#3D Scanning Reverse Engineering

Text

Exploring 3D Scanning in Chicago: Revolutionizing Industries Through Advanced Technology

In today’s rapidly advancing technological landscape, 3D scanning has emerged as a groundbreaking tool across various industries. From architecture to manufacturing, and even in art restoration, 3D scanning provides unparalleled precision, efficiency, and innovation. In cities like Chicago, where technology and industry meet, 3D scanning has become an essential service, transforming how businesses approach design, analysis, and production.

What is 3D Scanning?

3D scanning is a process that captures the physical characteristics of an object, person, or environment and converts them into digital 3D models. Using laser technology, structured light, or photogrammetry, the scanner captures the surface geometry and texture of the object in high detail. This data can then be used for various applications, including reverse engineering, quality control, virtual reality, and more.

The Role of 3D Scanning Companies in Chicago

Chicago, a hub for innovation and industry, is home to numerous companies that specialize in 3D scanning. These companies provide state-of-the-art scanning services tailored to meet the specific needs of various sectors. Whether it’s for architectural restoration, product design, or forensic analysis, 3D scanning companies in Chicago offer expertise and cutting-edge technology to help businesses achieve their goals.

1. 3D Scanning in Architecture and Construction

In the architecture and construction industries, precision is paramount. 3D scanning allows architects and engineers to create highly accurate digital models of buildings and structures. These models can be used for various purposes, such as renovations, retrofits, or new constructions. By using 3D scanning, professionals can capture every detail of an existing structure, ensuring that the new design integrates seamlessly with the old.

In Chicago, where historic buildings and modern skyscrapers coexist, 3D scanning has become an invaluable tool. For instance, when renovating a historic building, architects can use 3D scanning to document the existing structure in its entirety, preserving its integrity while making necessary updates.

2. 3D Scanning in Manufacturing and Product Design

Manufacturing and product design are other fields where 3D scanning has made a significant impact. In Chicago’s thriving manufacturing sector, companies rely on 3D scanning for quality control, prototyping, and reverse engineering. By scanning a physical part, manufacturers can create a digital twin, allowing them to analyze the design, identify flaws, and make improvements.

Reverse engineering, in particular, has benefited greatly from 3D scanning. When a company needs to recreate or improve an existing product without the original design files, 3D scanning provides a precise and efficient solution. By capturing the exact dimensions and features of the product, engineers can reverse engineer the design, ensuring that the new version meets or exceeds the original specifications.

3. 3D Scanning in Art and Cultural Preservation

Chicago is known for its rich cultural heritage and vibrant arts scene. Preserving art and cultural artifacts is a task that requires the utmost care and precision. 3D scanning has become an essential tool in this area, allowing conservators to document and restore priceless works of art.

For example, when restoring a damaged sculpture, conservators can use 3D scanning to create a detailed digital model of the piece. This model can then be used to guide the restoration process, ensuring that the restored sculpture is as close to the original as possible. Additionally, 3D scanning allows museums to create digital archives of their collections, making them accessible to a broader audience and preserving them for future generations.

The Importance of Reverse Engineering in 3D Scanning

One of the most powerful applications of 3D scanning is reverse engineering. In industries such as automotive, aerospace, and consumer goods, reverse engineering plays a crucial role in product development and innovation. By using 3D scanning to capture the precise details of a physical object, companies can create accurate digital models that can be used for analysis, redesign, or replication.

1. Enhancing Product Design and Innovation

Reverse engineering through 3D scanning allows companies to deconstruct a product to understand its design and functionality fully. This process is particularly useful when trying to improve an existing product or create a new one. By analyzing the scanned data, engineers can identify areas for improvement, such as material selection, structural integrity, or ergonomic design. This level of insight leads to more innovative and competitive products.

In Chicago, where industries such as automotive and aerospace are prominent, 3D scanning reverse engineering is a key tool for maintaining a competitive edge. Companies can quickly adapt to changing market demands by improving product design and reducing time-to-market.

