#3D Scanning And Reverse Engineering

Explore tagged Tumblr posts

Text

Driving Innovation in Mechanical Services: From 3D Scanning to Rapid Prototyping

In the dynamic world of architecture, where creativity converges with engineering precision, Engineer2Go emerges as the quintessential destination for those seeking the pinnacle of architectural design services. With an unwavering commitment to excellence, we bring forth a synergy of innovation, functionality, and aesthetics that redefine the realm of architectural design.

Crafting Brilliance: The Best Architectural Design Services

Engineer2Go stands as a beacon of ingenuity, offering unparalleled architectural design services that are meticulously tailored to your unique vision. Our seasoned team of architects and designers embarks on each project with a fervour for creating spaces that transcend ordinary boundaries. From residential abodes to commercial marvels, we craft architectural designs that epitomise elegance and functionality.

Setting the Standard: Drawing Requirements

Recognizing the significance of precise drawings in the architectural journey, we uphold the highest standards of drawing requirements. Our meticulous approach encompasses an intricate array of plans, elevations, sections, and intricately detailed layouts that form the blueprint of your dreams. Engineer 2Go's Drawing Requirements not only adhere to industry norms but exceed them, underscoring our dedication to realising your vision with utmost precision.

Precision Redefined: Engineering Drawings

The foundation of any successful construction endeavour lies in engineering drawings that lay out the intricate details of your project. Engineer2Go's proficient engineers translate concepts into meticulously detailed engineering drawings, encompassing everything from structural integrity to intricate MEP systems. Our engineering drawings serve as the linchpin for seamless execution, ensuring your vision becomes a tangible reality.

Beyond Imagination: 3D Architectural Design

Unlock a new dimension of architectural visualisation with our avant-garde 3D architectural design services. With technology as our ally, we breathe life into your ideas, creating immersive 3D renderings that transport you into your envisioned space. Engineer2Go's 3D designs offer insights into spatial dynamics, lighting nuances, and material interplay, empowering you to make informed decisions and witness your design come to life even before construction commences.

The Engineer2Go Advantage

Expertise: Our accomplished team of architects and engineers bring years of experience and a wealth of knowledge to every project.

Innovation: At Engineer2Go, innovation is the cornerstone. We integrate the latest trends and technologies to infuse a fresh perspective into our designs.

Client-Centric Approach: Your aspirations form the heart of our design process. We collaborate closely with you, understanding your goals to shape designs that resonate with your vision.

Uncompromising Quality: Excellence is our mantra. Every step of the way, we uphold the highest standards of quality to deliver outcomes that exude brilliance.

In a world where architectural dreams are forged with meticulous attention to detail, Engineer2Go emerges as a trailblazer. From the finest architectural design services to meeting the most intricate drawing requirements and harnessing the power of 3D architectural design, we stand as your partner in turning visions into tangible wonders. Embark on a journey of unrivalled design and engineering mastery with Engineer2Go - where innovation and imagination converge.

#Mechanical services#3D Scanning And Reverse Engineering#rapid prototyping 3d printing#Cad Drafting and Design

0 notes

Text

What Is Reverse Engineering and When Should You Use It?

In today’s competitive and innovation-driven manufacturing landscape, companies are continually searching for methods to optimize designs, streamline production, and gain deeper insight into existing products. One of the most powerful yet often misunderstood tools that supports these objectives is reverse engineering.

Reverse engineering enables organizations to deconstruct a product or system to understand its components, functions, and design principles. This process is not only used to replicate products but also to analyze their structure, improve upon them, or integrate them into new applications.

This article offers a comprehensive explanation of reverse engineering—what it is, how it works, the technologies involved, its applications across industries, and the scenarios where it proves most valuable.

Defining Reverse Engineering

At its core, reverse engineering is the process of disassembling or analyzing an object to understand how it was designed and manufactured. It involves extracting design information from existing products, often in the absence of technical documentation or original design files.

Unlike traditional engineering, which moves from concept to product, reverse engineering starts with the finished item and works backwards to deduce the original specifications. The insights gained are often used to:

Create 3D models and CAD files

Improve product design

Develop compatible components

Diagnose failures or weaknesses

Reproduce obsolete or legacy parts

Reverse engineering does not necessarily imply copying or duplication. Rather, it is a legitimate and valuable practice in modern product development, maintenance, and innovation.

