#cnc precision testing services

Explore tagged Tumblr posts

Text

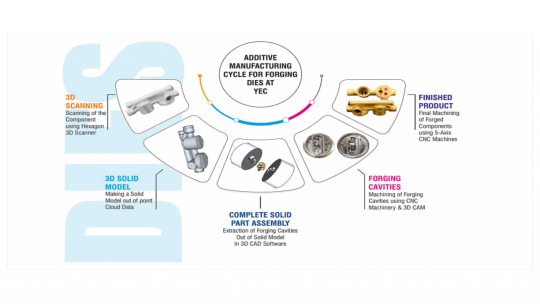

Unveiling the Potential of 3D Scanning in Reverse Engineering

In the realm of engineering innovation, the advent of 3D scanning has revolutionized traditional methodologies. Among its myriad applications, one particularly noteworthy domain is reverse engineering.

Enterprises worldwide are leveraging 3D scanning technologies to dissect and recreate intricate designs, breathing new life into legacy components and machinery. The process involves capturing detailed digital renderings of physical objects, which serve as blueprints for replication or enhancement.

In the heart of technological advancements, Yamunanagar Engineering Cluster stands as a beacon of ingenuity. Employing cutting-edge 3D scanning techniques, the cluster pioneers the restoration and optimization of industrial assets with unparalleled precision and efficiency.

Beyond restoration, 3D scanning facilitates product innovation, enabling engineers to analyze and enhance existing designs swiftly. It expedites prototyping, reduces time-to-market, and fosters a culture of continuous improvement.

As industries evolve, the fusion of 3D scanning reverse engineering propels progress, ushering in a new era of limitless possibilities and unparalleled innovation.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Video

youtube

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

Premium White Hard PTFE Sheets for Demanding Industrial Applications

Aohong's white hard PTFE sheet stands as a benchmark in high-performance fluoropolymer solutions, delivering exceptional mechanical strength and chemical resistance. Manufactured from 100% virgin PTFE (polytetrafluoroethylene), these rigid fluoropolymer sheets maintain superior dimensional stability across extreme temperatures (-200°C to +260°C), outperforming conventional filled PTFE variants in purity and longevity.

Unmatched Material Properties

Our pure white PTFE sheets exhibit critical advantages:

0.02% deformation under 20MPa compressive load (ASTM D695)

28MPa tensile strength – 40% higher than recycled PTFE blends

60kV/mm dielectric strength (IEC 60243 at 200°C)

Zero moisture absorption – ideal for semiconductor cleanrooms

Microscopic analysis reveals a homogeneous crystalline structure with <0.1% void content, achieved through Aohong's proprietary isostatic pressing technology.

Precision Manufacturing Process

At our ISO 9001:2015-certified Suzhou facility, each sheet undergoes:

Ultra-fine resin filtration (99.99% purity)

Cold compaction at 65MPa for density uniformity

Controlled sintering (375±5°C for 20 hours)

Precision machining to ±0.03mm tolerances

This process yields FDA-compliant white PTFE sheets meeting:

USP Class VI biological safety standards

EU 10/2011 food contact regulations

RoHS 3 Directive compliance

Industrial Applications

Medical Devices

MRI component insulators

Autoclavable surgical tool handles

Food Processing

Non-stick conveyor liners

Dairy equipment gaskets

Semiconductor

Wafer carrier components

Plasma etch chamber liners

Chemical Processing

Hydrofluoric acid tank linings

Chlor-alkali cell seals

Quality Verification

Every production batch includes:

FTIR spectroscopy for molecular integrity checks

DSC analysis confirming 327±2°C melt point

X-ray diffraction testing crystallinity (15-20% range)

100% thickness gauging with laser micrometers

Recent third-party testing demonstrated 300% longer service life versus Chinese Q/YZB standards for PTFE sheets in sulfuric acid exposure.

Customization Options

Aohong provides tailored solutions:

Thicknesses from 0.5mm to 150mm

Anti-static versions (10⁶-10⁹ Ω/sq)

High-wear grades with 15% improved abrasion resistance

FDA white color-stable formulations

Pre-cut blanks for CNC machining

Why Aohong Excels

With 18 years of PTFE specialization, we offer:

12-month performance guarantee

Teflon™-equivalent properties at competitive pricing

Technical support from materials PhDs

Case Study: A Shanghai semiconductor fab reduced particle contamination by 92% after switching to our ultra-clean white PTFE sheets for wafer handling.

Advanced White PTFE Sheet Solutions for Critical Environments Contact Aohong today to request samples or discuss your application requirements. Our engineers combine deep material science expertise with practical experience from 1,200+ successful installations worldwide.

2 notes

·

View notes

Text

Deccanew: Advanced Precision & Contract Manufacturing India

Discover Deccanew’s expertise in Precision Manufacturing India and Contract Manufacturing India customized for high-quality engineering solutions that drive your business forward.

The industrial world having high quality components delivered with speed, precision, and consistency has never been more important. A trusted engineering and manufacturing partner, provides top tier solutions through its cutting edge facilities and skilled professionals. From CNC machining to high precision assemblies, deccanew stands at the forefront of innovation and efficiency in the Indian manufacturing landscape.

Why Contract Manufacturing make a difference

Many companies are outsourcing their manufacturing processes to gain cost benefits and improve efficiency. Contract Manufacturing India has emerged as a preferred choice for industries looking for flexibility, quality assurance, and scalability without the burden of managing production in-house.

Contract manufacturing helps businesses:

Reduce capital investment in machinery and infrastructure

Focus on core business operations

Ensure quick turnarounds with high-quality standards

Access specialized manufacturing technologies and skilled labor

India has become a strategic hub for contract manufacturing due to its growing industrial ecosystem, skilled workforce, and favorable business environment. With companies like deccanew, businesses across the globe are turning to Indian manufacturers for their reliability, affordability, and commitment to excellence.

The Power of Precision in Manufacturing

Precision is not just a phrase; it is a necessary requirement for many sectors. such as aerospace, automotive, electronics, defense, and medical devices. Precision Manufacturing India delivers parts with tight tolerances, minimal error margins, and excellent surface finishes, all of which are vital to product safety and performance.

At the heart of precision manufacturing lies advanced technology, including:

CNC (Computer Numerical Control) Machining

Laser Cutting and Welding

CAD/CAM Design Integration

Multi-axis Milling and Turning

Quality Inspection and Metrology Systems

By offering these high-precision services, Indian manufacturers are not only meeting international quality standards but often exceeding them.

