#Circuit board reverse engineering

Explore tagged Tumblr posts

Text

0 notes

Note

I think someone from your organization appeared in my dreams last night. In the dream I played the elevator game and it worked and I ended up in a different universe, but then I couldn't get back. Someone who said they were with OPN showed up and was trying to figure out where I came from by comparing details about our universes (mostly based on books that exist in both worlds), and then after a while she told me to try to wake up, and I did. Should I be concerned?

Yeah, that sounds like one of ours.

Did she have a big helmet with a lot of diodes and circuit boards on it? That'd be someone from Oneirology. Oneironauts try to be discreet, but sometimes the dreamscape shifts and you don't have anything to hide in, or so I'm told. In those cases, it's best practices to simply introduce yourself to the dreamer, rather than appear as an unknown interloper.

The helmet is pretty recognizable. They're still using the same technology since the 80's. A guy whose name is....currently redacted, actually, approached the Office in 1984 saying he'd built a dream viewer out of his mother's old television, a bunch of junk radios, three Atari 2600 consoles, and an unknown number of 2600 cartridges. The big home console crash had just happened the previous year, so he'd purchased a storage container full of castoff Atari hardware for cheap and "needed to do something with it." He also claimed to be the reincarnation of Nikola Tesla and that he could make oranges turn blue with his mind. He was correct about the first part, at least - we haven't been able to reverse engineer it for four decades. We're still using the same three helmets he built out of Ataris.

Anyway - if she didn't seem to concerned, I wouldn't be. I'll check with the Oneirology Office, but let me know if you have any other weird dreams.

26 notes

·

View notes

Text

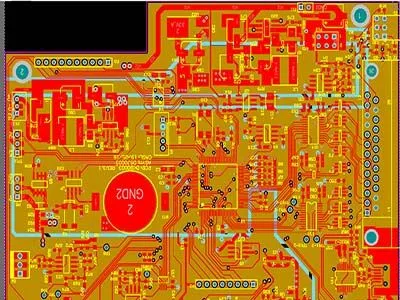

PCB Manufacturing-PCB Assembly-Hitech Circuits

Hitech Circuits is a lеаding PCB Manufacturing & PCB Assembly company with more than 20 years experience in the electronics manufacturing industry. We focus on PCB Design, PCB Layout, Circuit board fabrication, Turnkey PCB assembly, and electronic parts sourcing services.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

We offer a full range of Electronic manufacturing services.

-LED PCB

-Heavy Copper PCB

-Multilayer PCB

-HDI PCB

-Flexible PCB

-Rigid-Flex PCB

-High Speed PCB

-High Frequency PCB

-PCB Reverse Engineering

7 notes

·

View notes

Text

I decided to take a look at that adapter.

Now despite how much I would have liked to insert a wiring diagram, I don't know much about circuitry despite tinkering with it as a child. So images are all you're getting.

A Nexperia 74HC132D Quad 2-input NAND Schmitt trigger chip.

A Texas Instruments LM2937 500-mA Low Dropout Regulator.

And a Maxim Instruments MAX3232 Multichannel RS-232 Line Driver and Receiver, along with a Maxim MAX3491E RS-485/RS-422 Transceivers.

Just based off the chips' positions alone all this adapter seems to be doing is converting RS485 into RS232 and vice versa.

So I have a few electronic marquee signs laying around, I know more now that I did then, lets see if I can get it working

10 notes

·

View notes

Text

Analyze and document printed circuit boards with ease. Capture PCB images using your camera or import existing photos, then add component annotations like resistors, capacitors, diodes, and ICs to create detailed circuit documentation. Draw wire connections and traces to map out circuit paths and connections. Save your analysis projects for future reference and export annotated images to share your work. Perfect for electronics enthusiasts, students, and professionals who need to reverse-engineer or document Simple circuit boards.