How Reverse Engineering Works

The reverse engineering process varies depending on the object, industry, and intended outcome, but it generally follows a consistent sequence:

1. Data Acquisition

The first step involves capturing detailed information about the object’s geometry, dimensions, and features. This is typically done using advanced 3D scanning technologies such as:

Laser Scanners: Emit laser beams to detect surface contours.

Structured Light Scanners: Project light patterns and measure distortions to determine surface geometry.

Computed Tomography (CT) Scanners: Capture both internal and external features using X-ray technology.

Coordinate Measuring Machines (CMMs): Use touch probes to precisely measure specific points.

These tools collect millions of data points, forming a comprehensive digital representation of the object known as a point cloud.

2. Data Processing and Mesh Generation

The raw point cloud data is cleaned, aligned, and processed to remove noise and inconsistencies. The next step is to convert the point cloud into a polygonal mesh—a 3D surface composed of interconnected triangles.

This mesh is then optimized to ensure it accurately reflects the physical object’s shape while maintaining a manageable file size for further use.

3. 3D Modeling and CAD Conversion

Once a high-quality mesh is obtained, it is used to reconstruct the object in a computer-aided design (CAD) environment. Engineers develop a fully parametric or feature-based CAD model that replicates the part’s geometry.

At this stage, material specifications, tolerances, and functional features may also be analyzed and documented. The final CAD model can be edited, shared, or integrated into larger assemblies.

4. Analysis and Application

The finished model is then used for various purposes, including design improvements, simulation, tooling development, or manufacturing reproduction. Engineers may also perform stress tests, fit checks, and other simulations using the digital model.

Key Technologies in Reverse Engineering

Advances in digital manufacturing and metrology have significantly expanded the capabilities of reverse engineering. The following technologies are essential:

3D Scanning

High-resolution 3D scanning tools rapidly capture the surface geometry of physical objects, forming the foundation for all subsequent steps. These scanners vary in accuracy, speed, and suitability depending on the object's size, complexity, and material.

CAD Software

CAD platforms such as SolidWorks, Autodesk Inventor, Siemens NX, and others play a crucial role in interpreting scanned data and creating usable design files. These models are often parametric, allowing engineers to modify features and dimensions easily.

Simulation Tools

Finite Element Analysis (FEA) and other simulation tools are used in conjunction with CAD models to evaluate a product’s performance under various conditions. These insights support design optimization and failure analysis.

3D Printing and Prototyping

Rapid prototyping allows teams to test modifications derived from reverse engineering efforts. By printing physical models, engineers can assess fit, function, and ergonomics quickly and affordably.

When Should You Use Reverse Engineering?

Reverse engineering is applicable in a wide range of situations across multiple industries. It is especially useful when dealing with legacy components, product innovation, or systems integration. Below are the most common scenarios that justify the use of reverse engineering.

1. Recreating Obsolete or Legacy Parts

One of the primary uses of reverse engineering is to reproduce discontinued components for machines, vehicles, or systems that are no longer supported by the original manufacturer. With no access to original drawings or tooling, reverse engineering provides a reliable way to maintain critical assets and extend their lifecycle.

This is particularly valuable in aerospace, defense, rail, and heavy industries, where replacing entire systems is impractical or cost-prohibitive.

2. Product Improvement and Optimization

Reverse engineering enables manufacturers to analyze existing products and identify opportunities for improvement. Engineers can assess design weaknesses, material inefficiencies, or manufacturing complexities and apply innovative solutions to enhance performance, durability, or cost-effectiveness.

The process often leads to

Lighter and stronger designs

Reduced manufacturing steps

Better ergonomics or aesthetics

Improved energy efficiency

3. Competitive Analysis

Organisations often use reverse engineering to examine competitor products and gain insights into their features, performance, and manufacturing techniques. This helps in benchmarking, identifying intellectual property challenges, and driving innovation.

While care must be taken to respect legal and ethical boundaries, competitive reverse engineering is a legitimate practice used for market intelligence and strategic planning.

4. Integrating New Components with Existing Systems

In cases where new parts or systems need to work seamlessly with older components, reverse engineering ensures dimensional compatibility and functionality. By modeling the existing hardware accurately, engineers can design new components that align perfectly without trial and error.