How Company is Leading the Way

It combines state of the art infrastructure with deep technical knowledge to deliver comprehensive manufacturing solutions. Whether you're a startup looking to prototype or an established enterprise seeking bulk production, the company adapts to your needs with unmatched agility.

Key Capabilities:

CNC Machining & Milling

Precision Sheet Metal Fabrication

Tool & Die Making

Component Assembly

Quality Inspection & Testing

Reverse Engineering Services

Serving Diverse Industries with Tailored Solutions

Across multiple domains, clients rely on Indian engineering talent and manufacturing prowess to fulfill their project requirements. of industries such as:

Automotive: Engine parts, transmission components, and structural frames

Aerospace: Aircraft brackets, housings, and turbine parts

Medical Devices: Surgical tools, diagnostic parts, and implant components

Industrial Machinery: Shafts, gears, and enclosures

Electronics: Housings, connectors, and heat sinks

With such diverse exposure, deccanew has developed the capacity to quickly understand unique project demands and deliver accordingly.

The Benefits of Choosing Contract Manufacturing

Choosing Contract Manufacturing comes with several strategic advantages for businesses:

Cost-Effective Production: Lower labor and operational costs without compromising on quality

Access to Skilled Labor: Trained engineers and machinists ensure top-class outputs

Advanced Infrastructure: Modern equipment and digital tools enhance productivity

Faster Time-to-Market: Quicker prototyping and production cycles

Compliance & Certification: Adherence to global standards like ISO, RoHS, and more

By partnering with capable manufacturers, companies can scale their operations while maintaining product integrity.

Redefining Precision with Indian Expertise

Manufacturers are under pressure to push the limits of accuracy as the demand for complex and dependable components keeps growing. By providing excellent options to suit this demand, manufacturing has attracted attention from all over the world.

Indian manufacturers bring a unique blend of traditional engineering excellence and modern-day innovation. From the integration of Industry 4.0 principles to lean manufacturing practices, the journey toward precision is continuously evolving.

Commitment to Quality and Innovation

What separates a reliable manufacturing partner from the rest is a deep commitment to quality. It operates with a zero defect mindset, conducting rigorous quality checks throughout the production process. This includes:

Material verification

Dimensional inspection using CMM

Functional testing

Surface finish inspection

Final QC before dispatch

Innovation is also central to operations. The team at the company continually invests in new technology and training to stay ahead of market demands.

Sustainable and Scalable Manufacturing

Environmental responsibility is an emerging focus in the manufacturing industry. Forward-looking companies are adopting eco-friendly practices such as:

Waste minimization and recycling

Energy-efficient machining

Eco-safe raw materials

Lean processes to reduce emissions

Moreover, scalability is built into every project. Whether you need 100 or 100,000 components, the infrastructure is designed to handle varying volumes with the same commitment to precision.Precision and reliability are the cornerstones of modern manufacturing, and India is fast becoming a global hub for both. With specialized expertise in manufacturers helping businesses around the world realize their vision with confidence.

for high accuracy components or a complete manufacturing solution, the Indian ecosystem offers unmatched value, speed, and quality. The future of manufacturing is here, and it's being shaped with precision.

Visit: https://www.deccanew.com/precision-parts-manufacturing-india.phpContact: +91 9657039991

0 notes

Text

Why Piping Design Drawings and 3D BIM Modeling Services Are Vital for Modern Construction Projects

The Role of Piping Design Drawings in Project Planning

At the heart of any mechanical or plumbing system lies a complex web of pipes, valves, and fittings. Whether it's HVAC, water supply, or industrial process piping, these systems must be carefully planned and precisely executed. This is where piping design drawings come into play.

These technical illustrations represent the layout, size, material, and alignment of piping systems in a detailed and structured way. They provide essential information such as:

Pipe routing and elevation

Connection types and specifications

Flow direction and pressure ratings

Equipment locations and clearances

Piping design drawings serve as the blueprint for fabricators, contractors, and engineers. Mistakes or inconsistencies in these drawings can lead to costly delays, safety hazards, or operational inefficiencies. That’s why high-quality, well-coordinated piping drawings are non-negotiable for complex projects.

The Power of 3D BIM Modeling Services

While 2D drawings have their place, the construction industry is increasingly turning to 3D BIM modeling services (Building Information Modeling) to visualize and manage every component of a project. BIM allows stakeholders to create and interact with digital twins of physical spaces—models that include not only geometry but also valuable metadata.

BIM offers a wide range of benefits, including:

Clash detection: Identifying spatial conflicts between systems (e.g., HVAC duct vs. electrical conduit) before construction begins

Improved coordination: Sharing one unified model among architects, engineers, and contractors improves communication and accountability

Accurate quantity take-offs: Generating material lists and cost estimates directly from the model

Lifecycle management: Facility managers can use BIM data long after construction for maintenance and upgrades

For mechanical and piping systems in particular, 3D BIM modeling services allow for more accurate layouts, fewer surprises on-site, and better collaboration among trades.

How 3D Modeling Services Bridge the Gap Between Design and Construction

While BIM is a process and platform, 3D modeling services refer more broadly to the creation of three-dimensional digital models—whether for architectural visualization, mechanical design, or product development. In the context of piping and construction, 3D models act as a bridge between conceptual design and physical implementation.

The benefits of 3D modeling services include:

Visualization: Helping clients and stakeholders understand spatial relationships, aesthetics, and system functionality

Fabrication support: Generating shop drawings and CNC-ready files from accurate models

Simulation and testing: Running performance analyses before anything is built, saving time and money

Precision: Minimizing guesswork in construction through clear, photorealistic representation

With the right modeling approach, even the most complex piping networks can be virtually constructed, inspected, and modified—before a single pipe is installed.

Why Choose Funding Walk?

At Funding Walk, we combine technical expertise with cutting-edge technology to deliver superior piping design drawings, 3D BIM modeling services, and 3D modeling services tailored to your specific needs. We don’t just provide drawings—we deliver confidence. Our team understands how to balance design intent, regulatory compliance, and practical constructability to support your project from concept to completion.

Whether you’re an MEP engineer, a construction firm, or a project manager looking to streamline your operations, Funding Walk can help you:

Avoid costly design errors

Enhance team collaboration

Accelerate project timelines

Deliver better outcomes for clients and stakeholders

0 notes

Text

Precision Machinery Installation That Powers Your Industry

In the current era of speed in the industrial age, precision is more important than ever—particularly with regards to machinery installation. If you're installing a brand-new facility or replacing existing systems, the installation of your equipment is instrumental in safety, efficiency, and overall long-term performance. At B and D Industrial Services LLC, we pride ourselves on providing the best machinery installation solutions specific to the demands of today's manufacturing and heavy industries.

