#types of admixtures

Explore tagged Tumblr posts

Text

Meteor showers shed light on where comets formed in the early solar system

An international team of 45 researchers studying meteor showers has found that not all comets crumble the same way when they approach the Sun

An international team of 45 researchers studying meteor showers has found that not all comets crumble the same way when they approach the Sun. In a paper published in the journal Icarus this week, they ascribe the differences to the conditions in the protoplanetary disk where comets formed 4.5 billion years ago.

“The meteoroids we see as meteors in the night sky are the size of small pebbles,” said lead author and SETI Institute and NASA Ames meteor astronomer Peter Jenniskens. “They are, in fact, the same size as the pebbles that collapsed into comets during the formation of our solar system.”

As our solar system formed, tiny particles in the disk around the young Sun gradually grew larger until they became the size of small pebbles.

“Once pebbles grow large enough to no longer travel along with the gas, they are destroyed by mutual collisions before they can grow much bigger,” said NASA Ames planetary scientist and co-author Paul Estrada. “Comets and primitive asteroids instead were formed when clouds of these pebbles locally collapsed into kilometer-sized and larger bodies.” /p>

Fast forward 4.5 billion years: when comets approach the Sun today, they crumble into smaller pieces called meteoroids. Those meteoroids co-orbit with the comet for a while and can later create meteor showers when they hit Earth’s atmosphere.

“We hypothesized that comets crumble into the sizes of the pebbles they are made of,” said Jenniskens. “In that case, the size distribution and the physical and chemical properties of young meteoroid streams still contain information about the conditions in the protoplanetary disk during this collapse.”

Jenniskens and his team of professional and amateur astronomers use special low-light video cameras in networks all over the world to track meteors in a NASA-sponsored project called “CAMS” – or Cameras for Allsky Meteor Surveillance (http://cams.seti.org).

“These cameras measure the meteoroids’ paths, how high they are when they first light up, and how they slow down in Earth’s atmosphere,” said Jenniskens. “Specialized cameras measured the composition of some of these meteoroids.”

The team studied 47 young meteor showers. Most are the crumbs of two types of comets: Jupiter-family comets from the Scattered Disk of the Kuiper Belt beyond Neptune and long-period comets from the Oort Cloud surrounding our solar system. Long-period comets move on much wider orbits than the Jupiter-family comets and are much more loosely held by the Sun’s gravity.

“We found that long-period (Oort Cloud) comets often crumble into sizes indicative of gentle accretion conditions,” said Jenniskens. “Their meteoroids have a low density. The meteoroid streams contain a fairly constant 4% of a type of solid meteoroids that were heated in the past and now only brighten deeper in Earth’s atmosphere and typically are poor in the element sodium.”

On the other hand, Jupiter-family comets usually crumble into smaller, denser meteoroids. They also have a higher 8% of solid materials on average and show more diversity in that content.

“We concluded that these Jupiter-family comets are composed of pebbles that had reached the point where fragmentation became important in their size evolution,” said Estrada. “The higher admixture of materials that were heated in the past are expected closer to the Sun.”

Primitive asteroids formed even closer to the Sun, although still outside the orbit of Jupiter. These asteroids produce meteor showers with even smaller particles, showing their pebble building blocks experienced even more aggressive fragmentation.

“While there are exceptions in both groups, the implication is that most long-period comets formed under more gentle particle growth conditions, possibly near the 30 AU edge of the Trans Neptunian Disk,” said Estrada. “Most Jupiter family comets formed closer to the Sun where pebbles reached or passed the fragmentation barrier, while primitive asteroids formed in the region where the cores of the giant planets formed.”

How is this possible? While the giant planets were growing, Neptune moved outward and scattered comets and asteroids out of the remaining protoplanetary disk. This outward movement likely created both the Scattered Disk of the Kuiper Belt and the Oort Cloud. That would predict that both long period and Jupiter-family comets have the same properties, but the team found otherwise.

“It is possible that stars and molecular clouds in the birth region of the Sun perturbed the wide orbits of Oort Cloud comets early on, and the long-period comets we see today were scattered into such orbits only at a time when the Sun had moved out of this region,” said Jenniskens. “In contrast, Jupiter-family comets have always been on shorter orbits and sample all objects scattered by Neptune on its way out.”

TOP IMAGE: Protoplanetary disk. Figure from a computer simulation visualizing the formation of planets Credit NASA/JPL-Caltech

LOWER IMAGE: Three phases in the evolution of the outer solar system. (A) At the time of pebble collapse into comets, pointing to the likely origin region of asteroids (AST), Jupiter-family comets (JFC) and long-period comets (LPC); (B) At the time when Neptune scattered comets into a Scattered Disk of the Kuiper Belt; (C) After the Sun had left the birth star cluster and a planet instability created the outer Oort Cloud. Credit Jenniskens et al. (2024) Icarus

15 notes

·

View notes

Text

In this final installment of the FEV-spawned creatures, the Pedant turns its eye to three comparatively conventional mutants: the Scorchbeast, the Hound, and the Radscorpion. While other species also exhibit signs of FEV exposure - the giant mantis, the gecko, etc - they are better dealt with under other headings. Read on below the cut!

SCORCHBEASTS

FIGURE 1: An artist's illustration of a typical Scorchbeast (first described by Pagliarulo et al, 2018) attack. Note the unnervingly hominid arrangement of the newly developed second limbs and enlargement of the rear legs.

The Scorchbeast is a mutant bat, but it is a most marked variety of mutant. It has transformed from a tetrapodal beast to a hexapodal one, increased in size by something on the order of a hundred-fold to a thousand-fold, and developed a symbiotic relationship with the disease-causing agent of Appalachian Ultracite-associated Petrification Disease. This presents a modest challenge for taxonomy. It is clear that the Scorchbeast is no longer a member of the tetrapodae clade, requiring membership in a hexapodal sister-order to the Chiroptera.

To that end, we nominate them as the type species of the hexmammalian Secundocheravolariera|radiomutandis order, Macrochiropteriformidae family, with the Genus and species binomial of: Macrochiropteriforme virginiapathogenitorus. Their niche and mythotaxa are in turn: Megalobattus apexus predatorus Pseudodraconus horribilis macrobattus evdomintaeksi

The defining characteristics of the species and Genus are the presence of six limbs, of which the two foremost are adapted for flight with the four remaining limbs enlarged and prominent; diurnal tendencies; eusocial organization; the loss of eyes in mature breeding queens; and a symbiotic relationship with the causative agent of Appalachian Ultracite-associated Petrification Disease, incertae sedis ultracitogenum. Presumably, other species of Macrochiropteriforme hexbats from the Earth of the Black Isles - if discovered - will possess most of these traits, though not the symbiosis with ultracitogenum.

Their exact relation to FEV remains ambiguous, but it offers the clearest explanation for the extraordinary transformation these creatures have undertaken. It is submitted that one of the two known Appalachian strains, combined with the unique properties of Ultracite, produced both Macrochiropteriforme virginiapathogenitorus and incertae sedis ultracitogenum, with the latter being a distinct mutant lineage of FEV. It is also not clear where the genetic interference that produced a simultaneous revision of the bodily plan towards a hominid form, though it is entirely plausible that this has involved the admixture of human genetics into the species.

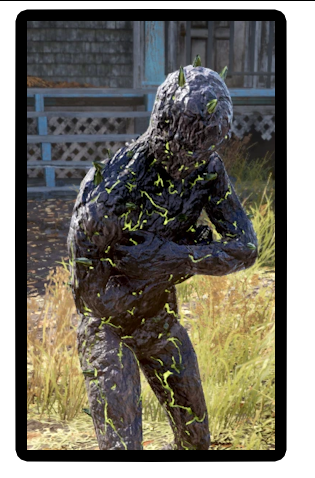

Though not a part of the Scorchbeasts themselves, the Scorched Plague also merits attention. This disease obeys none of the typical laws of disease from the mainline Anthropic Cluster worlds, and more closely resembles a wide variety of supernatural plagues. This plague produces rapid onset illness, delirium, and psychosis, followed by a lapse into membership in a kind of 'hive mind', progressive tissue necrosis and replacement by an ash-like substance, and most curiously, the progressive growth of radioactive crystals throughout bodily tissues. It is unknown whether the disease is best categorized as bacterial, viral, fungal, or as belonging to another category.