This use is common in:

Automotive retrofits

Industrial equipment upgrades

Electronic system integration

5. Quality Control and Inspection

Reverse engineering is sometimes used as a validation tool in quality assurance. By scanning and modeling a manufactured part, teams can compare it to the original design and detect any deviations or defects.

This process enhances dimensional verification, especially for complex geometries that are difficult to measure with traditional tools.

6. Digital Archiving

Preserving the design data of critical components through reverse engineering creates a digital archive for future reference. This is important in museums, aerospace restoration, and asset management, ensuring that data is never lost even if physical components degrade or disappear.

Industries Benefiting from Reverse Engineering

The versatility of reverse engineering means it is widely applicable across a variety of sectors:

Aerospace

Airplane components, many of which have long service lifecycles, often require replacement or refurbishment after the original manufacturing data is lost. Reverse engineering ensures structural integrity and regulatory compliance.

Automotive

Classic cars, custom vehicles, and prototype parts benefit greatly from reverse engineering. It enables part reproduction, modification, and even digital recreation of entire vehicle systems.

Medical Devices

Medical implants, prosthetics, and surgical instruments are reverse-engineered to improve functionality, ensure anatomical fit, or replicate discontinued designs.

Consumer Electronics

Electronics companies often disassemble products to understand PCB layouts, circuitry, and design logic. This enables repair, customization, or the development of compatible accessories.

Industrial Manufacturing

Reverse engineering supports tooling design, process improvement, and machine maintenance. It is also used to digitize old parts or machinery for integration into modern workflows.

The Role of Reverse Engineering in Innovation

Beyond its practical applications, reverse engineering fosters innovation by bridging the gap between legacy knowledge and modern capabilities. It encourages experimentation, cross-functional learning, and iterative improvement.

By understanding the details of how a product works, engineers can:

Identify underutilized features

Explore alternative materials

Develop more efficient manufacturing methods

Combine legacy and modern technologies

This approach is particularly important for companies striving to remain competitive in rapidly evolving markets. It allows them to leapfrog development stages, reduce R&D costs, and bring products to market faster.

Ethical and Legal Considerations

While reverse engineering is a powerful tool, it must be practiced within ethical and legal boundaries. It is important to respect patents, copyrights, trade secrets, and intellectual property (IP) rights.

Organizations using reverse engineering must ensure their efforts do not infringe on protected designs. In many jurisdictions, reverse engineering for interoperability or repair purposes is legal, but copying patented elements without permission is not.

Working with professional providers of reverse engineering services in Australia ensures that all procedures are carried out in compliance with local laws and international IP standards.

Choosing the Right Reverse Engineering Partner

The effectiveness of reverse engineering relies heavily on the skill, experience, and tools used. Partnering with specialists who understand materials science, digital modeling, and manufacturing processes ensures accurate, high-quality results.

Providers offering reverse engineering services in Australia are equipped with advanced scanning systems, robust CAD platforms, and cross-industry expertise. They help clients navigate complex engineering challenges, from legacy part digitization to modern product development, while maintaining confidentiality and regulatory compliance.

Conclusion

Reverse engineering is a powerful, multi-purpose process that enables organizations to derive valuable design and manufacturing data from existing physical products. Whether used for reproduction, enhancement, integration, or analysis, it offers significant advantages across the product lifecycle.

By turning physical objects into digital intelligence, reverse engineering allows industries to move forward while learning from the past. It supports innovation, sustainability, and precision in a world where adaptability and speed are crucial to success.

As industries increasingly adopt digital technologies and advanced manufacturing techniques, reverse engineering will play an even more integral role—especially when executed by trusted professionals who offer comprehensive reverse engineering services in Australia and beyond.

#reverse engineering#product development#3D scanning#CAD modeling#engineering services#component analysis#design replication

1 note

·

View note

Text

Artec Point

Introducing the Artec Point: Artec 3D's first target-based 3D laser scanner with ISO-certified, metrology-grade precision. Capture intricate surfaces with up to 0.02 mm accuracy, even on black or shiny finishes. Switch between grid, parallel, and single-laser modes for optimized results, while HD cameras tackle tight spaces. Built tough with a lightweight metal chassis for industrial use. Perfect for quality control and reverse engineering, delivering reliable data, fast!