Why Professional Machinery Installation Matters Installing heavy industrial machinery is not just about placing equipment in a designated spot. It involves:

Precision alignment

Rigging and leveling

Secure anchoring

Electrical and hydraulic integration

Compliance with safety and industry regulations

An improperly installed machine can lead to costly breakdowns, misalignments, or even workplace hazards. That’s why hiring experienced professionals is not an option—it’s a necessity.

Our Expertise at B and D Industrial Services LLC At B and D Industrial Services LLC, we are experts in the installation of industrial equipment of all sizes and complexities. From production line parts to CNC machines, our professionals take care to ensure that each part is installed with unparalleled precision and care.

We apply years of hands-on expertise, technical acumen, and specialized equipment to each assignment. We work hand-in-hand with facility managers, engineers, and OEMs to make sure every machine runs at optimum level from the first day.

What differentiates us is:

Turnkey Solutions – We take care of everything from offloading to complete testing.

Professionally Trained Technicians – Our skilled millwrights and installers apply a thorough knowledge of industrial mechanics.

Advanced Equipment – We employ the latest alignment equipment and hoisting machines.

Delivered on Time – We understand that downtime is expensive, so we work to deliver quickly and securely.

Customized to Your Business No matter if you're in manufacturing, processing, logistics, or heavy equipment services, B and D Industrial Services LLC has the know-how to fit your industry-specific needs. We know each project presents its own set of challenges—tight timelines, cramped spaces, specialized machinery—and we're all set to take them on.

We also serve high-demand applications like:

Power plants

Steel mills

Automotive manufacturing

Food processing plants

Warehousing and distribution facilities

Safety Is at the Core Safety is more than a box to check—it's a way of life at B and D Industrial Services LLC. Our staff is OSHA-trained and committed to adhering to the best safety protocols. Each machinery installation project starts with a complete risk analysis and site plan to safeguard your people, your assets, and your schedule.

Final Thoughts If you desire your equipment to run at its optimal, begin with a partner that installs it correctly the very first time. At B and D Industrial Services LLC, we are dedicated to energizing your operations with safe, accurate, and efficient machinery installation services.

#machinery installation#industrial millwright services#machinery installation services#preventive maintenance schedule#Millwright services

0 notes

Text

What Are Auto Gas Springs and How Do They Work?

When it comes to automotive comfort, safety, and reliability, even the smallest components play a vital role. One such unsung hero is the auto gas spring—a dynamic component that supports the smooth, controlled movement of car hoods, trunks, tailgates, and more. At TRAC Auto, we specialize in delivering high-performance gas springs, struts, and window regulators engineered for excellence across automotive, industrial, medical, and commercial applications.

What Is an Auto Gas Spring?

Auto gas springs—also known as gas struts or car dicky shockers—are mechanical devices designed to exert force through compressed gas and a piston mechanism. Unlike traditional springs, gas springs offer controlled motion, dampening, and reliable support without the need for external energy.

At TRAC, our flagship product, TRAC UltraLift™ Dynamic Gas Springs, is engineered for precision, durability, and performance. These gas springs are trusted by OEMs and end-users for their seamless functionality and long-lasting service life.

How Do Gas Springs Work?

Gas springs consist of a cylinder filled with nitrogen gas and a piston rod. As the rod moves into the cylinder, the gas compresses, creating a force that pushes the rod outward. This enables smooth opening, controlled closing, and secure holding positions in automotive components like hoods and tailgates.

Our UltraLift™ gas struts go beyond conventional design by incorporating dynamic hydraulic damping, ensuring a smooth, shock-free experience, especially in vehicles. The result? Controlled motion that’s silent, responsive, and safe.

Key Features of TRAC UltraLift™ Dynamic Gas Springs

TRAC’s gas springs are not just parts—they’re precision-engineered motion control solutions:

Precision Motion & Hydraulic Damping Designed for optimal control and fluidity in movement.

Customizable Force & Stroke Engineered to meet exact force and length requirements of different applications.

Corrosion Resistance & Maintenance-Free Design Ideal for harsh environments; designed for longevity.

Long Cycle Life Built to withstand repeated use without performance degradation.

ISO/IATF-Certified Manufacturing Produced using advanced CNC machining and in-house tooling.

These gas springs are extensively tested under real-world conditions, ensuring unmatched reliability and consistency.

Applications Across Industries

TRAC UltraLift™ gas springs are used in:

Automotive – Hoods, tailgates, trunks, seats

Medical Equipment – Beds, examination tables, over-bed tables

Industrial Machinery – Access panels, lids, and hatches

Furniture – Office chairs, cabinets, recliners

Commercial Equipment – Display systems, kiosks, POS machines

Whether it’s an OEM production run or a small batch requirement, TRAC provides custom gas springs tailored to the client’s specific needs.

Window Regulators: Seamless Automotive Performance

While gas springs handle motion control, TRAC Window Regulators ensure precise and reliable window operation. Built to match OE specifications, these regulators offer:

Durable, Maintenance-Free Operation

Compatibility with Manual and Power Windows

Perfect Fit Across Multiple Vehicle Makes and Models

They are trusted by auto repair professionals and OEMs alike for their quality, longevity, and ease of installation.

Why Choose TRAC Auto?

TRAC Auto is not just a component supplier—it’s a partner in innovation and precision. Here's why businesses and professionals trust us:

Engineering Expertise & Customization

ISO/IATF-Certified Quality

Eco-Friendly Manufacturing Practices

Dedicated Technical Support and Product Guidance

With customer-centric customization, TRAC ensures every product fits your performance and application goals—whether you're an OEM, dealer, or technician.

Explore the TRAC Advantage

If you’re looking for automotive gas struts, motion control solutions, or OE window regulators, TRAC Auto is your go-to partner. Discover our full product range on www.tracauto.in, request a custom quote, or reach out to our engineers for expert consultation.

Experience precision, performance, and reliability—experience TRAC.

