy to be damaged. In the early years, the inner and outer bags of the inner lining membrane bag and the outer bag need to be set together manually, and the inner and outer bags at the mouth of the bag need to be aligned and sewed, so the production efficiency is low, the waste of manpower is large, and the continuous and efficient production cannot be carried out. A skilled operator can only complete about 1000 bags by hand every day, and only about 300 bags can be sewn by hinge sewing machine every day. Nowadays, with the improvement of all-in-one machine, there are many machinery manufacturers in China that can produce all-in-one machines for bag cutting, sewing and lining. The technology has been widely used and tends to be mature, greatly improving the production efficiency.

Another kind of Coated plastic woven bag production must go through the coating process, using the extrusion coating machine to coat a layer of plastic film with a thickness of about 0.02 ~ 0.04mm on the outside of the woven pp cloth. Or at the same time, to use the coating material as the bonding medium, and then composite a layer of BOPP film on the surface, can achieve better waterproof effect, it was named BOPP pp woven laminated bag. When doing coating, the temperature of the extruded film is about 300 ℃, and the newly extruded film is combined with the braid by a pair of cooling rollers. However, such high temperature reduces the strength of the cloth surface, reduces the elasticity, increases the brittleness of the bag surface, and makes the bag easier to be damaged in the falling tests.

WHAT IS ARE VALVE BAGS?

Valve bags are packaging bags filled by machines. They come in plastic or paper. Here at Western Packaging, we are a wholesale manufacturer who offers the paper version, with many options. The three main things to consider are size, closure type, and coatings.

CHOOSE THE RIGHT SIZE

Paper valve bags come in a large range of sizes. We offer small to very large paper valve bags and multiple sizes in between. It is important to verify which sizes your valve bag machine handles.

DETERMINE WHICH TYPE OF CLOSURE YOU NEED

Once the size is determined, the type of closure is determined. All valve bags are automatically closed. The specific method of how this closing happens falls into three categories.

1. SELF- SEALING

The first and most common is self-sealing. These valve bags use the pressure of the contents to close and seal the bag.

2. HEAT SEALED

Alternatively, some bags can be sealed by heat. This may be a better option for the product and requires a machine and set up capable of this method.

3. ULTRASONIC SEALS

The third type of closure is much less common. Bags can be sealed ultrasonically. These valve bags are only used in very specific and limited industries. They require clean and sterile environments and very special machinery.

WHICH COATING IS BEST

Once the size and type of closure are decided, coatings in and on the bags is decided. The options are extensive. Western Packaging offers all the most common, and some uncommon, coatings available. The specific coating(s) depends on the product and the package’s method of storage, shipment, and display.

There is a large variety of coatings available. The coating options vary based on if the coating is going to be placed on the inside or outside of the bag. Some products may benefit from a coating on both.

THE DIFFERENCE BETWEEN INSIDE COATS

The inside coating is most important when the product contained in the bag is food or non-food products. In these situations, a food-safe coating must be applied to the inside of the bag. This coating helps ensure the contents remain safe for consumption, and also maintains the freshness. Interior coatings also help minimize moisture entering the product and/or keep the product from seeping out. These are very important features for many products.

Some outside coatings provide the same or similar benefits. Coatings can be applied to block moisture, block contamination of the interior from the outside, or make the bag easier to handle. While protection of the contents of the packaging is most important, ease of storage is also important. Outside coatings can be used to minimize friction when bags rub together and therefore help to minimize bag damage and loss of product. A simple coating can also help the filled bag maintain its shape.

THE BENEFITS OF VALVE BAGS

Valve bagging is when a bag is filled using a specialized machine. The machine uses a spout placed in or near the opening of the bag. A measured amount is placed in each bag. This can be done in a fully automated or semi-automated manner. This ensures consistency in quantity and minimizes lost product.

The benefits of these machines are numerous and span multiple industries. The biggest benefit is the volume of bags that can be filled and closed per hour. The output is significantly higher than if done by an employee. This increase in output translates to higher profit by filling orders more quickly. Businesses converting to this method often find the cost of the machine is quickly covered and a return on investment is recognized very soon.

Plastic, Paper or Cotton: Which Shopping Bag is Best?

Plastic bags

Plastic bags were invented in 1967, but only became widely used in stores in the 1970s. The most commonly found thin plastic shopping bag given out at cash registers are usually made of high-density polyethylene (HDPE), but some are made of low-density polyethylene plastic (LDPE).

The energy embodied in plastic bags comes initially from the mining of the raw materials needed to make them—natural gas and petroleum—whose extraction requires a lot of energy. The raw materials must then be refined, which requires yet more energy. Once at a processing facility, the raw materials are treated and undergo polymerization to create the building blocks of plastic. These tiny granules of polyethylene resin can be mixed with recycled polyethylene chips. They are then transported by truck, train or ship to facilities where, under high heat, an extruder shapes the plastic into a thin film. The film is flattened, then cut into pieces. Next, it is sent to manufacturers to be made into bags. The plastic bags are then packaged and transported around the world to vendors. While polyethylene can be reprocessed and used to make new plastic bags, most plastic bags are only used once or twice before they end up being incinerated or discarded in landfills. The Wall Street Journal estimated that Americans use and dispose of 100 billion plastic bags each year; and the EPA found that less than five percent are recycled.

