#welding and fabrication services

Text

Immortal Metals

Website: https://immortalmetals.com/

Address: 10410 66th St N Unit 2, Pinellas Park, Florida 33781, USA

Immortal Metals, a family-owned business led by Travis and Adelyn, specializes in custom metal fabrication and welding. With over 18 years of experience, they offer a range of services for residential, commercial, and industrial needs, including custom metal structures, welding, machining solutions, and heavy machinery repair. Their commitment to quality craftsmanship and personalized service makes them a prominent choice in Pinellas County, Florida.

Facebook: https://www.facebook.com/immortalmetalswelding

Instagram: https://www.instagram.com/immortalmetalswelding/

Linkedin: https://www.linkedin.com/company/immortalmetals/

Keywords:

welding services near me

sheet metal fabrication near me

metal polishing near me

custom metal fabrication near me

solar panel structure

heavy equipment repair near me

custom metal fabrication

machinery repair services

solar panel mounting structure

custom sheet metal fabrication

sheet metal custom fabrication

metal polish service

welding repair services

custom machined parts

welding repair services near me

solar panel shade structure

welding inspection services

complete welding services

welding and fabrication services

professional welder near me

welding mobile services

industrial welding projects

quality custom metal fabrication

heavy machinery repair near me

custom metal art fabrication

solar panel base structure

custom welding services

commercial metal buildings near me

custom welding fabrication near me

metal building repair service

custom metal fabrication services

solar panel carport structure

welding consultancy services

custom welding solutions

custom metal box fabrication

solar panel frame structure

solar panel internal structure

metal door repair services

metal roof repair services

commercial metal shade structures

quality sheet metal fabrication

mil spec welding

custom arc welding services

custom metal fabrication pinellas park

custom works metal fabrication

welding and brazing services near me

machining solutions near me

metal door repair services near me

metal gate repair services

metal shear repair service near me

heavy equipment machinery repair

heavy machinery mobile repair

customized auxiliary welding solutions

machining solutions pinellas park

commercial metal buildings pinellas park

robotic machine fabrication near me

flame cutting services near

unique metal projects

metalwork for residential projects

metal drilling service near me

mil spec welding service price

heavy machinery and equipment repair near me

heavy machinery and equipment repair pinellas park

high quality steel structures service

custom welding rates

custom metal structures service

custom steelwork

#welding services near me#sheet metal fabrication near me#metal polishing near me#custom metal fabrication near me#solar panel structure#heavy equipment repair near me#custom metal fabrication#machinery repair services#solar panel mounting structure#custom sheet metal fabrication#sheet metal custom fabrication#metal polish service#welding repair services#custom machined parts#welding repair services near me#solar panel shade structure#welding inspection services#complete welding services#welding and fabrication services#professional welder near me#welding mobile services#industrial welding projects#quality custom metal fabrication#heavy machinery repair near me#custom metal art fabrication#solar panel base structure#custom welding services#commercial metal buildings near me#custom welding fabrication near me#metal building repair service

1 note

·

View note

Text

Sheet metal fabrication

#design#autos#business#prototype#prototyping#rapid prototyping#prototype machining#sheet metal services tauranga#sheet metal manufacturing#sheet metal fabrication#sheet metal work contractor financing#sheet metal design#metal machining#sheet metal bending#sheet metal stamping#sheet metal welding#sheet metal

2 notes

·

View notes

Text

Best CNC laser cutting machine in India

As of my last knowledge update in January 2022, I don't have specific information on the latest CNC laser cutting machines available in India. However, I can provide you with some popular CNC laser cutting machine manufacturers that were well-regarded globally. It's important to note that advancements in technology and new models may have been introduced since then.

TRUMPF:

TRUMPF is a globally recognized company for manufacturing high-quality CNC laser cutting machines. They offer a range of laser cutting solutions for various industries.

Amada:

Amada is another well-known brand in the CNC machinery industry, including laser cutting machines. They have a reputation for producing reliable and efficient equipment.

Bystronic:

Bystronic is a Swiss manufacturer known for its advanced laser cutting systems. They provide solutions for sheet metal processing and have a presence in India.

Mazak:

Yamazaki Mazak Corporation, commonly known as Mazak, is a Japanese company that produces CNC laser cutting machines. They are known for their precision and innovation.

Han's Laser:

Han's Laser is a Chinese company with a global presence, manufacturing laser cutting machines. They offer a variety of models suitable for different applications.

LVD:

LVD is a Belgian company specializing in sheet metalworking equipment, including laser cutting machines. They are known for their innovative solutions.

When considering the best CNC laser cutting machine for your specific needs, factors such as the machine's power, cutting capabilities, ease of use, support services, and overall reputation of the manufacturer are important to consider.

To find the latest and best CNC laser cutting machines in India, it's recommended to check with local distributors, attend industry exhibitions, and explore online reviews and forums for updated information. Additionally, contacting the manufacturers directly or consulting with industry experts can help you make an informed decision based on your specific requirements.

We Provide:-

Best CNC laser cutting machine in India

CNC punching services in pune

Best MIG Welding Machine

Pre-Treatment for Surface Preparation in pune

Best CNC bending services India

Best SS fabrication services in India

Best spot welding services in pune

Best tube, pipe, and angle cutting services in pune

Best automotive manufacturers in pune

Best manufacturing and assembly services

#best cnc laser cutting machine in india#CNC punching services in pune#best MIG Welding Machine#Pre-Treatment for Surface Preparation in pune#best CNC bending services india#best SS fabrication services in india#best spot welding services in pune#best tube#pipe#and angle cutting services in pune

2 notes

·

View notes

Text

Sheet Metal Fabrication

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Sheet Metal Fabrication#Powder Coating & Welding#Complete Turnkey Solutions#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Text

With our powder coating services, which provide high-quality finishes for any application, you can elevate your projects. Our knowledgeable staff applies gorgeous, long-lasting coatings that improve both appearance and protection. Our solutions offer a durable, smooth finish and are perfect for use in commercial, industrial, and residential settings. Count on us for excellent powder coating outcomes! Visit us now to know more about Powder Coating Services.