For better understanding Watch now: Youtube

For Buy now : Amazon

0 notes

Text

Inspection Equipment Testing Services: Your Precision and Safety Experts

In industries, the growing competition requires optimum equipment operations that mark the paramount importance of precision and safety. This inspection equipment plays a crucial role in maintaining quality standards and preventing potential hazards avoiding any business disruption. For this reason, Inspection equipment testing services are essential for any business domain heavily dependent on machinery to ensure the accuracy and reliability of these tools.

We involve comprehensive quality checks and evaluation of various inspection tools, such as gauges, meters, scanners, and analysers, to verify their accuracy and functionality. These services are typically performed by specialized technicians who follow stringent testing protocols to test equipment on various parameters critical for the production process.

Importance of Inspection Equipment Testing Services:

Quality Assurance: Precise inspection equipment is crucial for maintaining product quality and process efficiency. It allows regular testing that guarantees that measurements will be accurate and consistent.

Safety Compliance: Industries like manufacturing, aerospace, and healthcare rely on inspection equipment for safety and compliance with best business practices. The correct functioning of devices through inspection reduces the risk of accidents and largely ensures adherence to regulations.

Cost Efficiency: Faulty inspection equipment can lead to flawed products, production downtime, and rework costs that can significantly hamper business image. Leveraging Inspection equipment testing services prevent these issues by detecting problems early, saving both time and money.

Data Integrity: Inspection equipment often generates crucial data that plays an important role in decision-making. If these instruments are inaccurate, it can lead to incorrect data conclusions which can be avoided by regular testing safeguards.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Text

Top Screw Supplier in India Quality Fasteners for Every Industry

Finding a reliable screw supplier in India is essential for industries ranging from construction and manufacturing to electronics and automotive. With India’s growing infrastructure and industrial sectors, the demand for high-quality, precision-engineered screws has surged. Top screw suppliers in the country offer a wide range of products, including stainless steel, brass, alloy, and customized screws to meet diverse application needs. These suppliers prioritize durability, corrosion resistance, and strict quality standards to ensure long-term performance. Whether you need bulk fasteners for large-scale projects or specialized components for niche applications, India’s screw suppliers deliver efficiency, affordability, and dependable supply across domestic and global markets.

Wide Range of Screws Available for Every Industry

Top screw supplier in India offer an extensive selection of screws to serve a wide variety of industries. From machine screws, wood screws, and self-tapping screws to hex bolts and custom fasteners, these suppliers cater to sectors such as construction, electronics, automotive, furniture, and heavy machinery. The diversity in product offerings ensures that clients can find the exact type, size, and material required for their specific applications. Many suppliers also provide corrosion-resistant, high-tensile, and precision-engineered screws that meet both Indian and international quality standards, making them a reliable one-stop destination for all fastening solutions.

Customization and Precision Engineering Solutions

Leading screw suppliers in India understand the unique requirements of different industries and offer customization services to meet specific project needs. Whether it's a particular material composition, threading style, head type, or coating requirement, these suppliers work closely with clients to deliver tailor-made solutions. Advanced manufacturing capabilities and CNC precision allow for the production of high-accuracy screws, ensuring perfect fit and optimal performance. This level of customization is crucial for sectors like aerospace, medical devices, and electronics, where even the smallest deviation can affect functionality. Indian suppliers combine technical expertise with flexibility to produce reliable, application-specific screws.

Commitment to Quality and International Standards

Quality assurance is a top priority for reputable screw suppliers in India. Most operate under ISO-certified facilities and adhere to global standards like DIN, ASTM, and BS. Their products undergo rigorous quality checks at every stage right from raw material inspection to final packaging to ensure consistency, durability, and safety. Many suppliers also provide test reports, certifications, and compliance documents for transparency and client assurance. With a growing emphasis on export readiness, Indian screw manufacturers ensure their fasteners meet the stringent demands of both domestic and international markets, making them a trusted partner in global supply chains.

Cost-Effective and Bulk Supply Capabilities

One of the major advantages of sourcing from a screw supplier in India is the cost-effectiveness without compromising quality. Indian manufacturers benefit from skilled labor, advanced production infrastructure, and efficient logistics, allowing them to offer competitive pricing for both small and bulk orders. Whether you're a large construction firm or a mid-sized OEM, suppliers in India can handle high-volume orders with consistent product quality and timely delivery. Many also offer scalable supply options, enabling clients to adjust order quantities as needed, making them ideal partners for long-term projects and rapidly growing industries.

Timely Delivery and Nationwide Distribution Network

Timely delivery is a critical factor in any industrial supply chain, and Indian screw suppliers excel in this area with robust distribution networks. Most established suppliers have well-organized logistics systems and warehouses in key locations, enabling fast delivery across the country. Whether you're based in a metro city or a remote industrial zone, they ensure that your orders arrive on schedule. In addition, many suppliers also offer real-time tracking, order updates, and customer support to keep the process transparent. Their logistics reliability helps businesses avoid project delays and maintain a smooth production workflow.

Eco-Friendly and Corrosion-Resistant Material Options

Environmental responsibility is becoming a growing concern, and many Indian screw suppliers are adopting eco-conscious manufacturing practices. They offer screws made from recyclable materials and use non-toxic, RoHS-compliant coatings and finishes. Additionally, corrosion-resistant options like stainless steel, brass, and zinc-plated screws are available to ensure longevity and performance in harsh conditions. These materials are especially beneficial for marine, outdoor, and chemical processing industries. By combining sustainability with high functionality, Indian suppliers not only meet the current industrial demands but also support green building practices and responsible manufacturing across sectors.

Choosing the Right Screw Supplier in India for Your Business

With numerous options available, choosing the right screw supplier in India involves evaluating key factors like product range, quality certifications, customization capabilities, delivery timelines, and after-sales service. It’s important to work with suppliers who understand your industry’s specific needs and offer technical support when required. Reading client reviews, checking certifications, and requesting samples can help ensure a reliable partnership. The best suppliers are those who prioritize long-term relationships, are transparent in their processes, and consistently deliver high-quality products. A well-chosen supplier not only meets your current requirements but also grows with your business over time.

Conclusion

Choosing a reliable screw supplier in India is essential for businesses that demand precision, durability, and timely delivery. With a wide range of products, strong quality control, competitive pricing, and customization options, Indian suppliers are well-equipped to serve both domestic and international markets. Their ability to deliver bulk quantities without compromising on quality makes them ideal partners for industries like construction, automotive, electronics, and manufacturing. By prioritizing certified suppliers with proven track records and nationwide logistics, businesses can ensure efficient operations and long-term success. Whether for standard fasteners or tailored solutions, India’s screw suppliers are a dependable choice for every need.