A 2014 study done for the Progressive Bag Alliance, which represents the U.S. plastic bag manufacturing and recycling industry, compared grocery bags made from polyethylene (HDPE), compostable plastic, and paper with 30 percent recycled fibers. It found that the HDPE bags ultimately used less fuel and water, and produced less greenhouse gas gases, acid rain emissions, and solid waste than the other two. The study, which did not consider litter, was peer-reviewed by Michael Overcash, then a professor of chemical engineering at North Carolina State University. Because the carrying capacity of a plastic and a paper bag are not the same, the study used the carrying capacity of 1,000 paper bags as its baseline and compared their impacts to the impacts of 1,500 plastic bags. The plastic bags used 14.9kg of fossil fuels for manufacturing compared to 23.2kg for paper bags. Plastic bags produced 7kg of municipal solid waste compared to 33.9kg for paper, and greenhouse gas emissions were equivalent to 0.04 tons of CO2 compared to paper’s 0.08 tons. Plastic bags used 58 gallons of fresh water, while paper used 1,004 gallons. Energy use totaled 763 megajoules for plastic, and 2,622 megajoules for paper.

Sulfur dioxide, a type of sulfur oxide, and nitrogen oxide emitted from coal-fired power plants that produce the energy for processing bags contribute to acid rain. The plastic bag produced 50.5 grams of sulfur oxides compared to 579 grams for the paper bag; and 45.4 grams of nitrogen oxides, compared to 264 grams for paper.

A 2011 U.K. study compared bags made of HDPE, LDPE, non-woven polypropylene, a biopolymer made from a starch polyester, paper and cotton. It assessed the impacts in nine categories: global warming potential, depletion of resources such as fossil fuels, acidification, eutrophication, human toxicity, fresh water toxicity, marine toxicity, terrestrial toxicity and smog creation. It found that HDPE bags had the lowest environmental impacts of the lightweight bags in eight of the nine categories because it was the lightest bag of the group.

Paper bags

Paper bags are made from a renewable resource and are biodegradable. In the U.S., over 10 billion paper bags are consumed each year, requiring the felling of 14 million trees.

Once the trees are cut down, the logs are moved to a mill where they can wait up to three years until they dry out. Once ready, bark is stripped off and the wood is chipped into one-inch cubes that are subjected to high heat and pressure. They are then mixed with limestone and sulfurous acid until the combination becomes pulp. The pulp is washed with fresh water and bleach then pressed into paper, which is cut, printed, packaged and shipped. As a result of the heavy use of toxic chemicals in the process, paper is responsible for 70 times more air pollution and 50 times more water pollution than plastic bag production according to a Washington Post analysis, resulting in more toxicity to humans and the environment than HDPE bags. And while 66 percent of paper and paperboard are recycled, the recycling process requires additional chemicals to remove the ink and return the paper to pulp, which can add to paper’s environmental impact.

Cotton totes

Cotton bags are made from a renewable resource and are biodegradable. They are also strong and durable so they can be reused multiple times.

Cotton first needs to be harvested, then cotton bolls go through the ginning process, which separates the cotton from stems and leaves. Only 33 percent of the harvested cotton is usable. The cotton is then baled and shipped to cotton mills to be fluffed up, cleaned, flattened and spun. The cotton threads are woven into fabric, which then undergoes a chemical washing process and bleaching, after which it can also be dyed and printed. Spinning, weaving and other manufacturing processes are energy intensive. Washing, bleaching, dyeing, printing and other processes use large amounts of water and electricity.

1 note

·

View note

Text

Ditch the Hot Glue Gun

You have no idea how irritated I get when I click on a crafting video or scroll on Instagram for craft ideas and run into people making anything imaginable with a hot glue gun. It is incredibly annoying, and let me tell you all why.

There are articles from many eco blogs stating that hot glue is eco friendly. While it does not release many toxins and does not use much energy, this does not mean that it can’t cause some serious issues. Even if we ignore the small strands of plastic that get all over the place.

What I am talking about is the massive amount of waste caused by this cheap and amatuer toy. It sucks when it comes to most projects, and sucks even when used as a glue.

Many videos showcase the use of a hot glue gun to mend and create costumes, clothing, holiday decorations, etc. I have even seen a video where someone hot glued the straps on a “no sew“ tote bag.

A great alternative for using tis glue to fix seams and patch jeans, is called sewing. It is easy to do, and it will not break off within 2 or 3 days, or one trip in the washing machine. Do not use hot glue for fabric crafts.

For most else, consider a more industrial glue, like e6000. It lasts a ton longer, is easy to apply, and anything you make with it is bound to last for years. That way, you are not tossing out tons of handmade decorations over the holidays, which is probably made of mostly plastic, because you used a hot glue gun, and it fell apart before the holiday was even over.

Hot glue might not be itself an eco hazard, but when tons of otherwise cheaply made items, mostly made from plastic, are being tossed in the trash, the America art of hot gluing EVERYTHING becomes extremely unsustainable, and very bad for the environment.

So PLEASE ditch the hot glue gun and make some crafts that are made to last for years, not for days.

***

If you like what I write, consider buying from:

My Etsy shop for upcycled bags, jewelry, and crafting supplies.

Or

My poshmark for reclaimed clothing.

#hot glue#hot glue gun#climate change#climate emergency#right to repair#eco friendly#sustainability#going green#climate crisis#plastic crisis#ocean plastic

87 notes

·

View notes