#Cfd Simulation

Explore tagged Tumblr posts

Text

CFD analysis for a spatial printing air flow nozzle

8 notes

·

View notes

Text

Computational Fluid Dynamics (CFD) for engineering solutions

Please contact us to support your projects with high fidelity CFD modelling analysis.

#engineering#design#cfd simulation#numerical modelling#simulation service#engineering analysis#fluid dynamics#fluid flows#rotating machines

0 notes

Text

Are you 18 years old? - YES - NO

1 note

·

View note

Text

Lattice Boltzmann simulation wherein a NACA 4 Airfoil is pitched to a nose-up orientation corresponding to a 30 degrees Angle of Attack. This allows vortex shedding characteristics observation inside the numerical wind tunnel.

#fluid dynamics#fluid simulation#Lattice Boltzmann Method#gas dynamics#wind tunnel#Airfoil#aerodynamics#cfd simulation#vortexes#vorticity#vortices

1 note

·

View note

Text

#cfd#cfdinaeroacoustics#aeroacoustics#simualtionvideo#cfd simulation#cfdcars#computationalfluiddynamics#computer#paanduvapplications#cfdconsulting#cfd analysis

0 notes

Text

Advanced CFD Simulation and Consulting Services

Improve product performance with advanced CFD simulation and consulting services tailored for automotive, aerospace, and industrial applications. To know more about CFD Simulation services visit https://eqmsol.com/CFD-simulation.php#breadcrumb

#CFD simulation#CFD consulting#engineering consultancy#product design service#thermal management solutions.

0 notes

Text

youtube

💡 What You'll Learn: Understanding outer rotor motors with real-world examples. How to set up and save motor designs in Ansys RM Expert. Step-by-step guide to running simulations in RM Expert. Transitioning from RM Expert to Maxwell 2D for detailed analysis. Visualizing and interpreting torque, flux, and magnetic field plots. Gain insights into the complete workflow of motor design, from analytical setup to electromagnetic field simulations, using Ansys tools.

💡Check out the previous episodes of this series here: https://www.youtube.com/playlist?list=PL9-f9hWLZS61I2GoQAXCVwwYLclPNZZwA

If you’re interested in speaking with our experts and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/3ZrJxZ9

#youtube#skilllync#mechanicalengineering#cfd simulation#ansysfluent#ansys#3d ansys#electric vehicles#electronic

0 notes

Text

youtube

0 notes

Text

Optimizing Performance: A Comprehensive Guide to Compressor Simulation in Fluid Dynamics

Compressors play a vital role in a wide range of industries, from HVAC systems and automotive applications to aerospace and manufacturing. Their efficiency and reliability are crucial for the systems they serve. To ensure optimal performance, engineers turn to compressor simulation in fluid dynamics, a powerful tool that allows for the detailed analysis and optimization of compressor designs. This blog provides a comprehensive overview of compressor simulation, focusing on how it can improve performance, enhance reliability, and lead to better product designs.

What is Compressor Simulation?

Compressor simulation is the use of Computational Fluid Dynamics (CFD) to model the behavior of air or gas within a compressor. CFD simulations enable engineers to visualize and analyze the flow patterns, pressure distribution, and thermal effects within the compressor. These simulations help predict how the compressor will perform under various operating conditions, ensuring the design meets the necessary performance criteria.

By simulating real-world conditions in a virtual environment, engineers can make informed decisions about the geometry, materials, and control strategies for the compressor, leading to improved efficiency and reduced energy consumption.

Key Benefits of Compressor Simulation

1. Performance Optimization

One of the primary goals of compressor simulation is to optimize performance. Through CFD, engineers can evaluate how different designs and operating conditions affect compressor efficiency. For example, they can analyze the impact of blade geometry, flow paths, and inlet/outlet configurations on pressure ratios, flow rates, and power consumption. By identifying areas of inefficiency, they can make adjustments to improve overall compressor performance.

2. Reduced Development Costs

Traditionally, designing compressors involved extensive trial-and-error testing with physical prototypes, which can be both time-consuming and expensive. CFD simulations significantly reduce the need for physical testing by providing accurate predictions of compressor behavior in a virtual environment. This leads to shorter development cycles, lower testing costs, and faster time-to-market for new products.