FIGURE 2: A petrified victim. Observe the replacement of all tissue with an ash-like composite of decayed flesh and what may be spores of the disease-causing agent.

Faced with a lack of meaningful information, we nominate the Scorched Plague as incertae sedis ultracitogenum, and for the present time refrain from identifying it formally as a deviant variant of FEV. Its mythotaxa is allocated as zombiformetipathy hivusmindus septaugintasixtus, and the condition it inflicts is nominated as Appalachian Ultracite-associated Petrification Disease. We briefly note that the petrification phenomenon is known to occur only in human beings, and find this suggestive in combination with the possibility that it is human genetics that contributed to the transformation of the legs of the Scorchbeasts that carry the causative agent.

HOUNDS

FIGURE 3: A typical Mutant Hound, first described by Pagliarulo et al, 2015.

The Mutant Hound is to the common dog as the Super Mutant is to the common human. Mutant hounds exhibit the same transformation as their homid masters and are known to arise only from the Appalachian and Boston strains of FEV. It is currently unknown whether they are sterile, though the lack of external genitalia is suggestive of either considerable reorganization of reproductive anatomy or near-complete atrophy of the same.

Relative to the original bodily form of a canine, the Mutant Hound exhibits comparatively minimal morphological alteration. While they possess additional dentition, the overall shape and arrangement of the skull is not markedly altered. No new digits are noted, dewclaws remain present, and sensory organs are as typical. Barring the total loss of fur and the muscular hypertrophy, they are otherwise little different from their Canis familiarus antecedents.

There is little more to be said. On the same basis that we have provided taxa to the Super Mutant, we nominate the Mutant Hound thus: Canis|radiomutans (robusta) muscularis Verticanis gargantocanis Monsteracanis anthropovorus mutandis

RADSCORPIONS

FIGURE 4: An artist's impression of the Capitoline Radscorpion, first described by Pagliarulo et al, 2008. [Adamowicz, circa 2005-2006.] Note the enlarged claws - typical of the Capitoline Radscorpion genus.

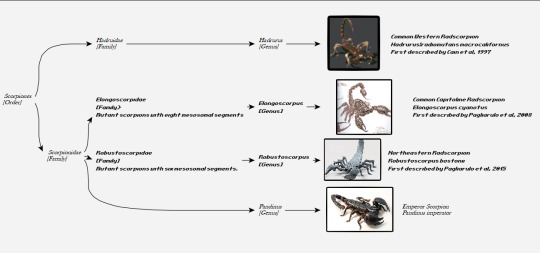

The common claim - that all Radscorpions are descendants of the common North American Emperor Scorpion - is poorly evidenced, and hindered by the absence of any such known species. It may be presumed that this is a post-war misnomer of the West African Emperor Scorpion, Pandinus imperator, which was a common pet species and among the largest Scorpions of the pre-war reality. But beyond this pedantic quibble (in which we, as proclaimed Universal Pedants, beg to be indulged), there are certain other peculiarities that prevent a clean nomination of the common Radscorpion as belonging to the species Pandinus imperator alongside its alleged precursor.

First, and most critically, the populations of Radscorpion so far observed are substantially divergent from one another. This suggests that even if all radscorpions properly-so-called share descent, they have subsequently speciated.

Second, several populations have been observed to be oviparous. This is in marked contrast to mainline anthropic earth populations, in which all known scorpions are ovovivparous - that is, they give live birth to offspring that hatch from eggs within their bodies, rather than laying eggs. In a further complication, there is anecdotal evidence of eusociality among Mojave populations, with 'Radscorpion queens' reported (though the extent to which they may be said to be eusocial is unclear.) In isolation, this evolution alone would suffice to mark the Radscorpion as highly distinct.

Third, all known populations exhibit marked morphological differences from Pandinus imperator. Hair is absent from the pedipalps and legs, and most populations exhibit atypical mesosomal segmentation (the North-Eastern population bearing 6, the Capitoline 8 segments, and the Western populations six in a less robust configuration than the North-Eastern.) The tail likewise exhibit morphological differences in different populations, and even the number and arrangement of eyes (10, 6, and an indeterminate number among the Western populations) is markedly distinct. They may or may not rely on book lungs - the altered physics of the Earth of the Black Isle renders the precise anatomical limitation of the book lung unclear.

The evidence is clear. The Radscorpions cannot constitute a single species, nor are they mere Pandinus specimens (marked by seven mesosomal segments and a five-segmented tail - a pattern not known among any Radscorpion populations.) As they satisfy all three limbs of the mutant test, there is both a clear need for, and no barrier to, identifying them as distinct species from both their alleged precursor and from one another.

It appears considerably more likely that the Western Radscorpions are members of the genus Hadrurus or the family Hadruridae, sharing a seven-segmented mesosoma and comparatively slender claws. Accordingly, we nominate them thus: Hadrurus|radiomutans macrocalifornus This species should not be confused with the Mojave Radscorpion, dealt with below, nor the Bark Scorpion.

The more robustly built Eastern specimens we propose as two distinct species, based on their distinct presentation of mesosomal segments, eye configuration, and shared large, powerful and muscular claws. The north-eastern population, having six largely fused mesosomal segments, we nominate as a type species of the novel family and genus Robustoscorpidae Robustoscorpus, as: Robustoscorpus bostonii.

A variety of differently pigmented subspecies are known, including bostonii subsp. sardonicus, the Deathskull scorpion, and the hyperpredatory bostonii subsp. carnopursuans. It has been suggested that remnant populations of Robustoscorpus bostonii in Appalachia represent the original breeding ground of this species, but this is unconfirmed.

The Capitoline population, bearing an additional segment - a neotonous adaptation from the usual embryonic developmental fusion of the eight segments into seven - we likewise nominate as type species of the Elongoscorpidae family, as: Elongoscorpus cyanotus

Sister populations have been observed as far West as the Mojave Desert, though they do not exhibit the aggressive burrowing behaviours of the Capitoline Radscorpion. The Temple is divided as to whether this population is a distinct species or merely a behaviourally distinct remnant population. The Mojave-native 'Bark Scorpion' is largely morphologically non-distinct from Elongoscorpus cyanotus, but is a distinct species marked by a less aggressive venom, a uniform sandy or bark-like pigmentation, and a considerably smaller size. It is accordingly nominated as subspecies cyanotus vittatusiformes.

FIGURE 5: A revised taxonomic tree of the Scorpions.

All radscorpions share the following niche and mythotaxa: Scorpus giganticus jumpscaricus Scorpionidae macroscorpo-irradiogenetum cainsii

+++

With that, we close out this entry. Next time - who knows? There are many universes to visit, and the Dragon taxonomy is long overdue.

#fantasy taxonomy#taxonomicon.fallout#fallout#fallout taxonomy#fallout 76#scorchbeasts#classic fallout#taxonomicon.mutants#radscorpions#taxonomicon.giant bats#taxonomicon.radscorpions#taxonomicon.diseases#taxonomicon.dogs

3 notes

·

View notes

Text

Scar “Good Times” Scardalph Aka Mr Landscape the magic man.

CR 20 N Humanoid

XP 307,200 (if used as npc for encounter)Half elf Alchemist 17 (Clone master) Rogue 3 (Charlatan)

Neutral (with chaotic tendencies) Medium humanoid, elf Init +4; Senses Perception +37

AC 36, touch 21, flat-footed 24 (+4 Dex, +7 Shield, +5 Deflection, +1 Intuition, +9 Armor) Hp 176 (20d8+83)

Fort +22, Ref +24, Will +16

Speed 30 ft. Melee Animate staff+16/11/6 1D6+2/1D6+2, +15/10/5 Poisoners gloves. Ranged Alchemist Atlatl+22/22/17/12 Bombs, Infusions.