#powder coating services#metal skills in new zealand#sheet metal fabrication#outsourced manufacturing#metal design#metal programming#laser cutting service#best laser cutting services in new zealand#metal skills#steel fabrication#metal fabrication#welding engineering#turret punches#welding services near me#perforated metal sheet#assembly line#hardware insertion

0 notes

Text

#Rebaring Services#Carbon Steel Rebar#construction technology#Epoxy-Coated Rebar Galvanized Rebar#Glass-Fiber-Reinforced-Polymer (GFRP) Rebar#Stainless Steel Rebar#Welded Wire Fabric

0 notes

Text

AG Price Fabrication Shop | Experienced Metal Fabrication in New Zealand

AG Price Fabrication Shop offers a wide range of metal fabrication services for various industries. Their experienced fitters can weld, stress relieve, and perform NDT inspections on-site. They have a long history and a variety of equipment to meet your needs.to know more please visit us for more details: https://www.agprice.co.nz/fabrication-shop

#mining industry#foundry#metal fabrication New Zealand#fabrication shop Auckland#welding services New Zealand#NDT inspection#metal fabrication#custom metal fabrication#metal fabrication company#fabrication workshop#stainless steel fabrication#steel fabrication#aluminum fabrication

0 notes

Text

Welding and Fabrication

Need a custom piece of kitchen equipment, rolling gate, or fence? Whether you require a minor repair or a custom solution, Andrew’s Construction employs skilled metal workers to handle your welding and fabrication needs in Arizona. We can weld damaged metals, or fabricate customer stainless steel and iron designs and equipment for your business.

0 notes

Text

Enhance Your Vehicle with Powder Coating Rims by Wheels Respray

Rims are one of the most noticeable and important parts of any vehicle. Not only do they contribute to the overall aesthetic appeal, but they also play a critical role in performance and durability. At Wheels Respray, we specialise in powder coating rims, offering a premium service that transforms your wheels into stunning, durable, and long-lasting components.

The Benefits of Powder Coating Rims

Powder coating rims is a process that involves applying a dry powder to the rims' surface, which is then cured under heat to form a hard, protective finish. This method offers numerous advantages over traditional painting. First and foremost, powder coating rims provide superior durability. The coating is highly resistant to chipping, scratching, and fading, ensuring that your rims maintain their pristine appearance even under harsh conditions.

Furthermore, powder coating rims enhance corrosion resistance. The protective layer formed during the curing process effectively seals the metal, preventing moisture and contaminants from causing rust and other forms of deterioration. This is particularly important for rims, as they are constantly exposed to road salt, water, and other elements that can lead to corrosion over time.

Why Choose Wheels Respray for Powder Coating Rims?

When it comes to powder coating rims, Wheels Respray stands out as a leader in the industry. Our team of experienced professionals is dedicated to delivering top-quality results that meet and exceed our clients' expectations. We use state-of-the-art equipment and the highest-quality powders to ensure a flawless finish every time.

At Wheels Respray, we understand that every vehicle and every driver has unique needs. That's why we offer a wide range of colors and finishes for powder coating rims, allowing you to customise your rims to match your style and preferences perfectly. Whether you prefer a classic glossy black, a vibrant red, or a sleek metallic finish, we have the options to make your vision a reality.

The Powder Coating Rims Process at Wheels Respray

Our powder coating rims process at Wheels Respray is meticulous and thorough, ensuring the highest quality results. The first step involves preparing the rims by cleaning and stripping them of any existing coatings or contaminants. This is crucial for achieving a smooth and even application of the powder coating.

Next, the rims are pre-treated to enhance adhesion and ensure the coating bonds effectively with the metal surface. This step is essential for the durability and longevity of the powder coating. Once the pre-treatment is complete, the powder is applied using an electrostatic spray gun. The charged powder particles adhere to the rims, forming a uniform layer.

The final step in the powder coating rims process is curing. The coated rims are placed in an oven, where they are heated to a specific temperature. This causes the powder to melt and flow, forming a solid, continuous layer that is both attractive and durable. The result is a set of rims that look fantastic and offer exceptional protection against wear and tear.

Customer Satisfaction with Powder Coating Rims

At Wheels Respray, customer satisfaction is our top priority. We take pride in our ability to deliver powder coating rims services that exceed our clients' expectations. Our team works closely with each customer to understand their specific needs and preferences, providing personalised solutions that meet their requirements.

We have received countless positive reviews and testimonials from satisfied customers who have experienced the transformative effects of our powder coating rims services. Many of our clients have reported that their powder-coated rims have remained in excellent condition for years, withstanding the rigors of daily driving and harsh environmental conditions.

The Future of Powder Coating Rims with Wheels Respray

As a leading provider of powder coating rims services, Wheels Respray is committed to staying at the forefront of industry trends and technological advancements. We continuously invest in research and development to improve our processes and offer innovative solutions to our clients.

Our goal is to set new standards in the powder coating rims industry, providing unparalleled quality and reliability. We are dedicated to expanding our range of services and options, ensuring that we can meet the evolving needs of our customers.

Powder coating rims are an excellent way to enhance the appearance, durability, and performance of your vehicle's wheels. At Wheels Respray, we specialise in providing top-quality powder coating rims services that deliver exceptional results. With our expertise, state-of-the-art equipment, and commitment to customer satisfaction, we are the premier choice for powder coating rims.

Choose Wheels Respray for all your powder coating rims needs and experience the difference that quality and dedication can make. Transform your rims into stunning, durable, long-lasting components that elevate your vehicle's overall appeal.