3. Enhanced Reliability and Durability

Another advantage of compressor simulation is the ability to predict wear and failure points within the system. By simulating the effects of heat transfer, vibration, and pressure fluctuations, engineers can identify potential areas of fatigue and design solutions to extend the compressor's operational life. This ensures higher reliability and reduces the likelihood of costly breakdowns and maintenance.

4. Customization for Specific Applications

Compressors are used in a variety of industries, each with its own specific requirements. Compressor simulation allows for the customization of designs to meet the unique demands of different applications. Whether it’s optimizing a compressor for maximum airflow in a large HVAC system or designing a compact, high-efficiency compressor for automotive use, CFD simulations provide valuable insights that help engineers tailor the design to its intended application.

CFD Tools for Compressor Simulation

Several CFD software options are available for compressor simulation, each offering different features and capabilities. Some popular tools include:

ANSYS Fluent: Known for its advanced turbulence models and ability to simulate complex flows, ANSYS Fluent is widely used in compressor design for its accuracy and versatility.

Siemens STAR-CCM+: This software excels in multidisciplinary simulations, allowing engineers to analyze fluid dynamics alongside structural and thermal performance.

Altair AcuSolve: A robust solver that offers fast and accurate results for high-fidelity simulations, AcuSolve is ideal for detailed compressor analysis.

Key Parameters in Compressor Simulation

When simulating a compressor, several key parameters must be considered:

Pressure Ratios: Simulating the pressure difference between the inlet and outlet is critical for determining the compressor’s efficiency.

Flow Rate: Analyzing how different flow rates affect performance can help engineers optimize the compressor for specific operating conditions.

Thermal Effects: Heat generated within the compressor can impact its efficiency and longevity, making thermal analysis a crucial part of any simulation.

Turbulence and Vortices: These flow patterns can lead to inefficiencies and energy loss, making it essential to simulate and mitigate their effects.

Conclusion

Compressor simulation is a valuable tool for optimizing performance, reducing development costs, and enhancing the reliability of compressors. By leveraging CFD technology, engineers can gain deeper insights into fluid behavior, make data-driven design decisions, and customize compressors to meet the needs of diverse industries. Whether you’re designing a new compressor or improving an existing one, CFD simulation is the key to achieving superior performance and efficiency.

Visit us to Know More Website:https://www.cfdsupport.com/ Location:CFD support, s.r.o., Sokolovská 270/201, 19000 Praha 9, Czech Republic. Contact Us:+420 212 243 883 Email:[email protected]

0 notes

Text

Engineering DNA offers custom engineering solutions including 3D printing, reverse engineering, drafting, and simulations. Specializing in production engineering, product design, and CFD simulation, we deliver accuracy and excellence. Contact us today for innovative mechanical design and FEA Analysis services.

#3D Printing Design#Reverse Engineering Services#Drafting Services#3D Simulation#Interior design 3D Modeling#CFD Simulation#Product Design Engineering#3D Modeling for 3D Printing#Manufacturing Engineering#Finite Element Analysis Services#Design and Drafting Services#3D CAD Services#Manufacturing Engineering Services#3D Modeling Services#3D Design Services

0 notes

Text

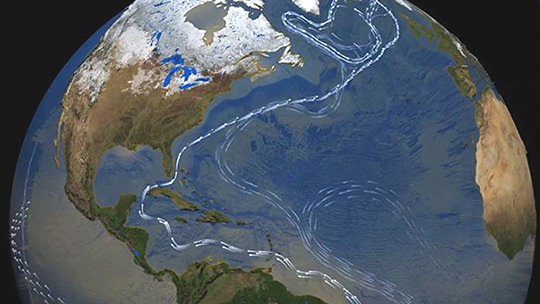

Resolution Effects on Ocean Circulation

The Gulf Stream current carries warm, salty water from the Gulf of Mexico northeastward. In the North Atlantic, this water cools and sinks and drifts southwestward, emerging centuries later in the Southern Ocean. Known as the Atlantic Meridional Overturning Circulation (AMOC), this circulation is critical, among other things, to Europe's temperate climate. (Image credit: illustration - Atlantic Oceanographic and Meteorological Laboratory, simulations - R. Gou et al.; research credit: R. Gou et al.; via APS Physics) Read the full article

#CFD#circulation#climate change#computational fluid dynamics#flow visualization#fluid dynamics#numerical simulation#ocean currents#oceanography#physics#science

79 notes

·

View notes

Text

Inorder to reduce higher cooling demands for buildings or industries, passive cooling by night-time flushing can be seen as a promising option.CFD simulations is performed for 24 hours in a peak summer day. During the day time operation, the internal loads coupled with solar heat gain is simulated. Choose the best CFD consulting services providers for high standard quality works.