Racial Elven immunities, Round ears, Elf blood, Multitalented(+3Hp +17 Skill points).

Traits Dyslexic, Incurable sickness, Hedge magician, Trade talk(Engineering).

Class features Bomb 9D4, Alchemy, Mutagen, Persistent mutagen, Throw anything, Poison resistance +4, Discoveries (Extend potion, Dilution, Combine extracts, Alchemical simulacrum, Doppelgänger simulacrum, Preserve organs, Explosive bombs, Enhance potions), Brew potions, Swift alchemy, Swift poisoning, Poison use, Natural born liar, Sneak attack +2d6, Evasion, Rogue talent(Rogue Finesse).

Str 12, Dex 18, Con 18, Int 28, Wis 18, Cha 12

Base Atk +14/9/4; CMB +15; CMD +29

Feats Smoke bombs, Cognatogen, Greater cognatogen, Point blank shot, Precise shot, Infusion, Precise bombs, Spontaneous healing, Promethean disciple, Fast bombs.

Skills Acrobatics+12, Appraise+17, Bluff+10, Climb +10, Craft(Alchemy)+30 (Redstone)+20 (Stone and metal)+32, Diplomacy +10, Disable device+27, Disguise +10, Escape artist+10, Fly +10, Heal+14, Intimidate +5,Knowledge (Arcana)+30 (Dungeoneering+32 (Local)+13 (Nature)+20, Linguistics+3, Perception+27, Perform(sing) +5, Profession(Engineer)+27, Sense motive+12, Spellcraft+32, Sleight of hand+12, Stealth+12, Survival+12, Swim+10, Use magic device+24.

Languages Common, Elf, Draconic, Aquan, Terran, Ignan, Undercommon, Alko.

Combat gear Mithral chainshirt+5 Impervious ghost touch, Ring of protection+5, Animated Darkwood shield+5 Impervious Arrow-catching, Ioun stones(Dusty rose prism, Lavender and green ellipsoid), Alchemical atlatl+4 of speed, Animate staff, 20 Alchemical bullets, Headband of mental prowess+6(INT, WIS, Dungeon), Belt of physical perfection+4, Cloak or resistance+5, Sipping jacket, Periapt of health, Sleeves of many garments, Poisoner’s gloves, Winged boots, Helm of comprehend languages and read magic(Shaped like a fancy top hat), Googles of brilliant light, Boro bead type VI and IV, Admixture vial, Campfire bead, Bag of holding type I, MWK wheelchair, Wand of protection from energy, Tome of clear thought+4(Used), Fancy dress, 200gp worth of alchemical materials, Alchemist kit, Alchemist lab, 200gp, 2 Alchemical golems(the first has a rune of shielding and it is dressed like a butler, the second is shaped like a spider can crawl on walls and can house a wheelchair), 12 Homunculi in Oompa Loompa attire.

Spellcasting CL20 DC19 formulae per day 8/7/7/6/6/3

VI-Heal, Twin form, Transmute golem.

V-Magic jar, Spell resistance, Polymorph, Ooze form, Monstrous physique III, Languid bomb admixture.

IV-Restoration, Stoneskin, Cure critical wounds, Freedom of movement, Dragon breath, Touch of slime.

III-Liquefy, Haste, Heroism, Cure serious wounds, Water breathing, Elemental aura, Displacement.

II-Vomit swarm, Protection from energy, Cure moderate wounds, Detect thoughts, Alchemical allocation, Barkskin, Lesser Restoration.

I-Cure light wounds, Bomber’s eye, Adhesive spittle, Detect secret doors, Ant haul, Crafter’s fortune, Firebelly, Reduce person.

Background Scar is a hilarious fellow from a far land known for his Hermits skilled in constructing magnificent structures and machineries that defies logic and reason. Despite being dyslexic, he is always in good mood and shares this good mood with the other Hermits. However, under this facade Scar is as his name suggest “Scarred” for he is afflicted by a muscular disease which is slowly taking over him. Despite everything, he smiles and keeps a happy demeanor to not bring worry to his fellow Hermits. One day as he woke up from a good night rest he started to choke and felt as if he was about to die but it passed away. A sense of dread took over almost overwhelming him… “Do you wish to be cured?” said a voice outside his bedroom door. Scar turned toward the door. “It is simple, do a mission for me and i will cure you. All you have to do is open the door accepting my request willingly. What say you little creature of flesh?” Scar thought if this was some kind of prank from his fellow Hermits but he knew no one would do something like this… nonetheless, the offer was too tempting and as he grabbed the knob he opened the door… and found himself in a different place… an old abandoned mansion. He was in a fancy dress with new equipment, knowledge and on a wheelchair. His legs where a bit shaky but he was capable of standing as he tried only to almost tumble down. But a mechanical arm reached form him, stabilizing his posture. A tall scrawny construct dressed like a butler with a jar for a head with fake mustaches helped him stand as other strange servants arrived… another large sized construct similar to a spider with a housing for his wheelchair and 12 small round brightly colored humanoids in outrageously colored attire. As soon as Scar regained his composure, they bowed to him in revered silence. “Your mission is simple… find the fragments of my lost daughter. Do it, and you shall receive gifts beyond your imagination. I will be watching.” Said the voice; Scar looked at the broken glass of the mansion and said: “Alrighty, first, let’s fix this place! We have work to do!” And he pulled up his wrists with a wide smile.

Spider Image from https://www.furaffinity.net/view/27494681/

Other images made with Hero forge.

#minecraft#roleplay game#pathfinder#hermitcraft#goodtimeswithscar#heroforge#pathfinder roleplaying game

8 notes

·

View notes

Text

Are Ashkenazi Jews white? Short answer, No!

Ashkenazi Jews may appear white, but are not. Some identify as white and some don't. Even many jewish news articles claim their not white.

But what do the facts say?

Ashkenazi Jews are a genetically and culturally Middle Eastern people, who only began to “integrate” into European society after the rise of Liberalism in the 17th or 18th Century. Their history in Europe has been full of conflict. Being continually massacred, and expelled from every single European country that they have ever inhabited. It was clear that white Europeans considered jews to be categorically separate race from them. (plus the Jews also considered themselves separate from white Europeans as well). Plus the overwhelming majority have distinctly non-European phenotypes that are obviously Middle Eastern in origin.

Plus, the claim that they're white, is not supported by scientific, genetic evidence.

Despite their long-term residence in different countries and isolation from one another, most Jewish populations were not significantly different from one another at the genetic level.

Admixture estimates suggested low levels of European Y-chromosome gene flow into Ashkenazi and Roman Jewish communities. Jewish and Middle Eastern non-Jewish populations were not statistically different. The results support the hypothesis that the paternal gene pools of Jewish communities from Europe, North Africa, and the Middle East descended from a common Middle Eastern ancestral population, and suggest that most Jewish communities have remained relatively isolated from neighboring non-Jewish communities during and after the Diaspora.”

The m values based on haplotypes Med and 1L were ~13% ± 10%, suggesting a rather small European contribution to the Ashkenazi paternal gene pool. When all haplotypes were included in the analysis, m increased to 23% ± 7%. This value was similar to the estimated Italian contribution to the Roman Jewish paternal gene pool.

About 80 Sephardim, 80 Ashkenazim and 100 Czechoslovaks were examined for the Yspecific RFLPs revealed by the probes p12f2 and p40a,f on TaqI DNA digests. The aim of the study was to investigate the origin of the Ashkenazi gene pool through the analysis of markers which, having an exclusively holoandric transmission, are useful to estimate paternal gene flow. The comparison of the two groups of Jews with each other and with Czechoslovaks (which have been taken as a representative source of foreign Y-chromosomes for Ashkenazim) shows a great similarity between Sephardim and Ashkenazim who are very different from Czechoslovaks. On the other hand both groups of Jews appear to be closely related to Lebanese. A preliminary evaluation suggests that the contribution of foreign males to the Ashkenazi gene pool has been very low (1 % or less per generation).