#powder coating rims#rims powder coating#powder coating#powder coating rims services#powder coating rims near me#vehicle powder coating#car powder coating#powder coating rims in sydney#powder coat#wheel repair#wheels#powder coating service#metal fabrication#powder coated wheels#welding#rim repair

0 notes

Text

Expert Welding Fabrication Services for your Industrial Needs

Staub Manufacturing Solutions offers top-notch welding fabrication services through skilled professionals and cutting-edge technology. From precision metalwork to customized solutions, they deliver excellence in welding services for diverse industrial needs. Contact them today!

0 notes

Text

Steel Shops Near You: Your Local Source for Quality Steel Products

Looking for steel shops near you? Look no further! Our local steel shops are your go-to source for quality steel products. Whether you're working on a small DIY project or a large-scale construction job, our shops have everything you need to get the job done right. From steel beams to sheet metal and everything in between, we offer a wide range of products to suit your needs. Plus, our knowledgeable staff are here to help you find the perfect steel for your project and offer expert advice on fabrication and welding. Visit our steel shops today and see why we're your local source for quality steel products.

#welders near me#metal fabrication shops near me#welding companies near me#welding services near me#welders in the northern district#steel welders near me

0 notes

Text

Pre-Treatment for Surface Preparation in Pune | Sawant Group

In the bustling city of Pune, where innovation meets tradition, the quest for perfection in surface preparation is more critical than ever. Whether you’re a homeowner looking to refresh your living space, a contractor striving for flawless finishes, or an industrial professional aiming for optimal performance, understanding the importance of pre-treatment is key. Pre-treatment serves as the foundation for any successful surface application, ensuring that coatings, paints, and finishes adhere properly and last longer. This blog post will delve into the nuances of surface preparation, exploring various techniques and best practices that can transform your projects from ordinary to extraordinary. Join us as we uncover the essential steps to achieving perfection, highlighting why investing time in pre-treatment can lead to stunning results and longevity in your work.

Introduction to Surface Preparation

Surface preparation is a critical preliminary step in various industries, especially in Pune, where the demand for high-quality finishes and long-lasting results is on the rise. Whether you’re working with metals, plastics, or wood, the condition of a surface can significantly influence the performance and durability of coatings, adhesives, and other treatments.

In simple terms, surface preparation involves cleaning, smoothing, and treating a surface to ensure optimal adhesion and functionality of subsequent applications. This process is not just about aesthetics; it sets the foundation for a successful project, whether you’re painting a wall, applying a protective coating to a steel structure, or preparing a substrate for a high-tech adhesive.

In Pune, a hub for industries ranging from manufacturing to construction, the significance of surface preparation cannot be overstated. The region’s unique climate, which includes high humidity and varying temperature extremes, adds an additional layer of complexity to surface treatments. Without proper preparation, the risk of peeling, chipping, or corrosion increases dramatically, leading to costly repairs and maintenance down the line.

Understanding the different methods of surface preparation — be it mechanical methods like sanding and blasting, or chemical methods such as etching and degreasing — is essential for achieving perfection in any project. As we delve deeper into this topic, we will explore the various techniques and their importance in ensuring that every project meets the highest standards of quality and longevity.

Understanding the Concept of Pre-Treatment

Pre-treatment is a crucial step in the surface preparation process, especially when it comes to achieving optimal results in various applications, from painting to coating. It refers to the processes and techniques employed to clean, treat, and prepare a substrate before any finishing work takes place. Understanding this concept is vital for anyone looking to enhance the durability and aesthetic appeal of their projects.

In Pune, where humidity and pollution levels can vary significantly, pre-treatment becomes even more essential. The primary goal of pre-treatment is to ensure that surfaces are free from contaminants such as dust, grease, rust, and old paint that may hinder adhesion. This can involve several methods, including mechanical cleaning, chemical treatments, or abrasive blasting, each chosen based on the specific requirements of the surface material.

For example, metal surfaces often require rust removal and degreasing, while wooden surfaces might need sanding and sealing to prevent moisture absorption. Additionally, the choice of pre-treatment technique can also depend on the final product being applied — whether it’s paint, a protective coating, or any other finish. By investing time and effort into a thorough pre-treatment process, you can significantly improve the bond between the substrate and the applied material, leading to a longer-lasting and more visually appealing outcome.

Incorporating effective pre-treatment methods not only enhances the performance of coatings but also reduces the likelihood of defects and failures, ultimately saving time and resources in the long run. As you embark on your projects in Pune, remember that understanding and implementing proper pre-treatment techniques is the foundation upon which your success will be built.

The Role of Surface Preparation in Achieving Perfection

Surface preparation is often the unsung hero in the quest for perfection, especially in industries where quality is paramount. In Pune, a city burgeoning with manufacturing and construction activities, the importance of meticulous surface preparation cannot be overstated. It lays the groundwork for any successful project, ensuring that the final finish not only meets but exceeds expectations.

Imagine embarking on a painting project without properly cleaning and priming the surface. The result would likely be a dismal display of peeling paint and uneven textures that scream negligence. Similarly, in Pune’s competitive market, where aesthetics and durability are key, surface preparation acts as the foundation for achieving a flawless finish.

Surface preparation involves a series of critical steps: cleaning, stripping, sanding, and priming. Each of these steps is designed to eliminate contaminants such as dust, grease, and rust, which can ultimately compromise the integrity of the coatings or finishes applied later. For instance, in the case of metal surfaces, proper rust removal and application of primer can significantly enhance the adhesion of paint, leading to a longer-lasting and more resilient finish.

Moreover, the type of surface preparation needed can vary significantly based on the materials being used. Whether it’s concrete, wood, or metal, each surface requires specific techniques to ensure it is in optimal condition to receive subsequent treatments. This tailored approach not only enhances the aesthetic appeal but also fortifies the surface against wear and tear, extending the lifespan of the finished product.