#PCBanalysis#circuitboarddocumentation#electronicsreverseengineering#componentidentification#circuittracing#PCBannotation#electronicstools#circuitdiagram#componentlabeling#wiremapping#electronicseducation#PCBdesign#circuitanalysis#electronicshobbyist#engineeringtools#schematiccapture#PCBphotography#componentsymbols#circuitdocumentation#electronicsreference#PCBreverseengineer#circuitboardmapping#electronicslearning#componentannotation#tracerouting#PCBviewer#electronicsstudent#circuitboardanalysis#PCBmarkup#electronicsdocumentation

0 notes

Text

How to Choose the Right EMS Provider in India for Quality and Faster Time-to-Market

Choosing the right Electronics Manufacturing Services provider in India can significantly impact your product quality, production efficiency, and speed to market. With India's growing reputation as a global electronics manufacturing hub, thanks to initiatives such as Make in India and robust infrastructure development, more businesses are turning to Indian EMS partners for their end-to-end electronic assembly needs.

In this answer, I’ll walk you through the key aspects to consider when selecting an EMS provider in India and how a trusted partner like Resolute GOC can help you accelerate innovation while maintaining high standards.

Why India for Electronics Manufacturing Services?

India has rapidly evolved into a preferred destination for electronics manufacturing for several reasons:

Cost Efficiency: Lower labor and operational costs make Indian EMS providers globally competitive.

Skilled Workforce: A large pool of engineering talent and trained technicians ensures production precision.

Government Support: Policies such as the PLI (Production Linked Incentive) scheme have incentivized electronics production.

Geopolitical Stability: Compared to some other Asian countries, India offers a more stable business environment.

What Should You Look for in an EMS Provider?

When evaluating an Electronics Manufacturing Services provider in India, consider the following factors:

1) Technical Capabilities: Look for a provider with extensive experience in Surface Mount Technology (SMT), Through-Hole Technology (THT), box builds, printed circuit board (PCB) assembly, testing, and final packaging. The more technically diverse the provider is, the more they can support your growth.

2) Quality Certifications: Your EMS partner should comply with international quality standards, such as ISO 9001, ISO 14001, IATF 16949 (for the automotive industry), and IPC-A-610. These certifications ensure that the manufacturer adheres to global quality benchmarks.

3) Design and Engineering Support: An ideal EMS partner should offer Design for Manufacturability (DFM) and Design for Testing (DFT) services to optimize your product from the early stages. Engineering support helps avoid costly mistakes later in the production cycle.

4) Scalability and Flexibility: Can the provider handle your volume requirements as you scale? Whether you're a startup launching a new product or an enterprise managing large-scale production, the ability to ramp up or down without compromising quality is critical.

5) Turnaround Time and Supply Chain: Efficient supply chain management and faster turnaround times will reduce your time-to-market. Look for a provider that maintains strong relationships with component suppliers and demonstrates expertise in managing supply chain risks.

6) Testing and Quality Assurance: A strong EMS partner will have automated and manual testing capabilities, including in-circuit testing, functional testing, burn-in testing, and environmental stress screening. This ensures product reliability and performance.

7) Aftermarket Services: Support doesn’t end with assembly. Services like repair, rework, and reverse logistics demonstrate a provider’s commitment to the entire product lifecycle.

How the Right EMS Partner Can Transform Your Business

Choosing a reliable EMS provider isn’t just about outsourcing production; it’s about establishing a strategic partnership that supports innovation and growth. Here's how:

Improved Product Quality: High-precision assembly processes, real-time monitoring systems, and rigorous quality assurance protocols ensure consistently high-quality output. This results in fewer returns, lower defect rates, and better customer satisfaction.

Faster Time to Market: A full-service EMS provider accelerates the design-to-delivery process. Their expertise in prototyping, tooling, and rapid manufacturing enables you to launch new products more quickly than if you were managing everything in-house.

Cost Reduction: From minimizing BOM (Bill of Materials) costs to reducing labor and operational expenses, EMS companies in India offer significant cost advantages without compromising quality.

Innovation Enablement: Providers like Resolute GOC support innovation with integrated services, including prototyping, product development, and scalable production. This means more time and resources for your team to focus on design and market strategy.

Why Consider Resolute GOC?

Resolute GOC is one of the leading Electronics Manufacturing Services providers in India, offering comprehensive solutions for companies across various sectors, including automotive, industrial, medical, telecom, and consumer electronics. Here’s what sets them apart:

Comprehensive Capabilities: SMT, PCB assembly, product design, and system integration under one roof.