Know More: https://altem.com/artec-point/

0 notes

Text

Sheet Metal Forming: Enhancing Precision with 3D Scanning and Reverse Engineering

Reverse Engineering

Sheet metal forming is a vital manufacturing process used to create metal components for industries such as automotive, aerospace, and heavy machinery. This process involves shaping metal sheets into various forms using techniques like bending, stamping, and drawing. While traditional methods are still widely used, the integration of 3D scanning and reverse engineering technologies has revolutionized sheet metal forming, making it more efficient and precise than ever before.

How 3D Scanning is Transforming Sheet Metal Forming

One of the main challenges in sheet metal forming is ensuring that the final product meets exact design specifications. In traditional setups, this requires manual inspections and measuring, which can be time-consuming and prone to human error. 3D scanning has changed this landscape by enabling manufacturers to capture detailed and accurate 3D models of metal components. These models allow for precise analysis and ensure that parts are produced to exact measurements.

With high-precision 3D metrology, manufacturers can significantly reduce material wastage, minimize errors, and streamline the overall production process. This not only improves efficiency but also cuts down on costs related to rework and rejected parts.

Reverse Engineering in Sheet Metal Forming

Reverse engineering is another critical tool that complements 3D scanning in sheet metal forming. It allows manufacturers to recreate or modify existing parts when original designs or documentation are unavailable. Using reverse engineering, companies can scan a physical part, analyze its geometry, and generate digital models that can be used for redesign or reproduction.

This process is particularly useful when working with legacy equipment or when making design improvements to existing parts. Reverse engineering enables manufacturers to optimize designs for better performance, durability, and ease of production. Additionally, it plays a crucial role in quality control and inspection services, ensuring that every piece of metalwork aligns with the required standards.

Benefits of 3D Scanning and Reverse Engineering in Metal Forming

The integration of 3D scanning and reverse engineering into the sheet metal forming process offers numerous advantages:

Accuracy: Both technologies ensure high precision, reducing errors and improving product quality.

Cost Efficiency: Faster inspections and reduced material waste lower production costs.

Speed: Digital models from 3D scanners accelerate the prototyping and production process.

Quality Control: Inspection using 3D data allows for comprehensive analysis, ensuring that all parts conform to design specifications.

Future of Sheet Metal Forming

As manufacturing technologies continue to advance, 3D scanning, reverse engineering, and related digital tools will play an even more significant role in shaping the future of sheet metal forming. The ability to produce accurate, high-quality parts with minimal error will become an industry standard, ensuring that manufacturers stay competitive in an increasingly digital world.

By leveraging 3D scanning, reverse engineering, and other advanced technologies, businesses can improve the efficiency and accuracy of their sheet metal forming operations, leading to enhanced production processes and better end products.

0 notes

Text

3d Scan Reverse Engineering

3D Scan Reverse Engineering Accelerating Product Development & Manufacturing Scan to CAD A qualified health and safety consultant may offer your business an expert, informed, and unbiased viewpoint on handling your health and safety needs. Your team of specialists is supported by health and safety consultants. We can assist you with the setup, execution, and upkeep of your safety program.A qualified health and safety consultant may offer your business a competent, educated, and unbiased viewpoint on how to manage your health and safety obligations. Your professional staff is supported by health and safety consultants. We can assist with setting up, ensuring the execution of, and maintaining your safety program.

6033 Shawson Dr Unit #23, Mississauga ON L5T 1H8

(289) 628-1455

0 notes

Text

3D Laser Scanning and Reverse Engineering Services in Noida | SixD India

In the Transforming field of engineering and construction perfection and accuracy are main. Creativity in technology has transformed traditional methods. It is introducing advanced solutions like 3D laser scanning and reverse engineering. Among the explorer in this world known as SixD India that provide advanced services in Noida.

0 notes

Text

#custom 3d printing near me#custom 3d printing services#custom 3d printing#3d print service near me#3d printing companies near me#3d printing cost#online 3d printing#3d printing online services#3d print vase#fused deposition modeling#3d printer service near me#large 3d printing services#sls 3d printing service#fused deposition modeling 3d printer#large industrial 3d printer#rapid prototyping 3d printing#3d scanning services cost#3d scale model maker#High resolution 3d scanning#Industrial 3d scanning#Reverse engineering services#Rapid Prototyping#Scale modeling#3d printing services#large 3d printing#best 3d printing service#large format 3d printing#3d model printing service#sls printing service#large scale 3d printing service

0 notes

Text

Unveiling the Potential of 3D Scanning in Reverse Engineering

In the realm of engineering innovation, the advent of 3D scanning has revolutionized traditional methodologies. Among its myriad applications, one particularly noteworthy domain is reverse engineering.