In Pune, where the climate can fluctuate dramatically, the role of surface preparation becomes even more crucial. The monsoon season, for instance, can cause moisture-related issues if surfaces are not adequately prepared. Neglecting this essential step can lead to problems such as blistering, peeling, and premature decay, ultimately resulting in costly repairs and diminished satisfaction for clients.

Ultimately, investing time and resources into thorough surface preparation is not just about aesthetics; it’s about laying a robust foundation for excellence. In the bustling landscape of Pune, where every detail matters, ensuring perfection begins with a commitment to meticulous surface preparation. By prioritizing these crucial steps, businesses can achieve the high standards of quality that clients expect and deserve, setting the stage for success in every project.

Common Surface Preparation Techniques

When it comes to achieving optimal results in any surface treatment project, understanding and employing the right surface preparation techniques is crucial. In Pune, where the climate and environmental conditions can significantly impact the longevity and effectiveness of coatings, selecting the appropriate method is essential for ensuring durability and aesthetic appeal. Here are some common surface preparation techniques that are widely used:

1. Abrasive Blasting: This technique involves propelling abrasive materials against the surface to clean and etch it. Abrasive blasting is particularly effective for removing rust, old paint, and other contaminants. It not only prepares the surface by creating a rough profile for better adhesion but also enhances the overall appearance. In Pune, where humidity can lead to corrosion, abrasive blasting is a highly recommended method for metal surfaces.

2. Chemical Cleaning: For surfaces that are sensitive to mechanical methods, chemical cleaning presents a viable alternative. This technique involves applying chemical solutions to dissolve and remove contaminants such as oils, greases, and other residues. It is particularly useful for delicate substrates or intricate parts that require careful handling. In Pune’s industrial landscape, where intricate machinery is common, chemical cleaning can ensure surfaces are pristine without risking damage.

3. Grinding and Sanding: These mechanical methods are ideal for smoothing out surfaces and preparing them for coatings. Grinding can remove imperfections, while sanding provides a finer finish. This technique is often employed on wood and metal surfaces, ensuring that they are smooth and free of debris. For artisans and manufacturers in Pune who work with custom furniture or metal fabrication, grinding and sanding are indispensable for achieving a flawless finish.

4. Power Washing: For larger surfaces, such as buildings or outdoor structures, power washing is an efficient way to remove dirt, mold, and mildew. This technique utilizes high-pressure water jets to clean surfaces thoroughly. In Pune, where pollution can accumulate on exteriors, power washing not only prepares surfaces for painting or sealing but also enhances the overall look of the property.

5. Hand Scraping and Wire Brushing: While more labor-intensive, hand scraping and wire brushing are effective for detailed and intricate surfaces. These methods allow for precision in cleaning and preparing surfaces, especially in areas where larger machines cannot reach. For craftspeople in Pune who prioritize craftsmanship, these techniques are vital for ensuring every detail is perfect.

By employing these surface preparation techniques, businesses and artisans in Pune can ensure their projects not only meet industry standards but also create lasting impressions. Proper surface preparation not only enhances adhesion and durability but also sets the stage for a flawless finish, ultimately leading to customer satisfaction and repeat business.

Why Pre-Treatment is Essential for Different Materials

Pre-treatment is a crucial step in the surface preparation process, especially when dealing with a variety of materials. In Pune, where the climate can vary significantly, understanding the specific needs of each material becomes even more vital for achieving optimal results.

For metals, pre-treatment not only enhances adhesion but also prevents rust and corrosion. Processes such as sandblasting or acid etching remove any surface contaminants and oxidized layers, creating a clean slate that allows paints and coatings to bond effectively. This is particularly important in an industrial hub like Pune, where metal components face exposure to harsh environmental conditions.

When it comes to wood, pre-treatment is equally critical. Wood is porous and can absorb moisture, which may lead to warping or deterioration over time. Applying a suitable pre-treatment sealant ensures that the wood is protected from moisture intrusion and provides a better surface for stains and paints to adhere to. In a city where humidity levels can fluctuate, this step is vital for prolonging the life and appearance of wooden surfaces.

For plastics, pre-treatment methods such as flame treatment or plasma treatment help to modify the surface energy, enhancing the adhesion of inks, adhesives, and coatings. Given the increasing use of plastics in various applications, ensuring optimal surface preparation through pre-treatment can significantly improve the performance and durability of the final product.

In summary, pre-treatment acts as a foundational step that caters to the unique requirements of different materials. By investing time and resources into this critical process, businesses in Pune can ensure that their surfaces are not only visually appealing but also durable and long-lasting, thereby achieving a level of perfection in their projects that stands the test of time.

Overview of Pre-Treatment Methods Used in Pune

In Pune, the importance of surface preparation cannot be overstated, and a key component of this process is pre-treatment. Various pre-treatment methods are employed by industries across the city to enhance the quality and durability of surfaces before they undergo further treatment, such as painting, coating, or finishing. Each method serves a unique purpose, tailored to the specific needs of the substrate and the final application.

One of the most common pre-treatment methods used in Pune is abrasive blasting. This technique involves the use of high-velocity particles to clean and prepare surfaces, effectively removing rust, old paint, and other contaminants. The result is a clean, roughened surface that promotes better adhesion of subsequent coatings. Industries that deal with metal fabrication and manufacturing frequently rely on this method to ensure optimal surface conditions.

Another prevalent pre-treatment method is chemical cleaning. This technique utilizes various chemical solutions to remove oils, grease, and other residues that may hinder the bonding of coatings. Chemical cleaning is particularly beneficial for intricate parts or components with complex geometries where abrasive methods may be less effective. In Pune, manufacturers often choose environmentally friendly chemical agents to align with sustainability practices while achieving the desired cleanliness.