State-of-the-Art Infrastructure: Modern facilities equipped with high-speed pick-and-place machines, AOI, X-ray inspection, and automated testing systems.

Scalability: From low-volume prototypes to high-volume production, Resolute GOC adapts to your needs.

Strong Engineering Backbone: Their engineering team offers DFM and DFT support to improve manufacturability and reliability.

Quality First Approach: Stringent quality control measures and internationally certified processes ensure consistency and compliance.

Whether you’re a startup looking to bring a prototype to life or an OEM seeking volume production, Resolute GOC can serve as a reliable partner throughout your product lifecycle.

Conclusion

Selecting the right Electronics Manufacturing Services provider in India is a strategic decision that influences your product’s success, your brand’s credibility, and your company’s bottom line. By focusing on capabilities, quality, scalability, and reliability, you can find a partner that not only meets your current manufacturing needs but also evolves with you.

As Indian EMS companies continue to invest in advanced technologies and quality frameworks, the opportunity to build globally competitive products has never been more accessible. Explore providers like Resolute GOC, who are well-positioned to deliver innovative, efficient, and scalable solutions tailored to your specific requirements.

If you’re looking to optimize your electronics manufacturing strategy and expand your reach, India’s EMS landscape is ready; the only question is, are you?

0 notes

Text

Modern Product Lifecycle Management Isn’t Just for Tech Anymore

Product lifecycle management (PLM) is often pigeonholed into the IT world—but at 3R Technology, we've taken a broader view. We’re not just handling end-of-life laptops. We're navigating the full arc of a product's journey, from surplus to second life, across industries.

Whether you’re clearing out a lab, liquidating manufacturing equipment, or streamlining your inventory strategy, our model is built to unlock value from the unexpected.

The Engine Behind the Recovery: What Sets Us Apart

Multi-Channel Sales Reach We don’t rely on just one outlet to remarket your products. Through our established multi-channel sales platform, we cast a wide net to capture the best possible value for every item, whether it’s a server rack or a surplus microscope.

A Broker Network That Works Our extensive broker network gives us access to niche buyers and markets that typical resale channels overlook. That means more eyes on your assets and better returns at the end of the line.

Decades of Tactical Sales Expertise We bring technical sales acumen that’s been refined over decades. Our team knows how to position, price, and place your inventory for optimal results, no matter the product category.

What We Remarket

At 3R Technology, the word “remarket” isn’t limited to tech. Here’s a snapshot of what we handle:

IT equipment and electronics

Laboratory instruments

Industrial and manufacturing machinery

Surplus components and unused inventory

Return logistics materials

Office furniture and fixtures

If you can box it, pallet it, or roll it out—chances are, we can find it a buyer.

More Than Sales: A Full-Service PLM Solution

It’s not just about selling. It’s about strategy.

Our team provides a suite of services that takes the pressure off your internal operations:

Logistics Management: From pickups to drop-offs, we’ve got it covered.

Onsite Project Management: We manage removals and asset transitions with minimal disruption.

Fulfilment & Warehousing: Need space or storage while assets are staged for sale? We’ve got the infrastructure.

Why It Matters Now

In a market defined by agility, every piece of idle inventory represents lost opportunity. By partnering with 3R Technology, you transform those assets into revenue while meeting sustainability and compliance goals.

We don’t just remarket—we rethink what product lifecycle management can be.

In today’s competitive environment, assets that sit idle aren’t just collecting dust—they're collecting costs. At 3R Technology, our Product Lifecycle Management (PLM) service is engineered to recover value from equipment, inventory, and materials across every sector, not just IT.

Our model is built on decades of technical sales knowledge, a high-performing broker network, and an infrastructure that supports resale, removal, and redistribution. From electronics to office furniture, we find a second life for almost anything.

Here’s a closer look at how we make it happen.

Components

Whether brand new, unused, or removed from equipment, electronic components often retain significant value. Rather than letting these items go to waste in storage, we remarket them through targeted sales channels that reach the right buyers—engineers, refurbishers, and niche manufacturers.