Enterprises worldwide are leveraging 3D scanning technologies to dissect and recreate intricate designs, breathing new life into legacy components and machinery. The process involves capturing detailed digital renderings of physical objects, which serve as blueprints for replication or enhancement.

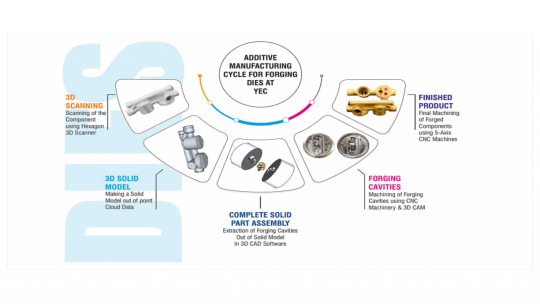

In the heart of technological advancements, Yamunanagar Engineering Cluster stands as a beacon of ingenuity. Employing cutting-edge 3D scanning techniques, the cluster pioneers the restoration and optimization of industrial assets with unparalleled precision and efficiency.

Beyond restoration, 3D scanning facilitates product innovation, enabling engineers to analyze and enhance existing designs swiftly. It expedites prototyping, reduces time-to-market, and fosters a culture of continuous improvement.

As industries evolve, the fusion of 3D scanning reverse engineering propels progress, ushering in a new era of limitless possibilities and unparalleled innovation.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Text

3d Scan Reverse Engineering

Reverse engineering using 3D scanning involves the process of capturing the physical shape and dimensions of an object and then creating a digital model from that data. This is useful for various purposes, such as replicating parts, modifying existing designs, or integrating physical objects into digital workflows. Here is a general overview of the process:

Selecting the Object:

Choose the physical object that you want to reverse engineer. It could be a product, prototype, or any item for which you need a digital model.

3D Scanning:

Use a 3D scanner to capture the geometry of the object. There are various types of 3D scanners, including laser scanners, structured light scanners, and photogrammetry systems. Select the appropriate scanner based on the size, complexity, and material of the object.

Data Acquisition:

Perform the scanning process, ensuring comprehensive coverage of the object's surface. Multiple scans may be required from different angles to capture intricate details.

Point Cloud Generation:

The 3D scanner produces a point cloud, which is a set of data points in three-dimensional space representing the object's surface.

Mesh Generation:

Convert the point cloud data into a 3D mesh. This mesh represents the surface geometry of the object and is composed of interconnected polygons.

Surface Reconstruction:

Refine the mesh to ensure a smooth and accurate representation of the object's surface. This step may involve using software tools to clean up noise and fill in any gaps.

Creating a Solid Model:

Depending on the application, you might convert the mesh into a solid model. This is particularly important if you intend to use the digital model for engineering and manufacturing purposes.

Parametric Modeling (Optional):

If your goal is to modify or enhance the object's design, you may use parametric modeling software to add features, adjust dimensions, or make other changes.

Quality Control:

Conduct a thorough quality check to ensure that the digital model accurately represents the physical object. Compare the digital model with the original object to identify any discrepancies.

Exporting the Model:

Export the final digital model in a suitable file format (e.g., STL, STEP) for your intended use.

Further Processing (Optional):

Depending on your project requirements, you might perform additional tasks, such as surface optimization, texture mapping, or color assignment.

It's important to note that the success of the reverse engineering process relies on the accuracy of the 3D scanning equipment, the skill of the operator, and the capabilities of the software used for data processing and model creation.

0 notes

Text

Best 3D Scanning Services in Vadodara, Gujarat. ✓3D Laser Scanner Services, ✓3D Scanning Services , ✓Portable CMM Laser Tracker Services, ✓ Reverse Engineering, ✓ 3D Plant Scanning.