Jewish populations show a high level of genetic similarity to each other, clustering together in several types of analysis of population structure. These results support the view that the Jewish populations largely share a common Middle Eastern ancestry and that over their history they have undergone varying degrees of admixture with non-Jewish populations of European descent. We find that the Jewish populations show a high level of genetic similarity to each other, clustering together in several types of analysis of population structure. Further, Bayesian clustering, neighbor-joining trees, and multidimensional scaling place the Jewish populations as intermediate between the non-Jewish Middle Eastern and European populations. These results support the view that the Jewish populations largely share a common Middle Eastern ancestry and that over their history they have undergone varying degrees of admixture with non-Jewish populations of European descent.

A sample of 526 Y chromosomes representing six Middle Eastern populations (Ashkenazi, Sephardic, and Kurdish Jews from Israel; Muslim Kurds; Muslim Arabs from Israel and the Palestinian Authority Area; and Bedouin from the Negev) was analyzed for 13 binary polymorphisms and six microsatellite loci. The investigation of the genetic relationship among three Jewish communities revealed that Kurdish and Sephardic Jews were indistinguishable from one another, whereas both differed slightly, yet significantly, from Ashkenazi Jews. The differences among Ashkenazim may be a result of low-level gene flow from European populations and/or genetic drift during isolation.

Archaeologic and genetic data support that both Jews and Palestinians came from the ancient Canaanites, who extensively mixed with Egyptians, Mesopotamian and Anatolian peoples in ancient times. Thus, Palestinian-Jewish rivalry is based in cultural and religious, but not in genetic, differences.

One study 2010 study stated that Both Ashkenazi Jews and Sephardic jews share only 30% European DNA with the rest being of middle east decent. And by a recent 2020 study on remains from Bronze Age (over 3000 years ago) southern Levantine (Canaanite) populations suggests Ashkenazi Jews derive more than half of their ancestry from Bronze Age Levantine populations with the remaining 41% of their ancestry being European and 50% being Middle Eastern.

24 notes

·

View notes

Text

Hybrid Class Review: Investigator part 2

(art by Nezart on DeviantArt)

Utility and Builds

Now with the preamble out of the way, let’s get into the meat of what makes the investigator tick.

At their core, the investigator gets proficiency with light armor, simple weapons, and a collection of thematically-appropriate weapons revolving around more subtle and dexterous weaponry. They also get a nice selection of class skills and a heaping helping of ranks to put into them, making them a very skill-focused class to begin with.

They also start out learning alchemy the same way alchemists do, able to use it to identify potions and elixers, as well as brew extracts, though they do not gain bombs or mutagens. They use the same spell list as alchemists, though obviously the bomb admixture extracts won’t work for them normally since they don’t gain bombs.

Honestly, I dislike the addition of alchemy to the base investigator, as it seems a little too out of place and/or too much a reference to Sherlock Holmes’ drug habit, but maybe that’s me seeing things that aren’t there.

The biggest mechanic, however, that the investigator is known for is their pool of inspiration. This pool allows them to add an extra d6 to skill checks. They can do this with any skill, though they can do it for free with knowledge skills and linguistics as long as they’ve trained in them. Additionally, they can spend double the points to use them with attacks and saves as well.

Their keen perception also gives them the roguish ability to notice traps with ease and disable even the magical ones.

They also study lots of lore on poisons, not only being able to handle and utilize them safely, but able to identify them with ease and even neutralize them.

That practice comes with a lot of errors and tests in the lab, and as a result, much like alchemists, they develop increasing resistance to poison, and even immunity later on.

Much like alchemist discoveries and rogue talents, investigators get their own supply of talents. These talents range from adding nasty extra effects to their studied strike (more on that in a moment), adding a limited list of alchemist discoveries or rogue talents, improving the base die of their inspiration, letting them apply inspiration for free on more types of skills, making using inspiration for combat purposes more efficient, new ways to spend inspiration to bolster themselves or others, and so on, leading to a lot of customization.

Their skill and instincts with traps Also makes them good at dodging them.

Much like rogues, investigators have their own advantage in combat, though it functions differently. By studying an opponents every move, from the way they attack to the subtle ways they give away past injuries and weaknesses, giving them bonuses on their aim and the damage they deal. However, normally such a foe immediately learns to compensate once the studied state ends, making it impossible to do again until at least a day has passed, that is, unless the investigator expends some of their inspiration to compensate for their compensation.

However, they can also end this studied state with a bang, ending the state in return for dealing a singular crippling strike against their target, the damage of which only increases with time, and can apply to both lethal and nonlethal strikes alike.

Much like alchemists, they also learn to brew their alchemical items with exceptional speed.

Finally, the most brilliant and skilled of these investigators can use their inspiration for free on all skills and ability checks. What’s more, their inspiration rolls two dice instead of one, boosting them to even greater heights whether they are applying it to skills or combat.

Of course, investigators got alternate capstones in Chronicle of Legends, with the one specific to the investigator making them even more lethal when studying a foe.

Aside from that, some become pinnacles of mental and physical fitness with Perfect Body, Flawless Mind; become the heads of organizations with The Boss; acquire a legendary weapon or piece of equipment with With This Sword; or become a death-defying legend akin to the apparent death and later resurrection of Sherlock Holmes by Doyle with Won’t Stay Dead.

The investigator class is very much a skill monkey, and arguably one of the best ones thanks to them able to add an extra dice to their rolls, often for free, not to mention being able to roll on all knowledge skills even without training. You can be anything from a rambling chatterbox that gets others to let slip information, to a sneaky investigator that seems more like a thief despite gathering evidence instead of riches, and so on, leading to so many different builds.

Additionally, their combat gimmick is fun and rewards strategic play, gaining a lesser passive buff for a while before striking at the right moment with a devastating blow, which may be at the end of your strike or whenever it would be most useful to damage the foe right now or apply a debilitating effect.

And on top of that, they have alchemical extracts as well, providing plenty of buffs with some blasting and strange other effects. Despite my misgivings about them, the base investigator can do a lot with them, though it’s no surprise that the Second Edition version of the class treats the alchemy side of the original as an optional possibility.

All in all, whether you use then as actual detectives, brilliant scholars putting their knowledge to good use, or even military tacticians or masterminds, the investigator truly is a class all about putting their intelligence to good use without having to be a caster (mostly).

That will do for today, but as we’ll see tomorrow, archetypes only improve the variety of brilliance that these investigators can command.

15 notes

·

View notes

Text

a (naked and chest censored, she usually wears clothes!) ref of Neha doing her disney princess bit. these are tame birds actually and my mum thinks they should be official Animal Companions, but I don't think Neha is really the type for naming her pets. she just feeds all the birds indiscriminately, not playing favourites

beneath the cut is some information about keshiramarutikaa (her species) in general

The keshiramarutika live in the sea in the ocean realm next door to the morgwin. They have a stony skin (colonised by algae) and flesh somewhat like clay, which they scrape off to manufacture their children. This clay is given life with the admixture of their holy life-milk. They have only one sex. They live extremely long lives but do everything slowly, and breed very infrequently. This causes them to value life very highly and do everything possible to avoid war or other needless death, so their politics is very complex and near incomprehensible to outsiders.

Keshiramarutikah start with a single personality but as they grow they connect to more “Advisors”, whose spirits come from earlier times. These are seen as separate souls, but are subservient to the main personality and do not control the body, merely “advising” from the mind. These old souls don't remember everything from their previous existences, but the later in life an Advisor joins the “Council” the more they will remember. The keshiramarutikah periodically descend to the sea floor where they go into a suspended state (deep-slumber) and just grow, and during this period (and only then) a new soul may join them. They take longer and longer rests like this until they eventually turn fully to stone during one. These undersea resting places/graveyards are very holy to them.