From semiconductors and circuit boards to power supplies and cabling, we handle the resale process end-to-end, ensuring return value on even the smallest components.

Return Logistics

Returns are part of business, but they don’t have to be a loss. Our return logistics service manages everything from reverse shipping coordination to item processing, evaluation, and resale.

Whether you’re managing high-volume returns or dealing with one-off speciality items, we step in to streamline operations and ensure assets are re-integrated into the value chain, not discarded

Surplus Inventory

Excess stock is common across industries, especially when forecasts shift or production slows. Letting surplus sit on shelves isn’t a viable strategy and liquidation doesn’t have to mean giving it away.

We specialise in remarketing surplus inventory, from packaging materials and raw components to finished goods. Our multi-channel sales platform and broad broker reach allow us to find buyers in secondary and tertiary markets where demand still exists.

Office Furniture

Office downsizing, renovations, or closures often result in a flood of used furniture, most of which still has life left. Rather than pay for removal and disposal, organisations can turn to us to remarket these assets.

We handle everything: assessment, pickup, storage, and resale. From desks and chairs to conference tables and filing systems, office furniture is a viable resale category that too often gets overlooked.

Manufacturing Excess

Unused production equipment and over-ordered supplies tie up capital and space. We help manufacturers offload machinery, tools, and materials through proven resale channels that maximise return.

Our team understands the complexity of manufacturing environments and provides tailored support from on-site project management and equipment removal to warehousing and fulfilment.

We Handle the Rest, Too

Logistics, fulfilment, storage, resale, and reporting—we handle every phase so your team doesn’t have to. Whether you’re managing an asset disposition project or clearing out a facility, we act as a single point of contact for full-service product lifecycle management.

3R Technology, a CTL Company

8002 S 208th St Suite E105 Kent, WA 98032

(206) 582-7100

0 notes

Text

icunlock-mcucrack

Embarking on the journey of reverse engineering printed circuit boards (PCBs) can be both fascinating. This intricate endeavor involves analyzing a PCB to reveal its inner workings, often without access to original https://www.icunlock-mcucrack.com/tech/

1 note

·

View note

Text

Why a Dual Shaft Shredder is the Ideal Choice for Industrial Waste Management

With the changing pace in the industrial world, effective waste management has assumed utmost importance. Shredding of plastic, metal, wood, or e-waste-all the right types of shredders are pivotal inputs for incremental operational efficiency and environmental responsibility. One of the most sought-after and powerful machines in its class is the dual shaft shredder.

What is a Dual Shaft Shredder?

A dual-shaft shredder, also termed a double-shaft shredder, is a robust industrial shredding machine that could shred difficult materials, which could otherwise not be shredded by a single-shaft shredder. These shredders shred even heavy materials as they consist of two rotating shafts fitted with cutting blades. The shredders are specifically designed to tear, shear and crush materials into smaller parts. These shredders are built for heavy-duty operation and find applications in recycling plants, manufacturing facilities, and waste treatment centers.

Also know about, Twin Shaft Shredder: How the Right Machine Impacts Your Industrial Success

Primary advantages of a double shaft shredder

The foremost advantage of the double-shaft shredder is that it allows processing a varied range of materials with very little clogging: the twin shafts turn slowly but are at high torque, thus allowing almost stubborn types of wastes such as tires, metal drums, and construction debris to be shredded down.

Here are some noteworthy advantages:

The Low Speed/High Torque - This provides a superior shredding force and the chance for overload within the system is negligible.

Flexible - Capable of processing plastics, rubbers, woods, metals, and even more.

Enduring - Made up of heavy-duty materials that can withstand wear & tear.

Energy-Efficient - Working at low speeds means lower energy consumption.

Applications of Twin Shaft Shredder Machine

The twin shaft shredder is well suited for the disposal industry, construction, and civil engineering works. Some of the standard applications include:

Plastics Recycling: Products such as PET bottles, containers, and plastic waste for packaging.

E-Waste Management: Breaking down hard disks, circuit boards, and other electronic devices.

Metal Processing: Crushing of light metal parts and aluminum scrap.

Municipal Waste: Bulk shredding of household black waste, mattresses, and furniture.