1 note

·

View note

Text

3D Lidar scanning services in Gujarat | The SUNCAD Training & Designers

Experience top-notch 3D Lidar scanning services in Gujarat with The SUNCAD Training & Designers. Our expert team utilizes cutting-edge technology to perform precise 3D scans of objects and spaces. Clients from various fields benefit from our accurate scanning solutions for design, analysis, and documentation purposes. Whether you're an architectural designer, engineering professional, or part of any industry, our reliable scanning services cater to your specific needs. Partner with The SUNCAD Training & Designers and unlock the efficiency and cost-effectiveness of 3D Terrestrial Scanning in Gujarat. For more information visit on : https://www.suncad.in/3d-lidar-scanning-data-processing/ or call us on : +91-9925023229

#reverse engineering in gujarat#heritage scanning services in gujarat#cmm inspection services in gujarat#3d scanning in gujarat#3d printing services in gujarat#leica rtc 360 scanning service provider in gujarat#laser tracker service in gujarat#3d inspection services in gujarat#faro scanner service provider in gujarat#solid edge training in gujarat

0 notes

Text

Ultimately i will absolutely mirror my lasts by 3d scanning the originals and 3d printing the copies, that and gluing a leather sole on the bottom for the tack to hold in the lasting process.

Because this is SO annoying.

I'm doing it now because i don't have access to a 3d printer rn but i do have time and wood on my hand and i want to make the 3 prototypes to know if these lasts fit me

I made them while following the method and measurements from both my foot and :

"The manufacture of boots and shoes 1902"

By F.Y Golding

The wood is wrong though, i have no charme or beech but i have a shit ton of pines of all sorts , already dried and set because it is mostly from old wardrobes and furniture i dismantled over the years.

I made no hinge for any of them because first of all it is a pain to make and second i cannot find a clear picture of how the hinges work so i can reverse engineer it. I have nor the energy not the wish to design the entire hinge system myself.

7 notes

·

View notes

Text

Is your project ready for the next level? 🚀 With our premium 3D scanning services, from rapid prototyping to reverse engineering, we help you see what’s beneath the surface. Get it right, the first time. #tripleinfotech #3dscanning #3dscanner #reverseengineering

📞 Call us: +91 78 99899008 🌐 Visit us: tripleinfotech.com

0 notes

Text

Unlocking the potential of tomorrow's innovations, Design and Automation Services' reverse engineering solutions redefine progress in design and manufacturing.

With over a decade of expertise, we specialize in: - Precision 3D scanning and modeling 📐 - Rapid prototyping for seamless product development 🚀 - Restoring obsolete designs to fuel innovation 🔧 - Collaborative solutions for competitive advantage 💡 Our dedication to excellence ensures your ideas evolve into tangible successes, shaping a smarter, more efficient future.

Contact Design and Automation Services today to transform your vision into reality. 🌟

Call us on 📞 +91 9574 024 279

or

Visit: https://www.designautomations.com/

#DesignAndAutomationServices#Innovation#ReverseEngineering#ProductDevelopment#PrecisionEngineering#FutureTech#CollaborativeSolutions#Manufacturing#TransformativeIdeas

2 notes

·

View notes

Text

Who the hell considers democracy a thoroughly failed experiment??

If it is, and if the Chinese Communist Party is an accurate rendition of the alternative, we're all SUPER DUPER SCREWED.

The Chinese government has spent the past decade putting millions of Uyghurs in literal concentration camps. Complete with daily torture, forced labor, systematic rape, racist attempts at brainwashing, forced sterilization, medical experimentation, and arbitrary killing.

Those who aren't in concentration camps are subjected to forced labor by the government.

So many of them have been enslaved by their own government, human rights investigators say anything made with parts or materials from anywhere in the entire Uyghur region is almost certainly made with slave labor.

The entire region is kept under complete and total surveillance at all times. The government monitors:

the “trajectory” and location data of every single person's phones, ID cards, and vehicles;

their electricity use;

what gas stations they visit, and when, and possibly how much gas they buy;

whether they leave the area where they're registered to live without police permission;

whether they get a new phone number, or are connected to someone who got a new phone number;

whether they know people outside of China, or are connected to someone who does;

what content and apps are on their phones, and whether they could consider any of those to be "violent audio-visual content";

whether they use encrypted apps like WhatsApp;

whether they use a phone that isn't registered to them;

whether they avoid socializing with their neighbors;

whether they often avoid using the front door;

And more!!

In a 2018 public letter titled “Totalitarianism” addressed to fellow China analysts, Norwegian sociologist and political scientist Stein Ringen wrote that “the final straw has been the imposition of outright tyranny in Xinjiang, with extremes of mass surveillance."