0 notes

Text

Precision and Innovation: Exploring the Role of Engineering Design and CAD Drawing Services

Imagine constructing a skyscraper or designing a complex machine without a detailed plan. This is where Engineering Design Services come into play, transforming abstract ideas into detailed blueprints. These services are essential in laying the groundwork for successful engineering projects, ensuring every aspect is meticulously planned and executed with precision.

Strategic Impact of Engineering Design Services

In the competitive world of engineering, Engineering Design Services provide a significant edge. They refine not only the aesthetic appeal of a project but also its functionality and sustainability. By collaborating with clients and stakeholders, these services ensure that every element of a project aligns with technical specifications and overall vision, setting the stage for successful implementation and long-term success.

The Role of CAD Drawing Services in Modern Engineering

Once the design phase is complete, the focus shifts to detailed visualizations provided by CAD Drawing Services. These services are indispensable in modern engineering, allowing for the creation of precise and detailed drawings. By visualizing every component in three dimensions, engineers and architects can ensure that all parts fit together seamlessly, reducing the risk of errors during the construction phase.

Enhancing Precision with CAD Drawing Services

The advancements in CAD Drawing Services have revolutionized the way engineering projects are visualized and executed. These services allow for the manipulation of intricate 3D models, providing a virtual simulation of the final product. This not only enhances the precision of the design but also allows for modifications to be made easily, ensuring that the final product meets all requirements and standards.

Navigating Future Challenges with Advanced Design Techniques

As technology continues to evolve, the integration of AI and machine learning with Engineering Design Services is becoming increasingly important. These advanced techniques provide predictive insights and automated design adjustments, which are crucial for managing complex projects. Similarly, CAD Drawing Services are evolving to include virtual reality and augmented reality, offering immersive experiences that allow for better design comprehension and client engagement.

Ensuring Compliance and Global Standards

In the evolving landscape of global industries, adhering to international standards and regulations is crucial for success. Engineering Design Services and CAD Drawing Servicesplay a pivotal role in ensuring that projects meet these stringent requirements. By incorporating global best practices and standards into the design and drafting processes, these services help companies expand their reach and maintain competitiveness in international markets. This focus on compliance not only ensures safety and quality but also enhances the credibility and reputation of businesses in the global arena.

Conclusion

In a world where precision and efficiency are paramount, the roles of Engineering Design Services and CAD Drawing Services are more critical than ever. For businesses looking to leverage these advanced services, visitingfeamax.comoffers a gateway to industry-leading expertise and innovative solutions. Whether it’s refining a complex design or ensuring that every component fits perfectly, the right design services can transform potential into reality, driving success in every project.

Blog Source URL :

#Computational Fluid Dynamics Consulting#CFD Consulting Services#Cad Design Services#Computer Aided Design Services#Engineering Design Services#Cad Drawing Services#FEA Consulting Services#Finite Element Analysis Consultants#FEA Simulation Services#Engineering Manufacturing Services#Manufacturing Sourcing Services#Mold Flow Analysis#Moldflow Service#Moldflow And Casting Analysis

0 notes

Text

youtube

This video showcases my third attempt at generating a vortex street behind a NACA 4-digit airfoil. The airfoil is pitched to a nose-up orientation, corresponding to an Angle of Attack (AoA) of 30 degrees. For this iteration, I have improved the rendering of particles by using sprites, making them visually more smooth.

#gas dynamics#aerodynamics#computational fluid dynamics#CFD#lattice boltzmann method#fluid simulation#particle simulation#vortices#vorticity#wind tunnel#airfoil#Youtube

1 note

·

View note

Text

#quantumcomputing#3d printing#cfd#additive manufacturing#cfd simulation#hvac services#3d printing simulation software#simulation#technology#aerospace engineering#additive manufacturing software#3d sculpting#blender#ai generated#artificial intelligence

0 notes

Text

Check out this #CFD simulation of a BMW z3’s aerodynamics! 🌬️🚗 Visualizing pressure distribution and airflow streamlines—notice the high pressure at the front and turbulent wake at the rear. Optimizing this can reduce drag and boost efficiency! Details here: https://fetchcfd.com/view-project/192-bmw-z3-simulation

0 notes