Phosphate conversion coating is also widely utilized, particularly in the automotive and appliance industries. This process involves applying a phosphate solution to metal surfaces, creating a protective layer that enhances corrosion resistance and improves paint adhesion. Pune’s automotive sector, in particular, has embraced this method to ensure longevity and durability in their products.

Furthermore, electrochemical treatments are gaining traction in Pune as a sophisticated means to prepare surfaces. By employing electrical current, these treatments can modify the surface properties of metals, enhancing their resistance to corrosion and wear. This method is particularly advantageous for high-performance applications where durability is paramount.

Overall, the pre-treatment methods employed in Pune are diverse and tailored to meet the specific demands of various industries. By investing in these essential processes, businesses not only improve the quality and longevity of their products but also contribute to a more sustainable manufacturing environment. The careful selection and execution of pre-treatment techniques are vital steps toward achieving perfection in surface preparation.

Benefits of Proper Surface Preparation

Proper surface preparation is the unsung hero of any successful coating or finishing project, and its benefits are manifold, especially in a bustling industrial hub like Pune. When surfaces are meticulously prepared, the end results are not just visually appealing; they are durable and long-lasting, which can significantly enhance the overall quality and performance of the finished product.

One of the most significant benefits of proper surface preparation is improved adhesion. When surfaces are cleaned, smoothed, and primed correctly, coatings adhere more effectively, reducing the risk of peeling, blistering, or chipping down the line. This translates into reduced maintenance costs and prolonged lifespan for applications ranging from industrial machinery to residential interiors.

Additionally, proper surface preparation helps to identify and rectify any underlying issues before they escalate. Whether it’s rust on metal or mold on wood, addressing these problems during the preparation phase ensures that the surface is not only ready for finishing but also robust against future deterioration. This proactive approach can save time and resources by preventing costly repairs and replacements in the future.

Moreover, investing time and effort into surface preparation can enhance the aesthetic appeal of the final product. A well-prepared surface allows for a smoother application of paint or finish, resulting in a flawless, professional look that can elevate the overall perception of quality. In competitive markets like Pune, where first impressions matter, this can be a key differentiator.

Finally, proper surface preparation contributes to safety and environmental compliance. By ensuring that surfaces are free of contaminants and prepared in accordance with industry standards, businesses can mitigate risks associated with hazardous materials and promote a safer working environment.

In summary, the benefits of proper surface preparation are clear: enhanced adhesion, identification of underlying issues, improved aesthetics, and adherence to safety standards. For businesses in Pune aiming for perfection, investing in this critical stage of the coating process is a strategic move that pays dividends in the long run.

The Impact of Climate on Surface Preparation in Pune

Pune, known for its diverse climate that ranges from the humid monsoon season to the dry summer months, presents unique challenges for surface preparation. Understanding these climatic variations is crucial for achieving a flawless finish in any surface treatment project.

During the monsoon season, which typically spans from June to September, the heavy rainfall and high humidity can significantly affect the curing and adhesion of paints and coatings. Moisture can lead to issues such as blistering, peeling, and uneven finishes, compromising the quality of the surface preparation. Therefore, it is essential to monitor humidity levels closely and consider using moisture-resistant primers or coatings specifically designed for high-humidity conditions.

Conversely, the dry heat of Pune’s summer months can also pose challenges. High temperatures can accelerate the curing process, leading to rapid evaporation of solvents in paints and coatings. This can result in a phenomenon known as “dry spray,” where the paint particles dry before adequately adhering to the surface, causing a rough and uneven texture. To mitigate this, it’s advisable to schedule surface preparation activities during the cooler parts of the day or use additives that allow for a slower drying time, ensuring a smooth and even application.

Additionally, the dust and particulate matter often prevalent during the summer can settle on surfaces, contaminating the area and leading to subpar adhesion. Regular cleaning and dust control measures become vital in this scenario to ensure surfaces are pristine before treatment.

In essence, recognizing the impact of Pune’s climate on surface preparation is not just about timing — it’s about employing strategies and materials that accommodate environmental conditions. By tailoring your approach to the specific weather patterns and seasonal changes, you can enhance the effectiveness of your surface preparation efforts, ensuring a durable and aesthetically pleasing finish that stands the test of time.

Choosing the Right Pre-Treatment Process for Your Project

Choosing the right pre-treatment process for your project is crucial to achieving the desired results and ensuring the longevity of the finished surface. In Pune, where the diverse climate can pose unique challenges to surface preparation, it’s essential to tailor your approach to suit the specific materials and environmental conditions you are working with.

First and foremost, assess the type of surface you are dealing with. Metal surfaces, for instance, may require processes such as sandblasting or acid etching to remove rust, old paint, or contaminants. These methods not only clean the surface but also create a profile that enhances adhesion for subsequent coatings. On the other hand, concrete surfaces may benefit from processes like shot blasting or grinding, which help to remove laitance and ensure a solid bond between the substrate and the overlay.

Consider the end use of the surface as well. For high-traffic areas or industrial applications, a more intensive pre-treatment like chemical cleaning may be warranted to ensure durability and resistance to wear and tear. Conversely, for decorative or lighter-duty surfaces, a simpler method may suffice, balancing efficiency with aesthetic appeal.

Another factor to weigh is the environmental impact of your chosen pre-treatment method. In Pune, where regulations on waste disposal and chemical use are becoming increasingly stringent, opting for eco-friendly alternatives can not only help you comply with local laws but also enhance your brand’s reputation as a responsible entity.

Lastly, don’t overlook the expertise of your team or contractors. A skilled professional can provide invaluable insights into the most effective pre-treatment strategy based on their experience with similar projects. Collaborating with experts familiar with Pune’s specific conditions and challenges will ultimately lead to a smoother process and superior outcomes.

By carefully selecting the appropriate pre-treatment process for your surface preparation project, you lay the groundwork for achieving perfection, ensuring the durability and aesthetic quality of your final finish.