2. Quality Control and Assurance

In manufacturing, maintaining high-quality standards is critical. 3D scanning provides a reliable method for quality control and assurance by allowing manufacturers to compare a finished product with its original design. By scanning the product and overlaying it with the digital model, any deviations or defects can be quickly identified and corrected.

This process is particularly important in industries where precision is essential, such as aerospace and medical devices. In these fields, even the smallest error can have significant consequences. 3D scanning ensures that products meet the required specifications, reducing the risk of costly mistakes.

The Future of 3D Scanning in Chicago

As technology continues to evolve, so does the potential of 3D scanning. In Chicago, a city known for its innovation and forward-thinking, 3D scanning is poised to play an even greater role in shaping the future. From smart cities to advanced manufacturing, the possibilities are endless.

1. Integration with Other Technologies

One of the most exciting developments in 3D scanning is its integration with other emerging technologies, such as artificial intelligence (AI), virtual reality (VR), and the Internet of Things (IoT). By combining 3D scanning with AI, for example, companies can automate the scanning process, making it faster and more efficient. This integration also opens up new possibilities for data analysis and decision-making.

In the field of VR, 3D scanning allows for the creation of highly realistic virtual environments. This technology is already being used in industries such as real estate, where potential buyers can take virtual tours of properties before they are built. As VR technology continues to improve, the applications of 3D scanning will expand even further.

2. Smart Cities and Urban Planning

Chicago is already known for its innovative approach to urban planning and development. With the advent of smart cities, 3D scanning will play a crucial role in creating more efficient, sustainable, and livable urban environments. By scanning existing infrastructure, city planners can create detailed digital models that can be used to optimize traffic flow, improve public transportation, and reduce energy consumption.

In addition, 3D scanning can be used to monitor the condition of buildings, bridges, and other infrastructure. By regularly scanning these structures, engineers can detect signs of wear and tear early on, allowing for timely maintenance and repairs. This proactive approach helps prevent costly and potentially dangerous failures.

Choosing the Right 3D Scanning Company in Chicago

Given the wide range of applications for 3D scanning, choosing the right company to meet your specific needs is essential. When selecting a 3D Scanning in Chicago, consider factors such as experience, technology, and customer service. A reputable company will have a proven track record of delivering high-quality results, using the latest scanning equipment and software.

Additionally, look for a company that offers a full range of services, from scanning to data processing and analysis. This ensures that you have a seamless experience from start to finish, with all your needs met under one roof.

Conclusion

3D scanning is transforming industries across the globe, and Chicago is no exception. With its wide range of applications, from architecture to manufacturing and art restoration, 3D scanning is helping businesses achieve greater precision, efficiency, and innovation. As the technology continues to evolve, the possibilities for 3D scanning in Chicago are limitless. Whether you’re looking to preserve a historic building, improve product design, or plan a smart city, 3D scanning is the tool that can make it happen.

0 notes

Text

Unveiling the Potential of 3D Scanning in Reverse Engineering

In the realm of engineering innovation, the advent of 3D scanning has revolutionized traditional methodologies. Among its myriad applications, one particularly noteworthy domain is reverse engineering.

Enterprises worldwide are leveraging 3D scanning technologies to dissect and recreate intricate designs, breathing new life into legacy components and machinery. The process involves capturing detailed digital renderings of physical objects, which serve as blueprints for replication or enhancement.

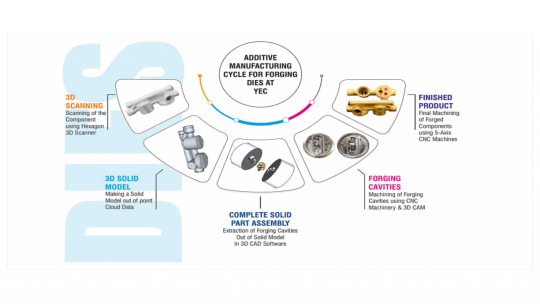

In the heart of technological advancements, Yamunanagar Engineering Cluster stands as a beacon of ingenuity. Employing cutting-edge 3D scanning techniques, the cluster pioneers the restoration and optimization of industrial assets with unparalleled precision and efficiency.