What makes the twin shaft shredder so unique is that it can be converted into continuous operation, with lower maintenance costs-an essential factor for large-scale operations.

Also Read, Shredder Machine Manufacturer: The Key to Effective E-Waste Management

Choosing an Appropriate Dual Shaft Shredder Machine

Use these considerations to select the best dual shaft shredder: type of material you want to shred, required output size, and throughput capacity. For instance, some machines allow custom blade sizing to support particular shredding activities. Also check whether it has an automated reverse system, a good safety system, and a user-friendly control panel.

Conclusion

Choosing a dual shaft shredder for business would be the best investment in optimizing waste and recycling processes. Its durability, performance, and versatility make it one of the most wanted solutions across industries.

EnvCure Technocrat LLP manufactures high-performance twin shaft shredder machines that can be effectively used in demanding applications for industrial facilities requiring reliable shredding solutions. EnvCure Technocrat LLP has established itself as a name trusted in environmental and waste management solutions continuing to walk on the path of quality and customer satisfaction.

0 notes

Text

Top Choice for Small Appliances: The Complete Guide to 12V DC Cooling Fans

Why 12V DC Fans Are Essential for Modern Small Appliances

In today’s smart homes, compact appliances demand efficient thermal solutions to ensure safety and longevity. 12V DC fans have emerged as the go-to cooling technology for small electronics and appliances, combining energy efficiency, quiet operation, and compact design. This guide breaks down their engineering, applications, and how to choose the best model for your needs.

How 12V DC Fans Work: The Science Behind Cooling Efficiency Unlike AC fans, 12V DC models operate with precision using direct current power, delivering superior energy efficiency (up to 30% less power consumption) and whisper-quiet performance. The science boils down to two key processes:

Smart Magnetic Control: Integrated circuits (ICs) monitor and reverse current flow to maintain smooth rotor motion.

Optimized Airflow: Rotating blades interact with stationary magnets, generating focused airflow to dissipate heat effectively.

Where 12V DC Fans Shine: Top Applications 1️⃣ Kitchen Essentials

Microwave ovens: Prevents control board overheating during heavy use.

Coffee makers: Extends pump and heating element lifespan.

2️⃣ Personal Care Devices

Hair dryers: Protects motors from burnout during extended styling sessions.

Electric shavers: Maintains battery performance under daily use.

3️⃣ Home Electronics

Wi-Fi routers: Prevents signal drops caused by thermal throttling.

Air purifiers: Enhances filtration efficiency with consistent airflow.

4️⃣ Smart Home Tech

Security cameras: Ensures 24/7 operation in confined outdoor housings.

Buying Guide: 6 Key Features to Evaluate

Troubleshooting Common Issues

Humming Noise: Check for loose mounting screws (85% of cases).

Vibration: Use silicone gaskets to dampen motor oscillations.

Failure to Spin: Test with a 9V battery – if dead, replace brushes.

Why Cooltron Leads the Market Industry tests show Cooltron’s 12V DC fans outperform competitors:

22% longer lifespan (15,000-hour MTBF)

18% lower power draw at equivalent CFM

IP55/IP65/IP67-rated dust/water resistance for harsh environments

Upgrade your appliance’s cooling with our engineering team’s expertise. Explore custom solutions at Cooltron Official Site or email [email protected] for volume discounts.

0 notes

Text

PCB Repair for Industrial Machinery

Printed Circuit Boards (PCBs) are the heart and soul of modern industrial machinery. They control the operation of various components, ensuring seamless functioning. However, PCBs can malfunction due to various factors, leading to downtime and operational inefficiencies. When it comes to PCB repair for industrial machinery, choosing a reliable and experienced service provider is crucial. Shreemeera Electronic Services, based in Pune, offers comprehensive PCB repair solutions for all types of industrial machinery, including AC DC, Servo, and VFD drives repair services.

Common PCB Failures in Industrial Machinery

PCBs in industrial machinery can fail due to several reasons, including:

Component failures: Individual components on the PCB, such as resistors, capacitors, transistors, and integrated circuits, can malfunction or fail.

Open circuits: Breaks or disconnections in the conductive traces on the PCB can prevent current flow.