Case Studies: Successful Projects in Pune

In the bustling city of Pune, where modernity intertwines with tradition, several successful projects exemplify the transformative power of effective pre-treatment for surface preparation. These case studies not only highlight the importance of meticulous preparation but also illustrate how it can elevate the quality and longevity of various surface applications.

One notable project involved a leading automotive manufacturer that sought to enhance the durability of their vehicle exteriors. Faced with the challenges of Pune’s diverse climate, which fluctuates between monsoons and dry spells, the company opted for a rigorous pre-treatment process. By implementing advanced techniques such as sandblasting and chemical cleaning, they successfully removed impurities and ensured a smooth surface for painting. The result? A significant reduction in corrosion-related issues, leading to increased customer satisfaction and a notable uptick in sales due to the enhanced aesthetic appeal of their vehicles.

Another compelling case can be found in Pune’s vibrant commercial sector, where a prominent office complex underwent extensive renovations. The project team recognized that the longevity of their floor finishes depended on thorough surface preparation. Utilizing diamond grinding techniques, they meticulously prepared the concrete surfaces, eliminating any imperfections. This attention to detail not only resulted in a flawless finish but also minimized future maintenance costs, demonstrating the economic benefits of investing in proper pre-treatment.

Lastly, a local hospital’s renovation project stands as a testament to the critical role of surface preparation in healthcare environments. With stringent hygiene requirements, the facility management team prioritized pre-treatment to ensure a clean and safe environment for patients. By employing high-pressure washing and antimicrobial surface treatments, they successfully created a sterile setting that exceeded industry standards. This commitment to quality not only enhanced the hospital’s reputation but also instilled confidence among patients and their families.

These case studies from Pune illustrate that the importance of pre-treatment for surface preparation extends beyond aesthetics; it is fundamental to performance, longevity, and overall satisfaction across various industries. As businesses continue to recognize the value of investing in quality surface preparation, they pave the way for successful projects that stand the test of time.

Common Mistakes to Avoid in Surface Preparation

When it comes to surface preparation, particularly in a bustling industrial hub like Pune, even the smallest missteps can lead to significant setbacks. To ensure your project achieves perfection, it’s crucial to be aware of and avoid common mistakes that can compromise the integrity of your surface treatment.

One prevalent error is neglecting thorough cleaning before applying any treatments. Dust, grease, and contaminants can hinder adhesion and lead to unsatisfactory results. Always start with a meticulous cleaning process, using the appropriate solvents or cleaners tailored to the specific surface material.

Another mistake is skipping the assessment of the surface condition. Failing to identify issues such as cracks, rust, or previous coatings can result in inadequate preparation. Conduct a thorough inspection and address any imperfections to create a uniform surface that can effectively receive subsequent treatments.

Additionally, using the wrong tools or techniques can also jeopardize your efforts. For instance, employing abrasive methods that are too harsh can damage delicate surfaces, while inadequate sanding may leave imperfections that are visible after treatment. Invest in the right tools and training to ensure that the chosen methods are suitable for your specific application.

Lastly, timing can be critical in surface preparation. Rushing through the process or applying treatments too soon can lead to poor adhesion or bubbling. Allow sufficient time for each step, ensuring that surfaces are dry and ready for the next stage.

By being mindful of these common pitfalls, you can enhance the efficacy of your surface preparation, paving the way for a flawless finish that stands the test of time in Pune’s demanding environment.

The Future of Surface Treatment Technologies

As we look toward the horizon of surface treatment technologies, it becomes increasingly clear that innovation is the driving force behind enhanced performance and sustainability. In Pune, where industries are rapidly evolving, the future of surface treatment is poised to leverage advanced techniques that not only improve product life but also minimize environmental impact.

One notable trend is the rise of eco-friendly treatments. With a growing emphasis on sustainability, manufacturers are exploring bio-based and non-toxic alternatives to traditional chemical treatments. These advancements not only reduce the ecological footprint of surface preparation processes but also cater to a market that is becoming more conscious of environmental issues. Industries that adopt these greener technologies will not only comply with regulatory standards but also attract customers who prioritize sustainability.

Moreover, the integration of automation and AI in surface treatment processes is set to revolutionize the industry. Automated systems can ensure consistency and precision in surface preparation, reducing human error and increasing efficiency. AI-driven analytics can provide real-time data on surface conditions, enabling businesses to make informed decisions and optimize their treatment strategies. This shift towards smart technologies will not only enhance productivity but also reduce costs in the long run.

Furthermore, as the demand for customization grows, surface treatment technologies will evolve to offer tailored solutions that meet specific client needs. From bespoke coatings that enhance aesthetic appeal to specialized treatments that improve functionality, the future will see a more personalized approach to surface preparation.

In essence, the future of surface treatment technologies in Pune is bright, characterized by sustainability, automation, and customization. As industries embrace these advancements, they will not only improve their operational efficiency but also position themselves as leaders in an increasingly competitive market. Embracing these changes will be essential for businesses aiming to achieve perfection in surface preparation and stay ahead in the game.

Expert Tips for Effective Surface Preparation

Effective surface preparation is the cornerstone of any successful finishing project, whether it’s painting, coating, or flooring. In Pune, where the climate can be both humid and dry, achieving perfection in surface preparation is essential to ensure longevity and durability of the finishes applied. Here are some expert tips to help you master the art of surface preparation:

1. Assess the Surface Condition: Before diving into any preparation work, take the time to thoroughly assess the surface. Look for existing coatings, rust, dirt, or any imperfections that may affect the final result. Understanding the current state of your surface will help you choose the right preparation method.

2. Choose the Right Tools: The tools you select can make a significant difference in the preparation process. For large areas, consider using a power sander or grinder, while smaller spaces might require hand tools like scrapers and sandpaper. Selecting the appropriate grit size is also crucial; coarser grits are ideal for removing old finishes, while finer grits prepare the surface for a smooth, even application.