Beyond restoration, 3D scanning facilitates product innovation, enabling engineers to analyze and enhance existing designs swiftly. It expedites prototyping, reduces time-to-market, and fosters a culture of continuous improvement.

As industries evolve, the fusion of 3D scanning reverse engineering propels progress, ushering in a new era of limitless possibilities and unparalleled innovation.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Text

IndiaCADworks (ICW) is a global leader in all types of reverse engineering techniques and provides steadfast support for new engineering product development projects from start to finish. The project teams at ICW offer complete reverse engineering services to provide part customization, out-of-production replacement parts, casting molds, and more. Utilizing skilled drafters and the latest software packages, ICW can produce 3D models, 2D drawings, part technical details, and other drafting services, allowing for an integrated engineering package.

0 notes

Text

What are the key benefits of making use of 3D Scanning for reverse Engineering?

In cases where the timeline is very critical and further delay can’t be tolerated, it is becoming highly important to give priority to the quality process instead of the bulk process to reinforce the part’s needs and to consistently add value to the manufacturing process.

In this scenario today, the parts that are being manufactured are on the increasing side with the demand for accurate measurements surpassing the traditional system of measurement to measure or more specifically reverse engineer them.

The process of 3D scanning is one such scenario that can bring versatility as well as accuracy to the ever-evolving environment of the metrology industry. It is a cost-effective solution for getting important benefits for 3D scanning reverse engineering.

Key Benefits of the 3D Scanning

Coverage

In just a fraction of a minute, the 3D scanning devices can effectively collect & measure the data with the help of thousands of data points present on the surface of the desired object. This kind of efficiency was unable to get prior to the 3D scanning technology.

Speed

If you measure something manually then it can take time & effort both and you will be under the limit while collecting the data practically. Whereas in the case of 3D scanning, you are getting a faster way to collect the data with millions of data points at the speed of light. You can reduce time & effort both and thus produces CAD models or similar other prototypes or even 2D drawings for reverse engineering. With the help of accurately increasing the surface data acquisition rate, the 3D scanning device will bring you unmatched, unparalleled faster inspection.

Accuracy

With the improvement in technology, the accuracy rate has also been improved by the 3D scanners over a period of time. With a higher degree of accuracy, you can expect better functionality.

Cost

The overall cost associated with the help of 3D scanning is much more competitive compared to other dimensional control technologies, especially when saving time is also important. The 3d scanners present in the market are very easier to use & can help you in maintaining the overall training schedules by lowering the costs.

#3D Scanning Reverse Engineering Services#3D Scanning#3D Scanning Reverse Engineering#Reverse Engineering#Engineering Services#sixd#sixd engineering#SixD Engineering Solutions

0 notes

Link

#SixD India#3D Scanning Application and Uses#3D Scanning#engineering#3D Scanning reverse engineering#SixD Engineering#SixD#3D Modelling#3D#SixD Engineering Solutions#India#Noida#Metrology#Metrology Services in Noida

0 notes

Text

Sheet Metal Forming: Enhancing Precision with 3D Scanning and Reverse Engineering

Reverse Engineering

Sheet metal forming is a vital manufacturing process used to create metal components for industries such as automotive, aerospace, and heavy machinery. This process involves shaping metal sheets into various forms using techniques like bending, stamping, and drawing. While traditional methods are still widely used, the integration of 3D scanning and reverse engineering technologies has revolutionized sheet metal forming, making it more efficient and precise than ever before.

How 3D Scanning is Transforming Sheet Metal Forming

One of the main challenges in sheet metal forming is ensuring that the final product meets exact design specifications. In traditional setups, this requires manual inspections and measuring, which can be time-consuming and prone to human error. 3D scanning has changed this landscape by enabling manufacturers to capture detailed and accurate 3D models of metal components. These models allow for precise analysis and ensure that parts are produced to exact measurements.