Short circuits: When conductive traces come into contact with each other, it can cause excessive current to flow, leading to damage.

Corrosion: Exposure to moisture, chemicals, or high temperatures can cause corrosion on the PCB, affecting its conductivity.

Physical damage: Accidental drops, impacts, or mishandling can cause physical damage to the PCB, leading to fractures or broken traces.

The Importance of Timely PCB Repair

PCB failures can have significant consequences for industrial operations. Downtime caused by faulty PCBs can lead to production losses, increased costs, and decreased efficiency. Therefore, it is essential to address PCB issues promptly to minimize disruptions and maintain optimal performance.

Shreemeera Electronic Services is a leading provider of industrial machine PCB repair services in Pune. With years of experience and expertise, they offer comprehensive solutions to address a wide range of PCB problems. Their team of skilled technicians is equipped with state-of-the-art equipment and diagnostic tools to accurately identify and rectify PCB failures.

Services Offered by Shreemeera Electronic Services

PCB repair and replacement: Shreemeera Electronic Services can repair damaged PCBs or replace faulty components to restore functionality.

PCB inspection and testing: They conduct thorough inspections to identify potential issues and perform diagnostic tests to pinpoint the root cause of problems.

PCB cleaning and maintenance: Regular cleaning and maintenance can help prevent PCB failures and extend their lifespan.

PCB reverse engineering: For obsolete or hard-to-find PCBs, Shreemeera Electronic Services can reverse engineer the board to create a replacement.

Emergency PCB repair: They offer emergency repair services to minimize downtime and ensure rapid restoration of operations.

Why Choose Shreemeera Electronic Services?

Expertise and experience: Their team of technicians has extensive experience in PCB repair for industrial machinery.

State-of-the-art equipment: They use advanced diagnostic tools and equipment for accurate diagnosis and repair.

Quick turnaround time: Shreemeera Electronic Services strives to provide timely repairs to minimize downtime.

Quality assurance: They adhere to strict quality standards to ensure the reliability and performance of repaired PCBs.

Competitive pricing: They offer competitive pricing without compromising on quality.

By choosing Shreemeera Electronic Services for your industrial machine PCB repair needs, you can be confident in their ability to provide reliable and efficient solutions. Their expertise and commitment to customer satisfaction make them a trusted partner for businesses across various industries.

#ac dc drives repair services in pune#industrial machine pcb repair services in pune#pcb repair services in pune#shreemeera electronic services

1 note

·

View note

Text

The Art and Science of PCB Reverse Engineering: A Comprehensive Guide

In the world of electronics, understanding how a printed circuit board (PCB) works can be crucial for troubleshooting, innovation, and learning. PCB reverse engineering is a process that allows engineers, hobbyists, and researchers to dissect and comprehend the intricate designs of existing PCBs. Whether you're looking to replicate an old design, learn about advanced technologies, or modify existing hardware, PCB reverse engineering offers valuable insights and opportunities. In this blog post, we’ll explore the essentials of PCB reverse engineering, its benefits, and practical tips for getting started.

What is PCB Reverse Engineering?

PCB reverse engineering is the process of analyzing and deconstructing a PCB to understand its layout, design, and functionality. This typically involves examining the physical board and its components to recreate or modify the circuit’s schematic diagram and design files. The goal is to uncover the design details that are not readily available from the manufacturer, enabling you to replicate or improve the existing design.

Why Engage in PCB Reverse Engineering?

Learning and Education: For students and hobbyists, reverse engineering provides a hands-on way to learn about electronic circuit design, component functions, and board layout. It’s a practical method to understand how various components interact within a circuit.

Repair and Maintenance: When dealing with older or discontinued hardware, PCB reverse engineering can help in diagnosing faults and replacing faulty parts. This is particularly useful for repairing vintage electronics where original schematics are no longer available.

Innovation and Design: Engineers often use reverse engineering to analyze competitor products, understand their design choices, and find areas for improvement. By learning from existing designs, they can innovate and create better, more efficient products.

Legacy Support: Companies maintaining legacy systems may need to reverse engineer PCBs to continue providing support, upgrades, or replacements for outdated technology.