3. Clean Thoroughly: Cleanliness is paramount. Dust, grease, and debris can hinder adhesion and lead to a poor finish. Use a suitable cleaner, such as a degreaser or a pressure washer, to ensure the surface is spotless. In Pune’s often dusty environment, this step is particularly vital to eliminate any contaminants.

4. Repair Imperfections: After cleaning, take a close look for any cracks, holes, or other imperfections. Fill these with a suitable filler and sand them down to create a uniform surface. This attention to detail not only enhances the aesthetic appeal but also strengthens the overall integrity of the finish.

5. Ensure Proper Drying: If you’re working with surfaces that have been recently cleaned or repaired, allow ample time for drying. In Pune, humidity can affect drying times, so it’s important to plan accordingly to avoid applying finishes on damp surfaces which can lead to peeling and bubbling.

6. Test a Small Area: Before proceeding with the full application, test your preparation on a small, inconspicuous area. This will allow you to confirm that your surface is ready and that the finishing products will adhere properly.

7. Follow Manufacturer Instructions: Each coating product may have specific surface preparation requirements, so always refer to the manufacturer’s guidelines. Following these can make a significant difference in the overall outcome.

By implementing these expert tips, you can ensure that your surface preparation is thorough and effective, setting the stage for a flawless finish that will withstand the test of time, even in Pune’s diverse weather conditions. Remember, the effort you put into preparation today pays off with stunning results tomorrow.

Conclusion: Striving for Perfection in Every Project

In the bustling industrial landscape of Pune, where precision and quality are paramount, the journey toward achieving perfection in surface preparation begins with a steadfast commitment to pre-treatment practices. As we conclude our exploration of this critical phase, it’s clear that the importance of meticulous surface preparation cannot be overstated.

Every project, whether it involves the application of coatings, adhesives, or other surface treatments, hinges on the foundation laid during pre-treatment. By investing time and resources into this essential step, businesses can not only enhance the durability and performance of their products but also minimize the need for costly rework and repairs down the line.

Striving for perfection means understanding that every detail matters. From thoroughly cleaning the surface to select appropriate methods for removing contaminants and defects, each aspect of the pre-treatment process contributes to the overall success of the project. In Pune, where competition is fierce and client expectations are high, maintaining a reputation for excellence can set a business apart.

As we move forward, let us embrace the philosophy that perfection is not merely a goal but a continuous journey. By prioritizing pre-treatment in every project, we ensure that we are not only meeting but exceeding industry standards and customer expectations. In doing so, we solidify our position as leaders in quality and innovation, paving the way for a brighter, more successful future in Pune’s dynamic market. Remember, the pursuit of perfection starts long before the final coat is applied; it begins with a commitment to thorough, diligent pre-treatment.

Resources for Further Reading and Learning

When it comes to mastering the art of surface preparation and understanding the pivotal role of pre-treatment, having access to reliable resources can significantly enhance your knowledge and skills. Whether you are a seasoned professional or a newcomer to the field, exploring additional materials can provide you with valuable insights and practical tips that can be applied in your projects.

Books and Manuals

Start with authoritative texts such as “Surface Preparation: The Key to Successful Coatings” by John Doe, which delves into various techniques and methodologies. For those looking for more technical guidance, “Coating Application and Surface Preparation” offers a comprehensive overview of processes and best practices in the industry.

Online Courses

Websites like Coursera and Udemy offer courses focused on surface preparation and pre-treatment processes. These courses often include video lectures, quizzes, and even practical assignments that can help solidify your understanding. Check for courses specifically tailored to the Indian market, as they may address local materials and practices.

Industry Journals and Articles

Stay updated with the latest research and trends by reading industry journals such as the Journal of Coatings Technology and Research. These publications often feature articles authored by experts discussing innovations, case studies, and the latest technologies in surface preparation.

Webinars and Workshops

Look for webinars hosted by industry leaders or organizations such as the Society for Protective Coatings. These interactive sessions can provide real-time insights and allow for Q&A sessions with experts, offering direct access to their knowledge and experience.

Local Networking

In Pune, consider joining local chapters of professional organizations or trade associations related to coatings and surface preparation. Engaging with fellow professionals through networking events can lead to valuable exchanges of information and mentorship opportunities.

By utilizing these resources, you can deepen your understanding of pre-treatment practices and elevate the quality of your work. Knowledge is power, and in the realm of surface preparation, staying informed ensures you are always at the top of your game.

In conclusion, achieving perfection in any surface preparation project in Pune hinges on the critical step of pre-treatment. As we’ve explored throughout this blog post, effective pre-treatment not only enhances the adhesion and longevity of coatings but also mitigates the risk of defects that can compromise your work. By understanding the various techniques and materials available for pre-treatment, you equip yourself with the tools necessary to elevate your projects to the highest standard. Whether you’re an industry professional or a DIY enthusiast, embracing these practices will lead to remarkable results and a polished finish that stands the test of time. We hope this guide empowers you to confidently approach your next surface preparation task, ultimately transforming your vision into perfection. Don’t hesitate to share your experiences and successes with us as you embark on this journey!

Read More

#cnc punching services in pune#best spot welding services in pune#best cnc bending services india#best mig welding machine#best ss fabrication services in india#pre-treatment for surface preparation in pune

0 notes

Text

What is steel fabrication machines do?

Let's dive in! Steel fabrication machines are essential tools used to shape and assemble steel materials into various structures and products. From cutting and bending to welding and finishing, these machines streamline the fabrication process, making it efficient and precise. Whether you're crafting intricate designs or industrial components, steel fabrication machines are the backbone of the manufacturing industry. Explore the world of steel fabrication and unleash your creativity!