With high-precision 3D metrology, manufacturers can significantly reduce material wastage, minimize errors, and streamline the overall production process. This not only improves efficiency but also cuts down on costs related to rework and rejected parts.

Reverse Engineering in Sheet Metal Forming

Reverse engineering is another critical tool that complements 3D scanning in sheet metal forming. It allows manufacturers to recreate or modify existing parts when original designs or documentation are unavailable. Using reverse engineering, companies can scan a physical part, analyze its geometry, and generate digital models that can be used for redesign or reproduction.

This process is particularly useful when working with legacy equipment or when making design improvements to existing parts. Reverse engineering enables manufacturers to optimize designs for better performance, durability, and ease of production. Additionally, it plays a crucial role in quality control and inspection services, ensuring that every piece of metalwork aligns with the required standards.

Benefits of 3D Scanning and Reverse Engineering in Metal Forming

The integration of 3D scanning and reverse engineering into the sheet metal forming process offers numerous advantages:

Accuracy: Both technologies ensure high precision, reducing errors and improving product quality.

Cost Efficiency: Faster inspections and reduced material waste lower production costs.

Speed: Digital models from 3D scanners accelerate the prototyping and production process.

Quality Control: Inspection using 3D data allows for comprehensive analysis, ensuring that all parts conform to design specifications.

Future of Sheet Metal Forming

As manufacturing technologies continue to advance, 3D scanning, reverse engineering, and related digital tools will play an even more significant role in shaping the future of sheet metal forming. The ability to produce accurate, high-quality parts with minimal error will become an industry standard, ensuring that manufacturers stay competitive in an increasingly digital world.

By leveraging 3D scanning, reverse engineering, and other advanced technologies, businesses can improve the efficiency and accuracy of their sheet metal forming operations, leading to enhanced production processes and better end products.

0 notes

Text

Digital Scan 3D specializes in 3D Scanning and applications. Apart from providing some of the best scanners and software in the world,

Digital Scan 3D also offers 3D Services as below:

3D Scanning Services

Reverse Engineering Services

Metrology Services (QA/QA)

Engineering Services

3D Printing

Training and Support

For More Info Visit Us At: https://digitalscan3d.com/

#Artec Leo wireless 3D Scanner in Oregon#USA#Geomagic Design X Software in Oregon#Automated 3D Scanner in Oregon#Automated 3D Scanner in Oregon#Reverse Engineering Services in Oregon#3D Scanning Services in Oregon#Reverse Engineering software in Oregon

0 notes

Text

The Transformative Impact of Professional Scale Modeling in Architecture

In the architectural industry, the ability to effectively communicate and visualize complex designs is critical. Professional scale modeling has long been an essential tool in this process, providing tangible, precise representations of architectural concepts. With the advent of advanced technologies such as 3D printing, professional scale modeling has reached new heights, offering unprecedented levels of detail and accuracy. This article explores the significance of professional scale modeling in architecture and how it enhances design, communication, and project execution.

The Role of Professional Scale Modeling in Architecture

Enhanced Design Visualization: Professional scale models allow architects to visualize their designs in a three-dimensional form, providing a comprehensive understanding of the spatial relationships and proportions of the structure. This helps in identifying potential design flaws and making necessary adjustments early in the design process.

Effective Communication: Scale models serve as an excellent tool for communicating design concepts to clients, contractors, and other stakeholders. They provide a clear and tangible representation of the project, facilitating better understanding and discussions around design elements and modifications.

Detailed Representation: The precision involved in professional scale modeling ensures that every aspect of the design is accurately represented. This includes intricate details such as facades, interiors, and landscapes, which are crucial for comprehensive project presentations and approvals.

Marketing and Presentation: High-quality scale models are powerful marketing tools that can be used in presentations, exhibitions, and client meetings. They showcase the architect’s vision and craftsmanship, helping to secure new projects and impress potential clients.

The Evolution of Scale Modeling with 3D Printing

The integration of 3D printing technology into professional scale modeling has revolutionized the way architectural models are created and utilized. Here are some key advantages:

Precision and Accuracy: 3D printing allows for the creation of highly detailed and accurate scale models. This precision is particularly beneficial for modern architectural designs that include complex geometries and intricate details.