The PCB Reverse Engineering Process

Reverse engineering a PCB involves several steps, each requiring precision and careful analysis. Here’s a simplified overview of the process:

Disassemble the PCB

Carefully remove the PCB from its enclosure or casing. Use tools like tweezers and anti-static mats to handle the board and avoid damaging sensitive components.

Document the Board

Take high-resolution photographs of both the top and bottom layers of the PCB. These images will serve as reference material during the reverse engineering process. Ensure that the images are clear and well-lit.

Identify Components

Label and identify all components on the PCB. This includes resistors, capacitors, integrated circuits (ICs), and connectors. Use a multi meter or component tester to help identify and measure components if necessary.

Trace the Circuit

Use the photographs to trace the circuit connections. This involves mapping out the paths of electrical connections between components. Tools like PCB design software can assist in recreating the circuit schematic.

Create the Schematic Diagram

Based on your tracing, create a schematic diagram that represents the electrical design of the PCB. This step is crucial for understanding how the circuit functions and for making any modifications.

Design the PCB Layout

Once the schematic is complete, design a PCB layout that matches the original design. PCB design software can be used to create and refine the layout, ensuring that it accurately reflects the original board’s design.

Verify and Test

Before finalizing the design, verify that the recreated PCB functions as intended. Build a prototype and test it to ensure that it meets the required specifications and performs correctly.

PCB reverse engineering is a powerful technique for understanding and working with electronic circuits. Whether you’re aiming to repair vintage hardware, learn about circuit design, or innovate in the field of electronics, mastering the art of PCB reverse engineering can provide significant advantages. By following the steps outlined in this guide and utilizing the right tools, you can delve into the intricate world of PCB design and uncover the secrets behind your favorite electronic devices.

0 notes

Text

PCB Reverse Engineering Guide: Easily Replicate Designs

PCB reverse engineering refers to the process of obtaining a physical PCB and conducting research to analyze its characteristics and wiring layout. In earlier reverse engineering efforts, the primary focus was on deducing the schematic diagram by reverse-engineering PCB design files or sketching a PCB circuit diagram directly from the physical product. This allows for understanding the board’s circuitry and functionality. The schematic is also used to analyze the product’s features.

#pcb#pcb design#pcb assembly#astronomy#pcb manufacturer#batman#captain america#the owl house#transformers

0 notes

Text

Your Trusted Partner for High-Reliability Electronic Manufacturing--Hitech Circuits

Printed Circuit Boards (PCBs) play a vital role in modern technology, serving as the foundation for nearly every electronic device we rely on daily. From smartphones and medical equipment to automotive systems and industrial machinery, PCBs are at the heart of innovation, enabling seamless functionality and advanced capabilities.

At Hitech Circuits, we specialize in providing high-quality PCB manufacturing and assembly services designed to meet the needs of diverse industries. With state-of-the-art technology, strict quality control, and a highly skilled team, we deliver solutions that combine reliability, precision, and efficiency.

We can provide turnkey electronic manufacturing services. The services include:

PCB Manufacturing from Prototyping to Mass Production

Components Purchasing at competitive prices

PCB Assembly(Mechanical & Electronic Components)

Shell customization and assembly

Function Testing

PCB Reverse Engineering

With the experiences of over 20 years in the electronics manufacturing industrial, we are devoted to providing superior services and have cooperated with many famous brands. The end customers we serve are in industries such as aerospace, medical & life sciences, industrial,military & defence.

If you want to know the prices from us, please email Pelina--Hitechpcb<[email protected]> Below is the guideline of basic information you are supposed to provide or specify:

Complete GERBER files including the Excellon Drill File

Quantities

Need expedited service or not(for PCB prototype onlly)

Panelization Requirements

Materials Requirements

Surface Finish Requirements

Board Thickness

Copper Thickness

Assembly Requirements (including full turn key)

Any Other Requirements

Don't know what any of these items are? Call us. We can help.(Phone Number: 86-18033061378 )

Your custom quote for PCB or PCBA usually will be delivered within 24 hours(working day). We will always do our best to meet your needs and get your quote returned to you as soon as possible.