0 notes

Text

Cutting-Edge EV Trends Impacting Automotive OEM Services in Grand Rapids MI

The automotive landscape is shifting at lightning speed as electric vehicles (EVs) redefine performance and sustainability. For companies in Michigan’s booming manufacturing corridor, adapting quickly isn’t optional—it’s essential. In this article, we’ll dive into the hottest trends transforming Automotive OEM Services Grand Rapids MI, showcase real‑world success, and share how you can leverage these insights to outpace competitors.

Lightweight Materials for Extended Range

Reducing vehicle mass directly increases battery efficiency and range. Advanced composites—like carbon-fiber–reinforced polymers—and high-strength aluminum alloys are in high demand. Local Automotive OEM Suppliers Grand Rapids MI have invested in state‑of‑the‑art CNC equipment and automated fiber placement to deliver these precision components. In fact, Arrow Manufacturing helped a regional EV startup cut chassis weight by 15%, boosting range by 8%—a game‑changer on consumer test drives.

Smart Factory Integration (Industry 4.0)

Data-driven production is the backbone of modern manufacturing. Sensors across assembly lines feed live analytics into predictive‑maintenance platforms, slashing downtime and scrap rates. By partnering with an experienced Automotive OEM Services Grand Rapids MI provider, you gain turnkey IoT integration, from PLC configuration to dashboard visualization. This approach led one automotive tier‑1 supplier to improve OEE (Overall Equipment Effectiveness) by 12% within six months.

Digital Twin Technology for Rapid Validation

Imagine testing thermal loads, vibration profiles, and electromagnetic interference in a virtual environment—before building a single prototype. That’s the power of digital twins. With this tool, engineers can iterate designs in hours instead of weeks, driving down development costs. Forward‑thinking Automotive OEM Suppliers Grand Rapids MI now include digital‑twin services in their portfolios, helping clients compress time‑to‑market by up to 30%.

Circular Manufacturing & Green Practices

Sustainability isn’t a buzzword—it’s a mandate. OEMs are adopting closed-loop recycling for aluminum extrusions and switching to water‑based cleaning agents to reduce VOC emissions. Arrow Manufacturing’s facility reclaims over 90% of machining scrap, translating to a 20% reduction in material spend year‑over‑year. By choosing a Automotive OEM Services Grand Rapids MI partner with green credentials, you not only meet regulatory targets but also appeal to eco-conscious consumers.

Collaborative Robots (Cobots) and Human‑Centric Automation

Cobots are transforming small‑batch and precision tasks, working safely alongside operators without extensive guarding. They handle repetitive duties—like fastening EV battery modules—while humans focus on quality assurance and complex assembly. Our recent cobot deployment reduced cycle times by 25% on a high‑voltage harness line, demonstrating how Automotive OEM Suppliers Grand Rapids MI can deliver both speed and precision.

Augmented Reality (AR) for Training & Maintenance

AR headsets overlay digital instructions on physical components, guiding technicians through complex EV assemblies and safety checks. This technology cut onboarding time by 40% for new hires at one Grand Rapids facility. When you engage Automotive OEM Services Grand Rapids MI experts who integrate AR workflows, you’ll minimize errors and maintain consistent quality—especially critical when dealing with high‑voltage systems.

Get Your Free EV Component Checklist

To help you implement these trends effectively, we’ve created a complimentary EV Component Checklist—covering material selection, digital‑twin best practices, and cobot integration tips. Download your copy now and start benchmarking your processes against industry leaders.

Ready to Accelerate Your EV Program?

Whether you’re launching a new model or scaling production, partnering with a seasoned Automotive OEM Suppliers Grand Rapids MI provider is the fastest path to success. Contact Arrow Manufacturing & Assembly today for a free consultation, and discover how our proven solutions can optimize your manufacturing footprint, improve efficiency, and drive down costs.

By embracing lightweight materials, Industry 4.0 technologies, and sustainable practices, you’ll not only stay competitive—you’ll lead the pack in the next generation of automotive innovation.

0 notes

Text

Cutting-Edge Trends in Agricultural Machinery Fabrication Manufacturers

In today’s rapidly evolving agricultural landscape, innovation is no longer optional—it’s essential. As growers demand safer, more efficient, and sustainable solutions, agricultural machinery fabrication manufacturers are rising to the challenge. From 3D-printed components to AI-driven diagnostics, these pioneers are redefining what modern farming equipment can achieve.

One of the most transformative developments is the integration of precision engineering into traditional farming implements. Leading agricultural machinery fabrication manufacturers are leveraging advanced CNC machining and laser cutting to produce parts with unparalleled accuracy. This not only extends the lifespan of critical components but also reduces downtime on the field—translating to higher yields and lower operating costs for farmers.

Sustainability plays a pivotal role in the future of farming, and savvy businesses recognize this. As an agriculture equipment manufacturing company committed to eco-friendly practices, many enterprises now utilize lightweight alloys and biodegradable polymers. By rethinking raw materials, these manufacturers help reduce both fuel consumption and waste, ushering in a new era of green agriculture.

Connectivity is another trend that’s reshaping the industry. Smart sensors embedded in tractors, planters, and irrigation systems gather real-time data on soil conditions, plant health, and machine performance. The insights generated by these networks empower growers to make data-driven decisions—whether adjusting seeding rates on the go or scheduling timely maintenance. This level of intelligence was unheard of just a few years ago but is becoming the standard for forward-thinking agricultural machinery fabrication manufacturers.

Customization has also entered the spotlight. No two farms are identical, and equipment that’s one-size-fits-all often falls short. That’s where a flexible agriculture equipment manufacturing company shines. By offering modular designs and rapid prototyping services, manufacturers can tailor machines to the exact specifications of each operation. Whether expanding a combine’s header width or integrating specialized attachments, bespoke solutions help farmers overcome unique challenges.

Automation continues to advance at breakneck speed. Robotic harvesters and autonomous tillers were once the domain of science fiction; today, they’re tangible realities. Early adopters report significant labor savings and improved consistency in crop handling. Behind these breakthroughs are dedicated teams within agricultural machinery fabrication manufacturers, tirelessly testing prototypes and refining control algorithms to ensure safe, reliable operation in diverse weather and terrain conditions.

Training and support remain key differentiators. Even the most sophisticated equipment needs skilled hands to operate it effectively. That’s why leading outfits in the sector invest heavily in comprehensive user education—from interactive online tutorials to hands-on workshops at demonstration farms. By empowering operators, these companies ensure that every piece of cutting-edge machinery delivers its full potential in the field.