Time and Cost Efficiency: Traditional scale modeling can be labor-intensive and time-consuming. 3D printing significantly reduces the time required to produce models, allowing for faster iterations and quicker project timelines. Additionally, while the initial setup costs for 3D printing can be high, the overall production costs are generally lower than traditional methods.

Customization and Flexibility: 3D printing offers unparalleled flexibility, allowing architects to easily customize models and make quick adjustments. This is especially useful during the design development phase when changes and refinements are frequent.

Material Versatility: 3D printing supports a wide range of materials, from durable plastics to high-quality resins. This versatility enables the creation of models that are not only aesthetically pleasing but also robust and durable.

C3D: Leading the Way in Professional Scale Modeling

At C3D, we are committed to leveraging the latest technologies to provide exceptional scale modeling services for the architectural industry. Our state-of-the-art 3D printing capabilities ensure that your architectural models are of the highest quality, offering both visual appeal and functional precision.

Our Services Include:

Custom 3D Scale Models: We specialize in creating custom models tailored to your specific design needs. Whether you need a simple conceptual model or a highly detailed presentation piece, we have the expertise to deliver.

High-Resolution Printing: Our advanced 3D printers produce high-resolution models that capture the finest details of your design, enhancing the overall presentation quality.

Material Options: We offer a range of materials to suit different project requirements, ensuring that your models are both aesthetically pleasing and durable.

Expert Support: Our team of experts is dedicated to providing exceptional service, from initial consultation to final delivery. We work closely with you to ensure that your vision is accurately represented.

Conclusion

Professional scale modeling plays a vital role in the architectural industry, enhancing design visualization, improving communication, and supporting successful project outcomes. With advancements in 3D printing technology, the possibilities for scale modeling have expanded, offering architects new levels of precision, efficiency, and flexibility. At C3D, we are at the forefront of this evolution, providing high-quality scale modeling services that help bring architectural visions to life. Trust C3D to be your partner in architectural innovation and excellence.

#fdm 3d printing#custom trophies#bespoke trophy manufacturing#professional scale modeling#custom scale models#industrial 3d scanning#3d scanning services cost#sls 3d printing service#scale model prototyping#online 3d printing services#custom 3d printing#3d printing service#rapid prototyping 3d printing#3d printing online services#3d scale model maker#3d printer service near me#3d printing companies near me#3d scanning services#fused deposition modeling 3d printer#high strength 3d printed parts#scale modeling#precision model making#industrial grade 3d printing#unique 3d printed floral containers#custom 3d printed vases#high resolution 3d scanning#corporate recognition awards#prototyping#reverse engineering services#3d print vase

0 notes

Text

3d Scan Reverse Engineering

3D Scan Reverse Engineering Accelerating Product Development & Manufacturing Scan to CAD A qualified health and safety consultant may offer your business an expert, informed, and unbiased viewpoint on handling your health and safety needs. Your team of specialists is supported by health and safety consultants. We can assist you with the setup, execution, and upkeep of your safety program.A qualified health and safety consultant may offer your business a competent, educated, and unbiased viewpoint on how to manage your health and safety obligations. Your professional staff is supported by health and safety consultants. We can assist with setting up, ensuring the execution of, and maintaining your safety program.

6033 Shawson Dr

Unit #23, Mississauga ON L5T 1H8

(289) 628-1455

0 notes

Text

#custom 3d printing near me#custom 3d printing services#custom 3d printing#3d print service near me#3d printing companies near me#3d printing cost#online 3d printing#3d printing online services#3d print vase#fused deposition modeling#3d printer service near me#large 3d printing services#sls 3d printing service#fused deposition modeling 3d printer#large industrial 3d printer#rapid prototyping 3d printing#3d scanning services cost#3d scale model maker#High resolution 3d scanning#Industrial 3d scanning#Reverse engineering services#Rapid Prototyping#Scale modeling#3d printing services#large 3d printing#best 3d printing service#large format 3d printing#3d model printing service#sls printing service#large scale 3d printing service

0 notes

Text

3d Scan Reverse Engineering

Reverse engineering using 3D scanning involves the process of capturing the physical shape and dimensions of an object and then creating a digital model from that data. This is useful for various purposes, such as replicating parts, modifying existing designs, or integrating physical objects into digital workflows. Here is a general overview of the process:

Selecting the Object:

Choose the physical object that you want to reverse engineer. It could be a product, prototype, or any item for which you need a digital model.