It also collected DNA samples from the entire population, along with iris scans, 3D body scans, voiceprints, fingerprints, and high-definition photos, in both Xinjiang and Tibet.

And this is the part where I have to point out that if TikTok were owned by a random company in Israel, people would be falling all over themselves to give up TikTok. And praise the government for banning it.

But somehow, none of the shit I just described is even on the Left's radar -- much less considered to be the biggest human rights crisis on the planet.

But don't fret. The government doesn't want to unfairly subject the Uyghurs and Tibetans to totalitarian surveillance that nobody else gets! (Just concentration camps and forced labor.)

It's been rolling out constant surveillance for everyone else in China, too!!

The Chinese government has collected DNA samples on a huge number of men across the rest of China. Enough that, five years ago, it was able to develop family trees filling in the gaps of the rest of the men in China.

The Chinese state has an extensive history of using threats and violence against the families of regime targets in order to stamp out opposition to the Communist Party. Leaked documents obtained by the International Consortium of Investigative Journalists and The New York Times reveal that authorities in Xinjiang collect information on family members of detainees in the region’s "re-education" camps, and a detainee’s release is conditional upon the behaviour of their family members outside the camps.

Parents and children of prominent human rights lawyers, and the siblings of overseas government critics, were already routinely being detained and tortured by Chinese police. Developing a detailed database of interpersonal connections through DNA and other forms of surveillance is making this much, much easier.

Police databases across China already track the movements of all government protesters and religious believers.

As of 2016, constantly-monitored surveillance cameras connected to loudspeakers were being installed in 50 rural villages across China. By 2018, there was a surveillance camera on every block in Beijing: a total of 176,000,000 across China. It's far larger now.

The "Sharp Eyes" surveillance system is also broadcast to cell phones and neighborhood televisions. Anyone can tune in and press a button to report a crime. Anyone can watch you at any time.

The South China Morning Post wrote an article about it. While researching the piece, they talked to a local Communist Party secretary, Yin Xiuqin, who told them how great the system in Anxi Village was, and how well it worked. So well, in fact, that: "About 40 minutes into the interview, her phone rang. It was her boss. Yin apologised and said she was not allowed to discuss Sharp Eyes with foreigners."

That same Norwegian sociologist and political scientist Stein Ringen wrote went on to condemn the Chinese government's "rule upheld by terror… rule reaching into the regulation of natural human bonds in private spheres…rule exercised through an extensive and impersonal bureaucracy… and, the state operating under the authority of a commanding ideology.”

It's very fucking bad.

Beyond just punishing people who speak out, China has created an environment in which people don't speak out because there's no way for them to hear about what their government is doing.

In a November 2024 interview, the head of Uniqlo was asked if Uniqlo uses Xinjiang cotton -- cotton picked and processed through slave labor. He started to say, "We're not using--" and then stopped himself. But he had already said too much. He faced MASSIVE outrage across Chinese social media for even implying that he might not support their definitely-not-slave-picked cotton. That is the act of a population that's being systematically lied to and controlled.

But wait, there's more! 🙃

In 2020, the Chinese military hacked Japan's military.

The hackers had deep, persistent access and appeared to be after anything they could get their hands on — plans, capabilities, assessments of military shortcomings, according to three former senior U.S. officials, who were among a dozen current and former U.S. and Japanese officials interviewed, who spoke on the condition of anonymity because of the matter’s sensitivity.

“It was bad — shockingly bad,” recalled one former U.S. military official.

Not only that, but they had access to Japan's most confidential security networks for months.

That is not the act of a friendly country. That is an unnervingly hostile violation.

China is flat-out imperialist. It's claiming that everything in the western Pacific ocean -- like Japan and Taiwan -- is part of its historic dominion.

It fired ballistic missiles into Japan’s exclusive economic zone last August after then-House Speaker Nancy Pelosi (D-Calif.) visited Taiwan, a self-ruled democracy that China claims. It has embarked on a major nuclear weapons buildup. And it has engaged in dangerous air and naval maneuvers with U.S., Canadian and Australian ships and jets in the Pacific.

hahaha oh fuck remember when it was buzzing American airspace and there was like a medium chance it was trying to start a world war out of nowhere? That was fun, huh

Since mid-2021, the U.S. government and Western cybersecurity firms have documented increasing Chinese penetration of critical infrastructure in the United States, Guam and elsewhere in the Asia-Pacific. The targets include communication, transportation and utility systems, Microsoft said in May.