11 notes

·

View notes

Text

0 notes

Note

The conversation about the whether Z will ever be in a movie that's "for the culture" is interesting. There's a lot to unpack there. In films, black woman characters are usually caricatures of a sort. And I would understand Z not wanting to be pigeonholed in a way. And taking it out of film, even in the black community there's an "acceptable" form of being black or a black girl/woman. Which Z already gets backlash on. Thoughts?

No, I definitely agree with you. I can see her not wanting to be pigeon-holed in certain roles that are made for black women by black creatives. But I won't say that ALL roles made for women by black creatives are necessarily "negative" either though.

Are there "acceptable" forms of being black in the black community? Yea, sure .... Sometimes there are. I have TWO black parents and even I have been told I'm not "black enough" before by other black people (which is completely ridiculous to me😒🙄).

So yea, I def think there's this totally rigid way in which black people (unfortunately) view each other, and sometimes it feels like you have to fit into this neat little "black box" and fit certain criteria, otherwise, you're just "not black enough". 😒 It's exhausting, and honestly a bit insulting. 🥴

Then, there's also the flipside as well though, because by Hollywood's standards, Zendaya is also the "acceptable" form of a "black woman" who will be garnered certain roles due to the her looks, her hair texture, etc. And it's not just in the black community that this happens. They do it to Asian men as well, Latina women, etc. If you have some white "admixture", you're acceptable for a certain type of film/role in Hollywood.

15 notes

·

View notes

Text

Steel Reinforcement Inhibitors: Protecting Concrete for the Long Haul

Steel-corrosion inhibitors significantly boost the durability and service life of concrete structures. Because reinforced concrete supports nearly all contemporary building projects-bridges, office towers, highways, even seawalls-its performance is vital. Yet when moisture, chlorides, or carbon dioxide reach the embedded steel, corrosion can start, weakening the whole assembly. Deterioration spreads quickly and repairs can be costly, repeatedly draining maintenance budgets. By introducing corrosion inhibitors, designers adopt a reliable, long-standing defense that shields rebar and preserve structural function.

Corrosion inhibitors are chemical additives mixed into fresh concrete or brushed onto cured surfaces. They work either by coating the steel with a protective film or by neutralizing harmful ions before damage begins. Operating at the molecular scale, these agents slow the electrochemical processes that produce rust, making them indispensable in modern materials science.

Corrosion professionals recognize three main classes of inhibitors for steel reinforcement: anodic, cathodic, and mixed compounds. Anodic inhibitors create a protective oxide film that slows the forward course of rusting at the metal surface. Cathodic types reduce the speed of reduction reactions, thus limiting electron flow that drives corrosion. Mixed products unite both actions, yielding robust protection across shifting environmental conditions.

Calcium nitrite remains a go-to anodic inhibitor for most applications. It strengthens the passive layer on steel and shines in chloride-laden settings-salt-swept roadways, seaside decks, and other coastal structures. A second choice comes from biodegradable organic blends based on amines and carboxylates, offering a greener, less toxic alternative.

Using corrosion inhibitors yields clear advantages. The first is simply longer service life; by guarding the steel, they delay rust-related cracking, delamination, and spalling of the concrete cover. Extended durability cuts upkeep costs, protects public safety, and spares budgets from sudden, major repairs. In the larger picture, inhibitors help keep resources and energy by reducing the frequent cycle of demolition, replacement, and waste typical of rust-damaged structures.

These chemical inhibitors are deployed in a broad array of structures-from bridges, marine docks, and parking garages to tunnels and water-treatment plants. They prove vital in settings where air is humid or salt-laden, conditions that hasten the rusting of embedded steel. Whether at the outset of new work or during the upgrade of aging assets, these admixtures afford a budget-friendly and dependable guard against corrosion.

In short, corrosion inhibitors for steel reinforcement have become essential to modern strategies for concrete durability. By acting from within the slab, they counter one of the toughest threats to reinforced concrete: steel corrosion. Their straightforward blending, lasting performance, and lower environmental footprint explain why designers and contractors lean on them when aiming for infrastructure that endures. As the push for greener, low-maintenance facilities intensifies, the role of these inhibitors will only grow more prominent.

0 notes

Text

How an RMC Plant in Navi Mumbai Supports Infrastructure Development

In a rapidly growing city like Navi Mumbai, where construction activities are booming, the need for high-quality and reliable concrete is greater than ever. This is where an RMC plant in Navi Mumbai plays a critical role in shaping the city’s infrastructure. From residential towers and commercial complexes to highways, flyovers, and metro projects, ready mix concrete (RMC) has become the backbone of modern construction.

The Growing Demand for RMC in Navi Mumbai

Navi Mumbai is witnessing massive urbanization with several infrastructure and real estate projects taking shape simultaneously. This rapid development demands concrete that not only meets stringent quality standards but is also delivered on time. An RMC plant in Navi Mumbai provides just that—offering a steady supply of ready mix concrete that supports large-scale construction and infrastructure initiatives.

Unlike traditional site-mixed concrete, ready mix concrete from an RMC plant in Navi Mumbai is manufactured under controlled conditions using advanced batching equipment. This ensures uniformity in mix design, strength, and durability—essential qualities for structures that are expected to last for decades.

Enhancing Construction Speed and Efficiency

One of the biggest advantages of using concrete from an RMC plant in Navi Mumbai is the speed at which large volumes can be produced and delivered. Infrastructure development often operates on tight deadlines, where every day counts. Ready mix concrete eliminates delays associated with on-site mixing and helps contractors complete their work faster without compromising on quality.

With efficient logistics and dedicated transit mixers, RMC plants ensure that concrete reaches the site fresh and ready for use. This enhances productivity and reduces wastage—a critical factor in large-scale infrastructure projects like bridges, expressways, and airports.

Supporting Sustainable Construction

Sustainability is no longer a buzzword but a necessity in today’s construction sector. A well-established RMC plant in Navi Mumbai contributes to sustainable infrastructure development by minimizing material wastage, reducing dust pollution, and conserving water.

Since the concrete is produced in a central facility, emissions at construction sites are significantly lowered. Moreover, leading players like Gaamup Infra ensure that their RMC plants follow eco-friendly practices, such as using recycled water in the batching process and sourcing aggregates responsibly. This commitment not only supports green construction but also aligns with the vision of building a smarter and cleaner Navi Mumbai.

Maintaining Quality for Long-Lasting Structures

Quality control is at the heart of any RMC plant in Navi Mumbai that aims to support infrastructure development. Whether it’s a metro rail pillar or a multi-lane highway, the strength of the concrete determines the safety and longevity of the structure.

RMC plants deploy strict testing procedures to ensure that every batch of concrete meets the required specifications. From checking the quality of raw materials like cement, aggregates, and admixtures to continuous monitoring of mix proportions, no aspect is left to chance. This ensures that the concrete used in infrastructure projects can withstand harsh weather conditions and heavy loads for years to come.

Catering to Diverse Infrastructure Needs

An RMC plant in Navi Mumbai is equipped to produce customized concrete mixes for different types of infrastructure projects. For example, high-strength concrete is supplied for elevated roadways and flyovers, while flowable mixes may be used for foundations or pile caps.

This versatility allows infrastructure developers to get exactly the type of concrete their project requires, improving both the design and performance of the structure. In a dynamic city like Navi Mumbai, where multiple projects run concurrently, such flexibility is invaluable.

Conclusion

The contribution of an RMC plant in Navi Mumbai to the city’s infrastructure growth is undeniable. By delivering consistent, high-quality, and sustainable concrete, these plants form the backbone of modern construction. They help speed up project timelines, ensure safety standards, and support the city’s vision for sustainable urban development.

Companies like Gaamup Infra continue to set benchmarks in this field, offering reliable ready mix concrete solutions that power the infrastructure dreams of Navi Mumbai. As the city expands and evolves, the role of RMC plants will only become more critical in shaping a future-ready urban landscape.

#rmc plant in navi mumbai#rmc plant#navi mumbai#cement supplier#construction equipments provider in mumbai#construction

0 notes

Text

Construction Chemical Companies: The Unsung Heroes Behind Stronger, Smarter Buildings

A few years ago, a builder in Kerala faced endless headaches — cracks in new concrete, peeling paint within months, and water seepage even after expensive waterproofing. The culprit? Low-grade construction chemicals. Fast-forward to today, with the right products from trusted construction chemical companies, his buildings not only stand tall but stand the test of time. This transformation is what today’s customers demand — quality, performance, and peace of mind.

Why Construction Chemicals Matter Today

In 2025, the construction industry is more dynamic than ever. From high-rises to villas, construction chemicals play a vital role in everything from bonding and waterproofing to insulation and sustainability. Customers — be it contractors, architects, or homeowners — are no longer just looking for cement and bricks. They want smart solutions that improve lifespan, efficiency, and cost-effectiveness.

What Today’s Customers Expect from Construction Chemical Companies

✅ Quality Assurance: Customers are demanding internationally certified products that meet IS, ASTM, or BS standards. Poor-quality chemicals can lead to early repairs and structural damage — costly mistakes nobody wants.

✅ Eco-Friendly Options: With green buildings and energy-saving regulations in focus, many prefer low-VOC, non-toxic, and sustainable chemicals. Whether it’s heat-reflective coatings like Suntrap or eco-friendly admixtures, sustainability sells.

✅ After-Sales Support & Expertise: End-users appreciate suppliers who don’t just sell — but educate. Companies like Icon Trading win trust by offering technical guidance, on-site demos, and customized solutions based on Kerala’s climate and construction style.

✅ Product Range: From tile adhesives and waterproofing agents to epoxy floor coatings and concrete admixtures, the demand is for one-stop partners, not just sellers. Versatility builds loyalty.

Why Icon Trading is Among Kerala’s Top Construction Chemical Companies

At Icon Trading, we believe your buildings deserve better. That’s why we bring together premium brands, proven performance, and expert advice — all under one roof. We serve contractors, builders, and renovation experts across Kerala with a curated range of solutions tailored for South Indian climates, monsoons, and soil types.

Our offerings include:

Admixtures that improve workability and strength

Waterproofing solutions for rooftops, bathrooms, and basements

Tile adhesives and grouts for flawless finishes

Epoxy coatings for industrial and commercial flooring

Solar heat-reflecting compounds to reduce indoor temperatures

Conclusion

Whether you’re building a skyscraper or a dream home, choosing the right construction chemical company can make all the difference. With quality products, expert advice, and a commitment to long-term results, Icon Trading stands as a trusted name among construction professionals in Kerala.

Looking for durable, smart, and sustainable construction chemical solutions? 📞 Contact Icon Trading today and build with confidence.

0 notes

Text

Building Better: Benefits of Using Ready Mix Concrete in Pakistan

In the ever-evolving world of construction, speed, efficiency, and quality are the three cornerstones of a successful project. Whether you're developing residential homes, commercial buildings, or infrastructure megaprojects, the material you choose plays a pivotal role. In Pakistan, one solution has stood out as the go-to option for both small and large-scale projects Ready Mix Concrete. Allied Materials, a leading supplier in the field, has transformed the construction landscape by offering reliable, high-performance Ready Mix Concrete in Pakistan. This article explores the many advantages of using ready mix concrete, how it supports modern construction needs, and why Allied Materials is your ideal partner.

What is Ready Mix Concrete?

Ready mix concrete (RMC) is a type of concrete that is manufactured in a batching plant under strict quality controls and then delivered to a construction site in a ready-to-use state. Unlike on-site mixing, where quality and proportions can vary, ready mix concrete ensures consistency, strength, and durability.

It is made using a precise mixture of cement, water, aggregates, and sometimes admixtures, all combined in a centralized facility and transported using mixer trucks. This ready-to-pour solution eliminates much of the manual work and margin of error involved in traditional concrete preparation.

Why Pakistan Needs Ready Mix Concrete

As urbanization accelerates and infrastructure development booms, Pakistan's construction industry is under increasing pressure to deliver faster, more durable, and cost-effective projects. In cities like Karachi, Lahore, and Islamabad, time constraints, space limitations, and labor shortages make traditional concrete mixing inefficient.

Ready Mix Concrete in Pakistan offers a solution to these challenges by enabling streamlined operations and higher output with fewer errors. From high-rise buildings to roads and bridges, RMC is becoming a necessity rather than a luxury.

Top Benefits of Using Ready Mix Concrete

1. Consistent Quality

One of the biggest advantages of using ready mix concrete is the consistency in its quality. At Allied Materials, advanced batching plants use automated processes to measure and mix materials in exact proportions. This precision ensures uniform strength, durability, and performance every time.

2. Faster Construction Times

Time is money in the construction world. Ready mix concrete helps accelerate the project timeline by eliminating on-site mixing and reducing downtime. With ready-to-use concrete delivered directly to your site, projects progress faster and more efficiently.

3. Reduced Labor Costs

Traditional concrete mixing requires a dedicated team of workers for measuring, mixing, and quality control. With RMC, most of this work is handled off-site, significantly reducing the labor required and thereby cutting costs.

4. Minimized Waste

On-site mixing often leads to material wastage due to inaccurate measurements or spillage. RMC production is carefully managed in a plant, ensuring minimal waste and better use of resources.

5. Eco-Friendly Option

Concrete production can be environmentally intensive, but ready mix concrete reduces the impact by optimizing resource use and limiting emissions. Allied Materials adopts sustainable practices and quality checks to ensure that their processes are as eco-conscious as possible.

6. Space Saving on Site

Especially in urban areas like Karachi or Lahore, construction sites are often cramped. On-site mixing requires space for raw material storage and mixing machinery. Ready mix concrete eliminates the need for these setups, freeing up valuable site space.

7. Enhanced Worksite Safety

With reduced handling of raw materials and equipment, the risks of accidents and injuries decrease significantly. Pre-mixed concrete also means less noise, dust, and manual intervention, ensuring a safer environment for workers.

Applications of Ready Mix Concrete in Pakistan

The versatility of ready mix concrete makes it suitable for a variety of construction needs, including:

Residential Construction: Foundations, walls, driveways, and floors

Commercial Projects: Shopping malls, offices, and parking lots

Infrastructure Development: Roads, bridges, flyovers, and airports

Industrial Facilities: Warehouses, factories, and manufacturing units

From small private projects to government-funded mega-infrastructure, ready mix concrete has found its place across all segments in Pakistan.

Why Choose Allied Materials?

If you're seeking quality, reliability, and performance, Allied Materials is your trusted source for Ready Mix Concrete in Pakistan. Here’s what sets them apart:

1. State-of-the-Art Batching Plants

Allied Materials uses cutting-edge technology and computerized systems in their batching plants to ensure consistency and precision in every batch.

2. Experienced Team

From engineers and technicians to logistics and customer service, Allied Materials boasts a team of experienced professionals who understand construction challenges and provide tailored solutions.

3. On-Time Delivery

Time is critical on any project, and Allied Materials guarantees prompt delivery through a well-maintained fleet of transit mixers, ensuring your site is never left waiting.

4. Custom Mix Designs

Different projects require different specifications. Allied Materials offers customizable mix designs based on your structural and environmental needs.

5. Nationwide Service

Operating across Pakistan, Allied Materials serves major cities and remote project sites alike, making them a nationwide leader in the RMC industry.

The Future of Construction in Pakistan

As Pakistan continues its journey toward modernization and urban development, construction methods must evolve. Ready mix concrete aligns perfectly with this evolution, offering efficiency, sustainability, and long-term value. Whether it’s smart cities, green buildings, or infrastructural resilience, RMC plays a foundational role.