3D Scanning:

Use a 3D scanner to capture the geometry of the object. There are various types of 3D scanners, including laser scanners, structured light scanners, and photogrammetry systems. Select the appropriate scanner based on the size, complexity, and material of the object.

Data Acquisition:

Perform the scanning process, ensuring comprehensive coverage of the object's surface. Multiple scans may be required from different angles to capture intricate details.

Point Cloud Generation:

The 3D scanner produces a point cloud, which is a set of data points in three-dimensional space representing the object's surface.

Mesh Generation:

Convert the point cloud data into a 3D mesh. This mesh represents the surface geometry of the object and is composed of interconnected polygons.

Surface Reconstruction:

Refine the mesh to ensure a smooth and accurate representation of the object's surface. This step may involve using software tools to clean up noise and fill in any gaps.

Creating a Solid Model:

Depending on the application, you might convert the mesh into a solid model. This is particularly important if you intend to use the digital model for engineering and manufacturing purposes.

Parametric Modeling (Optional):

If your goal is to modify or enhance the object's design, you may use parametric modeling software to add features, adjust dimensions, or make other changes.

Quality Control:

Conduct a thorough quality check to ensure that the digital model accurately represents the physical object. Compare the digital model with the original object to identify any discrepancies.

Exporting the Model:

Export the final digital model in a suitable file format (e.g., STL, STEP) for your intended use.

Further Processing (Optional):

Depending on your project requirements, you might perform additional tasks, such as surface optimization, texture mapping, or color assignment.

It's important to note that the success of the reverse engineering process relies on the accuracy of the 3D scanning equipment, the skill of the operator, and the capabilities of the software used for data processing and model creation.

0 notes

Text

Structured Blue Light Scanning: How Does it Work?

Structured blue light scanning is revolutionizing modern quality control by providing unparalleled precision in the inspection of intricate components. This non-contact measurement technique uses a grid of blue light, which has a shorter wavelength, allowing for higher resolution and more accurate measurements than traditional methods. The process involves projecting this structured light onto an object, capturing the reflected patterns with high-resolution cameras, and processing the data to create an accurate 3D model. Calibrated dots are placed on the object's surface to serve as reference points, ensuring the scan’s accuracy. This technology is versatile, quick, and non-invasive, making it ideal for various industries that require meticulous inspection of complex geometries. As industries evolve, blue light scanning is poised to set new standards for precision and accuracy in manufacturing.

Visit Here to Know More: https://www.nelpretech.com/blog/structured-blue-light-scanning-how-does-it-work

0 notes

Text

Inspection Equipment Testing Services: Your Precision and Safety Experts

In industries, the growing competition requires optimum equipment operations that mark the paramount importance of precision and safety. This inspection equipment plays a crucial role in maintaining quality standards and preventing potential hazards avoiding any business disruption. For this reason, Inspection equipment testing services are essential for any business domain heavily dependent on machinery to ensure the accuracy and reliability of these tools.

We involve comprehensive quality checks and evaluation of various inspection tools, such as gauges, meters, scanners, and analysers, to verify their accuracy and functionality. These services are typically performed by specialized technicians who follow stringent testing protocols to test equipment on various parameters critical for the production process.

Importance of Inspection Equipment Testing Services:

Quality Assurance: Precise inspection equipment is crucial for maintaining product quality and process efficiency. It allows regular testing that guarantees that measurements will be accurate and consistent.