Looking ahead, we can expect continued convergence of agronomy and technology. Emerging areas such as block chain-based supply chain tracking and nanotechnology-enhanced coatings promise to further elevate machine performance and traceability. No matter how the landscape shifts, one truth remains constant: choosing the right agricultural machinery fabrication manufacturers and agriculture equipment manufacturing company can make all the difference in your farming success.

Partner with a Leader in Agricultural Innovation

As the agriculture industry advances, having a reliable manufacturing partner by your side is essential. Whether you're seeking durable components, custom fabrication, or next-generation equipment integration, working with an experienced agriculture equipment manufacturing company can set your operation apart.

Look for a team that understands your challenges, delivers precision-built machinery, and stays ahead of evolving trends. Choosing a trusted agricultural machinery fabrication manufacturer not only boosts your efficiency but also supports long-term sustainability and growth.

Now is the time to invest in solutions built for tomorrow’s farm—by experts who understand the needs of today.

0 notes

Text

Elevator Bucket Bolt Manufacturer In India – Rajat Exports

In the industrial world of material handling, precision, safety, and strength are non-negotiable. One of the most essential components in bulk material handling systems is the elevator bucket bolt. These bolts secure elevator buckets to belts or chains, ensuring smooth vertical transport of materials such as grains, minerals, and chemicals. As a trusted name in this niche yet vital industry, Rajat Exports has emerged as a leading Elevator Bucket Bolt Manufacturer in India, delivering reliability, performance, and world-class quality.

Why Elevator Bucket Bolts Matter

Elevator bucket bolts are specially designed fasteners that play a crucial role in bucket elevators – machines used extensively in various industries for vertical transportation of bulk goods. Their function is simple, yet critical: they hold elevator buckets tightly in place while withstanding high loads and vibrations. Therefore, the need for bolts that are strong, corrosion-resistant, and durable is paramount. This is exactly where Rajat Exports shines.

Rajat Exports: Setting Standards in Bolt Manufacturing

With decades of experience, Rajat Exports stands as a pioneer in manufacturing a wide range of industrial fasteners, with specialization in elevator bucket bolts. Being a trusted Elevator Bucket Bolt Manufacturer in India, the company adheres to stringent quality standards to ensure that each bolt delivers long-lasting performance, even in the most demanding industrial environments.

Our bolts are made from high-grade raw materials and undergo rigorous quality checks at every stage of production. Whether it's mild steel, stainless steel, or galvanized finishes, we offer solutions that suit a variety of industry needs. Precision threads, robust heads, and high tensile strength make our bolts the first choice for manufacturers and engineers across India and abroad.

Product Range & Applications

Rajat Exports offers a comprehensive range of elevator bucket bolts including:

Oval head bolts

Fanged bolts

Norway bolts

Euro bolts

Sabre bolts

These bolts are available in multiple sizes and coatings, allowing customization based on project requirements. Our elevator bucket bolts are widely used in:

Agricultural grain elevators

Fertilizer plants

Cement industries

Food processing units

Power plants

Chemical industries

As a renowned Elevator Bucket Bolt Manufacturer in India, we continuously upgrade our manufacturing processes and invest in technology to ensure top-tier quality and consistent supply.

Quality, Precision, and Reliability

At Rajat Exports, quality is more than a promise – it is a commitment. Our team of experienced engineers and quality control specialists ensures that every bolt meets international safety and performance benchmarks. We understand the critical nature of our products and leave no room for compromise.

We use advanced CNC machinery and automated processes to maintain uniformity, reduce human error, and deliver bolts that perform flawlessly under pressure. Moreover, our bolts go through rigorous testing for tensile strength, impact resistance, corrosion protection, and dimensional accuracy.

Customer Satisfaction Is Our Priority

Our success is built on strong customer relationships, dependable service, and consistent product quality. Rajat Exports provides timely delivery, technical assistance, and bulk supply capabilities – making us a preferred Elevator Bucket Bolt Manufacturer in India for major industrial clients.

We take pride in offering not just products but complete fastening solutions. Whether you're a small agricultural unit or a large-scale industrial plant, our team works closely with you to provide the right bolts for your specific application.

Choose Rajat Exports ��� Choose Excellence

When you choose Rajat Exports, you're choosing a brand synonymous with strength, precision, and reliability. As a reputed Elevator Bucket Bolt Manufacturer in India, we are committed to powering industries with the highest quality fastening products.

Get in touch with Rajat Exports today and discover why we're the trusted partner for countless businesses across India and beyond. Let us help you elevate your operations — bolt by bolt.

0 notes

Text

High-Precision Brass Components for Electrical Applications

In the evolving world of electrical engineering and industrial automation, high-precision brass components play a vital role in ensuring safe, efficient, and long-lasting connections. Their excellent conductivity, corrosion resistance, and mechanical strength make them the material of choice for a wide range of electrical applications.

At Saryu Industries, we specialize in delivering finely machined brass electrical fitting parts that meet both national and international quality standards. Our components are widely used in switchgear, panel boards, wiring systems, and electrical enclosures—offering unmatched reliability in performance-critical environments.

Engineered for Precision and Durability

Brass is a trusted metal in the electrical industry for its ability to withstand high temperatures and electrical loads without compromising structural integrity. That’s why every part we manufacture is crafted using cutting-edge CNC machinery, tested for dimensional accuracy, and inspected to ensure flawless integration in your final assembly.

Whether you need threaded inserts, electrical terminals, contact pins, or earthing accessories, we provide solutions that deliver optimal performance in high-stress environments.

Custom Solutions for Your Industry

We understand that every application is unique. That’s why we offer custom manufacturing services tailored to your specifications. From prototyping to bulk production, we work closely with your engineering team to deliver parts that are application-specific and built to last.

Our ability to offer both standardized and tailor-made components has made us one of the most trusted brass manufacturers in India. Our commitment to quality, precision, and timely delivery ensures that your supply chain never slows down.

Choose the Right Brass Partner

If your electrical projects demand consistency, longevity, and precision, you can count on our brass components to meet the challenge. We serve industries across India and export globally, supporting OEMs, electrical contractors, and panel board manufacturers with reliable parts that exceed expectations.

Explore our full range of brass electrical fitting parts and experience the difference of working with experienced brass manufacturers in India. Let’s power your innovation—one component at a time.