Contractors, developers, and government bodies are increasingly recognizing this shift and integrating ready mix solutions into their project planning and budgeting. Allied Materials, with its proven track record and technical excellence, is at the forefront of this transformation.

Tips for Using Ready Mix Concrete Effectively

Plan Ahead: Schedule deliveries based on site readiness and pour timelines to minimize waiting time.

Choose the Right Mix: Work with Allied Materials to select the best mix design suited for your specific project requirements.

Ensure Proper Handling: While RMC is designed for ease, correct pouring and curing practices must still be followed on site.

Check for Certification: Always source from suppliers like Allied Materials that adhere to ISO standards and national construction guidelines.

Conclusion

Choosing the right building materials can make or break a project. With ready mix concrete, you gain consistency, efficiency, and a superior finish. As one of the leading suppliers in Pakistan, Allied Materials ensures your construction goals are met with high-quality materials and unmatched service. If you're ready to upgrade your project outcomes and build stronger, faster, and smarter, it's time to switch to Ready Mix Concrete in Pakistan with Allied Materials.

0 notes

Text

Concrete Supplier

The Critical Role of a Concrete Supplier in Modern Construction Concrete is the backbone of modern construction. From high-rise towers to residential foundations, sidewalks to industrial facilities, concrete provides the durability, stability, and strength needed to create long-lasting structures. Behind every successful project is a dependable concrete supplier—an unsung hero that ensures the construction site never runs dry of the materials needed to build strong. The role of a concrete supplier goes beyond simply delivering a product; it encompasses quality control, logistics, innovation, and partnership in the building process. In this article, we’ll explore the importance of a concrete supplier, the value they bring to various construction sectors, the technical and logistical factors that make them essential, and why their reliability can make or break a project. The Foundation of Every Project: What a Concrete Supplier Provides A concrete supplier plays a pivotal role in providing ready-mix concrete and other custom concrete products to contractors, developers, and engineers. These suppliers typically operate batching plants where raw materials like cement, aggregates (gravel, sand, or crushed stone), water, and admixtures are proportioned and mixed to specification. The result is a highly engineered material that can be customized for strength, workability, durability, and setting time, depending on project needs. Concrete is not a one-size-fits-all material. Different projects require different types of mixes. For example, a parking garage might need a high-compressive-strength mix with added reinforcement, while a sidewalk or driveway may require a mix optimized for surface smoothness and finish. A concrete supplier must have the expertise and capability to adjust mixes precisely and consistently. Timeliness is another critical component. Because concrete begins to cure the moment water is added, it has a limited window before it sets. The supplier must coordinate delivery carefully to ensure the material arrives at the site ready to pour—on time, every time. Delays or miscalculations can lead to waste, weakened structures, or costly rework. Why Concrete Suppliers Are Essential to Construction Success Every building, whether residential, commercial, or industrial, relies on the integrity of its foundation and structural components. These elements, often made entirely of concrete or heavily reinforced with it, demand precision and quality. A concrete supplier ensures this quality by managing the material from raw input to finished mix. The supplier’s responsibilities include: • Material sourcing: High-quality cement and aggregates are essential. Poor-quality materials can result in weak concrete that deteriorates prematurely. • Mix design: Engineering a custom mix based on the intended use, environmental conditions, and structural demands. • Batch consistency: Delivering consistent batches that meet strength, slump, and durability requirements across multiple pours or days. • Testing and quality control: Performing compressive strength tests, air content analysis, and moisture checks to ensure compliance with building codes and standards. • Delivery and logistics: Coordinating fleet vehicles, managing delivery times, and planning around weather or site access challenges. In essence, a concrete supplier is a critical partner in quality assurance. Their role ensures that the materials used in construction not only meet but exceed expectations, helping prevent structural failures, project delays, and safety issues. Applications Across Industries: Where Concrete Suppliers Add Value The scope of projects requiring concrete is vast. A skilled concrete supplier supports a wide range of industries, including:

Residential Construction In residential building, concrete is used for driveways, patios, foundations, basement floors, and retaining walls. Homebuilders rely on a concrete supplier to provide workable mixes that meet code and aesthetic requirements. Suppliers also often work with finishing contractors to ensure the product performs well during stamping or texturing.

Commercial and Industrial Construction High-rise buildings, office complexes, parking structures, and warehouses all require massive amounts of concrete. These projects need specialized mixes such as high-early-strength concrete for fast turnaround or fiber-reinforced concrete for increased load tolerance. A concrete supplier helps design and deliver these mixes while coordinating batch delivery with large-scale pour schedules.

Infrastructure and Civil Engineering Public works projects—roads, bridges, dams, tunnels, airports—rely heavily on concrete. These projects demand not only high durability and weather resistance but also strict compliance with governmental and engineering standards. Suppliers in this sector must have the capability to scale production and maintain extreme consistency across thousands of yards of concrete.

Agriculture and Utility Installations From barns and silos to utility vaults and wind turbine pads, concrete is essential to rural and industrial infrastructure. A concrete supplier ensures that rural job sites are not left out, making logistics and service reliability just as important as product quality.

Decorative and Specialty Projects Stamped concrete patios, exposed aggregate walkways, stained concrete floors—these are growing in popularity for both aesthetic and functional reasons. Concrete suppliers must work closely with decorative contractors to deliver the right slump, coloring agents, and timing for optimal results. Technology and Innovation in Concrete Supply Today’s concrete suppliers don’t just mix and deliver—they innovate. Technology has transformed the concrete industry with advancements in materials science, delivery systems, and digital logistics. For example, smart sensors are used to monitor the curing process in real-time, allowing suppliers and contractors to track strength development and optimize pour schedules. GPS and telematics systems help dispatchers reroute trucks in real-time to avoid delays, while cloud-based software allows construction managers to order, track, and adjust concrete deliveries from the job site. Moreover, many suppliers now invest in eco-friendly solutions like carbon-reducing additives, recycled aggregates, and water-saving processes. These innovations not only improve concrete performance but also help reduce the environmental footprint of construction—an increasingly important factor in sustainable development. The Human Element: Communication and Coordination Even with all the technology in the world, construction is a team sport. A reliable concrete supplier brings a human touch that can’t be replaced: clear communication, problem-solving, and a willingness to collaborate. When unforeseen challenges arise—a delivery delay, a batch problem, a weather-related schedule change—a dependable supplier helps find a solution, not an excuse. Contractors often build long-term relationships with their concrete suppliers because trust, familiarity, and service consistency are crucial to job site performance. A supplier who understands the unique rhythm and demands of a contractor’s workflow becomes an asset on every job. Conclusion: Why Choosing the Right Concrete Supplier Matters Behind every successful structure stands a reliable concrete supplier—one that combines quality, consistency, expertise, and reliability. Their role stretches far beyond delivery; they are partners in planning, execution, and long-term performance. Whether it’s a backyard patio or a 50-story tower, the quality of the concrete and the precision of its delivery can shape the integrity of the entire project. In the world of construction, where timing is tight, safety is paramount, and quality cannot be compromised, a dependable concrete supplier isn’t just a vendor—they are the heartbeat of the build. Choosing the right one ensures that projects start strong and stay strong, from the foundation to the final finish.

readymixconcretesupplier #readymixconcrete #concrete #construction #buildingmaterials #concretelife #concretetruck #volumetricconcrete #mobileconcretemixer #mixonsiteconcrete #familyownedbusiness #fresh #volumetricmixer #midlandtx #odessatx #westtexas #permianbasin #midlandtexas #midland #bigspringtx #texas

1 note

·

View note

Text

#cherrytomato is a type of small round tomato believed to be an intermediate genetic admixture between wild currant-type tomatoes and domesticated garden tomatoes.[3] Cherry tomatoes range in size from a thumbtip up to the size of a golf ball, and can range from spherical

0 notes

Text

Is Cementitious Waterproofing Suitable for All Types of Surfaces?