Oh good!! I'm so very excited to hear that the Chinese government inexplicably wants to know where we're all going and what we're saying! That's not terrifying at all!

They were doing it through a government system called Volt Typhoon that time, not through their military.

What Microsoft specifically said was:

Microsoft assesses with moderate confidence that this Volt Typhoon campaign is pursuing development of capabilities that could disrupt critical communications infrastructure between the United States and Asia region during future crises.

In other words: they're trying to quietly get control of the communications infrastructure in the U.S.

So that if, for example, China bombed Japan, it could keep the U.S. from hearing about it, or could keep the U.S. government from being able to talk to people in the Japanese government and offer help.

That's just off the top of my head; I don't think I really grasp the full potential scope of any of this.

(sidebar: anyone else feel a weird affection for the way Microsoft always manages to make itself seem robotic and inhuman?)

Volt Typhoon has been active since mid-2021 and has targeted critical infrastructure organizations in Guam and elsewhere in the United States. In this campaign, the affected organizations span the communications, manufacturing, utility, transportation, construction, maritime, government, information technology, and education sectors.

Um. That's a lot.

Like. Imagine if China just cut off all shipping to the U.S., and jacked up one or two of those industries. If it developed the capability to do that thoroughly enough, it could bring the country to its knees. It wouldn't face any real military opposition to anything in Japan, or Taiwan, or any other country it wants.

So, yeah. I do think the U.S. government is GODAWFUL at explaining why it wants to ban TikTok.

I mean, just amazingly fucking bad at communication in general.

But IMHO, all of this shit adds up to maybe they're fucking right that the government of China shouldn't have access to anybody's data.

And if all of the above actually IS communism, and calling itself the Chinese Communist Party isn't just bullshit PR, then fuck communism too.

"tiktok has massive problems that even if you don't agree with a complete ban have to be addressed for all social media platforms" and "the Chinese government is doing pretty awful things" and "there is a lot of sinophobic fearmongering and double standards in the conversation about tiktok" and "people should exercise basic caution signing up to foreign or domestic social media" and "most Chinese citizens like US citizens are just people living their life and cultural exchange between them can be beneficial for both sides" and "some people being on the same social media site isn't going to solve everything " and "I want to study the linguistics happening there under a microscope" are opinions that can coexist

#long post#didn't expect to end up at “oh THAT'S why they're banning tiktok” but here we are#also welcome to phase two of me losing all trust in the left#wall of words#also I'm just gonna point out again that if this were an Israeli company people would be humping congress with joy#certainly NOT hopping to a similar app that was wholly owned by the Israeli government

29K notes

·

View notes

Text

Inspection Equipment Testing Services: Your Precision and Safety Experts

In industries, the growing competition requires optimum equipment operations that mark the paramount importance of precision and safety. This inspection equipment plays a crucial role in maintaining quality standards and preventing potential hazards avoiding any business disruption. For this reason, Inspection equipment testing services are essential for any business domain heavily dependent on machinery to ensure the accuracy and reliability of these tools.

We involve comprehensive quality checks and evaluation of various inspection tools, such as gauges, meters, scanners, and analysers, to verify their accuracy and functionality. These services are typically performed by specialized technicians who follow stringent testing protocols to test equipment on various parameters critical for the production process.

Importance of Inspection Equipment Testing Services:

Quality Assurance: Precise inspection equipment is crucial for maintaining product quality and process efficiency. It allows regular testing that guarantees that measurements will be accurate and consistent.

Safety Compliance: Industries like manufacturing, aerospace, and healthcare rely on inspection equipment for safety and compliance with best business practices. The correct functioning of devices through inspection reduces the risk of accidents and largely ensures adherence to regulations.

Cost Efficiency: Faulty inspection equipment can lead to flawed products, production downtime, and rework costs that can significantly hamper business image. Leveraging Inspection equipment testing services prevent these issues by detecting problems early, saving both time and money.

Data Integrity: Inspection equipment often generates crucial data that plays an important role in decision-making. If these instruments are inaccurate, it can lead to incorrect data conclusions which can be avoided by regular testing safeguards.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes