#API Spec Q1

Explore tagged Tumblr posts

Text

How Many Do You Know?

A–Z of API Certification Abbreviations

Here’s your quick-hit A–Z glossary of the most common abbreviations you'll encounter in API Q1, Q2, and Monogram programs.

#APIStandards#QualityManagement#OilAndGas#APICertification#apicompliance#ManufacturingExcellence#VegasConsulting#API Spec Q1#API Spec Q2

0 notes

Text

In the dynamic and high-stakes environment of the oil and gas industry, ensuring consistent quality and minimizing risks is essential for operational excellence. API Spec Q2, the standard developed by the American Petroleum Institute (API), plays a pivotal role in achieving these goals. This article explores how API Spec Q2 can help your business enhance its operations, reduce risks, and maintain a competitive edge.

0 notes

Text

What Saudi Businesses Must Understand Before Choosing a Mobile App Development Company

In 2025, mobile apps are no longer just digital add-ons — they are the core of customer engagement and business efficiency in Saudi Arabia. From eCommerce stores in Jeddah to logistics firms in Riyadh, mobile applications are driving growth, automation, and real-time access.

But hiring the right mobile app development company in Saudi Arabia is a decision that can either accelerate your success or cause serious setbacks.

If you are a Saudi business owner planning to invest in an app this year, here are the key things you must understand before choosing a development partner.

1. One Size Does Not Fit All — Understand Your App’s Purpose

Before selecting any agency, you must define what your app is supposed to achieve. Not all apps are created equal — and not every company is skilled in custom app development.

Ask yourself:

Are you building a customer-facing app for online shopping?

Do you need a backend admin panel to manage deliveries in Riyadh?

Are you developing an internal app to streamline HR or inventory?

Understanding your app’s primary purpose allows you to choose developers with relevant expertise. Five Programmers, for example, starts every project by digging deep into your business goals and pain points — not just tech specs.

2. Local Expertise in Saudi Arabia Is a Game-Changer

When building for the Saudi market, localization is not optional — it’s essential.

You want a development company that understands:

The Saudi user experience (UX) preferences

Arabic/English bilingual app interfaces

Integration with local payment gateways like STC Pay and Mada

Compliance with local data regulations like the Saudi PDPL (Personal Data Protection Law)

3. Data Security Isn’t Optional — It’s Mandatory in 2025

Security breaches damage reputations — and your mobile app will likely store customer data, financial transactions, or business operations.

Make sure your developers implement:

End-to-end encryption

Secure APIs and authentication flows

PDPL compliance (especially for apps handling user data)

Secure server hosting, preferably within Saudi Arabia

Reputable firms like Five Programmers offer dedicated security audits and best-practice architecture for peace of mind.

4. Custom Development Is Better Than Templates

Free or cheap templates might look attractive initially, but they don’t scale. You’ll face limitations in design, speed, features, and even ownership rights.

Choose a development company that builds from scratch:

Unique UI/UX design aligned with your branding

Flexible architecture for future upgrades

Ownership of the source code

Seamless integration with your business software (CRM, ERP, POS)

Five Programmers offers full-cycle custom development, which means your app grows with your business, not against it.

5. Post-Launch Support Is Where the Real Work Begins

Many businesses focus only on the launch — but successful apps evolve over time. Bugs appear, user feedback rolls in, and OS updates require adjustments.

Check if your chosen company offers:

Ongoing maintenance plans

Performance monitoring tools

Feature updates and version control

Support channels for urgent fixes

Without solid post-launch support, your app can quickly fall behind.

With Five Programmers, the partnership continues after delivery — keeping your app secure, stable, and future-ready.

Need a Reliable App Development Partner in Saudi Arabia?

Looking to turn your app idea into reality with zero stress and maximum results?

Whether you run a logistics startup in Riyadh or a retail chain across Jeddah, Five Programmers offers:

End-to-end custom app development

Saudi market localization

Agile development processes

Affordable pricing with transparency

FAQs – Choosing a Mobile App Development Company in Saudi Arabia (2025)

Q1: How long does it take to build a custom mobile app?

A: It usually takes between 2 to 6 months depending on complexity, number of features, and testing cycles.

Q2: What platforms should I target — Android or iOS?

A: In Saudi Arabia, Android holds a larger market share, but it’s wise to consider both for full reach.

Q3: Should I sign an NDA with the development company?

A: Yes, always. Reputable firms like Five Programmers respect client confidentiality and will sign NDAs without hesitation.

Q4: Can I request custom features like payment gateways or delivery tracking?

A: Absolutely. With custom development, features can be tailored specifically to your business needs.

Q5: How can I track progress during development?

A: Through milestone-based reporting, project management tools (like Jira or Trello), and weekly updates from your development team.

📝 Final Thoughts

Choosing the right mobile app development company in Saudi Arabia is one of the most important business decisions you’ll make in 2025. From understanding your market to ensuring long-term support, it’s not just about hiring a team — it’s about choosing a growth partner.

With the right partner like Five Programmers, your mobile app won’t just be functional — it will be future-proof, user-loved, and business-focused.

📲 Need guidance on your mobile app strategy? 📞 Get a Quote Now or ��� Talk to Five Programmers — we’ll help you build the next big thing in the Saudi app ecosystem.

#mobile app development company in Saudi Arabia#Mobile app in Riyadh#Flutter app development company in Riyadh

0 notes

Text

Industrial-Grade Kevlar Packing: When Ductile Meets Indestructible

Where Steel Fibers Throw in the Towel, We’re the Last Line of Defense Against Blowout

[Problem: Why Metals Fail] Ever seen a stainless steel braid turn into a metallic noodle under cyclic stress? Or watched graphite packing disintegrate faster than a sugar cube in hot coffee? Traditional seals crumble when faced with three enemies: ghost threads (micro-abrasions that haunt seal surfaces), packing memory (material fatigue after 10,000+ cycles), and the dreaded gland chatter (vibrational fretting at 120+ Hz).

Our R&D team dissected 143 failed seals from Texas tea seals to offshore rigs. Verdict? 82% failed below 60% of their rated specs. Time to rewrite the rules.

[Materials Science Breakthrough] The KP-8800 series isn’t your granddad’s Kevlar. We’ve hybridized para-aramid fibers with ceramic nanoparticles using a MIL-DTL-64154C (2023 rev.) compliant process. Thermal shock? Handled. The magic’s in the proprietary cross-weave:

38mm width (1.5") braid density: 92 threads/in² vs 68 in standard grades

Phenolic core infusion resists swelling in H₂S environments (API 6A Annex F validated)

Fire resistance? EN 1366-8:2020 tested – survives 1,832°F hydrocarbon fires for 27 minutes

[Field Note] “Had to cut packing with plasma torch – standard shears just laughed” – Gulf Coast valve tech

[Installation War Stories] Do: ■ Break-in with 20% load increments (ASTM D4778 Procedure C) ➢ Use zinc stearate paste, not grease (Avoid WD-40 – reacts with phenolic cores) ▪ Clock joints at 137° offset for >300 rpm shafts

Don’t: • Trust old-school tension gauges – our Dichtungsprüfung-grade testing needs laser torque meters • Mix v3.2 and v3.1 rings (flange patterns mismatch) • Forget the DeMattia flex test legacy – pre-2017 data lies

[Industry-Specific Formulations] Oilfield (Texas Tea Seals):

15% denser weave tackles sour gas blowouts

Survives 72hr frack fluid exposure (pH 1.8–13.5)

Marine:

MIL-SPEC salt fog resistance (5,000hr salt spray test)

Zero galvanic corrosion with bronze glands

Pharma (Mill Liners):

FDA 21 CFR 177.2600 compliant

0.08µm surface finish prevents biofilm nesting

[Certification Deep Dive] Our KP-8800 line carries:

API Monogram 6A (Annex F dynamic testing)

EN 1366-8:2020 fire compliance (rare for non-metallic seals)

Dual-scale pressure charts (psi/MPa) for global sites

Statistically magnificent lifespan gains (37% vs basalt)

[Legacy Product Sunset Notice] Retiring KP-7600 series effective Q1 2025:

Max 48" loop diameter (new ovens handle 72")

Lacks ceramic nanoparticle infusion

Fails EN 1366-8 fire tests at 14min

1 note

·

View note

Text

API Q1 Training

API Q1 Training by AQSS USA helps create very efficient and consistent processes.

Phone : 713 789 0885 E-mail : [email protected] Website : http://www.aqss-usa.com/training-courses/

#API Q1 Training#API Q1 course#ISO 9001 Lead Auditor Course#ISO 9001 Internal Auditor Course#AS9100 Internal Auditor Course#Inspection Services in USA#Inspection Services in Houston#Witness Inspection#Supplier Audits#Expediting Services#API Spec#API Q1#API Specification#Training#TrainingServices#education and training

0 notes

Photo

API Spec Q1 Consulting

The American Petroleum Industry developed API Specification Q1 to meet industry demands for improved quality management systems. Ibex Systems provide Management Consulting services to help you develop an API Q1 Quality Management System and related procedures and/or operational controls. Contact us for API Spec Q1 consulting in Middle East.

0 notes

Photo

Drilling Tools International stocks rod-type, slotted-type, perforated-type retrievable andnon-retrievable Drill Pipe Screens manufactured from both steel and stainless steel.

These high-quality mud screens are available in both 24” and 36” lengths with additional lengths available upon request.

Our Quality Management System is certified in compliance to ISO 9001, and API Spec Q1 and our manufacturing is licensed to API Spec 7-1. Our Quality Management System governs all of our processes from planning, to process control, to delivery. This ensures that we consistently manufacture products that not only meet API standards but also meet the ever-changing needs of our customers.

0 notes

Text

GMP Grade High Purity Parmaceutical Intermediate API Raw Powder CAS # 83905-01-5 Azithromycin Dihydrate

Azithromycin is a semi-synthetic 15-membered macrolide antibiotic. White or quasi-white crystalline powder; odorless, bitter; slightly damp. This product is soluble in methanol, acetone, chloroform, anhydrous ethanol or dilute hydrochloric acid, and almost insoluble in water.

Basic information: Azithromycin dihydrate 83905-01-5

Product Description

Product Name Azithromycin dihydrate

Synonyms AZITHROMYCIN 2-HYDRATE;1-Oxa-6-azacyclopentadecan-15-one, 13-(2,6-dideoxy-3-C-methyl-3-O-methyl-.alpha.-L-ribo-hexopyranosyl)oxy-2-ethyl-3,4,10-trihydroxy-3,5,6,8,10,12,14-heptamethyl-11-3,4,6-trideoxy-3-(dimethylamino)-.beta.-D-xylo-hexopyranosyloxy-, dihydrate, (2R,3S,4R,5R,8;AZITHROMYCINDIHYDRATE(PATENTED-NOSUPPLY);1-Oxa-6-azacyclopentadecan-15-one, 13-[(2,6-dideoxy-3-C-methyl-3-O-methyl-a-L-ribo-hexopyranosyl)oxy]-2-ethyl-3,4,10-trihydroxy-3,5,6,8,10,12,14-heptamethyl-11-[[3,4,6-trideoxy-3-(dimethylamino)-β-D-xylo-hexopyranosyl]oxy]-, dihydrate, (2R,3S,4R,5R,8R,10R;1-Oxa-6-azacyclopentadecan-15-one, 13-[(2,6-dideoxy-3-C-methyl-3-O-methyl-a-L-ribo-hexopyranosyl)oxy]-2-ethyl-3,4,10-trihydroxy-3,5,6,8,10,12,14-heptamethyl-11-[[3,4,6-trideoxy-3-(dimethylamino)-β-D-xylo-hexopyranosyl]oxy]-, dihydrate, [2R-(2R*,3S*,4R*,5R*,8R*,10R*,11R*,12S*,13S*,14R*)]-;azithromycin hydrate;Azithromycin (100 mg);(2R,3S,4R,5R,8R,10R,11R,12S,13S,14R)-13-[(2,6-Dideoxy-3-C-Methyl-3-O-Methyl-α-L-ribo-hexopyranosyl)oxy]-2-ethyl-3,4,10-trihydroxy-3,5,6,8,10,12,14-heptaMethyl-11-[[3,4,6-trideoxy-3-(diMethylaMino)-β-D-xylo-hexopyranosyl]oxy]-1-oxa-6-azacyclopentadecan-15-one Dihydrate

CAS 83905-01-5

MF C38H72N2O12

MW 748.99

EINECS 1592732-453-0

Product Categories Macrolides (Antibiotics for Research and Experimental Use);Antibiotics for Research and Experimental Use;Biochemistry;Carbohydrates & Derivatives;Chiral Reagents;Intermediates & Fine Chemicals;Pfizer compounds;Pharmaceuticals;SELDANE;Inhibitors

applicationFor respiratory infections, urinary tract infections, skin and soft tissue infections and sexually transmitted diseases

Chemical Properties: Azithromycin dihydrate 117772-70-0

Melting point 126 C

Boiling point 717ºC

alpha D26 -41.4° (c = 1 in CHCl3)

refractive index 47 ° (C=2, EtOH)

RTECS RN6960000

Fp >110°(230°F)

storage temp. -20°C Freezer

solubility Soluble in DMSO at 20mg/ml. Also soluble in chloroform or ethylene chloride

Merck 14,915

Spec. Azithromycin dihydrate 117772-70-0

ITEMSSPECIFICATIONSRESULTS

AppearanceA White or almost white crystalline powder Conforms

SolubilityPractically insoluble in water,freely soluble in

anhydrous ethanol and in methylene chloride Conforms

IdentificationIRConforms

HPLC

CrystallinityMeet the requirements Conforms

PH9.0 ~ 11.09.9

Related substancesDesosaminylazithromycin ≤0.3%DL

N-demethylazithromycin ≤0.7%0.001

Any other single impurity ≤1.0%Conforms

Total impurities≤3.0 %0.015

Residual solventsAcetone ≤0.5%0.003

Loss on drying4.0 % ~ 5.0%0.045

Residue on Ignition≤0.3%0.0004

Melting point50 °C ~ 60 °C50 °C ~ 60 °C

Sulphate ash≤0.1%0.0005

Heavy metals≤ 25 ppmNMT25 ppm

Assay

( calculated on the anhydrous basis)945 ug ~ 103 ug of azithromycin per mg982 ug/ mg

ConclusiionThis product complied with the standard of Enterprise/USP

TestsSpecificationResults

DescriptionWhite or almost white powderComplies

SolubilityPractically insoluble in water, freely soluble in ethanol and in methylene chloride.Complies

Identification

A)IR spectrumConforms to azithromycin RSComplies

B)Rt HPLCConforms to azithromycin RSComplies

Specific rotationBetween -45°and -49°-47.6°

CrystallinityMeets the requirementsMeets the requirements

PHBetween 9.0 and 11.010.32

WaterBetween 4.0%and 5.0%4.7%

Residue on ignitionNot more than 0.3%0.08%

Heavy metalsNot more than 25ppmComplies

AssayNot less than 945μg and more than 1030μg of azithromycin(C38H72N2O12) per mg, calculated on the anhydrous basis967μg per mg

MethanolNot more than 0.3%0.031%

EthanolNot more than 0.05%0.0068%

AcetoneNot more than 0.5%0.1475%

ChloroformNot more than 0.006%0.0037%

Function

Temozolomide is used in the treatment of adults with refractory pleomorphic glioblastoma and anaplastic astrocytoma of chemotherapy drugs.

1.Azithromycin Dihydrate is used for acute throat and tonsillitis which are caused by streptococcus pyogenes, otitis media sinusitis acute bronchitis skin soft tissue infection which are caused by sensitive bacteria.

2.Azithromycin Dihydrate is also used for pneumonia urethritis cervicitis and so on.

Suitable for sensitive caused by the bacterium respiratory tract, skin soft tissue infection caused by the original body of garment of sexually transmitted diseases. For influenzae, pneumococci and mo draw CARDS he caused by bacteria etc of acute brochitis, chronic obstructive pulmonary disease amalgamative infection, pneumonic wait for the efficient above 90%, bacterial remoal reach 85%. For pyogenes, aureaus etc caused furuncle swollen, cellulitis wait, use this product daily 1 times 5 therapy (1.5 g), total cure for 53% ~ 74%, efficient 90%, its curative effect and the benzene thiazole Westwood, erythromycin and cephalosporins ampicillin similar. Single-agent 1g treatment for chlamydial infection, its curative effect with ciprofloxacin or doxycycline grain phase.

Packing

1. Client is first. We are trying to bring maximum profit to our clients and we only share small.

2. Credibility is the most important.

3. Quality control is our life.

4. Great sense of responsibility.

5. We will be responsible for not only our products, our clients, our suppliers, also the society

FAQ

Q1:Can I get a sample?

A:Of course. For most products we can provide you a free sample, while the shipping cost should undertake by your side.

Q2:What's the MOQ?

A: For the high value product, our MOQ starts from 1g and generally starts from 10g.

For other low value product, our MOQ starts from 100g and 1kg.

Q3:Is there any discount?

A:Yes, different quantity has different discount.

Q4: How to confirm the Product Quality before placing orders?

A: By sending you our available free samples.Or if you have special requirement on the goods, we can prepare samples according to your requirement for your confirmation.

Q5:What's your lead time?

A:We can arrange the shipment in 3 working days after receiving your payment, except the customised products.

introduce

1.Azithromycin is used to treat or prevent certain bacterial infections, most often those causing middle ear infection, strep throat , pneumonia, typhoid, and sinusitis

2.It has used primarily to prevent bacterial infections in infants and those with weaker immune system

3.It is also effective aganinst certain sexually transmitted infections , such as non-gonococcal urethritis, chlamydia and cervicitis

4.Azithromycin cin is use for acute pharyngitis , acute tonsillitis caused by Streptococcus pyogenes

5.Azithromycin is used for acute throat and tonsilitis which are caused by streptococcus pyogenes , otitis

6.Azithromycin can treatment of mrdia sinusitis acute bronchitis skin soft tissue infection which are caused by sensitive bacteria

7.Azithromycin is also used for pneumonia urethritis cervicitis and so on.

Company Profile

Arshine Group is composed of 5 subsidiaries, including Arshine Pharmaceutical Co.,Ltd, Arshine Food Additive Co., Ltd, Arshine Animal Healthcare Co., Ltd, Arshine Life Science Co., Ltd and Hangzhou Arshine Branch. Arshine specializes in exporting human and veterinary API, vitamins, amino acids, minerals, food and feed additives and plant extracts etc. Arshine has exported around 2000 products to 90 countries and areas in Europe, Middle East, East Asia and South Asia. Since establishment, Arshine’s annual sales volume has increased from USD 1 million to USD 100 million, growing hundredfold in 10 years. Having established long-term cooperation with more than 800 manufacturers, Arshine is regional sales representative or even exclusive agent for many manufacturers nowadays. To our pride, Arshine ranks among top 10 in all pharmaceutical raw materials export enterprises in China, top 3 in the private exporters.

After-sale Service : Sales: 24hours to reply your E-mail Market information trend share with customers Suggestion for purchase decision Financial: Different payment terms: TT, LC, DP and so on Sino-Sure credit application and market risk control Shipment conditions: Update the whole process from China to destination 10 days by air & 14 days by sea to finish usually Fast custom clearance at destination Doc after shipment date: Same day for air shipment and LCL sea shipment 3 working days for FCL sea shipment 100% clear and perfect docs Reputation: Implementing contract terms strictly Timely solve any discrepancy or goods claims Take our responsibility for loss if it is our liability Others: Assistant: sample working; help you solve the problem in China with others Registration: pr

More details:http://arshine.lookchem.com/

If you have a need, visit our website lookchem.com; register a Lookchem member account and you will have two free opportunities to experience the Lookchem consignment service within the following 12 months. If you have any questions about the content of this notice, please contact the customer feedback, customer service telephone 0571-87562588, thank you!

Julie

LookChem Service Team

Tel:0571-87562563

Email: [email protected]

Website: www.lookchem.com

0 notes

Photo

Mud pump,drilling pump,F-800, F-1000, F1300, F1600,PZ-8, PZ-9, PZ-10 available comply wih API Spec 7K.Products have been verified by API Q1 Quality System, comply with API Spec 7K and all the parts can be traced back.

https://www.orchidenergyglobal.com/productinfo/458829.html

0 notes

Link

CSA Z 662 Reference publications and definitions

June 13, 2020

P.Eng.

Meena Rezkallah

2.1 Reference publications There is a commentary available for this Clause. This Standard refers to the following publications, and where such reference is made, it shall be to the edition listed below, unless the user finds it more appropriate to use newer or amended editions of such publications. CSA Group A3000-13 Cementitious materials compendium A3001-13 Cementitious materials for use in concrete A3002-13 Masonry and mortar cement B51-14 Boiler, Pressure Vessel, and Pressure Piping Code B137 Series-13 Thermoplastic pressure piping compendium B149.1-10 Natural Gas and Propane Installation Code B149.2-10 Propane Storage and Handling Code C22.1-15 Canadian Electrical Code, Part I CAN/CSA-C22.3 No. 4-13 Control of electrochemical corrosion of underground metallic structures CAN/CSA-C22.3 No. 6-13 Principles and practices of electrical coordination between pipelines and electric supply lines PLUS 663-04 Land use planning for pipelines: A guideline for local authorities, developers, and pipeline operators S408-1981-11 Guidelines for the development of limit states design standards CAN/CSA-S471-04 (withdrawn) General requirements, design criteria, the environment, and loads

W48-14 Filler metals and allied materials for metal arc welding W59-13 Welded steel construction (metal arc welding) W178.2-14 Certification of welding inspectors Z245.1-14 Steel pipe Z245.6-06 (R2011) Coiled aluminum line pipe and accessories Z245.11-13 Steel fittings Z245.12-13 Steel flanges Z245.15-13 Steel valves Z245.20 Series-14 Plant-applied external coatings for steel pipe Z245.20-14 Plant-applied external fusion bond epoxy coating for steel pipe Z245.21-14 Plant-applied external polyethylene coating for steel pipe Z245.22-14 Plant-applied external polyurethane foam insulation coating for steel pipe Z245.30-14 Field-applied external coatings for steel pipeline systems Z246.1-13 Security management for petroleum and natural gas industry systems Z276-15 Liquefied natural gas (LNG) — Production, storage, and handling Z341 Series-14 Storage of hydrocarbons in underground formations CAN/CSA-Z731-03 (R2014) Emergency preparedness and response

CAN/CSA-ISO 9001-08 (R2014) Quality management systems — Requirements CAN/CSA-ISO 31000-10 Risk management — Principles and guidelines AGA (American Gas Association) B109.1-2000 (R2008) Diaphragm-Type Gas Displacement Meters (Under 500 Cubic Feet per Hour Capacity) (Catalogue # XQ0008) API (American Petroleum Institute) 5L-2012 (SPEC) Specification for Line Pipe 5LCP-2006 (R2013) (SPEC) Coiled Line Pipe 6D-2014 (SPEC) Specification for Pipeline and Piping Valves 15HR-2001 (R2010) (SPEC) High Pressure Fiberglass Line Pipe 15LE-2008 (R2013) (SPEC) Polyethylene (PE) Line Pipe 15S-2006 (R2013) (RP) Qualification of Spoolable Reinforced Plastic Line Pipe 17J-2014 (SPEC) Specification for Unbonded Flexible Pipe 17K-2005 (R2010) (SPEC) Specification for Bonded Flexible Pipe 510-20146 (STD) Pressure Vessel Inspection Code: In-Service Inspection, Rating, Repair, and Alteration 572-2009 (RP) Inspection Practices for Pressure Vessels 576-2009 (RP) Inspection of Pressure-relieving Devices 599-2013 (STD) Metal Plug Valves-Flanged, Threaded and Welding Ends 600-2009 (STD) Steel Gate Valves-Flanged and Butt-welding Ends, Bolted Bonnets

602-2009 (STD) Steel Gate, Globe and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries 608-2012 (STD) Metal Ball Valves-Flanged, Threaded and Welding Ends 609-2009 (STD) Butterfly Valves: Double-flanged, Lug- and Wafer-type 610-2010 (STD) Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries 617-2002 (R2009) (STD) Axial and Centrifugal Compressors and Expander-compressors for Petroleum, Chemical and Gas Industry Services 618-2007 (STD) Reciprocating Compressors for Petroleum, Chemical and Gas Industry Services 650-2013 (STD) Welded Tanks for Oil Storage 651-2007 (RP) Cathodic Protection of Aboveground Petroleum Storage Tanks 652-2005 (RP) Linings of Aboveground Petroleum Storage Tank Bottoms 653-2009 (STD) Tank Inspection, Repair, Alteration, and Reconstruction 1604-1996 (R2010) (RP) Closure of Underground Petroleum Storage Tanks 2015-2014 (STD) Requirements for Safe Entry and Cleaning of Petroleum Storage Tanks 2028-2002 (R2010) (RP) Flame Arresters in Piping Systems 2350-2012 (STD) Overfill Protection for Storage Tanks in Petroleum Facilities 2610-2005 (R2010) (STD) Design, Construction, Operation, Maintenance, and Inspection of Terminal & Tank Facilities Q1-2013 (SPEC) Specification for Quality Management System Requirements for Manufacturing Organizations for the Petroleum and Natural Gas Industry

ASME (The American Society of Mechanical Engineers) B1.1-2003 (R2008) Unified Inch Screw Threads, (UN and UNR Thread Form) B1.20.1-2013 Pipe Threads, General Purpose, Inch B16.1-2010 Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250 B16.5-2013 Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard B16.9-2012 Factory-Made Wrought Buttwelding Fittings B16.11-2011 Forged Fittings, Socket-Welding and Threaded B16.20-2012 Metallic Gaskets for Pipe Flanges: Ring Joint, Spiral Wound, and Jacketed B16.21-2011 Nonmetallic Flat Gaskets for Pipe Flanges B16.24-2011 Cast Copper Alloy Pipe Flanges and Flanged Fittings: Classes 150, 300, 600, 900, 1500 and 2500 B16.33-2009 Manually Operated Metallic Gas Valves for Use in Gas Piping Systems up to 175 psi (Sizes NPS ½ through NPS2) B16.34-2013 Valves Flanged, Threaded and Welding End B16.36-2009 Orifice Flanges B16.40-2013 Manually Operated Thermoplastic Gas Shutoffs and Valves in Gas Distribution Systems B16.47-2011 Large Diameter Steel Flanges: NPS 26 through NPS 60 Metric/Inch Standard B16.48-2010 Line Blanks B16.49-2012 Factory-Made, Wrought Steel, Buttwelding Induction Bends for Transportation and Distribution Systems

B18.2.1-2012 Square, Hex, Heavy Hex, and Askew Head Bolts and Hex, Heavy Hex, Hex Flange, Lobed Head, and Lag Screws (Inch Series) B18.2.2-2010 Nuts for General Applications: Machine Screw Nuts, Hex, Square, Hex Flange, and Coupling Nuts (Inch Series) B31G-2012 Manual for Determining the Remaining Strength of Corroded Pipelines B31.3-2012 Process Piping B31.8-2012 Gas Transmission and Distribution Piping Systems B31.8S-2012 Managing System Integrity of Gas Pipelines B36.19M-2004 (R2010) Stainless Steel Pipe Boiler and Pressure Vessel Code, 2013: Section II: Materials Section V: Nondestructive Examination Section VIII: Pressure Vessels — Division 1 Section VIII: Pressure Vessels — Division 2 — Alternative Rules Section IX: Welding and Brazing Qualifications PCC-2-2015 Repair of Pressure Equipment and Piping ASTM International (American Society for Testing and Materials) A53/A53M-12 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless A105/A105M-13 Standard Specification for Carbon Steel Forgings for Piping Applications A106/A106M-14 Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service A126-04 (R2014) Standard Specification for Gray Iron Castings for Valves, Flanges, and Pipe Fittings

A193/A193M-14 Standard Specification for Alloy-Steel and Stainless Steel Bolting for High Temperature or High Pressure Service and Other Special Purpose Applications A194/A194M-14 Standard Specification for Carbon and Alloy Steel Nuts for Bolts for High-Pressure or High-Temperature Service, or Both A216/A216M-14 Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service A234/A234M-13e1 Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service A268/A268M-10 Standard Specification for Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service A269-14e1 Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service A307-12 Standard Specification for Carbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile Strength A320/A320M-14 Standard Specification for Alloy/Steel Bolting Materials for Low-Temperature Service A333/A333M-13 Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service and Other Applications with Required Notch Toughness A350/A350M-13 Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components A352/A352M-06 (2012) Standard Specification for Steel Castings, Ferritic and Martensitic, for Pressure-Containing Parts, Suitable for Low-Temperature Service A354-11 Standard Specification for Quenched and Tempered Alloy Steel Bolts, Studs, and Other Externally Threaded Fasteners A381-96 (2012) Standard Specification for Metal-Arc-Welded Steel Pipe for Use with High-Pressure Transmission Systems

A395/A395M-99 (2014) Standard Specification for Ferritic Ductile Iron Pressure-Retaining Castings for Use at Elevated Temperatures A420/A420M-13 Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service A563/A563M-07 Standard Specification for Carbon and Alloy Steel Nuts A694/A694M-13 Standard Specification for Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service A707/A707M-13 Standard Specification for Forged Carbon and Alloy Steel Flanges for Low-Temperature Service A789/A789M-10a Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service A860/A860M-13 Standard Specification for Wrought High-Strength Ferritic Steel Butt-Welding Fittings A984/A984M-03 (withdrawn) Standard Specification for Steel Line Pipe, Black, Plain-End, Electric-Resistance-Welded A1005/A1005M-00 (2010) Standard Specification for Steel Line Pipe, Black, Plain End, Longitudinal and Helical Seam, Double Submerged-Arc Welded A1024/A1024M-02 (2012) Standard Specification for Steel Line Pipe, Black, Plain-End, Seamless A1037/A1037M-05 (2012) Standard Specification for Steel Line Pipe, Black, Furnace-Butt-Welded B43-14 Standard Specification for Seamless Red Brass Pipe, Standard Sizes B75/B75M-11 Standard Specification for Seamless Copper Tube B88-09 Standard Specification for Seamless Copper Water Tube B241/B241M-12e1 Standard Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube

B361-08 Standard Specification for Factory-Made Wrought Aluminum and Aluminum-Alloy Welding Fittings D257-14 Standard Test Methods for DC Resistance or Conductance of Insulating Materials D323-08(2014) Standard Test Method for Vapor Pressure of Petroleum Products (Reid Method) D570-98(2010)e1 Standard Test Method for Water Absorption of Plastics D1000-10 Standard Test Methods for Pressure-Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications D1002-10 Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal) D1525-09 Standard Test Method for Vicat Softening Temperature of Plastics D1653-13 Standard Test Methods for Water Vapor Transmission of Organic Coating Films D1693-13 Standard Test Method for Environmental Stress-Cracking of Ethylene Plastics D2240-05 (2010) Standard Test Method for Rubber Property — Durometer Hardness D2290-12 Standard Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe D2343-09 Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced Plastics D2412-11 Standard Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel- Plate Loading D2584-11 Standard Test Method for Ignition Loss of Cured Reinforced Resins D2837-2013 (E2014) Standard Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for Thermoplastic Pipe Products

D2992-12 Standard Practice for Obtaining Hydrostatic or Pressure Design Basis for “Fiberglass” (Glass-Fiber- Reinforced Thermosetting-Resin) Pipe and Fittings D3261-2012 (E2014) Standard Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastic Pipe and Tubing D3350-14 Standard Specification for Polyethylene Plastics Pipe and Fittings Materials D3839-14 Standard Guide for Underground Installation of “Fiberglass” (Glass-Fiber Reinforced Thermosetting- Resin) Pipe D3895-07 Standard Test Method for Oxidative-Induction Time of Polyolefins by Differential Scanning Calorimetry D4060-10 Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser D4541-09e1 Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers D5064-07 (2012) Standard Practice for Conducting a Patch Test to Assess Coating Compatibility D5084-10 Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter E18-14 rev 4 Standard Test Methods for Rockwell Hardness of Metallic Materials E21-09 Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials E23-12c Standard Test Methods for Notched Bar Impact Testing of Metallic Materials E29-13 Standard Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications E114-10 Standard Practice for Ultrasonic Pulse-Echo Straight-Beam Contact Testing E384-11 (E2012) Standard Test Method for Knoop and Vickers Hardness of Materials

E747-04 (2010) Standard Practice for Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used for Radiology E1025-11 Standard Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI) Used for Radiology E1820-13 Standard Test Method for Measurement of Fracture Toughness E1901-13 Standard Guide for Detection and Evaluation of Discontinuities by Contact Pulse-Echo Straight-Beam Ultrasonic Methods F1290-08 (withdrawn) Standard Practice for Electrofusion Joining Polyolefin Pipe and Fittings F1973-2013 (E2013) Standard Specification for Factory Assembled Anodeless Risers and Transition Fittings in Polyethylene (PE) and Polyamide II (PAII) and Polyamide 12 (PA12) Fuel Gas Distribution Systems F2206-11 (R2014) Standard Specification for Fabricated Fittings of Butt-Fused Polyethylene (PE) F2620-13 Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings F2634-10 Standard Test Method for Laboratory Testing of Polyethylene (PE) Butt Fusion Joints Using Tensile- Impact Method G8-96 (2010) Standard Test Methods for Cathodic Disbonding of Pipeline Coatings G9-07(2013)e1 Standard Test Method for Water Penetration into Pipeline Coatings G10-10 Standard Test Method for Specific Bendability of Pipeline Coatings G11-04(2012) Standard Test Method for Effects of Outdoor Weathering on Pipeline Coatings G14-04 (2010)e1 Standard Test Method for Impact Resistance of Pipeline Coatings (Falling Weight Test) G17-07(2013) Standard Test Method for Penetration Resistance of Pipeline Coatings (Blunt Rod)

G18-07(2013) Standard Test Method for Joints, Fittings, and Patches in Coated Pipelines G19-88 (withdrawn) Standard Test Method for Disbonding Characteristics of Pipeline Coatings by Direct Soil Burial G20-10 Standard Test Method for Chemical Resistance of Pipeline Coatings G21-13 Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Fungi G42-11 Standard Test Method for Cathodic Disbonding of Pipeline Coatings Subjected to Elevated Temperatures G55-07 (2013) Standard Test Method for Evaluating Pipeline Coating Patch Materials G80-88 (withdrawn) Standard Test Method for Specific Cathodic Disbonding of Pipeline Coatings G154-12a Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials UOP163-10 Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric Titration AWS (American Welding Society) A5.32/A5.32M-11 Welding Consumables — Gases and Gas Mixtures for Fusion Welding and Allied Processes D3.6M-10 Underwater Welding Code AWWA (American Water Works Association) C205-12 Cement-Mortar Protective Lining and Coating for Steel Water Pipe — 4 In. (100 mm) and Larger – Shop Applied BSI (British Standards Institution) BS EN 253:2013 District heating pipes. Preinsulated bonded pipe systems for directly buried hot water networks. Pipe assembly of steel service pipe, polyurethane thermal insulation and outer casing of polyethylene BS EN 489:2009 District heating pipes. Preinsulated bonded pipe systems for directly buried hot water networks. Joint assembly for steel service pipes, polyurethane thermal insulation and outer casing of polyethylene

BS 7910:2013 Guide to methods for assessing the acceptability of flaws in metallic structures PD 6493:1991 (withdrawn) Guidance on methods for assessing the acceptability of flaws in fusion welded structures CAPP (Canadian Association of Petroleum Producers) 2004-0022 Planning Horizontal Directional Drilling for Pipeline Construction 2009-0009 Best Management Practice — Use of Reinforced Composite Pipe (Non-Metallic Pipelines) 2009-0010 Mitigation of Internal Corrosion in Oilfield Water Pipelines 2009-0011 Mitigation of External Corrosion on Buried Pipeline Systems 2009-0012 Mitigation of Internal Corrosion in Oil Effluent Pipeline Systems 2009-0013 Mitigation of Internal Corrosion in Sour Gas Gathering Systems 2009-0014 Mitigation of Internal Corrosion in Sweet Gas Gathering Systems CCME (Canadian Council of Ministers of the Environment) PN 1180 Environmental Guidelines for Controlling Emissions of Volatile Organic Compounds from Aboveground Storage Tanks CEPA (Canadian Energy Pipeline Association) Stress Corrosion Cracking Recommended Practices, 2nd ed. (December 2007) Facilities Integrity Management Program (FIMP) Recommended Practices, 1st ed. (May 2013) Development of a Pipeline Surface Loading Screening Process & Assessment of Surface Load Dispersing Methods (Final Report No. 05-44R1) (October 2009) CGA (Canadian Gas Association) OCC-1-2013 Recommended Practice for the Control of External Corrosion on Buried or Submerged Metallic Piping Systems CGA (Common Ground Alliance) Best Practices, Version 10.0 (March 2012)

CGSB (Canadian General Standards Board) CAN/CGSB-48.9712-2014/ISO 9712:2012 Non-destructive Testing — Qualification and certification of NDT personnel DIN (Deutsches Institut für Normung e.V.) 30672-2000 Tape and shrinkable materials for the corrosion protection of buried or underwater pipelines without cathodic protection for use at operating temperatures up to 50 °C DNV (Det Norske Veritas) DNV-OS-F101-2013 Submarine Pipeline Systems DNV-RP-F101-2010 Corroded Pipelines DNV-RP-J202-2010 Design and Operation of CO2 Pipelines DOT (US Government, Department of Transportation) DTRS56-02-D-70036 (2005) Derivation of Potential Impact Radius Formulae for Vapor Cloud Dispersion Subject to 49 CFR 192 ESI (Electricity Supply Industry) 98-2-1979 (withdrawn) Ultrasonic Probes: Medium Frequency, Miniature Shear Wave, Angle Probes Government of USA US Code of Federal Regulations, Title 33, Chapter I, Part 154, Appendix A, ��Guidelines for Detonation Flame Arresters” (referenced as 33 CFR 154, Appendix A) US Code of Federal Regulations, Title 49, Part 192, Transportation of Natural and Other Gas by Pipeline: Minimum Federal Safety Standards (referenced as 49 CFR 192) IGEM (Institution of Gas Engineers & Managers) IGEM/TD/1 Steel pipelines and associated installations for high pressure gas transmission, ed. 5 The INGAA Foundation Guidelines for Parallel Construction of Pipelines, December 2008 ISO (International Organization for Standardization) 2566-1:1984 (R2010) Steel — Conversion of elongation values — Part 1: Carbon and low alloy steels 3183:2012 Petroleum and natural gas industries — Steel pipe for pipeline transportation systems

3898:2013 Bases for design of structures – Names and symbols of physical quantities and generic quantities 5579:2013 Non-destructive testing — Radiographic testing of metallic materials using film and X- or gamma rays — Basic rules 9080:2012 Plastics piping and ducting systems — Determination of the long-term hydrostatic strength of thermoplastics materials in pipe form by extrapolation 12162:2009 Thermoplastics materials for pipes and fittings for pressure-applications — Classification, designation and design coefficient 12176-1:2012 Plastic pipes and fittings — Equipment for fusion joining polyethylene systems — Part 1: Butt fusion 12176-2:2008 Plastic pipes and fittings — Equipment for fusion joining polyethylene systems — Part 2: Electrofusion 12176-3:2011 Plastic pipes and fittings — Equipment for fusion joining polyethylene systems — Part 3: Operator’s badge 12176-4:2003 Plastic pipes and fittings — Equipment for fusion joining polyethylene systems — Part 4: Traceability coding 13953-2001 Polyethylene (PE) pipes and fittings — Determination of the tensile strength and failure mode of test pieces from a butt-fused joint 14175:2008 Welding consumables — Gases and gas mixtures for fusion welding and allied processes 14555:14 Welding — Arc stud welding of metallic materials 15156-2:2009 Petroleum and natural gas industries — Materials for use in H2S-containing environments in oil and gas production — Part 2: Cracking-resistant carbon and low-alloy steels, and the use of cast irons 15156-3:2009 Petroleum and natural gas industries — Materials for use in H2S-containing environments in oil and gas production — Part 3: Cracking-resistant CRAs (corrosion-resistant alloys) and other alloys 15653:2010 Metallic materials — Method of test for the determination of quasistatic fracture toughness of welds

16708:2006 Petroleum and natural gas industries — Pipeline transportation systems — Reliability-based limit state methods 19232-1:2013 Non-destructive testing — Image quality of radiographs — Part 1: Determination of the image quality value using wire-type image quality indicators ISO TR 19480:2005 Polyethylene pipes and fittings for the supply of gaseous fuels or water — Training and assessment of fusion operators ISO/TS 24817:2006 Petroleum, petrochemical and natural gas industries — Composite repairs for pipework — Qualification and design, installation, testing and inspection MSS (Manufacturers Standardization Society) SP-6-2012 Standard Finishes for Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings ANSI/MSS-SP-25-2013 Standard Marking System for Valves, Fittings, Flanges and Unions SP-75-2014 Specification for High-Test, Wrought, Butt Welding Fittings SP-79-2011 Socket Welding Reducer Inserts (Includes Errata Amended 7/8/2012) SP-83-2014 Class 3000 Steel Pipe Unions, Socket-Welding and Threaded SP-95-2014 Swage(d) Nipples and Bull Plugs SP-97-2012 Integrally Reinforced Forged Branch Outlet Fittings — Socket Welding, Threaded and Buttwelding Ends NACE International ANSI/NACE MR0175/ISO 15156-2-2009 Petroleum and natural gas industries — Materials for use in H2S-containing environments in oil and gas production — Part 2: Cracking-resistant carbon and low-alloy steels, and the use of cast irons Note: Including circular 1-2011 and circular 2-2014. ANSI/NACE MR0175/ISO 15156-3-2009 Petroleum and natural gas industries — Materials for use in H2S-containing environments in oil and gas production — Part 3: Cracking-resistant CRAs (corrosion-resistant alloys) and other alloys Note: Including circular 1-2011, circular 2-2014, circular 3-2013, circular 4-2014.

SP0285-2011 Corrosion Control of Underground Storage Tank Systems by Cathodic Protection SP0204-2008 Stress Corrosion Cracking (SCC) Direct Assessment Methodology SP0206-2008 Internal Corrosion Direct Assessment Methodology for Pipelines Carrying Normally Dry Natural Gas SP0502-2008 Pipeline External Corrosion Direct Assessment Methodology NEB (National Energy Board) Pipeline Abandonment: A Discussion Paper on Technical and Environmental Issues, November 1996 NEN (Nederlands Normalisatie-instituut) 3650-1:2012 n1 Requirements for pipeline systems – Part 1: General requirements NFPA (National Fire Protection Association) 10-2013 Standard for Portable Fire Extinguishers 30-2015 Flammable and Combustible Liquids Code NRCC (National Research Council Canada) National Building Code of Canada, Chapter 4 of Commentary B, 2015 National Fire Code of Canada, 2010 PEI (Petroleum Equipment Institute) RP100-11 Recommended Practices for Installation of Underground Liquid Storage Systems PPI (Plastics Pipe Institute) TR-3-2012 Policies and Procedures for Developing Hydrostatic Design Basis (HDB), Hydrostatic Design Stresses (HDS), Pressure Design Basis (PDB), Strength Design Basis (SDB), Minimum Required Strength (MRS) Ratings and Categorized Required Strength (CRS) for Thermoplastic Piping Materials or Pipe TR-4-2014 PPI Listing of Hydrostatic Design Basis (HDB), Hydrostatic Design Stress (HDS), Strength Design Basis (SDB), Pressure Design Basis (PDB) and Minimum Required Strength (MRS) Ratings for Thermoplastic Piping Materials or Pipe PRCI (Pipeline Research Council International) PR-3-805,1989 Modified Criterion for Evaluating the Remaining Strength of Corroded Pipe (RSTRENG)

PR-218-9822, 1999 Guidelines for the Assessment of Dents on Welds PR-218-9925, 2008 Acceptance Criteria for Mild Ripples in Pipeline Field Bend PR-227-9424, 2008 Installation of Pipelines by Horizontal Directional Drilling — An Engineering Design Guide PR-268-9823, 2003 Guidelines for the Seismic Design and Assessment of Natural Gas and Liquid Hydrocarbon Pipelines Report 194, 1992 Hydrotest Strategies for Gas Transmission Pipelines Based on Ductile-Flaw-Growth Considerations SSPC (The Society for Protective Coatings) PA 2-2004 Measurement of Dry Coating Thickness with Magnetic Gages Transport Canada 621.19-2000 Standards Obstruction Markings Manual

Read More:

CSA Z662-15 (Oil and gas pipeline systems)

TAGS:

CSA Z 662

Engineering Consulting Services

0 notes

Text

Vegas Consulting Group is a dynamic and forward-thinking firm dedicated to transforming businesses through strategic guidance and innovative solutions. At Vegas Consulting we offer reliable services like API Spec Q1, Q2, and monogram consulting, design packages, audit services, ISO certification assistance and comprehensive training programs.

Our Goal is to improve the oil and gas industry management specification and compliance. We use our own in-house portal “The Vegas Connit” to efficiently oversee and streamline the entire project. This tool ensures a centralized and effective approach to manage every facet of our projects, fostering enhanced collaboration and optimal results. Elevate your business with Vegas Consulting Group – where vision meets execution.

#Vegas Consulting#API QMS Consulting Firm#API Spec Q1 Consulting#API Spec Q2 Consulting#API Monogram Consultancy#Vegas Consulting Group#ISO Certification Consulting services

0 notes

Text

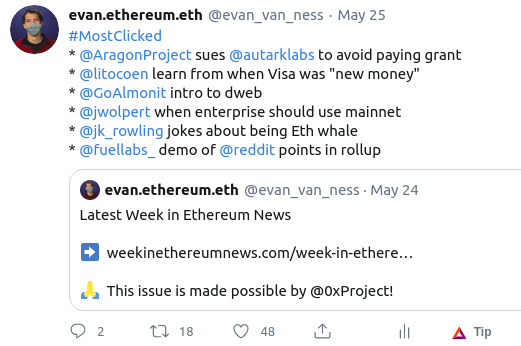

Annotated edition for the May 24, 2020, Week in Ethereum News

Several people this week have told me they want a “drama” section in the newsletter and have asked me to annotate the Aragon and Autark Ado this week.

Perhaps that’s why the Aragon drama leads the most clicked list:

So why is Aragon suing its grantee? Aragon held a vote where the community approved these grants. Aragon now does not want to pay, claiming breach of contract - presumably that they did not believe Autark was not delivering fast enough or that products that were up to snuff. It’s a bit hard to follow the play-by-play but at some point Aragon decided that after spending 600k of the 1.6m awarded grant, they did not want to pay any longer, so Autark threatened to sue. Aragon offered to settle for $250k of the remaining million in grant payments, but it appears Autark rejected because Aragon would cut off the ANT incentive payments. So Aragon sued Autark, to make sure that the case happens on its home turf in Switzerland which benefits their deep pockets versus Autark’s (now unfunded) startup budget.

For what it’s worth, I believe I voted against Autark’s first request and while I thought I voted against the second one, it turns out I didn’t vote. There were a lot of votes in that round, and it was obviously going to pass (it passed “unanimously” with only 1 ANT voting against), so i must have decided not to spend the gas.

This all seems pretty boring, it’s just back and forth arguing over a contract, why are other people commenting on it?

1. Aragon has a reputation for not paying people.

It has long been an open secret in the industry that Aragon routinely doesn’t pay people in full or on time.

Grants are hard! I can empathize with both Aragon (presumably feeling like it wasn’t getting enough ROI) and Autark (presumably thinking that a community approved grant couldn’t be secretly overturned by Jorge and Luis).

2. Aragon sold a token for tens of millions of dollars, but after 3 years the only use for the token was a tokenholder vote. Now, the results of those votes are unilaterally and privately discarded.

It’s been over 3 years since Aragon raised a crazy amount of money selling a token. In that time frame, the only use for the token has been these votes.

If Jorge and Luis could decide by themselves to countermand the results of any of those votes without even telling the tokenholders anything, then what was the point of these votes? Why did I waste my ETH paying gas to vote in these things?

[Digression: They also recently released an ANJ token that you can exchange ANT for, but I don’t count being able to exchange a token for another token as utility. After more than 3 years, I cannot think of any other possible utility for ANT. Note: i’m very bearish on “dispute resolution by tokenholder vote”]

3. Aragon marketing hasn’t matched Aragon actions

The Aragon Manifesto was a clarion call. In black and white terms it paints the picture of transparency and technology as a solution for society’s problems of centralization, censorship and oppression.

Yet the rhetoric hasn’t matched the reality. They’ve declared that Aragon is the world’s court, yet go running to Swiss courts to claim jurisdiction rather than even attempt to use Aragon Court in parallel (since they can’t possibly lose in either venue).

They’re the rich ones with deep pockets, yet they’ve repeatedly chosen not to pay grantees who have very little leverage in negotiation (with the exception of Prysmatic after they complained).

None of it has been transparent (though of course there are often good reasons).

----

The Aragon team so far has responded to all these concerns by saying things like “you’re questioning our good intentions” or “the courts will decide”.

It is obvious that Aragon will win in the courts. They have the deep pockets; Autark doesn’t. They drafted the contract, and any decent lawyer will have drafted it so Aragon can’t possibly lose. Even if the contract somehow wasn’t one-sided, Aragon chose to run to the home field courts. It would be shocking if they lost.

Aragon’s intentions aren’t bad; that’s not really in question. I’m 100% sure that Jorge and Luis’s intentions are good and that any individual decision is defensible.

What is in question is their decision making overall. When you stake your brand on “transparency” and anti-oppression, then people will feel disappointed when your brand promises do not match your actions.

------------------------------------------------------

Enough with the drama. As with last week, a few things I think I’d read if i were an Eth holder interested in high level things.

Carl Beekhuizen’s Eth2 keys explainer

5 things crypto can learn from Visa’s struggle for adoption in the 1970s

Brave’s anti-fingerprinting v2, available in the beta releases but coming soon in the main releases

Working in reverse order, it’s always surprising to me how little people understand how much info your browser is leaking. Fingerprinting basically lets people figure out who you are even if you switch IP addresses, clear your browsing history, etc. I used to work in anti-fraud, and I was surprised how often you could figure stuff out from the fingerprints. Good for anti-fraud, but bad for privacy. Brave is changing the game on fighting fingerprinting!

I’m old enough to remember when Visa and especially Amex were not the ubiquitous things that they are today in America. There were some interesting parallels around their ads “think of it as money.” The more things change, the more things stay the same.

A good Eth2 keys explainer, definitely worth reading if you’re interesting in staking.

On to the annotations. The stuff that I think might deserve extra comment, not necessarily the stuff I think is most important.

Eth1

Péter Szilágyi’s snap sync, and some benchmarking of snap vs fast sync

Discovery peer advertisement efficiency analysis, also applicable to eth2

Sync improvements are a big deal, as the initial sync time is one of the things that most people find daunting around running a full node.

Depending on who you are, this may not be considered sexy, but it’s an important thing for eth1 usability.

Eth2

phase 0 spec v0.12 – added latest IETF standard. This is THE spec for the eth2 launch, barring any updates for bugs

Lighthouse client update – BLS key implementation, under Trail of Bits audit, 300mb RAM to run 2000 validators

Lodestar client update – syncing to both Schlesi and Topaz testnets

Prysmatic client update – Schlesi fork post-mortem, slashing client and protection

Fizzy v0.1 – WASM interpreter written in C++

Carl Beekhuizen’s Eth2 keys explainer

There’s been plenty of talk around “this is the spec” before, so I sorta can’t blame someone who says “but you’ve already said that before!”

Basically, they were all true, but with specific exceptions. And that’s still true - there will likely be some kind of bug or clarification found so that that this isn’t THE spec that launches the eth2 chain in a few months. But unless something crazy happens, this spec for the eth2 chain isn’t going to change except to fix bugs.

Layer2

Fuel does a demo of Reddit’s community points in an optimistic rollup that reduces transaction fees by 60x

Loopring to pass 1 million trades on its zk rollup in just 3 months of being live

Gazelle (formerly Plasma Chamber) alpha release with an API for deposit, transfer and exit

Fuel’s demo is pretty cool. It’s obviously just a demo - they don’t have a way to withdraw back to the testnet where Reddit’s community points are house.

Dexes continue to improve! Using their zk rollup, Loopring has a trading experience that is just as good as a centralized exchange, but with much cheaper fees and no risk of centralized exchanges getting hacked and losing your crypto.

This newsletter is made possible by 0x!

0x is excited to sponsor Week in Ethereum News and invite readers to try out our new DEX!

Sign up here to get early access to Matcha, your new home for fast, secure token trading.

Stuff for developers

web3js v1.2.8 with Ethers v5 ABI coder integration, ENS’s contenthash, and EIP-1193’s AbstractProvider

Mocking Solidity code with Waffle

A writeup of Solhint v3’s features

How to get randomness onchain using Chainlink’s VRF

Offchain voting for personal tokens, tutorial from Austin Griffith

Gas and circuit constraint benchmarks of binary and quinary incremental Merkle trees using Poseidon

Loopring’s new approach to generating frontend keys to sign offchain requests

Hegic had to shut down again because of an exploit that Sam Sun reported weeks beforehand

tBTC found a bug during their rollout; launch delayed

Matic’s mainnet is in the process of going live

I’ve seen some games migrate over to Matic.

Matic is “in the process” of going live. I note the “in the process” because I see a bunch of new blockchain projects saying that they are live, but....they aren’t really by any definition I would use.

But as I said previously in an annotated edition, it’s a process. It’s not exactly some binary “we’re live now.” Even Ethereum went live in July 2015 with less than full features.

Ecosystem

Tornado.cash non-custodial mixer is now trustless, with the admin function burned and the frontend available at https://tornadocash.eth.link

Ethereum Foundation q1 update, including how EF thinks about funding

Intro to dwebsites. dweb = ENS + IPFS (and equivalents)

Network usage is at an all time high. With similar use of the Eth2 chain, Ethereum will have negative issuance of ETH because part of every transaction fee is burned

I was surprised that gas usage is so high that we’d be in negative issuance if Eth2 was live.

I’ve said before that I’m not sure how I feel about negative issuance. On the one hand, the worry is that negative issuance means that no one has any incentive to use their ETH. On the other hand, that’s already the reality today - hardly anyone wants to pay for anything in ETH at $200, because basically every ETH holder I know has obscenely high expectations for what the price is likely to do in the near to medium term.

Some interesting thoughts in the EF update about how EF thinks about funding.

Meanwhile it’s great to see Tornado continue to improve the trustlessness of their product. Incredible work from the Roman S team. (if you missed the joke, it’s because both of them are named Roman and have last names that begin with S)

Enterprise

Using Eth mainnet, Baseline Protocol privately and securely synchronizes data and business logic across SAP and Microsoft Dynamics

Hyperledger Fabric founder John Wolpert’s common sense statement on using blockchain and Ethereum mainnet

The Baseline Protocol as lean strategy

Depository Trust & Clearing Corporation’s Project Whitney using Ethereum mainnet to “support private market securities, from issuance through secondary markets”

I’m surprised by how quickly the use mainnet approach has taken hold. If you rewind back to the last hype cycle, relatively few even considered the idea, even as enterprises were buying private chains that didn’t make much sense. (hat tip to GridPlus CEO Mark D’Agostino’s seminal No Country for Private Blockchains article)

DAOs and Standards

Aragon sues to avoid paying grantee a community-voted grant

Exploring DAOs as a new kind of institution

MetaCartel is becoming a DAO incubator

ERC2665: ERC721 transfer fee extension

EIP2666: Repricing of precompiles and Keccak256 function

Application layer

Uniswap v2 launched, with more features – direct token pairs, price oracles, flash swaps, etc

UMA launches the ETHBTC synthetic token, so you can bet on The Flippening

idle v3 – stablecoin yield rebalancer adds dydx, USDT, and a risk-adjusted strategy

Maker changes USDC stability fee to .75% and WBTC to 1%. Also, how Dai became a favorite in Latin America

Argent launches v1 of smart contract wallet with one touch access to TokenSets, PoolTogether, Aave, Uniswap V2, Compound, Maker and Kyber.

5/5 DeFi in the app layer section. Of course what I put in the app layer section vs what I put elsewhere is certainly arbitrary.

And hey, why isn’t Tornado Cash on DeFiPulse? It’s got a decent amount of value locked up.

Tokens/Business/Regulation

5 things crypto can learn from Visa’s struggle for adoption in the 1970s

WBTC mints another 1500 BTC on May 21. There’s now 5200 BTC on Ethereum compared to less than 3000 BTC on Lightning and Liquid combined

Blockchain code as antitrust, Schrepel and Buterin paper

ETH to soon surpass BTC on Bitcoiners’ preferred stock-to-flow metric

Staking will turn Ethereum into a functional store of value

What’s interesting about that 3000 BTC is that Liquid is just a trusted sidechain, and it has 2200 of the 3000 BTC. Now to be fair, WBTC definitely has some trust assumptions as well.

Still isn’t it interesting to see BTC migrate to Ethereum, where it can be used relatively trustlessly, rather than go to Blockstream’s products?

General

KYC puts lives at risk: BlockFi hack leaks client name, address, and crypto addresses. Similarly, a hacker claims to have exploited Shopify for Trezor and Ledger databases, though Ledger says the databases don’t match

Using zero knowledge proofs for vulnerability disclosure

World Economic Forum’s principles for a decentralized future (transparency, self-sovereign data, privacy and accountability)

JK Rowling jokes about trolling BTC because of her significant ETH holdings

The Winklevosses say they own a similar amount of ETH and BTC

Brave’s anti-fingerprinting v2, available in the beta releases but coming soon in the main releases

Using zero knowledge proofs for vulnerability disclosures is very cool. It’s a pretty classic problem if you’re a whitehat hacker - how do you disclose the vulnerability and then trust that you get anywhere near the value back that you deserve from someone’s bug bounty program? There are examples - even in the Ethereum space, where people should understand the value - of responsible disclosure not getting paid anything commensurate to what they deserved.

I’ll be interested to see if BlockFi suffers as a result of the hack. They’ve certainly put at risk any whales which used their service and didn’t give a PO Box/false address/whatever. Yet the history of database hacks even in our space is that most people just eventually return as if no hack ever happened.

Soon this annotated edition will be going paid, more details coming soon.

That’s all for this week!

Housekeeping

Follow me on Twitter @evan_van_ness to get the annotated edition of this newsletter, usually forthcoming in a day or so, as well as a real-time source of Eth news.

Did you get forwarded this newsletter? Sign up to receive it weekly

Permalink: https://weekinethereumnews.com/week-in-ethereum-news-may-24-2020/

Dates of Note

Upcoming dates of note (new/changes in bold):

May 26 – last day to apply for Ethereum India fellowship

May 28 – EIP1559 implementation call

May 29 – core devs call

May 29-June 16 – SOSHackathon

June 16 – deadline to apply for Gitcoin’s Kernel incubator

[Post updated at night for accuracy.]

0 notes

Text

API Q1 Training for oil and gas industry

API Spec Q1 Certification is a quality management system specification distributed by the American Petroleum Institute (API), explicitly composed for industries that manufacture items for the oil and flammable gas industry, otherwise called the oil and gas industry. If your organization produces parts for the oil and gas industry, executing an API Spec Q1 quality management system by AQSS USA might be perfect for you. The ninth version of API Spec Q1 was distributed in June-2013 and represented a noteworthy change for the business.

The specification was made to give assistance to the industry and improve hazard assessment and the management of their procedures utilized to create its products. Accomplishing API Spec Q1 training will enable your organization to expand its incomes by ending up increasingly attractive. Numerous organizations presently expect companies to be API Spec Q1 confirmed, to even bid on a venture. Getting API Spec Q1 confirmed will open up doors for your organization to do business with organization's that can truly take your incomes to the next level.

#API Q1 Training#oil and gas industry#API Q1 Course#API Q1 Training Course#API Q1#oil#gas#education and training#training#training services#houston#texas#USA#AQTS-USA

0 notes

Photo

Third Coast Gage & Calibration specialize in American Petroleum Institute (API) Spec 7-2 & 5B thread gage manufacturing and calibration. We outsource manufacturing and control calibration to approved suppliers using API certified masters in our calibration lab in Alvin, TX. All gages are provided with a NIST Contribution Certificate or internationally recognized standards, as required by API Q1 and ISO 9001. We also offers Custom design and manufacturing services having more than 20 years of experience in the API thread calibrator industry. To get in touch, visit www.thirdcoastgage.com

#Thread Gage#Thread Gage Calibration#Api Thread Gages#Gage Calibration#Api 5B Plug#Calibration Custom Designs

0 notes

Photo

API Q1 Training by AQSS USA remains one of the most highly requested API Spec .

Phone : 713 789 0885 E-mail : [email protected] Website : http://www.aqss-usa.com/training-courses/

0 notes

Photo

Get API Consultancy | Ibex Systems

We have an experienced team of API Spec Q1 consultants, auditors, technical writers, and trainers who can help firms attain API Q1 certification by providing API consulting services. For any organization that works with us, we assist you in becoming API certified.

0 notes