#steel fabrication#steel fabricators near me#custom sheet metal fabrication#welding machine#welding services

0 notes

Text

Custom Best Laser Cutting Services for All Industries

With our custom best laser cutting services, suitable for all industries, you can experience precision! With the use of cutting-edge laser technology, we produce flawless, high-quality cuts for everything from complex designs to massive projects. Put your trust in our experience for precise, effective, and dependable results, whether it be for manufacturing, construction, or custom work. With the help of our best laser cutting services, elevate your projects!

#laser cutting service#best laser cutting services in new zealand#metal skills#metal skills new zealand#metal fabrication#stainless welding

0 notes

Text

Choosing the Right Technique for Sheet Metal Welding: MIG vs. TIG Welding

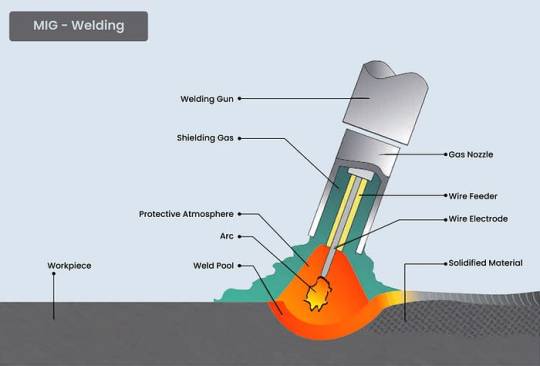

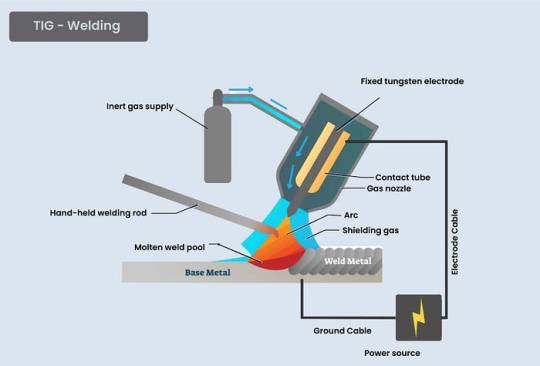

Welding is a crucial process in metal fabrication, and when it comes to sheet metal cutting, two popular techniques stand out — MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding. Each technique has its strengths and weaknesses, making the choice between them essential for achieving optimal results in sheet metal applications. In this blog, we will delve into the key differences between MIG and TIG welding, explore their suitability for sheet metal cutting, discuss the pros and cons of each method, highlight factors influencing the choice between them, and provide real-life examples of successful sheet metal cutting using both techniques.

What is MIG welding?

MIG welding involves a continuous wire feed that is fed through a welding gun and melted into the joint. A shielding gas, typically a mixture of argon and carbon dioxide, protects the weld pool from atmospheric contaminants. MIG welding is known for its efficiency and speed, making it a popular choice for various applications

What is TIG welding?

TIG welding is done by using a non-consumable tungsten electrode. The welder manually feeds a filler rod into the weld pool, which is protected by an inert gas, usually argon. TIG welding is recognized for its precision, control, and ability to produce high-quality welds on thin materials.

Which Welding Technique Is More Suitable for Sheet Metal Welding?

The choice between MIG and TIG welding for sheet metal cutting depends on several factors, including the thickness of the metal, the required precision, and the desired finish.

– MIG Welding for Sheet Metal Welding:

MIG welding is well-suited for cutting thin sheet metals due to its high travel speed and efficiency. It is ideal for projects where speed is crucial, such as in mass-production environments. However, MIG welding may not provide the same level of precision as TIG welding, and the heat input can sometimes be a concern for thinner materials.

– TIG Welding for Sheet Metal Welding:

TIG welding is preferred for cutting thinner sheet metals when precision and a clean finish are essential. It offers excellent control over the heat input, reducing the risk of warping or distortion in the metal. TIG welding is commonly used for intricate designs and projects where aesthetics and precision are critical.

What are The Pros and cons of MIG and TIG welding in sheet metal applications?

Pros:

High welding speed, making it suitable for mass production.

Good for thicker sheet metals.

Minimal skill requirement compared to TIG welding.

Cons:

Limited precision, which may not be suitable for intricate designs.

More heat input increases the risk of warping with thin materials.

Pros:

Excellent precision and control, making it ideal for thin sheet metals.

Clean and aesthetically pleasing welds.

Low heat input, reducing the risk of distortion.

Cons:

Slower welding speed compared to MIG welding.

Requires a higher skill level.

What Factors Need to Be Consider When Selecting the Appropriate Welding Method?

Choosing the right welding method for sheet metal cutting involves considering various factors to ensure the desired outcome. Here are some key considerations:

– Material Thickness:

MIG welding is more suitable for thicker sheet metals, while TIG welding excels in precision work on thinner materials.

– Precision Requirements:

If the project demands high precision and intricate detailing, TIG welding is often the preferred choice.

– Speed and Efficiency:

MIG welding is faster and more efficient, making it suitable for projects with tight deadlines and large production volumes.

– Skill Level:

Consider the skill level of the welder, as TIG welding requires more expertise than MIG welding.

– Aesthetics:

If the appearance of the weld is crucial, such as in architectural or decorative applications, TIG welding is often preferred for its cleaner finish.

– Cost Considerations:

Evaluate the cost of equipment, consumables, and labour associated with each welding method to determine the most economical choice for the project.

Read More-https://www.lsw.co.in/choosing-the-right-technique-for-sheet-metal-welding-mig-vs-tig-welding/

#manufacturing#aviation#construction#sheet metal fabrication manufacturers#metalworking#welding services

0 notes

Text

We are a reliable steel fabricator in NYC! We weld our steel plates with quality and precision to ensure all our customers are happy and inspections are always passed. Call us for a quote today! http://tinyurl.com/mpvmmesp

0 notes