0 notes

Text

Discover the Difference: Why Our Ball Valves Outperform the Competition

Ball valves are the unsung heroes of industrial fluid control, relied upon in sectors like oil & gas, chemicals, water treatment, power generation, and many more. With so many options out there, how do you choose a ball valve that truly excels in safety, reliability, and value?

As a leading name in ball valve manufacturing, we offer products that provide performance and peace of mind that you just won’t find with generic alternatives. Here’s why engineers and project managers around the globe trust our ball valves for their critical applications—and why you should, too.

1. Engineered for Excellence: Precision, Performance, and Peace of Mind

Our ball valves are meticulously designed with a strong emphasis on precision engineering and operational safety. Each valve goes through extensive testing and quality control, guaranteeing leak-tight performance and smooth operation even under pressure.

What makes us different:

- CNC-machined components for tight tolerances and a perfect fit

- Advanced sealing technology for zero-leak performance

- Anti-blowout stems and fire-safe designs

- Full compliance with global standards (API, ASME, ISO)

While other market solutions might skimp on machining or materials, we never cut corners. Our dedication to engineering excellence means you get reliable shut-off, a longer service life, and safer operations for your facility.

2. Materials Built for Every Challenge

Industrial environments come in all shapes and sizes, and so do your fluid control needs. Our ball valves are available in a variety of materials to meet any challenge:

- Stainless Steel (304, 316, 316L)

- Carbon Steel

- Duplex & Super Duplex

- Monel, Inconel, Hastelloy, and other exotic alloys

Each valve is crafted from high-quality forgings or bar stock, ensuring strength, corrosion resistance, and pressure tolerance in even the toughest conditions. Whether you’re dealing with aggressive chemicals, high temperatures, or seawater, we have the perfect material solution for you.

3. Innovative Designs for Versatile Applications

Not all ball valves are made the same. Our dedicated R&D team is always pushing the envelope to deliver both custom and standard designs tailored to your specific needs:

- Trunnion-mounted and floating ball designs

- Full-bore and reduced-bore options

- Three-piece, two-piece, and one-piece construction

- Fire-safe, anti-static, and anti-blowout features

- Soft-seated and metal-seated designs

This level of versatility ensures you receive a ball valve that’s perfectly suited to your precise pressure, temperature, and media requirements—something that generic manufacturers just can’t match.

4. Global Certifications and Compliance

We don’t just make promises—we back them up with top-notch certifications from around the globe:

- API 6D / API 607

- ASME B16.34

- ISO 9001:2015 and PED

- ATEX, SIL, CE, and more

This means our ball valves are trusted and recognized by EPCs, operators, and regulators across the Americas, Europe, the Middle East, and Asia-Pacific.

5. Installation Simplicity and Low Maintenance

Our ball valves are crafted for quick, hassle-free installation and easy maintenance:

- Universal end connections: threaded, flanged, welded, socket-weld, and more

- Lightweight, compact design for effortless handling

- Blow-out proof stems and anti-static features for enhanced safety

- Clear, laser-etched markings for easy identification

Our design streamlines installation, reduces downtime, and ensures smooth integration with both new and existing systems.

6. Customization for Unique Needs

Every industry and application has its own quirks. That’s why we provide custom-engineered solutions, including:

- Special pressure ratings and high-temperature designs

- Tailored face-to-face dimensions and end connections

- Actuator mounting pads for automation and control

- Specialized coatings for corrosion and abrasion resistance

Our engineering team works hand-in-hand with your project teams to create ball valves that fit your process like a glove—no compromises, no costly modifications.

7. Competitive Pricing with Global Support

You don’t have to break the bank to get high quality. Thanks to our global supply chain and manufacturing know-how, we can provide:

Top-notch quality at prices that won’t make you cringe

Quick deliveries to any corner of the world

Discounts for bulk orders and long-term agreements

Around-the-clock technical support and attentive after-sales service

When you choose us, you’re not just purchasing a valve—you’re partnering with a team dedicated to your long-term success.

8. Trusted by Industry Leaders Worldwide

Our ball valves are trusted in refineries, power plants, offshore rigs, chemical factories, and water treatment facilities all over the globe. Leading international EPCs and operators turn to us for our:

Proven history of quality and performance

Quick turnaround on custom needs and tight timelines

Dependable and consistent supply chain

Make the Smart Choice—Upgrade to Our Ball Valve Solutions

Why settle for the average when you can invest in valves that offer outstanding performance, durability, and top-tier safety? With our extensive range, engineering expertise, and customer-first approach, you’ll enjoy peace of mind and exceptional value—project after project, year after year.

0 notes

Text

Explore the Best Forged Valve Manufacturers in Ahmedabad

When it comes to sourcing durable and high-performance valves, industrial buyers across sectors trust forged valve manufacturers in Ahmedabad. Known for their superior strength, reliability, and resistance to extreme conditions, forged valves are widely used in critical applications including oil & gas, petrochemical, water treatment, and power generation. Ahmedabad, a rapidly growing industrial hub, is home to several reputable manufacturers offering precision-engineered forged valves that meet both domestic and international standards.

MNC Valves, a leader in industrial valve solutions, takes pride in being a prominent name among these elite forged valve manufacturers. With an emphasis on quality, customization, and customer satisfaction, MNC Valves continues to set benchmarks in the valve manufacturing industry.

Why Forged Valves Are Preferred in Critical Applications

Forged valves are manufactured by shaping metal under high pressure, which enhances their mechanical properties and structural integrity. Compared to cast valves, forged valves offer:

Higher Strength

Improved Resistance to Pressure and Temperature

Lower Risk of Porosity or Defects

Longer Service Life

These features make them ideal for high-stress applications where safety and durability are non-negotiable. Industries that cannot afford valve failures rely on forged valves for uninterrupted operations.

MNC Valves: A Leader Among Forged Valve Manufacturers in Ahmedabad

Commitment to Quality and Innovation

At MNC Valves, quality begins at the source. The company uses certified raw materials and follows strict quality control protocols at every stage of production. Each valve is tested for pressure, temperature tolerance, and performance under real-world conditions.

Whether you need standard or custom-built forged valves, MNC Valves offers:

Gate Valves

Globe Valves

Check Valves

Ball Valves

Needle Valves

Custom Forged Solutions

All valves are designed in compliance with ASME, API, DIN, and other global standards to ensure wide-ranging applicability.