0 notes

Text

PCB Clone Services: Precision in Reproduction

What is PCB Cloning?

PCB Clone is the process of creating an exact replica of an existing printed circuit board (PCB). This service is essential when you need to reproduce a board for which the original design files are unavailable. PCB cloning involves reverse engineering the board to generate the necessary data for manufacturing a duplicate.

The Role of PCB Clone Services

PCB Cloning Service are vital in scenarios where you need an identical copy of an electronic circuit board. Whether it’s for replacing obsolete hardware, producing additional units, or creating backups, these services ensure precision in reproduction.

How PCB Cloning Works

1. Initial Analysis

The cloning process begins with a detailed analysis of the original PCB. This includes examining the board’s layout, components, and circuitry. Engineers carefully inspect every detail to ensure accurate replication.

2. Reverse Engineering

After the initial analysis, the reverse engineering phase begins. Engineers trace the circuitry, identify components, and create a schematic of the board. This step is crucial in understanding how the PCB functions.

3. Schematic Capture and Layout Design

Once the reverse engineering is complete, a schematic diagram is created. This diagram serves as a blueprint for the new board. Engineers then use specialized software to design a PCB layout that matches the original.

4. Prototyping and Testing

Before full-scale production, a prototype of the cloned PCB is manufactured. This prototype undergoes rigorous testing to ensure it functions exactly like the original board. Any necessary adjustments are made during this phase.

5. Mass Production

Once the prototype passes all tests, the PCB is ready for mass production. The final product is an exact clone of the original board, ready for use in any application.

Benefits of PCB Cloning Services

• Obsolete Hardware Reproduction: Clone services are ideal for replicating outdated circuit boards, ensuring continued operation of legacy systems.

• Cost-Effective: Cloning is often more cost-effective than redesigning a PCB from scratch.

• Fast Turnaround: PCB cloning services can quickly produce duplicates, reducing downtime for critical systems.

Challenges in PCB Cloning

PCB cloning, while beneficial, is not without its challenges. Complex multilayer boards, proprietary components, and encrypted firmware can complicate the cloning process. Skilled engineers are essential to navigate these obstacles and deliver an accurate clone.

Choosing the Right PCB Clone Service

When selecting a Clone PCB Service, consider factors such as experience, technology, and the ability to handle complex projects. A reliable service provider will ensure that your cloned PCBs meet the highest standards of quality and performance.

Conclusion

PCB cloning services play a crucial role in the electronics industry. Whether for preserving legacy systems or producing additional units, these services provide a reliable solution for duplicating PCBs with precision. With the right expertise, PCB cloning ensures that your electronic systems continue to function smoothly, regardless of the challenges posed by outdated or unavailable designs.

0 notes

Text

Offers Flying Probe (Fixtureless) Test as the Ideal Low Cost Solution - Topscom Technology

With the rapidly increasing complexity of assemblies, electrical verification at the prototype level has become a necessity to meet time-to-market requirements. Flying Probe (or Fixtureless) test allows your engineers to focus their efforts on prototype design verification, instead of debugging process issues. Flying Probe test development is low cost and very fast, making it an ideal tool for prototype verification. There is no fixture to purchase, eliminating costly tooling procurement and allowing the ultimate in flexibility to incorporate design changes. Often used in a combinational strategy with AXI or AOI, Flying Probe allows detection and repair of electrical defects such as wrong parts, reversed parts, missing parts, solder opens, and solder bridges before they are in your engineer hands. Flying Probe at Topscom can help you improve your products time-to-market at the highest possible quality levels. https://is.gd/EWoJq8

PCB SMT assembly, China printed circuit board assembly, China PCB factory, China PCB fabrication, China PCB manufacturing, China PCB board, China PCB manufacturer, China PCB service, China PCB prototype, China PCB supplier, China PCB, PCB China, China PCB online, PCB board, China PCB assembly, PCBA China, China PCB design, PCB assembly, China PCB quote, PCBA, contract manufacturing China, China contract manufacturing, contract manufacturing, China electronic assembly, China electronic manufacturing, electronics manufacturing, electronic board manufacturers, China OEM manufacturing, OEM manufacturing, China cable wire harness assembly

0 notes