Waterproofing is one of the most essential aspects of construction and maintenance in regions with high humidity, frequent rainfall, or extreme temperatures. In cities like Dubai, where the climate is characterized by intense heat and occasional heavy rains, effective waterproofing becomes even more crucial. Among the various types of waterproofing methods available, cementitious waterproofing has gained considerable popularity. But a common question that arises is—Is cementitious waterproofing suitable for all types of surfaces?

In this blog, we’ll explore what cementitious waterproofing is, where it is most effective, its limitations, and how it compares to other methods such as acrylic waterproofing in Dubai UAE.

What is Cementitious Waterproofing?

Cementitious waterproofing is a method that involves applying a cement-based compound to surfaces in order to prevent water infiltration. The mix usually includes cement, sand, and a waterproofing agent or admixture. Once applied and cured, it forms a hard, durable, and water-resistant layer.

This method is often used in wet areas such as:

Bathrooms

Kitchens

Water tanks

Basements

Swimming pools

Sewage treatment plants

It is especially valued for its ease of application, cost-effectiveness, and compatibility with concrete surfaces.

Advantages of Cementitious Waterproofing

1. Easy Application

One of the most appealing aspects of cementitious waterproofing in Dubai UAE is that it can be applied easily using a brush, trowel, or spray. This makes it a favorite among contractors for smaller or internal projects.

2. Strong Adhesion to Concrete

Since cementitious materials are essentially made from cement, they bond extremely well with concrete substrates, forming a monolithic structure that resists water penetration.

3. Cost-Effective

Compared to other waterproofing systems, cementitious solutions are more affordable and are a great choice for budget-conscious projects.

4. Durability

Once properly applied and cured, the coating becomes rigid and long-lasting, especially in areas that are not exposed to movement or UV rays.

5. Non-toxic

Many cementitious waterproofing products are non-toxic, making them ideal for use in potable water tanks and food-related facilities.

Limitations of Cementitious Waterproofing

While cementitious waterproofing has many advantages, it is not without its limitations.

1. Lack of Flexibility

Cementitious coatings are rigid after curing. They cannot accommodate structural movements such as expansion, contraction, or vibrations. This makes them unsuitable for surfaces that are prone to movement or minor shifting.

2. UV Sensitivity

These coatings are not UV-stable. When exposed to direct sunlight for extended periods, they can degrade, crack, or lose their waterproofing capability.

3. Surface Type Restrictions

Cementitious waterproofing is best suited for concrete or masonry surfaces. It does not adhere well to wood, metal, or flexible plastic surfaces without significant surface preparation or additional bonding agents.

4. Brittle Nature

Being cement-based, the final coating can become brittle over time. This is especially a concern in environments with thermal cycling, where expansion and contraction are common.

Where Cementitious Waterproofing Works Best

Given its limitations and strengths, cementitious waterproofing in Dubai UAE is best suited for the following applications:

- Basements and Foundations

These areas are typically made from concrete and are not exposed to direct sunlight or significant movement. Cementitious waterproofing offers a long-lasting solution here.

- Water Tanks and Pools

These require a non-toxic, water-resistant coating that bonds well with concrete. Cementitious materials fulfill this role effectively.

- Bathrooms and Kitchens

Indoor wet areas are ideal for cementitious waterproofing, especially when the surfaces are concrete or cement plaster.

- Retaining Walls

Concrete retaining walls in gardens or buildings can benefit from this method, provided they are not exposed to high structural movement.

Surfaces Not Ideal for Cementitious Waterproofing

To answer the primary question—no, cementitious waterproofing is not suitable for all types of surfaces. Here are some scenarios where alternative methods like acrylic waterproofing in Dubai UAE may be more appropriate:

- Roofs and Terraces

These surfaces are exposed to direct sunlight and are subject to thermal expansion and contraction. The rigidity and UV sensitivity of cementitious coatings make them a poor choice for these applications.

- Wooden or Metallic Surfaces

Cementitious materials do not bond well with wood or metal, which are also prone to expansion and contraction. These surfaces need a more flexible and adhesive-friendly waterproofing solution.

- Pre-fabricated Structures

Structures made from non-concrete materials or that have frequent movement require waterproofing membranes that are elastic and UV-stable.

The Role of Acrylic Waterproofing

In contrast to cementitious systems, acrylic waterproofing in Dubai UAE offers a flexible, UV-resistant, and aesthetically pleasing solution for many exterior surfaces.

Benefits of Acrylic Waterproofing:

Highly Elastic: It can accommodate surface movement, cracks, and temperature changes.

UV Resistant: It performs well under direct sunlight, making it ideal for terraces, balconies, and external walls.

Smooth Finish: Offers a paint-like appearance, which is often desired in visible areas.

Water-Based: Environmentally friendly and easier to clean up during application.

Ideal Applications:

Roof terraces

External walls

Metal or wooden structures

Pre-cast panels

When compared side-by-side, cementitious waterproofing works better for internal, concrete-heavy, and static surfaces, while acrylic systems shine in external, dynamic, and visually exposed areas.

Hybrid Approaches

Some modern construction projects combine both cementitious and acrylic systems to achieve optimal waterproofing. For example, a basement might use a cementitious coating on the inside and an acrylic membrane on the exterior wall to provide both internal and external protection.

Important Considerations Before Choosing a Waterproofing Method

Before deciding on a waterproofing system, you should evaluate the following:

Surface Material: What is the surface made of—concrete, wood, metal, or something else?

Movement and Flexibility Needs: Will the surface expand, contract, or vibrate over time?

Exposure to Elements: Will it be exposed to direct sunlight, heavy rain, or high humidity?

Aesthetic Requirements: Is the area visible to occupants or purely functional?

Budget: How much can you invest in waterproofing, and what is the cost of future repairs if the solution fails?

Matching your surface characteristics with the right waterproofing solution is essential for long-term success.

Common Mistakes to Avoid

Even the best waterproofing product can fail if it is not applied correctly. Here are some mistakes to avoid when working with cementitious waterproofing in Dubai UAE or any other system:

Improper Surface Preparation: Always clean and prime the surface before applying any coating.

Skipping Curing Time: Allow proper curing time to ensure durability.

Applying on Damp or Wet Surfaces: Cementitious coatings need a surface that is moist but not soaked.

Ignoring Joints and Cracks: All joints and cracks should be treated with reinforcing fabric or sealant prior to applying the main coating.

Single-Layer Application: Most systems require multiple coats for effective waterproofing. Don’t cut corners.

Final Thoughts

Cementitious waterproofing in Dubai UAE remains a reliable and cost-effective solution for specific applications, particularly those involving concrete surfaces in interior or underground settings. However, it is not suitable for all types of surfaces due to its rigidity, lack of flexibility, and vulnerability to UV rays.

For exterior or more dynamic surfaces, acrylic waterproofing in Dubai UAE provides a more suitable alternative thanks to its flexibility, UV resistance, and versatility. The key to successful waterproofing lies in choosing the right system for your specific surface and environment, ensuring proper application, and conducting regular inspections for maintenance.

Ultimately, understanding the characteristics of each waterproofing method enables property owners and contractors to make informed decisions that enhance durability, reduce long-term maintenance costs, and protect buildings against water damage effectively.

#Sealants Manufacturers in UAE#MS Sealants in Dubai UAE#Construction Chemicals Manufacturers in UAE#Construction Chemicals in Dubai UAE#Best concrete Repair Product#Concrete Repair in Dubai UAE#PU Sealant Manufacturers#Polysulphide Sealants in Dubai UAE#Acrylic Sealants in Dubai UAE#PU Waterproofing in Dubai UAE#Cemetitious Waterproofing in Dubai UAE#Acrylic Waterproofing in Dubai UAE#Polyurethane flooring in Dubai UAE#Epoxy Flooring Manufacturers#Industrial coatings in Dubai UAE

0 notes