Safety Compliance: Industries like manufacturing, aerospace, and healthcare rely on inspection equipment for safety and compliance with best business practices. The correct functioning of devices through inspection reduces the risk of accidents and largely ensures adherence to regulations.

Cost Efficiency: Faulty inspection equipment can lead to flawed products, production downtime, and rework costs that can significantly hamper business image. Leveraging Inspection equipment testing services prevent these issues by detecting problems early, saving both time and money.

Data Integrity: Inspection equipment often generates crucial data that plays an important role in decision-making. If these instruments are inaccurate, it can lead to incorrect data conclusions which can be avoided by regular testing safeguards.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Text

Best 3D Scanning Services in Vadodara, Gujarat. ✓3D Laser Scanner Services, ✓3D Scanning Services , ✓Portable CMM Laser Tracker Services, ✓ Reverse Engineering, ✓ 3D Plant Scanning.

1 note

·

View note

Text

3D Lidar scanning services in Gujarat | The SUNCAD Training & Designers

Experience top-notch 3D Lidar scanning services in Gujarat with The SUNCAD Training & Designers. Our expert team utilizes cutting-edge technology to perform precise 3D scans of objects and spaces. Clients from various fields benefit from our accurate scanning solutions for design, analysis, and documentation purposes. Whether you're an architectural designer, engineering professional, or part of any industry, our reliable scanning services cater to your specific needs. Partner with The SUNCAD Training & Designers and unlock the efficiency and cost-effectiveness of 3D Terrestrial Scanning in Gujarat. For more information visit on : https://www.suncad.in/3d-lidar-scanning-data-processing/ or call us on : +91-9925023229

#reverse engineering in gujarat#heritage scanning services in gujarat#cmm inspection services in gujarat#3d scanning in gujarat#3d printing services in gujarat#leica rtc 360 scanning service provider in gujarat#laser tracker service in gujarat#3d inspection services in gujarat#faro scanner service provider in gujarat#solid edge training in gujarat

0 notes

Text

SixD India - 3D Scanning Application and Uses

The field of science and engineering is growing each day. New technologies are coming in to make the lives of both businesses and individuals easier. One such technology is 3D scanning. 3D Scanning reverse engineering is important for engineers looking for high-end technology or doctors or prosthetists looking for accurate means to make prosthetic limbs.

What is 3D Scanning?

3D scanning is a technology to create the most precise, high-quality 3D models or prints of any tangible entity. It works by taking multiple snapshots of an object. Then the shots are assembled to create a three-dimensional model of the object. This 3D model could be viewed on your computer in a 360-degree sight.

A 3D scan is a three-dimensional view of an object that could be used for reverse engineering and control quality, design, and precision in multiple industries. You can check by searching for 3D scanning services near me.

Here are some of the Major uses of 3D Scanning

Healthcare Industry

The healthcare or medical industry has hugely benefitted from 3D scanning technology. Not only that, but it also helped the medical industry to create some ground-breaking developments in the field of public health. The application of 3D scanners in the health industry has helped it achieve big milestones in improving the existing technologies as well as creating new ones. Because of the usage of 3D scanning, customized healthcare has been possible.

Industrial Engineering

An industry that has profited the most from 3D scanning is industrial engineering. Without the advanced 3D scanner devices from the metrology services in India, analyzing data of the measurements was expensive and laborious. It also took a lot of time. These scanners take minimum supervision while supplying accurate data on large types of machinery.

Forensics

Forensics demand the most precise data that only a 3D scanning reverse engineering can deliver on time. 3D scanners are a smart break of the traditional data capture methods in forensics, like tape measures and photographs. 3D scanning also allows the forensic team to store the digitized version of the evidence collected for safely using the same later.

Conclusion

With so many uses of a 3D scanner, it is only expected to develop the industries it is being used in.

#3D Scanning reverse engineering#3D scanning services near me#3D Scanning#Healthcare Industry#Industrial Engineering#metrology services in India#3D scanning reverse#3D scanners#3D Scanning Application and Uses#SixD India

0 notes