State-of-the-Art Manufacturing Facilities

MNC Valves operates from a fully equipped plant in Ahmedabad, featuring modern forging units, CNC machining centers, pressure testing labs, and CAD/CAM design capabilities. This in-house infrastructure ensures precision, speed, and flexibility in order fulfillment.

Moreover, the company continually invests in research and development to introduce better designs and materials that align with evolving industrial needs.

How to Choose the Right Forged Valve Manufacturer?

Choosing the right forged valve manufacturers in Ahmedabad is crucial for ensuring optimal system performance. Here are some important factors to consider:

✅ Certifications and Standards

Make sure the manufacturer adheres to national and international quality standards like ISO 9001, API 6D, and PED certifications.

✅ Product Range

A wider product portfolio is beneficial when you need different types of valves for varied pressure ratings, materials, and operating conditions.

✅ Testing and Inspection

A reliable manufacturer should conduct 100% pressure testing, NDT, and third-party inspections when required.

✅ After-Sales Support

Check whether the company offers installation assistance, documentation, spare parts, and maintenance services.

MNC Valves checks all these boxes, making it a go-to source for industries that cannot compromise on performance or safety.

Applications of Forged Valves in Industry

The forged valves from Ahmedabad-based manufacturers like MNC Valves find applications in:

Oil & Gas Pipelines

Refineries and Petrochemical Plants

Chemical Processing Units

Power Generation Systems

Pharmaceutical and Food Processing Industries

Water Treatment Plants

With stringent safety and quality requirements in these sectors, forged valves continue to play a pivotal role in maintaining system integrity and operational efficiency.

Advantages of Partnering with MNC Valves

As one of the trusted forged valve manufacturers in Ahmedabad, MNC Valves offers several advantages:

Timely delivery and consistent stock availability

Technical support for selection and specification

Customization to suit unique project requirements

Eco-friendly manufacturing practices

Excellent client satisfaction record

These qualities position MNC Valves as a long-term partner for industrial clients worldwide.

FAQ – Forged Valve Manufacturers in Ahmedabad

What is the difference between forged and cast valves Answer: Forged valves are made by compressing metal under high pressure, resulting in denser and stronger structures. Cast valves, on the other hand, are made by pouring molten metal into molds, which can sometimes result in defects like porosity or cavities.

Are forged valves suitable for high-temperature applications Answer: Yes, forged valves are ideal for high-temperature and high-pressure environments due to their superior mechanical properties and structural integrity.

Do MNC Valves offer customization for specific industries Answer: Absolutely. MNC Valves provides custom-forged valve solutions tailored to the specific requirements of industries like oil & gas, petrochemical, and power generation.

What standards do forged valves from Ahmedabad manufacturers typically meet Answer: Most leading forged valve manufacturers in Ahmedabad, including MNC Valves, comply with global standards such as API, ASME, DIN, BS, and IS.

Can I request third-party inspection before dispatch Answer: Yes. MNC Valves facilitates third-party inspections (TPI) through reputed agencies upon client request.

Conclusion

In an industrial environment where safety, reliability, and performance are paramount, selecting the right valve partner is key. Forged valve manufacturers in Ahmedabad, especially industry leaders like MNC Valves, are raising the bar by delivering high-quality, standard-compliant, and cost-effective valve solutions. Whether for critical pipeline systems or precision fluid control applications, forged valves from Ahmedabad are proving to be a reliable choice across the globe.

0 notes

Text

Pirado Switches: A Leading Name Among Metal Clad PCB Manufacturers in India

In the world of high-performance electronics, efficient heat dissipation is crucial. Devices operating at high power levels generate significant heat, which, if not managed properly, can reduce efficiency, cause malfunction, or even result in total system failure. This is where Metal Clad PCBs (MCPCBs) come into play. These specialized printed circuit boards are designed to offer superior thermal performance and durability. Among the top Metal Clad PCB manufacturers in India, Pirado Switches stands out for its quality engineering, precision manufacturing, and commitment to innovation.

What is a Metal Clad PCB?

A Metal Clad PCB, often referred to as MCPCB, is a type of PCB that uses a metal base (commonly aluminum or copper) instead of traditional fiberglass or epoxy. The metal base is bonded with a dielectric layer and a copper circuit layer on top. The key advantage is enhanced thermal conductivity, making it ideal for applications where managing heat is critical.

Typical applications include:

LED lighting systems

Power converters

Automotive electronics

Industrial machinery

Solar inverters

Why Metal Clad PCBs Matter

As electronic components become smaller and more powerful, the need for efficient thermal management becomes essential. Unlike traditional FR4 PCBs, MCPCBs transfer heat away from components much faster, increasing performance and extending the lifespan of the product.

This makes choosing the right Metal Clad PCB manufacturer a critical decision for OEMs, product designers, and engineers.

Pirado Switches: Trusted for High-Quality Metal Clad PCBs

Pirado Switches has earned its position as a reliable and progressive manufacturer of metal clad PCBs in India. With state-of-the-art production facilities, a skilled technical team, and a customer-centric approach, Pirado delivers cutting-edge solutions tailored to a wide range of thermal management challenges.

What Makes Pirado Switches a Top Choice?

Advanced Manufacturing Technology: Pirado uses modern CNC drilling machines, automatic solder mask printers, and laser-based inspection systems to ensure precision in every MCPCB produced.

Superior Materials: Only high-grade aluminum and copper substrates are used, guaranteeing excellent heat dissipation and mechanical stability.

Customized Solutions: From single-layer to multi-layer metal clad boards, Pirado provides custom design and fabrication services based on the customer’s specifications.

Strict Quality Control: Every batch undergoes rigorous testing for insulation resistance, thermal conductivity, and layer adhesion to meet international standards.

Quick Turnaround & Scalability: Whether you need a prototype or bulk production, Pirado ensures timely delivery and scalable solutions.

Applications Served by Pirado’s Metal Clad PCBs

Pirado’s metal clad PCBs are trusted in a variety of high-demand sectors, including:

LED streetlights and downlights

Electric vehicle charging systems

Industrial power supplies

Telecom infrastructure equipment

Conclusion

If your project requires advanced thermal management, choosing a dependable metal clad PCB manufacturer is non-negotiable. Pirado Switches brings technical expertise, robust quality assurance, and flexible production capabilities to every order. Whether you're designing the next-gen LED lighting solution or developing high-efficiency power systems, Pirado’s MCPCBs provide the performance and durability you need.

Visit:- https://www.vaishnavielectronics.co.in/metal-clad-pcb.html

0 notes